How to Source 2.75 Diameter Grade J Ptfe Rod Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for 2.75 diameter grade j ptfe rod

In today’s competitive manufacturing landscape, sourcing high-quality materials like the 2.75 diameter grade J PTFE rod poses significant challenges for international B2B buyers. With its exceptional chemical resistance, low friction properties, and versatility across various applications, this fluoropolymer rod is crucial for industries ranging from aerospace to food processing. However, navigating the complexities of procurement—such as identifying reliable suppliers, understanding pricing structures, and ensuring compliance with international standards—can be daunting, particularly for businesses operating in regions like Africa, South America, the Middle East, and Europe.

This comprehensive guide aims to empower B2B buyers by providing a thorough overview of the 2.75 diameter grade J PTFE rod. We will explore its various types, common applications, and critical performance characteristics. Additionally, we will offer insights into effective supplier vetting processes, cost considerations, and best practices for ensuring quality and compliance. By equipping buyers with actionable information, this guide fosters informed purchasing decisions that can enhance operational efficiency and reduce risks in the supply chain.

Whether you are a procurement manager in Saudi Arabia or a product developer in Vietnam, understanding the nuances of sourcing PTFE rods will enable you to make strategic choices that align with your business objectives. Let us delve into the essential aspects of this vital material and navigate the global market together.

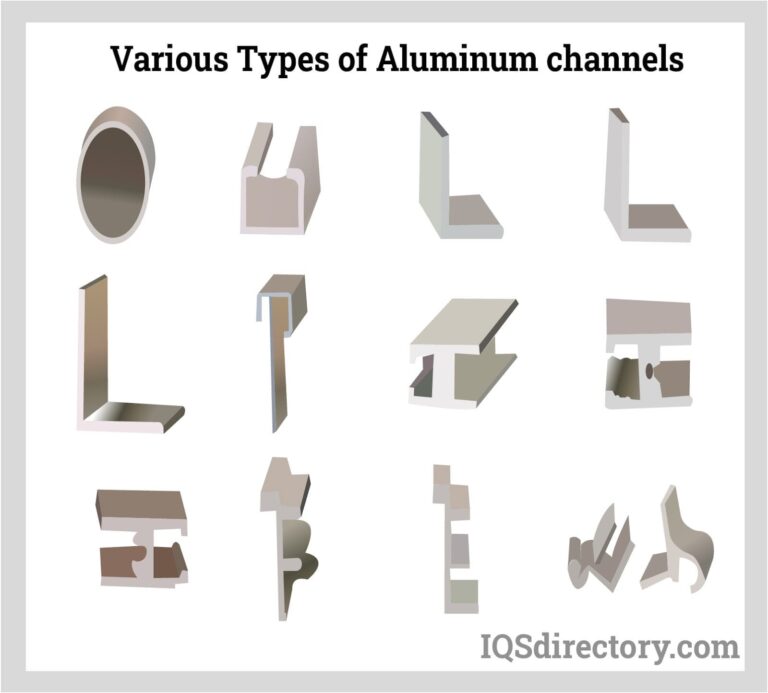

Understanding 2.75 diameter grade j ptfe rod Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Virgin PTFE Rod | High chemical resistance, low friction, non-stick surface | Seals, gaskets, industrial machinery | Pros: Excellent durability; Cons: Lower strength compared to other materials. |

| FDA Compliant PCTFE Rod | Cold flow resistance, FDA approved for food and pharmaceutical use | Food processing, aerospace applications | Pros: Safe for sensitive applications; Cons: Higher cost due to compliance. |

| Filled PTFE Rod | Enhanced mechanical properties, often reinforced with glass or carbon | Bearings, bushings, and wear strips | Pros: Increased strength and stiffness; Cons: Potentially higher wear rates. |

| Custom-Cut PTFE Rod | Tailored dimensions and lengths for specific applications | Custom machinery, specialized manufacturing processes | Pros: Meets unique specifications; Cons: Longer lead times for production. |

| Natural PTFE Rod | Standard grade with basic properties, often lower in cost | General industrial applications | Pros: Cost-effective; Cons: Limited performance in extreme conditions. |

What Are the Characteristics of Virgin PTFE Rods?

Virgin PTFE rods are renowned for their exceptional chemical resistance and low friction properties, making them ideal for a variety of industrial applications. These rods are typically used in seals and gaskets, as well as in machinery where a non-stick surface is essential. Buyers should consider the operational environment, as while virgin PTFE offers durability, it may not withstand extreme mechanical stress as effectively as some reinforced alternatives.

Why Choose FDA Compliant PCTFE Rods?

PCTFE rods, particularly those compliant with FDA regulations, are designed for use in industries where safety and cleanliness are paramount, such as food processing and pharmaceuticals. Their unique cold flow resistance ensures they maintain shape and integrity under cryogenic conditions, making them suitable for a variety of specialized applications. While they offer significant benefits in regulated environments, the cost may be a consideration for budget-sensitive projects.

What Advantages Do Filled PTFE Rods Offer?

Filled PTFE rods are modified with materials like glass or carbon to enhance their mechanical properties, making them stronger and more suitable for demanding applications such as bearings and bushings. These rods are particularly valuable in high-wear environments where standard PTFE may falter. Buyers should weigh the enhanced performance against potential increases in wear rates and costs associated with these advanced materials.

How Do Custom-Cut PTFE Rods Cater to Specific Needs?

Custom-cut PTFE rods provide flexibility in dimensions and lengths, allowing businesses to meet specific design requirements without compromising on material integrity. This adaptability is essential in specialized manufacturing processes where standard sizes may not suffice. However, buyers should be prepared for longer lead times and potentially higher costs associated with custom orders.

When to Use Natural PTFE Rods?

Natural PTFE rods are a cost-effective option for general industrial applications where extreme performance is not a critical requirement. They provide basic chemical resistance and low friction properties, making them suitable for a wide range of applications. However, buyers should be aware that natural PTFE may not perform as well under extreme conditions compared to more specialized variants.

