How to Source 6 Inch Aluminum Pipe Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for 6 inch aluminum pipe

Navigating the intricate landscape of sourcing 6 inch aluminum pipe can pose significant challenges for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. The demand for this versatile material, known for its lightweight properties and corrosion resistance, is surging across various industries, including construction, automotive, and manufacturing. However, the complexities of supplier vetting, quality assurance, and cost management can hinder efficient procurement processes.

This comprehensive guide aims to empower B2B buyers by providing insights into the diverse types of 6 inch aluminum pipe available, their specific applications, and the critical factors to consider when selecting suppliers. From understanding the differences between various aluminum alloys to evaluating pricing structures and shipping logistics, this resource serves as a roadmap for making informed purchasing decisions.

By addressing key challenges and equipping buyers with actionable knowledge, this guide not only facilitates smoother transactions but also fosters long-term partnerships in a global market. Whether you’re navigating regulations in Brazil or assessing supplier reliability in Saudi Arabia, this guide is tailored to meet the needs of B2B professionals seeking to optimize their sourcing strategies for 6 inch aluminum pipe.

Understanding 6 inch aluminum pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 6061-T6 Aluminum Pipe | High strength-to-weight ratio, excellent corrosion resistance | Aerospace, automotive, structural applications | Pros: Lightweight, good machinability; Cons: Higher cost than some alternatives. |

| 6063-T832 Aluminum Pipe | Good corrosion resistance, excellent extrudability | Architectural applications, window frames | Pros: Aesthetic finish, good for shaping; Cons: Lower strength compared to 6061. |

| Seamless Aluminum Pipe | No seams, higher pressure tolerance | Oil and gas, hydraulic systems | Pros: Greater durability, fewer leak points; Cons: More expensive due to manufacturing process. |

| Welded Aluminum Pipe | Fabricated from flat sheets, typically less expensive | General construction, piping systems | Pros: Cost-effective, readily available; Cons: May be less durable under high pressure. |

| Aluminum Round Tube | Circular cross-section, typically lighter than pipes | Marine hardware, electrical components | Pros: Lightweight, versatile; Cons: Limited structural support compared to square tubes. |

What are the Characteristics of 6061-T6 Aluminum Pipe?

6061-T6 aluminum pipe is renowned for its high strength-to-weight ratio and excellent corrosion resistance, making it a popular choice in demanding applications like aerospace and automotive industries. This alloy can be heat-treated to enhance its strength, and its machinability allows for easy fabrication. B2B buyers should consider its higher cost compared to other aluminum types; however, the long-term benefits in performance and durability often justify the investment.

How Does 6063-T832 Aluminum Pipe Differ from Other Types?

6063-T832 aluminum pipe is distinguished by its excellent extrudability and good corrosion resistance, making it suitable for architectural applications such as window frames and decorative structures. It offers a smooth surface finish that is often preferred for aesthetic reasons. While its strength is lower than that of 6061-T6, its workability and cost-effectiveness make it appealing for projects where high strength is not the primary concern.

Why Choose Seamless Aluminum Pipe for High-Pressure Applications?

Seamless aluminum pipe is manufactured without seams, which enhances its ability to withstand higher pressures, making it ideal for oil and gas applications. The absence of welds reduces the risk of leaks and increases the overall durability of the pipe. B2B buyers should weigh the higher costs associated with seamless manufacturing against the benefits of reliability and performance in critical applications.

What are the Advantages of Welded Aluminum Pipe?

Welded aluminum pipe is constructed from flat sheets and is generally more cost-effective than seamless options. It is widely used in general construction and piping systems due to its availability and lower price point. However, buyers should consider that welded pipes may not perform as well under high-pressure conditions, and the quality of the welds can vary, impacting overall durability.

How Does Aluminum Round Tube Fit into B2B Applications?

Aluminum round tubes are characterized by their circular cross-section and lightweight nature, making them versatile for applications such as marine hardware and electrical components. They provide good strength while being easier to handle and install. However, they may not offer the same level of structural support as square tubes, so buyers should evaluate their specific application requirements when choosing this type of aluminum pipe.

Key Industrial Applications of 6 inch aluminum pipe

| Industry/Sector | Specific Application of 6 inch aluminum pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Used in fuel and pneumatic systems for aircraft | Lightweight and corrosion-resistant, improving fuel efficiency | Compliance with aerospace standards (e.g., AMS, ASTM) is critical. |

| Oil & Gas | Employed for low-pressure oil transfer and hydraulic systems | Durable under harsh conditions, reducing maintenance costs | Verify pressure ratings and material specifications for safety. |

| Construction | Structural support in building frameworks and facades | Provides strength without added weight, enhancing design flexibility | Sourcing from certified suppliers to ensure quality and compliance. |

| Marine | Utilized in boat frames and piping systems for water transport | Excellent corrosion resistance, extending the lifespan of marine vessels | Consider local regulations and certifications for marine applications. |

| Manufacturing | Integral in pneumatic cylinder designs for automated machinery | Enhances efficiency and reliability in production processes | Ensure compatibility with existing systems and equipment. |

How is 6 Inch Aluminum Pipe Used in Aerospace Applications?

In the aerospace sector, 6 inch aluminum pipes are critical components in fuel and pneumatic systems. Their lightweight nature significantly contributes to fuel efficiency, which is paramount in aviation. Additionally, aluminum’s corrosion resistance is vital for maintaining system integrity under varying atmospheric conditions. International buyers should prioritize suppliers who comply with stringent aerospace standards, such as AMS and ASTM, to ensure that the materials meet safety and performance requirements.

What Role Does 6 Inch Aluminum Pipe Play in Oil & Gas?

