How to Source Air Cooled Chiller Cycle Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for air cooled chiller cycle

In today’s rapidly evolving industrial landscape, sourcing efficient air cooled chiller cycles poses a significant challenge for businesses across various sectors. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of these cooling systems is crucial for making informed purchasing decisions. Air cooled chillers are essential for maintaining optimal temperatures in commercial and industrial applications, yet their effectiveness depends on a variety of factors, including system design, energy efficiency, and operational costs.

This comprehensive guide delves into the diverse types of air cooled chillers, their applications across different industries, and essential considerations for supplier vetting. From understanding the technical specifications to evaluating cost-effectiveness, we equip you with the knowledge needed to navigate the global market confidently. Furthermore, we’ll explore the latest advancements in chiller technology and the implications of regional regulations, ensuring you are well-informed about potential challenges and opportunities.

By leveraging this guide, B2B buyers will gain valuable insights that empower them to select the right air cooled chiller cycle tailored to their specific needs. Whether you’re in Brazil, Vietnam, or elsewhere, making strategic decisions about your cooling solutions can lead to enhanced operational efficiency and cost savings, positioning your business for long-term success.

Understanding air cooled chiller cycle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Scroll Chillers | Utilizes a compact design with fewer moving parts for efficiency. | Small to medium commercial buildings, data centers. | Pros: Energy-efficient, low maintenance. Cons: Limited capacity compared to others. |

| Screw Chillers | Features twin-screw compressors for high efficiency and reliability. | Industrial applications, large commercial facilities. | Pros: High capacity, durable. Cons: Higher initial cost, more complex repairs. |

| Reciprocating Chillers | Employs pistons for compression, versatile in design. | Laboratories, food processing, and pharmaceuticals. | Pros: Cost-effective, adaptable to various needs. Cons: Noisy operation, less energy-efficient. |

| Glycol Chillers | Uses a glycol-water mix for lower temperature applications. | Ice rinks, breweries, and HVAC systems in cold climates. | Pros: Capable of very low temperatures. Cons: Requires more maintenance and monitoring. |

| Modular Chillers | Comprises multiple smaller units for scalability and redundancy. | Large commercial spaces, hospitals, and schools. | Pros: Flexible installation, easy to expand. Cons: Higher upfront investment, space requirements. |

What Are the Characteristics and Suitability of Scroll Chillers?

Scroll chillers are designed with a compact architecture, making them ideal for small to medium-sized commercial buildings and data centers. Their fewer moving parts enhance reliability and reduce maintenance needs. When purchasing, buyers should consider the energy efficiency ratings and installation space, as scroll chillers are best suited for environments with limited footprint requirements.

How Do Screw Chillers Stand Out in Industrial Applications?

Screw chillers utilize twin-screw compressors, providing high efficiency and reliability, particularly in industrial settings and large commercial facilities. Their ability to handle significant cooling loads makes them suitable for processes requiring consistent temperature control. Buyers should evaluate the total cost of ownership, including energy consumption and maintenance, as these chillers often have a higher initial investment but lower operational costs.

Why Choose Reciprocating Chillers for Versatility?

Reciprocating chillers use pistons for compression and are known for their adaptability, making them suitable for diverse applications like laboratories, food processing, and pharmaceuticals. They are typically more cost-effective upfront compared to other types, but potential buyers should consider noise levels and energy efficiency, as these units may not operate as quietly or efficiently as scroll or screw models.

What Advantages Do Glycol Chillers Offer for Low-Temperature Needs?

Glycol chillers are specifically designed to operate at lower temperatures by using a glycol-water mixture, making them ideal for applications such as ice rinks and breweries. They provide the capability to achieve temperatures well below freezing. However, buyers should be aware of the increased maintenance requirements associated with glycol systems, as well as the need for monitoring fluid levels and concentrations.

How Do Modular Chillers Provide Scalability for Large Facilities?

Modular chillers consist of multiple smaller units that can be deployed in a scalable manner, providing flexibility for large commercial spaces, hospitals, and schools. Their modular design allows for easy expansion as cooling needs grow. When considering a modular chiller, buyers should evaluate the available installation space and upfront costs, as they may require a larger investment but offer significant advantages in terms of redundancy and energy efficiency.

Key Industrial Applications of air cooled chiller cycle

| Industry/Sector | Specific Application of air cooled chiller cycle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Process Cooling for Manufacturing | Ensures optimal temperature control for product quality | Energy efficiency, reliability, and local climate adaptability |

| Pharmaceuticals | Controlled Environment for Drug Production | Maintains precise temperature for sensitive compounds | Compliance with industry standards and maintenance support |

| Data Centers | Cooling for IT Equipment | Prevents overheating, ensuring operational uptime | Scalability, energy consumption, and redundancy features |

| Textile Manufacturing | Cooling for Dyeing and Finishing Processes | Enhances product quality and process efficiency | Customization options and compatibility with existing systems |

| Chemical Processing | Cooling for Reaction Control | Prevents overheating in exothermic reactions | Safety features, material compatibility, and local support |

How is the Air Cooled Chiller Cycle Used in Food and Beverage Manufacturing?

In the food and beverage industry, air cooled chillers are crucial for maintaining the desired temperatures during production processes. They are employed in cooling systems for fermentation tanks, pasteurization, and storage areas. By ensuring precise temperature control, these chillers help maintain the quality and safety of food products. For international buyers, considerations include energy efficiency, reliability, and the ability to adapt to local climate conditions, which can affect performance.

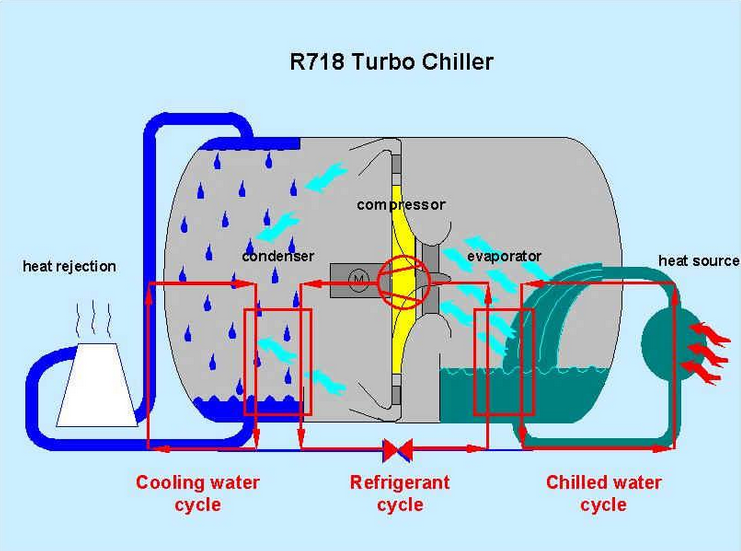

Illustrative image related to air cooled chiller cycle

What Role Do Air Cooled Chillers Play in Pharmaceuticals?

Pharmaceutical manufacturers rely on air cooled chillers to create controlled environments for drug production. These chillers help maintain specific temperatures essential for the stability of sensitive compounds and formulations. The benefit lies in ensuring product efficacy and compliance with stringent regulations. Buyers must consider sourcing chillers that meet industry standards, offer robust maintenance support, and provide reliable operation to avoid costly production delays.

How Do Data Centers Utilize Air Cooled Chillers?

Data centers use air cooled chillers to cool IT equipment and maintain optimal operating temperatures. This is critical to prevent overheating, which can lead to system failures and downtime. The value of these chillers lies in their ability to enhance operational efficiency and protect valuable data. Buyers should prioritize features such as scalability to accommodate growth, energy consumption metrics for cost management, and redundancy options to ensure continuous cooling during maintenance or failures.

In What Ways Are Air Cooled Chillers Important for Textile Manufacturing?

