Hot Food Vending Machine: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for hot food vending machine

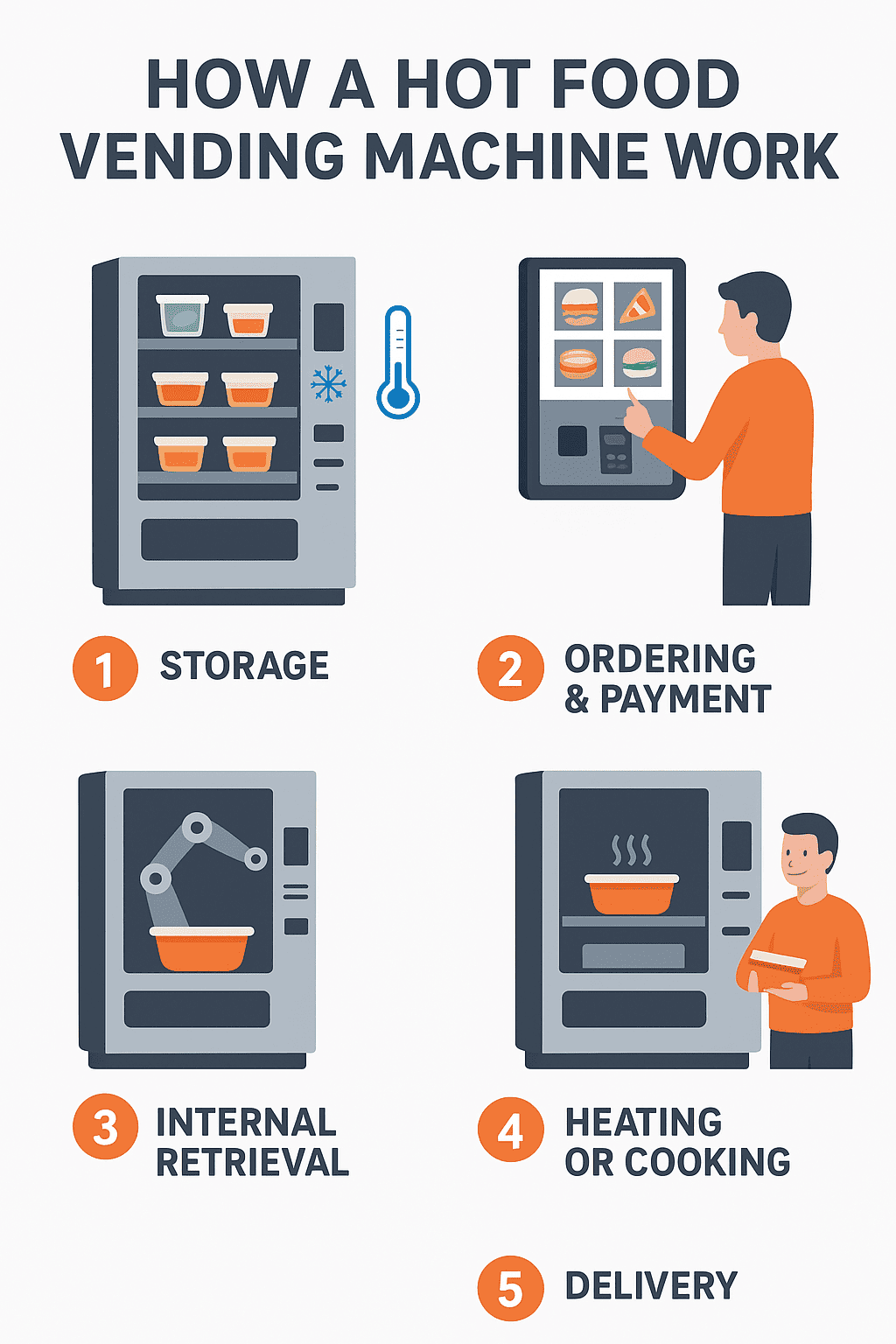

In today’s fast-paced global market, sourcing innovative hot food vending machines presents a unique challenge for international B2B buyers. With the growing demand for convenient, high-quality food options—especially in emerging markets across Africa, South America, the Middle East, and Europe—businesses must navigate a complex landscape of suppliers and technologies. This comprehensive guide offers invaluable insights into the diverse types of hot food vending machines available, their applications, and the latest advancements in technology, such as smart ovens and customizable options.

Buyers will learn how to effectively vet suppliers, ensuring they partner with reputable manufacturers capable of delivering reliable, cutting-edge solutions. Additionally, the guide explores cost considerations, helping businesses make informed purchasing decisions that align with their operational budgets and market needs. By understanding the trends and innovations shaping the hot food vending machine industry, B2B buyers can position themselves to meet customer expectations and enhance their service offerings.

This resource is designed specifically for businesses in regions like Nigeria and Saudi Arabia, where the appetite for accessible hot meal options is on the rise. By leveraging the information presented in this guide, buyers can confidently navigate the global market, empowering their organizations to thrive in an increasingly competitive landscape.

Understanding hot food vending machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Robotic Hot Food Kiosks | Automated cooking with robotics; can prepare a variety of meals on demand | Corporate offices, educational institutions, airports | Pros: Fresh food, customizable menus. Cons: Higher initial investment. |

| Combination Ovens | Utilizes microwave, convection, and infrared heating; suitable for diverse cuisines | Restaurants, cafes, convenience stores | Pros: Versatile cooking options. Cons: Requires regular maintenance. |

| Frozen Meal Heating Machines | Dispenses frozen meals and heats them on demand | Hospitals, gyms, residential complexes | Pros: Convenience, extended shelf life. Cons: Limited menu variety. |

| Modular Hot Food Machines | Configurable units that can serve multiple types of food simultaneously | Micro markets, event venues | Pros: Space-saving, flexible. Cons: Complexity in setup and operation. |

| Smart Food Vending Solutions | Integrates IoT technology for remote monitoring and inventory management | Retail environments, transportation hubs | Pros: Enhanced operational efficiency. Cons: Potential cybersecurity risks. |

What Are Robotic Hot Food Kiosks and Their B2B Suitability?