In the oil and gas industry, 6 inch aluminum pipe is commonly used for low-pressure oil transfer and hydraulic systems. Its ability to withstand harsh environments without significant degradation makes it an ideal choice for these applications. The durability of aluminum helps reduce maintenance costs over time. Buyers should verify the pressure ratings and material specifications to ensure that the pipes can handle the operational demands safely.

How is 6 Inch Aluminum Pipe Applied in Construction?

In construction, 6 inch aluminum pipes serve as structural supports in building frameworks and facades. Their strength-to-weight ratio allows for innovative architectural designs without compromising structural integrity. This versatility can lead to cost savings during the construction phase. Buyers should focus on sourcing from certified suppliers to ensure that the materials meet industry standards and are suitable for load-bearing applications.

Why is 6 Inch Aluminum Pipe Important in Marine Applications?

Marine industries utilize 6 inch aluminum pipes in boat frames and piping systems for water transport. The inherent corrosion resistance of aluminum is particularly beneficial in saltwater environments, extending the lifespan of marine vessels. International buyers must consider local regulations and certifications when sourcing aluminum pipes for marine applications to ensure compliance and reliability.

How Does 6 Inch Aluminum Pipe Enhance Manufacturing Processes?

In manufacturing, 6 inch aluminum pipes are integral to the design of pneumatic cylinders used in automated machinery. Their lightweight and durable properties enhance the efficiency and reliability of production processes. Buyers should ensure compatibility with existing systems and equipment to maximize operational efficiency. Proper sourcing from reputable suppliers can also lead to better pricing and supply chain reliability.

3 Common User Pain Points for ‘6 inch aluminum pipe’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Aluminum Pipe for Specific Applications

The Problem: B2B buyers often face challenges when sourcing 6-inch aluminum pipes that meet stringent quality and specification requirements. This is particularly critical in industries such as aerospace or automotive, where material integrity is paramount. Buyers may struggle with inconsistent quality from suppliers, leading to concerns over structural reliability and potential project delays. Furthermore, navigating the variety of aluminum alloys and grades can be overwhelming, especially when considering factors such as corrosion resistance and weldability.

The Solution: To effectively source high-quality 6-inch aluminum pipe, buyers should start by identifying reputable suppliers with a proven track record in their specific industry. It’s advisable to request material certifications (such as ASTM or AMS) that demonstrate compliance with necessary standards. Additionally, engaging in discussions with suppliers about the intended application will allow them to recommend the most suitable aluminum alloy, such as 6061-T6 for structural applications or 6063-T832 for lightweight needs. Buyers should also consider ordering samples for testing before placing bulk orders to verify quality and compatibility with their requirements.

Scenario 2: Miscalculating Shipping Costs and Delivery Times

The Problem: Another common pain point for B2B buyers is the miscalculation of shipping costs and delivery times associated with ordering 6-inch aluminum pipes. Due to the size and weight of these pipes, shipping can become a significant part of the overall project budget. Unexpected delays can disrupt project timelines, leading to financial penalties or lost contracts. Buyers often find themselves caught between choosing cost-effective shipping options and ensuring timely delivery.

The Solution: To mitigate shipping issues, buyers should clarify shipping policies and costs with suppliers upfront. They can achieve this by discussing potential shipping methods, such as freight versus standard shipping, and understanding how size and weight impact these costs. Opting for smaller cut lengths can often reduce shipping fees significantly. Additionally, establishing a reliable communication channel with the supplier can help buyers track orders more effectively, allowing for better planning and management of project timelines.

Scenario 3: Ensuring Compatibility with Existing Infrastructure

The Problem: When integrating new 6-inch aluminum pipes into existing systems, buyers frequently encounter compatibility issues. These challenges can arise from differences in dimensions, wall thickness, or material specifications, leading to costly modifications or replacements. Such incompatibilities can be particularly problematic in industries where precise measurements are crucial, such as plumbing or HVAC systems.

The Solution: To ensure compatibility, buyers should conduct a thorough assessment of the existing infrastructure before placing an order. This includes measuring current pipes and fittings, considering factors like wall thickness and inner diameter. Providing this information to the supplier can enable them to recommend the appropriate 6-inch aluminum pipe that fits seamlessly into the existing system. It may also be beneficial to consult with engineers or industry specialists who can provide insights on best practices for integration and potential modifications that may be necessary. Implementing a proactive approach to compatibility can save time and resources, allowing for smoother project execution.

Strategic Material Selection Guide for 6 inch aluminum pipe

What are the Key Properties of Common Materials for 6 Inch Aluminum Pipe?

When selecting materials for 6 inch aluminum pipes, it is crucial to consider the specific properties that influence product performance, including temperature and pressure ratings, as well as corrosion resistance. Below are analyses of three common materials used for manufacturing 6 inch aluminum pipes, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does 6061 Aluminum Alloy Perform in Pipe Applications?

6061 aluminum alloy is one of the most widely used materials for aluminum pipes due to its excellent mechanical properties. It offers good corrosion resistance and is lightweight, making it suitable for a variety of applications, including structural components and transportation. The alloy can withstand temperatures up to 200°C (392°F) and has a pressure rating suitable for most industrial applications.

Pros: The key advantages of 6061 aluminum include its high strength-to-weight ratio, good weldability, and ease of machining. It is also relatively affordable compared to other high-strength materials.

Cons: However, 6061 aluminum can be less resistant to certain corrosive environments, particularly those involving chlorides, which can lead to pitting.

Impact on Application: This alloy is compatible with various media, including water and air, but may not be suitable for aggressive chemicals.

