How to Source Altran Corp Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for altran corp

In an increasingly interconnected global market, sourcing high-quality custom transformers from reputable manufacturers like Altran Corp can pose significant challenges for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, understanding the nuances of transformer specifications, compliance standards, and supplier reliability is essential for making informed purchasing decisions. This comprehensive guide delves into the diverse range of products offered by Altran Corp, including custom inductors, audio transformers, and power transformers, while also exploring their applications across various industries such as medical, energy, and audio.

Navigating the complexities of supplier vetting, product costs, and compliance requirements can be daunting. This guide empowers B2B buyers by providing actionable insights and practical advice on selecting the right transformer solutions that align with specific project needs and budget constraints. By outlining the key factors to consider—such as manufacturing standards, design capabilities, and service responsiveness—this resource aims to facilitate a smoother procurement process.

With a focus on enhancing understanding and ensuring quality in transformer sourcing, this guide equips decision-makers with the knowledge necessary to forge successful partnerships with Altran Corp, ultimately contributing to operational efficiency and project success in their respective markets.

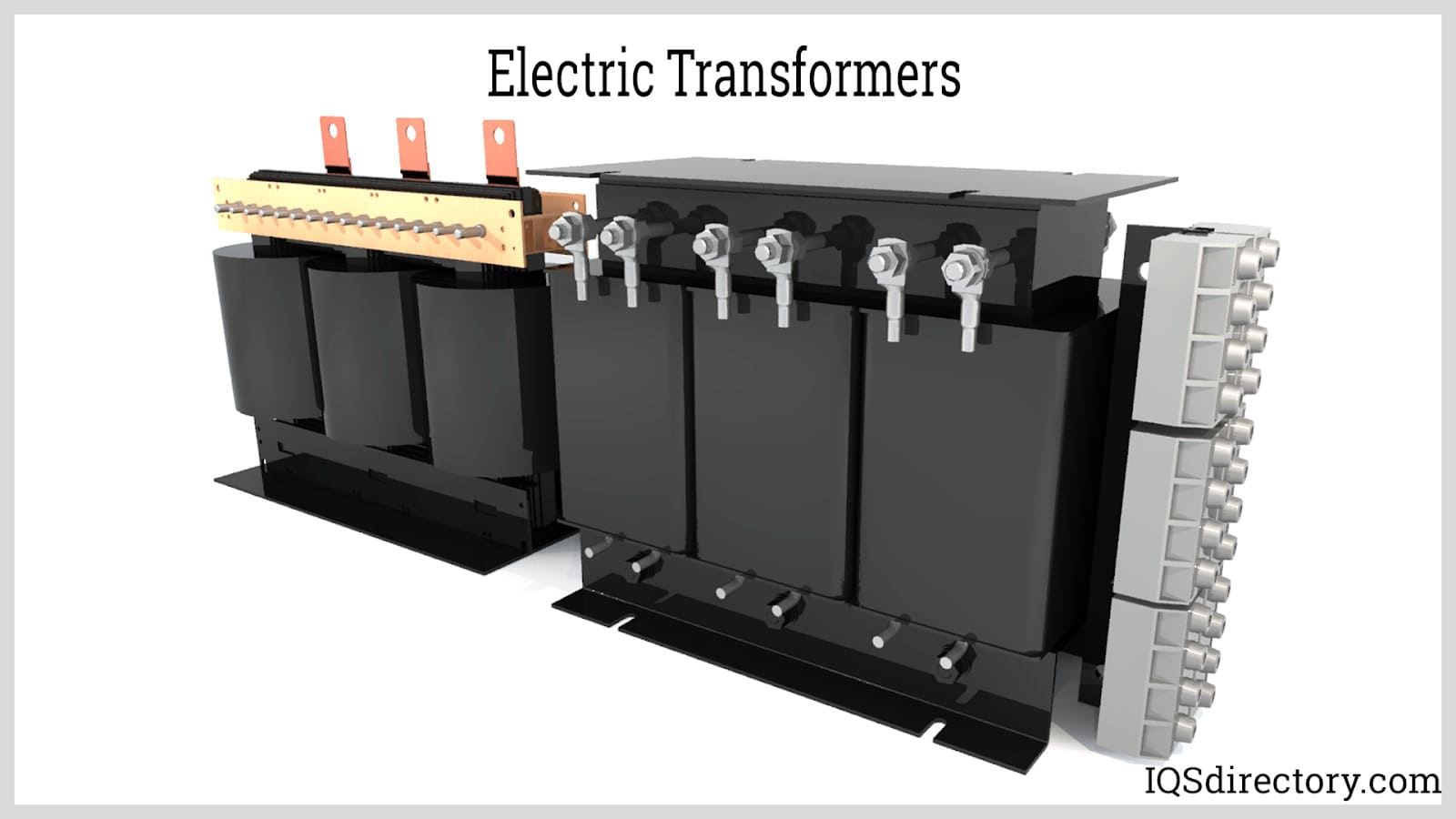

Understanding altran corp Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Power Transformers | Designed for specific voltage and power requirements | Industrial automation, utility systems | Pros: Tailored solutions, high efficiency. Cons: Longer lead times for custom designs. |

| Medical Transformers | Built to meet stringent safety and performance standards | Medical imaging, diagnostic equipment | Pros: Compliance with health regulations, reliability. Cons: Higher costs due to specialized requirements. |

| Audio Transformers | Optimized for sound quality and fidelity | Music production, audio equipment | Pros: Enhanced audio performance, specific design for sound quality. Cons: May be over-engineered for non-audio applications. |

| Isolation Transformers | Provides electrical isolation to protect sensitive equipment | Telecommunications, medical devices | Pros: Reduces noise and interference, enhances safety. Cons: Bulkier design may limit space efficiency. |

| Toroidal Transformers | Donut-shaped design for compactness and efficiency | Power supplies, audio applications | Pros: Lower electromagnetic interference, space-saving design. Cons: Higher manufacturing complexity can increase costs. |

What are the Key Characteristics of Custom Power Transformers?

Custom power transformers are engineered to meet specific voltage and power requirements, making them ideal for industrial automation and utility systems. Their design allows for high efficiency and tailored solutions that align closely with operational needs. Buyers should consider lead times, as custom designs may require longer production periods, but the investment often results in significant operational benefits.

Why are Medical Transformers Essential in Healthcare?

Medical transformers are critical in the healthcare sector, designed to comply with stringent safety and performance standards. They are primarily used in medical imaging and diagnostic equipment, ensuring reliability and compliance with health regulations. While they offer peace of mind and performance assurance, buyers should be prepared for potentially higher costs due to the specialized nature of these products.

How Do Audio Transformers Enhance Sound Quality?

Audio transformers are specifically optimized to deliver superior sound quality and fidelity, making them essential in music production and high-end audio equipment. Their design focuses on enhancing audio performance, which is crucial for applications that demand high fidelity. However, buyers should be aware that these transformers may be unnecessarily complex for applications that do not prioritize sound quality.