In textile manufacturing, air cooled chillers are vital for cooling dyeing and finishing processes. They help maintain consistent temperatures, which is essential for achieving high-quality fabric finishes. This application not only improves product quality but also enhances overall process efficiency. Buyers need to consider customization options to fit specific production lines and compatibility with existing systems to ensure seamless integration.

Why Are Air Cooled Chillers Critical in Chemical Processing?

Air cooled chillers play a significant role in the chemical processing sector by controlling temperatures in exothermic reactions. They help prevent overheating, which can be hazardous and lead to product degradation. The benefits include enhanced safety, improved product yield, and compliance with environmental regulations. When sourcing, buyers should focus on chillers with safety features, material compatibility to handle various chemicals, and local support for maintenance and service.

3 Common User Pain Points for ‘air cooled chiller cycle’ & Their Solutions

Scenario 1: Inconsistent Cooling Performance Leading to Operational Disruptions

The Problem: B2B buyers often struggle with inconsistent cooling performance from air-cooled chillers, especially in varying ambient temperature conditions. This can lead to operational disruptions in facilities like data centers, manufacturing plants, or commercial buildings where stable temperatures are critical. When the chiller fails to maintain the desired setpoint, it can result in overheating equipment, reduced efficiency, and ultimately, financial losses due to downtime or damaged products.

The Solution: To mitigate this challenge, buyers should focus on selecting chillers with advanced control systems that can adapt to fluctuating outdoor temperatures. Look for chillers equipped with variable speed fans and advanced microprocessor controls. These features allow the chiller to adjust its performance dynamically based on the real-time temperature and load conditions, ensuring consistent cooling. Additionally, consider implementing a predictive maintenance program that utilizes IoT sensors to monitor chiller performance and ambient conditions. This proactive approach can help detect issues before they escalate, ensuring optimal operation and minimizing disruptions.

Illustrative image related to air cooled chiller cycle

Scenario 2: High Energy Costs Due to Inefficient Chiller Operation

The Problem: Energy costs represent a significant portion of operational expenses for businesses utilizing air-cooled chillers. Many buyers find that their chillers are consuming more energy than expected, leading to inflated utility bills. This inefficiency can stem from outdated equipment, improper sizing, or inadequate maintenance practices, which not only increases costs but can also negatively impact the environment and corporate sustainability goals.

The Solution: Buyers should prioritize energy-efficient models when sourcing air-cooled chillers. Look for units that are rated with high energy efficiency ratios (EER) or seasonal energy efficiency ratios (SEER). Additionally, proper sizing is crucial; an oversized chiller will cycle on and off frequently, leading to energy waste. Engage with HVAC professionals to perform a load calculation to determine the appropriate chiller size for your facility. Regular maintenance, including cleaning coils, checking refrigerant levels, and ensuring proper airflow, can also enhance efficiency. Implementing an energy management system can provide insights into usage patterns and identify opportunities for savings.

Scenario 3: Frequent Breakdowns and Maintenance Issues

The Problem: Frequent breakdowns and maintenance issues are a common pain point for B2B buyers using air-cooled chillers. These issues can stem from a variety of factors, including poor installation, lack of regular maintenance, or using low-quality components. Each breakdown not only incurs repair costs but can also lead to substantial losses in productivity as operations come to a halt during repairs.

The Solution: To reduce the frequency of breakdowns, buyers should ensure that their air-cooled chillers are installed by certified professionals who adhere to best practices. This includes proper alignment, secure connections, and adequate airflow around the unit. Furthermore, establishing a comprehensive maintenance plan that includes routine inspections, cleaning, and system checks is essential. Buyers should consider investing in high-quality components and systems with robust warranties to minimize the risk of failure. Training staff on basic operational best practices can also help in identifying early warning signs of potential issues, allowing for timely interventions before breakdowns occur.

By addressing these common pain points through informed sourcing, proactive maintenance, and energy-efficient practices, B2B buyers can optimize their air-cooled chiller systems, ensuring reliability and cost-effectiveness in their operations.

Strategic Material Selection Guide for air cooled chiller cycle

What Materials Are Commonly Used in Air Cooled Chiller Cycles?

When selecting materials for air cooled chiller cycles, several factors must be considered, including thermal conductivity, corrosion resistance, cost, and manufacturing complexity. Here, we analyze four materials that are frequently utilized in the construction of air cooled chillers, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Copper Perform in Air Cooled Chiller Applications?

Copper is a widely used material in the manufacturing of evaporators and condensers due to its excellent thermal conductivity and corrosion resistance. It can withstand high pressures and temperatures, making it suitable for the demanding environments of air cooled chillers.

Pros: Copper’s high thermal conductivity ensures efficient heat transfer, which is crucial for the performance of chillers. Its natural resistance to corrosion extends the lifespan of components, reducing maintenance costs.

Cons: The primary drawback of copper is its relatively high cost compared to alternatives like aluminum or steel. Additionally, copper is heavier, which may complicate installation and increase transportation costs.

Impact on Application: Copper is compatible with a variety of refrigerants, making it versatile for different chiller designs. However, its susceptibility to certain forms of corrosion, such as pitting in chlorinated environments, should be considered.

Considerations for International Buyers: Buyers from regions with high humidity or saline environments, such as parts of Africa and the Middle East, should ensure that copper components are treated or alloyed to enhance corrosion resistance. Compliance with ASTM standards is also critical for ensuring quality.

What Role Does Aluminum Play in Air Cooled Chillers?

Aluminum is another popular choice for air cooled chillers, particularly in the construction of heat exchangers and condenser coils. Its lightweight nature and good thermal conductivity make it an attractive option.

Pros: Aluminum is significantly lighter than copper, which facilitates easier handling and installation. It is also less expensive, making it a cost-effective choice for large-scale applications.

Cons: While aluminum has good corrosion resistance, it is not as robust as copper under high temperatures and pressures. This limitation can affect its performance in extreme conditions.

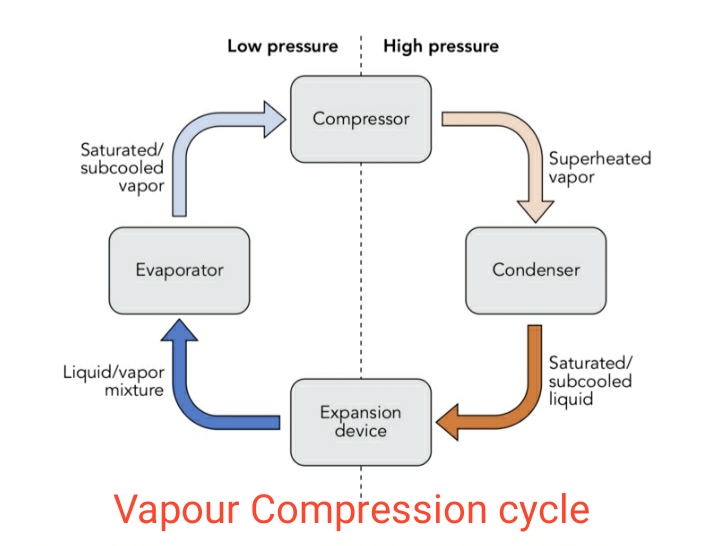

Illustrative image related to air cooled chiller cycle

Impact on Application: Aluminum is suitable for use with various refrigerants, but its lower melting point can restrict its application in high-temperature environments.

Considerations for International Buyers: Buyers in Europe and South America should be aware of the specific alloy grades required for optimal performance. Compliance with DIN standards is essential for ensuring that aluminum components meet industry requirements.

How Does Stainless Steel Compare in Air Cooled Chiller Cycles?

Stainless steel is often chosen for its strength and corrosion resistance, particularly in components that are exposed to aggressive environments or where durability is paramount.