Considerations for International Buyers: Compliance with international standards such as ASTM B221 and ASTM B429 is essential. Buyers in regions like Africa and South America should also consider local environmental conditions that may impact corrosion resistance.

What Makes 6063 Aluminum Alloy a Suitable Choice?

6063 aluminum alloy is often chosen for applications requiring excellent surface finish and good corrosion resistance. It is typically used in architectural applications and offers a good balance of strength and workability. The temperature rating is similar to that of 6061, making it versatile for various uses.

Pros: The primary advantage of 6063 aluminum is its superior aesthetic qualities, making it ideal for decorative applications. It also has better extrusion characteristics than 6061, allowing for more complex shapes.

Cons: The downside is that 6063 has a lower tensile strength compared to 6061, which may limit its use in high-stress applications.

Impact on Application: This alloy is suitable for carrying water and other non-aggressive fluids but may not perform well under high-pressure conditions.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is crucial, and buyers should also assess local market preferences for aesthetic finishes, particularly in Europe and the Middle East.

How Does 6060 Aluminum Alloy Compare in Performance?

6060 aluminum alloy is another option, known for its good corrosion resistance and moderate strength. It is often used in applications where high strength is not a primary requirement, such as in lightweight structures.

Pros: The advantages of using 6060 include its excellent extrudability and good surface finish, making it suitable for architectural applications.

Cons: However, it has lower mechanical properties compared to both 6061 and 6063, which may limit its application scope.

Impact on Application: 6060 aluminum is ideal for applications involving low-pressure fluids but is not recommended for high-stress environments.

Considerations for International Buyers: Buyers should ensure compliance with local standards, particularly in regions with stringent regulations, such as Europe.

Summary Table of Material Selection for 6 Inch Aluminum Pipe

| Material | Typical Use Case for 6 inch aluminum pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 Aluminum | Structural components, transportation | High strength-to-weight ratio | Less resistant to chlorides | Medium |

| 6063 Aluminum | Architectural applications | Superior aesthetic qualities | Lower tensile strength | Medium |

| 6060 Aluminum | Lightweight structures | Excellent extrudability | Lower mechanical properties | Low |

This guide provides actionable insights for B2B buyers considering 6 inch aluminum pipes, focusing on material properties, application suitability, and compliance considerations tailored to international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 6 inch aluminum pipe

The manufacturing process and quality assurance for 6-inch aluminum pipes are critical aspects that B2B buyers must understand to ensure they receive high-quality products that meet international standards. This section delves into the typical manufacturing stages, key techniques, and quality control measures employed in the production of these aluminum pipes.

What Are the Main Stages of Manufacturing 6-Inch Aluminum Pipes?

The manufacturing of 6-inch aluminum pipes typically involves four main stages: material preparation, forming, assembly, and finishing. Each of these stages plays a vital role in ensuring the final product meets the required specifications.

-

Material Preparation

– The process begins with the selection of aluminum alloys, commonly 6061 and 6063, which are known for their excellent mechanical properties and corrosion resistance. The raw material is sourced from reputable suppliers who adhere to international standards like ASTM B221 and ASTM B429.

– Once the material is procured, it is subjected to rigorous inspection to ensure it meets the specified chemical composition and mechanical properties. This initial quality control is crucial as it determines the performance of the final product. -

Forming Techniques

– The forming process for aluminum pipes typically involves extrusion. In this method, heated aluminum billets are forced through a die to create the desired pipe shape. This technique is favored for its efficiency and ability to produce consistent wall thickness.

– For 6-inch pipes, the outer diameter is maintained at 6 inches, with wall thicknesses usually ranging from 0.125 inches to 0.25 inches. Advanced CNC (Computer Numerical Control) machinery is often employed to ensure precision in the forming process. -

Assembly

– While the production of aluminum pipes generally does not require complex assembly processes, any additional components, such as fittings or valves, may be integrated at this stage. If the pipes are intended for specific applications, such as pneumatic systems, they may undergo additional machining to ensure compatibility with other components.

– It is essential that the assembly process follows strict guidelines to maintain the integrity of the pipe. This includes ensuring that all joints and connections are secure and leak-proof. -

Finishing Processes

– The finishing stage involves several treatments to enhance the pipe’s durability and aesthetics. Common techniques include anodizing, which increases corrosion resistance, and polishing, which improves surface finish.

– Depending on the application, pipes may also receive additional coatings to meet specific environmental conditions, such as UV resistance for outdoor use.

How Is Quality Assurance Implemented in the Manufacturing of Aluminum Pipes?

Quality assurance is a fundamental aspect of the manufacturing process, ensuring that the final products meet both customer expectations and international standards. Various quality control checkpoints and testing methods are employed throughout the production cycle.

-

What Are the Relevant International Standards for Aluminum Pipes?

– Manufacturers of 6-inch aluminum pipes must comply with international standards such as ISO 9001, which outlines requirements for a quality management system, ensuring consistent quality in production.

– Industry-specific standards, such as CE marking for European markets and API (American Petroleum Institute) standards for oil and gas applications, are also critical. These certifications assure buyers of the product’s quality and safety, particularly for applications in harsh environments. -

What Are the Key Quality Control Checkpoints?

– Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials upon arrival at the manufacturing facility. It includes testing for chemical composition and physical properties.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, operators conduct regular checks to monitor parameters such as dimensions, wall thickness, and surface finish. Any deviations are addressed immediately to prevent defects.

– Final Quality Control (FQC): Before shipping, the finished products undergo a comprehensive inspection that includes dimensional checks, pressure testing, and surface quality assessments. This ensures that only products meeting quality standards are dispatched. -

What Common Testing Methods Are Used?