Key Industrial Applications of 2.75 diameter grade j ptfe rod

| Industry/Sector | Specific Application of 2.75 diameter grade j ptfe rod | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Chemical Processing | Linings for tanks and pipes to handle aggressive chemicals | Enhanced chemical resistance minimizes downtime and maintenance | Ensure compliance with local regulations and certifications |

| Food and Beverage | Gaskets and seals in processing equipment | Non-stick and FDA-compliant properties ensure product safety | Verify compliance with international food safety standards |

| Aerospace | Components for high-temperature applications | High thermal stability increases operational reliability | Source from suppliers with aerospace certifications |

| Oil and Gas | Valve components and seals for high-pressure systems | Durability under extreme conditions reduces failure risk | Assess supplier capabilities for custom manufacturing requirements |

| Pharmaceutical | Seals and gaskets in drug manufacturing processes | Maintains purity and prevents contamination | Ensure materials meet stringent pharmaceutical industry standards |

How is the 2.75 Diameter Grade J PTFE Rod Used in Chemical Processing?

In the chemical processing industry, the 2.75 diameter grade J PTFE rod is predominantly utilized for linings in tanks and pipes. Its exceptional chemical resistance allows it to withstand harsh solvents and acids, preventing corrosion and extending the lifespan of equipment. This application is crucial for businesses aiming to minimize downtime due to maintenance and ensure continuous operations. International buyers should consider sourcing from manufacturers that provide detailed chemical compatibility data and certifications to comply with local regulations.

What Role Does the 2.75 Diameter Grade J PTFE Rod Play in Food and Beverage Industries?

The food and beverage sector employs the 2.75 diameter grade J PTFE rod for creating gaskets and seals in processing equipment. Its non-stick surface and FDA compliance are vital for maintaining hygiene and ensuring product safety. This application helps businesses reduce waste and enhance efficiency during production. Buyers, especially from regions with strict food safety regulations, should confirm the material’s compliance with international standards to ensure safe food processing.

How Does the Aerospace Industry Benefit from the 2.75 Diameter Grade J PTFE Rod?

In aerospace applications, the 2.75 diameter grade J PTFE rod is used in components that require high thermal stability, such as seals and bearings in engines. Its ability to perform under extreme temperatures and pressures enhances the reliability of aircraft systems. This is critical for minimizing maintenance costs and ensuring safety in flight operations. Buyers should prioritize suppliers with aerospace industry certifications and proven track records in high-performance materials.

Why is the 2.75 Diameter Grade J PTFE Rod Important in Oil and Gas Applications?

The oil and gas industry utilizes the 2.75 diameter grade J PTFE rod for manufacturing valve components and seals that operate in high-pressure environments. Its durability and resistance to harsh chemicals help prevent leaks and failures, which can be costly in terms of safety and operational efficiency. Buyers must evaluate suppliers for their ability to meet custom specifications and industry standards, ensuring that the materials can withstand the demanding conditions typical in this sector.

What is the Importance of the 2.75 Diameter Grade J PTFE Rod in Pharmaceuticals?

In the pharmaceutical industry, the 2.75 diameter grade J PTFE rod is essential for seals and gaskets in drug manufacturing processes. Its properties help maintain the purity of pharmaceutical products by preventing contamination during production. This application is critical for compliance with stringent industry standards. Buyers should ensure that their suppliers can provide materials that meet these high standards, including certifications for pharmaceutical use, to ensure product integrity and safety.

3 Common User Pain Points for ‘2.75 diameter grade j ptfe rod’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem:

B2B buyers often face challenges with the quality consistency of 2.75 diameter grade J PTFE rods. Suppliers may offer products that vary in chemical resistance, mechanical properties, or even dimensions. This inconsistency can lead to increased production costs, product failures, and ultimately damage relationships with customers. For example, if a company sources a batch of rods that do not meet the required specifications, it can result in delays and additional expenditures on replacements.

The Solution:

To ensure consistent quality, B2B buyers should implement a rigorous supplier evaluation process. Start by requesting material certifications and performance data for the PTFE rods from potential suppliers. Look for suppliers who provide transparent documentation on their manufacturing processes and quality control measures. Additionally, establishing long-term partnerships with a few trusted suppliers can help maintain quality consistency. Consider conducting periodic audits or visits to the supplier’s facility to verify their production processes. Implementing a quality assurance program that includes regular sampling and testing of incoming materials can further safeguard against variability in quality.

Scenario 2: Difficulty in Sizing and Customization

The Problem:

When sourcing 2.75 diameter grade J PTFE rods, buyers may encounter challenges related to sizing and customization for specific applications. Standard sizes may not fit the precise needs of their machinery or equipment, resulting in inefficiencies or the necessity for additional machining work, which can increase lead times and costs.

The Solution:

Buyers should prioritize suppliers that offer custom cutting and machining services for PTFE rods. When placing an order, clearly communicate your specific size requirements and application details. Some suppliers offer the option to cut rods to the desired length or provide machining services that can include drilling, milling, or shaping. Additionally, consider discussing potential modifications with your supplier to create a tailored solution that meets your exact specifications. Utilizing CAD drawings or technical sketches can also aid in conveying your requirements more effectively. By working closely with suppliers, buyers can ensure that the delivered products are ready for immediate use, minimizing the need for further processing.

Scenario 3: Managing Lead Times and Shipping Costs

The Problem:

B2B buyers often struggle with long lead times and high shipping costs associated with sourcing 2.75 diameter grade J PTFE rods, particularly when ordering from international suppliers. Extended lead times can disrupt production schedules, while high shipping costs can erode profit margins, especially for smaller orders.

