How to Source Airplane Wire Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for airplane wire

In the increasingly competitive global market for airplane wire, sourcing high-quality materials that meet stringent safety and performance standards poses a significant challenge for B2B buyers. As industries across Africa, South America, the Middle East, and Europe strive to enhance their aviation capabilities, understanding the nuances of airplane wire types, applications, and supplier reliability becomes essential. This comprehensive guide aims to equip international buyers with the knowledge needed to navigate this complex landscape, providing insights into various wire types, their specific uses, and the factors influencing cost.

From galvanized and stainless steel cables to specialized applications in both commercial and military aviation, the scope of this guide covers all critical aspects of airplane wire procurement. We delve into best practices for supplier vetting, emphasizing the importance of quality certifications and compliance with international standards. Additionally, we address the economic factors influencing pricing, enabling buyers to make informed purchasing decisions that align with their operational budgets.

By empowering buyers with actionable insights and a thorough understanding of the airplane wire market, this guide serves as a vital resource for companies looking to enhance their procurement strategies. Whether you’re in Nigeria, Brazil, or elsewhere, the knowledge gained here will help streamline your sourcing process, ensuring you select the right materials for your aviation needs.

Understanding airplane wire Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 7×19 Galvanized Aircraft Cable | Made of high-strength steel, available in various diameters, cost-effective | General rigging, fencing, and winching | Pros: Cost-effective, good strength; Cons: Less corrosion resistance compared to stainless steel. |

| 7×19 Stainless Steel Aircraft Cable | Higher corrosion resistance, available in Type 304 and Type 316 | Marine applications, high-moisture environments | Pros: Excellent durability, rust-resistant; Cons: Higher cost than galvanized options. |

| Vinyl-Coated Aircraft Cable | Protective vinyl coating enhances durability and grip | Outdoor rigging, safety applications | Pros: Increased protection against abrasion; Cons: Slightly reduced strength due to coating. |

| Custom Wire Rope | Tailored specifications for unique applications | Specialized lifting and rigging tasks | Pros: Customization for specific needs; Cons: Longer lead times and potentially higher costs. |

| Rotation-Resistant Wire Rope | Designed to prevent twisting under load | Heavy-duty lifting and industrial uses | Pros: Maintains stability under load; Cons: More complex and potentially more expensive. |

What Are the Key Characteristics of 7×19 Galvanized Aircraft Cable?

7×19 Galvanized Aircraft Cable is a popular choice for various applications due to its high-strength steel construction and cost-effectiveness. Typically available in diameters up to 3/8″, this cable is suitable for general rigging, fencing, and winching tasks. Buyers should consider its break strength and the environments in which it will be used, as it offers good strength but less corrosion resistance compared to stainless steel options.

How Does 7×19 Stainless Steel Aircraft Cable Compare?

7×19 Stainless Steel Aircraft Cable, available in Type 304 and Type 316, is ideal for environments prone to moisture, such as marine applications. Its superior corrosion resistance makes it suitable for long-term use in challenging conditions. When purchasing, B2B buyers should assess the specific type of stainless steel based on their environmental needs, as Type 316 offers better rust resistance but is slightly weaker than Type 304.

Why Choose Vinyl-Coated Aircraft Cable?

Vinyl-Coated Aircraft Cable features a protective layer that enhances its durability and grip, making it an excellent choice for outdoor rigging and safety applications. The coating protects against dirt and moisture, prolonging the cable’s lifespan. Buyers should weigh the benefits of added protection against potential reductions in strength due to the coating.

What Are the Advantages of Custom Wire Rope?

Custom Wire Rope allows B2B buyers to specify precise dimensions and materials for unique applications, such as specialized lifting tasks. While customization can lead to higher costs and longer lead times, the ability to meet specific requirements can significantly enhance operational efficiency and safety. Companies should evaluate their unique needs to determine if the investment in custom solutions is justified.

When to Consider Rotation-Resistant Wire Rope?

Rotation-Resistant Wire Rope is specifically designed to prevent twisting under load, making it ideal for heavy-duty lifting and industrial applications. This type of wire rope can enhance safety and efficiency in operations where stability is paramount. Buyers should consider the complexity and potential costs associated with rotation-resistant options, ensuring they align with their operational requirements.

Key Industrial Applications of airplane wire

| Industry/Sector | Specific Application of Airplane Wire | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aviation & Aerospace | Aircraft control systems | Ensures safety and reliability in flight operations | Compliance with aviation regulations and certifications |

| Maritime Industry | Rigging and mooring for vessels | Provides strength and durability in harsh marine environments | Corrosion resistance and material specifications |

| Construction & Infrastructure | Temporary supports and scaffolding | Enhances safety and stability during construction projects | Load ratings and length customization |

| Renewable Energy | Wind turbine installations | Facilitates secure connections for energy transmission | Resistance to environmental conditions and fatigue |

| Telecommunications | Aerial cable installations | Supports reliable communication networks | Flexibility and tensile strength |