What are the Benefits of Isolation Transformers?

Isolation transformers are designed to provide electrical isolation, which protects sensitive equipment from noise and interference. This feature is particularly beneficial in telecommunications and medical devices, where signal integrity is paramount. Although they enhance safety and performance, their bulkier design may pose challenges in space-constrained environments, which buyers should consider.

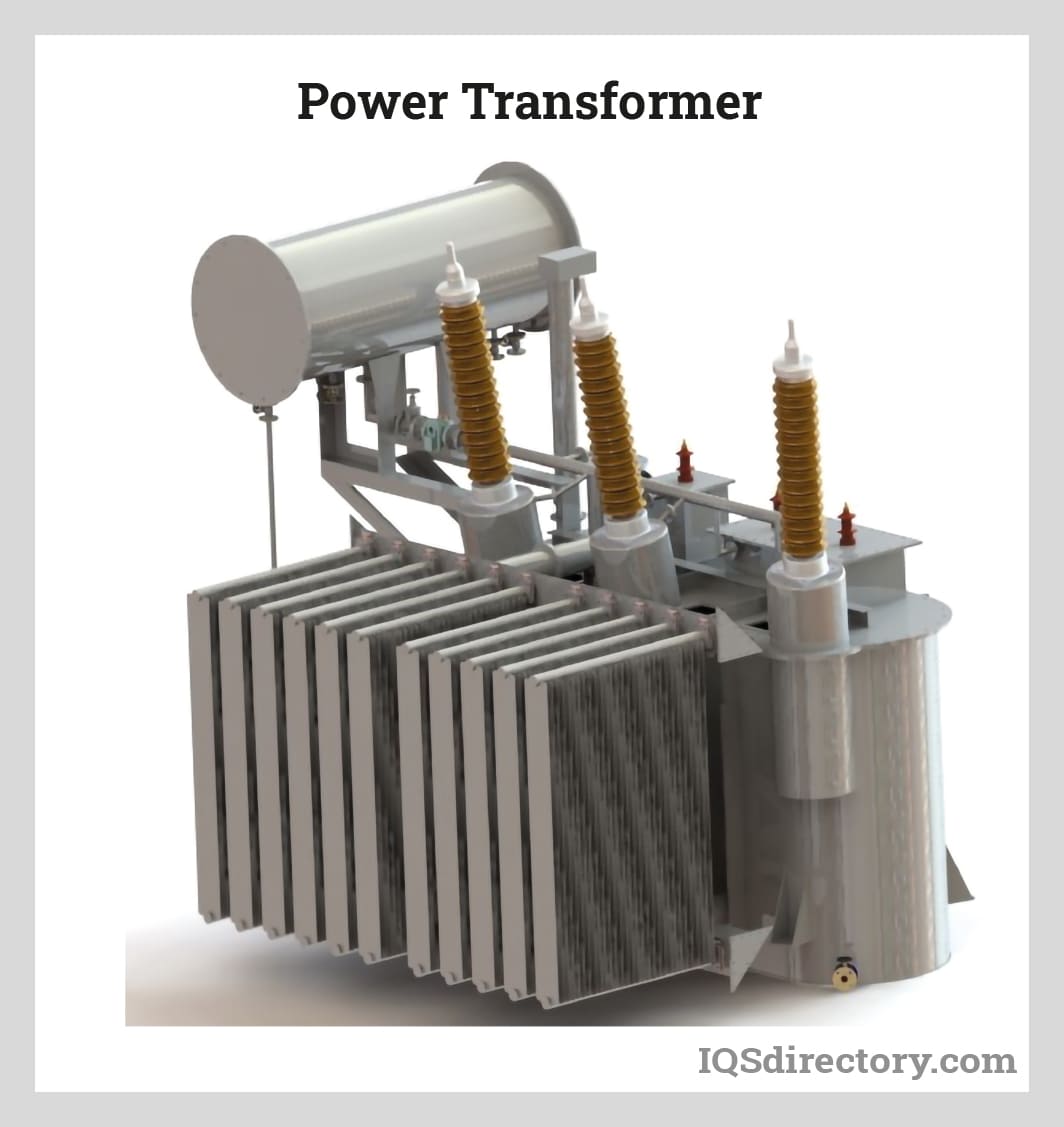

What Makes Toroidal Transformers a Compact Solution?

Toroidal transformers feature a unique donut-shaped design that allows for compactness and efficiency. They are commonly used in power supplies and audio applications, providing lower electromagnetic interference. While their space-saving design is advantageous, the increased complexity in manufacturing can lead to higher costs, making it essential for buyers to weigh the benefits against their budget constraints.

Key Industrial Applications of altran corp

| Industry/Sector | Specific Application of Altran Corp | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Custom Medical Transformers | Ensures reliability in life-saving equipment, such as x-ray machines. | Compliance with medical regulations and standards. |

| Renewable Energy | Custom Inductors for Wind and Solar Systems | Enhances efficiency in energy conversion and storage. | Durability and performance under varied environmental conditions. |

| Audio Equipment | Custom Audio Transformers | Delivers high-quality sound for professional audio applications. | Specific design requirements for sound fidelity and compactness. |

| Oil & Gas Exploration | Specialized Transformers for Harsh Environments | Increases operational reliability in extreme conditions. | Ability to withstand high temperatures and corrosive environments. |

| Industrial Automation | Power Transformers for Automation Systems | Supports seamless operation of machinery and equipment. | Voltage specifications and integration with existing systems. |

How Altran Corp. Serves the Medical Device Industry

In the medical device sector, Altran Corp. specializes in designing custom medical transformers that power essential equipment, such as x-ray machines. These transformers must meet stringent regulatory standards to ensure safety and reliability, making them critical components in life-saving technologies. International buyers, especially in developing regions, should prioritize sourcing transformers that comply with local medical regulations while also considering the longevity and efficiency of the components in varying conditions.

What Role Does Altran Corp. Play in Renewable Energy Solutions?

Altran Corp. provides custom inductors specifically designed for wind and solar energy systems. These components play a vital role in improving energy conversion efficiency, which is crucial for maximizing output in renewable energy applications. Buyers from regions like South America and Africa, where renewable energy is rapidly expanding, need to ensure that sourced components are durable and capable of performing optimally in diverse environmental conditions, including high humidity and temperature fluctuations.

How Does Altran Corp. Enhance Audio Equipment Performance?

In the audio equipment industry, Altran Corp. offers custom audio transformers that are essential for achieving high sound fidelity. These transformers are tailored to meet specific design requirements that impact sound quality, making them ideal for professional audio applications. Buyers in Europe and the Middle East, particularly those focused on high-end audio equipment, should consider the precision craftsmanship and performance metrics of these transformers to ensure they meet the demands of their target markets.

Why are Altran Corp.’s Solutions Critical for Oil & Gas Exploration?