– Common testing methods for aluminum pipes include hydrostatic testing, which checks for leaks and structural integrity, and tensile testing, which measures the material’s strength.

– Non-destructive testing (NDT) methods, such as ultrasonic testing, may also be employed to identify internal defects without damaging the product. This is particularly important for applications in critical industries such as aerospace and oil & gas.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those sourcing from international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial.

-

Conducting Audits and Inspections

– Buyers should consider conducting on-site audits of potential suppliers. This involves assessing their manufacturing facilities, quality control practices, and compliance with international standards.

– Engaging third-party inspection services can also provide an unbiased evaluation of a supplier’s quality assurance processes. These inspections typically include reviewing quality management systems, testing procedures, and product samples. -

Requesting Quality Control Reports and Certifications

– Suppliers should provide documentation of their quality control processes, including inspection reports and certifications. This documentation should detail compliance with relevant standards, inspection results, and any corrective actions taken for non-conformities.

– Buyers should also verify that the supplier maintains up-to-date certifications and is regularly audited by accredited bodies to ensure ongoing compliance with quality standards. -

Understanding Quality Control Nuances for International Buyers

– B2B buyers must be aware of potential differences in quality standards across regions. For instance, European standards may differ from those in the Middle East or South America, necessitating a thorough understanding of local regulations.

– It is advisable to establish clear communication with suppliers regarding quality expectations and to include quality assurance clauses in contracts. This can help mitigate risks and ensure that both parties are aligned on quality standards.

In conclusion, understanding the manufacturing processes and quality assurance measures for 6-inch aluminum pipes is essential for B2B buyers looking to source high-quality products. By focusing on material preparation, forming techniques, and robust quality control practices, buyers can make informed decisions and ensure they receive products that meet their specifications and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘6 inch aluminum pipe’

In this guide, we aim to provide a structured approach for B2B buyers seeking to procure 6-inch aluminum pipe. By following these steps, buyers can ensure they make informed decisions, minimize risks, and secure quality products that meet their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to clarify your technical requirements. Determine the specific dimensions, wall thickness, and alloy type (such as 6061 or 6063 aluminum) necessary for your application. This step is crucial as it ensures that the materials you procure will meet the operational demands of your project.

- Consider the application: Understand whether the pipe will be used for structural support or for transporting fluids, as this affects the required specifications.

- Quality standards: Familiarize yourself with relevant industry standards such as ASTM or ISO to ensure compliance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in aluminum pipes. Look for companies with a proven track record and expertise in the specific type of aluminum you require. This research will help you narrow down your options to reliable partners.

- Check online directories: Utilize platforms like ThomasNet or Alibaba to find suppliers with good reputations.

- Leverage industry connections: Reach out to industry peers for recommendations based on their experiences.

Step 3: Verify Supplier Certifications

Once you have a list of potential suppliers, it’s imperative to verify their certifications and quality assurance processes. Suppliers should have appropriate certifications, such as ISO 9001, to demonstrate their commitment to quality.

- Request documentation: Ask for copies of quality certifications and compliance with relevant standards.

- Assess quality control processes: Understand how the supplier maintains quality throughout the manufacturing and delivery processes.

Step 4: Request Detailed Quotes

After narrowing down your supplier options, request detailed quotes from each. Ensure that the quotes include all relevant costs, including shipping, handling, and any potential tariffs or duties for international shipments.

- Compare pricing: Analyze the quotes not just based on price, but also on the quality of materials and terms of service.

- Clarify payment terms: Ensure you understand the payment methods accepted and any upfront costs required.

Step 5: Evaluate Supplier Capabilities

Assess the capabilities of each supplier to ensure they can meet your volume and delivery requirements. This involves looking at their production capacity, lead times, and logistical capabilities.

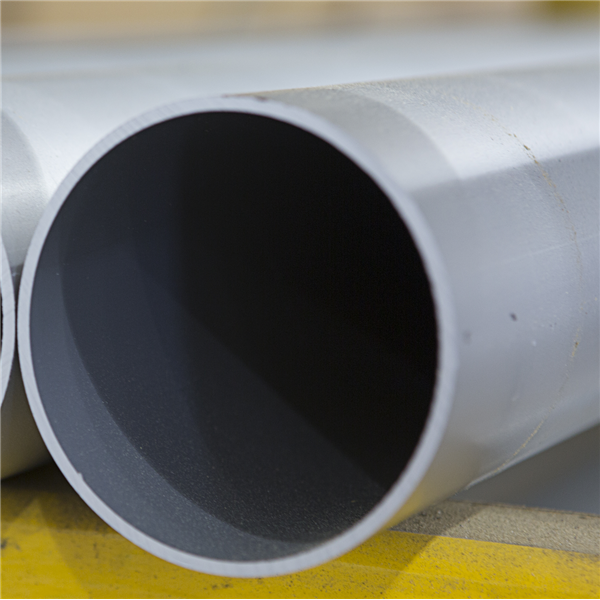

Illustrative image related to 6 inch aluminum pipe

- Ask about manufacturing processes: Inquire whether they use extrusion, seamless production, or other methods that might affect quality and delivery.

- Review past projects: Request case studies or references from previous clients to gauge their reliability.

Step 6: Conduct a Site Visit (if possible)

If feasible, conduct a site visit to the supplier’s manufacturing facility. This allows you to see their operations firsthand and assess their adherence to quality standards and safety protocols.

- Observe production practices: Pay attention to the cleanliness of the facility and the professionalism of the staff.

- Discuss potential challenges: Use this opportunity to address any concerns directly with the supplier.