Pros: Stainless steel offers excellent resistance to corrosion and can handle high pressures and temperatures, making it ideal for critical components like compressors and piping.

Cons: The primary disadvantage is its cost, which can be significantly higher than both copper and aluminum. Additionally, stainless steel can be more challenging to manufacture and weld, potentially increasing production time.

Illustrative image related to air cooled chiller cycle

Impact on Application: Stainless steel is compatible with a wide range of refrigerants and is particularly effective in environments where corrosion is a concern, such as coastal areas.

Considerations for International Buyers: Buyers should ensure that the stainless steel used complies with relevant international standards, such as ASTM or JIS, to guarantee quality and performance.

Why Is Plastic Used in Air Cooled Chillers?

Plastics, particularly high-performance polymers, are increasingly being used in air cooled chillers for non-structural components, such as insulation and casings.

Pros: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes, which makes them versatile for various applications.

Cons: The main limitation is that plastics typically have lower thermal conductivity than metals, which can affect heat transfer efficiency. Additionally, they may not withstand high temperatures as effectively as metals.

Impact on Application: Plastics are suitable for insulation and non-load-bearing applications, but their use in critical components should be carefully evaluated.

Considerations for International Buyers: Buyers should consider the specific environmental conditions in their region, such as UV exposure or temperature extremes, which can affect the longevity of plastic components. Compliance with local standards is also essential.

Summary Table of Material Selection for Air Cooled Chiller Cycles

| Material | Typical Use Case for air cooled chiller cycle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Evaporators and condensers | Excellent thermal conductivity | Higher cost and weight | High |

| Aluminum | Heat exchangers and condenser coils | Lightweight and cost-effective | Lower performance under high temperatures | Medium |

| Stainless Steel | Compressors and piping | High strength and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Insulation and non-structural components | Lightweight and corrosion-resistant | Lower thermal conductivity | Low |

This strategic material selection guide provides B2B buyers with essential insights into the materials commonly used in air cooled chiller cycles, enabling informed decisions that enhance operational efficiency and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for air cooled chiller cycle

What Are the Main Stages in the Manufacturing Process of Air Cooled Chillers?

The manufacturing of air cooled chillers involves several key stages that ensure the final product meets industry standards for performance and reliability. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Air Cooled Chillers?

Material preparation is the foundational step in manufacturing air cooled chillers. It involves sourcing high-quality materials such as steel, copper, and aluminum, which are essential for the chiller’s frame, heat exchangers, and piping systems. Suppliers must adhere to international material standards, ensuring that the materials are free from defects and suitable for HVAC applications.

Materials are often subjected to pre-treatment processes, such as cleaning and coating, to enhance their corrosion resistance and longevity. This is particularly important for air cooled chillers exposed to varying environmental conditions, especially in regions with high humidity or saline air.

What Techniques Are Used in the Forming Process?

The forming stage includes processes such as cutting, bending, and welding. Advanced CNC (Computer Numerical Control) machines are typically used for precise cutting and shaping of metal components. This ensures that each part fits perfectly, reducing the risk of leaks and inefficiencies in the cooling cycle.

Welding techniques, including MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas), are commonly employed to join components together. These methods provide strong, durable joints that can withstand the pressures and temperatures found within the chiller system. Quality control during this phase is crucial; welds are often inspected through non-destructive testing methods to ensure structural integrity.

