How to Source 8 Hardware Cloth Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for 8 hardware cloth

Navigating the complexities of sourcing 8 hardware cloth can be a daunting task for B2B buyers, especially in the diverse international markets of Africa, South America, the Middle East, and Europe, including countries like Germany and Brazil. With its myriad applications—from construction and landscaping to agricultural fencing and craft projects—understanding the specifications, types, and optimal uses of hardware cloth is crucial for making informed purchasing decisions.

This comprehensive guide delves into the various types of 8 hardware cloth available in the market, exploring their unique features, applications, and advantages. We provide actionable insights into supplier vetting, enabling you to identify reputable manufacturers and distributors that meet your quality and compliance standards. Additionally, we cover cost considerations, helping you navigate pricing structures and negotiate better deals.

Whether you’re looking to enhance your product offerings or seeking reliable materials for your next project, this guide empowers you with the knowledge needed to make strategic decisions. By equipping yourself with the right information, you can streamline your procurement process, minimize risks, and ensure that your investments in hardware cloth yield maximum value for your business. Embrace the opportunity to enhance your supply chain and meet the demands of your market with confidence.

Understanding 8 hardware cloth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Galvanized Steel | Corrosion-resistant, strong, and durable | Fencing, animal enclosures, construction sites | Pros: Long-lasting; Cons: Heavier than alternatives. |

| Stainless Steel | High corrosion resistance, aesthetic finish | Architectural applications, food processing | Pros: Excellent durability; Cons: Higher cost. |

| Welded Wire Mesh | Uniform openings, high tensile strength | Industrial applications, security barriers | Pros: Strong and secure; Cons: Less flexible. |

| PVC Coated | Weather-resistant, available in various colors | Landscaping, decorative applications | Pros: Aesthetic appeal; Cons: Can be less durable than metal. |

| Hardware Cloth | Variety of mesh sizes (1/4″, 1/2″, etc.) | Gardening, pest control, crafting | Pros: Versatile and easy to work with; Cons: Lower strength compared to welded options. |

What are the Characteristics and Suitability of Galvanized Steel Hardware Cloth?

Galvanized steel hardware cloth is coated with zinc to enhance corrosion resistance, making it ideal for outdoor applications. It is characterized by its strength and durability, often used in fencing, animal enclosures, and construction projects. B2B buyers should consider the weight of galvanized options, which can be heavier than other materials, potentially increasing shipping costs. Nevertheless, its longevity makes it a cost-effective choice for businesses looking for durable solutions.

How Does Stainless Steel Hardware Cloth Stand Out in the Market?

Stainless steel hardware cloth is known for its high resistance to corrosion and an appealing finish, making it suitable for both functional and aesthetic applications. It is commonly used in architectural designs and food processing environments where hygiene is critical. While the initial investment is higher compared to other materials, its durability and low maintenance costs can provide significant long-term savings, making it an attractive option for discerning B2B buyers.

Why Choose Welded Wire Mesh for Industrial Applications?

Welded wire mesh offers uniform openings and high tensile strength, making it a go-to choice for industrial applications such as security barriers and partitions. Its robust construction provides enhanced safety and security, which is crucial for businesses in sectors like manufacturing and logistics. However, its rigidity may limit flexibility in certain applications, so buyers should assess their specific needs before purchase.

What Advantages Does PVC Coated Hardware Cloth Offer?

PVC coated hardware cloth is designed for weather resistance and comes in a variety of colors, making it a popular choice for landscaping and decorative projects. Its coating not only enhances durability but also adds aesthetic value, making it suitable for visible installations. However, while it offers aesthetic benefits, the trade-off may be a reduction in overall strength compared to galvanized or stainless steel options, which should be considered based on the intended use.

How Versatile is Traditional Hardware Cloth for Various Uses?

Traditional hardware cloth is available in a range of mesh sizes, such as 1/4″ and 1/2″, making it a versatile option for gardening, pest control, and crafting projects. It is lightweight and easy to cut, allowing for customization in various applications. B2B buyers should note that while it is user-friendly, its strength may not match that of welded wire options, which could be a critical factor depending on the project’s requirements.

Key Industrial Applications of 8 hardware cloth

| Industry/Sector | Specific Application of 8 hardware cloth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop protection and pest control | Prevents damage from pests while allowing airflow | Need for durability, corrosion resistance, and size options |

| Construction | Reinforcement in concrete and masonry applications | Enhances structural integrity and reduces cracking | Gauge, mesh size, and compliance with local regulations |

| Beekeeping | Hive ventilation and pest exclusion | Maintains hive health by preventing unwanted pests | Lightweight, easy to cut, and specific mesh sizes |

| Landscaping & Gardening | Garden fencing and trellis supports | Protects plants from animals while providing support | Custom sizes and flexibility for various designs |

| Industrial Manufacturing | Filtration and screening in production processes | Improves efficiency by filtering out unwanted materials | Material type, mesh size, and compatibility with existing systems |

How is 8 hardware cloth utilized in agriculture for pest control?

In agriculture, 8 hardware cloth is extensively used for crop protection and pest control. Farmers utilize this material to create barriers that prevent animals and insects from damaging crops while allowing for adequate airflow and sunlight. This application is crucial in regions where pests are prevalent, as it directly impacts yield and quality. Buyers in this sector should consider the cloth’s durability, corrosion resistance, and appropriate mesh size to ensure effective protection against specific pests encountered in their local environments.

What role does 8 hardware cloth play in construction?

In the construction industry, 8 hardware cloth serves as a reinforcement material in concrete and masonry applications. It enhances structural integrity, reducing the risk of cracking and other structural failures. This application is especially relevant in areas with fluctuating temperatures or seismic activity. B2B buyers must focus on sourcing cloth that meets specific gauge requirements and local building codes to ensure compliance and safety in their projects.

How does 8 hardware cloth benefit beekeeping operations?

Beekeepers use 8 hardware cloth for hive ventilation and pest exclusion, which is essential for maintaining hive health. The fine mesh allows airflow while preventing pests, such as mice and other critters, from entering the hive. This application not only protects the bees but also contributes to their productivity. Buyers should prioritize lightweight options that are easy to cut and adapt to various hive sizes, ensuring they meet the unique needs of their beekeeping operations.

In what ways is 8 hardware cloth useful in landscaping and gardening?

In landscaping and gardening, 8 hardware cloth is commonly used for creating garden fencing and trellis supports. It protects plants from animals while providing structural support for climbing plants. This application is valuable for gardeners looking to maintain a healthy ecosystem without using harmful chemicals. Buyers should consider the flexibility and availability of custom sizes to accommodate various garden designs and layouts, ensuring optimal functionality.

How does 8 hardware cloth enhance industrial manufacturing processes?

In industrial manufacturing, 8 hardware cloth is utilized for filtration and screening in various production processes. It helps improve operational efficiency by filtering out unwanted materials and contaminants. This application is critical in sectors such as food processing, pharmaceuticals, and chemical manufacturing. Buyers should focus on sourcing materials that meet specific mesh sizes and material types, ensuring compatibility with existing systems and compliance with industry standards.