Step 7: Finalize the Contract

Once you have selected a supplier, draft a comprehensive contract that outlines all terms and conditions, including delivery schedules, payment terms, and warranties.

- Include performance metrics: Specify any quality benchmarks that must be met upon delivery.

- Review legal implications: Ensure that the contract protects your interests in case of delays or defects.

By following this checklist, B2B buyers can navigate the procurement process for 6-inch aluminum pipe with confidence, ensuring they secure high-quality materials that meet their specific requirements.

Comprehensive Cost and Pricing Analysis for 6 inch aluminum pipe Sourcing

What Are the Key Cost Components in Sourcing 6 Inch Aluminum Pipes?

When sourcing 6 inch aluminum pipes, understanding the cost structure is crucial for effective budgeting and pricing negotiation. The main cost components include:

-

Materials: The primary material for these pipes is aluminum, specifically alloys like 6061 or 6063, which are favored for their strength and corrosion resistance. The price of aluminum fluctuates based on global market conditions, impacting the overall cost significantly.

-

Labor: Labor costs vary by region and can be influenced by the skill level required for manufacturing and assembly. Labor-intensive processes such as welding or custom machining will increase costs.

-

Manufacturing Overhead: This encompasses costs related to facility maintenance, utilities, and administrative expenses. Efficient production processes can help minimize overhead costs.

-

Tooling: Custom tooling may be necessary for unique specifications or designs. This upfront investment can increase initial costs but may lead to savings in the long run through optimized production runs.

-

Quality Control (QC): Ensuring that products meet specified standards requires robust QC processes. Investing in quality assurance can reduce the risk of defects, which can lead to costly returns or project delays.

-

Logistics: Transportation and handling costs are essential to consider, especially when importing materials or finished products across international borders. These costs can vary widely depending on shipment size, distance, and chosen transportation methods.

-

Margin: Suppliers typically include a markup for profit, which can vary based on market conditions and competition. Understanding this margin can aid in negotiation.

How Do Price Influencers Affect the Cost of 6 Inch Aluminum Pipes?

Several factors can influence pricing in the B2B marketplace for aluminum pipes:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Understanding MOQ requirements can help buyers negotiate better pricing.

-

Specifications and Customization: Custom designs or specific alloy compositions can lead to higher costs. Buyers should balance their needs with budget constraints.

-

Material Quality and Certifications: Pipes that meet higher quality standards or certifications (like ISO or ASTM) may come at a premium. However, investing in quality can reduce long-term maintenance costs.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can impact pricing. Established suppliers may charge more, but they often provide better service and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. For instance, an Ex-Works (EXW) agreement places more responsibility on the buyer, potentially increasing logistics costs.

What Are Essential Buyer Tips for Negotiating Prices on 6 Inch Aluminum Pipes?

To optimize sourcing strategies and manage costs effectively, international buyers should consider the following tips:

-

Negotiate Effectively: Use insights from market research to negotiate better prices. Highlight potential for repeat business or larger orders to leverage lower pricing.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not just the purchase price but also transportation, installation, and maintenance costs. A lower initial price may not always equate to better value.

-

Understand Pricing Nuances for International Trade: Buyers from regions like Africa, South America, the Middle East, and Europe may encounter unique challenges such as tariffs, import duties, and varying shipping costs. Familiarizing oneself with these factors can mitigate unexpected expenses.

-

Stay Informed on Market Trends: Regularly monitor global aluminum prices and industry trends to make informed purchasing decisions. This knowledge can provide leverage during negotiations.

Disclaimer on Indicative Prices

Prices for 6 inch aluminum pipes can fluctuate based on market conditions, supplier pricing strategies, and custom requirements. Therefore, it is advisable to request quotes from multiple suppliers and consider current market trends when making purchasing decisions.

Alternatives Analysis: Comparing 6 inch aluminum pipe With Other Solutions

When considering the best piping solutions for industrial applications, it’s crucial to evaluate various alternatives to the 6-inch aluminum pipe. Understanding the strengths and weaknesses of different materials and technologies will enable B2B buyers to make informed decisions that align with their operational needs and budget constraints.

Comparison Table

| Comparison Aspect | 6 Inch Aluminum Pipe | PVC Pipe | Carbon Steel Pipe |

|---|---|---|---|

| Performance | High strength, lightweight, and corrosion-resistant; ideal for various applications. | Good chemical resistance but limited in high-temperature applications. | Excellent strength and durability; suitable for high-pressure applications. |

| Cost | Moderate cost; typically more expensive than PVC but cheaper than carbon steel. | Low cost; one of the most affordable piping options. | Higher upfront cost due to material and manufacturing processes. |

| Ease of Implementation | Relatively easy to install; requires specific tools for cutting and joining. | Very easy to install; can be cut and joined with minimal tools. | More complex installation due to heavier weight and welding requirements. |

| Maintenance | Low maintenance; resistant to rust and corrosion. | Requires periodic inspection for chemical degradation; may become brittle over time. | Moderate maintenance; susceptible to rust if not properly coated. |

| Best Use Case | Ideal for structural applications, fluid transport, and environments requiring lightweight materials. | Best for residential plumbing and drainage systems where low pressure is involved. | Suitable for industrial applications, oil and gas transport, and high-pressure systems. |

Pros and Cons of Alternative Solutions

PVC Pipe

PVC (Polyvinyl Chloride) pipe offers a lightweight, cost-effective solution for various plumbing and drainage applications. Its resistance to corrosion and chemicals makes it a popular choice for residential and commercial plumbing. However, PVC has limitations when it comes to temperature tolerance and pressure ratings, which may restrict its use in more demanding environments. Additionally, the installation process is straightforward, making it accessible for both professionals and DIY projects.