The Solution:

To effectively manage lead times and shipping costs, buyers should consider a few strategic approaches. First, consolidate orders to increase volume, which can lead to better pricing and potentially lower shipping rates. Engage with suppliers that offer flexible shipping options, such as expedited shipping for urgent needs or bulk shipping to reduce costs. Additionally, building a local supplier network in the target regions of Africa, South America, the Middle East, and Europe can significantly cut down on shipping times and costs. Conduct thorough research to identify suppliers who can meet your needs closer to your operational base. Lastly, maintaining an optimal stock level of critical materials can provide a buffer against supply chain disruptions, allowing your operations to continue smoothly while waiting for new shipments.

Strategic Material Selection Guide for 2.75 diameter grade j ptfe rod

When selecting materials for a 2.75 diameter grade J PTFE rod, it is essential to consider various options based on their properties, advantages, and limitations. This analysis focuses on four common materials: Virgin PTFE, PCTFE, Filled PTFE, and UHMW-PE. Each material has unique characteristics that influence its suitability for specific applications.

What are the Key Properties of Virgin PTFE for Industrial Applications?

Virgin PTFE (Polytetrafluoroethylene) is renowned for its excellent chemical resistance, low friction, and high-temperature tolerance (up to 260°C). It is non-reactive, making it suitable for various aggressive media. The material is also FDA compliant, which is crucial for food and pharmaceutical applications.

Pros: Virgin PTFE offers exceptional durability and longevity, making it ideal for seals, gaskets, and bearings in industries such as chemical processing and food production. Its low friction properties enhance the lifespan of moving components.

Cons: However, Virgin PTFE has lower mechanical strength compared to other materials, which may limit its use in high-stress applications. Additionally, it can be more expensive than alternative materials.

Impact on Application: Virgin PTFE is compatible with a wide range of chemicals, making it suitable for applications in diverse industries. Its non-stick surface also facilitates easy cleaning in food processing environments.

How Does PCTFE Compare as an Alternative Material?

PCTFE (Polychlorotrifluoroethylene) is another fluoropolymer known for its excellent chemical stability and cold flow resistance. It can withstand harsh chemicals and radiation exposure, making it suitable for aerospace and food processing applications.

Pros: PCTFE has superior dimensional stability and is FDA compliant, which is essential for applications in regulated industries. Its cold flow resistance prevents deformation under extreme conditions.

Cons: The primary drawback of PCTFE is its higher cost compared to Virgin PTFE. Additionally, it may not perform as well in high-temperature applications, limiting its versatility.

Impact on Application: PCTFE is particularly effective in applications requiring high purity and resistance to aggressive chemicals, making it a preferred choice in the pharmaceutical sector.

What are the Advantages of Filled PTFE for Specific Applications?

Filled PTFE incorporates various fillers, such as glass or carbon, to enhance its mechanical properties. This material retains the chemical resistance of Virgin PTFE while improving strength and wear resistance.

Pros: Filled PTFE offers improved dimensional stability and can handle higher loads, making it suitable for demanding applications like bearings and bushings.

Cons: The addition of fillers can reduce the material’s chemical resistance and increase its brittleness. It may also be more challenging to machine compared to Virgin PTFE.

Impact on Application: Filled PTFE is ideal for applications requiring enhanced strength and wear resistance, particularly in mechanical components exposed to friction.

How Does UHMW-PE Fit into the Selection Process?

UHMW-PE (Ultra-High Molecular Weight Polyethylene) is a thermoplastic known for its high impact strength and low friction properties. While not a fluoropolymer, it offers excellent wear resistance and is often used in applications involving sliding surfaces.

Pros: UHMW-PE is cost-effective and easy to machine, making it a popular choice for various industrial applications. Its low friction properties reduce wear on mating surfaces.

Cons: However, UHMW-PE has lower chemical resistance compared to PTFE materials, which may limit its application in aggressive chemical environments. It also has a lower temperature tolerance, typically up to 80°C.

Impact on Application: UHMW-PE is suitable for applications in bulk material handling and conveyor systems but may not be ideal for environments requiring high chemical resistance.

Summary Table of Material Selection for 2.75 Diameter Grade J PTFE Rod

| Material | Typical Use Case for 2.75 diameter grade j ptfe rod | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Virgin PTFE | Seals, gaskets, bearings in chemical processing | Excellent chemical resistance | Lower mechanical strength | High |

| PCTFE | Aerospace, food processing applications | Superior dimensional stability | Higher cost compared to PTFE | High |

| Filled PTFE | Bearings, bushings in mechanical applications | Enhanced strength and wear resistance | Reduced chemical resistance | Medium |

| UHMW-PE | Bulk material handling, conveyor systems | Cost-effective and easy to machine | Lower chemical resistance | Low |

This strategic material selection guide provides essential insights for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the properties, advantages, and limitations of each material will facilitate informed decision-making in selecting the most suitable option for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for 2.75 diameter grade j ptfe rod

What Are the Main Stages of Manufacturing for 2.75 Diameter Grade J PTFE Rod?

The manufacturing process for 2.75 diameter grade J PTFE rods involves several key stages that ensure high-quality output suitable for demanding applications.

Material Preparation

The first step involves sourcing high-grade virgin PTFE resin. The resin is typically in powder form and must meet specific purity standards. This powder is subjected to a pre-processing phase, where it is thoroughly mixed and sometimes blended with additives to enhance properties like thermal stability or color.

Forming Techniques

The forming process for PTFE rods can vary, but the most common method is extrusion. During extrusion, the mixed resin is heated and forced through a die to create a continuous rod shape. This technique allows for precise control over dimensions and consistency. For applications requiring tighter tolerances, machining may follow the extrusion process.

Assembly and Finishing

For the 2.75 diameter grade J PTFE rods, assembly is generally minimal since the rods are often used as standalone components. However, finishing processes like cutting to specific lengths, surface polishing, or applying surface treatments may be employed to enhance performance characteristics. These processes ensure that the rods meet the required specifications for applications such as seals, gaskets, and industrial machinery.

How Is Quality Assurance Implemented in PTFE Rod Manufacturing?

Quality assurance (QA) is critical in the manufacturing process of PTFE rods to guarantee that products meet both international standards and customer specifications.