For the oil and gas exploration sector, Altran Corp. manufactures specialized transformers designed to operate reliably in harsh environments. These transformers must withstand extreme temperatures and potential exposure to corrosive substances, which are common in this industry. Buyers from regions with significant oil and gas activities, such as the Middle East, should focus on sourcing transformers that are not only robust but also engineered for efficiency to minimize operational disruptions.

How Does Altran Corp. Support Industrial Automation?

Altran Corp. provides power transformers that are integral to industrial automation systems. These transformers ensure that machinery operates seamlessly and efficiently, which is vital for maintaining productivity in manufacturing environments. International buyers, especially from emerging markets, should consider the voltage specifications and compatibility of these transformers with existing automation systems to facilitate smooth integration and operation.

Illustrative image related to altran corp

3 Common User Pain Points for ‘altran corp’ & Their Solutions

Scenario 1: Navigating Complex Customization Needs for Transformers

The Problem: B2B buyers often face the challenge of sourcing transformers that meet highly specific technical requirements for unique applications. This is particularly true in industries such as medical or renewable energy, where standard solutions may not suffice. Buyers might struggle with ambiguous specifications or feel overwhelmed by the technical jargon and options available, leading to delays in project timelines and increased costs.

The Solution: To effectively address this issue, buyers should engage Altran Corp. early in their design process. By initiating a collaborative design engagement, companies can leverage Altran’s engineering expertise to refine their specifications. This proactive approach enables businesses to optimize transformer designs for performance and manufacturability. Additionally, requesting a quote that outlines all technical requirements upfront ensures clarity and helps in aligning expectations. Buyers should consider utilizing Altran’s build-to-print services, which allow for precise adherence to existing designs while benefiting from Altran’s quality assurance processes.

Scenario 2: Managing Production Timelines and Inventory Concerns

The Problem: Timely delivery of transformers is crucial for maintaining production schedules in industries reliant on continuous operations. Buyers often encounter delays due to unforeseen manufacturing challenges or miscommunication regarding lead times. This can be particularly damaging for businesses in sectors like audio engineering or medical technology, where equipment downtime can lead to significant financial losses.

The Solution: To mitigate risks associated with production delays, B2B buyers should establish a clear communication channel with Altran Corp. at the outset of their project. By discussing potential timelines and production capabilities, buyers can set realistic expectations for delivery. Furthermore, considering Altran’s ability to handle both one-off prototypes and high-volume orders allows buyers to adjust their inventory management strategies accordingly. Utilizing Altran’s in-house engineering and vertically integrated manufacturing capabilities can also streamline processes, ensuring that any design modifications are quickly implemented without sacrificing timelines.

Scenario 3: Ensuring Compliance and Quality Control in Transformer Specifications

The Problem: Compliance with industry standards and regulations is a significant concern for B2B buyers, especially when sourcing electrical components like transformers. Buyers may find it challenging to verify that the products meet required certifications such as CSA, UL, and CE, which can lead to compliance risks and potential liabilities down the line.

The Solution: B2B buyers can alleviate compliance concerns by thoroughly reviewing Altran Corp.’s certifications and quality assurance processes during the sourcing phase. Engaging with Altran’s representatives to discuss their adherence to RoHS guidelines and other industry standards can provide peace of mind. Additionally, buyers should request documentation of compliance with specific regulations relevant to their industry. By prioritizing suppliers with robust quality management systems and a track record of compliance, companies can mitigate risks and ensure that their products meet all necessary legal and performance standards. Investing time in understanding Altran’s manufacturing capabilities and their commitment to quality can lead to long-term partnerships that enhance operational reliability.

Strategic Material Selection Guide for altran corp

When selecting materials for custom transformers and inductors, Altran Corp. focuses on a variety of factors that can significantly influence product performance and suitability for specific applications. Below is an analysis of four common materials used in their manufacturing processes, with insights tailored for international B2B buyers.

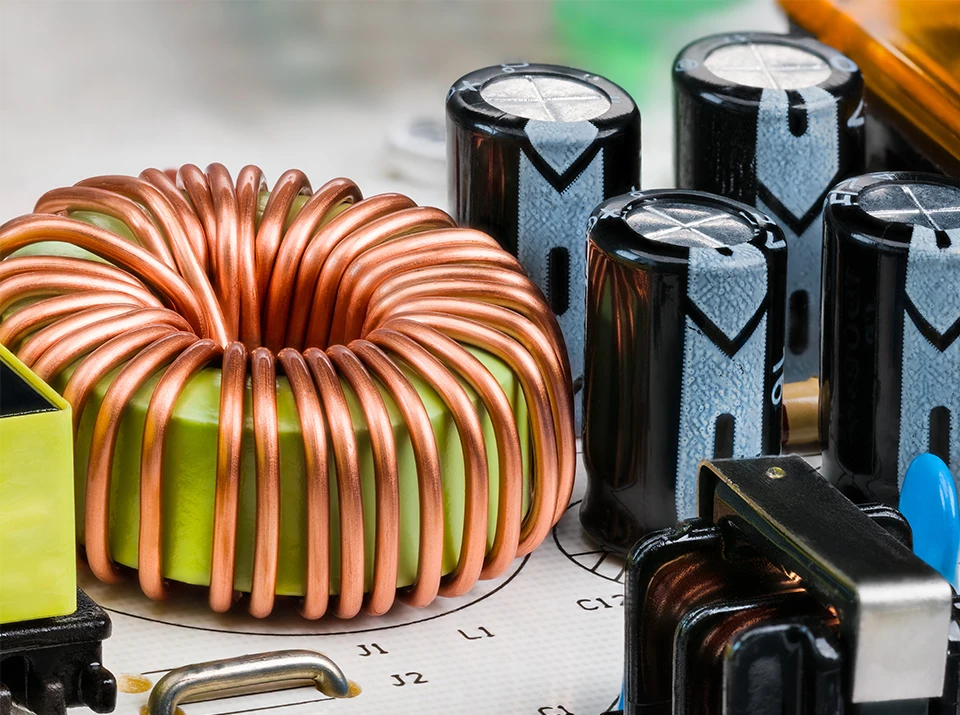

What Are the Key Properties of Copper in Transformer Manufacturing?

Copper is a primary conductor material used in transformer windings due to its excellent electrical conductivity. It typically has a temperature rating of around 200°C and exhibits good resistance to corrosion, especially when coated. The high thermal and electrical conductivity ensures efficient energy transfer, which is critical in applications like power transformers and inductors.

Illustrative image related to altran corp

Pros and Cons of Using Copper:

The primary advantage of copper is its superior conductivity, which allows for smaller wire sizes without compromising performance. However, copper is relatively expensive compared to alternatives like aluminum. Additionally, the manufacturing complexity can increase due to the need for specialized handling and insulation techniques to prevent oxidation.

Impact on Application:

Copper’s compatibility with high-frequency applications makes it ideal for audio transformers and inductors. However, international buyers should consider local regulations regarding the sourcing and use of copper, as well as compliance with standards such as ASTM B170.