Carbon Steel Pipe

Carbon steel pipe is known for its strength and durability, making it suitable for high-pressure applications in industries such as oil and gas. It can withstand extreme temperatures and is often used in critical infrastructure projects. However, the initial cost is higher compared to aluminum and PVC pipes, and it requires regular maintenance to prevent rust and corrosion. Installation can also be complex, necessitating specialized skills for welding and handling heavy materials.

Conclusion: How to Choose the Right Piping Solution for Your Needs

Selecting the right piping solution involves assessing your specific requirements, including application, budget, and long-term performance expectations. The 6-inch aluminum pipe is an excellent choice for those seeking a lightweight, corrosion-resistant option with moderate costs. However, if your application involves chemical exposure or low pressure, PVC may be more suitable. Conversely, for high-pressure and high-temperature needs, carbon steel could be the best fit despite its higher initial investment and maintenance requirements. By carefully evaluating these alternatives, B2B buyers can make decisions that enhance operational efficiency and reduce long-term costs.

Essential Technical Properties and Trade Terminology for 6 inch aluminum pipe

When sourcing a 6-inch aluminum pipe, understanding its essential technical properties and trade terminology is crucial for making informed purchasing decisions. This guide outlines the key specifications and common jargon that will help international B2B buyers navigate their procurement process more effectively.

What Are the Key Technical Properties of a 6-Inch Aluminum Pipe?

-

Material Grade:

The most common aluminum alloys used for pipes are 6061-T6 and 6063-T832. The 6061 alloy offers high strength and good corrosion resistance, making it ideal for structural applications. In contrast, 6063 is often chosen for its aesthetic appeal and excellent finish, suitable for architectural applications. Understanding the material grade is essential, as it directly impacts the pipe’s performance, durability, and cost. -

Wall Thickness:

Typically measured in inches, wall thickness can vary, commonly found in 0.125 inches for a 6-inch aluminum pipe. A thicker wall enhances strength and pressure tolerance, making it suitable for high-stress applications. Buyers should consider their specific application needs when selecting wall thickness, as this affects both the performance and weight of the pipe. -

Inner and Outer Diameter (ID and OD):

The outer diameter (OD) of a 6-inch aluminum pipe is, as the name suggests, 6 inches, while the inner diameter (ID) can vary depending on the wall thickness. For instance, a pipe with a 0.125-inch wall will have an ID of approximately 5.75 inches. Accurate measurements are crucial for ensuring compatibility with fittings and other components in the system. -

Tensile Strength:

Tensile strength is a measure of the pipe’s resistance to being pulled apart and is typically expressed in KSI (kilo-pounds per square inch). For 6061 aluminum, the yield tensile strength is around 40 KSI, which indicates its ability to withstand substantial forces. This property is vital for applications where the pipe will be subjected to mechanical stress. -

Corrosion Resistance:

Aluminum naturally forms a protective oxide layer that enhances its resistance to corrosion. However, the specific alloy and temper can influence this property. For instance, 6061-T6 exhibits superior corrosion resistance, making it suitable for outdoor applications or environments with high humidity. Buyers must evaluate the operating environment to ensure longevity and reliability.

What Are Common Trade Terms in the Aluminum Pipe Industry?

-

OEM (Original Equipment Manufacturer):

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of aluminum pipes, OEMs often supply custom solutions tailored to specific applications, making it crucial for buyers to identify reliable OEM partners. -

MOQ (Minimum Order Quantity):

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for budget planning and inventory management, especially for businesses looking to maintain optimal stock levels without overcommitting financially. -

RFQ (Request for Quotation):

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. This process is critical in B2B transactions, as it allows buyers to compare prices and terms across multiple suppliers, ensuring they get the best deal. -

Incoterms (International Commercial Terms):

These are standardized international trade terms that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is essential for international transactions, as they clarify who is responsible for shipping, insurance, and tariffs, helping to avoid misunderstandings and disputes. -

Lead Time:

This term refers to the time it takes from placing an order until it is delivered. Knowing the lead time is crucial for project planning, especially in industries where timing is critical. Buyers should always confirm lead times with suppliers to ensure that they can meet their project deadlines.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that they select the right 6-inch aluminum pipe for their specific needs while navigating the complexities of international trade effectively.

Navigating Market Dynamics and Sourcing Trends in the 6 inch aluminum pipe Sector

What Are the Key Trends Shaping the 6 Inch Aluminum Pipe Market?

The global market for 6-inch aluminum pipes is experiencing significant growth driven by several factors. Demand for lightweight and corrosion-resistant materials is surging across industries such as construction, automotive, and aerospace. Emerging technologies like advanced manufacturing and automation are enhancing production efficiencies, allowing suppliers to meet international standards while reducing costs. Additionally, the rise of e-commerce platforms has transformed the sourcing landscape, enabling international B2B buyers from regions like Africa, South America, the Middle East, and Europe to access a broader range of suppliers and products.

Sourcing trends are also evolving, with buyers increasingly favoring suppliers that offer customization options. This flexibility allows businesses to tailor products to specific applications, enhancing functionality and performance. Furthermore, the emphasis on supply chain transparency is becoming paramount. Buyers are now more inclined to partner with suppliers who can demonstrate robust quality assurance processes and certifications, particularly those adhering to international standards like ASTM and ISO.

How Can Sustainability and Ethical Sourcing Benefit B2B Buyers?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the aluminum pipe sector. The aluminum production process has significant environmental impacts, including high energy consumption and greenhouse gas emissions. Buyers are encouraged to prioritize suppliers who employ sustainable practices, such as using recycled materials and implementing energy-efficient manufacturing processes. This not only minimizes environmental footprints but can also enhance brand reputation in an increasingly eco-conscious market.