What International Standards Are Relevant for PTFE Rods?

For manufacturing PTFE rods, compliance with international standards such as ISO 9001 is essential. This standard emphasizes a quality management system that focuses on continuous improvement and customer satisfaction. Additionally, industry-specific certifications may be required, including CE marking for compliance with European regulations or API standards for applications in the oil and gas sector.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in the manufacturing of PTFE rods typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial phase inspects raw materials to ensure they meet specified standards. Tests may include dimensional checks and chemical composition analysis.

-

In-Process Quality Control (IPQC): During manufacturing, random samples of PTFE rods are taken for inspection. Key parameters such as diameter, length, and surface finish are measured to ensure consistency and adherence to specifications.

-

Final Quality Control (FQC): Once production is complete, the finished rods undergo a final inspection. This includes tests for mechanical properties, chemical resistance, and thermal stability to confirm that they meet the required standards before shipment.

What Common Testing Methods Are Used for PTFE Rods?

Testing methods for PTFE rods can vary based on their intended applications, but some common techniques include:

-

Dimensional Inspection: Utilizing calipers and gauges to ensure that the rod dimensions meet specified tolerances.

-

Mechanical Testing: Assessing properties like tensile strength, elongation, and compressive strength through standardized tests.

-

Chemical Resistance Testing: Exposing samples to various chemicals to evaluate performance and durability under specific conditions.

-

Thermal Analysis: Using Differential Scanning Calorimetry (DSC) or Thermogravimetric Analysis (TGA) to determine thermal stability and behavior under heat.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is crucial for ensuring product reliability.

What Are Effective Ways to Audit Suppliers?

Conducting supplier audits is one of the most effective ways to verify quality control practices. Buyers should assess:

-

Documentation: Request quality management system documentation, including ISO certifications and quality manuals.

-

Process Observations: Observe manufacturing processes to understand how QC is integrated into each stage of production.

-

Sampling Plans: Review the supplier’s sampling and testing plans to ensure they align with industry best practices.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide additional assurance of product quality. These organizations can conduct independent assessments and audits, offering unbiased reports on compliance with specified standards and practices. This is particularly important for international buyers who may face language barriers or cultural differences that complicate direct communication with suppliers.

What Are the QC and Certification Nuances for International Buyers?

International buyers should be aware of specific nuances in quality control and certification that can impact procurement decisions.

How Do Regional Regulations Affect Quality Standards?

Different regions may have unique regulatory requirements that affect the quality standards of PTFE rods. For example, the European Union has stringent regulations regarding materials used in food applications, which may not be as strict in other regions. Buyers should ensure that their suppliers comply with local regulations, particularly if the rods are intended for critical applications such as food processing or medical devices.

What Should Buyers Consider Regarding Product Traceability?

Product traceability is vital for quality assurance, particularly in industries like aerospace and pharmaceuticals. Buyers should inquire about the traceability of materials used in the manufacturing of PTFE rods, ensuring that suppliers can provide documentation that verifies the origin and quality of their raw materials.

In summary, understanding the manufacturing processes and quality assurance practices for 2.75 diameter grade J PTFE rods is essential for B2B buyers. By focusing on international standards, effective QC checkpoints, and thorough supplier verification methods, buyers can ensure they procure high-quality products that meet their specific application needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2.75 diameter grade j ptfe rod’

In the competitive landscape of industrial procurement, sourcing a 2.75 diameter grade J PTFE rod requires a strategic approach. This guide provides an actionable checklist to help international B2B buyers streamline their purchasing process while ensuring quality and compliance with specific industry needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the PTFE rod, including dimensions, grade (in this case, grade J), and any specific performance characteristics. This ensures you receive products that meet your application needs, such as chemical resistance, temperature tolerance, and mechanical properties. Consider the following:

– Chemical Resistance: Identify the chemicals the rod will be exposed to.

– Physical Properties: Specify requirements like tensile strength and thermal stability.

Step 2: Research Supplier Options

Conduct comprehensive research to identify potential suppliers specializing in PTFE products. Look for manufacturers and distributors with a strong reputation in the market. Key factors to consider include:

– Industry Experience: Suppliers with a proven track record in your industry will better understand your needs.

– Product Range: Ensure they offer a variety of PTFE products, which might be useful for future projects.

Step 3: Verify Supplier Certifications

It’s essential to confirm that suppliers hold relevant certifications that ensure product quality and compliance with industry standards. This includes ISO certifications and any specific certifications for chemical safety or food-grade materials. Pay attention to:

– Quality Assurance Processes: Inquire about their manufacturing quality control.

– Compliance with Regulations: Ensure adherence to local and international standards.

Step 4: Request Material Data Sheets (MDS)

Before placing an order, request detailed material data sheets for the grade J PTFE rods. These documents provide critical information regarding the physical and chemical properties of the material, allowing you to make informed decisions. Look for:

– Mechanical Properties: Information on tensile strength, elongation, and hardness.

– Chemical Resistance Charts: A list of chemicals the material can withstand.

Step 5: Evaluate Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare pricing and payment terms. While it’s tempting to choose the lowest price, consider the total cost of ownership, which includes shipping, handling, and potential import duties. Key considerations include:

– Volume Discounts: Inquire about pricing for bulk orders.

– Payment Flexibility: Look for terms that allow for secure transactions and reasonable payment timelines.

Step 6: Assess Shipping and Delivery Options

Understanding the logistics of shipping is crucial, especially for international purchases. Evaluate the supplier’s shipping capabilities and delivery timelines to ensure they align with your project schedules. Important points to check:

– Shipping Methods: Confirm whether they offer expedited shipping options if necessary.

– Tracking and Support: Ensure you can track your order and that the supplier provides support during the shipping process.

Step 7: Establish a Long-Term Relationship

After successfully procuring the PTFE rods, consider establishing a long-term relationship with your chosen supplier. This can lead to better pricing, priority service, and access to new products. Focus on:

– Feedback Mechanisms: Provide feedback on product performance to improve future transactions.