Robotic hot food kiosks are cutting-edge vending solutions that utilize robotics to prepare a wide range of meals on demand. These machines can serve everything from freshly baked goods to gourmet sandwiches, making them ideal for high-traffic areas like corporate offices and educational institutions. B2B buyers should consider factors such as customization options, operational costs, and the potential for attracting a diverse customer base when investing in these kiosks.

How Do Combination Ovens Enhance Food Vending Operations?

Combination ovens represent a significant advancement in hot food vending technology by combining multiple cooking methods—microwave, convection, and infrared. This versatility allows businesses like cafes and convenience stores to offer a diverse menu, appealing to various consumer tastes. When evaluating combination ovens, B2B buyers should assess the machine’s cooking capacity, energy efficiency, and ease of maintenance, as these factors can directly impact operational success.

Why Choose Frozen Meal Heating Machines for Your Business?

Frozen meal heating machines are designed to dispense frozen meals that are heated on demand, making them particularly suitable for environments such as hospitals and gyms. These machines offer convenience and a longer shelf life for products, which can reduce food waste. However, B2B buyers should consider the limitations in menu variety and the importance of regular inventory turnover to ensure freshness and customer satisfaction.

What Are the Benefits of Modular Hot Food Machines?

Modular hot food machines provide a flexible solution for businesses looking to serve multiple types of food simultaneously. These machines can be customized to fit various spaces, making them ideal for micro markets and event venues. While they offer significant space-saving benefits, B2B buyers must be prepared for the complexities involved in setup and operation, as well as ongoing maintenance requirements.

How Do Smart Food Vending Solutions Transform Operations?

Smart food vending solutions leverage IoT technology for features like remote monitoring and inventory management, enhancing operational efficiency in retail environments and transportation hubs. These machines can provide real-time data on sales and inventory, allowing businesses to make informed decisions. However, B2B buyers should also be aware of potential cybersecurity risks associated with connected devices and ensure they have robust security measures in place.

Key Industrial Applications of hot food vending machine

| Industry/Sector | Specific Application of Hot Food Vending Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Providing healthy meal options in hospitals | Enhances patient satisfaction and nutrition | Compliance with health regulations, menu variety |

| Education | On-campus food services for students | Increases convenience and accessibility for students | Customization options, payment systems, energy efficiency |

| Corporate Offices | Employee dining solutions | Boosts employee morale and productivity | Machine size, menu adaptability, remote monitoring |

| Transportation Hubs | Quick meal solutions in airports and train stations | Reduces wait times and enhances traveler experience | Space constraints, 24/7 operation capability |

| Retail Environments | Snack and meal options in shopping centers | Increases foot traffic and sales | Branding opportunities, inventory management software |

How Are Hot Food Vending Machines Used in Healthcare Settings?

In healthcare facilities, hot food vending machines serve as a vital source of nutritious meals for patients and staff. They help alleviate issues related to limited food service hours and cater to diverse dietary needs. Buyers in this sector should consider machines that comply with health regulations, offer a variety of meal options, and have robust inventory management systems to ensure freshness and availability.

What Role Do Hot Food Vending Machines Play in Educational Institutions?

Colleges and universities utilize hot food vending machines to provide students with convenient access to meals on campus. This application addresses the problem of limited dining options during off-hours. For international buyers, customization of menu offerings to reflect local tastes and dietary restrictions is crucial, along with energy-efficient machines that minimize operational costs.

How Do Hot Food Vending Machines Benefit Corporate Offices?

In corporate environments, hot food vending machines enhance employee satisfaction by providing easy access to hot meals and snacks. This convenience can lead to increased productivity and lower employee turnover. Businesses should prioritize sourcing machines that allow for menu flexibility and integration with cashless payment systems, ensuring a seamless dining experience for employees.

Why Are Hot Food Vending Machines Essential in Transportation Hubs?

Airports and train stations benefit significantly from hot food vending machines, offering travelers quick and satisfying meal options. This application addresses the challenges of long wait times and limited food availability. When sourcing machines for this sector, considerations include the ability to operate 24/7, compact design for space constraints, and the capability to serve a variety of cuisines to cater to diverse passenger preferences.

How Can Retail Environments Leverage Hot Food Vending Machines?

In shopping centers, hot food vending machines provide a convenient solution for hungry shoppers, increasing foot traffic and potential sales. This application can help retailers capitalize on impulse purchases. Key sourcing considerations include branding opportunities on machine exteriors, effective inventory management software, and the ability to offer a rotating menu to keep customer interest high.

3 Common User Pain Points for ‘hot food vending machine’ & Their Solutions

Scenario 1: Difficulty in Ensuring Food Quality and Freshness

The Problem: One of the primary challenges faced by B2B buyers in the hot food vending machine sector is maintaining food quality and freshness. As operators, they are often concerned about the perception of their offerings, especially in regions where food safety and quality are paramount. Inconsistent heating or lack of proper storage can lead to unsatisfactory customer experiences, ultimately harming the brand’s reputation. Additionally, with diverse culinary preferences across markets like Africa and South America, ensuring that the food meets local tastes while remaining fresh poses a significant hurdle.