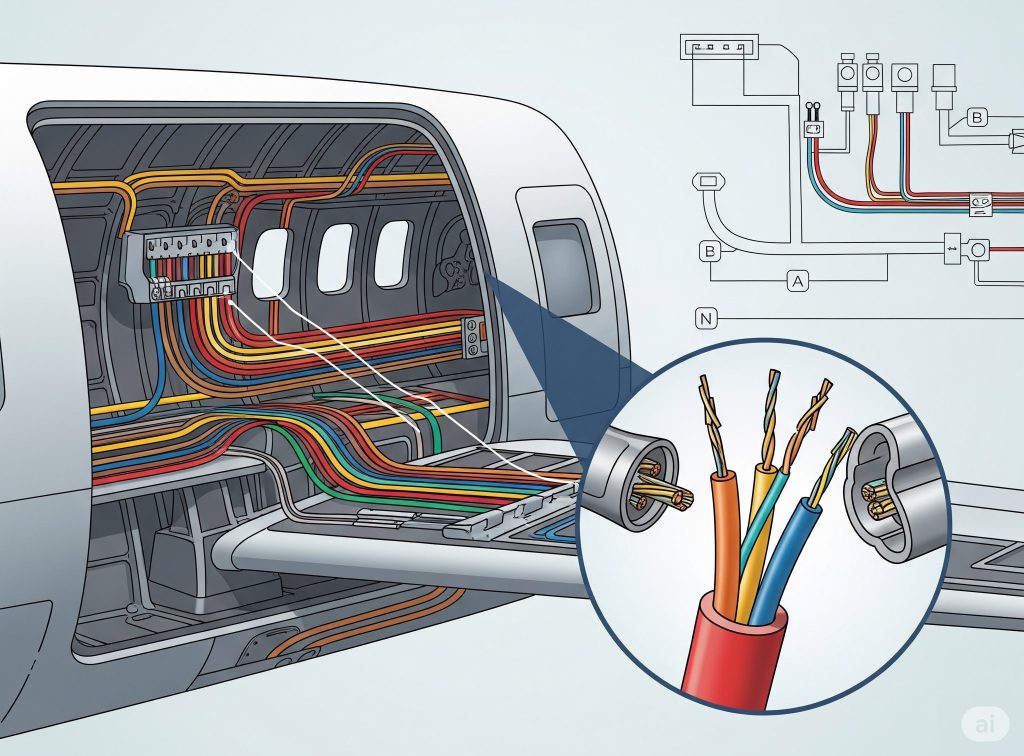

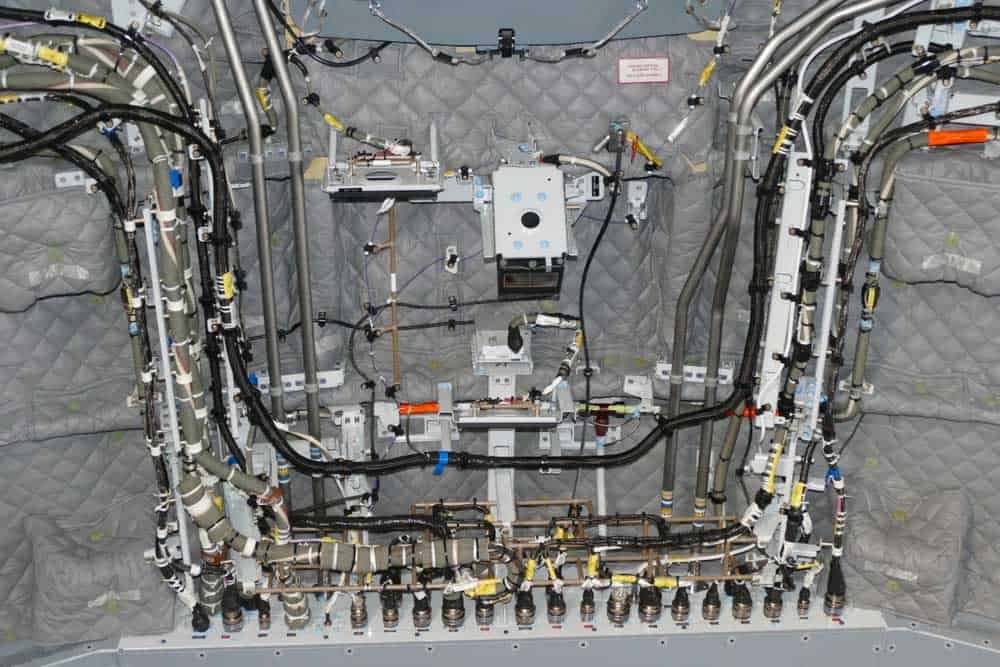

How Is Airplane Wire Used in Aviation and Aerospace Applications?

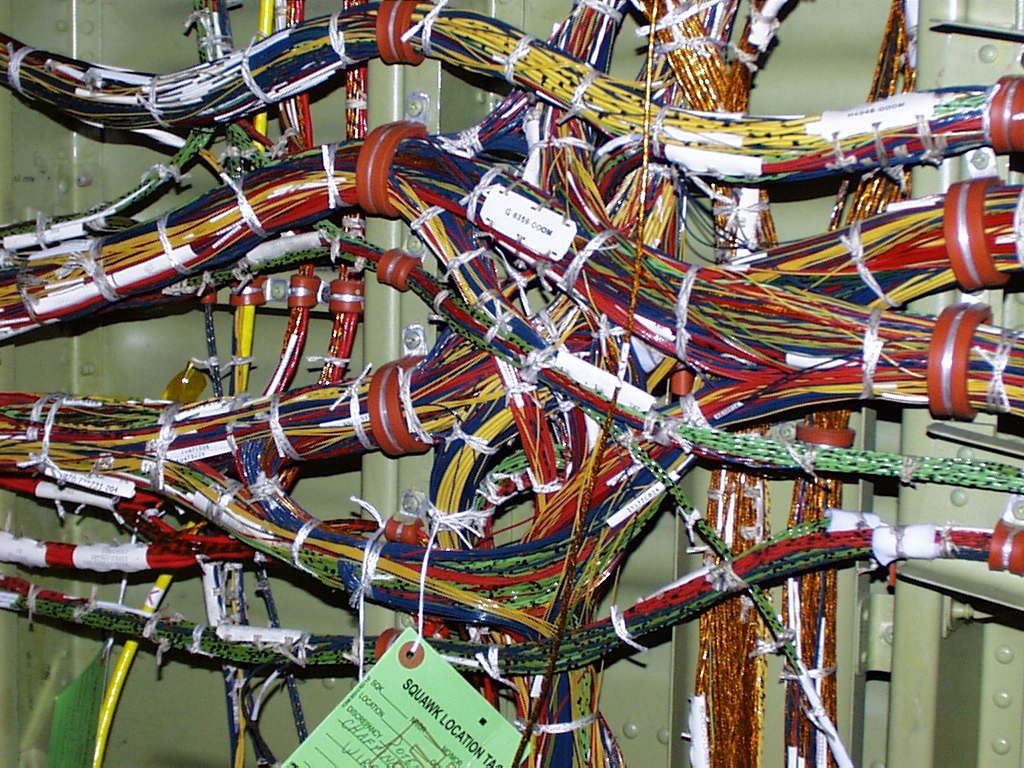

In the aviation and aerospace sectors, airplane wire is critical for aircraft control systems. This wire is engineered to withstand high tension and environmental stresses, ensuring the safety and reliability of flight operations. Buyers in this sector must prioritize sourcing wires that meet stringent aviation regulations and certifications, ensuring compliance with international standards. Additionally, considerations around weight and flexibility are paramount, as they can impact overall aircraft performance and fuel efficiency.

What Role Does Airplane Wire Play in the Maritime Industry?

In the maritime industry, airplane wire is extensively utilized for rigging and mooring applications. Its high tensile strength and durability make it ideal for securing vessels in challenging marine environments. Businesses operating in this sector benefit from corrosion-resistant materials, particularly stainless steel options, which extend the lifespan of the wire in salty and humid conditions. Buyers should ensure the wire’s specifications align with the unique demands of marine applications, including resistance to wear and environmental fatigue.

How Is Airplane Wire Applied in Construction and Infrastructure?

Airplane wire finds significant utility in construction and infrastructure projects, particularly for temporary supports and scaffolding. It enhances safety by providing stability during construction activities, which is crucial for worker safety and project timelines. B2B buyers in this industry need to consider load ratings and the ability to customize lengths to fit specific project requirements. Additionally, sourcing wire that meets local safety standards and regulations is essential to avoid compliance issues.

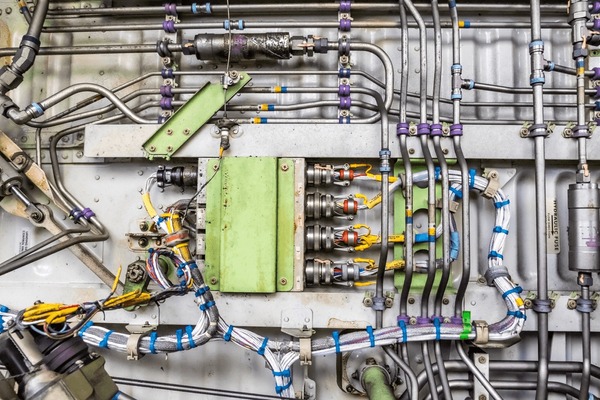

Illustrative image related to airplane wire

Why Is Airplane Wire Important for Renewable Energy Projects?

In renewable energy, especially in wind turbine installations, airplane wire is vital for secure connections that facilitate energy transmission. The wire must be robust enough to handle dynamic loads while maintaining flexibility for installation. Businesses benefit from sourcing wire with resistance to environmental conditions, such as UV exposure and fatigue from constant movement. Buyers should also focus on sourcing materials that align with sustainability goals, as this can enhance the overall appeal of their projects.

How Does Airplane Wire Support Telecommunications Infrastructure?

Airplane wire is crucial in telecommunications for aerial cable installations, where it supports the infrastructure necessary for reliable communication networks. The wire’s flexibility and tensile strength are essential for ensuring that cables can withstand environmental stresses while maintaining signal integrity. Businesses should prioritize sourcing wires that offer excellent performance under varying conditions, including temperature fluctuations and physical stress, to ensure long-term reliability of their telecommunications networks.