Moreover, ethical supply chains are crucial for maintaining long-term relationships with customers and stakeholders. Companies that commit to ethical sourcing practices often benefit from greater customer loyalty and trust. Buyers should look for suppliers with certifications such as ISO 14001 for environmental management and those that comply with global sustainability initiatives. These certifications signal a supplier’s commitment to responsible practices, which can be a significant differentiator in competitive markets.

What Is the Historical Context of the 6 Inch Aluminum Pipe Industry?

The evolution of the 6-inch aluminum pipe industry can be traced back to the early 20th century when aluminum began to gain popularity due to its lightweight and corrosion-resistant properties. Initially used in aerospace and military applications, the versatility of aluminum soon found its way into various sectors, including construction and automotive.

Illustrative image related to 6 inch aluminum pipe

The introduction of advanced alloys, such as 6061 and 6063, further expanded the applications of aluminum pipes, making them more durable and suitable for high-stress environments. Over the decades, innovations in extrusion techniques and welding technology have improved the performance and reliability of aluminum pipes. This historical context is essential for B2B buyers, as it highlights the ongoing advancements that continue to shape product offerings and market dynamics today.

In summary, understanding the current market trends, embracing sustainability, and appreciating the historical context are key for B2B buyers in effectively navigating the 6-inch aluminum pipe sector. By leveraging these insights, businesses can make informed sourcing decisions that align with both operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of 6 inch aluminum pipe

-

How do I ensure the quality of 6 inch aluminum pipe before purchase?

To ensure the quality of 6 inch aluminum pipe, request Material Test Reports (MTRs) from suppliers. MTRs provide information about the material’s compliance with industry standards, such as ASTM specifications. Additionally, inquire about the manufacturing process, such as whether the pipe is extruded or seamless, as these factors influence quality. For extra assurance, consider conducting third-party inspections or audits of the supplier’s facilities, especially if sourcing from international vendors. -

What specifications should I consider when sourcing 6 inch aluminum pipe?

When sourcing 6 inch aluminum pipe, key specifications include the alloy type (e.g., 6061 or 6063), wall thickness, outer diameter, and inner diameter. Understanding the mechanical properties, such as yield strength and corrosion resistance, is also crucial for your application. Be sure to confirm compliance with relevant standards, such as ASTM B221 or AMS-QQ-A-200/8. These specifications ensure that the pipe meets your performance requirements in various environmental conditions. -

What is the typical lead time for international orders of 6 inch aluminum pipe?

Lead times for international orders of 6 inch aluminum pipe can vary significantly based on factors such as supplier location, production capacity, and shipping logistics. Typically, expect lead times ranging from 2 to 6 weeks. To expedite your order, communicate your timeline clearly with the supplier and consider placing orders in advance. Discussing shipping methods, such as air freight for urgent needs or sea freight for cost-effective solutions, can also impact delivery times. -

What are the common payment terms for international purchases of aluminum pipe?

Payment terms for international purchases of aluminum pipe typically include options like upfront payment, letter of credit, or payment upon delivery. The choice of payment method often depends on the buyer’s relationship with the supplier and the order size. Ensure to negotiate terms that provide security for both parties. Familiarize yourself with international trade payment practices to mitigate risks, especially when dealing with new suppliers in regions like Africa, South America, or the Middle East. -

How can I verify the credibility of a supplier for aluminum pipe?

To verify the credibility of a supplier for aluminum pipe, conduct thorough due diligence. Start by checking their business registration, certifications, and industry reputation through online reviews or trade associations. Request references from previous clients and consider visiting their manufacturing facilities if feasible. Utilizing third-party services for supplier audits or credit checks can provide additional assurance about their reliability and financial stability. -

What customization options are available for 6 inch aluminum pipe?

Many suppliers offer customization options for 6 inch aluminum pipe, including varying lengths, wall thicknesses, and finishes. You can also request specific alloy grades or treatments, such as anodizing or powder coating, based on your project requirements. Discuss your needs with the supplier to determine available options and any associated costs. Custom orders may require longer lead times, so plan accordingly to meet your project deadlines. -

What are the logistics considerations for shipping aluminum pipe internationally?

When shipping aluminum pipe internationally, consider factors such as shipping method, customs regulations, and potential tariffs. Depending on the order size, you may choose between air freight for speed or sea freight for cost efficiency. Ensure proper packaging to prevent damage during transit and confirm that the supplier provides all necessary documentation for customs clearance. Collaborating with a logistics partner experienced in international shipping can help streamline the process. -

What should I do if I receive defective aluminum pipe?

If you receive defective aluminum pipe, promptly contact the supplier with detailed documentation, including photographs and descriptions of the defects. Review the supplier’s return policy and warranty terms to understand your rights. Most reputable suppliers will offer remedies such as replacements, refunds, or repairs. Maintaining clear communication and documentation throughout the process will facilitate a smoother resolution and reinforce your relationship with the supplier.