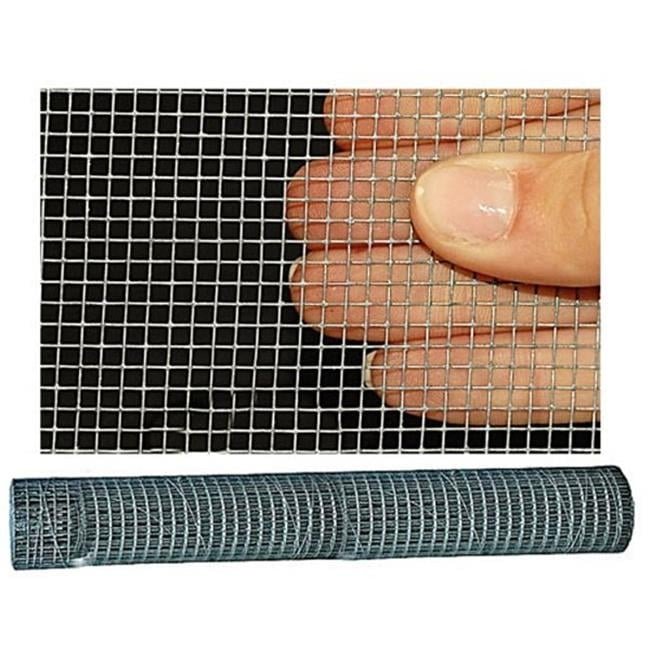

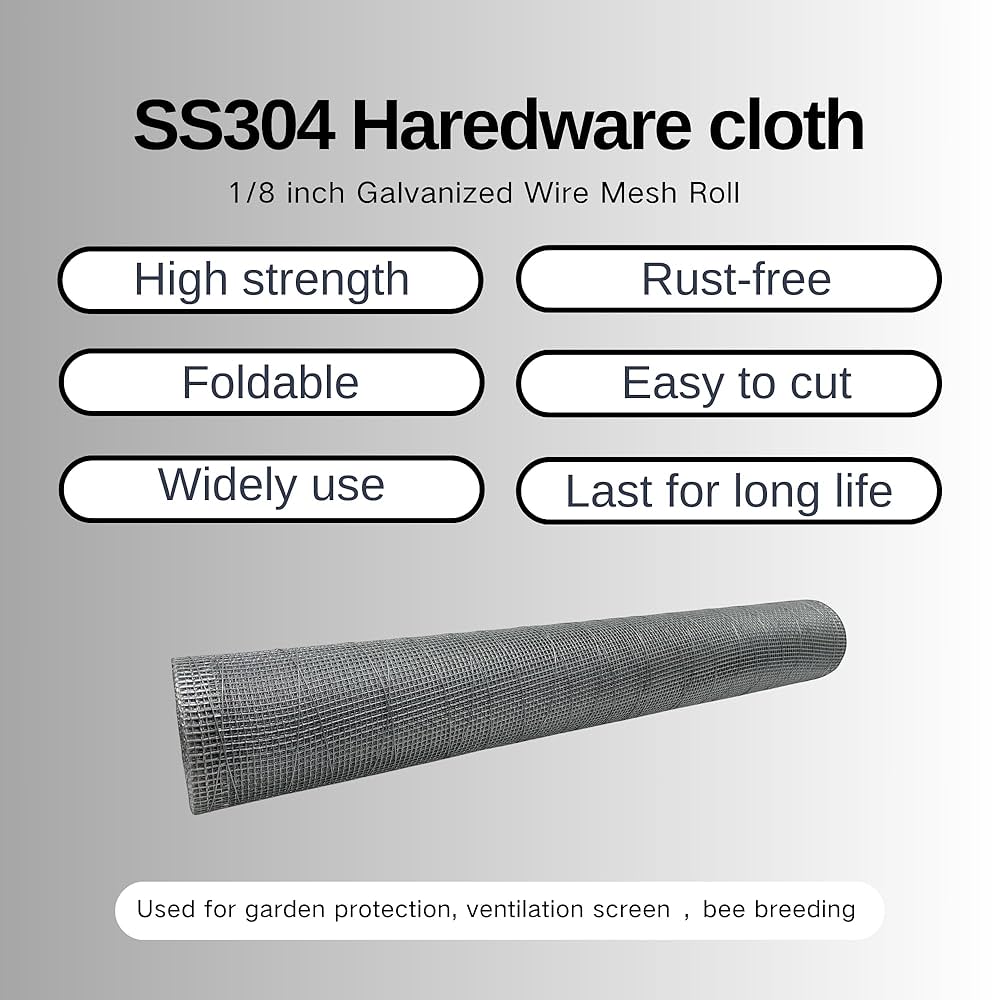

Illustrative image related to 8 hardware cloth

3 Common User Pain Points for ‘8 hardware cloth’ & Their Solutions

Scenario 1: Sourcing Quality and Specifications for Unique Applications

The Problem: B2B buyers often struggle to find high-quality hardware cloth that meets specific project requirements, especially when dealing with unique applications such as beekeeping or specialized construction. Many suppliers offer generic options, but these may not fulfill the necessary criteria for durability, mesh size, or corrosion resistance. This can lead to project delays, increased costs, and subpar outcomes if the wrong materials are used.

The Solution: To effectively source the right hardware cloth, buyers should start by clearly defining their project specifications, including desired mesh size, gauge, and material type (e.g., galvanized steel for corrosion resistance). Utilizing detailed product catalogs from reputable manufacturers can provide insight into various options available on the market. Additionally, reaching out to suppliers for samples can help assess quality before committing to a bulk order. Engaging with suppliers that specialize in niche applications, such as those offering #8 hardware cloth for beekeeping, ensures that the chosen product aligns with the specific needs of the project, minimizing risks and optimizing performance.

Scenario 2: Installation Challenges with Different Mesh Types

The Problem: Buyers frequently encounter difficulties during the installation of hardware cloth due to varying mesh types and gauges. Improper installation can lead to significant issues, such as gaps that allow pests to infiltrate, compromising the integrity of the structure or enclosure. Furthermore, the flexibility and cutability of different cloth types can create confusion, especially for teams with limited experience in handling such materials.

The Solution: To overcome installation challenges, it is crucial to invest time in proper training for the installation team. Suppliers often provide installation guides and resources that can aid in understanding the nuances of different hardware cloth types. For instance, opting for a lightweight yet durable option like #8 hardware cloth can facilitate easier handling and cutting with tools like tin snips. Additionally, pre-measuring and planning the layout before installation can prevent costly mistakes. If possible, consider hiring a professional installation service that specializes in hardware cloth applications to ensure that the installation is executed correctly and efficiently.

Scenario 3: Long-Term Durability and Maintenance Concerns

The Problem: After the initial installation, many B2B buyers face long-term durability and maintenance issues with hardware cloth. Factors such as environmental conditions, exposure to moisture, and physical wear can degrade the material over time. This is particularly problematic in regions with extreme weather, where the integrity of the cloth is critical for functionality and safety.

The Solution: To address durability concerns, buyers should choose high-quality, galvanized hardware cloth known for its resistance to corrosion and wear. It is also beneficial to conduct regular inspections and maintenance to identify any signs of wear or damage early on. Establishing a maintenance schedule that includes cleaning and repairs can prolong the lifespan of the hardware cloth. Furthermore, suppliers may offer maintenance products or protective coatings that can enhance durability against environmental factors. By being proactive in maintenance and selecting the right product from the beginning, buyers can ensure long-lasting performance and minimize replacement costs in the future.

Strategic Material Selection Guide for 8 hardware cloth

What Are the Key Materials Used in 8 Hardware Cloth?

When selecting hardware cloth, especially for international B2B applications, understanding the various materials available is crucial. The choice of material can significantly influence performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the production of 8 hardware cloth: galvanized steel, stainless steel, aluminum, and vinyl-coated wire.

How Does Galvanized Steel Perform in 8 Hardware Cloth Applications?

Galvanized steel is a popular choice for hardware cloth due to its excellent corrosion resistance, achieved through a protective zinc coating. This material can withstand moderate temperatures and pressures, making it suitable for various applications, including fencing, animal enclosures, and garden projects.

Pros:

– High durability and strength, ideal for outdoor use.

– Cost-effective compared to stainless steel.

– Easy to work with and install.

Illustrative image related to 8 hardware cloth

Cons:

– The zinc coating can wear off over time, especially in harsh environments, leading to rust.

– Limited temperature resistance compared to stainless steel.