3 Common User Pain Points for ‘airplane wire’ & Their Solutions

Scenario 1: Sourcing High-Quality Airplane Wire for Diverse Applications

The Problem: Many B2B buyers struggle with sourcing high-quality airplane wire that meets both industry standards and specific application requirements. For instance, a buyer in Nigeria may need wire that can withstand high humidity and temperatures for marine applications, while a client in Brazil may require wire suitable for construction purposes. The challenge is compounded by the variability in quality among suppliers, which can lead to safety hazards, increased costs, and project delays.

The Solution: To address this issue, buyers should prioritize suppliers who provide comprehensive product specifications, including compliance with relevant federal and international standards such as ASTM A1023. Conducting thorough research on suppliers is essential—look for customer reviews, certifications, and case studies that demonstrate their capability to meet specific needs. Additionally, consider establishing relationships with manufacturers who can offer customization options, such as corrosion-resistant coatings or specialized wire configurations. By directly communicating the specific environmental conditions and load requirements, buyers can ensure they receive the right type of airplane wire tailored to their applications.

Illustrative image related to airplane wire

Scenario 2: Ensuring the Right Specifications for Airplane Wire

The Problem: Another common pain point arises when buyers fail to specify the correct type of airplane wire for their projects. This can lead to using inappropriate wire, resulting in structural failures or safety issues. For example, a company in the Middle East might need stainless steel wire for a project exposed to saline environments, but they mistakenly order galvanized wire, which is not suitable for such conditions.

The Solution: To mitigate this risk, buyers should develop a clear understanding of the properties and specifications of different types of airplane wire, such as 7×19 galvanized versus stainless steel options. It is beneficial to create a checklist that includes factors like tensile strength, corrosion resistance, and application environment. Consulting with industry experts or engineers during the specification phase can also provide valuable insights. Furthermore, leveraging tools such as load calculators can help buyers accurately determine the required wire strength and diameter based on their specific project needs. This proactive approach will enhance project safety and efficiency.

Scenario 3: Managing Inventory and Reducing Costs with Airplane Wire

The Problem: Many businesses face the challenge of managing their inventory of airplane wire effectively, leading to overstocking or stockouts. This is especially true for companies operating in regions with fluctuating demand, such as South America, where seasonal projects can cause drastic changes in wire requirements. Overstocking ties up capital, while stockouts can lead to project delays and lost revenue.

The Solution: Implementing an inventory management system tailored to the unique demands of airplane wire can significantly alleviate this issue. Buyers should analyze historical usage patterns to forecast future needs accurately, allowing for just-in-time ordering. Collaborating with suppliers to establish a reliable supply chain that includes flexible ordering options can also help maintain optimal inventory levels. Additionally, consider negotiating bulk purchasing agreements for long-term projects, which can yield cost savings and ensure availability when needed. By adopting these strategies, companies can streamline their operations, minimize waste, and ultimately reduce costs associated with airplane wire procurement.

Strategic Material Selection Guide for airplane wire

What are the Key Properties of Common Materials Used for Airplane Wire?

When selecting materials for airplane wire, several common options stand out based on their properties, performance, and suitability for various applications. The most frequently used materials include galvanized steel, stainless steel (Type 304 and Type 316), and aluminum. Each material has distinct characteristics that influence its performance in aviation applications.

Galvanized Steel: What are Its Key Properties and Applications?

Galvanized steel is a popular choice for airplane wire due to its excellent strength-to-weight ratio and cost-effectiveness. The galvanization process involves coating the steel with zinc to enhance its corrosion resistance, making it suitable for various environments. It typically performs well in moderate temperatures and can withstand significant mechanical stress.

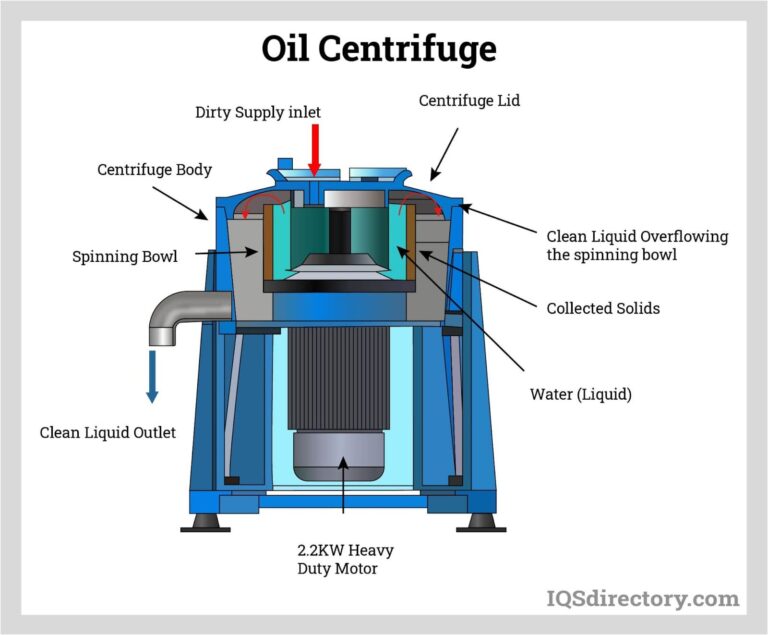

Illustrative image related to airplane wire

Pros: The primary advantages of galvanized steel include its affordability and high tensile strength, which makes it ideal for general-purpose applications. Additionally, its corrosion resistance is adequate for many environments, particularly where exposure to moisture is limited.

Cons: However, galvanized steel may not perform well in highly corrosive environments, such as marine applications or areas with high humidity. The zinc coating can wear off over time, leading to potential rusting of the underlying steel.

Impact on Application: Galvanized steel is commonly used in applications where cost is a primary concern, but it may require regular maintenance to ensure longevity.

Stainless Steel (Type 304): How Does It Compare?

Type 304 stainless steel is renowned for its excellent corrosion resistance and mechanical properties. It is suitable for a variety of applications, particularly those exposed to moisture or corrosive substances. This material can withstand temperatures up to 870°C (1600°F) and is often used in environments where hygiene is crucial.

Pros: The key advantage of Type 304 stainless steel is its durability and resistance to rust and corrosion. It is also relatively easy to fabricate and weld, making it a versatile choice for many applications.

Cons: The main drawback is its higher cost compared to galvanized steel. Additionally, while it offers good resistance to corrosion, it may not be sufficient in extremely harsh environments, such as those with high chloride exposure.

Impact on Application: Type 304 is suitable for applications requiring high strength and corrosion resistance, making it a preferred choice in the aerospace industry.

Stainless Steel (Type 316): What Makes It Unique?

Type 316 stainless steel is often referred to as marine-grade stainless steel due to its superior resistance to corrosion, particularly in chloride-rich environments. It contains molybdenum, which enhances its resistance to pitting and crevice corrosion.

Pros: The key advantage of Type 316 is its exceptional corrosion resistance, making it ideal for use in marine and high-moisture applications. It also maintains its strength at elevated temperatures.

Cons: The primary limitation is its cost, which is typically higher than both galvanized and Type 304 stainless steel. Additionally, while it is highly resistant to corrosion, it may not be as strong as galvanized steel under certain conditions.

Illustrative image related to airplane wire

Impact on Application: Type 316 is often selected for applications in coastal or marine environments, ensuring longevity and reliability in challenging conditions.

Aluminum: What are Its Benefits and Limitations?

Aluminum is another material used in airplane wire applications, particularly in lightweight constructions. It is known for its excellent strength-to-weight ratio and resistance to corrosion due to the formation of a protective oxide layer.

Pros: The main advantage of aluminum is its lightweight nature, which contributes to overall fuel efficiency in aviation. It is also resistant to corrosion and does not require additional coatings.

