How to Source Airless Spray Guns Sale In Ca.Made In China $20 Effectively: A 2025…

Introduction: Navigating the Global Market for airless spray guns sale in ca.made in china $20

In the competitive landscape of global manufacturing, sourcing reliable airless spray guns—especially those priced at $20 and made in China—poses unique challenges for international B2B buyers. The need for efficient, high-quality spraying equipment is paramount, particularly for industries ranging from construction to automotive refinishing. This guide aims to navigate the complexities of sourcing airless spray guns, providing insights into various types, applications, and essential supplier vetting processes.

International buyers from regions such as Africa, South America, the Middle East, and Europe (including Brazil and Vietnam) will benefit from a comprehensive understanding of cost structures, quality assurance, and market trends. By exploring the features and specifications of different airless spray gun models, this guide empowers decision-makers to make informed purchasing choices that align with their operational needs.

Additionally, we will delve into practical considerations, such as the importance of after-sales support and spare parts availability, which can significantly influence the total cost of ownership. Whether you are a small business owner or a procurement manager, this guide will equip you with the knowledge necessary to navigate the global market effectively and secure the best value for your investment in airless spray guns.

Understanding airless spray guns sale in ca.made in china $20 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| LVLP Spray Guns | Low air consumption, fine atomization, versatile. | Furniture, cabinetry, automotive. | Pros: Efficient, cost-effective; Cons: May require more skill for optimal results. |

| HVLP Spray Guns | High volume, low pressure; ideal for thin materials. | Fine finishing, detailed work. | Pros: Excellent finish quality; Cons: Less efficient for thicker materials. |

| Airless Spray Guns | High pressure, no air needed; ideal for thicker paints. | Large surfaces, industrial coatings. | Pros: Fast application, great for heavy materials; Cons: Can overspray and require cleanup. |

| Electric Spray Guns | Electric-powered, user-friendly, portable. | DIY projects, small businesses. | Pros: Easy to use, portable; Cons: Limited power for heavy-duty applications. |

| Pneumatic Spray Guns | Compressed air operation, customizable. | Automotive, industrial applications. | Pros: Versatile, high-quality finishes; Cons: Requires compressor, more maintenance. |

What are the Characteristics of LVLP Spray Guns?

LVLP (Low Volume Low Pressure) spray guns operate efficiently with lower air consumption, making them suitable for a variety of finishes, including water-based and solvent-based products. Their ability to produce fine atomization allows for a smooth finish, ideal for furniture and cabinetry applications. B2B buyers should consider the compatibility of LVLP guns with their existing compressor systems, as they work best with lower SCFM ratings. These guns are generally more affordable, making them a popular choice for small to medium-sized businesses.

How Do HVLP Spray Guns Differ in Functionality?

HVLP (High Volume Low Pressure) spray guns are designed to deliver a high volume of paint at low pressure, making them perfect for detailed work and fine finishes. They minimize overspray, which is beneficial for intricate projects in industries like woodworking and automotive refinishing. B2B purchasers should evaluate the types of materials they plan to use, as HVLP guns excel with thinner materials but may struggle with thicker paints. While they provide excellent finish quality, they may not be the most efficient option for larger applications.

What Advantages Do Airless Spray Guns Offer?

Airless spray guns utilize high pressure to atomize paint without the need for compressed air, making them ideal for large-scale applications such as industrial coatings and exterior painting. Their ability to spray thicker materials quickly and efficiently is a significant advantage for businesses that require high productivity. However, B2B buyers must be aware of potential overspray and the need for thorough cleanup after use. These guns are generally more expensive but can offer long-term savings through increased efficiency.

Why Choose Electric Spray Guns for Smaller Projects?

Electric spray guns are user-friendly and portable, making them an excellent option for DIY projects and small businesses. They are typically less expensive and require minimal setup compared to pneumatic options. For B2B buyers, the ease of use and lower initial investment can be appealing, especially for those not engaged in heavy-duty applications. However, they may lack the power needed for larger jobs, which could limit their effectiveness in commercial settings.

What are the Benefits of Pneumatic Spray Guns?

Pneumatic spray guns operate using compressed air, allowing for high-quality finishes and customization options. They are versatile and suitable for various applications, from automotive refinishing to industrial tasks. B2B buyers should consider the need for an air compressor and the associated maintenance costs. While pneumatic guns can deliver excellent results, their complexity and operational requirements may not be ideal for every business, especially those with budget constraints.

Key Industrial Applications of airless spray guns sale in ca.made in china $20

| Industry/Sector | Specific Application of airless spray guns sale in ca.made in china $20 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Exterior and interior painting of buildings and structures | Provides a uniform finish, reducing labor costs | Ensure compatibility with local paints and coatings |

| Automotive Repair | Application of primers and paints on vehicles | Achieves high-quality finishes with minimal overspray | Check for durability and resistance to solvents and chemicals |

| Woodworking | Finishing wood products such as furniture and cabinetry | Enhances product appearance and durability | Verify nozzle sizes suitable for different types of finishes |

| Agriculture | Spraying pesticides and herbicides on crops | Increases efficiency and coverage of application | Confirm compliance with agricultural regulations in target markets |

| Manufacturing | Coating metal components and machinery | Improves corrosion resistance and extends lifespan | Assess the gun’s compatibility with various industrial coatings |

How Are Airless Spray Guns Used in Construction and Renovation?

In the construction and renovation sector, airless spray guns are primarily used for painting both the exteriors and interiors of buildings. These guns deliver a fine mist of paint that adheres well to surfaces, ensuring a uniform finish that enhances aesthetic appeal. For international B2B buyers, particularly in regions like Africa and South America, sourcing these guns requires attention to compatibility with local paint formulations and environmental conditions. Additionally, understanding the gun’s efficiency can help reduce labor costs and project timelines.