Impact on Application:

Galvanized steel hardware cloth is particularly effective in environments where moisture is present, such as gardens or agricultural settings. However, it may not be suitable for applications involving exposure to acidic or alkaline substances.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure compliance with local standards for galvanization. Familiarity with ASTM standards can help in assessing quality.

What Advantages Does Stainless Steel Offer for 8 Hardware Cloth?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it a premium choice for hardware cloth. It can handle a wide range of temperatures and is less likely to degrade over time.

Pros:

– Superior durability and longevity, even in harsh environments.

– High resistance to corrosion, making it suitable for coastal areas.

Cons:

– Higher cost compared to galvanized steel.

– More challenging to cut and work with due to its strength.

Impact on Application:

Stainless steel hardware cloth is ideal for applications requiring high hygiene standards, such as food processing or pharmaceutical industries. Its non-reactive nature makes it suitable for sensitive environments.

Considerations for International Buyers:

European buyers, particularly in Germany, often prefer stainless steel due to stringent quality standards (DIN). Ensuring compliance with local regulations is essential.

How Does Aluminum Compare as a Material for 8 Hardware Cloth?

Aluminum hardware cloth is lightweight and resistant to corrosion, making it an attractive option for various applications. It is particularly useful in scenarios where weight is a concern, such as in portable fencing or temporary enclosures.

Pros:

– Lightweight and easy to handle.

– Naturally resistant to rust and corrosion.

Cons:

– Less durable than steel options, particularly under heavy loads.

– Can be more expensive than galvanized steel.

Impact on Application:

Aluminum is suitable for applications where flexibility and ease of installation are prioritized. However, it may not hold up well in high-stress environments.

Considerations for International Buyers:

Buyers in the Middle East may find aluminum appealing due to its resistance to saltwater corrosion, making it ideal for coastal applications. Understanding local material preferences can enhance procurement strategies.

What Role Does Vinyl-Coated Wire Play in 8 Hardware Cloth?

Vinyl-coated wire offers an additional layer of protection over traditional wire mesh, enhancing durability and aesthetic appeal. This coating provides resistance to corrosion and UV degradation, making it suitable for outdoor applications.

Pros:

– Enhanced corrosion resistance and aesthetics.

– Available in various colors, allowing for design flexibility.

Cons:

– The coating can wear off over time, especially in high-traffic areas.

– Generally more expensive than uncoated wire options.

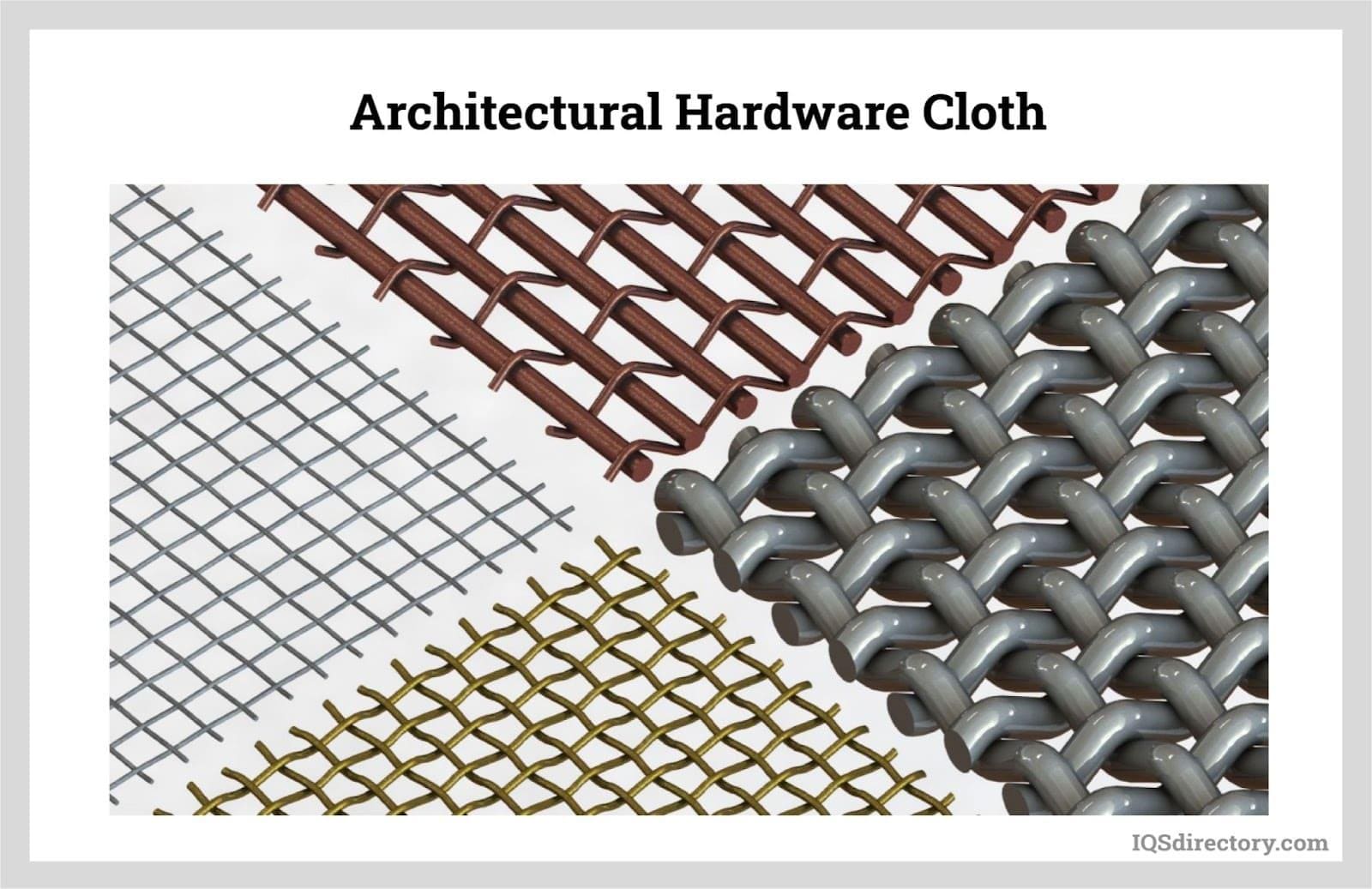

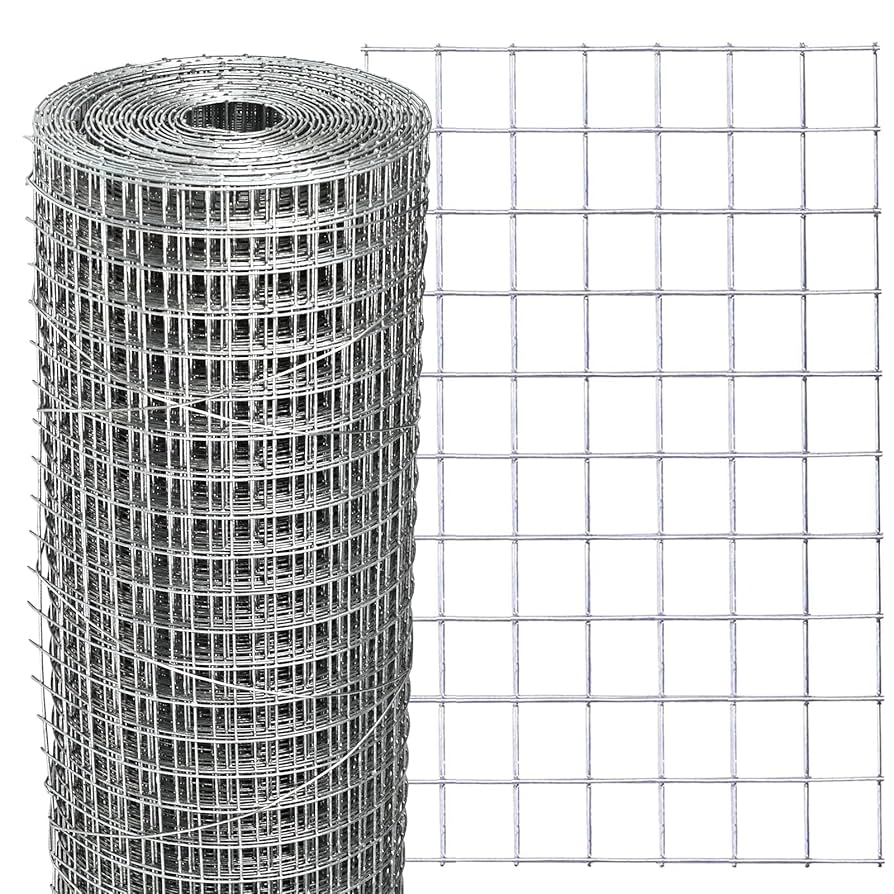

Illustrative image related to 8 hardware cloth

Impact on Application:

Vinyl-coated hardware cloth is ideal for decorative fencing and garden applications where appearance matters. It also provides a safer option for environments involving children or pets.