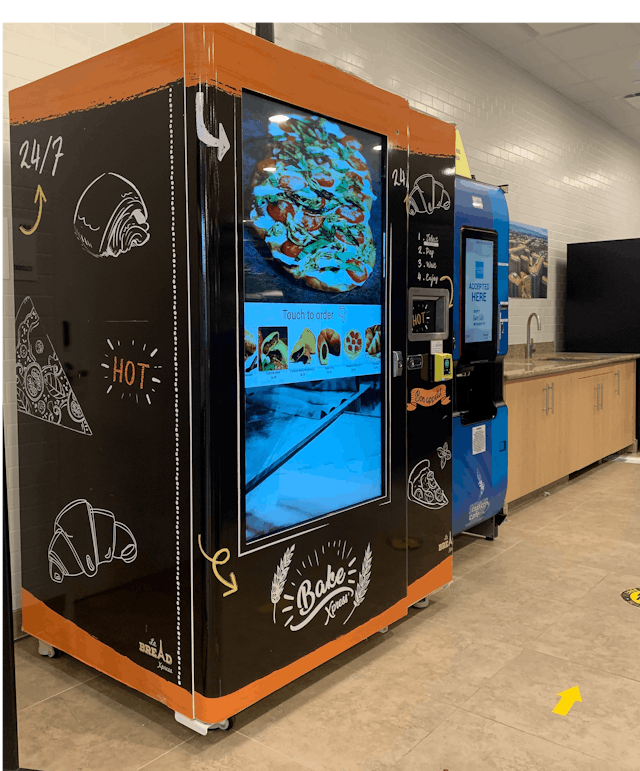

Illustrative image related to hot food vending machine

The Solution: To overcome this challenge, buyers should prioritize sourcing machines that feature advanced heating technologies, such as microwave, infrared, and convection systems, which provide even cooking and proper food temperature maintenance. Brands like Bake Xpress offer machines that can bake a variety of foods on-demand, ensuring that customers receive freshly prepared items. Buyers should also consider partnering with local suppliers for menu customization, allowing for regional favorites that resonate with the target audience. Investing in cloud-based vending management software can facilitate real-time monitoring of food quality and inventory, enabling operators to make data-driven decisions that enhance customer satisfaction.

Scenario 2: Managing Operational Costs and Maintenance

The Problem: B2B buyers often struggle with the operational costs associated with hot food vending machines, particularly in regions where maintenance and repair services may be limited. High energy consumption, along with the costs of sourcing quality ingredients and ensuring compliance with health regulations, can eat into profits. Additionally, machines that frequently break down or require excessive maintenance can lead to downtime, reducing potential sales and frustrating customers.

The Solution: To effectively manage these operational costs, buyers should seek machines that are designed for durability and ease of maintenance. Opting for models with a plug-and-play setup can minimize installation costs and reduce reliance on specialized technicians. It’s advisable to choose machines equipped with remote monitoring capabilities, allowing operators to track performance metrics and receive alerts for maintenance needs before they escalate. Furthermore, negotiating service agreements with local technicians can ensure quicker response times while controlling repair costs. Utilizing energy-efficient machines can also lead to significant savings on utility bills, further enhancing the bottom line.

Scenario 3: Navigating Regulatory Compliance and Safety Standards

The Problem: Compliance with local health and safety regulations is a significant concern for B2B buyers in the hot food vending machine market. Different regions, including those in the Middle East and Europe, have varying standards regarding food safety, machine hygiene, and operational permits. The complexity of navigating these regulations can create barriers to entry for new operators and add layers of responsibility for existing businesses. Failure to comply can result in fines, machine confiscation, or reputational damage.

The Solution: Buyers should begin by conducting thorough research on local regulations regarding food vending operations. Engaging with local health authorities early in the planning process can provide insights into necessary permits and inspections. Selecting machines that meet international safety standards and feature easy-to-clean designs can help ensure compliance. Additionally, investing in training programs for staff on food handling and machine maintenance can foster a culture of safety and compliance. Collaborating with legal experts familiar with local regulations can also streamline the compliance process, allowing operators to focus on providing quality service rather than worrying about legal pitfalls.

Illustrative image related to hot food vending machine

Strategic Material Selection Guide for hot food vending machine

When selecting materials for hot food vending machines, it is essential to consider their properties, advantages, and limitations, especially for international B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe. The right material choice can significantly impact performance, compliance with local standards, and overall product lifecycle.

What Are the Key Properties of Stainless Steel for Hot Food Vending Machines?

Stainless steel is a popular choice for hot food vending machines due to its excellent corrosion resistance and high-temperature tolerance. It typically withstands temperatures up to 800°F (427°C) and pressures up to 1500 psi, making it suitable for various cooking methods, including convection and microwave heating.

Pros and Cons:

Stainless steel is durable and resistant to rust and staining, ensuring long-term use in various environments. However, it can be more expensive than other materials and may require complex manufacturing processes, such as welding and polishing, which can increase production costs.

Impact on Application:

Stainless steel’s resistance to corrosion makes it ideal for environments with high humidity or exposure to food acids. It is also easy to clean, which is crucial for maintaining hygiene standards in food service applications.

Illustrative image related to hot food vending machine

Considerations for International Buyers:

Buyers should ensure compliance with international food safety standards, such as those set by the FDA or EFSA. Additionally, understanding local regulations regarding food contact materials is vital for successful market entry.

How Does Aluminum Perform in Hot Food Vending Machines?

Aluminum is another common material used in hot food vending machines, known for its lightweight and excellent thermal conductivity. It can withstand temperatures up to 600°F (316°C) and is often used for components that require quick heating.

Pros and Cons:

The primary advantage of aluminum is its cost-effectiveness and ease of manufacturing, allowing for more straightforward designs. However, it is less durable than stainless steel and can be prone to warping or denting under high temperatures or pressure.

Impact on Application:

Aluminum’s thermal properties enable efficient heating of food items, making it suitable for machines that rely on rapid heating methods. However, its lower corrosion resistance compared to stainless steel may limit its use in certain environments.

Considerations for International Buyers:

Buyers should be aware of the varying standards for aluminum food contact materials across different regions. Compliance with local regulations, such as those from ASTM or DIN, is crucial for ensuring product safety.

What Role Does Glass Play in Hot Food Vending Machines?

Glass is often utilized in the design of hot food vending machines, particularly for display purposes. It can withstand temperatures up to 500°F (260°C) and is often treated for increased durability.