What Role Do Airless Spray Guns Play in Automotive Repair?

In automotive repair, airless spray guns are essential for applying primers and topcoats to vehicles. The ability to achieve high-quality finishes with minimal overspray is critical in this industry, as it reduces waste and improves the overall quality of the repair work. Buyers from the Middle East and Europe should consider the durability of the spray guns and their resistance to solvents when selecting equipment, ensuring they can withstand the rigors of automotive applications.

How Are Airless Spray Guns Beneficial in Woodworking?

In woodworking, airless spray guns are utilized for finishing products such as furniture and cabinetry. These guns provide a smooth application of stains and sealants, enhancing the appearance and longevity of wooden items. For international B2B buyers, it’s important to verify the availability of various nozzle sizes to accommodate different types of finishes. This flexibility allows woodworkers to achieve the desired finish while minimizing material waste.

How Are Airless Spray Guns Applied in Agriculture?

Agriculture benefits from airless spray guns for the efficient application of pesticides and herbicides. These guns enable farmers to cover large areas quickly and evenly, improving the effectiveness of crop protection measures. Buyers in agricultural sectors should ensure that the spray guns comply with local regulations regarding chemical application, particularly in regions with strict environmental laws. This compliance not only ensures safety but also enhances the credibility of the business.

What Are the Manufacturing Applications of Airless Spray Guns?

In manufacturing, airless spray guns are used for coating metal components and machinery, providing a protective layer that improves corrosion resistance. This application is vital for extending the lifespan of equipment and ensuring quality control in production. For B2B buyers, assessing the compatibility of the spray gun with various industrial coatings is crucial, as it impacts the overall efficiency and effectiveness of the manufacturing process.

3 Common User Pain Points for ‘airless spray guns sale in ca.made in china $20’ & Their Solutions

Scenario 1: Navigating Quality Concerns with Low-Cost Airless Spray Guns

The Problem: One of the primary challenges for B2B buyers, particularly in regions like Africa and South America, is the skepticism surrounding the quality of airless spray guns priced at $20, especially those manufactured in China. Buyers often fear that these budget options will lead to poor performance, inconsistent finishes, and ultimately, dissatisfied customers. The concern extends to the longevity of the equipment, as low-cost tools may not withstand the rigors of daily professional use, leading to frequent replacements and increased operational costs.

The Solution: To address quality concerns, buyers should prioritize sourcing from reputable suppliers who offer transparency regarding manufacturing processes and quality control standards. Investigate certifications or industry standards that the product meets. Additionally, look for reviews or case studies from other businesses that have successfully used these spray guns in similar environments. It’s advisable to order samples before making bulk purchases, allowing for practical testing on various surfaces and finishes. Furthermore, investing in maintenance kits and understanding the proper care for these guns can significantly extend their lifespan, ensuring that the initial investment remains viable over time.

Scenario 2: Understanding Compatibility with Various Coatings

The Problem: Another common pain point arises from the compatibility of airless spray guns with different types of coatings, such as water-based finishes, solvent-based paints, and latex. Buyers may find that a gun that works well with one type of finish fails to perform with another, leading to issues such as clogging, uneven application, or excessive overspray. This can be particularly frustrating for businesses that require versatility in their spraying equipment to accommodate diverse projects.

The Solution: To mitigate these compatibility issues, buyers should conduct thorough research on the specifications of the airless spray guns. It’s crucial to verify the recommended viscosity levels for various coatings and ensure that the selected gun can handle the materials intended for use. Creating a testing protocol that includes trial runs with different finishes can help identify the optimal settings and nozzle sizes for each application. Additionally, suppliers should be consulted for guidance on which products work best with their spray guns, as they can often provide valuable insights based on customer feedback and product performance data.

Scenario 3: Dealing with Limited Technical Support and Guidance

The Problem: B2B buyers often face limited technical support when purchasing low-cost airless spray guns, particularly from international sources. This lack of assistance can lead to improper usage, resulting in suboptimal performance and potential damage to both the spray gun and the surfaces being painted. Furthermore, without adequate training or resources, buyers may struggle to maximize the efficiency and effectiveness of their equipment.