Considerations for International Buyers:

Buyers should verify the quality of the vinyl coating and ensure it meets local environmental regulations, particularly in Europe, where standards for chemical safety are stringent.

Summary Table of Material Selection for 8 Hardware Cloth

| Material | Typical Use Case for 8 Hardware Cloth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Fencing, animal enclosures | Cost-effective and durable | Susceptible to rust over time | Low |

| Stainless Steel | Food processing, pharmaceutical use | Superior corrosion resistance | Higher cost and harder to work with | High |

| Aluminum | Portable fencing, temporary enclosures | Lightweight and easy to handle | Less durable under heavy loads | Medium |

| Vinyl-Coated Wire | Decorative fencing, garden applications | Enhanced aesthetics and corrosion resistance | Coating can wear off over time | Medium |

This guide provides a comprehensive overview of material options for 8 hardware cloth, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 8 hardware cloth

What Are the Key Stages in the Manufacturing Process of 8 Hardware Cloth?

The manufacturing of hardware cloth, particularly the #8 variant, involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. Here’s an overview of the main stages:

Material Preparation: What Raw Materials Are Used?

The primary raw materials for hardware cloth are steel wires, typically galvanized to enhance corrosion resistance. The wire is usually produced in bulk rolls, which are then cut to the required gauge and length. Galvanization involves coating the steel with a layer of zinc, which protects it from rust and extends its lifespan, making it suitable for various applications in different environments.

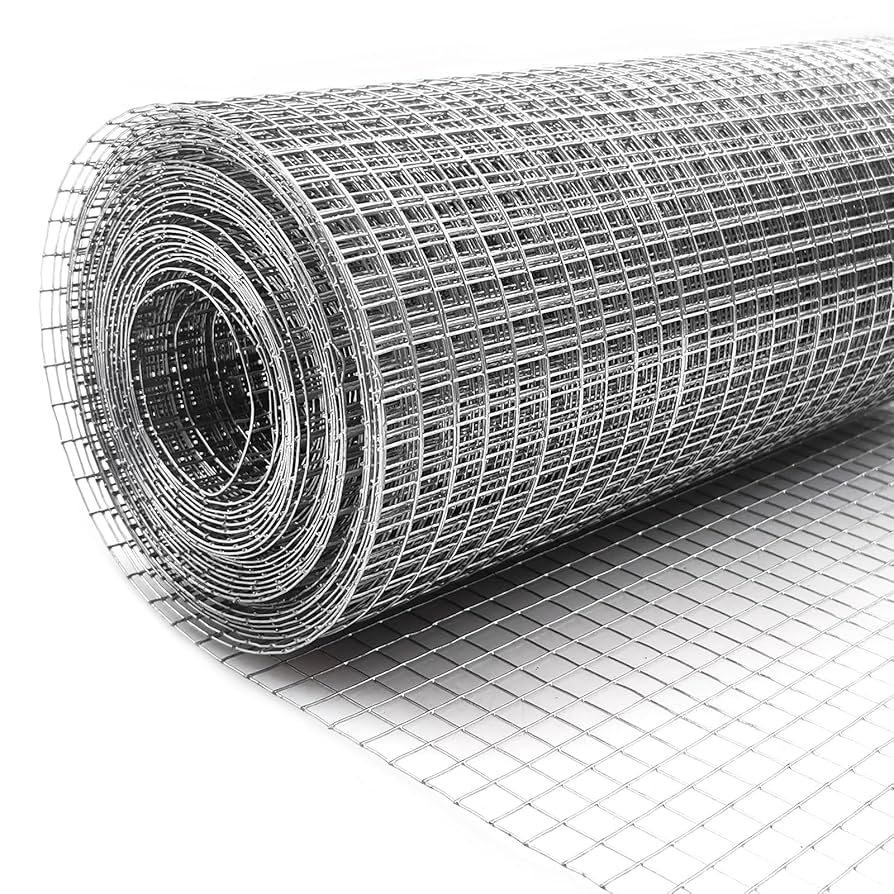

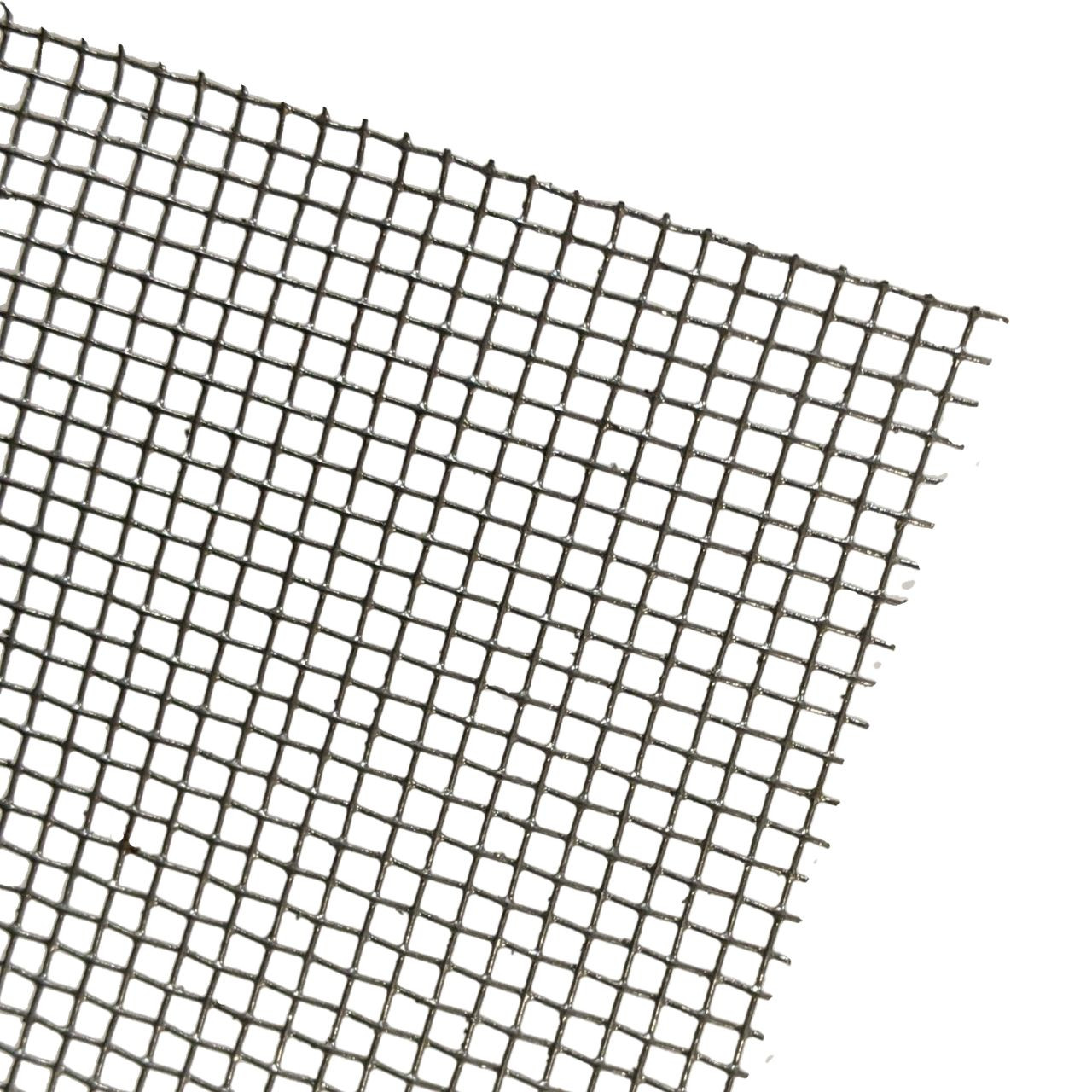

Illustrative image related to 8 hardware cloth

Forming: How Is Hardware Cloth Structured?