Illustrative image related to air cooled chiller cycle

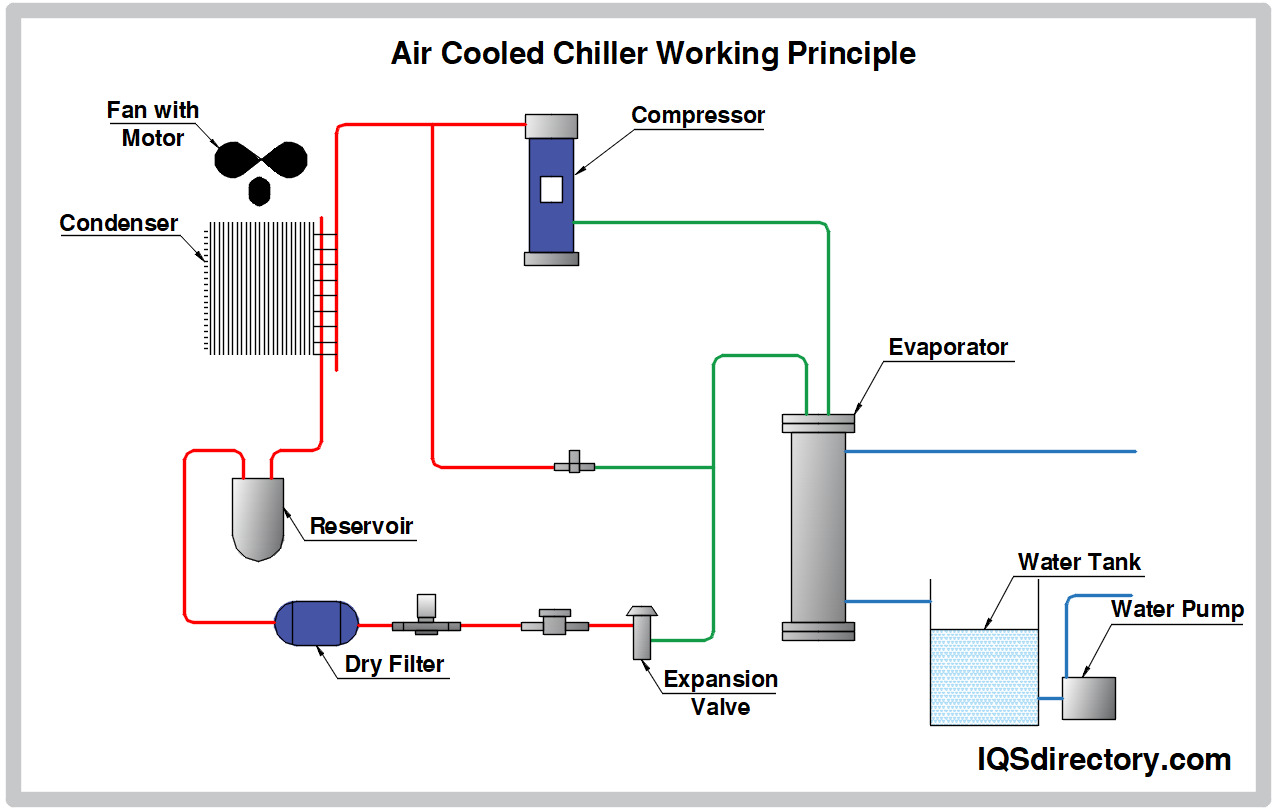

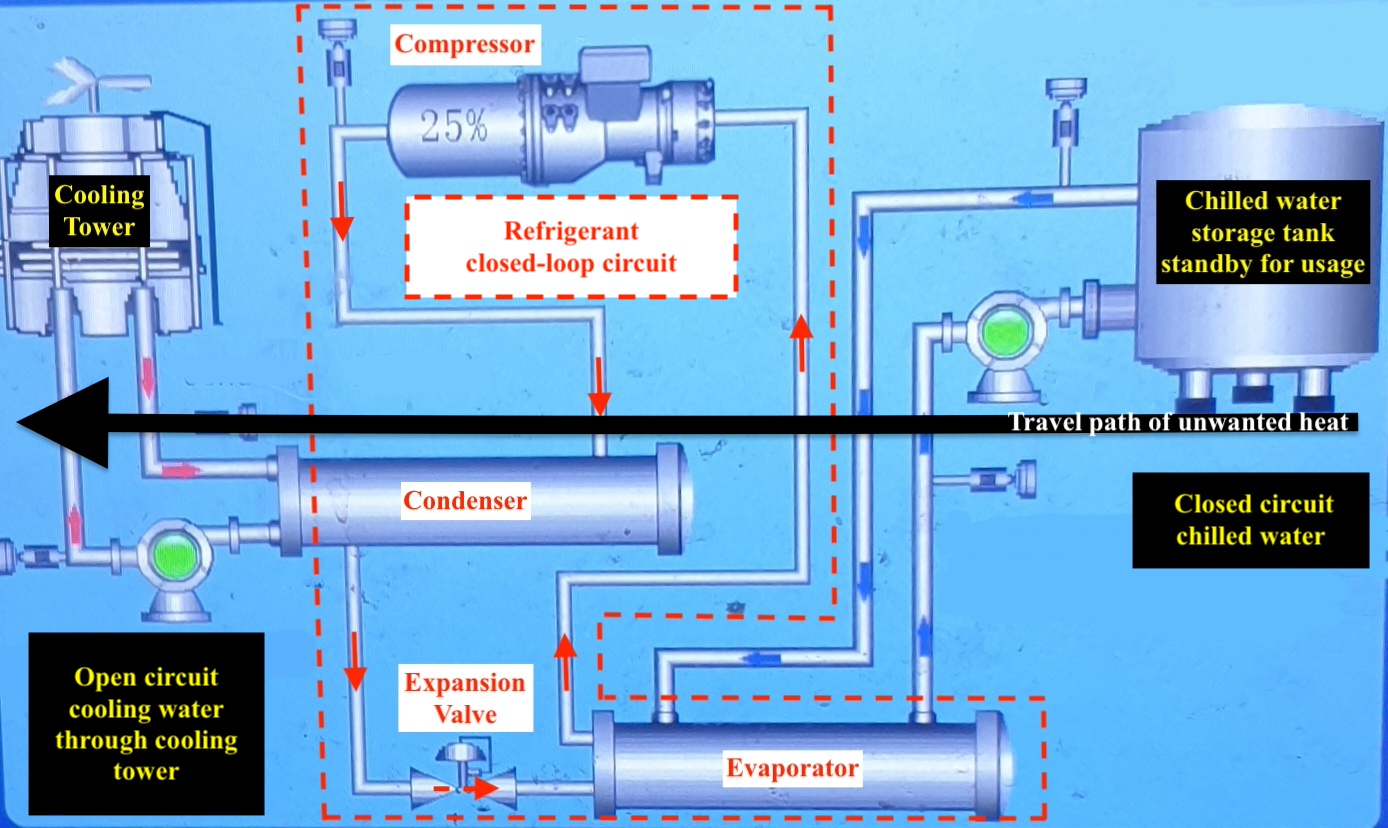

How Are Components Assembled in Air Cooled Chillers?

The assembly phase integrates all components, including the compressor, condenser, evaporator, and expansion valve. Skilled technicians follow detailed assembly guidelines to ensure that each unit is built to specifications. This stage may also include the installation of electrical components and controls, which are essential for the chiller’s operation.

Quality checks during assembly, known as In-Process Quality Control (IPQC), involve monitoring the assembly process at various checkpoints. Technicians verify that components are properly aligned, securely fastened, and free from defects. This proactive approach helps identify potential issues before the unit is fully assembled.

What Finishing Techniques Are Used for Air Cooled Chillers?

Finishing processes, including painting and coating, are crucial for enhancing the aesthetic appeal and durability of air cooled chillers. Protective coatings, often made from powder or epoxy, are applied to prevent corrosion and ensure longevity, particularly in outdoor installations.

After finishing, units undergo Final Quality Control (FQC) checks, where the entire chiller is tested for functionality. This includes pressure testing to identify leaks and operational tests to confirm that the chiller performs as expected under various conditions.

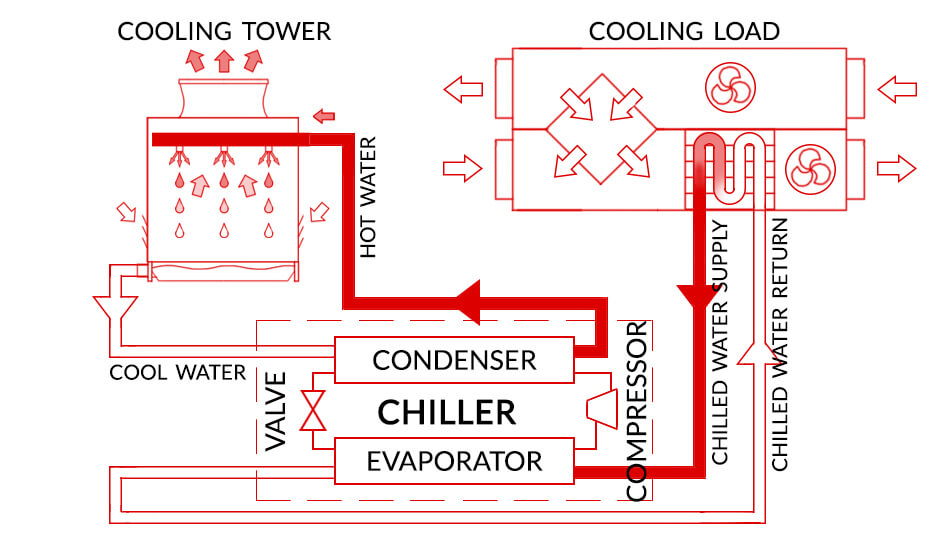

Illustrative image related to air cooled chiller cycle

What Are the Key Quality Assurance Standards for Air Cooled Chillers?

Quality assurance is a critical aspect of the manufacturing process for air cooled chillers. Adhering to international standards ensures that products meet safety, efficiency, and environmental requirements.

Which International Standards Are Relevant for Air Cooled Chillers?

ISO 9001 is one of the most recognized quality management standards globally. It emphasizes a process-driven approach to manufacturing, focusing on customer satisfaction and continuous improvement. Manufacturers of air cooled chillers often pursue ISO 9001 certification to demonstrate their commitment to quality.

Other relevant certifications include CE marking for compliance with European health and safety standards, and API (American Petroleum Institute) standards for systems used in oil and gas applications. These certifications provide assurance to B2B buyers that the chillers are safe, reliable, and efficient.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control in the manufacturing of air cooled chillers typically involves three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

IQC: This stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Quality inspectors verify that materials meet specified standards before they are used in production.

-

IPQC: During the assembly process, quality checks are conducted to ensure that each component is correctly installed and functions as intended. This ongoing monitoring helps catch defects early.

-

FQC: The final stage of quality control involves a comprehensive inspection of the finished product. Testing may include performance evaluation under simulated operating conditions to ensure the chiller meets its rated capacity and efficiency.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers need to ensure that their suppliers adhere to stringent quality assurance practices. Here are some actionable strategies:

Illustrative image related to air cooled chiller cycle

What Steps Can Buyers Take to Conduct Supplier Audits?

Conducting supplier audits is a vital step in verifying quality assurance practices. Buyers should request access to the supplier’s quality management system documentation and audit reports. This can include evidence of ISO certifications, internal audits, and corrective action reports.

On-site audits can also be beneficial, allowing buyers to observe the manufacturing process firsthand. This direct engagement provides insights into the supplier’s operational capabilities and commitment to quality.

How Can Third-Party Inspections Enhance Confidence in Supplier Quality?

Employing third-party inspection services can further validate a supplier’s quality assurance practices. Independent inspectors can provide unbiased assessments of the manufacturing process and product quality. Buyers can request third-party inspection reports as part of their procurement process to ensure that the chillers meet specified standards before shipment.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance. Understanding regional regulations and standards is crucial. For instance, compliance with local environmental regulations may differ significantly from one region to another.