How Does Aluminum Compare as a Transformer Material?

Aluminum is often used as an alternative to copper due to its lower cost and lighter weight. It has a temperature rating of approximately 90°C and is also resistant to corrosion when properly treated. While its electrical conductivity is about 60% that of copper, it can still be effective in many applications.

Pros and Cons of Using Aluminum:

The main advantage of aluminum is its cost-effectiveness, making it a popular choice for large-scale production. However, its lower conductivity means that larger wire sizes may be required, which can affect design compactness. Additionally, aluminum can be more susceptible to mechanical fatigue over time.

Impact on Application:

Aluminum is suitable for applications where weight savings are critical, such as in portable devices or automotive transformers. Buyers from regions like Africa and South America should ensure compliance with local standards, such as NEMA and IEC, particularly for electrical safety.

What Role Does Steel Play in Transformer Cores?

Steel, particularly silicon steel, is commonly used in transformer cores due to its magnetic properties. With a temperature rating of around 150°C, it provides excellent magnetic permeability, which is essential for efficient energy transfer. Steel cores can also be treated to enhance their performance under high-frequency conditions.

Pros and Cons of Using Steel:

The key advantage of steel is its ability to improve efficiency by minimizing energy losses due to hysteresis and eddy currents. However, steel can add significant weight to the transformer, which may not be suitable for all applications. Moreover, the manufacturing process can be complex, requiring precise cutting and laminating.

Impact on Application:

Steel cores are ideal for heavy-duty applications, including industrial transformers and those used in power generation. Buyers must consider compliance with international standards like ASTM A1008 for steel quality, especially when sourcing materials from different regions.

How Do Composite Materials Enhance Transformer Performance?

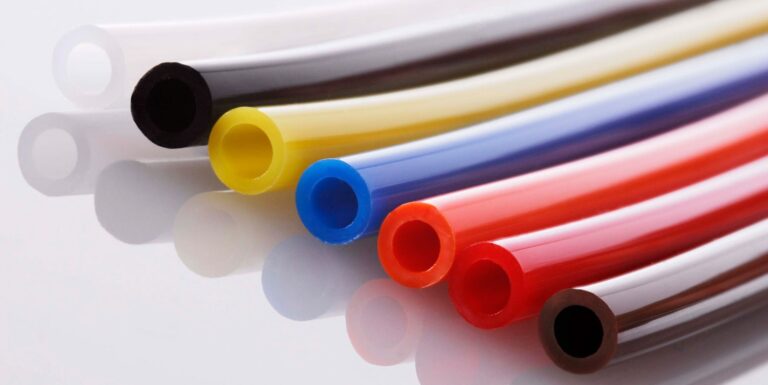

Composite materials, such as polymer-based insulations and resin-impregnated materials, are increasingly used in transformer manufacturing for their dielectric properties. These materials can withstand high temperatures and pressures, making them suitable for various environments.

Illustrative image related to altran corp

Pros and Cons of Using Composites:

Composite materials offer excellent insulation properties and can be engineered for specific applications, enhancing performance and longevity. However, they can be more expensive and may require specialized manufacturing techniques, which can complicate production.

Impact on Application:

Composites are particularly useful in high-voltage applications and environments with extreme conditions. International buyers should ensure that these materials meet specific compliance standards, such as UL and CE, to ensure safety and reliability.

Summary Table of Material Selection for Altran Corp.

| Material | Typical Use Case for Altran Corp | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Power transformers, inductors | Superior electrical conductivity | Higher cost, manufacturing complexity | High |

| Aluminum | Lightweight transformers | Cost-effective, lightweight | Lower conductivity, larger sizes | Medium |

| Steel | Industrial transformers | Improved energy efficiency | Adds weight, complex manufacturing | Medium |

| Composites | High-voltage applications | Excellent insulation properties | Higher cost, specialized techniques | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions tailored to their specific needs and compliance requirements.

Illustrative image related to altran corp

In-depth Look: Manufacturing Processes and Quality Assurance for altran corp

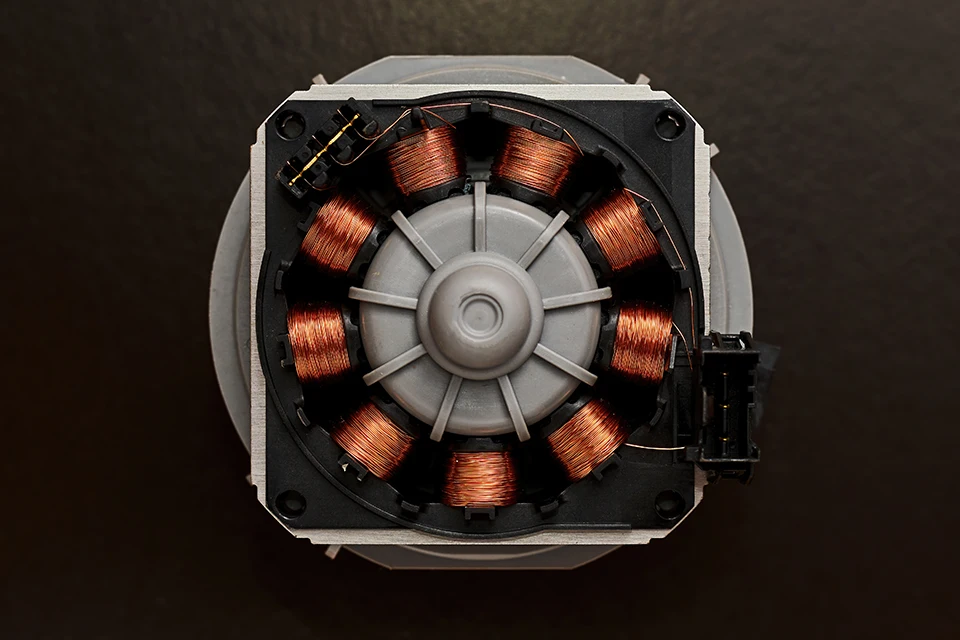

What Are the Key Stages in Altran Corp’s Manufacturing Processes?

Altran Corp employs a comprehensive manufacturing process to produce high-quality custom transformers and inductors tailored to meet specific client needs. The manufacturing process generally involves four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing journey begins with the selection of high-grade materials. Altran sources raw materials that comply with international standards, ensuring that each component can withstand the rigorous demands of various applications. These materials undergo rigorous inspection before use, including chemical analysis and dimensional checks, to ensure they meet the necessary specifications.