Once the wires are prepared, they undergo a forming process. The wires are woven or welded together to create a mesh. In the case of welded hardware cloth, wires are arranged in a grid pattern and then welded at the intersections using high-frequency electric resistance welding techniques. This results in a strong, durable product that can withstand significant tension and stress, making it ideal for fencing, gardening, and industrial uses.

Assembly: Are There Additional Components?

After forming, the hardware cloth may undergo assembly, where it is cut to specific dimensions or shapes required by the customer. This stage may also include adding protective coatings or treatments to enhance durability and resistance to environmental factors. Customization options are available for B2B clients who may need specific sizes or mesh configurations.

Finishing: What Final Treatments Are Applied?

The finishing process often involves additional treatments such as coating with PVC or powder for enhanced weather resistance. These coatings not only improve the aesthetic appeal of the hardware cloth but also add to its longevity, especially in harsh climates. Quality finishing ensures the product meets international standards for safety and performance.

What Quality Assurance Measures Are Critical for Hardware Cloth?

Quality assurance (QA) is paramount in the manufacturing of hardware cloth, particularly for international B2B transactions. Below are key QA measures that ensure product reliability and compliance with industry standards.

Which International Standards Should B2B Buyers Be Aware Of?

Compliance with international standards such as ISO 9001 is essential for manufacturers. ISO 9001 outlines the criteria for a quality management system, emphasizing consistent quality and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the specific use case of the hardware cloth, especially in construction and industrial applications.

Illustrative image related to 8 hardware cloth

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps detect defects early, allowing for immediate corrective actions.

- Final Quality Control (FQC): The finished product undergoes rigorous testing to ensure it meets all required specifications before shipping.

How Are Common Testing Methods Conducted?

Testing methods vary but generally include tensile strength tests, mesh size inspections, and corrosion resistance evaluations. B2B buyers should inquire about the specific tests conducted and the results to ensure the product meets their needs.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying supplier quality control practices is crucial to ensure product reliability. Here are some strategies:

What Audits and Reports Should Buyers Request?

Buyers should request documentation of quality audits conducted by third parties. These reports provide insights into the manufacturer’s compliance with quality standards and their overall production capabilities.

How Can Third-Party Inspections Be Utilized?

Engaging third-party inspection services during the production process can provide an additional layer of assurance. These inspectors can verify that manufacturing processes align with international standards and the buyer’s specifications, offering peace of mind.

What Are the QC and Certification Nuances for International Buyers?

When dealing with international suppliers, it’s essential to understand the nuances of QC and certification. Different regions may have varying standards, so B2B buyers should ensure that the supplier’s certifications are recognized in their target markets.

Illustrative image related to 8 hardware cloth

For instance, European buyers may require CE marking, while North American buyers might prioritize compliance with ASTM (American Society for Testing and Materials) standards. It’s advisable for buyers to establish clear communication with suppliers about the necessary certifications and to conduct due diligence on the supplier’s track record in meeting these standards.

Conclusion: Ensuring Quality in Hardware Cloth Procurement

In summary, understanding the manufacturing processes and quality assurance measures for #8 hardware cloth is critical for B2B buyers. By familiarizing themselves with the stages of production, key international standards, and effective verification methods, buyers can make informed decisions, ensuring they procure high-quality products that meet their specific needs. This knowledge is particularly vital for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, where product reliability and compliance can significantly impact operational success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘8 hardware cloth’

In today’s competitive marketplace, sourcing the right hardware cloth is crucial for businesses involved in construction, agriculture, or home improvement. This guide provides a systematic approach for B2B buyers to effectively procure #8 hardware cloth, ensuring that they meet their project requirements while maximizing value.