Cons: However, aluminum may not offer the same tensile strength as steel options, making it less suitable for high-stress applications. It is also more expensive than galvanized steel.

Impact on Application: Aluminum is often used in applications where weight reduction is critical, such as in aircraft components and structures.

Summary Table of Material Selection for Airplane Wire

| Material | Typical Use Case for Airplane Wire | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | General-purpose wire applications | Cost-effective and strong | Limited corrosion resistance | Low |

| Stainless Steel 304 | Aerospace components requiring hygiene | Excellent corrosion resistance | Higher cost than galvanized steel | Med |

| Stainless Steel 316 | Marine and high-moisture applications | Superior corrosion resistance | Higher cost and potentially lower strength | High |

| Aluminum | Lightweight structural applications | Lightweight and corrosion-resistant | Lower tensile strength than steel | Med |

This guide serves as a comprehensive overview for B2B buyers looking to make informed decisions regarding material selection for airplane wire, considering performance, cost, and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for airplane wire

What Are the Main Stages of Manufacturing Airplane Wire?

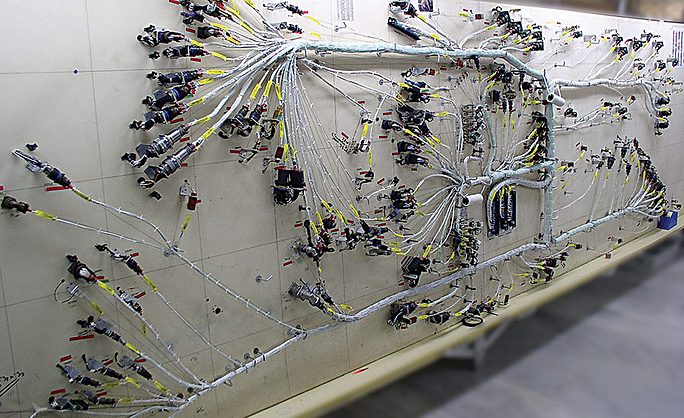

The manufacturing process for airplane wire involves several critical stages that ensure the final product meets stringent performance and safety standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Raw Material Processed for Airplane Wire?

The process begins with sourcing high-quality raw materials, typically high-strength steel for galvanized wires or stainless steel for corrosion-resistant applications. The materials undergo a thorough inspection to ensure they meet specifications. This often includes testing for tensile strength, ductility, and other mechanical properties. The raw materials are then cut into appropriate lengths and prepared for the next phase.

Illustrative image related to airplane wire

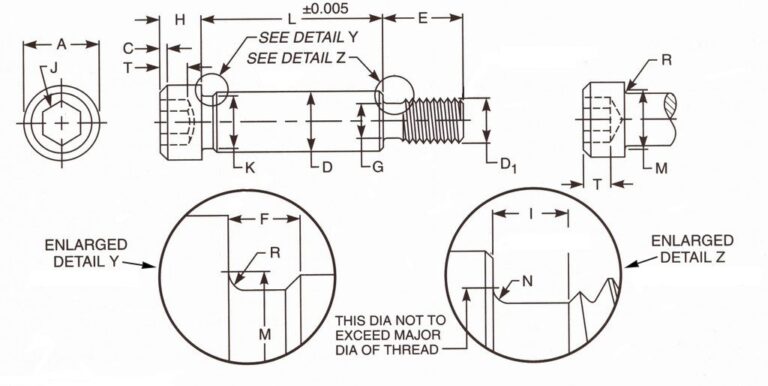

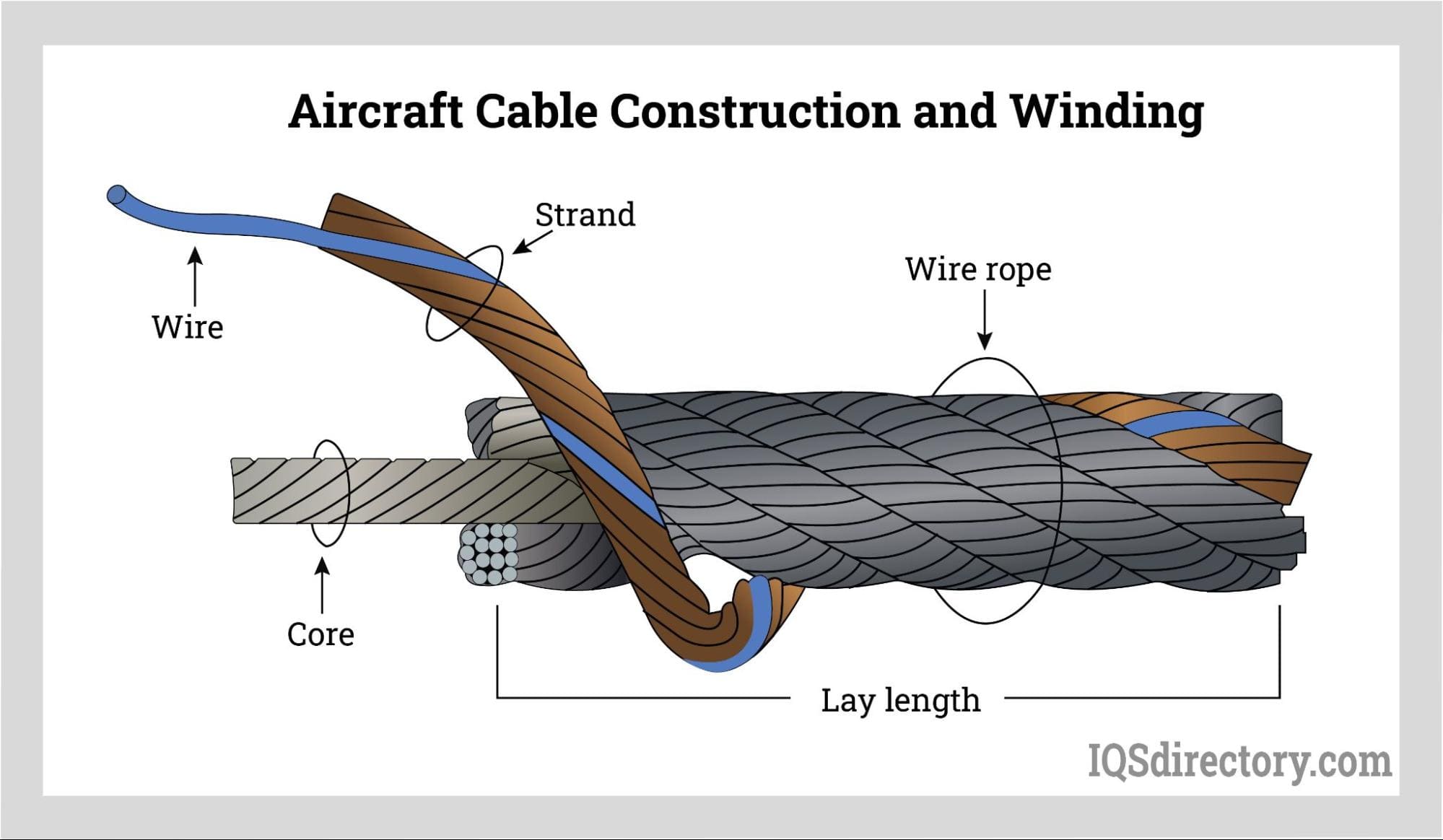

Forming: What Techniques Are Used to Shape Airplane Wire?

Forming involves several techniques, including drawing and twisting. In wire drawing, the raw material is pulled through a series of dies to reduce its diameter and increase its length. This process enhances tensile strength and flexibility. For airplane wire, a common configuration is the 7×19 construction, which consists of seven outer strands twisted around a central core. The twisting process is crucial as it provides the wire with the required flexibility and strength.