Buyers should also be aware of potential cultural differences in business practices and quality expectations. Establishing clear communication and setting defined quality metrics can help bridge these gaps, ensuring that both parties have aligned expectations regarding product quality and performance.

In conclusion, the manufacturing processes and quality assurance measures for air cooled chillers are complex and multifaceted. By understanding these processes and implementing best practices for supplier verification, international B2B buyers can ensure they procure reliable, high-quality chillers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air cooled chiller cycle’

Introduction

When sourcing an air-cooled chiller cycle, it is crucial to follow a systematic approach to ensure you select the right equipment for your specific needs. This checklist provides a structured guide that will help international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, to make informed procurement decisions. By adhering to these steps, you can mitigate risks, enhance operational efficiency, and ensure a sustainable investment.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, establish your technical requirements based on the intended application. This includes understanding the cooling capacity needed, refrigerant type, and energy efficiency ratings.

– Cooling Capacity: Assess the total heat load of your facility to determine the chiller size.

– Energy Efficiency: Look for units with high Energy Efficiency Ratios (EER) or Seasonal Energy Efficiency Ratios (SEER) to minimize operational costs.

Step 2: Research Market Trends and Innovations

Stay updated on the latest advancements in air-cooled chiller technology. Understanding market trends will help you identify features that can enhance performance and reliability.

– New Technologies: Look for innovations such as variable-speed drives and advanced control systems that improve efficiency.

– Sustainability Practices: Consider chillers that utilize eco-friendly refrigerants or incorporate energy-saving features.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure reliability and quality. Request company profiles, product certifications, and references from other businesses in your industry.

– Certifications: Verify compliance with international standards such as ISO 9001 and relevant local regulations.

– Experience: Assess the supplier’s experience in your geographical area and sector, as this can influence support and service.

Step 4: Request Detailed Proposals

Once you have shortlisted suppliers, request detailed proposals that outline specifications, pricing, and delivery timelines. This step allows for a comprehensive comparison.

– Comparative Analysis: Use a standardized format to compare proposals easily, focusing on key factors such as warranty terms and after-sales support.

– Transparency: Ensure that all costs, including installation and maintenance, are clearly outlined to avoid hidden fees later.

Step 5: Conduct Site Visits and Inspections

If feasible, visit the supplier’s manufacturing facility or client sites to evaluate their operations and product performance. This firsthand experience can provide valuable insights.

– Quality Control: Observe the manufacturing processes to assess quality assurance measures in place.

– Client Feedback: Speak with existing clients to gather feedback on product performance and supplier reliability.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to clarify terms of service, warranty coverage, and pricing structures. Effective negotiation can lead to better deals and ensure you receive optimal support.

– Warranties: Ensure that warranties cover critical components and include provisions for service and parts replacement.

– Payment Terms: Discuss flexible payment options that align with your financial strategy.

Step 7: Plan for Installation and Maintenance

Finally, ensure you have a clear plan for the installation and ongoing maintenance of the chiller. Proper setup and regular upkeep are essential for optimal performance.

– Installation Support: Confirm that the supplier provides installation guidance or services.

– Maintenance Contracts: Consider establishing a maintenance contract to ensure regular servicing and reduce downtime.

By following this checklist, you can make a well-informed decision when procuring an air-cooled chiller cycle, leading to improved operational efficiency and cost savings for your business.

Comprehensive Cost and Pricing Analysis for air cooled chiller cycle Sourcing

What Are the Key Cost Components in Air Cooled Chiller Cycle Sourcing?

Understanding the cost structure of air cooled chillers is crucial for B2B buyers looking to make informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The materials used in manufacturing air cooled chillers significantly influence cost. Common materials include high-grade steel for the chassis, aluminum for heat exchangers, and specialized refrigerants. Prices fluctuate based on market demand and material availability, which can impact the final price.

-

Labor: Labor costs encompass the wages of skilled technicians involved in the assembly and quality assurance of chillers. Regions with higher labor costs, such as parts of Europe, may see increased pricing compared to areas with lower labor expenses, like parts of Asia or Africa.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient production processes can mitigate these costs, but they still play a significant role in overall pricing.

-

Tooling: The initial investment in tooling for manufacturing specific chiller models can be substantial. Customization often requires specialized tools, which can raise the cost, particularly for small production runs.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards. While this increases upfront costs, it can lead to significant savings by reducing warranty claims and enhancing customer satisfaction.

-

Logistics: The cost of transporting chillers from the manufacturer to the buyer’s location varies based on distance, shipping method, and the volume of units ordered. Buyers should consider these logistics costs when evaluating total expenses.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. This margin varies by supplier and can be influenced by their market position and customer relationship.

How Do Price Influencers Affect Air Cooled Chiller Costs?

Several factors can influence the final pricing of air cooled chillers:

-

Volume/MOQ: Purchasing in bulk often results in lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to maximize savings.

-

Specifications and Customization: Customized solutions tailored to specific applications can lead to increased costs. Buyers should clearly communicate their requirements to avoid unexpected expenses.

-

Materials Quality and Certifications: Higher-quality materials and certifications (e.g., ISO, ASHRAE) often lead to increased costs. However, investing in certified products can enhance reliability and efficiency.

-

Supplier Factors: The reputation and reliability of the supplier can greatly influence pricing. Established suppliers may charge a premium for their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: The terms of shipping and delivery (Incoterms) can significantly affect pricing. Buyers should understand the responsibilities and risks associated with each term to avoid hidden costs.

What Are the Best Negotiation Tips for International B2B Buyers?

When sourcing air cooled chillers, especially in diverse markets like Africa, South America, the Middle East, and Europe, negotiation is key:

-

Conduct Market Research: Understand the prevailing market prices and competitor offerings to strengthen your negotiation position.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also installation, maintenance, energy efficiency, and potential downtime costs. A lower upfront price may result in higher long-term expenses.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, favorable terms, and priority service.

-

Be Flexible: Be open to alternative specifications or materials that may reduce costs without sacrificing performance.

-

Request Multiple Quotes: Solicit bids from various suppliers to foster competition and obtain the best possible pricing.

Conclusion and Disclaimer

While the above analysis provides a framework for understanding the costs and pricing of air cooled chillers, actual prices may vary based on market conditions, supplier capabilities, and specific project requirements. It is advisable for buyers to conduct thorough due diligence and consider all factors influencing total costs before finalizing their procurement decisions.

Alternatives Analysis: Comparing air cooled chiller cycle With Other Solutions

Exploring Alternatives to Air Cooled Chiller Cycles for Efficient Cooling Solutions