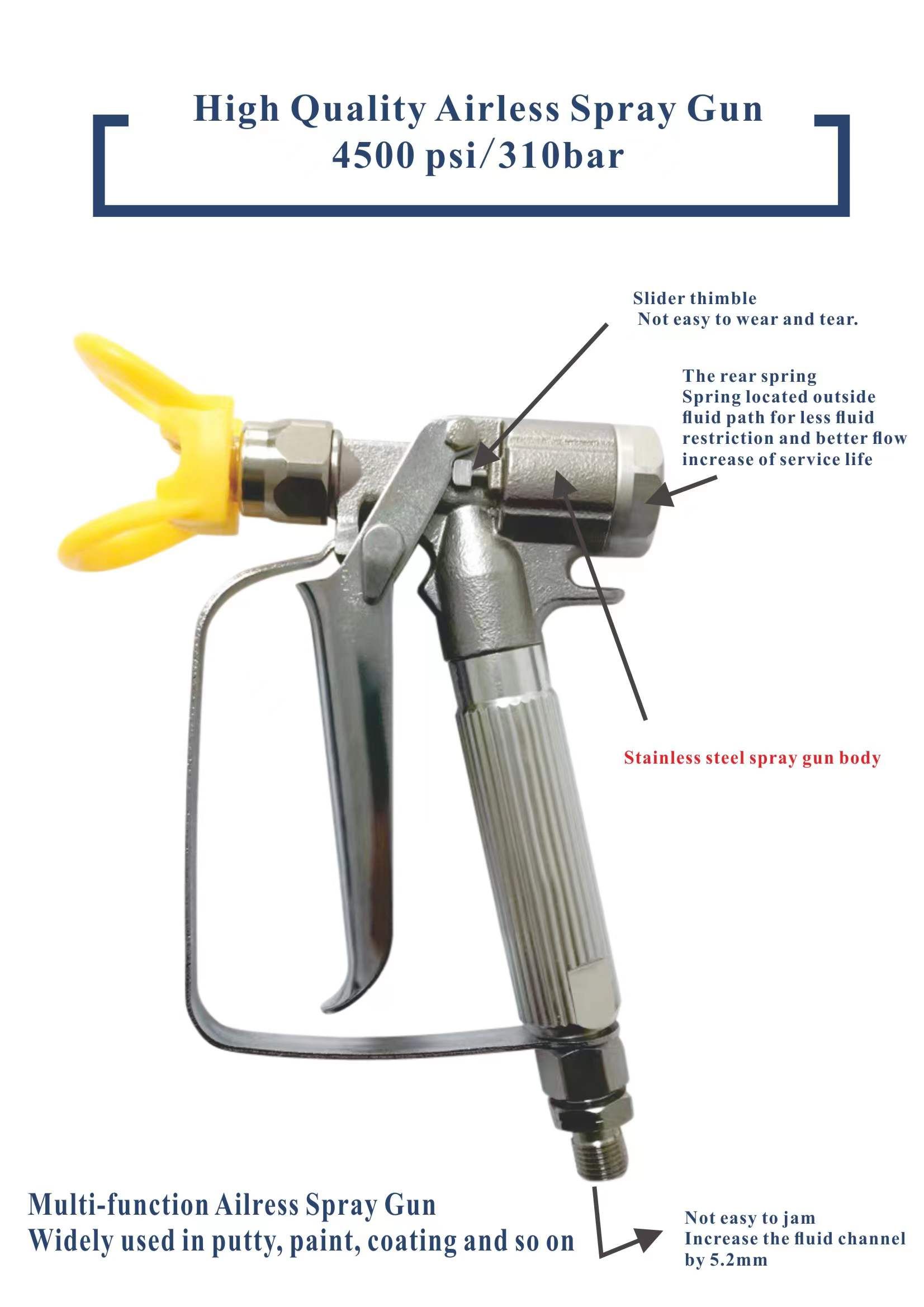

Illustrative image related to airless spray guns sale in ca.made in china $20

The Solution: To combat this challenge, buyers should seek out suppliers who offer robust technical support, including user manuals, instructional videos, and access to customer service representatives. It can be beneficial to request training sessions or workshops, especially for teams that will be using the equipment extensively. Additionally, establishing a relationship with a knowledgeable local distributor can provide ongoing support and resources. Creating a centralized repository of best practices and troubleshooting tips within the company can also empower users, ensuring that they are well-equipped to handle common issues independently. By fostering a culture of continuous learning and resource sharing, businesses can enhance their operational efficiency and satisfaction with the equipment.

Strategic Material Selection Guide for airless spray guns sale in ca.made in china $20

What Materials Are Commonly Used in Airless Spray Guns?

When selecting airless spray guns, particularly those priced around $20 and manufactured in China, it is essential to understand the materials used in their construction. The choice of materials directly affects performance, durability, and application suitability. Here, we will analyze four common materials used in these spray guns: aluminum, stainless steel, plastic, and brass.

How Does Aluminum Impact Airless Spray Gun Performance?

Aluminum is a prevalent material in airless spray gun construction due to its lightweight nature and resistance to corrosion. It typically has a temperature rating of up to 400°F and can handle pressures of around 3000 PSI, making it suitable for various coatings.

Pros: Aluminum is durable, lightweight, and cost-effective. Its resistance to rust and corrosion makes it ideal for use with water-based finishes, which are common in many applications.

Cons: While aluminum is strong, it can be prone to dents and scratches. Its lower strength compared to steel may also limit its use in high-pressure applications.

Impact on Application: Aluminum spray guns can effectively handle a range of media, including water-based paints and solvents. However, they may not be suitable for highly abrasive materials.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding material safety and environmental standards.

What Role Does Stainless Steel Play in Airless Spray Guns?

Stainless steel is often used in high-end airless spray guns due to its superior corrosion resistance and strength. It can withstand high temperatures (up to 800°F) and pressures (up to 5000 PSI), making it suitable for demanding applications.

Pros: The primary advantage of stainless steel is its durability and resistance to corrosion, which extends the lifespan of the spray gun. It is also less likely to react with various chemicals.

Cons: The main drawback is the higher cost compared to aluminum and plastic. Additionally, stainless steel can be heavier, which may affect the ease of use.

Impact on Application: Stainless steel guns are ideal for both solvent-based and water-based coatings, making them versatile for various industries.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial for buyers in Europe and the Middle East, where quality assurance is paramount.

How Does Plastic Influence the Functionality of Airless Spray Guns?

Plastic components are commonly found in lower-cost airless spray guns. They offer a lightweight alternative to metal parts and can be molded into complex shapes.

Pros: Plastic is cost-effective and lightweight, making it easy to handle. It also resists corrosion and is suitable for water-based paints.

Cons: However, plastic may not withstand high pressures and temperatures as effectively as metal. It can also be less durable over time, particularly when exposed to harsh chemicals.