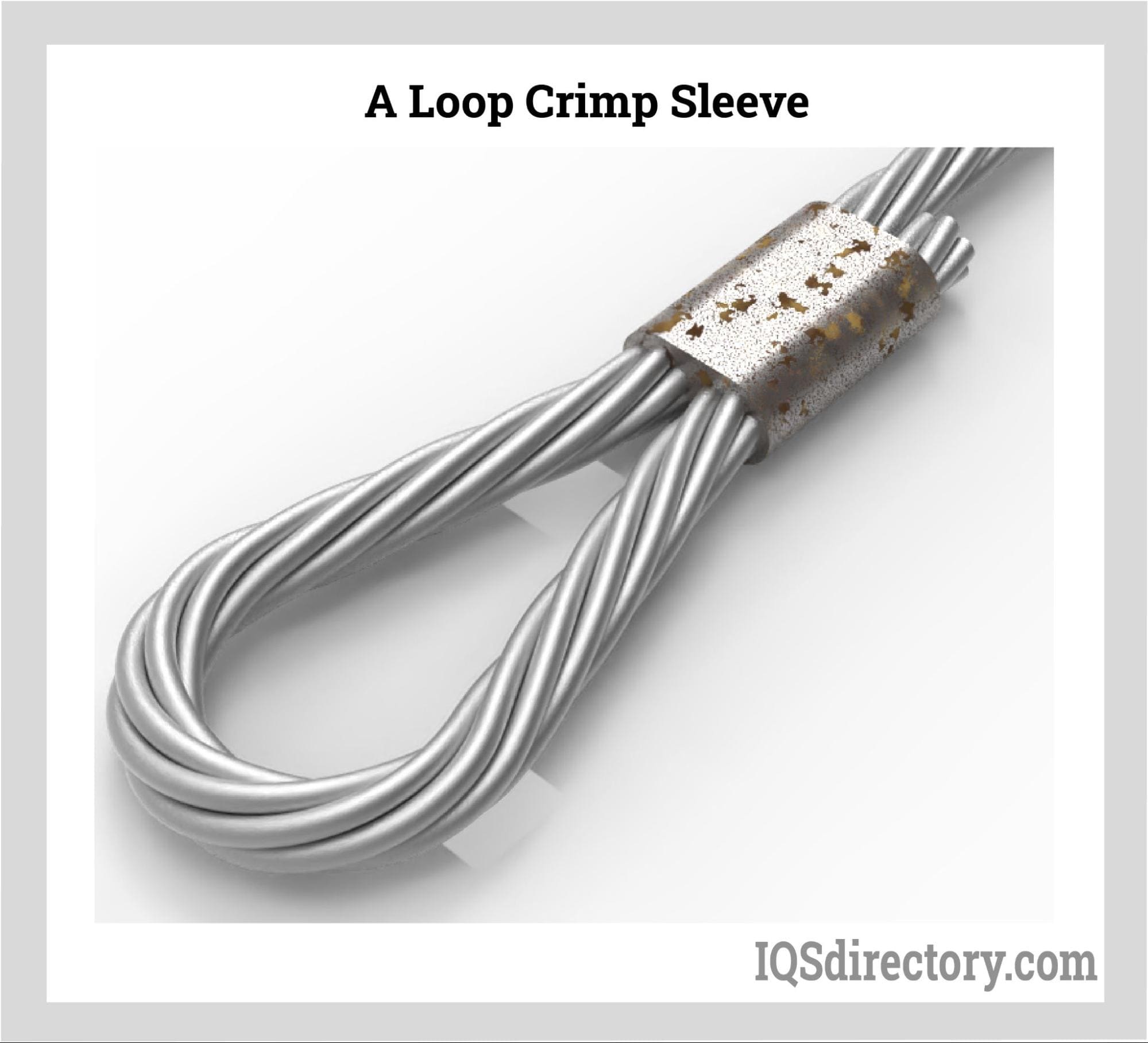

Assembly: How Are the Components of Airplane Wire Joined?

Once the wire is formed, it may require assembly with other components, such as fittings or connectors, depending on its intended application. This stage often utilizes swaging or crimping techniques to securely attach these components. Quality assurance is critical at this stage, as improper assembly can lead to failures during operation.

Finishing: What Final Treatments Are Applied to Airplane Wire?

The finishing stage includes surface treatments such as galvanization or coating. Galvanization, which involves applying a layer of zinc to prevent corrosion, is common for wire exposed to harsh environments. Alternatively, stainless steel options may be polished to enhance their corrosion resistance. For added protection, a vinyl coating can be applied, which helps seal in lubrication and protects against abrasion.

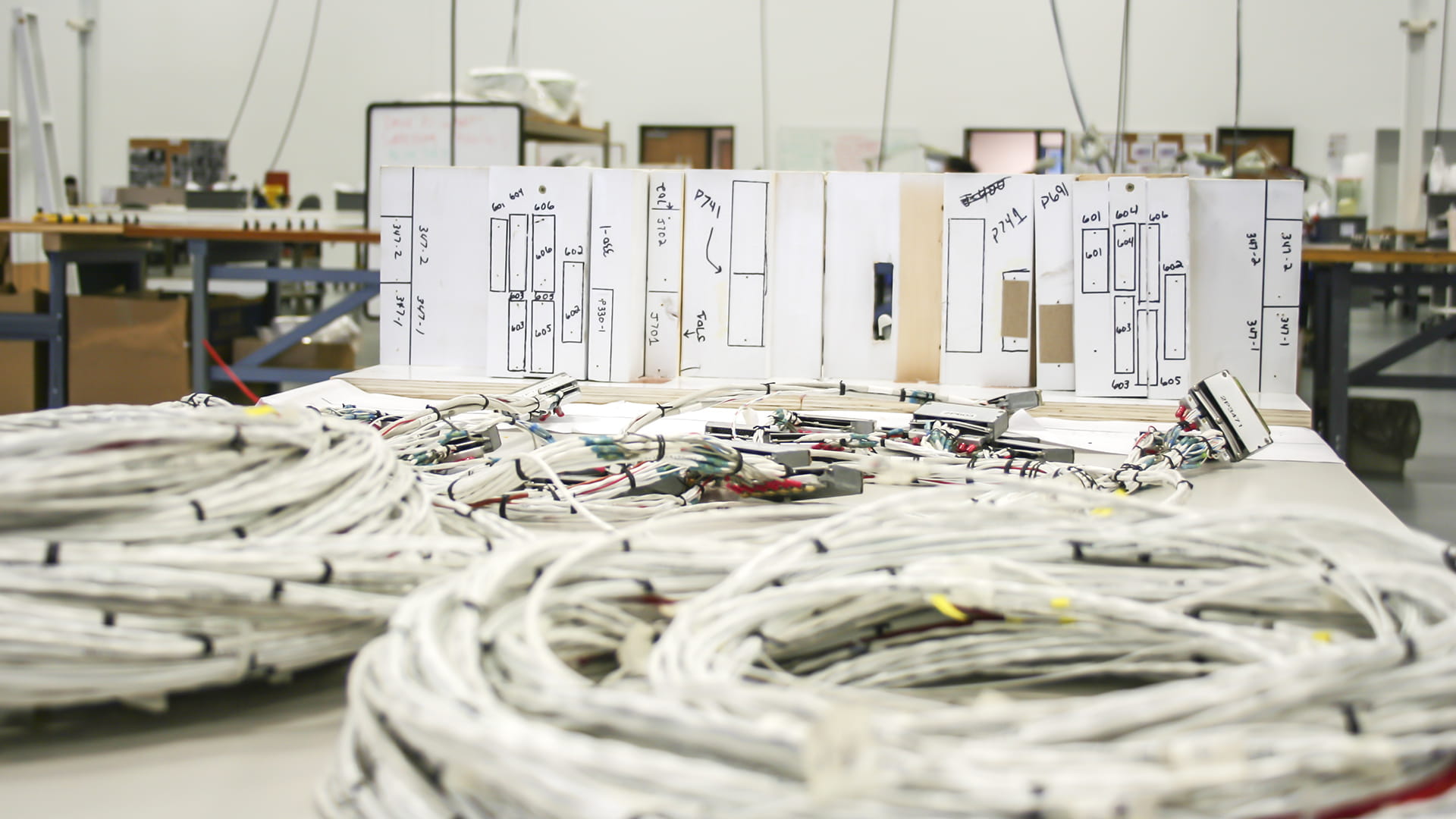

What Quality Assurance Practices Are Essential for Airplane Wire?