-

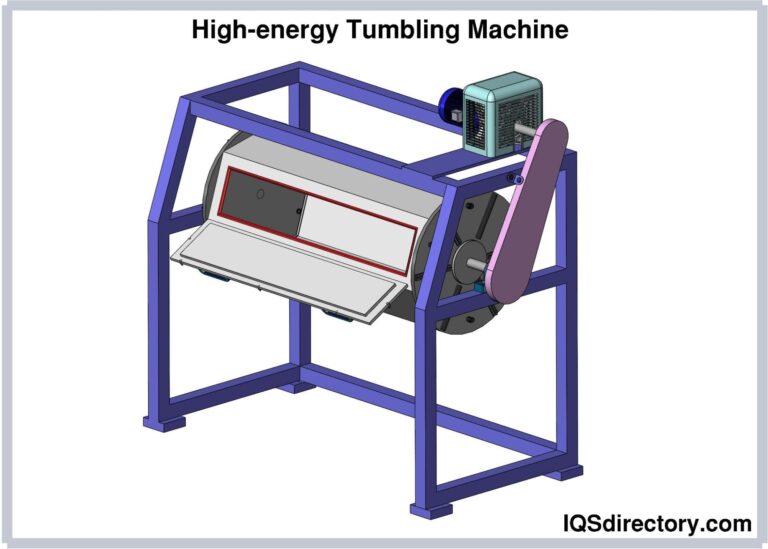

Forming: In this stage, the raw materials are shaped into the required forms. Techniques such as winding, stamping, and molding are employed, depending on the transformer type. For example, toroidal transformers may require precision winding around a toroidal core to achieve optimal performance. Advanced machinery and technology are utilized to ensure accuracy and consistency, reducing the risk of defects.

-

Assembly: Once formed, components are assembled into final products. This stage involves both manual and automated processes, where skilled technicians integrate various parts, including cores, windings, and insulation materials. Altran’s engineers work closely with assembly teams to ensure designs are executed accurately, and they perform real-time checks to maintain quality during this critical phase.

-

Finishing: The finishing stage includes insulation, coating, and final assembly checks. Products are insulated to prevent electrical faults, and protective coatings may be applied to enhance durability. This stage also involves final inspections to ensure that products meet performance specifications and aesthetic standards.

How Does Altran Corp Ensure Quality Control Throughout the Manufacturing Process?

Altran Corp adheres to stringent quality control measures at every step of the manufacturing process. The company follows internationally recognized standards, including ISO 9001, which establishes a framework for quality management systems. Additionally, they comply with industry-specific certifications such as CE and API, ensuring that products meet both safety and performance criteria.

-

Incoming Quality Control (IQC): Before any material is used in production, it undergoes IQC to verify that it meets predefined quality standards. This step is crucial for ensuring that only high-quality materials enter the manufacturing process, thereby reducing the likelihood of defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC checkpoints are established to monitor processes and ensure adherence to specifications. Technicians perform regular audits and tests to identify any issues early in the production cycle. This proactive approach minimizes waste and enhances overall efficiency.

-

Final Quality Control (FQC): After assembly and finishing, each product undergoes FQC, which includes rigorous testing for electrical performance, thermal efficiency, and durability. Testing methods may involve load testing, insulation resistance testing, and environmental simulations to assess product reliability under varying conditions.

What Testing Methods Does Altran Corp Utilize to Verify Product Quality?

Altran Corp employs a variety of testing methods to ensure that its transformers and inductors meet industry standards and customer expectations. These methods include:

-

Load Testing: This method simulates real-world conditions by applying electrical loads to the transformers, verifying their performance under operational stress.

-

Thermal Testing: Products are subjected to high-temperature conditions to evaluate their thermal efficiency and ensure they can operate safely within specified temperature ranges.

-

Electrical Insulation Testing: Insulation resistance is measured to ensure that the products can withstand electrical shocks and prevent short circuits.

-

Environmental Testing: Products may be exposed to extreme conditions, such as humidity and temperature variations, to ensure they maintain performance and reliability.

How Can B2B Buyers Verify Quality Control Practices with Altran Corp?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers like Altran Corp is essential for ensuring product reliability and compliance with regional standards.

-

Supplier Audits: Conducting regular audits of the supplier’s manufacturing facilities can provide insights into their quality control processes. Buyers can assess compliance with international standards, review quality documentation, and evaluate the overall manufacturing environment.

-

Requesting Quality Reports: Buyers can request quality assurance reports that detail testing results, inspection findings, and compliance with industry standards. These reports serve as evidence of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These agencies can conduct audits and tests to validate the supplier’s claims regarding product quality and compliance.

-

Certifications and Compliance: Buyers should verify that the supplier holds the necessary certifications (e.g., ISO, CE) and complies with regional regulations. This information can often be found on the supplier’s website or through direct inquiries.

What Are the Nuances of Quality Control for International Buyers?

Understanding the nuances of quality control is crucial for international buyers to mitigate risks associated with cross-border transactions. Different regions may have varying standards and regulations, so it’s essential to consider the following:

-

Regulatory Compliance: Buyers must ensure that products meet the regulatory requirements of their specific markets. This could involve additional testing or certification beyond what is required in the supplier’s country.

-

Cultural Differences: Communication styles and business practices vary across cultures. Buyers should be mindful of these differences when discussing quality expectations and addressing concerns.

-

Lead Times and Logistics: Quality assurance processes may impact lead times, especially if additional testing or inspections are required. Buyers should factor in these considerations when planning orders and supply chain logistics.

By understanding Altran Corp’s manufacturing processes and quality assurance practices, B2B buyers can make informed decisions that align with their operational needs and quality expectations. This detailed insight not only helps in selecting a reliable supplier but also fosters long-term business relationships built on trust and quality assurance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘altran corp’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in effectively procuring products from Altran Corp, a leading manufacturer of custom transformers and inductors. By following this step-by-step checklist, you can ensure a streamlined procurement process that meets your technical requirements, budget constraints, and timeline expectations.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of a successful procurement process. This includes understanding the specific type of transformer or inductor needed, such as power transformers, audio transformers, or custom inductors. Consider factors like voltage ratings, size constraints, and environmental conditions to ensure that the products align with your operational needs.

Step 2: Research Altran Corp’s Product Offerings

Take time to familiarize yourself with Altran Corp’s extensive range of products. Their offerings include custom transformers tailored for various industries, such as medical, audio, and renewable energy. Understanding the specific capabilities and applications of their products will enable you to make informed decisions that fit your project requirements.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that Altran Corp holds relevant certifications, such as CSA, UL, and CE. These certifications indicate adherence to industry standards for safety and quality, ensuring that the products you receive will perform reliably in your applications. Additionally, check for RoHS compliance to confirm that their manufacturing processes meet environmental regulations.

Step 4: Request Detailed Quotations

Once your specifications are clear, request detailed quotations from Altran Corp. A comprehensive quote should include pricing, lead times, and terms of service. Pay attention to the breakdown of costs and any potential additional fees for custom designs or expedited shipping, as this will help you manage your budget effectively.

Step 5: Assess Manufacturing Capabilities

Inquire about Altran Corp’s manufacturing capabilities, including their production technologies and quality control measures. Understanding their vertical integration allows you to gauge how well they can meet your volume requirements and maintain quality throughout the production process. Ask about their ability to handle both one-off prototypes and high-volume production runs.