Impact on Application: Plastic spray guns are generally suitable for light-duty applications and water-based coatings but may struggle with thicker or solvent-based media.

Considerations for International Buyers: Buyers should be aware of the quality of plastics used, as subpar materials can lead to premature failure and safety issues.

What Advantages Does Brass Offer in Airless Spray Guns?

Brass is often used for fittings and connectors in airless spray guns due to its strength and resistance to corrosion.

Pros: Brass components provide excellent durability and are less likely to corrode than other metals. They can handle high pressures and temperatures, making them suitable for various applications.

Cons: The main disadvantage is the cost, as brass is generally more expensive than aluminum and plastic. Additionally, brass can be heavy, impacting the overall weight of the spray gun.

Impact on Application: Brass fittings ensure a secure connection, which is crucial for maintaining pressure and preventing leaks during use.

Considerations for International Buyers: Buyers should check for compliance with international standards to ensure the quality and safety of brass components.

Summary Table of Material Analysis

| Material | Typical Use Case for airless spray guns sale in ca.made in china $20 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General-purpose spray guns for water-based finishes | Lightweight and corrosion-resistant | Prone to dents and scratches | Low |

| Stainless Steel | High-end spray guns for industrial applications | Superior durability and corrosion resistance | Higher cost and weight | High |

| Plastic | Budget-friendly spray guns for light-duty applications | Cost-effective and lightweight | Less durable and pressure-resistant | Low |

| Brass | Fittings and connectors in airless spray guns | Excellent durability and corrosion resistance | Higher cost and weight | Med |

This analysis provides a comprehensive understanding of the materials commonly used in airless spray guns, enabling international B2B buyers to make informed purchasing decisions based on their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for airless spray guns sale in ca.made in china $20

What Are the Key Manufacturing Processes for Airless Spray Guns Made in China?

The manufacturing of airless spray guns, especially those priced around $20, involves several critical stages. Understanding these processes is essential for B2B buyers who prioritize quality and efficiency.

How Is Material Prepared for Airless Spray Guns?

The first step in manufacturing airless spray guns is material preparation. High-grade materials, such as aluminum and stainless steel, are typically used to ensure durability and resistance to corrosion. Suppliers often source these materials from reputable vendors, ensuring they meet the required specifications for strength and longevity.

Before fabrication, materials undergo a thorough inspection to verify their quality. This may include checking for impurities, dimensions, and overall integrity. Buyers should seek suppliers who can provide material certifications to confirm compliance with international standards.

What Forming Techniques Are Commonly Used?

Once the materials are prepared, the next stage is forming. This typically involves precision machining and casting processes. For airless spray guns, various components such as the body, nozzle, and trigger are created using CNC (Computer Numerical Control) machining. This technology allows for high precision and repeatability, essential for ensuring that each gun performs consistently.

Casting is also used for specific parts that require complex shapes. This process involves pouring molten metal into molds, which is then cooled to form the desired shape. Buyers should inquire about the techniques used by manufacturers to ensure that they employ advanced methods that enhance product reliability.

How Is Assembly Conducted in the Manufacturing Process?

Assembly is a critical phase in the manufacturing of airless spray guns. Components are meticulously put together, often in a cleanroom environment to prevent contamination. Automated assembly lines may be utilized, which can improve efficiency and reduce human error.

During assembly, components undergo functional testing to ensure they fit together properly and operate as intended. Each gun is typically assembled by trained technicians who follow strict guidelines to maintain quality standards. B2B buyers should confirm that the assembly process includes comprehensive checks to prevent defects.

What Finishing Techniques Are Used to Enhance Quality?

The finishing stage is essential for both aesthetics and functionality. Airless spray guns often undergo surface treatments such as anodizing or powder coating. These processes not only enhance the appearance but also provide an additional layer of protection against wear and corrosion.

Finishing techniques may also include polishing and applying lubricants to moving parts to ensure smooth operation. Buyers should request information on the finishing processes employed by manufacturers to gauge their commitment to quality.

What Quality Assurance Measures Are Implemented in Airless Spray Gun Manufacturing?

Quality assurance is paramount in the production of airless spray guns. Manufacturers typically adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards ensures that products meet customer and regulatory requirements consistently.

How Do International Standards Impact Quality Control?

International standards like CE and API certifications are crucial for B2B buyers, especially those importing products from China. CE marking indicates that a product meets European safety and health requirements, while API certification may be relevant for products used in specific industrial applications.

Understanding the implications of these certifications can help buyers make informed decisions. Suppliers should be able to provide documentation proving compliance with these standards, which adds credibility to their manufacturing processes.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral throughout the manufacturing process. Common QC stages include:

Illustrative image related to airless spray guns sale in ca.made in china $20

-

Incoming Quality Control (IQC): This initial checkpoint ensures that materials meet specifications before they enter the production line. Buyers can request IQC reports to verify material quality.

-

In-Process Quality Control (IPQC): During assembly, ongoing inspections are conducted to catch defects early. This includes monitoring machinery and ensuring that assembly procedures are followed correctly.

-

Final Quality Control (FQC): After assembly, each airless spray gun undergoes a final inspection. This includes functional testing and visual checks for any cosmetic defects. Buyers should inquire about the criteria used during FQC to ensure thoroughness.

What Testing Methods Are Commonly Used for Quality Assurance?

Various testing methods are employed to ensure that airless spray guns function effectively and safely. Common tests include:

-

Functional Testing: Evaluates the operational performance of the spray gun, ensuring that it meets specifications for pressure, flow rate, and atomization.

-

Durability Testing: Assesses the longevity and reliability of the spray gun under simulated operating conditions.