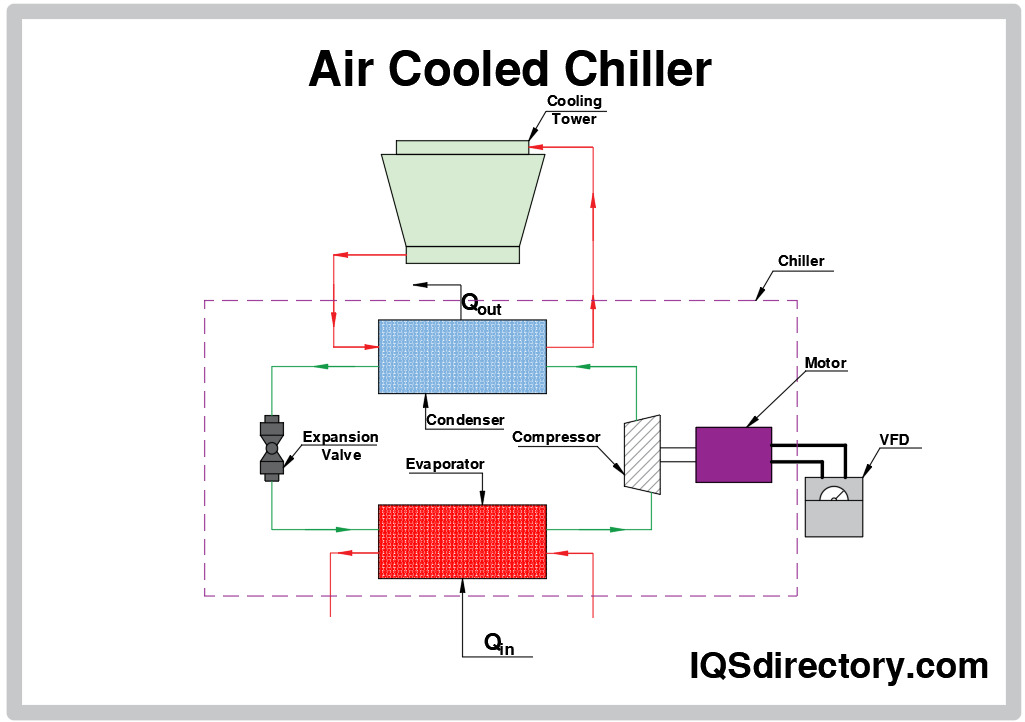

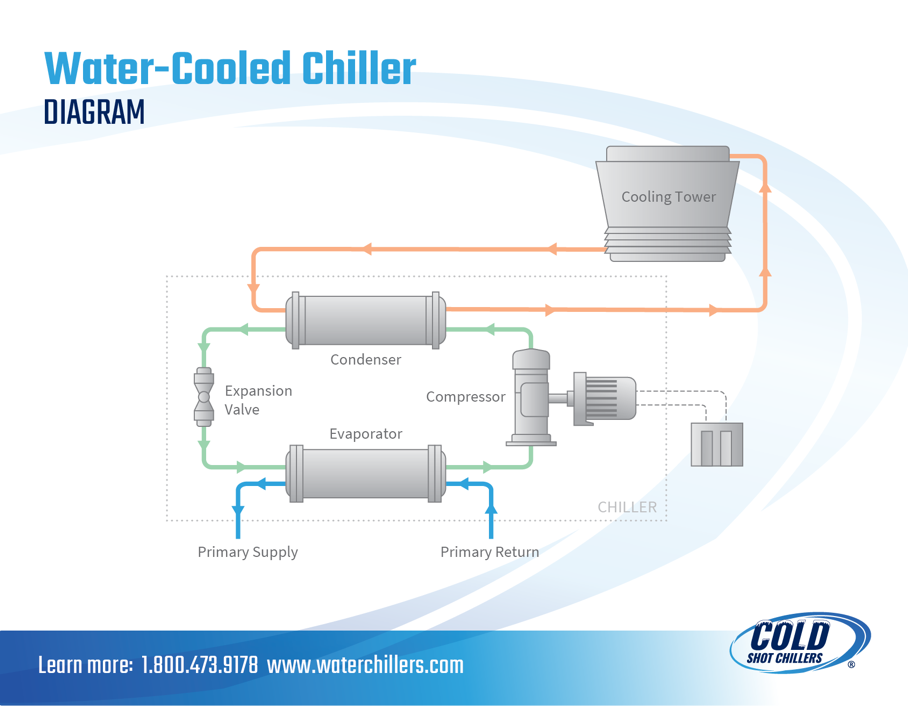

In the realm of commercial cooling solutions, air cooled chillers are a popular choice, especially for small to medium-sized buildings. However, various alternatives exist that cater to different operational needs, climates, and budgets. This section provides a comparative analysis of air cooled chillers against two viable alternatives: water cooled chillers and cooling towers. Understanding the strengths and weaknesses of each option can empower B2B buyers to make informed decisions.

| Comparison Aspect | Air Cooled Chiller Cycle | Water Cooled Chiller | Cooling Towers |

|---|---|---|---|

| Performance | Moderate efficiency; suitable for smaller loads. | High efficiency; ideal for larger systems. | Very high efficiency; excels in large industrial applications. |

| Cost | Lower initial investment; higher operational costs in hot climates. | Higher upfront costs; generally lower operating costs. | Moderate to high initial costs; low operating costs due to evaporation. |

| Ease of Implementation | Simple installation; minimal site requirements. | More complex setup; requires a water source and space for cooling towers. | Requires significant space and infrastructure; dependent on local climate. |

| Maintenance | Generally low; easy access for servicing. | Higher maintenance needs due to water treatment requirements. | Regular maintenance required; potential for water quality issues. |

| Best Use Case | Ideal for small to medium buildings with limited space. | Best for large commercial or industrial facilities needing consistent cooling. | Suitable for large-scale operations, especially in arid climates where water is readily available. |

Detailed Breakdown of Alternatives

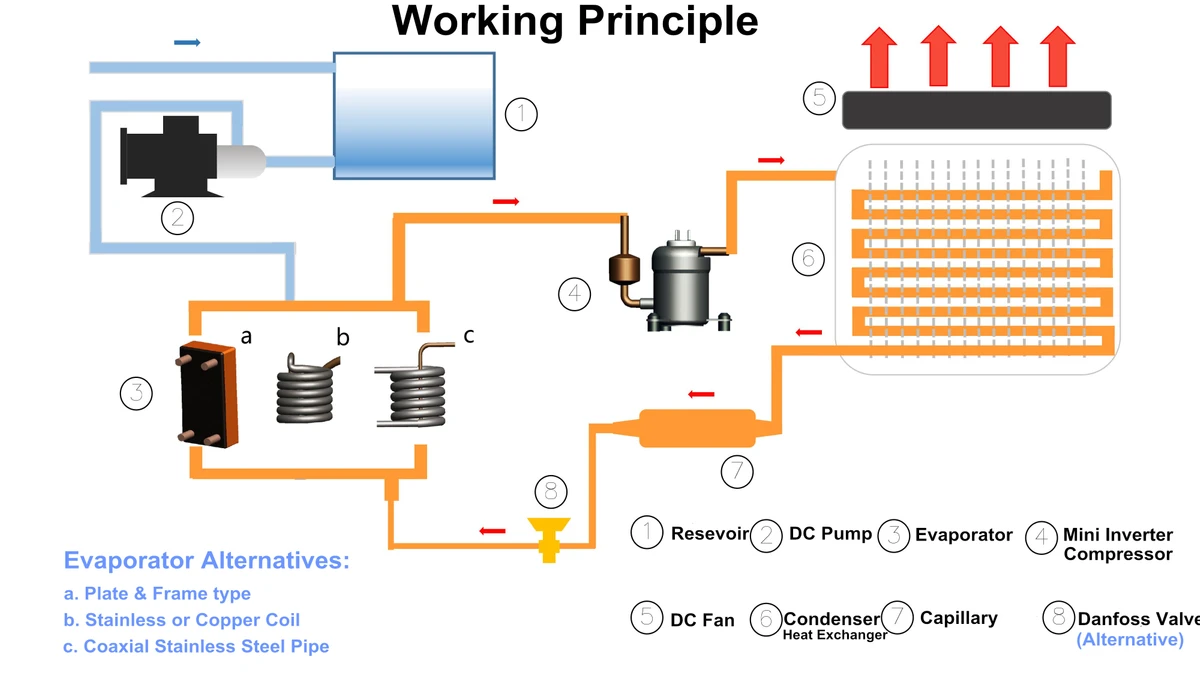

Water Cooled Chillers

Water cooled chillers utilize water as a cooling medium, offering enhanced efficiency compared to air cooled systems. They are particularly effective in larger buildings where heat loads are significant. The main advantage is their ability to maintain lower operational costs due to their high coefficient of performance (COP). However, they demand a more complex installation process, including the need for a cooling tower and a consistent water supply, which could limit their applicability in certain regions.