Pros and Cons:

The aesthetic appeal of glass enhances the visibility of food items, attracting customers. However, glass is more fragile than metal alternatives and can pose safety risks if not properly tempered or laminated. Additionally, its manufacturing process can be more complex and costly.

Impact on Application:

Glass is ideal for showcasing food items while allowing customers to see the product before purchase. However, its fragility can limit its application in high-traffic environments.

Considerations for International Buyers:

Buyers must ensure that the glass used complies with safety standards relevant to their market, particularly in regions with stringent regulations regarding food safety and consumer protection.

How Does Plastic Factor into Hot Food Vending Machine Design?

Plastic materials, particularly high-temperature resistant polymers, are increasingly being used in hot food vending machines for components like casings and internal parts. These plastics can typically withstand temperatures up to 400°F (204°C).

Pros and Cons:

Plastics are lightweight and can be molded into complex shapes, providing design flexibility. However, they may not offer the same level of durability or heat resistance as metals, potentially limiting their application in high-heat areas.

Illustrative image related to hot food vending machine

Impact on Application:

Plastics are excellent for non-structural components and can enhance the machine’s overall design. However, their lower heat resistance may restrict their use in areas directly exposed to high temperatures.

Considerations for International Buyers:

Buyers should verify that the plastics used meet local safety standards for food contact. Additionally, understanding the environmental impact and recyclability of plastics is increasingly important for buyers in regions focused on sustainability.

Summary Table of Material Selection for Hot Food Vending Machines

| Material | Typical Use Case for hot food vending machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, cooking chambers | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Heating elements, lightweight structures | Cost-effective and good thermal conductivity | Less durable, prone to warping | Medium |

| Glass | Display panels, visibility features | Aesthetic appeal and product visibility | Fragile, higher manufacturing cost | Medium |

| Plastic | Casings, non-structural components | Lightweight and design flexibility | Lower heat resistance and durability | Low |

This guide provides a comprehensive overview of material selection for hot food vending machines, enabling international B2B buyers to make informed decisions based on their specific market requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hot food vending machine

What Are the Key Stages in the Manufacturing Process of Hot Food Vending Machines?

The manufacturing process of hot food vending machines is intricate and involves several critical stages. Understanding these stages can help B2B buyers assess the quality and reliability of potential suppliers.

Illustrative image related to hot food vending machine

Material Preparation: How Are Components Sourced and Prepared?

The first stage involves sourcing high-quality materials such as stainless steel for the machine’s body, heat-resistant plastics for internal components, and specialized electronic parts for the control systems. Suppliers often engage in rigorous vendor evaluation to ensure that materials meet industry standards. This phase may also include pre-treatment processes like cleaning and coating to enhance corrosion resistance and durability.

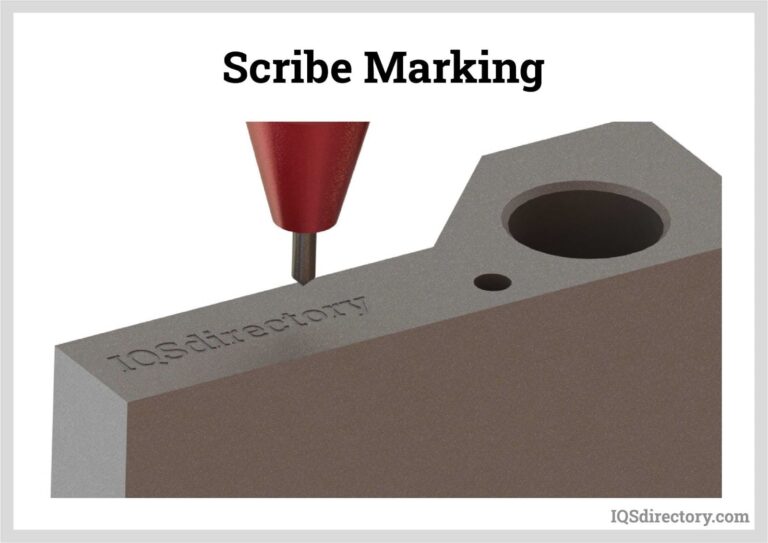

Forming: What Techniques Are Used to Shape Machine Components?

In the forming stage, various techniques such as stamping, molding, and laser cutting are employed to create machine components. Advanced machinery, such as CNC (Computer Numerical Control) machines, ensures precision and consistency in producing parts. This stage focuses on the creation of the machine’s shell, internal compartments for food storage, and heating elements, making it crucial for the overall functionality and safety of the vending machine.

Assembly: How Are Components Integrated into a Functional Unit?

The assembly stage is where all components come together. Skilled technicians assemble the various parts, integrating the heating systems, sensors, and control interfaces. This stage often involves the use of automated assembly lines to increase efficiency and maintain quality standards. Quality assurance checkpoints are typically established during assembly to ensure that each component fits correctly and functions as intended.

Finishing: What Final Touches Are Applied Before Quality Checks?

Once assembled, the machines undergo a finishing process that may include painting, branding, and testing of electrical systems. This stage not only enhances the machine’s aesthetics but also ensures that all electronic and mechanical systems are operational. Aesthetic touches, such as custom branding, allow B2B buyers to differentiate their products in the marketplace.

What Quality Assurance Standards Are Relevant to Hot Food Vending Machines?

Quality assurance is critical in the production of hot food vending machines, ensuring that they meet safety, reliability, and performance standards. Several international and industry-specific standards govern this process.

Illustrative image related to hot food vending machine

Which International Standards Should B2B Buyers Be Aware Of?

ISO 9001 is a widely recognized standard for quality management systems. It ensures that manufacturers maintain consistent quality in their processes and products. Compliance with this standard is a strong indicator of a supplier’s commitment to quality and continuous improvement.

What Industry-Specific Certifications Are Important?

In addition to ISO standards, specific certifications such as CE marking (for compliance with European safety standards) and UL certification (for electrical safety) are crucial for hot food vending machines. These certifications indicate that the machines have been rigorously tested for safety and performance, providing reassurance to B2B buyers.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is embedded throughout the manufacturing process, with several checkpoints designed to catch defects and ensure product quality.