-

Leak Testing: Ensures that all seals and connections are secure, preventing any product leakage during use.

Buyers can request detailed reports on testing methods and results to gauge product quality before making a purchase.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is crucial for B2B buyers. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and QC measures. This is particularly important for international buyers who may not be familiar with local practices.

-

Quality Reports: Requesting documentation of quality tests and certifications can help verify the supplier’s adherence to international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing processes and product quality before shipment.

What Are the Unique QC Considerations for International Buyers?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider specific nuances in quality control. These include:

Illustrative image related to airless spray guns sale in ca.made in china $20

-

Regulatory Compliance: Different regions may have varying regulations regarding product safety and performance. Understanding these requirements is crucial for seamless market entry.

-

Cultural and Language Barriers: Communication challenges can impact the verification process. Establishing clear lines of communication with suppliers can mitigate misunderstandings.

-

Shipping and Handling: Quality assurance does not end at manufacturing. Ensuring that products are packaged correctly to withstand shipping is vital for maintaining quality upon arrival.

By taking these factors into account, B2B buyers can effectively navigate the complexities of sourcing airless spray guns from China, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘airless spray guns sale in ca.made in china $20’

To successfully procure airless spray guns made in China for sale in California at a price point of around $20, it is essential to follow a structured sourcing approach. This guide provides a step-by-step checklist to help international B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications for the airless spray guns you intend to purchase is crucial. Consider factors such as the type of materials to be sprayed (e.g., water-based or solvent-based), required nozzle sizes, and compatible air pressure settings. Defining these specifications will help you identify suppliers that can meet your specific needs.

- Material Compatibility: Ensure the gun can handle the specific types of paints or finishes you plan to use.

- Performance Metrics: Look for details on spray pattern, flow rate, and pressure requirements.

Step 2: Conduct Market Research

Explore the market landscape for airless spray guns, focusing on manufacturers in China. Utilize online platforms, trade shows, and industry publications to gather information about potential suppliers. Understanding market trends and competitor products will help you make informed decisions.

- Compare Products: Look at different brands and models to see which offers the best balance of quality and price.

- Identify Leading Brands: Focus on manufacturers with a solid reputation in the industry.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step ensures that you partner with reliable suppliers who have a proven track record.

- Check Certifications: Verify if the supplier has relevant quality certifications, such as ISO or CE, which can indicate adherence to international standards.

- Assess Experience: Look for suppliers with extensive experience in manufacturing airless spray guns.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the airless spray guns. Testing samples allows you to evaluate the quality, performance, and usability of the products firsthand. It’s a critical step to ensure that the guns meet your specifications.

- Conduct Performance Tests: Test the spray guns with different materials to assess their effectiveness.

- Evaluate Ergonomics: Ensure that the design and weight of the guns are comfortable for prolonged use.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your selected suppliers to secure the best pricing and terms. Be transparent about your budget and seek to establish long-term relationships that could lead to better pricing in the future.

- Volume Discounts: Inquire about discounts for bulk purchases or future orders.

- Payment Terms: Discuss flexible payment options that can accommodate your cash flow.

Step 6: Finalize the Purchase Agreement

After reaching a satisfactory agreement, ensure all terms are documented in a formal purchase agreement. This document should outline product specifications, pricing, delivery timelines, and payment terms.

- Review Legal Aspects: Consider consulting with a legal expert to ensure compliance with international trade regulations.

- Include Warranty Information: Make sure warranty terms are included to protect your investment.

Step 7: Plan for Logistics and Delivery

Finally, coordinate the logistics for shipping and delivery of the airless spray guns. Ensure that you understand the shipping process, customs requirements, and expected delivery timelines.

- Choose Reliable Freight Forwarders: Work with freight forwarders who have experience in handling shipments from China.

- Track Shipments: Implement a tracking system to monitor your shipment’s progress until it reaches your location.

By following this checklist, B2B buyers can streamline their procurement process and ensure they make informed decisions when sourcing airless spray guns from China.

Comprehensive Cost and Pricing Analysis for airless spray guns sale in ca.made in china $20 Sourcing

What Are the Key Cost Components for Airless Spray Guns Made in China?

When analyzing the cost structure of airless spray guns sourced from China at a price point of $20, several key components need to be considered. The main cost elements include:

Illustrative image related to airless spray guns sale in ca.made in china $20

-

Materials: The quality of materials used significantly influences the overall cost. Common materials include aluminum and various plastics, which can vary in price based on sourcing and quality. Higher-grade materials may increase costs but offer better durability and performance.

-

Labor: Labor costs in China are relatively low compared to Western countries. However, this can vary by region and factory reputation. Skilled labor may demand higher wages, affecting the final price of the product.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, maintenance, and administration. Efficient factories often have lower overhead costs, allowing for competitive pricing.

-

Tooling: Initial tooling costs for mold creation can be significant. For lower-volume orders, these costs are amortized over fewer units, potentially raising the per-unit price.

-

Quality Control (QC): A robust QC process ensures that products meet specified standards. While this adds an upfront cost, it is essential for maintaining quality, especially for international markets where standards can vary.

-

Logistics: Shipping costs are a critical component, particularly for international buyers. Factors such as shipping method, distance, and freight costs can significantly affect the final landed cost.

-

Margin: Manufacturers typically include a profit margin in their pricing. This margin can vary based on the competitive landscape and the perceived value of the product.

How Do Price Influencers Impact Airless Spray Gun Costs?

Several factors can influence the pricing of airless spray guns, especially for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Negotiating MOQs can lead to better pricing, but buyers must balance their inventory needs with cost savings.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers seeking unique designs or functionalities should be prepared for higher prices due to the additional resources required for production.