Step 6: Review Past Customer Experiences

Seek references or case studies from Altran Corp’s previous clients, particularly those in your industry or region. Learning about their experiences can provide valuable insights into the company’s reliability, customer service, and product performance. This step can help mitigate risks and set realistic expectations for your engagement.

Illustrative image related to altran corp

Step 7: Establish Communication Channels

Set up clear communication channels with Altran Corp to facilitate ongoing dialogue throughout the procurement process. Establishing a point of contact within the company will ensure you receive timely updates on your order status, design iterations, and any potential issues. Effective communication is essential for resolving concerns quickly and keeping your project on track.

By following this checklist, B2B buyers can confidently navigate the procurement process with Altran Corp, ensuring that they receive high-quality products that meet their specific needs and expectations.

Comprehensive Cost and Pricing Analysis for altran corp Sourcing

What Are the Key Cost Components in Altran Corp’s Pricing Structure?

When considering sourcing from Altran Corp, understanding the cost structure is crucial for international B2B buyers. The primary components of the cost structure include:

Illustrative image related to altran corp

-

Materials: The selection of raw materials significantly influences the final price. Altran uses high-quality materials to ensure reliability and performance, particularly for specialized products like medical transformers and high-performance inductors.

-

Labor: Skilled labor is essential in the manufacturing of custom transformers. Altran employs experienced engineers and technicians, which contributes to the overall labor cost. The complexity of the product design can also affect labor intensity.

-

Manufacturing Overhead: This includes expenses related to maintaining the manufacturing facility, utilities, and equipment maintenance. Altran’s vertically integrated operations allow for better control over these costs, which can be beneficial for pricing.

-

Tooling: Custom projects often require specialized tooling, which can be a significant upfront cost. Buyers should inquire about tooling costs, especially for one-off prototypes or highly customized designs.

-

Quality Control (QC): Altran adheres to stringent quality standards (CSA, UL, and CE certifications), and the associated QC processes add to the overall cost. Quality assurance ensures that products meet performance specifications, which is critical for industries like medical and energy.

-

Logistics: Shipping costs can vary based on the volume of the order and the destination. For international buyers, understanding shipping terms and potential tariffs is essential for accurate cost estimation.

-

Margin: Altran’s pricing strategy includes a margin that reflects their commitment to quality and innovation. Buyers should consider this margin when evaluating the total cost against competitors.

How Do Pricing Influencers Impact Altran Corp’s Offerings?

Several factors can influence the pricing of Altran’s products:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs. Buyers should assess their needs and negotiate for favorable pricing based on potential order quantities.

-

Specifications and Customization: Customized solutions often come with a premium due to the added engineering and production complexity. Buyers should clearly define their specifications to avoid unexpected costs.

-

Material Choices: The type of materials selected can significantly impact pricing. Premium materials may enhance performance but also increase costs.

-

Quality and Certifications: Products that require specific certifications can incur additional costs. Buyers should weigh the importance of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of Altran as a supplier can influence pricing. Established suppliers may command higher prices due to their track record of delivering quality products consistently.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is essential for calculating total costs. Incoterms dictate who is responsible for shipping costs and risks, which can significantly affect the overall pricing strategy.

What Tips Can Help Buyers Optimize Costs When Sourcing from Altran Corp?

For international buyers, especially those from Africa, South America, the Middle East, and Europe, here are actionable tips:

-

Negotiate Effectively: Leverage your purchasing power by discussing potential discounts for larger orders or long-term contracts. Building a strong relationship with Altran can also lead to better pricing.

-

Focus on Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with maintenance, operational efficiency, and the durability of the products. Investing in higher-quality transformers may lead to lower TCO over time.

-

Understand Pricing Nuances: Be aware of currency fluctuations, import duties, and local taxes that could affect the final cost. Conducting thorough market research can provide insights into the pricing landscape.

-

Request Detailed Quotations: Ask for itemized quotes that break down costs into materials, labor, and logistics. This transparency can help in identifying areas for potential savings.

-

Evaluate Local Alternatives: While Altran provides high-quality American-made products, exploring local suppliers in your region may offer competitive pricing, especially when considering shipping costs.

Disclaimer on Indicative Prices

The prices associated with Altran Corp’s products can vary widely based on the aforementioned factors. It is advisable for buyers to engage directly with Altran to obtain accurate quotes tailored to specific requirements and circumstances.

Alternatives Analysis: Comparing altran corp With Other Solutions

Understanding Alternatives in Custom Transformer Solutions

When evaluating custom transformer solutions for your business, it’s crucial to consider various alternatives that can meet your specific needs. Altran Corp, known for its high-quality American-made transformers and inductors, offers a robust range of products tailored for various industries. However, other manufacturers and technologies may also provide viable solutions. This analysis compares Altran Corp with two alternative providers, allowing B2B buyers to make informed decisions.

Comparison Table of Custom Transformer Solutions

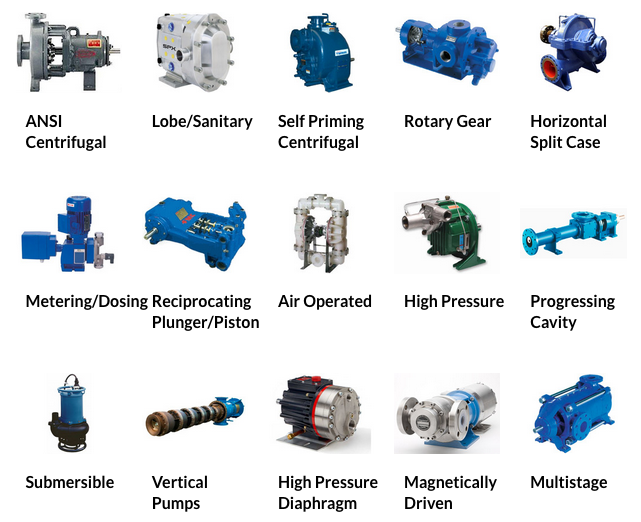

| Comparison Aspect | Altran Corp | Alternative 1: IDEAL Industries | Alternative 2: Hammond Manufacturing |

|---|---|---|---|

| Performance | High efficiency; tailored for specific applications | Reliable for standard applications; less customization | High-quality audio and power transformers; extensive product range |

| Cost | Competitive pricing for custom solutions | Generally lower prices for standard products | Premium pricing for specialized transformers |

| Ease of Implementation | Flexible design process; responsive service | Quick delivery for standard orders | Requires more lead time for custom designs |

| Maintenance | In-house support and repair services | Limited support for custom solutions | Strong support network; high-quality components |

| Best Use Case | Custom applications in medical, energy, and audio | General electrical applications and tools | Specialized audio and industrial applications |

Detailed Breakdown of Alternatives

Alternative 1: IDEAL Industries

IDEAL Industries is a well-established manufacturer specializing in a broad range of electrical products, including transformers. The main advantage of IDEAL is its competitive pricing for standard transformer solutions, making it an attractive option for businesses seeking reliable yet cost-effective products. However, IDEAL may lack the customization capabilities that some projects require, limiting its appeal for specialized applications. Their quick delivery times for standard products can benefit companies with immediate needs, but those seeking tailored solutions might find their offerings insufficient.