Cooling Towers

Cooling towers function by removing heat from water through evaporation, making them incredibly efficient for large-scale cooling needs. They excel in environments where water is abundant and can significantly reduce energy consumption. Nevertheless, the initial setup can be costly and requires ample space, which may not be feasible for all businesses. Furthermore, cooling towers necessitate ongoing maintenance to manage water quality and prevent issues like scaling or biological growth.

Making the Right Choice for Your Cooling Needs

When selecting a cooling solution, B2B buyers should consider several factors, including operational efficiency, installation complexity, and ongoing maintenance requirements. Air cooled chillers may be more suitable for businesses with space constraints and lower heat loads, while water cooled chillers and cooling towers offer superior efficiency for larger operations. Ultimately, understanding the specific cooling needs, budget constraints, and environmental conditions will guide buyers to the optimal solution tailored to their unique requirements.

Essential Technical Properties and Trade Terminology for air cooled chiller cycle

What Are the Essential Technical Properties of Air Cooled Chiller Cycles?

Understanding the technical specifications of air cooled chillers is crucial for B2B buyers, as these properties directly impact the performance, efficiency, and cost-effectiveness of HVAC systems. Below are some critical specifications to consider:

1. Cooling Capacity

Cooling capacity, measured in tons or kilowatts, indicates the amount of heat the chiller can remove from the system in a given time frame. This property is essential for sizing the chiller to meet the specific cooling demands of a facility. A properly sized chiller ensures energy efficiency and optimal performance, avoiding oversizing or undersizing issues that can lead to increased operational costs.

2. Energy Efficiency Ratio (EER) / Coefficient of Performance (COP)

EER and COP are metrics used to evaluate the energy efficiency of air cooled chillers. EER is calculated by dividing the cooling capacity by the power input, while COP measures the ratio of useful heating or cooling provided to the energy consumed. High EER or COP values indicate a more efficient system, which is particularly important in regions with high energy costs. Buyers should prioritize models with superior efficiency ratings to reduce long-term operational expenses.

3. Refrigerant Type

The type of refrigerant used in the chiller plays a significant role in its environmental impact and operational efficiency. Common refrigerants include R-410A and R-134A, each with different ozone depletion potential (ODP) and global warming potential (GWP). Buyers must consider local regulations regarding refrigerants, especially in regions where environmental standards are stringent. Selecting chillers with low-GWP refrigerants can enhance corporate responsibility and align with sustainability goals.

4. Operating Temperature Range

The operating temperature range defines the ambient conditions under which the chiller can function effectively. Air cooled chillers typically operate best within specific temperature thresholds, and exceeding these limits can affect performance and longevity. Understanding the operating conditions of the installation site helps buyers choose a chiller that can maintain efficiency and reliability throughout its service life.

5. Noise Levels

Noise levels, measured in decibels (dB), are an important consideration, particularly in commercial and residential environments. Air cooled chillers are equipped with fans that can generate significant noise during operation. Buyers should consider noise-reducing features and select models designed for quieter operation, especially if the installation site is near sensitive areas like schools or hospitals.

What Are the Common Trade Terms Related to Air Cooled Chiller Cycles?

Familiarity with industry terminology is vital for effective communication and negotiation in B2B transactions involving air cooled chillers. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or equipment that are used in another company’s end products. In the context of air cooled chillers, buyers may work directly with OEMs to source chillers or components, ensuring quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory levels and ensure that they meet supplier requirements while balancing their own needs for scalability and cost efficiency.

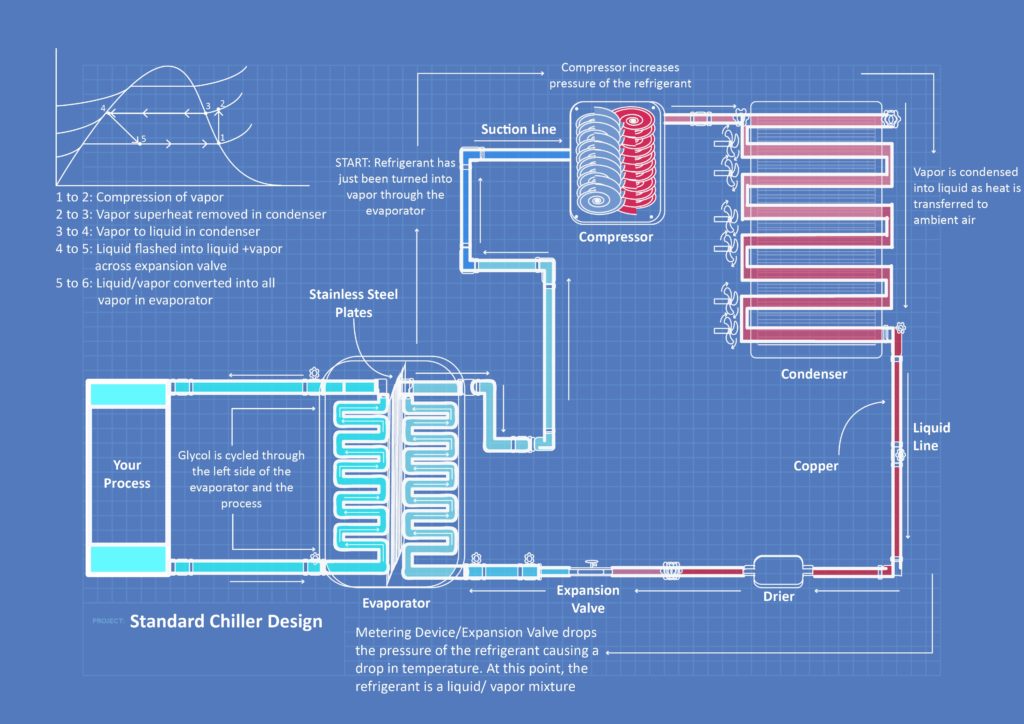

Illustrative image related to air cooled chiller cycle

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by buyers to solicit price quotes from suppliers for specific products or services. It is crucial for comparing costs and evaluating different suppliers in terms of pricing, terms, and specifications, thereby facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international shipping. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) helps buyers understand their obligations regarding shipping costs, risk transfer, and delivery, which can significantly affect overall procurement costs.

5. Warranty Period

The warranty period is the duration during which the manufacturer guarantees the performance and reliability of the chiller. Understanding warranty terms helps buyers assess the risk and value of their investment, as a longer warranty often indicates greater manufacturer confidence in the product’s durability.

Illustrative image related to air cooled chiller cycle

By grasping these essential technical properties and trade terminology, B2B buyers can make informed decisions when selecting air cooled chillers that align with their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the air cooled chiller cycle Sector

What Are the Global Drivers Influencing the Air Cooled Chiller Market?

The air cooled chiller market is experiencing robust growth driven by several global factors. Increasing urbanization, particularly in emerging economies in Africa and South America, is leading to heightened demand for efficient HVAC systems. As commercial and residential buildings proliferate, the need for reliable cooling solutions becomes paramount. Additionally, stringent regulations regarding energy efficiency and greenhouse gas emissions are pushing manufacturers to innovate and provide more sustainable options. In Europe and the Middle East, the focus is shifting towards advanced technologies that enhance energy efficiency while minimizing environmental impact.

Which B2B Tech and Sourcing Trends Are Emerging in the Air Cooled Chiller Sector?

A notable trend is the rise of smart technology integration within air cooled chillers. IoT-enabled systems allow for real-time monitoring and predictive maintenance, which can significantly reduce operational costs and downtime. Furthermore, the adoption of modular chiller systems is gaining traction, offering flexibility and scalability for businesses looking to optimize their cooling needs. As international buyers increasingly seek competitive pricing, sourcing from regions with lower manufacturing costs, such as Southeast Asia, is becoming common. This trend is particularly relevant for buyers from Brazil and Vietnam, who are looking for cost-effective yet reliable solutions.