What Are the Main QC Checkpoints?

-

Incoming Quality Control (IQC): This is the first line of defense, where raw materials and components are inspected upon arrival. Tests may include visual inspections and measurements to verify that materials meet specifications.

-

In-Process Quality Control (IPQC): During the assembly process, periodic checks are conducted to ensure that components are being assembled correctly. This may involve functional testing of sub-assemblies before final assembly.

-

Final Quality Control (FQC): After assembly, the complete machine undergoes comprehensive testing. This includes functional tests, safety checks, and performance evaluations to ensure that it operates as intended.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers have a vested interest in ensuring that their suppliers adhere to rigorous quality control practices. Here are some actionable steps to verify these practices.

What Should Buyers Look for in Supplier Audits and Reports?

-

Supplier Audits: Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes and quality control measures. Buyers should request to see audit reports and certifications to assess compliance with international standards.

-

Testing Reports: Requesting detailed testing reports for products can provide evidence of a supplier’s commitment to quality. These reports should outline the methodologies used and the results of various tests performed on the machines.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These inspections can be scheduled at different stages of the manufacturing process to ensure compliance with agreed-upon standards.

What Are the Nuances of Quality Control for International B2B Buyers?

For B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial.

Illustrative image related to hot food vending machine

How Do Regional Regulations Affect Quality Assurance?

Different regions may have specific regulations that affect the manufacturing and quality assurance processes. For example, the Middle East may have stricter food safety regulations that impact how hot food vending machines are designed and tested. Buyers should familiarize themselves with these regulations to ensure compliance.

What Challenges Do B2B Buyers Face in Quality Assurance?

B2B buyers often face challenges such as language barriers, differing standards, and variations in quality expectations across regions. Establishing clear communication with suppliers and understanding local regulations can help mitigate these challenges. Additionally, building relationships with reliable suppliers who prioritize quality assurance can lead to smoother transactions and better product outcomes.

Conclusion: Why Quality Assurance Is Essential in Hot Food Vending Machine Manufacturing

In conclusion, understanding the manufacturing processes and quality assurance measures involved in hot food vending machines is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control practices, buyers can ensure they partner with suppliers who meet their standards. As the global market for hot food vending machines continues to expand, especially in emerging markets, prioritizing quality will be key to successful business operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hot food vending machine’

To assist B2B buyers in procuring hot food vending machines, this guide offers a structured checklist that outlines essential steps to ensure a successful sourcing process. By following these steps, buyers can make informed decisions, minimize risks, and maximize the potential for profitability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial as it helps narrow down the options available in the market. Consider factors such as the types of food you wish to offer, the machine’s heating technology (e.g., convection, microwave), and its size and energy requirements. A well-defined specification aligns your needs with the capabilities of potential machines.

Illustrative image related to hot food vending machine

Step 2: Research Market Trends and Innovations

Understanding current market trends and technological innovations can provide insights into what features are available and what consumers are looking for. Look for machines that offer advanced functionalities such as remote monitoring, customizable interfaces, and energy-efficient operations. Staying informed helps you select a machine that not only meets today’s demands but is also future-proof.

Step 3: Evaluate Potential Suppliers

Before making a purchase, it’s essential to vet potential suppliers thoroughly. Request company profiles, case studies, and references from other businesses in your industry. Look for suppliers with a strong track record, especially in regions similar to your own, as this indicates their capability to meet your specific needs.

- Key Considerations:

- Supplier certifications and compliance with local regulations.

- Customer service and support options post-purchase.

Step 4: Request and Analyze Quotes

Once you have a shortlist of suppliers, request detailed quotes that outline all costs associated with the vending machines. Analyze each quote not just for price, but also for value, including warranty terms, delivery timelines, and installation services. This step ensures you are comparing apples to apples and can identify the best overall deal.

Step 5: Conduct Site Assessments

Before finalizing your order, it’s advisable to conduct site assessments to determine the best locations for the machines. Consider factors such as foot traffic, accessibility, and proximity to power sources. A well-planned placement can significantly enhance the visibility and usage of your vending machines.

Step 6: Negotiate Terms and Finalize Contracts

Effective negotiation is key to securing favorable terms that protect your investment. Discuss payment terms, return policies, and maintenance agreements in detail. Ensure all verbal agreements are documented in the contract to avoid misunderstandings later on.

Illustrative image related to hot food vending machine

Step 7: Plan for Installation and Maintenance

After purchasing the machines, plan for their installation and ongoing maintenance. Coordinate with the supplier for installation support and establish a routine maintenance schedule to ensure the machines operate efficiently. Proper maintenance can extend the life of the vending machines and improve customer satisfaction.

By following this practical checklist, B2B buyers can navigate the complexities of sourcing hot food vending machines with confidence, ensuring they invest in solutions that meet their operational needs and align with market demands.

Comprehensive Cost and Pricing Analysis for hot food vending machine Sourcing

Understanding the cost structure and pricing of hot food vending machines is crucial for international B2B buyers seeking to invest in this growing market. The costs associated with these machines can be broken down into several components, each influencing the overall price.

What Are the Key Cost Components in Hot Food Vending Machines?

-

Materials: The primary materials include stainless steel for the machine body, high-quality heating elements, and food-grade components for safety. Advanced technology integrations, such as touchscreen interfaces and smart sensors, also contribute to material costs.

-

Labor: Labor costs encompass both the workforce involved in manufacturing and the skilled technicians required for assembly and testing. These costs can vary significantly based on the region, with labor rates differing between, for example, Europe and Africa.

-

Manufacturing Overhead: This includes expenses related to factory utilities, equipment depreciation, and administrative costs. Efficient production processes can help minimize these overheads, impacting the final pricing.

-

Tooling: Custom tooling may be necessary for specific machine designs or features. This upfront investment is crucial for manufacturers and can affect the price per unit, especially for customized orders.