– Ongoing Communication: Maintain regular communication to stay informed about new offerings and industry trends.

Illustrative image related to 2.75 diameter grade j ptfe rod

By following this checklist, B2B buyers can effectively navigate the procurement process for 2.75 diameter grade J PTFE rods, ensuring they make informed decisions that align with their operational requirements.

Comprehensive Cost and Pricing Analysis for 2.75 diameter grade j ptfe rod Sourcing

What Are the Key Cost Components in Sourcing 2.75 Diameter Grade J PTFE Rods?

When sourcing 2.75 diameter grade J PTFE rods, various cost components come into play, impacting the overall pricing structure. The primary components include:

-

Materials: The cost of virgin PTFE resin is a significant factor. PTFE is known for its exceptional chemical resistance and low friction properties, which justify its premium pricing. The quality of the raw material directly affects performance and application suitability.

-

Labor: Manufacturing PTFE rods requires skilled labor, particularly in extrusion processes. Labor costs can vary by region, impacting the final price. Countries with higher labor costs may have higher pricing, while regions with lower labor costs may offer more competitive rates.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. In regions with advanced manufacturing capabilities, such as parts of Europe, these costs may be higher, influencing the pricing of PTFE rods.

-

Tooling: The initial setup for manufacturing PTFE rods can be substantial, especially if custom tooling is required for specific applications. This upfront cost is often amortized over the production run, affecting the pricing for bulk orders.

-

Quality Control (QC): Ensuring the rods meet industry standards necessitates a robust QC process. The cost of inspections and certifications can add to the overall price, particularly for industries with stringent compliance requirements, such as food and pharmaceuticals.

-

Logistics: Transportation costs can vary significantly based on the origin of the materials and the destination of the products. International shipping, tariffs, and local taxes can all contribute to higher logistics costs, particularly for buyers in Africa, South America, and the Middle East.

-

Margin: Suppliers will include a profit margin in their pricing. This margin can vary based on the supplier’s market position, competition, and the demand for PTFE products.

How Do Price Influencers Affect the Cost of 2.75 Diameter Grade J PTFE Rods?

Several factors can influence the pricing of PTFE rods:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts due to economies of scale. Buyers should inquire about bulk pricing and consider consolidating orders to reach MOQs that can secure better rates.

-

Specifications and Customization: Custom sizes or specifications (e.g., specific lengths, grades) can increase costs. Standard products typically have lower prices due to established production processes.

-

Material Quality and Certifications: Higher quality materials and certifications (like FDA compliance) can lead to increased costs. Buyers should assess their requirements to avoid paying for unnecessary certifications.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more for their reliability and quality assurance, while newer suppliers might offer lower prices to attract business.

-

Incoterms: Understanding international shipping terms is crucial. Different Incoterms (e.g., FOB, CIF) can affect who bears the cost of shipping and insurance, impacting the total cost of ownership for international buyers.

What Are the Best Tips for Buyers Looking to Source 2.75 Diameter Grade J PTFE Rods?

For international B2B buyers, particularly from diverse markets such as Africa, South America, the Middle East, and Europe, it’s essential to adopt strategic sourcing practices:

-

Negotiate Pricing: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers may offer discounts for volume purchases or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront cost but also the long-term implications of sourcing decisions. Consider factors such as shipping costs, potential downtime, and the reliability of the supplier.

-

Be Aware of Pricing Nuances: International buyers should be cognizant of currency fluctuations, local tariffs, and import duties that may affect the final cost.

-

Request Samples: Before committing to large orders, request samples to evaluate quality and performance. This can save costs in the long run by ensuring you are satisfied with the product.

By understanding these cost components and price influencers, B2B buyers can make informed decisions that align with their business needs while optimizing their sourcing strategies.

Illustrative image related to 2.75 diameter grade j ptfe rod

Alternatives Analysis: Comparing 2.75 diameter grade j ptfe rod With Other Solutions

Introduction: Exploring Alternatives to the 2.75 Diameter Grade J PTFE Rod

In the realm of industrial materials, finding the right solution for specific applications is crucial. The 2.75 diameter Grade J PTFE rod is a popular choice due to its excellent chemical resistance and low friction properties. However, there are alternative materials that may better suit certain applications or provide cost benefits. This analysis compares the 2.75 diameter Grade J PTFE rod with two viable alternatives: PCTFE (polychlorotrifluoroethylene) rod and UHMW (Ultra-High Molecular Weight) polyethylene rod.

Comparison Table

| Comparison Aspect | 2.75 Diameter Grade J PTFE Rod | PCTFE Rod | UHMW Polyethylene Rod |

|---|---|---|---|

| Performance | Excellent chemical resistance; low friction; non-stick surface | Superior cold flow resistance; FDA compliant; high strength | High impact resistance; good wear properties; lower friction than many plastics |

| Cost | $504.24 for 6 ft | Price varies; typically higher | Generally lower than PTFE and PCTFE |

| Ease of Implementation | Readily available; easy to machine | Requires specific cutting tools; less common | Easy to machine; widely available |

| Maintenance | Minimal; long lifespan | Minimal; very durable | Low; can wear in high-friction applications |

| Best Use Case | Seals, gaskets, industrial machinery | Aerospace, food processing, pharmaceutical | Conveyor systems, bearings, and wear strips |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of PCTFE Rod?

PCTFE rod offers exceptional cold flow resistance and chemical stability, making it suitable for applications in extreme environments, including aerospace and food processing. Its FDA compliance also makes it an excellent choice for industries requiring stringent safety standards. However, PCTFE is often more expensive than PTFE, and its availability may be limited in some regions, potentially complicating procurement for B2B buyers.

How Does UHMW Polyethylene Rod Compare?