How Are Sustainability and Ethical Sourcing Being Addressed in the Air Cooled Chiller Market?

Sustainability is becoming a cornerstone of purchasing decisions in the air cooled chiller sector. Buyers are increasingly aware of the environmental impact associated with HVAC systems, prompting a shift towards products that utilize eco-friendly refrigerants and energy-efficient technologies. Certifications such as Energy Star and LEED are gaining importance, as they signal compliance with stringent environmental standards. Additionally, ethical supply chains are crucial for fostering trust and credibility in business relationships. Companies that prioritize transparency in their sourcing practices and demonstrate a commitment to reducing their carbon footprint are more likely to attract discerning B2B buyers.

What Are the Key Environmental Considerations for Air Cooled Chillers?

The environmental impact of air cooled chillers is significant, particularly concerning energy consumption and refrigerant leakage. Traditional refrigerants can contribute to global warming, making the choice of refrigerants critical. The industry is gradually transitioning to low-GWP (Global Warming Potential) alternatives. Moreover, the efficiency of air cooled chillers is closely tied to their operational design and maintenance practices. Regular maintenance not only extends the lifespan of the equipment but also optimizes energy use, thus reducing environmental impact. As international buyers become more eco-conscious, they are increasingly favoring suppliers that prioritize sustainable practices.

Illustrative image related to air cooled chiller cycle

How Has the Air Cooled Chiller Market Evolved Over Time?

The air cooled chiller market has evolved significantly since its inception. Initially, these systems were primarily used in small to medium-sized commercial buildings. However, advancements in technology have led to the development of larger, more efficient units capable of servicing larger facilities. The integration of digital controls and smart technology has further transformed operational capabilities, allowing for more precise temperature control and energy management. As global awareness of climate change and energy conservation grows, the market continues to adapt, emphasizing sustainability and efficiency as key drivers of future innovation.

Conclusion: What Should B2B Buyers Consider When Sourcing Air Cooled Chillers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding market dynamics and sourcing trends is critical. As the demand for energy-efficient, sustainable solutions grows, buyers should prioritize suppliers that offer advanced technology, ethical sourcing practices, and environmentally friendly products. Engaging with manufacturers who are committed to innovation and sustainability will not only ensure compliance with regulations but also align with the values of eco-conscious consumers.

Frequently Asked Questions (FAQs) for B2B Buyers of air cooled chiller cycle

-

1. How do I choose the right air cooled chiller for my business needs?

Selecting the appropriate air cooled chiller involves evaluating your cooling requirements, including the size of the space, the heat load, and the ambient temperature conditions. Assess the chiller’s cooling capacity (measured in tons or kilowatts) and efficiency ratings (EER or COP). Consider additional factors such as noise levels, energy consumption, and maintenance requirements. Consulting with an HVAC professional or supplier can provide insights tailored to your specific operational needs and help you make an informed decision. -

2. What are the benefits of using air cooled chillers in commercial applications?

Air cooled chillers are advantageous for commercial settings due to their lower installation and maintenance costs compared to water cooled systems. They do not require cooling towers or extensive plumbing, simplifying the setup process. These chillers operate efficiently in moderate climates and are ideal for small to medium-sized buildings. Additionally, their environmental impact is reduced as they utilize ambient air for cooling, making them a sustainable choice for businesses aiming to minimize their carbon footprint. -

3. What are the common challenges when sourcing air cooled chillers internationally?

International sourcing of air cooled chillers can present challenges such as navigating regulatory compliance, shipping logistics, and tariffs. Buyers must ensure that the chillers meet local standards for efficiency and safety. Communication barriers may also arise, complicating negotiations and technical discussions. It’s essential to conduct thorough research on potential suppliers, including their reputation, certifications, and customer feedback, to mitigate these challenges effectively. -

4. How can I verify the reliability of a supplier for air cooled chillers?

To verify a supplier’s reliability, start by checking their industry certifications and compliance with international standards such as ISO. Request references from previous clients and seek testimonials regarding product performance and customer service. Conducting a site visit, if feasible, can also provide valuable insights into their manufacturing processes and quality control measures. Additionally, consider third-party reviews and ratings from industry-specific platforms to gauge the supplier’s reputation. -

5. What customization options are typically available for air cooled chillers?

Many manufacturers offer customization options for air cooled chillers to meet specific operational needs. Common customizations include varying cooling capacities, energy-efficient components, and control systems compatible with existing building management systems. Buyers can also request modifications related to size, noise reduction features, and refrigerant types. Discussing customization options with suppliers can lead to tailored solutions that enhance system performance and align with business goals. -

6. What is the typical minimum order quantity (MOQ) for air cooled chillers?

The minimum order quantity (MOQ) for air cooled chillers varies by supplier and can depend on factors such as the size and complexity of the units. Generally, manufacturers may set MOQs ranging from one unit to multiple units, especially for custom configurations. It’s advisable to inquire directly with suppliers to understand their MOQ policies and explore options for smaller orders if required. Some suppliers may offer flexibility for first-time buyers or bulk orders. -

7. What payment terms should I expect when purchasing air cooled chillers?

Payment terms for purchasing air cooled chillers can vary widely among suppliers. Common practices include upfront deposits (often 30-50%), followed by the balance due upon delivery or installation. Some suppliers may offer financing options or extended payment terms for large orders. It’s essential to clearly negotiate and document payment terms in the contract to avoid misunderstandings. Additionally, consider using secure payment methods to protect your investment during international transactions. -

8. How do I ensure quality assurance for air cooled chillers?

Quality assurance for air cooled chillers can be ensured by selecting suppliers that adhere to strict manufacturing standards and quality control processes. Request documentation of testing procedures, certifications, and warranties for the chillers. Conducting inspections during production and before shipment can help verify the quality of the units. Establishing a clear communication channel with the supplier for ongoing support and maintenance can further enhance the reliability of the equipment you purchase.

Top 2 Air Cooled Chiller Cycle Manufacturers & Suppliers List

1. Advantage Engineering – Water Chiller Schematic

Domain: advantageengineering.com

Registered: 1996 (29 years)

Introduction: Water Chiller Animated Schematic | Typical 2 – 30 Tons | Air-Cooled

Key Components:

1. Compressor: Removes refrigerant vapor from the evaporator, reduces pressure, and raises refrigerant vapor pressure for condensing.

2. Air-Cooled Condenser: Heat exchanger that releases process heat to the air, allowing vapor to condense to liquid.

3. High Pressure Limit: Protects against excessive pressure in t…

2. Johnson Controls – Chillers

Domain: johnsoncontrols.com

Registered: 1995 (30 years)

Introduction: This company, Johnson Controls – Chillers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for air cooled chiller cycle

In conclusion, the air-cooled chiller cycle presents a robust solution for businesses seeking efficient cooling systems, particularly in regions where water resources are scarce. These chillers offer numerous advantages, including lower operational costs, minimal maintenance needs, and ease of installation, making them ideal for small to medium-sized commercial applications. Strategic sourcing of air-cooled chillers not only ensures access to the latest technology but also enables buyers to negotiate better terms, optimize supply chain logistics, and enhance overall operational efficiency.

As international B2B buyers from Africa, South America, the Middle East, and Europe evaluate their cooling needs, it is essential to consider suppliers who can provide customized solutions that align with local climates and regulatory requirements. By leveraging strategic sourcing strategies, businesses can secure the best value while ensuring reliable performance and energy efficiency.

Looking ahead, the demand for sustainable and cost-effective cooling solutions will only grow. We encourage buyers to actively engage with suppliers and explore innovative technologies that can enhance the efficiency of air-cooled chiller systems. Investing in these solutions today will position your business for a more sustainable and profitable tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.