Illustrative image related to altran corp

Alternative 2: Hammond Manufacturing

Hammond Manufacturing is renowned for its extensive selection of high-quality transformers, particularly in the audio and industrial sectors. Their products are often regarded as premium solutions, which can mean higher costs compared to other options. Hammond’s commitment to quality is a significant advantage, especially for applications that demand superior performance, such as audio equipment and specialty industrial uses. However, the lead time for custom designs may be longer than that of competitors, which could impact projects with tight timelines. Additionally, their strong support network provides reassurance for businesses investing in more expensive transformer solutions.

How to Choose the Right Custom Transformer Solution

Selecting the right custom transformer solution involves evaluating your specific needs against the strengths and weaknesses of each alternative. Consider factors such as performance requirements, budget constraints, and the level of customization needed. Altran Corp excels in providing tailored solutions with a strong emphasis on quality and service, making it a compelling choice for specialized projects. However, if cost and quick delivery of standard products are your primary concerns, IDEAL Industries may serve you better. For those requiring high-quality components with a focus on audio applications, Hammond Manufacturing could be the preferred option. Ultimately, aligning your selection with your project’s unique demands will ensure you choose the most effective transformer solution for your business.

Essential Technical Properties and Trade Terminology for altran corp

What Are the Essential Technical Properties for Custom Transformers?

When considering custom transformers from Altran Corp, several technical properties are crucial for ensuring that the products meet specific operational needs. Understanding these specifications is vital for B2B buyers looking to make informed decisions.

Illustrative image related to altran corp

-

Material Grade: The type of materials used in transformer construction significantly impacts performance and durability. Common materials include silicon steel for cores and copper or aluminum for windings. High-quality materials enhance efficiency, reduce energy loss, and extend the lifespan of transformers, making them essential for industries like medical, audio, and renewable energy.

-

Tolerance: This specification refers to the permissible limit or limits of variation in a physical dimension or measured value. In transformer manufacturing, tight tolerances are critical to ensure that the device operates correctly and efficiently. For B2B buyers, understanding tolerance levels can help in selecting products that will integrate seamlessly into their systems without unexpected failures or inefficiencies.

-

Thermal Efficiency: This property indicates how well a transformer can convert electrical energy with minimal heat loss. High thermal efficiency is crucial for applications in harsh environments or where energy conservation is a priority. B2B buyers should prioritize transformers with superior thermal efficiency to reduce operational costs and enhance system reliability.

-

Voltage Rating: The voltage rating specifies the maximum voltage the transformer can handle safely. Selecting a transformer with the correct voltage rating is essential to prevent overheating or failure, ensuring that the equipment operates within safe limits. B2B buyers must align voltage ratings with their operational requirements to avoid costly downtimes.

-

Frequency Response: This indicates how well a transformer can operate across various frequencies. In industries like audio and telecommunications, frequency response is critical for performance. Understanding this property helps buyers ensure that transformers will meet their application’s specific frequency demands.

What Trade Terminology Should B2B Buyers Understand?

Navigating the procurement process involves familiarity with specific industry terminology. Here are essential terms that buyers should know when dealing with Altran Corp.

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers seeking custom solutions that integrate with existing systems, ensuring compatibility and performance.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to manage inventory costs and ensure they can meet production needs without excess stock.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and other information for specific products or services. For businesses looking to procure custom transformers, issuing an RFQ can help compare offers and determine the best value for their needs.

-

Incoterms (International Commercial Terms): These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. Understanding Incoterms helps B2B buyers clarify responsibilities regarding shipping, insurance, and tariffs, which is essential when importing transformers from manufacturers like Altran.

-

Build-to-Print: This term describes a manufacturing process where a supplier builds a product according to the specifications provided by the buyer. For companies that have precise design requirements, understanding build-to-print can help ensure that the final product meets their exact needs.

-

Lead Time: This refers to the amount of time it takes from placing an order until the product is delivered. For B2B buyers, knowing the lead time is essential for planning production schedules and managing supply chain expectations.

Understanding these technical properties and trade terms enables B2B buyers to make informed decisions and engage effectively with manufacturers like Altran Corp. By focusing on these aspects, companies can ensure they select products that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the altran corp Sector

What Are the Key Market Dynamics and Trends Affecting Altran Corp’s Sector?

The global market for custom transformers and inductors, as exemplified by Altran Corp, is currently driven by several factors that international B2B buyers should consider. Rapid technological advancements and the increasing demand for energy-efficient solutions are reshaping the landscape. In regions like Africa, South America, and the Middle East, the growth of renewable energy sectors is propelling the need for specialized transformers that can handle varying load conditions and integrate seamlessly with smart grid technologies. Additionally, Europe is experiencing a shift toward more compact and efficient designs, emphasizing the importance of thermal management and durability in transformer applications.

Emerging B2B technology trends, such as automation in manufacturing and the use of advanced modeling tools, are allowing companies like Altran to enhance production efficiency and reduce costs. Buyers from countries like Vietnam and Brazil should note that these innovations not only improve product reliability but also align with the growing expectations for quicker turnaround times in the supply chain. The integration of Industry 4.0 principles, including IoT-enabled monitoring and predictive maintenance, is becoming increasingly crucial, allowing companies to offer more tailored solutions that meet specific client needs.

Moreover, the demand for customized solutions is on the rise, driven by diverse industry applications ranging from medical equipment to audio technology. This demand necessitates a collaborative approach between manufacturers and clients, with a focus on optimizing designs for cost-effectiveness and performance. International buyers must remain agile, adapting to these dynamic market conditions to secure the best sourcing strategies.

How Is Sustainability and Ethical Sourcing Transforming the B2B Landscape for Altran Corp?

Sustainability is becoming a cornerstone of B2B sourcing, particularly in the manufacturing sector. For Altran Corp, embracing environmentally friendly practices is not just a regulatory requirement but a competitive advantage. The company adheres to RoHS guidelines, emphasizing the elimination of hazardous substances in its manufacturing processes. This commitment to sustainability resonates with international buyers, particularly in regions where regulatory frameworks are tightening, and consumer awareness of environmental issues is rising.

Ethical sourcing is another critical aspect that B2B buyers must consider. Transparency in the supply chain and responsible sourcing of materials can significantly enhance brand reputation and customer loyalty. For Altran, utilizing ‘green’ materials and processes not only reduces environmental impact but also aligns with the values of an increasingly conscientious customer base. Certifications such as CSA, UL, and CE serve as quality benchmarks, providing assurance that products meet stringent safety and environmental standards.

Illustrative image related to altran corp

Furthermore, as businesses strive to meet their own sustainability goals, partnering with suppliers committed to ethical practices can enhance corporate social responsibility (CSR) initiatives. Buyers from Africa, South America, the Middle East, and Europe can leverage these partnerships to foster innovation while contributing to a more sustainable future.