UHMW polyethylene rod is known for its high impact resistance and good wear properties. It is often used in applications such as conveyor systems, bearings, and wear strips. One of the significant advantages of UHMW is its lower cost compared to both PTFE and PCTFE, making it an attractive option for budget-conscious projects. However, it does not offer the same level of chemical resistance as PTFE or PCTFE, which can limit its applicability in environments with harsh chemicals.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate material for your industrial application requires careful consideration of performance characteristics, cost, and specific use cases. While the 2.75 diameter Grade J PTFE rod excels in chemical resistance and low friction, alternatives like PCTFE and UHMW polyethylene may provide better cost efficiency or enhanced performance in certain scenarios. B2B buyers should assess their specific requirements, including environmental conditions and budget constraints, to determine which material will best meet their operational needs. By understanding the strengths and weaknesses of each option, buyers can make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for 2.75 diameter grade j ptfe rod

What Are the Key Technical Properties of a 2.75 Diameter Grade J PTFE Rod?

When considering the procurement of a 2.75 diameter grade J PTFE rod, understanding its essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications to consider:

-

Material Grade

The grade of PTFE indicates the purity and specific properties of the material. Grade J PTFE is a virgin material, meaning it is unfilled and free from any additives that could affect its performance. This high purity level contributes to excellent chemical resistance and low friction, making it suitable for demanding applications such as seals and gaskets in various industries. -

Diameter and Length Tolerance

For a 2.75-inch diameter rod, the manufacturing process typically involves specific tolerances, which define the allowable variations in size. Tolerances are crucial for ensuring that components fit correctly in their applications, preventing issues such as leakage in seals or malfunction in machinery. Standard tolerances for PTFE rods can range from ±0.125 inches, but always confirm with suppliers for precise specifications. -

Chemical Resistance

One of the standout properties of PTFE is its remarkable resistance to a wide variety of chemicals, including acids, bases, and organic solvents. This characteristic is vital for industries such as chemical processing, where materials must withstand harsh environments without degrading. Understanding the chemical compatibility of PTFE with specific substances is essential for ensuring longevity and reliability in applications. -

Temperature Range

PTFE rods can operate effectively across a broad temperature range, typically from -450°F to +500°F (-268°C to +260°C). This capability makes them suitable for high-temperature applications, such as in electrical insulation or in the food and pharmaceutical industries, where thermal stability is essential. -

Mechanical Properties

While PTFE is known for its low friction, it does have lower tensile strength compared to other materials. This means that while it can withstand sliding contact and wear, it may not be suitable for applications requiring high structural integrity. It is crucial to assess whether the mechanical properties align with the intended use of the rod in specific applications. -

Non-Stick Characteristics

The inherent non-stick properties of PTFE make it an ideal choice for applications requiring easy release, such as molds or coatings. Understanding this property can aid in selecting the right material for industries focused on food processing or manufacturing non-stick surfaces.

What Trade Terms Are Commonly Used in the Procurement of PTFE Rods?

Navigating the procurement process involves familiarity with specific trade terminology. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for ensuring that the PTFE rod meets the quality standards required for integration into larger systems. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is essential for budgeting and inventory management, especially for international buyers who may be interested in large-scale procurement. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for a specific quantity of goods. It is vital for comparing costs and ensuring that you receive competitive pricing for the PTFE rods needed for your applications. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is essential for international buyers to understand their obligations and rights in the procurement process. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is crucial for planning production schedules, particularly in industries where time-sensitive operations are critical. -

Certification

Many industries require specific certifications for materials, such as FDA compliance for food-related applications. Knowing the certifications associated with PTFE rods can help ensure that the materials meet industry standards and regulations.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions regarding the procurement of 2.75 diameter grade J PTFE rods, ensuring they meet the specific requirements of your applications.

Navigating Market Dynamics and Sourcing Trends in the 2.75 diameter grade j ptfe rod Sector

What Are the Key Market Drivers for the 2.75 Diameter Grade J PTFE Rod Sector?

The global market for 2.75 diameter grade J PTFE rods is driven by several key factors, including increased demand for materials with exceptional chemical resistance and low friction properties. Industries such as aerospace, automotive, food processing, and pharmaceuticals are actively seeking PTFE rods for applications ranging from seals and gaskets to electrical insulation. Emerging markets in Africa and South America, along with established industries in Europe and the Middle East, are prioritizing these materials due to their performance in harsh environments.

Recent advancements in B2B technology are reshaping how international buyers source PTFE rods. Online platforms and e-commerce solutions are enhancing visibility and accessibility for suppliers, while data analytics are being utilized to forecast demand trends and optimize inventory management. Additionally, sustainability considerations are influencing sourcing decisions, leading to a preference for suppliers who demonstrate environmental responsibility and compliance with regulations.

The competitive landscape is also evolving, with manufacturers focusing on product innovation to meet specific industry requirements. For instance, the introduction of FDA-compliant PTFE rods is catering to the food and pharmaceutical sectors, while advancements in production techniques are reducing lead times and costs. This dynamic environment necessitates that international B2B buyers stay informed about market trends to make strategic sourcing decisions.

How Important Is Sustainability and Ethical Sourcing for B2B Buyers of PTFE Rods?

Sustainability is becoming a critical factor in the sourcing of 2.75 diameter grade J PTFE rods. The environmental impact of materials used in manufacturing processes is under scrutiny, prompting businesses to seek suppliers who prioritize eco-friendly practices. Ethical supply chains are essential not only for compliance with international regulations but also for enhancing brand reputation and customer loyalty.

Buyers are increasingly looking for ‘green’ certifications, such as ISO 14001, which demonstrate a commitment to environmental management. Additionally, materials that are recyclable or produced using sustainable practices are gaining traction. The PTFE rod sector is not exempt from these trends; manufacturers are exploring ways to incorporate recycled materials into their products or implement sustainable production methods.

Ethical sourcing also extends to labor practices within the supply chain. International buyers are urged to ensure that their suppliers adhere to fair labor practices, contributing to a responsible global economy. Engaging with suppliers that have transparent supply chains can mitigate risks and enhance the overall value proposition of the procurement process.