Top 7 6 Inch Aluminum Pipe Manufacturers & Suppliers List

1. Global Tech – 6 14 Gauge Aluminum Tubing

Domain: globaltecheng.com

Registered: 2003 (22 years)

Introduction: {“Product Name”: “6” 14 Gauge Aluminum Tubing-Twenty Foot Piece”, “SKU”: “TU60114-20”, “Size”: “6.0 inch”, “Gauge”: “14”, “Material”: “Aluminum”, “Wall Thickness”: “.083 inch”, “Alloy”: “6063”, “Length”: “20 feet”, “Price”: “$261.40”, “Shipping Information”: “Shipped via Common Carrier due to length. Options: Freight Collect or Prepaid and Add.”}

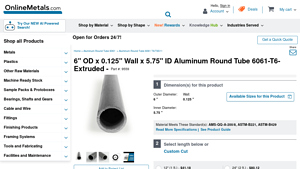

2. Online Metals – Aluminum 6061 Extruded Round Tube 6 OD x 0.125 Wall

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {‘outer_diameter’: ‘6’, ‘wall_thickness’: ‘0.125’, ‘inner_diameter’: ‘5.75’, ‘max_length’: ‘240’, ‘alloy’: ‘6061’, ‘temper’: ‘T6’, ‘production_method’: ‘Extruded’, ‘metal_type’: ‘Aluminum’, ‘shape’: ‘Tube-Round’, ‘mtr_availability’: ‘Yes’, ‘rohs’: ‘Yes’, ‘reach’: ‘Yes’, ‘weight_per_lineal_foot’: ‘2.72 pounds’, ‘material_standards’: [‘AMS-QQ-A-200/8’, ‘ASTM-B221’, ‘ASTM-B429’], ‘applications’: [‘ae…

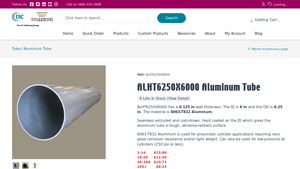

3. CRConline – 6063-T832 Aluminum Tube

Domain: crconline.com

Registered: 2000 (25 years)

Introduction: {“SKU”:”ALHT6250X6000″,”Material”:”6063-T832 Aluminum”,”Inside Diameter”:”6 in”,”Outside Diameter”:”6.25 in”,”Wall Thickness”:”0.125 in”,”Weight”:”0.24 lbs per IN”,”Features”:”Seamless extruded and cold-drawn, hard coated interior, corrosion resistance, good weldability, no machining required on the ID”,”Applications”:”Pneumatic cylinder applications requiring very good corrosion resistance and/or…

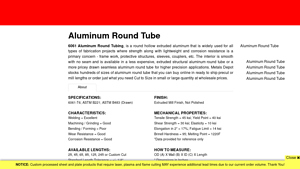

4. Metals Depot – Aluminum Round Tube 6061

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Aluminum Round Tube 6061; Type: Round hollow extruded aluminum; Applications: Fabrication projects, framework, protective structures, sleeves, couplers; Interior: Smooth with no seam; Options: Extruded structural aluminum round tube (less expensive) or drawn seamless aluminum round tube (higher precision); Specifications: 6061-T6; ASTM B221; ASTM B483 (Drawn); Finish: Extruded Mill Finish, Not Pol…

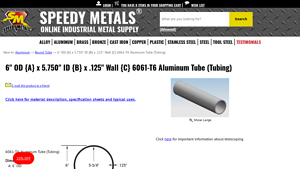

5. Speedy Metals – 6061-T6 Aluminum Round Tube

Domain: speedymetals.com

Registered: 2001 (24 years)

Introduction: {“Dimensions”:{“Outer Diameter”:”6 inch”,”Inner Diameter”:”5.750 inch”,”Wall Thickness”:”0.125 inch”},”Material”:”Aluminum”,”Grade”:”6061-T6″,”Shape”:”Round Tube”,”Weight Options”:{“12 inch”:”2.6400 lbs”,”18 inch”:”3.9600 lbs”,”24 inch”:”5.2800 lbs”,”36 inch”:”7.9200 lbs”,”48 inch”:”10.5600 lbs”,”60 inch”:”13.2000 lbs”,”72 inch”:”15.8400 lbs”},”Base Price”:”$5.42″,”Custom Lengths Available”:”Yes”,…

6. Direct Pivot Parts – 6 Aluminum Pipe

Domain: directpivotparts.com

Registered: 2016 (9 years)

Introduction: 6″ Aluminum Pipe .060 Thickness

7. Midwest Steel Supply – 6061-T6 Aluminum Round Tube

Domain: midweststeelsupply.com

Registered: 2005 (20 years)

Introduction: Product Name: 6061-T6 Aluminum Round Tube

Material: 6061-T6 Aluminum

Size Options: Various sizes ranging from 7/16 X .125 to 8 X .250 inches

Tensile Strength: 20 to 42 KSI

Standards: Conforms to ASTM B221

Applications: Used for engineering, structural, framing, marine, transportation, and general machining parts.

Cutting Tolerance: -0/+.125 inches

Stock Size: 288 inches

Pricing: Priced from 2 to 3…

Strategic Sourcing Conclusion and Outlook for 6 inch aluminum pipe

In navigating the complexities of sourcing 6-inch aluminum pipes, international buyers must prioritize strategic sourcing to ensure quality, cost-effectiveness, and timely delivery. Key considerations include selecting reputable suppliers who adhere to industry standards such as ASTM and ISO certifications. Understanding regional shipping logistics is essential, particularly for markets in Africa, South America, the Middle East, and Europe, where transportation infrastructure can impact lead times and costs.

The versatility of aluminum, particularly alloys like 6061 and 6063, makes it an excellent choice for a range of applications, from construction to aerospace. As global demand for lightweight and durable materials increases, investing in quality aluminum pipes can provide a competitive edge in various industries.

Looking ahead, B2B buyers are encouraged to foster relationships with suppliers that not only meet immediate needs but also align with long-term sustainability goals. By leveraging technology and innovative procurement practices, businesses can enhance their sourcing strategies, ensuring resilience in an ever-evolving market landscape. Engage with trusted suppliers today to secure the best options for your projects and drive success in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.