How Has Altran Corp Evolved to Meet B2B Market Needs?

Founded in 1983, Altran Corp has evolved into a leading manufacturer of custom transformers and inductors, reflecting over four decades of industry expertise. The company’s commitment to innovation and quality has allowed it to adapt to changing market demands, including the shift towards more energy-efficient and compact designs. By investing in advanced manufacturing technologies and a vertically integrated production process, Altran ensures that it maintains control over quality at every stage, from design to final testing.

This evolution has positioned Altran as a trusted partner across diverse sectors, from medical and audio applications to energy and industrial automation. Their focus on custom solutions and responsive service has enabled them to build long-term relationships with B2B clients, ensuring that they remain at the forefront of the transformer manufacturing industry. As they continue to navigate the complexities of the global marketplace, Altran Corp exemplifies the importance of adaptability and customer-centric innovation in achieving sustainable growth.

Frequently Asked Questions (FAQs) for B2B Buyers of altran corp

-

How do I ensure the quality of custom transformers from Altran Corp?

To ensure quality, Altran Corp employs a vertically integrated manufacturing process that maintains control over every production stage, from core winding to final testing. They adhere to strict industry standards, including CSA, UL, and CE certifications. B2B buyers can also request detailed quality assurance documentation and performance testing results to verify compliance with their specific requirements. Engaging in a collaborative design process with Altran’s engineers can further enhance the quality and performance of the custom products. -

What are the customization options available for transformers at Altran Corp?

Altran Corp specializes in creating custom transformers tailored to the specific needs of various industries, such as medical, audio, and energy. Options include design specifications for size, voltage, and thermal efficiency. Buyers can collaborate with Altran’s engineering team to optimize designs for manufacturability and cost-effectiveness, ensuring that the final product meets both technical and operational requirements. This flexibility makes Altran an ideal partner for projects requiring unique specifications. -

What is the minimum order quantity (MOQ) for custom transformers from Altran Corp?

Altran Corp typically accommodates both low-volume prototype orders and high-volume production runs. The MOQ may vary based on the complexity of the design and the materials required. It’s advisable to discuss your specific project needs directly with their sales team to understand the MOQ for your order, ensuring that your procurement strategy aligns with your project timelines and budget constraints. -

What payment terms does Altran Corp offer for international B2B buyers?

Altran Corp provides flexible payment terms tailored to the needs of international buyers. Payment options may include upfront deposits, net 30/60 terms, or other arrangements depending on the order size and customer relationship. It’s recommended to clarify payment conditions during the quote request process to ensure alignment with your company’s financial policies and to facilitate smooth transactions. -

How does Altran Corp handle logistics for international shipments?

Altran Corp has established logistics partnerships to streamline the shipping process for international orders. They can coordinate freight forwarding, customs clearance, and delivery to ensure timely arrival of products. Buyers should communicate their preferred shipping methods and timelines during the ordering process, allowing Altran to align logistics with your project schedules and mitigate any potential delays. -

What industries does Altran Corp serve with its transformer solutions?

Altran Corp caters to a wide range of industries, including medical, audio, oil exploration, renewable energy, and gaming. Their expertise in custom transformer manufacturing allows them to support unique applications, from life-saving medical devices to high-fidelity audio equipment. B2B buyers should evaluate how Altran’s product offerings align with their industry requirements to ensure compatibility and performance. -

How can I request a quote for custom transformers from Altran Corp?

Requesting a quote is straightforward. B2B buyers can visit Altran Corp’s website and fill out the request form, providing details about their project specifications, required quantities, and any unique design considerations. Alternatively, buyers can contact Altran directly via phone or email to discuss their needs in detail. Prompt communication will help expedite the quoting process and facilitate a more tailored response. -

What steps does Altran Corp take to ensure compliance with international regulations?

Altran Corp adheres to rigorous compliance standards, including RoHS guidelines for hazardous substances and certifications from CSA, UL, and CE. They maintain updated documentation to support international trade compliance. Buyers should inquire about specific compliance certifications relevant to their regions or industries, ensuring that the transformers meet all necessary regulatory requirements for safe and effective use in their applications.

Top 5 Altran Corp Manufacturers & Suppliers List

1. Altran Corp – Electric Transformers

Domain: electrictransformers.net

Registered: 2001 (24 years)

Introduction: Altran Corp. specializes in the design, manufacturing, and testing of electric transformers for industrial and commercial applications. Their product lineup includes custom and standard transformer solutions such as power transformers, distribution transformers, and specialized units for harsh environments. They offer repair, refurbishment, and retrofitting services. Key types of transformers incl…

2. LinkedIn – Dedicated API Solution

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: To scrape Linkedin use our dedicated Linkedin API.

3. Altran Corp – Electronic Coils & Transformers

Domain: bloomberg.com

Registered: 1993 (32 years)

Introduction: Altran Corp manufactures electronic coils and transformers.

4. Altran Corp – Electric Transformers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Altran Corp. specializes in the design, manufacturing, and testing of electric transformers for industrial and commercial applications. Their product lineup includes custom and standard transformer solutions such as power transformers, distribution transformers, and specialized units for harsh environments. They focus on engineering excellence, precision craftsmanship, and innovation. Altran offer…

5. Altran Magnetics – DC Contactors, EMI Filters, Solid State Relays

Domain: altranmagnetics.com

Registered: 2014 (11 years)

Introduction: Altran Magnetics offers a range of products including: 1. DC Contactors – Trusted solutions for DC switching needs with various options available. 2. EMI Filters – Designed to reduce electromagnetic interference, ensuring seamless and efficient system performance. 3. Solid State Relays – Reliable and efficient switching solutions, built to last with multiple options for specific applications. 4. M…

Strategic Sourcing Conclusion and Outlook for altran corp

How Can Strategic Sourcing Enhance Your Supply Chain with Altran Corp.?

In conclusion, Altran Corp. stands as a pivotal partner for international B2B buyers seeking high-quality, custom transformer solutions. Their extensive experience and commitment to precision craftsmanship position them as a leader in the manufacturing of transformers and inductors for diverse industries, including medical, audio, and energy sectors. By leveraging Altran’s capabilities, businesses can optimize their supply chains through strategic sourcing, ensuring not only reliability and performance but also cost-effectiveness.

Investing in custom-designed solutions from Altran allows companies to meet specific project requirements while benefitting from American manufacturing quality and standards. The ability to collaborate closely with engineers on design and production means that international buyers can achieve tailored outcomes that enhance operational efficiency and reduce time-to-market.

As global markets continue to evolve, the demand for innovative and dependable electrical components will only increase. Now is the time for B2B buyers in Africa, South America, the Middle East, and Europe to engage with Altran Corp. to secure a competitive edge in their industries. Reach out today to explore how Altran can help meet your unique sourcing needs and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.