-

Quality Control (QC): Ensuring that machines meet international standards requires rigorous testing and inspection, which adds to the overall cost. Certifications for safety and quality can enhance marketability but may also increase production costs.

-

Logistics: Shipping and handling costs are significant, particularly for international buyers. Factors such as shipping methods, distance, and customs duties can dramatically affect the total cost.

-

Margin: Suppliers typically apply a profit margin to cover risks and business sustainability. This margin can vary based on market competition and the uniqueness of the offering.

What Influences Pricing for Hot Food Vending Machines?

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to price reductions. Manufacturers may offer discounts for larger quantities, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Customized machines tailored to specific needs or branding can significantly influence pricing. The more specialized the machine, the higher the potential costs due to additional materials and labor.

-

Materials and Quality Certifications: Premium materials and certifications (like ISO or HACCP) can elevate costs but are often necessary for compliance and customer trust.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their brand value and the assurance of quality.

-

Incoterms: Understanding the terms of shipping and delivery is essential. Different Incoterms can determine who bears the cost of freight, insurance, and customs, thus affecting the total purchase price.

What Tips Can Buyers Use for Cost-Efficiency and Negotiation?

-

Negotiate Terms: Always seek to negotiate on price, MOQ, and payment terms. Many suppliers are open to discussions, especially for larger orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also the operational costs, maintenance, and energy consumption over the machine’s lifespan. A higher upfront cost may lead to lower operational expenses.

-

Research Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers can reduce logistics costs and lead times. It also helps in navigating local regulations more easily.

-

Stay Informed on Market Trends: Keeping abreast of technological advancements and market shifts can provide leverage during negotiations and assist in making informed purchasing decisions.

-

Consider Partnerships: Forming partnerships with suppliers for ongoing needs can lead to better pricing and priority service.

Conclusion

The market for hot food vending machines is expanding, driven by consumer demand for convenience and quality. Understanding the cost structure, pricing influences, and negotiation strategies is vital for international B2B buyers looking to make informed investments in this sector. Prices can vary widely, so careful consideration of the total cost and supplier relationships can lead to significant savings and better product offerings. Always remember that prices are indicative and may fluctuate based on market conditions and individual supplier circumstances.

Alternatives Analysis: Comparing hot food vending machine With Other Solutions

Introduction to Alternative Solutions in Food Dispensing

As the demand for quick and convenient meal options grows, businesses are exploring various solutions beyond traditional hot food vending machines. While these machines offer unique features, there are alternative technologies and methods that can serve similar purposes. Understanding these alternatives allows B2B buyers to make informed decisions based on their specific operational needs, budget constraints, and customer preferences.

Comparison of Hot Food Vending Machines and Alternative Solutions

| Comparison Aspect | Hot Food Vending Machine | Robotic Food Kiosk | Smart Micro Markets |

|---|---|---|---|

| Performance | Offers freshly baked and heated meals on demand. | Provides a variety of freshly prepared foods, including customizable options. | Delivers a wide selection of meals and snacks, typically pre-packaged and heated as needed. |

| Cost | Initial investment can be high; ongoing maintenance costs are moderate. | Higher upfront costs due to advanced technology; maintenance costs can vary. | Moderate initial investment; ongoing costs depend on inventory management. |

| Ease of Implementation | Simple plug-and-play setup; requires minimal installation. | More complex setup; may require specialized installation and training. | Requires space for multiple units; inventory management systems need to be established. |

| Maintenance | Requires regular stock replenishment and occasional technical servicing. | Higher maintenance due to complexity; may need specialized technicians. | Regular stock management; minimal technical maintenance required. |

| Best Use Case | Ideal for locations needing 24/7 hot meal options, such as workplaces or schools. | Best suited for urban areas where demand for gourmet fast food is high. | Suitable for a variety of settings, including offices and community centers, where diverse food options are preferred. |

In-Depth Look at Alternative Solutions

Robotic Food Kiosk

Robotic food kiosks represent an innovative leap in food service technology. These machines can prepare a range of meals on-site, including gourmet burgers and pizzas, using automated cooking processes. Their primary advantage lies in their ability to deliver high-quality, freshly made meals, which can attract a customer base seeking unique dining experiences. However, the higher initial investment and the complexity of maintenance can be significant drawbacks for businesses with tighter budgets or operational constraints.

Smart Micro Markets

Smart micro markets provide an alternative that combines convenience with variety. These setups feature a range of pre-packaged meals, snacks, and beverages in a self-service format. They are particularly appealing for locations where diverse food options are needed, as they can accommodate a wide range of dietary preferences. While the initial investment may be moderate, the real challenge lies in effective inventory management and ensuring that products remain fresh and appealing to customers.

Conclusion: Choosing the Right Food Dispensing Solution

When selecting a food dispensing solution, B2B buyers should carefully consider their specific operational needs, budget, and target customer preferences. Hot food vending machines offer the convenience of freshly prepared meals, making them ideal for high-demand environments. In contrast, robotic food kiosks and smart micro markets provide alternative options that may better suit businesses looking to offer variety and unique dining experiences. By analyzing the performance, costs, implementation ease, maintenance requirements, and best use cases for each option, businesses can make a strategic choice that aligns with their goals and customer expectations.

Illustrative image related to hot food vending machine

Essential Technical Properties and Trade Terminology for hot food vending machine

What Are the Key Technical Properties of Hot Food Vending Machines?