-

Material Quality and Certifications: Products that meet international quality standards (e.g., ISO certifications) may command higher prices. Buyers should assess whether the additional cost aligns with their quality requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more but reduce risks associated with defects or delays.

-

Incoterms: Understanding Incoterms is crucial for international shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total cost, as they define responsibilities and costs between buyer and seller.

What Are the Best Buyer Tips for Negotiating Airless Spray Gun Prices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Effectively: Build a good rapport with suppliers and be clear about your needs. Leverage volume orders to negotiate better pricing or terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and replacement. A cheaper initial price may lead to higher costs over time if quality is compromised.

-

Understand Pricing Nuances: Be aware that prices can fluctuate based on market conditions, raw material costs, and exchange rates. Regularly update your pricing strategy to reflect these changes.

-

Conduct Supplier Research: Thoroughly vet potential suppliers, looking for reviews, certifications, and previous client feedback. This due diligence can prevent costly mistakes.

-

Explore Alternative Sourcing Options: Don’t limit your search to one region or supplier. Investigate multiple sources to find the best balance of quality and price.

By understanding the cost structure, price influencers, and effective negotiation strategies, international buyers can make informed decisions when sourcing airless spray guns from China at competitive prices.

Alternatives Analysis: Comparing airless spray guns sale in ca.made in china $20 With Other Solutions

Exploring Alternatives to $20 Airless Spray Guns Made in China

When evaluating the purchase of airless spray guns, particularly the economical $20 models made in China, it is essential to consider alternative solutions that may offer enhanced performance, reliability, and suitability for specific applications. The following analysis compares the $20 airless spray guns against two viable alternatives: a professional-grade HVLP (High Volume Low Pressure) spray gun and a premium LVMP (Low Volume Medium Pressure) spray gun.

Comparison Table

| Comparison Aspect | Airless Spray Guns Sale In Ca.Made In China $20 | HVLP Spray Gun | LVMP Spray Gun |

|---|---|---|---|

| Performance | Adequate for light projects; may lack precision | Excellent atomization; versatile | Better atomization than HVLP; suitable for various finishes |

| Cost | Low initial investment, around $20 | Moderate, typically $150-$500 | Higher, usually $300-$600 |

| Ease of Implementation | Simple setup; user-friendly | Requires some skill; setup can be complex | Moderate complexity; user knowledge beneficial |

| Maintenance | Minimal; potential for clogging | Regular cleaning needed | Requires maintenance for optimal performance |

| Best Use Case | Small DIY projects, occasional use | Professional finishes, cabinetry | Versatile applications, including water and solvent-based finishes |

Detailed Breakdown of Alternatives

HVLP Spray Gun

HVLP spray guns are renowned for their superior atomization and efficiency. They operate at lower pressures, which significantly reduces overspray and provides a finer finish, making them ideal for professional applications such as cabinetry and furniture. Although the initial investment is higher, typically ranging from $150 to $500, the performance benefits often justify the cost. However, users may need to invest time in understanding the setup and operation, which could be a drawback for those seeking simplicity.

LVMP Spray Gun

The LVMP spray gun offers a compelling middle ground between HVLP and traditional airless systems. It utilizes lower air pressure while still providing excellent atomization, making it suitable for a wide range of coatings, including both water and solvent-based products. With costs typically between $300 and $600, LVMP guns are designed for users who require versatility and high-quality finishes. While they may require a bit more maintenance and user knowledge than the airless options, their performance can significantly enhance the quality of the work produced.

Conclusion: How to Choose the Right Solution for Your Needs

Choosing the right spray gun depends on various factors, including budget, application needs, and the desired finish quality. The $20 airless spray gun may appeal to buyers with limited budgets or those requiring a simple solution for light projects. However, for businesses focused on delivering high-quality finishes or working with a variety of coatings, investing in an HVLP or LVMP spray gun may prove more beneficial in the long run. Understanding the specific use cases and performance characteristics of each option will enable B2B buyers to make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for airless spray guns sale in ca.made in china $20

What Are the Key Technical Specifications for Airless Spray Guns?

When considering airless spray guns, especially those priced around $20 and manufactured in China, it’s essential to understand several critical specifications that can influence performance and suitability for various applications. Below are some key technical properties:

Illustrative image related to airless spray guns sale in ca.made in china $20

-

Material Grade

The quality of materials used in airless spray guns is paramount. Most guns are made from aluminum or high-grade plastic, which affect durability and weight. High-quality materials ensure resistance to corrosion, especially when using solvent-based paints. For B2B buyers, choosing a gun with superior material grade can translate into longer service life and reduced maintenance costs. -

Nozzle Size

Nozzle size is a significant factor that determines the spray pattern and finish quality. Common sizes range from 0.5 mm to 2.0 mm, with smaller nozzles suitable for fine finishes and larger ones designed for thicker materials. Understanding the nozzle size required for specific applications allows buyers to select the right gun for their needs, thereby improving efficiency in production. -

Operating Pressure

Operating pressure, typically measured in PSI (pounds per square inch), is crucial for the performance of airless spray guns. Most airless guns operate between 2000 to 3000 PSI. Higher pressure allows for a finer spray and better atomization of materials. For businesses, this means achieving a smoother finish with fewer coats, which can enhance productivity. -

Flow Rate

The flow rate, measured in liters per minute (L/min), indicates how much material the spray gun can deliver within a specific timeframe. A higher flow rate is beneficial for large projects, reducing the time spent on painting. Buyers should assess their project requirements to ensure they choose a spray gun that can handle the necessary flow rate efficiently. -

Weight and Ergonomics

The weight of the spray gun impacts user comfort, especially during extended use. A lightweight design reduces fatigue and improves maneuverability. Ergonomic features, such as a comfortable grip, can significantly enhance user experience. For B2B buyers, investing in ergonomically designed guns can lead to increased worker productivity and satisfaction.