Quality assurance (QA) is paramount in the manufacturing of airplane wire, ensuring compliance with international standards and industry regulations. Buyers should be aware of the various QA practices that suppliers implement.

Illustrative image related to airplane wire

Which International Standards Apply to Airplane Wire Manufacturing?

Airplane wire manufacturers often adhere to international quality management standards, such as ISO 9001, which outlines requirements for an effective quality management system. Additionally, industry-specific certifications like CE marking and API standards may apply, depending on the wire’s intended use in aviation or other sectors. Compliance with these standards assures buyers that the products are manufactured with a focus on safety and reliability.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) involves several checkpoints throughout the manufacturing process, which can be categorized into Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): At this initial stage, raw materials are inspected for compliance with specifications before they enter the production line. Any materials that do not meet the required standards are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor critical parameters such as wire diameter, tensile strength, and assembly integrity. This ongoing assessment helps identify any deviations from quality standards early, allowing for corrective actions to be taken.

-

Final Quality Control (FQC): Once production is complete, the finished airplane wire undergoes a comprehensive inspection. This may include testing for electrical conductivity, tensile strength, and corrosion resistance. Certificates of compliance may be issued for products that pass these rigorous tests.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers looking to source airplane wire should take proactive steps to verify the quality control measures of their suppliers. This can be achieved through several methods:

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. Buyers should request access to the supplier’s quality management system documentation, including their ISO certifications, process flows, and records of past audits. On-site audits can also provide valuable insights into the manufacturing environment and adherence to quality standards.

Illustrative image related to airplane wire

Are There Reliable Reports and Certifications That Buyers Can Request?

Buyers should ask for detailed quality assurance reports and certificates from the supplier. These documents should outline the testing methodologies used, results of previous inspections, and any third-party certifications that validate the manufacturer’s compliance with international standards.

How Important Are Third-Party Inspections in the QC Process?

Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These inspections can take place at various stages of the manufacturing process and provide an additional layer of assurance for buyers, particularly those operating in international markets where regulations may vary.

What QC and Certification Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification processes.

Illustrative image related to airplane wire

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying standards for quality assurance and certification. Buyers should familiarize themselves with local regulations and expectations in their target markets. This knowledge ensures that the sourced airplane wire complies with both international and regional standards, facilitating smoother market entry.

What Role Does Cultural Understanding Play in Supplier Relationships?

Cultural understanding is essential when negotiating with suppliers from different regions. Buyers should be aware of communication styles, negotiation tactics, and business practices that may differ across cultures. Building strong relationships with suppliers can enhance collaboration and improve the overall quality assurance process.

In conclusion, understanding the manufacturing processes and quality assurance practices for airplane wire is crucial for B2B buyers. By focusing on these elements, buyers can make informed decisions, ensuring they source high-quality products that meet international safety standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘airplane wire’

When sourcing airplane wire, particularly for international B2B transactions, it’s essential to follow a structured approach. This guide provides a comprehensive checklist to assist buyers in making informed decisions, ensuring product quality and supplier reliability.

Step 1: Define Your Technical Specifications

Understanding the technical requirements of the airplane wire is fundamental. This includes determining the type (e.g., galvanized or stainless steel), diameter, length, and break strength needed for your specific application. Clearly defined specifications help you communicate effectively with suppliers and avoid costly errors.

Illustrative image related to airplane wire

- Break Strength: Know the load requirements to ensure safety and compliance.

- Material Type: Choose between galvanized for cost-effectiveness or stainless steel for corrosion resistance, especially in harsh environments.

Step 2: Research Regulatory Standards

Compliance with international and local regulations is critical when sourcing airplane wire. Investigate the standards applicable to your industry, such as ASTM or ISO certifications. Ensuring that your supplier adheres to these standards mitigates risks associated with product failure.

- Certifications: Request documentation that proves compliance with relevant safety and quality standards.

- Regional Requirements: Different regions may have specific regulations; be aware of these to avoid legal complications.

Step 3: Evaluate Potential Suppliers

Before finalizing a supplier, conduct a thorough evaluation. Look for established companies with a proven track record in providing high-quality airplane wire. This includes checking their reputation, financial stability, and production capabilities.

- References and Reviews: Seek testimonials from previous clients, particularly those in similar industries or regions.

- Production Capacity: Ensure the supplier can meet your volume requirements consistently.

Step 4: Request Samples for Testing

Always request samples of the airplane wire before placing a large order. This allows you to assess the quality firsthand and determine if it meets your specifications. Testing the samples under actual conditions can provide insights into performance and durability.

- Quality Assurance: Conduct tests to verify strength, flexibility, and corrosion resistance.

- Comparison: Compare samples from multiple suppliers to identify the best option.

Step 5: Negotiate Terms and Conditions

Once you’ve selected a supplier, it’s essential to negotiate favorable terms. Discuss pricing, payment terms, lead times, and return policies. Clear agreements help prevent misunderstandings and ensure a smooth transaction process.

Illustrative image related to airplane wire

- Payment Terms: Consider options such as letters of credit to secure your investment.

- Delivery Schedule: Ensure the supplier can meet your timeline to avoid project delays.

Step 6: Verify Supplier Certifications

Before finalizing your order, verify that the supplier holds the necessary certifications for quality and safety. This step is crucial, especially for international transactions, where standards may vary significantly.

- Quality Management Systems: Look for ISO 9001 certification as a hallmark of quality management.

- Material Certifications: Ensure the wire meets specific material certifications relevant to aviation.

Step 7: Establish a Communication Plan

Finally, set up a communication plan with your supplier. Regular updates on production status, shipment tracking, and quality checks can help build a strong partnership and facilitate problem-solving if issues arise.

- Point of Contact: Designate a contact person for efficient communication.

- Regular Updates: Schedule periodic check-ins to discuss progress and address any concerns.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing airplane wire, ensuring they select the right product and supplier for their needs.

Comprehensive Cost and Pricing Analysis for airplane wire Sourcing

What Are the Key Cost Components in Airplane Wire Sourcing?

When sourcing airplane wire, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Illustrative image related to airplane wire

-

Materials: The choice of wire material (e.g., galvanized steel, stainless steel) significantly affects cost. Stainless steel typically commands a higher price due to its superior corrosion resistance, making it ideal for marine or high-moisture environments.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Skilled labor may be required for specialized wire production, influencing overall costs.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative costs associated with production. Efficient manufacturing processes can help mitigate these expenses.

-

Tooling: Custom tooling for specific wire specifications can incur additional costs. Buyers should consider whether they need standardized products or custom solutions, as this can impact pricing.

-

Quality Control (QC): Ensuring that products meet industry standards (e.g., ASTM A1023) requires investment in QC processes. Suppliers with robust QC measures may charge higher prices, but the assurance of product reliability can justify the cost.