How Has the 2.75 Diameter Grade J PTFE Rod Sector Evolved Over Time?

The evolution of the 2.75 diameter grade J PTFE rod sector is a testament to the advancements in polymer science and manufacturing technologies. Initially, PTFE was primarily utilized in industrial applications due to its remarkable chemical resistance and non-stick properties. Over the years, as industries recognized the material’s versatility, the demand for various grades and forms, including rods, began to grow.

In the late 20th century, the introduction of advanced manufacturing techniques allowed for improved production efficiency and customization of PTFE rods. This facilitated the expansion of applications across diverse sectors, including aerospace, medical devices, and food processing. Today, the focus is shifting towards innovation in product formulations, such as the development of PTFE rods that meet stringent regulatory requirements for food and pharmaceutical applications.

As the global marketplace continues to evolve, so too does the landscape for PTFE rod sourcing. Buyers are encouraged to remain agile and informed, leveraging technological advancements and sustainability initiatives to enhance their procurement strategies in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 2.75 diameter grade j ptfe rod

-

How do I choose the right grade of PTFE rod for my application?

Choosing the right grade of PTFE rod, such as Grade J, requires understanding the specific needs of your application. Consider factors like chemical exposure, temperature range, and mechanical stresses. Grade J PTFE offers excellent chemical resistance and low friction, making it suitable for seals and gaskets in various industries. Consult with suppliers to match the rod’s properties with your application requirements, and consider requesting samples to assess performance before placing a bulk order. -

What are the typical applications for a 2.75 diameter Grade J PTFE rod?

A 2.75 diameter Grade J PTFE rod is widely used in applications requiring high chemical resistance and low friction. Common uses include manufacturing seals, gaskets, bearings, and components in chemical processing, food production, and pharmaceutical industries. Its non-stick properties also make it ideal for applications where material buildup is a concern. Understanding your specific application can help in leveraging the benefits of this material effectively. -

What are the minimum order quantities (MOQ) for international buyers?

Minimum order quantities (MOQ) for 2.75 diameter Grade J PTFE rods vary by supplier and can depend on factors like manufacturing costs and shipping logistics. Typically, MOQs can range from 10 to 50 pieces, but it’s crucial to confirm with your supplier. Some manufacturers may offer flexibility for smaller orders, especially for long-term partnerships. Always communicate your needs upfront to negotiate favorable terms. -

What payment terms should I expect when sourcing PTFE rods internationally?

Payment terms for international orders of PTFE rods often vary between suppliers but generally include options like advance payment, net 30, or letter of credit. Many suppliers prefer partial upfront payments to secure the order, with the balance due upon shipping. It’s essential to clarify these terms before placing an order to avoid misunderstandings. Additionally, consider using secure payment methods to protect your financial interests. -

How can I ensure the quality of the PTFE rods I purchase?

To ensure the quality of PTFE rods, request material certifications, which verify that the rods meet industry standards and specifications. Look for suppliers who provide detailed product specifications, including chemical resistance and temperature ratings. Quality assurance processes, such as third-party testing and inspection reports, can also provide assurance. Establishing a good relationship with suppliers who prioritize quality control is vital for long-term success. -

What are the best practices for shipping PTFE rods internationally?

When shipping PTFE rods internationally, choose a reliable logistics partner familiar with handling sensitive materials. Ensure that the rods are properly packaged to prevent damage during transit. Discuss shipping options, including express versus standard shipping, to meet your timeline and budget. Additionally, consider customs regulations in your destination country to avoid delays, and ensure that all necessary documentation is prepared in advance. -

Can I customize the dimensions or specifications of the PTFE rods?

Yes, many suppliers offer customization options for PTFE rods, including specific lengths, diameters, and grades. If you have unique requirements for your application, communicate these to the supplier. Custom manufacturing can affect lead times and pricing, so it’s important to discuss these factors upfront. Some suppliers may also offer prototype services to help you evaluate the customized product before committing to larger orders. -

What certifications should I look for when sourcing PTFE rods?

When sourcing PTFE rods, look for certifications that indicate compliance with international quality and safety standards. Common certifications include ISO 9001 for quality management systems and FDA compliance for food-safe applications. Depending on your industry, you may also require certifications related to chemical resistance or environmental impact. Always verify that the supplier can provide relevant certifications to ensure the rods meet your specific regulatory requirements.

Top 10 2.75 Diameter Grade J Ptfe Rod Manufacturers & Suppliers List

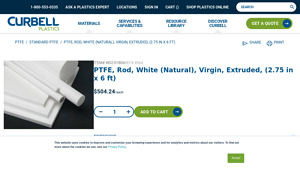

1. Curbell Plastics – PTFE Rod, White (Natural), Virgin, Extruded

Domain: curbellplastics.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “PTFE Rod, White (Natural), Virgin, Extruded”, “Dimensions”: {“Diameter”: “2.75 in”, “Length”: “6 ft”}, “Price”: “$504.24 /each”, “Performance Characteristics”: {“Chemical Resistance”: “Excellent protection against a wide range of chemicals”, “Low Friction”: “Reduces wear and enhances lifespan of components”, “Non-Stick Surface”: “Ensures easy release in applications requiring a n…

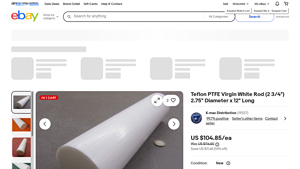

2. Teflon – PTFE Virgin White Rod

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Teflon PTFE Virgin White Rod”, “Diameter”: “2.75 inches”, “Length”: “12 inches”, “Condition”: “New”, “Price”: “$104.85”, “Original Price”: “$116.50”, “Discount”: “10% off”, “Quantity Available”: “2”, “Shipping Cost”: “$20.45”, “Shipping Time”: “2–4 days”, “Returns”: “30 days returns”, “Seller”: “K-mac Distribution”, “Seller Rating”: “99.7% positive”, “Country of Manufacture”: “Un…