When considering the procurement of hot food vending machines, understanding the technical specifications is crucial. Here are some essential properties that B2B buyers should evaluate:

-

Heating Technology

Hot food vending machines typically utilize a combination of heating technologies, such as microwave, convection, and infrared. These technologies ensure that food is heated evenly and efficiently. For instance, machines like Bake Xpress use a smart oven system that combines these methods to deliver quality meals quickly. Understanding the heating technology is vital for ensuring optimal food quality and customer satisfaction. -

Power Requirements

Most hot food vending machines operate on a standard voltage of 220V, requiring a 20A circuit. This specification is crucial for B2B buyers to consider during installation planning. Ensuring the right power supply can prevent operational downtime and additional installation costs, making it an important factor in the purchasing decision. -

Internet Connectivity

Many modern vending machines come equipped with wireless connectivity options such as WiFi, LTE, or Ethernet. This feature enables remote monitoring and management of inventory and sales through cloud-based vending management systems. For businesses operating in various regions, having reliable connectivity is essential for real-time data access and operational efficiency. -

Customization Options

Customization capabilities allow businesses to brand the machine with their logos and marketing materials. This aspect is particularly valuable for companies looking to enhance brand visibility in competitive markets. Understanding the extent of customization available can help buyers tailor the machines to their specific business needs. -

Compact Design

The physical dimensions of hot food vending machines are often designed to fit in small spaces, making them suitable for various locations such as offices, schools, and hospitals. A compact design allows for easy placement without requiring extensive modifications to the existing infrastructure. -

User Interface

A user-friendly interface, often featuring touchscreens, enhances customer experience by making transactions seamless. This property is critical as it directly impacts customer satisfaction and repeat business.

What Are Common Trade Terms Related to Hot Food Vending Machines?

Navigating the procurement process requires familiarity with industry jargon. Here are several key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or complete machines that are sold under another company’s brand name. Understanding OEM relationships can help buyers ensure they are sourcing high-quality equipment from reputable manufacturers. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and budget planning. Buyers should inquire about MOQs to ensure they can meet supplier requirements without overcommitting to inventory. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. It is a vital part of the procurement process, allowing businesses to compare offers from multiple vendors and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers, as they clarify issues related to shipping, insurance, and tariffs. -

Lead Time

Lead time refers to the time taken from placing an order until it is fulfilled. This term is critical for operational planning, as longer lead times can affect inventory levels and customer satisfaction. -

After-Sales Support

This term encompasses the services provided by a supplier after the purchase of equipment, including maintenance, repairs, and customer service. Understanding the level of after-sales support available is crucial for ensuring long-term operational efficiency and minimizing downtime.

By comprehensively understanding these technical properties and trade terms, B2B buyers can make more informed decisions when investing in hot food vending machines, ultimately leading to enhanced operational success and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the hot food vending machine Sector

What Are the Current Market Dynamics and Key Trends in Hot Food Vending Machines?

The hot food vending machine market is witnessing significant growth, driven by urbanization, changing consumer habits, and advancements in technology. The global market is projected to reach approximately $4.8 billion in 2024, with a robust compound annual growth rate (CAGR) of 6.60% anticipated through 2034. Key drivers include the increasing demand for convenient food options, particularly in urban areas, and the rise of on-demand services that cater to busy lifestyles. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, there is an emerging trend towards machines that offer customizable menus and the ability to prepare a wide variety of fresh meals on-site.

Innovative technologies are transforming the sector, with machines now incorporating smart ovens that combine microwave, convection, and infrared cooking methods, thus enabling the preparation of high-quality meals in minutes. This shift is accompanied by the integration of advanced vending management software that allows operators to monitor inventory and sales remotely, enhancing operational efficiency. Furthermore, the trend towards automation is leading to partnerships between vending solutions and coffee machines or even robotic systems, offering comprehensive service solutions that attract a broader customer base.

How Is Sustainability Influencing Hot Food Vending Machine Sourcing?

Sustainability is becoming a crucial consideration in the hot food vending machine sector, as both consumers and businesses increasingly prioritize environmental responsibility. The sourcing of materials for these machines is evolving, with a focus on eco-friendly components and ‘green’ certifications. This shift not only reduces the environmental impact but also enhances brand reputation among consumers who are more conscious of their choices.

Ethical sourcing practices are essential for B2B buyers looking to establish a sustainable supply chain. This includes selecting suppliers who adhere to fair labor practices and environmentally friendly production processes. The use of recyclable materials in machine construction, energy-efficient designs, and waste reduction strategies are becoming benchmarks for responsible sourcing in this industry. Buyers should seek vendors that can demonstrate their commitment to sustainability through certifications and transparent supply chain practices, aligning their business models with the growing demand for ethical consumerism.

What Has Been the Evolution of Hot Food Vending Machines?

The evolution of hot food vending machines can be traced back to traditional vending systems that primarily offered snacks and cold beverages. However, as consumer preferences shifted towards fresher, healthier options, the industry began integrating cooking technology into vending machines. This transition started gaining momentum in the late 2010s with the introduction of machines that could heat and cook food on demand, offering consumers a greater variety of meal options.

Illustrative image related to hot food vending machine

Recent advancements have seen the emergence of fully automated systems, such as robotic kiosks capable of preparing gourmet meals and snacks in real-time. These innovations not only cater to the growing demand for convenience but also enhance the quality of food offered, setting a new standard in the vending industry. Today, hot food vending machines represent a fusion of technology, culinary innovation, and consumer convenience, positioning themselves as a viable solution for modern food service needs.

Frequently Asked Questions (FAQs) for B2B Buyers of hot food vending machine

-

How do I choose the right hot food vending machine for my business needs?

Choosing the right hot food vending machine involves assessing your target market’s preferences, available space, and budget. Consider machines that offer a diverse menu, such as pizzas, sandwiches, and pastries, to cater to various tastes. Evaluate the technology behind the machines, including heating methods like microwave and convection, for consistent food quality. Additionally, look for customization options that allow you to brand the machine and tailor the menu to your clientele. Partnering with suppliers who provide robust customer support and training can also enhance your operational efficiency. -

What are the key features to look for in a hot food vending machine?

When sourcing a hot food vending machine, prioritize features such as menu flexibility, ease of use, and maintenance requirements. Ensure the machine has advanced heating technology for optimal food quality, like a combination of microwave and convection ovens. Look for remote monitoring capabilities to track inventory and sales data, as well as customizable branding options for a personalized touch. Additionally, confirm that the machine is compact and easy to install, which can significantly reduce setup costs and time. -

What are the typical payment terms when purchasing hot food vending machines internationally?