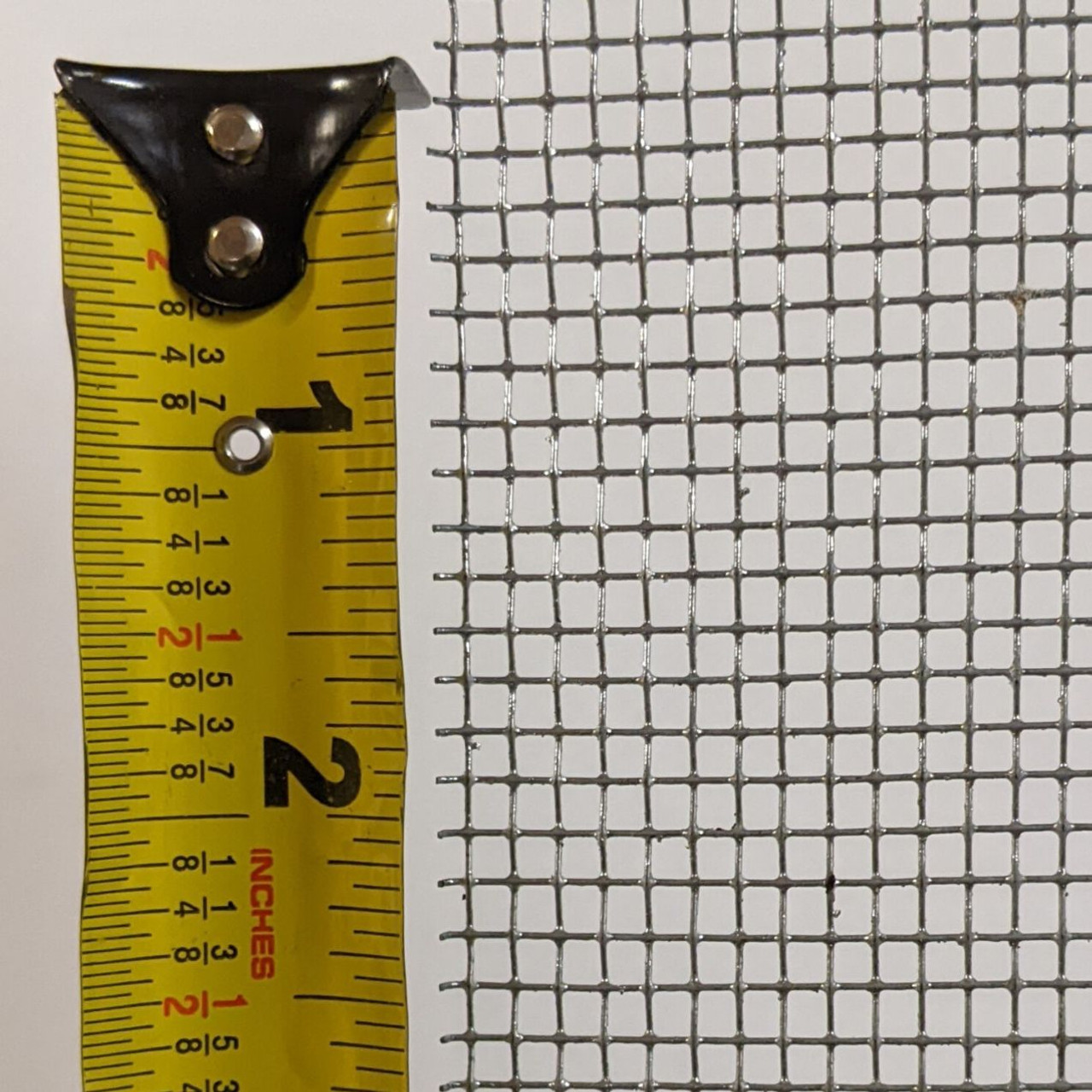

Step 1: Define Your Technical Specifications

Understanding your specific needs is the foundation of effective sourcing. Determine the mesh size, gauge, and material type that best suits your application—whether for fencing, ventilation, or other uses. For example, #8 hardware cloth typically features 1/8-inch openings and 27-gauge galvanized steel, which provides a balance of strength and flexibility.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in hardware cloth. Look for companies with a strong reputation in your target markets, such as Africa, South America, the Middle East, and Europe. Utilize platforms like industry trade shows, online directories, and local business networks to compile a list of potential suppliers.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. Check for ISO certifications or any regional quality assurance certifications that may apply. This step ensures that the products meet safety and quality regulations, which is especially important in markets with strict compliance requirements.

Step 4: Request Samples for Quality Assessment

Always request product samples before placing a bulk order. This allows you to assess the material’s durability, flexibility, and overall quality firsthand. Pay attention to the finish and gauge of the hardware cloth to ensure it aligns with your specifications and can withstand the intended environmental conditions.

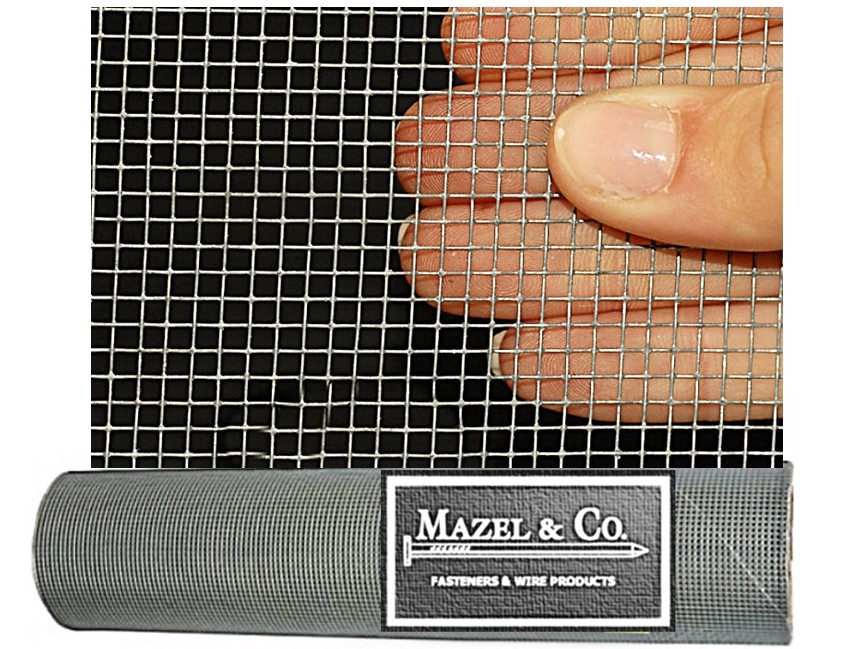

Illustrative image related to 8 hardware cloth

Step 5: Analyze Pricing Structures

Pricing can vary significantly among suppliers. Obtain detailed quotes that include shipping costs, taxes, and any additional fees. Compare these costs while considering the quality of the product and the reliability of the supplier. It’s essential to balance cost-effectiveness with quality to avoid future issues.

Step 6: Negotiate Terms and Conditions

Once you have identified a preferred supplier, engage in negotiations regarding payment terms, delivery schedules, and warranty conditions. Clear communication of your expectations can prevent misunderstandings and ensure smoother transactions. Look for suppliers who offer favorable terms, such as bulk discounts or flexible payment options.

Step 7: Establish a Logistics Plan

Finally, develop a logistics plan for the delivery of your hardware cloth. Consider factors such as lead time, shipping methods, and potential customs regulations in your region. Ensure that your supplier can provide tracking information and timely updates to avoid disruptions in your supply chain.

By following this checklist, B2B buyers can navigate the complexities of sourcing #8 hardware cloth effectively, ensuring they secure the best products for their projects while establishing reliable supplier relationships.

Illustrative image related to 8 hardware cloth

Comprehensive Cost and Pricing Analysis for 8 hardware cloth Sourcing

In the realm of sourcing hardware cloth, understanding the comprehensive cost structure is crucial for international B2B buyers. The overall pricing for hardware cloth involves several critical components, including materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

What Are the Key Cost Components for Hardware Cloth?

Materials: The primary cost driver for hardware cloth is the raw materials used, typically galvanized steel. The cost can fluctuate based on market conditions, such as the price of steel, which is subject to global supply and demand dynamics.

Labor and Manufacturing Overhead: Labor costs can vary significantly by region. In countries with higher labor costs, such as Germany, the overall manufacturing cost may increase. Manufacturing overhead, including utilities and facility maintenance, also impacts pricing.

Tooling and Quality Control: Initial tooling costs can be substantial, particularly for custom specifications. Quality control processes ensure that the product meets industry standards, which can add to the total cost but is essential for maintaining a reliable supply chain.

Logistics: Shipping and handling costs are particularly significant for international buyers. Factors such as distance, shipping methods, and customs duties can considerably affect the final price.

Illustrative image related to 8 hardware cloth

Margin: Suppliers will typically add a profit margin that varies based on the complexity of the product, competition, and market demand.

How Do Price Influencers Affect Hardware Cloth Pricing?

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to lower per-unit costs. Suppliers are more willing to negotiate pricing for higher volumes, making it essential for buyers to assess their needs accurately.

Specifications and Customization: Customized hardware cloth, such as specific mesh sizes or materials, generally incurs additional costs. Buyers should consider whether standard products meet their needs to avoid unnecessary expenses.

Material Quality and Certifications: Higher-quality materials or certifications (e.g., ISO, ASTM) can increase costs but provide assurance of durability and compliance with industry standards. Buyers should evaluate the trade-off between cost and quality based on their applications.

Illustrative image related to 8 hardware cloth

Supplier Factors: The reputation, reliability, and location of the supplier can influence pricing. Established suppliers might charge a premium but offer better service and quality assurance.

Incoterms: Understanding Incoterms is vital for international transactions. They define who is responsible for shipping, insurance, and tariffs, which can significantly impact the total landed cost of goods.

What Tips Can Help Buyers Negotiate Better Prices?

Effective Negotiation Strategies: Engage in discussions with multiple suppliers to gauge the market rate. Leverage bulk purchasing power and explore long-term contracts for better pricing.

Focus on Cost Efficiency: Calculate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as durability, maintenance, and potential replacement costs when evaluating suppliers.

Be Aware of Pricing Nuances in International Markets: Pricing can vary widely based on geographical factors. For instance, buyers in Africa and South America may face different logistics and import duties compared to those in Europe. Understanding local market conditions can provide leverage during negotiations.

Request Samples: Before committing to large orders, request samples to evaluate quality. This can help avoid costly mistakes and ensure that the product meets your specifications.

Conclusion

In summary, sourcing hardware cloth requires a thorough understanding of cost components and price influencers. By focusing on negotiation strategies, cost-efficiency, and the nuances of international markets, buyers can make informed decisions that align with their operational needs while optimizing their budgets. As prices can fluctuate, it’s advisable to seek indicative pricing and maintain flexibility in sourcing strategies.