-

Logistics: Transportation and handling can add significant costs, especially for international shipments. Understanding Incoterms can help buyers manage logistics expenses effectively.

-

Margin: Supplier profit margins can vary widely. Established suppliers may have higher margins due to brand reputation and reliability, while newer entrants might offer lower prices to gain market share.

How Do Price Influencers Impact Airplane Wire Costs?

Several factors influence the pricing of airplane wire, and understanding these can lead to better sourcing decisions.

-

Volume/MOQ (Minimum Order Quantity): Ordering in bulk often results in lower per-unit prices. Buyers should negotiate for volume discounts, especially if they anticipate ongoing needs.

-

Specifications and Customization: Custom specifications can lead to higher costs. When possible, opting for standard products can help reduce expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications add to the cost but may be necessary for specific applications. Buyers should weigh the benefits of premium materials against their budget constraints.

-

Supplier Factors: Supplier reliability, lead times, and production capacity can affect pricing. Building a relationship with suppliers can lead to better terms and pricing.

-

Incoterms: Understanding the terms of shipping and delivery can significantly impact total costs. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers anticipate additional charges.

What Buyer Tips Can Help Secure Cost-Efficient Airplane Wire?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies for cost-efficient sourcing.

-

Negotiation: Leverage volume commitments or long-term contracts to negotiate better prices. Suppliers are often willing to offer discounts for assured business.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with airplane wire, including maintenance, durability, and replacement costs. Sometimes a higher upfront cost can lead to savings over time.

-

Understand Pricing Nuances: Be aware that prices can fluctuate based on market demand, raw material costs, and geopolitical factors. Staying informed about industry trends can provide leverage in negotiations.

-

Local Sourcing Considerations: For buyers in developing regions, consider sourcing from local suppliers to reduce logistics costs and support local economies. This can also lead to quicker delivery times.

-

Request Multiple Quotes: Obtaining quotes from various suppliers allows for price comparisons and helps identify competitive pricing. It also provides insight into the market landscape.

Disclaimer on Indicative Prices

Prices for airplane wire can vary significantly based on the factors mentioned above. The prices presented in this analysis are indicative and should be verified with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing airplane wire With Other Solutions

Exploring Alternatives to Airplane Wire: What Are Your Options?

When considering wire solutions for aviation or other industrial applications, it’s essential to evaluate various alternatives to airplane wire. Each option presents distinct advantages and disadvantages, influencing performance, cost, and suitability for specific tasks. Below, we compare airplane wire against two viable alternatives: synthetic rope and traditional steel wire rope.

| Comparison Aspect | Airplane Wire | Synthetic Rope | Steel Wire Rope |

|---|---|---|---|

| Performance | High strength; corrosion-resistant options (stainless steel, galvanized) | Lightweight; excellent flexibility but lower tensile strength | Very high tensile strength; durable but heavier |

| Cost | Moderate; varies by material (galvanized vs. stainless) | Lower initial cost; potential for higher long-term costs due to wear | Generally higher upfront costs due to material and manufacturing |

| Ease of Implementation | Requires specific fittings and installation expertise | Easy to handle and install; less specialized equipment needed | Can require specialized tools for installation |

| Maintenance | Low maintenance; resistant to corrosion | Requires regular inspection for wear and UV damage | Requires periodic lubrication and inspection to prevent rust |

| Best Use Case | Applications requiring high strength and corrosion resistance | Non-load bearing applications, marine use, or temporary setups | Heavy-duty applications like lifting or towing |

What Are the Pros and Cons of Synthetic Rope as an Alternative to Airplane Wire?

Synthetic rope, often made from materials like nylon or polyester, is an increasingly popular alternative to airplane wire. Its lightweight nature makes it easy to handle and transport, which can reduce labor costs during installation. Additionally, synthetic ropes are resistant to UV rays and water, making them suitable for marine applications. However, their lower tensile strength compared to airplane wire can be a significant drawback in high-load situations. Regular inspections are necessary to monitor wear, which could lead to higher long-term costs.

How Does Traditional Steel Wire Rope Compare to Airplane Wire?

Traditional steel wire rope is renowned for its exceptional strength and durability, making it an ideal choice for heavy-duty applications such as lifting and towing. It offers high resistance to abrasion and impact, ensuring longevity in harsh environments. However, its weight can be a disadvantage when considering transport and installation. Maintenance is also crucial, as steel wire rope requires regular lubrication to prevent rust and corrosion. Moreover, the installation process can be more complex, requiring specialized tools and skills.

Conclusion: Which Solution Should B2B Buyers Choose?

When selecting the right wire solution, B2B buyers must consider their specific needs, including application, budget, and maintenance capabilities. Airplane wire is an excellent choice for high-strength, corrosion-resistant applications, particularly in aviation and industrial settings. For lighter, non-load bearing applications, synthetic rope may provide a cost-effective and easy-to-install alternative. Traditional steel wire rope, while more expensive and heavier, excels in heavy-duty contexts. Ultimately, the decision should align with the operational requirements and long-term strategy of the buyer’s business.

Illustrative image related to airplane wire

Essential Technical Properties and Trade Terminology for airplane wire

What Are the Key Technical Properties of Airplane Wire?

Understanding the essential technical properties of airplane wire is crucial for B2B buyers to ensure they select the right product for their specific applications. Here are some critical specifications:

1. Material Grade

Airplane wire is primarily made from high-strength steel, with common grades including 304 and 316 stainless steel, as well as galvanized options. The choice of material impacts the wire’s corrosion resistance, strength, and overall durability. For instance, while 304 stainless steel offers good corrosion resistance, 316 stainless steel contains molybdenum for enhanced rust protection, making it suitable for marine or high-moisture environments.

2. Construction Type

The construction of airplane wire often follows the 7×19 strand configuration, which means it consists of seven outer strands twisted around a central core. This design provides flexibility and strength, making it ideal for applications like rigging and winching. Understanding construction types is vital for buyers to ensure the wire meets the demands of their specific use cases.

3. Break Strength

Break strength is a critical property that indicates the maximum load the wire can withstand before failure. It varies by diameter and material; for example, a 3/8″ galvanized aircraft cable has a break strength of approximately 14,400 lbs. This specification is essential for B2B buyers, as it directly influences safety and performance in applications involving lifting or load-bearing.

Illustrative image related to airplane wire

4. Diameter and Tolerance

The diameter of airplane wire typically ranges from 3/32″ to 3/8″. Tolerance refers to the permissible limits of variation in the wire’s diameter. It is crucial for ensuring compatibility with fittings and hardware, which can affect the overall safety and effectiveness of the application. Buyers must be aware of these measurements to avoid mismatches that could lead to operational failures.

5. Coating Options

Airplane wire can come with various coatings, such as vinyl or galvanized finishes. Vinyl coatings provide additional protection against dirt and moisture, enhancing the wire’s lifespan. Galvanized wire, on the other hand, is treated for corrosion resistance, making it suitable for outdoor applications. Choosing the right coating can be critical for the wire’s performance and durability in specific environments.

What Are Common Trade Terms Related to Airplane Wire?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some commonly used trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For airplane wire buyers, understanding whether a supplier is an OEM can ensure they are sourcing high-quality, reliable products that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it can affect inventory levels and purchasing strategies. Understanding MOQs helps in planning procurement and managing costs effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on the supply of specific goods or services. For buyers, issuing an RFQ is a strategic way to gather pricing information and terms from multiple vendors, allowing for informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in the delivery of goods. Familiarity with these terms can help B2B buyers understand shipping costs, risks, and insurance responsibilities, which are critical for international transactions.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. Knowing lead times is essential for B2B buyers to manage their supply chains and ensure timely delivery for projects or operational needs.