Payment terms for international purchases of hot food vending machines can vary widely among suppliers. Common practices include a deposit upfront (usually 30-50% of the total cost), with the remaining balance due before shipping or upon delivery. It’s crucial to clarify the payment methods accepted, such as bank transfers or letters of credit, and to understand any additional fees related to currency conversion. Negotiating favorable terms that align with your cash flow and operational needs can enhance the purchasing experience. -

How can I ensure the quality of hot food vending machines before purchasing?

To ensure the quality of hot food vending machines, conduct thorough supplier vetting. Request product samples or demonstrations to evaluate the machine’s performance and food quality. Check for certifications and compliance with international food safety standards, which can assure you of the machine’s reliability. Additionally, seek reviews and testimonials from other buyers in your region. Establishing communication with suppliers regarding warranty policies and after-sales support can also help mitigate risks. -

What are the minimum order quantities (MOQ) for hot food vending machines?

Minimum order quantities (MOQ) for hot food vending machines can differ significantly based on the manufacturer and the complexity of the machines. Some suppliers may have a MOQ of one unit, especially for customized machines, while others might require a bulk order to justify production costs. It is advisable to discuss your specific needs with potential suppliers to negotiate terms that suit your business model. Understanding the implications of MOQ on pricing and logistics is crucial for budget planning. -

What logistical considerations should I keep in mind when importing hot food vending machines?

Logistical considerations for importing hot food vending machines include shipping methods, customs regulations, and local distribution channels. Choose a reliable freight forwarder who understands the complexities of international shipping and can handle customs clearance efficiently. Factor in shipping times, which can vary based on the origin and destination. Additionally, be aware of any import duties or taxes that may apply, as these can impact your overall costs. Establishing a clear logistics plan will help ensure timely delivery and minimize disruptions. -

How can I customize hot food vending machines to fit my brand?

Customization options for hot food vending machines often include exterior branding, menu selection, and user interface design. Many suppliers offer white-label solutions, allowing you to incorporate your logo and colors. You can also work with suppliers to create a unique menu that reflects local tastes and dietary preferences. Consider integrating technology, such as digital screens, to enhance customer engagement through promotions and nutritional information. Discuss your branding vision with the supplier to explore all available customization avenues. -

What are the maintenance requirements for hot food vending machines?

Maintenance requirements for hot food vending machines generally include regular cleaning, inspection of heating elements, and restocking of food items. Establish a routine maintenance schedule to ensure optimal performance and food safety. Suppliers often provide guidelines on cleaning procedures and recommended maintenance intervals. Additionally, consider machines with remote monitoring capabilities, which can alert you to potential issues before they escalate. Training your staff on proper machine care can significantly extend the lifespan of your investment and enhance customer satisfaction.

Top 4 Hot Food Vending Machine Manufacturers & Suppliers List

1. Vendlife – Healthy Hot Food Vending Machines

Domain: vendlife.cn

Registered: 2019 (6 years)

Introduction: Healthy Hot and Fresh Food Vending Machine – Vendlife. Features include: Smooth shipment, Anti-Condensation-proof electric heat glass. Product types include: Oven Frozen Lunch Box Meal Automatic Hot Food Vending Machine, Elevator Bread Fast Heat Hot Food Pizza Vending Machine with Double Microwave, Mini Fresh Salad Food Vending Machine for Meals & Drink, Frozen Food Vending Machine with Microwave …

2. TCN – Hot Food Vending Machines

Domain: tcnvend.com

Registered: 2018 (7 years)

Introduction: Hot Food Vending Machine – TCN-CFM-8V with 21.5 inch touch screen, convenient lunch and dinner service, refrigerates at -18 C, includes various models such as Mini hot food vending machine, Double Microwave Hot Food Vending Machine, and TCN Breakfast Vending Machine. TCN offers OEM/ODM options for warm food and hot meal fast food vending machines.

3. FoodtoGo – Hot Food Vending Machine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”Hot Food Vending Machine”,”Seller”:”f foodtogo”,”Price”:”US $13,000.00″,”Condition”:”New”,”Shipping Cost”:”US $85.41″,”Location”:”Homestead, Florida, United States”,”Estimated Delivery”:”Between Mon, Sep 22 and Sat, Sep 27 to 20147″,”Returns”:”Seller does not accept returns”,”Payment Options”:”As low as $624.11/mo with Klarna”,”Item Number”:”356249429436″,”Model”:”TCN-CFM-8V+CFM-Z…

4. Lovefood – Unusual Hot Food Vending Machines

Domain: lovefood.com

Registered: 2003 (22 years)

Introduction: This company, Lovefood – Unusual Hot Food Vending Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for hot food vending machine

In the evolving landscape of the hot food vending machine industry, strategic sourcing plays a pivotal role in ensuring that international B2B buyers can capitalize on emerging trends and technologies. The integration of advanced features such as customizable menus, remote monitoring, and innovative heating technologies positions these machines as versatile solutions for various market segments. As demand for convenient, fresh, and hot meal options increases, especially in urban areas across Africa, South America, the Middle East, and Europe, sourcing high-quality machines that meet local preferences is essential.

Moreover, the ability to adapt and customize these machines to reflect regional tastes and branding will enhance market penetration and consumer loyalty. As the market is projected to grow significantly, with estimates reaching over $9 billion by 2034, now is the time for businesses to invest in hot food vending solutions that are not only efficient but also scalable.

B2B buyers are encouraged to explore partnerships with leading manufacturers and technology providers to leverage the latest innovations. By taking proactive steps in strategic sourcing, you can position your business at the forefront of this lucrative market, ensuring you meet the evolving demands of consumers while maximizing profitability. Embrace the future of vending—your next hot food solution awaits!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to hot food vending machine

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.