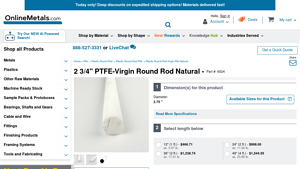

3. Online Metals – 2 3/4 PTFE-Virgin Round Rod Natural

Domain: onlinemetals.com

Registered: 1997 (28 years)

Introduction: {‘name’: ‘2 3/4″ PTFE-Virgin Round Rod Natural’, ‘part_number’: ‘6524’, ‘diameter’: ‘2.75 inches’, ‘available_lengths’: [{‘length’: ’12 inches’, ‘price’: ‘$466.71’, ‘weight’: ‘5.97 lb’}, {‘length’: ’24 inches’, ‘price’: ‘$908.00’, ‘weight’: ‘11.94 lb’}, {‘length’: ’36 inches’, ‘price’: ‘$1,238.74’, ‘weight’: ‘17.91 lb’}, {‘length’: ’48 inches’, ‘price’: ‘$1,544.55’, ‘weight’: ‘23.88 lb’}], ‘materi…

4. McMaster – Rulon J Rods

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Rulon J Rods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Interstate Plastics – PTFE Rod

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: PTFE Rod | Virgin Polytetrafluoroethylene

– Material: PTFE (Polytetrafluoroethylene)

– Characteristics: Resistant to heat and chemicals, inert to most chemicals, extremely low coefficient of friction, FDA approved for food handling, exceptional resistance to high temperatures, chemicals, corrosion, and stress cracking.

– Temperature Range: Functions in environments up to 500°F and as low as -350°F…

6. ePlastics – PTFE Rods

Domain: eplastics.com

Registered: 1998 (27 years)

Introduction: This company, ePlastics – PTFE Rods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Trident Plastics – Virgin Electrical Grade PTFE Rod

Domain: plastics.tridentplastics.com

Registered: 1999 (26 years)

Introduction: {‘product_name’: ‘Virgin Electrical Grade PTFE – Extruded Rod’, ‘material’: ‘PTFE / Teflon®’, ‘properties’: {‘melting_point’: ‘621°F’, ‘density’: ‘2.13 to 2.19 g’, ‘dielectric_constant’: ‘2.1’, ‘coefficient_of_friction’: ‘lower than almost any other material’, ‘temperature_range’: ‘cryogenic temperatures to 500°F’}, ‘sizes’: [{‘item_number’: ‘4240-0125’, ‘diameter’: 0.125, ‘weight’: ‘0.013 lb/ft’}…

8. Interstate AM – PTFE Rod

Domain: interstateam.com

Registered: 2022 (3 years)

Introduction: PTFE Rod | Virgin Polytetrafluoroethylene

– SKU: TFENEV RR

– Available Diameters: .25″, .312″, .375″, .437″, .5″, .562″, .625″, .75″, 1″, 1.125″, 1.25″, .875″, 1.375″, 1.5″, 1.625″, 1.75″, 1.875″, 2″, 2.25″, 2.5″, 2.75″, 3″, 3.25″, 3.5″, 3.75″, 4″, 4.5″, 4.75″, 5″, 5.5″, 6″, 6.5″, 7″, 7.5″, 8″

– Price for .25″ Diameter – 1 Feet: $2.04

– Estimated Shipping: $22.22

– Material: PTFE (Polytetrafluoroe…

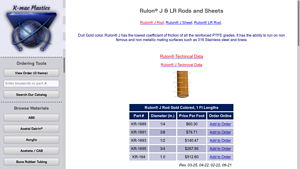

9. KMAC – Rulon J Rod

Domain: kmac-plastics.net

Registered: 2012 (13 years)

Introduction: {‘Rulon_J_Rod’: {‘color’: ‘Gold’, ‘lowest_coefficient_of_friction’: True, ‘compatible_materials’: [‘316 Stainless Steel’, ‘Brass’], ‘sizes’: [{‘part_number’: ‘KR-1689’, ‘diameter_in’: 0.25, ‘price_per_foot’: 60.3}, {‘part_number’: ‘KR-1691’, ‘diameter_in’: 0.375, ‘price_per_foot’: 78.71}, {‘part_number’: ‘KR-1693’, ‘diameter_in’: 0.5, ‘price_per_foot’: 140.47}, {‘part_number’: ‘KR-1695’, ‘diameter…

10. Sterling Plastics – RULON® Filled PTFE

Domain: sterlingplasticsinc.com

Registered: 2005 (20 years)

Introduction: RULON® (FILLED PTFE) is a reinforced PTFE material offered by Sterling Plastics. It provides high compressive strength, low coefficient of friction, chemical resistance, electrical insulation, and excellent abrasion and corrosion resistance without lubrication. Operating temperature range is -400º F to 500º F. Rulon® AR has ceramic fillers, offering flexibility and load carrying properties, common…

Strategic Sourcing Conclusion and Outlook for 2.75 diameter grade j ptfe rod

In conclusion, the strategic sourcing of 2.75 diameter grade J PTFE rods presents significant advantages for businesses across diverse sectors. The inherent properties of virgin PTFE, including outstanding chemical resistance, low friction, and non-stick capabilities, make these rods ideal for applications in industries such as food processing, aerospace, and chemical manufacturing. By prioritizing suppliers that offer high-quality materials, international buyers can enhance operational efficiency and extend the lifespan of their machinery and components.

As the global market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, companies must leverage strategic sourcing to navigate challenges such as fluctuating prices and supply chain disruptions. Establishing strong partnerships with reliable suppliers will ensure access to the best materials while optimizing costs.

Looking ahead, businesses are encouraged to stay informed about advancements in PTFE technology and seek out innovative solutions that align with their operational needs. By embracing proactive sourcing strategies, buyers can secure a competitive edge and drive growth in their respective markets. Now is the time to act—connect with trusted suppliers and explore the extensive benefits that 2.75 diameter grade J PTFE rods can offer.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.