What Are Common Trade Terms in the Airless Spray Gun Industry?

Understanding industry terminology is vital for B2B buyers to navigate purchasing processes effectively. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. When sourcing airless spray guns, buyers may encounter OEM options that offer customization in design or features, allowing for branded products that meet specific market needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for buyers to plan inventory and manage cash flow. For instance, if a supplier has an MOQ of 100 units, businesses must assess whether they can sell that quantity to justify the purchase. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ helps in comparing prices and terms from different suppliers, facilitating informed purchasing decisions. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping goods. Familiarity with terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is essential for buyers to understand shipping costs and risks associated with international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Shorter lead times are often preferred as they allow businesses to respond quickly to market demands. Understanding lead times helps in planning production schedules and inventory management. -

Warranty and Support

Warranty refers to the guarantee provided by manufacturers for their products, often covering defects and performance issues for a specified period. Knowing the warranty terms is essential for B2B buyers to mitigate risks and ensure product reliability.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when purchasing airless spray guns, ensuring they select products that meet their operational needs and market requirements.

Navigating Market Dynamics and Sourcing Trends in the airless spray guns sale in ca.made in china $20 Sector

Global drivers are shaping the market for airless spray guns priced at around $20, particularly those manufactured in China. The burgeoning construction and automotive industries across Africa, South America, the Middle East, and Europe are primary catalysts for demand. These regions are witnessing rapid urbanization and infrastructure development, leading to increased usage of spray guns for painting, finishing, and protective coating applications. Additionally, the shift towards DIY projects has expanded the consumer base for airless spray guns, making them accessible to smaller contractors and individual craftsmen.

Emerging trends in B2B technology are influencing sourcing strategies as well. The integration of e-commerce platforms has simplified procurement processes, enabling international buyers to access a variety of suppliers and product specifications. Moreover, the adoption of data analytics tools allows businesses to track market trends, consumer preferences, and pricing strategies more effectively. This is particularly relevant for buyers from regions like Brazil and Vietnam, where understanding local market dynamics can significantly impact purchasing decisions.

Furthermore, competitive pricing from Chinese manufacturers, combined with improvements in product quality, is driving market dynamics. Buyers are increasingly looking for suppliers who can offer a balance of cost-effectiveness and reliability. As a result, the focus has shifted towards establishing long-term partnerships with manufacturers who can guarantee consistent product performance and timely delivery.

How Does Sustainability and Ethical Sourcing Influence the Airless Spray Gun Market?

The environmental impact of manufacturing processes is a crucial consideration for B2B buyers today. The push towards sustainability in manufacturing has led to increased scrutiny of supply chains, particularly for products like airless spray guns. Buyers are keenly aware of the carbon footprint associated with production and transportation, prompting a demand for more sustainable practices among suppliers.

Ethical sourcing has become a non-negotiable aspect of procurement strategies. Buyers are increasingly seeking manufacturers who adhere to responsible sourcing standards, ensuring that materials are obtained from environmentally friendly sources and that workers are treated fairly. Certifications such as ISO 14001, which focuses on effective environmental management systems, and other ‘green’ certifications are becoming critical criteria in supplier selection.

In the airless spray gun sector, the use of eco-friendly materials and production techniques is gaining traction. Manufacturers are exploring innovations in design that reduce waste and enhance energy efficiency, ultimately leading to a more sustainable product lifecycle. By prioritizing sustainability and ethical sourcing, businesses can not only meet regulatory requirements but also enhance their brand reputation and appeal to environmentally conscious consumers.

What is the Historical Context of Airless Spray Guns in the B2B Market?

The evolution of airless spray guns can be traced back to the mid-20th century when they were primarily used in industrial applications. Over the decades, advancements in technology have led to the development of more efficient and user-friendly models, catering to both professional contractors and DIY enthusiasts. The introduction of airless technology significantly improved the application of paints and coatings, allowing for a smoother finish and faster application times.

In recent years, the airless spray gun market has seen a shift towards affordability and accessibility, particularly with the rise of Chinese manufacturers. This has democratized access to high-quality spray equipment, enabling small businesses and individual craftsmen to compete in the market. As international B2B buyers continue to seek cost-effective solutions, understanding the historical context of airless spray guns can provide valuable insights into current trends and future developments in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of airless spray guns sale in ca.made in china $20

1. How do I choose the right airless spray gun for my business needs?

Selecting the right airless spray gun involves assessing the specific applications you plan to undertake. Consider the viscosity of the materials you’ll be using, such as water-based or solvent-based paints. Look for a gun that offers adjustable pressure settings for versatility. Additionally, evaluate the gun’s compatibility with your existing compressor specifications, particularly its CFM rating. Supplier reviews and product specifications can guide you towards reliable options, especially when sourcing from manufacturers in China.

2. What is the best airless spray gun for a budget of $20?

For a budget of $20, the Sprayit SP-352 model is highly recommended. It operates efficiently at low CFM levels, making it suitable for smaller compressors. This model is known for its reliability and good atomization, especially when spraying water-based finishes. Ensure you check for parts availability and customer support from the supplier, as these factors can enhance your long-term satisfaction with the purchase.