Alternatives Analysis: Comparing 8 hardware cloth With Other Solutions

Exploring Alternatives to 8 Hardware Cloth

When considering fencing, screening, or protective applications, it’s essential for businesses to evaluate various materials and methods that can effectively meet their needs. While 8 hardware cloth is a popular choice, alternatives exist that may offer distinct advantages depending on the specific application and context. Below is a comparison of 8 hardware cloth against two viable alternatives: welded wire fencing and plastic mesh fencing.

| Comparison Aspect | 8 Hardware Cloth | Welded Wire Fencing | Plastic Mesh Fencing |

|---|---|---|---|

| Performance | High tensile strength; durable; resistant to pests | Very strong; suitable for livestock and heavy-duty applications | Lightweight; good for temporary or low-security uses |

| Cost | Moderate, varies by gauge and size | Generally higher due to material and construction | Low-cost, but durability can vary significantly |

| Ease of Implementation | Requires tools for cutting and installation; can be customized | Requires more effort for installation; may need professional help | Easy to install; often comes in rolls and can be cut with scissors |

| Maintenance | Low maintenance; galvanized options resist corrosion | Low maintenance; sturdy construction can last years | Moderate maintenance; UV degradation over time |

| Best Use Case | Ideal for garden fencing, animal enclosures, and ventilation | Best for securing large areas, livestock fencing, and industrial applications | Suitable for temporary barriers, garden protection, and lightweight projects |

Detailed Breakdown of Alternatives

Welded Wire Fencing

Welded wire fencing is known for its strength and durability, making it a popular choice for agricultural and industrial applications. Its construction involves welding vertical and horizontal wires at the intersection points, creating a rigid and sturdy barrier. This type of fencing is particularly effective for livestock containment and offers a longer lifespan than many alternatives. However, the installation can be labor-intensive and may require specialized tools or professional assistance, which can increase overall costs.

Illustrative image related to 8 hardware cloth

Plastic Mesh Fencing

Plastic mesh fencing is a lightweight and cost-effective alternative. It is often used for temporary solutions, such as construction sites or garden protection. The ease of installation is one of its primary advantages, as it can be quickly rolled out and cut to size with basic tools. However, while it is resistant to rust and corrosion, it may not withstand heavy pressure or animal interactions as effectively as metal options. Additionally, UV exposure can lead to degradation over time, necessitating more frequent replacements.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers navigating the options available for fencing and protective materials, understanding the unique characteristics of each alternative is crucial. When choosing between 8 hardware cloth, welded wire fencing, and plastic mesh fencing, consider factors such as the intended application, budget constraints, and installation capabilities. By aligning these aspects with the specific needs of the project, businesses can make informed decisions that ensure long-lasting and effective solutions for their operations.

Essential Technical Properties and Trade Terminology for 8 hardware cloth

What Are the Key Technical Properties of 8 Hardware Cloth?

When considering 8 hardware cloth for various applications, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications that buyers should be aware of:

Illustrative image related to 8 hardware cloth

-

Material Grade

Hardware cloth is typically made from galvanized steel, which offers excellent corrosion resistance. The quality of the material influences the cloth’s durability and lifespan. Higher-grade materials can withstand harsher environments, making them suitable for outdoor use and in industrial applications. -

Wire Gauge

The wire gauge indicates the thickness of the wire used in the hardware cloth. Common gauges range from 19 to 27. A lower gauge number signifies a thicker wire, which generally provides greater strength and durability. Buyers must choose the appropriate gauge based on the intended use, such as fencing, animal enclosures, or crafting projects. -

Mesh Size

Mesh size refers to the openings between the wires in the cloth. Standard sizes include 1/4 inch and 1/2 inch, which dictate what can pass through the mesh. Smaller openings are ideal for keeping out small animals or insects, while larger sizes may be better for ventilation or visibility. Understanding the correct mesh size is crucial for ensuring the cloth meets specific application requirements. -

Roll Length and Width

Hardware cloth is available in various roll sizes, typically ranging from 25 feet to 100 feet in length and widths of 2 feet to 4 feet. This flexibility allows buyers to select the appropriate size for their projects without excess waste. Assessing the dimensions needed for specific applications can lead to cost savings and improved efficiency. -

Finish and Coating

The finish of the hardware cloth can significantly affect its performance. Options include hot-dipped galvanization for enhanced corrosion resistance and vinyl coatings for additional weather protection. Choosing the right finish is vital for applications exposed to moisture or corrosive environments, particularly in regions with extreme weather conditions.

What Are Common Trade Terms Related to 8 Hardware Cloth?

Understanding industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some key terms related to hardware cloth:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products based on specifications provided by another company. In the context of hardware cloth, OEM suppliers may offer custom sizes or materials tailored to specific project requirements. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of MOQs to ensure they can meet the supplier’s requirements while also balancing their inventory needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For hardware cloth, an RFQ may include details such as material specifications, quantities, and delivery timelines. This is a critical step in the procurement process for ensuring competitive pricing. -

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international trade. Understanding these terms is essential for B2B buyers, as they dictate who is responsible for shipping, insurance, and tariffs when purchasing hardware cloth from overseas suppliers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This is particularly important for businesses that rely on timely delivery to meet project deadlines. Buyers should inquire about lead times when negotiating contracts to avoid disruptions in their operations.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing 8 hardware cloth more effectively, ensuring that they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the 8 hardware cloth Sector

What Are the Current Market Dynamics and Key Trends in the 8 Hardware Cloth Sector?

The global hardware cloth market is witnessing significant transformation driven by rising urbanization, increased DIY projects, and a growing emphasis on home and garden improvement. B2B buyers from regions such as Africa, South America, the Middle East, and Europe, particularly Germany and Brazil, are increasingly sourcing hardware cloth for diverse applications ranging from construction to agricultural fencing. Notably, the demand for galvanized steel hardware cloth is surging due to its durability and corrosion resistance, making it a preferred choice in various industrial and agricultural settings.

Emerging technologies are also reshaping sourcing trends. E-commerce platforms and digital supply chains have enabled buyers to access a wider range of products and suppliers, facilitating competitive pricing and faster delivery. Additionally, the integration of advanced analytics in procurement processes allows businesses to make data-driven decisions regarding supplier selection and inventory management, ensuring optimal stock levels and reducing overhead costs.

Another key trend is the increasing focus on customization. Buyers are seeking specific mesh sizes and gauges to meet unique project requirements, prompting manufacturers to offer tailored solutions. This trend is particularly evident among businesses engaged in niche sectors, such as beekeeping and landscaping, where specialized hardware cloth configurations are essential.

Illustrative image related to 8 hardware cloth

How Are Sustainability and Ethical Sourcing Impacting the 8 Hardware Cloth Market?

In the context of hardware cloth, sustainability has become a crucial consideration for B2B buyers. The environmental impact of production processes and the materials used in hardware cloth are increasingly under scrutiny. Buyers are now prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and adopting eco-friendly practices. This includes sourcing raw materials from sustainably managed forests or utilizing recycled metals in production.

Ethical supply chains are equally important. Businesses are recognizing the need for transparency in sourcing practices, particularly concerning labor conditions and environmental stewardship. Buyers are more inclined to partner with suppliers who possess certifications such as ISO 14001 for environmental management and other ‘green’ certifications that attest to responsible manufacturing practices.

The trend towards sustainability is also reflected in the growing demand for eco-friendly materials. Products that are PVC-coated or made from recycled materials are gaining traction, as they offer both durability and a reduced environmental impact. As such, international buyers should actively seek out suppliers who can provide sustainable options that align with their corporate social responsibility goals.

What Is the Historical Context of the 8 Hardware Cloth Industry?

The evolution of hardware cloth can be traced back to the early 20th century when it was primarily used in agricultural applications and home construction. Initially made from woven wire, the introduction of welded wire mesh revolutionized the industry by providing enhanced strength and durability. Over the decades, the material has diversified, with advancements in galvanization techniques improving corrosion resistance and longevity.