Illustrative image related to airplane wire

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational needs and business objectives.

Navigating Market Dynamics and Sourcing Trends in the airplane wire Sector

What Are the Key Drivers Shaping the Airplane Wire Market?

The airplane wire market is experiencing significant growth, driven by several global factors. The increasing demand for air travel, particularly in emerging markets like Nigeria and Brazil, is propelling the aviation sector forward, thus enhancing the need for high-quality airplane wire products. In addition, advancements in technology, such as the integration of smart materials and lightweight solutions, are reshaping product offerings and influencing sourcing strategies. International B2B buyers are now more inclined toward suppliers that provide innovative solutions, including customized wire products that meet specific aerospace standards.

Sourcing trends are also evolving, with a notable shift towards digital platforms that facilitate easier procurement processes. Technologies such as artificial intelligence and blockchain are being adopted to streamline supply chain management, improve traceability, and enhance transparency. For businesses in Africa and South America, leveraging these technologies can lead to more efficient sourcing and inventory management, thereby reducing costs and improving service delivery. Furthermore, as regulatory frameworks tighten globally, compliance with safety and quality standards has become paramount, pushing suppliers to adhere to stringent specifications.

How Is Sustainability Influencing Sourcing Decisions in the Airplane Wire Sector?

Sustainability is becoming an integral component of sourcing strategies for airplane wire. As environmental concerns gain prominence, businesses are increasingly focusing on minimizing their ecological footprint. This includes opting for materials that are either recyclable or sourced from sustainable practices. For instance, airplane wires made from stainless steel or galvanized materials are favored for their durability and corrosion resistance, which extend the product lifecycle and reduce waste.

Ethical sourcing is also crucial for building brand reputation, especially in regions where consumers are becoming more environmentally conscious. Buyers are now looking for suppliers who can demonstrate a commitment to ethical supply chains, which includes fair labor practices and environmentally friendly manufacturing processes. Certifications such as ISO 14001 for environmental management and other green certifications can significantly influence sourcing decisions. By prioritizing suppliers with these credentials, B2B buyers can ensure that their procurement practices align with global sustainability goals.

Illustrative image related to airplane wire

How Has the Airplane Wire Industry Evolved Over Time?

The evolution of the airplane wire industry can be traced back to the early days of aviation, where the need for lightweight yet strong materials was paramount. Initially, traditional metals dominated the market; however, advancements in metallurgy and technology have led to the development of specialized wires that cater specifically to the aviation sector’s demanding requirements.

Over the years, the introduction of innovative materials like aluminum alloys and high-strength steel has revolutionized the design and functionality of airplane wires. The focus has shifted towards enhancing performance while also addressing safety concerns, leading to rigorous testing and adherence to international standards. As the industry continues to evolve, B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with current and future market dynamics.

Frequently Asked Questions (FAQs) for B2B Buyers of airplane wire

-

How do I choose the right airplane wire for my specific application?

When selecting airplane wire, consider factors such as the type of environment, load requirements, and regulatory standards. Evaluate whether you need galvanized or stainless steel options; galvanized wire is cost-effective but less corrosion-resistant than stainless steel. Additionally, assess the wire’s diameter and break strength to ensure it meets your operational demands. Consulting with suppliers for recommendations based on your specific use case can also provide valuable insights. -

What is the best type of airplane wire for marine environments?

For marine applications, Type 316 stainless steel airplane wire is ideal due to its superior corrosion resistance, which is enhanced by the presence of molybdenum. This type of wire offers excellent durability in high-moisture conditions, making it suitable for marine rigging and other applications where exposure to saltwater is a concern. While it may be slightly weaker than Type 304 stainless steel, its longevity in challenging environments justifies the choice. -

What are the minimum order quantities (MOQs) for airplane wire?

Minimum order quantities for airplane wire can vary significantly by supplier and product type. Typically, MOQs can range from as low as 100 feet to several thousand feet, depending on the material and customization options. It’s essential to communicate with potential suppliers to understand their policies and negotiate terms that align with your purchasing needs, especially if you require smaller quantities for specific projects. -

How can I vet suppliers for airplane wire in international trade?

To effectively vet suppliers, start by researching their reputation through customer reviews and industry certifications. Request references from previous clients and confirm their compliance with international standards, such as ASTM or ISO. Additionally, consider visiting their facilities if possible, or conducting virtual audits to assess their production capabilities and quality control processes. Engaging with suppliers who have a proven track record in your target market can minimize risks. -

What payment terms are common when purchasing airplane wire internationally?

Payment terms for international transactions typically include options such as letter of credit, advance payment, or payment upon delivery. The choice often depends on the relationship with the supplier and the level of trust established. Many suppliers may offer favorable terms for repeat customers, so it’s advisable to negotiate terms that protect your investment while ensuring timely payment for the supplier. -

How is the quality of airplane wire ensured during manufacturing?

Quality assurance in airplane wire manufacturing involves several key processes, including material selection, adherence to industry standards, and rigorous testing. Suppliers should provide certifications that demonstrate compliance with relevant regulations, such as RR-W-410 or ASTM A1023. Additionally, ask about their testing methods, including tensile strength tests and corrosion resistance evaluations, to ensure that the wire meets your operational requirements. -

What logistics considerations should I keep in mind when importing airplane wire?

When importing airplane wire, consider factors such as shipping costs, customs regulations, and delivery timelines. Ensure that your supplier can provide accurate shipping documentation to facilitate smooth customs clearance. It’s also essential to assess the mode of transport that best suits your timeline and budget, whether by air or sea freight. Collaborating with a logistics partner experienced in international shipping can help streamline the process. -

Can I customize the specifications of airplane wire for my project?

Yes, many suppliers offer customization options for airplane wire, including variations in diameter, length, coating, and material type. Customization allows you to tailor the wire to specific application requirements, enhancing performance and safety. When discussing your project with suppliers, provide detailed specifications and inquire about the lead times and costs associated with custom orders to ensure they align with your project timeline.

Top 1 Airplane Wire Manufacturers & Suppliers List

1. US Cargo Control – Aircraft Cable Options

Domain: uscargocontrol.com

Registered: 2005 (20 years)

Introduction: Aircraft Cable options include: 7×19 Galvanized Aircraft Cable, 7×19 304 Stainless Steel Aircraft Cable, 7×19 316 Stainless Steel Aircraft Cable, 7×19 Galvanized Aircraft Cable – Vinyl-Coated, 7×19 304 Stainless Steel Aircraft Cable – Vinyl-Coated. Break Strengths range from 920 lbs to 14400 lbs across various products.

Strategic Sourcing Conclusion and Outlook for airplane wire

In the ever-evolving aerospace industry, strategic sourcing of airplane wire remains paramount for international B2B buyers. Key takeaways emphasize the importance of selecting the right materials, such as galvanized and stainless steel aircraft cables, which cater to specific environmental conditions and applications. Understanding the differences in break strength and corrosion resistance is crucial for ensuring safety and longevity in operations.

Moreover, leveraging suppliers that offer custom solutions and quick shipping can significantly enhance operational efficiency and reduce lead times. This is especially vital for buyers in Africa, South America, the Middle East, and Europe, where access to reliable resources can impact project timelines and costs.

Looking ahead, the demand for high-quality airplane wire will only increase as global aviation expands. B2B buyers are encouraged to foster partnerships with reputable suppliers who prioritize quality and compliance with industry standards. By doing so, they can position themselves advantageously in the competitive market, ensuring the reliability and safety of their aerospace operations. Engage with leading manufacturers and distributors today to secure the best materials for your future projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to airplane wire

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.