3. How can I verify the quality of airless spray guns from Chinese suppliers?

To ensure quality, request samples before placing a bulk order. Conduct thorough research on the supplier’s reputation through online reviews and trade platforms. Additionally, inquire about quality assurance processes, including certifications like ISO. Consider using third-party inspection services to verify product quality before shipment. Establishing direct communication with the supplier can also help clarify any concerns regarding product specifications and quality.

4. What are the minimum order quantities (MOQ) for airless spray guns?

Minimum order quantities can vary significantly by supplier. Typically, for airless spray guns manufactured in China, MOQs may range from 100 to 500 units. However, some suppliers may offer lower MOQs for first-time buyers or specific promotional offers. It’s advisable to negotiate MOQs based on your business needs and future purchasing potential. Always confirm the MOQ upfront to avoid unexpected costs.

5. What payment terms should I expect when sourcing airless spray guns internationally?

Payment terms vary by supplier but typically include options like T/T (telegraphic transfer), PayPal, or Letter of Credit. Many suppliers may require a deposit (usually 30% to 50%) before production, with the balance due before shipment. It’s crucial to clarify these terms early in negotiations to ensure they align with your cash flow and budgeting strategies. Always consider using secure payment methods to protect your investment.

6. How can I customize the airless spray guns for my branding?

Most manufacturers in China offer customization options, such as branding, color, and packaging. Discuss your specific requirements with the supplier, including logo placement and color schemes. Be prepared to provide design files and specifications. Note that customization may affect MOQs and lead times, so plan accordingly. Confirm any additional costs associated with customization during your negotiations.

7. What logistics should I consider when importing airless spray guns?

Logistics play a crucial role in international trade. Consider shipping methods, such as sea or air freight, based on urgency and budget. Ensure you understand customs regulations in your country regarding import duties and taxes. It’s beneficial to work with a freight forwarder who can assist with documentation and ensure timely delivery. Additionally, confirm the delivery timeline with your supplier to manage customer expectations.

8. How can I handle post-purchase support and warranty claims?

Before finalizing your purchase, inquire about the supplier’s warranty policy and post-purchase support services. Ensure that the warranty covers defects and malfunctions for a reasonable period. Establish clear communication channels for support, including email or phone contacts. It’s also wise to document all transactions and communications regarding the purchase, as this can facilitate smoother warranty claims or support requests in the future.

Top 5 Airless Spray Guns Sale In Ca.Made In China $20 Manufacturers & Suppliers List

1. Chinese vs American – Airless Sprayers Comparison

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Chinese vs American – Airless Sprayers Comparison, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. SafeWorld – Aerosol Spray Can Tool

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Top rated products include: 1. SafeWorld International 02012 Aerosol Spray Can Tool with Grip Trigger – Black, Price: $6.99 New, $3.00 Used, 100% recommend. 2. Graco SG3 Metal Spray Gun – 243012, Price: $107.99 New, $43.99 Used, 100% recommend. 3. Graco Contractor & FTX Gun Repair Kit 288488, Price: $74.95 New, 100% recommend. 4. Graco 17A226 TrueCoat 360 Flexliner Paint Bags, Price: $8.55 New, 10…

3. Automotive Paint Gun – Key Product

Domain: automotivepaintgun.com

Registered: 2020 (5 years)

Introduction: Key Product Details:

1. Types of Airless Sprayers:

– Pneumatic airless paint sprayers: Versatile for contractors and industrial facility managers, suitable for various nozzle sizes.

– Electric airless paint sprayers: Ideal for smaller, residential contractors.

– Gas airless paint sprayers: Suitable for industrial contractors but limited by explosive environments.

– Handheld airless pai…

4. Air Paint Sprayer – Airless Sprayers

Domain: airpaintsprayer.com

Registered: 2020 (5 years)

Introduction: Airless sprayers atomize fluid into small droplets without compressed air, using high pressure through a spray tip. Key advantages include large coverage area, even application of coating, ease of use, quick setup, time efficiency, and good working conditions with minimal pollution. Types of airless sprayers include high pressure, low pressure, electric, and handheld models, suitable for various a…

5. CA Technologies – Premium Spray Gun

Domain: waterbasedfinish.com

Registered: 2019 (6 years)

Introduction: {“Product Name”: “Premium Spray Gun by CA Technologies”, “Product SKU”: “CAT.PSG.01”, “Price”: “$450.00”, “Manufacturer”: “CA Technologies”, “Exclusive Distributor”: “MK Sales Inc.”, “Authorized Reseller”: “WaterBasedFinish.com”, “Country of Origin”: “Made In Germany”, “Weight”: “20 lbs”, “Dimensions”: “12 × 12 × 15 in”, “Shipping Restrictions”: “No”, “Retail Packaging”: “No”, “Facility Availabili…

Strategic Sourcing Conclusion and Outlook for airless spray guns sale in ca.made in china $20

In conclusion, the market for airless spray guns, particularly those priced around $20 and manufactured in China, presents significant opportunities for international B2B buyers. Strategic sourcing is essential for maximizing value and ensuring high-quality products that meet diverse application needs. By understanding the technical specifications and performance capabilities of various spray gun models, businesses can make informed purchasing decisions that align with their operational requirements.

For buyers in regions such as Africa, South America, the Middle East, and Europe, leveraging relationships with reliable suppliers can lead to cost savings and improved product availability. As demand for efficient, versatile spray solutions continues to grow, exploring partnerships with manufacturers that prioritize quality and innovation will be crucial.

Looking ahead, now is the time to engage with suppliers, evaluate product offerings, and secure competitive pricing. By taking proactive steps in your sourcing strategy, you can enhance your product lineup and meet the evolving needs of your customers. Embrace the potential of airless spray guns to drive your business forward in a dynamic global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.