As urbanization increased, the applications for hardware cloth expanded beyond traditional uses. It began to serve various sectors including construction, landscaping, and even arts and crafts. The demand for customized solutions has further propelled innovation, leading to the development of specialized hardware cloth options tailored for specific industries, such as beekeeping and pest control.

Today, the hardware cloth market is characterized by a blend of traditional applications and modern innovations, with international B2B buyers seeking both quality and sustainability in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of 8 hardware cloth

-

How do I choose the right hardware cloth for my application?

Selecting the appropriate hardware cloth involves assessing your specific needs. Consider factors such as mesh size, gauge (thickness), and material (galvanized steel, stainless steel, etc.). For example, a finer mesh size (like 1/8″) is ideal for small animals and ventilation, while a larger mesh size (like 1/2″) may be better for larger fencing projects. Additionally, evaluate the environmental conditions; galvanized options offer corrosion resistance, making them suitable for outdoor use. Always consult with suppliers for recommendations based on your project’s requirements. -

What is the best gauge of hardware cloth for fencing purposes?

The best gauge for hardware cloth used in fencing typically ranges from 14 to 19. A 14-gauge cloth provides a robust barrier against larger animals, while a 19-gauge option is lighter and more suited for smaller animal control or garden protection. Consider the specific threats in your area; for instance, if larger animals are prevalent, opt for a heavier gauge. Always balance strength with cost-effectiveness based on your project’s budget and expected wear. -

How can I verify the credibility of a hardware cloth supplier?

To vet a hardware cloth supplier, conduct thorough research by checking their business credentials, customer reviews, and years of operation. Request samples to assess product quality and inquire about certifications, such as ISO or industry-specific standards. Engaging in direct communication can also reveal their responsiveness and willingness to address your concerns. Additionally, connecting with other businesses in your network who have sourced from the supplier can provide firsthand insights into their reliability. -

What are the common payment terms in international hardware cloth transactions?

Payment terms can vary widely depending on the supplier and the buyer’s location. Common arrangements include advance payment, letter of credit, or payment upon delivery. It’s essential to negotiate terms that protect both parties. For large orders, consider installment payments based on shipment milestones. Always ensure that payment methods are secure, and consider using escrow services for high-value transactions to mitigate risk. -

What is the minimum order quantity (MOQ) for hardware cloth?

Minimum order quantities for hardware cloth can vary significantly by supplier, typically ranging from 100 to 1,000 square feet or more. Factors influencing MOQ include the supplier’s production capacity, material availability, and shipping logistics. If your project requires a smaller quantity, inquire about the possibility of combining orders with other buyers or sourcing through a distributor that caters to smaller purchases. -

How can I customize hardware cloth for specific applications?

Customization options for hardware cloth include varying mesh sizes, gauges, and roll dimensions. Many suppliers offer the ability to create custom-sized rolls based on your project requirements. For specialized applications, such as unique architectural designs or specific industrial uses, discuss your needs directly with the supplier. They may also provide additional treatments, like PVC coating, to enhance durability and weather resistance. -

What logistics considerations should I keep in mind when importing hardware cloth?

When importing hardware cloth, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. Choose a reliable freight forwarder familiar with your region’s import laws to ensure smooth clearance. Also, factor in potential tariffs and duties that may apply, as these can affect overall costs. Planning for storage upon arrival is crucial, as some materials may require specific conditions to maintain quality. -

What quality assurance measures should I expect from hardware cloth suppliers?

Quality assurance measures can include product testing for strength, durability, and compliance with industry standards. Suppliers should provide certificates of quality, detailing the material specifications and testing results. It’s advisable to request information on their manufacturing processes, including any quality control checks performed throughout production. Establishing clear expectations in your contract regarding quality standards will help ensure you receive a product that meets your specifications.

Top 5 8 Hardware Cloth Manufacturers & Suppliers List

1. McNICHOLS – Square Wire Mesh Galvanized 340817

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: {‘Product_Name’: ‘Square Wire Mesh Galvanized 340817’, ‘Product_Line’: ‘Wire Mesh’, ‘Mesh_Type’: ‘Square’, ‘Series_Name’: ‘HARDWARE & INDUSTRIAL CLOTH’, ‘Series_Number’: ‘2775’, ‘Construction_Type’: ‘Woven’, ‘Primary_Material’: ‘Galvanized Steel (GV)’, ‘Alloy_Grade_Type’: ‘Hot Dipped (HD)’, ‘Material_Finish’: ‘Mill Finish’, ‘Weave_Type’: ‘Woven – Plain Weave’, ‘Mesh_Size’: ‘8 x 8’, ‘Opening_Size’:…

2. Meyer Bees – #8 Wire Mesh Hardware Cloth

Domain: meyerbees.com

Registered: 2017 (8 years)

Introduction: {“name”: “#8 Wire Mesh Hardware Cloth 1/8\” opening”, “price_range”: “$14.95 – $119.95”, “sizes_available”: [“2 ft x 36\””, “12 ft x 36\””, “24 ft x 36\””], “description”: “Perfect size for screened bottom boards and ventilation covers. Allows airflow while preventing critters and mice from passing through. Comes in a bulk roll 24\” x 36\” for project use. Can be cut to size using tin snips.”, “fe…

3. McMaster-Carr – Hardware Cloth Selection

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster-Carr – Hardware Cloth Selection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Online Metals – 8×8 Mesh Galvanized Wire Cloth

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “8×8 Mesh .017″ Wire Dia. Steel Woven Hardware Cloth Galvanized”, “Part Number”: “mp-00003693”, “Opening Size”: “0.108””, “Wire Diameter”: “0.017””, “Mesh Size”: “8×8”, “Open Area”: “0.746””, “Available Sizes”: [{“Size”: “36” X 1200″”, “Price”: “$170.00”, “Weight”: “45.0 lb”}, {“Size”: “48” X 1200″”, “Price”: “$220.00”, “Weight”: “60.0 lb”}], “Lead Time to Ship”: “3 Business Days”…

5. Blythewood Bee Company – 1/8 Inch Galvanized Wire Cloth

Domain: blythewoodbeecompany.com

Registered: 2006 (19 years)

Introduction: 1/8 Inch Wire Cloth – Galvanized Hardware Cloth

– Price: $12.95 per foot, $295.00 per roll

– Dimensions: 36″ wide; available in lengths of 1 foot increments (1 foot x 36″ piece)

– Material: High-quality galvanized metal

– Features: 8 metal squares per inch, durable and long-lasting

– Applications: Suitable for beekeeping components such as screened bottom boards and screen inner covers

– Weight: 0…

Strategic Sourcing Conclusion and Outlook for 8 hardware cloth

In navigating the strategic sourcing landscape for hardware cloth, international B2B buyers must recognize the critical importance of quality, versatility, and cost-effectiveness. The variety of hardware cloth options, ranging from galvanized steel to various mesh sizes, allows for a multitude of applications across different industries, including agriculture, construction, and home improvement. Buyers should prioritize suppliers who offer customization and bulk purchasing options to meet specific project needs while ensuring sustainability and compliance with regional standards.

Moreover, leveraging strategic sourcing can significantly enhance procurement efficiency and foster long-term partnerships. Engaging with suppliers that prioritize innovation and customer service can lead to better pricing, improved delivery timelines, and enhanced product quality. As market dynamics evolve, particularly in emerging markets across Africa, South America, and the Middle East, staying informed about global supply chain trends is essential.

Looking ahead, it is crucial for B2B buyers to actively seek out reliable suppliers who can provide not only competitive pricing but also innovative solutions tailored to their unique market demands. Embrace the opportunities presented by strategic sourcing to drive business growth and resilience in an increasingly interconnected world.

Illustrative image related to 8 hardware cloth

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.