Hidden Piano Hinge Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for hidden piano hinge

In today’s competitive landscape, sourcing high-quality hidden piano hinges can present a significant challenge for international B2B buyers. With various materials, designs, and applications available, navigating the intricacies of the global market requires a keen understanding of product specifications and supplier reliability. This guide serves as a comprehensive resource, addressing critical aspects such as types of hidden piano hinges, their applications across diverse industries, and essential criteria for vetting suppliers.

By exploring the unique features of hidden piano hinges, including their concealed functionality and durability, buyers can make informed decisions that enhance the longevity and aesthetic appeal of their projects. Additionally, this guide delves into cost considerations, helping you weigh the benefits of investing in high-quality hinges against budget constraints.

Whether you are operating in Africa, South America, the Middle East, or Europe, understanding these elements will empower you to navigate the complexities of the hinge market confidently. Our insights will equip you with the knowledge needed to select the right products for your specific applications, ensuring that your sourcing process is both efficient and effective. Embrace this opportunity to enhance your procurement strategy and achieve greater success in your projects.

Understanding hidden piano hinge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Concealed Leaf Continuous Hinge | Leaves are hidden between the door and frame, providing a seamless look. | Commercial doors, cabinetry, and furniture | Pros: Aesthetic appeal, enhanced security. Cons: Installation complexity. |

| Full Surface Continuous Hinge | Entire hinge is mounted on the surface, offering easy installation and maintenance. | High-traffic doors, industrial applications | Pros: Easy to install, robust for heavy use. Cons: Less discreet appearance. |

| Heavy Duty Continuous Hinge | Designed for high load-bearing applications; often made from stainless steel or aluminum. | Industrial doors, large commercial openings | Pros: Long-lasting durability, ideal for heavy doors. Cons: Higher cost. |

| Modular Continuous Hinge | Flexible design allows for customization and easy transport, often used in modular constructions. | Prefabricated structures, portable units | Pros: Versatile and easy to install. Cons: May require specialized knowledge for optimal use. |

| Fire-Rated Continuous Hinge | Compliant with fire safety regulations, often constructed from specialized materials. | Fire doors in commercial buildings | Pros: Safety compliance, critical in emergency scenarios. Cons: Limited aesthetic options. |

What are the Characteristics of Concealed Leaf Continuous Hinges?

Concealed leaf continuous hinges are designed to hide the hinge mechanism, creating a clean and streamlined appearance. They are particularly suitable for commercial doors and high-end cabinetry, where aesthetics are paramount. When purchasing, buyers should consider the installation requirements, as these hinges can be more complex to fit compared to traditional options. Additionally, their aesthetic appeal can enhance the overall design of a space, making them a popular choice in upscale environments.

How Do Full Surface Continuous Hinges Differ in Functionality?

Full surface continuous hinges are mounted directly onto the surfaces of the door and frame, making them straightforward to install and maintain. They are ideal for high-traffic areas where durability is essential, such as industrial applications. Buyers should weigh the benefits of easy installation against the less discreet look, as these hinges are visible when the door is closed. Their robust design is advantageous for environments where doors face significant wear and tear.

Why Choose Heavy Duty Continuous Hinges for Your Business?

Heavy duty continuous hinges are engineered to support substantial weight, making them perfect for industrial doors and large commercial openings. Typically made from materials like stainless steel or aluminum, they promise longevity and resistance to corrosion. When selecting heavy-duty hinges, businesses must consider the initial investment, as they tend to be pricier. However, their durability can result in lower long-term maintenance costs, making them a smart investment for high-use applications.

What Makes Modular Continuous Hinges a Flexible Option?

Modular continuous hinges offer adaptability and ease of transport, making them ideal for prefabricated structures and portable units. Their design allows for customization, catering to various applications. Buyers should assess the installation process, as they may require specialized knowledge for optimal usage. The versatility of these hinges makes them a valuable addition to projects where flexibility is essential, enabling quick adjustments on-site.

How Do Fire-Rated Continuous Hinges Ensure Safety Compliance?

Fire-rated continuous hinges are specifically designed to meet stringent fire safety regulations, making them critical components in commercial buildings. They are constructed from materials that can withstand high temperatures, ensuring doors remain functional during emergencies. When selecting fire-rated hinges, businesses should prioritize compliance with local safety codes, as failure to do so can have serious implications. While they may offer limited aesthetic options, their importance in enhancing safety cannot be overstated.

Illustrative image related to hidden piano hinge

Key Industrial Applications of hidden piano hinge

| Industry/Sector | Specific Application of hidden piano hinge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Seamless cabinet doors and foldable furniture designs | Enhanced aesthetics and durability; minimizes maintenance | Material compatibility (wood, metal); weight capacity; design flexibility |

| Transportation | Heavy-duty truck and trailer doors | Improved security and longevity under harsh conditions | Corrosion resistance; load-bearing capacity; compliance with industry standards |

| Construction | High-traffic commercial building doors | Extended lifespan; reduced wear and tear; safety compliance | Fire ratings; material choice (stainless steel, aluminum); installation ease |

| Marine Applications | Access hatches and compartment doors in vessels | Resistance to harsh marine environments; safety features | Saltwater corrosion resistance; weight considerations; custom sizes |

| Healthcare | Hospital room doors and equipment access panels | Hygiene compliance and easy access; smooth operation | Sterilizable materials; durability; noise reduction features |

How is hidden piano hinge utilized in furniture manufacturing?

In the furniture manufacturing sector, hidden piano hinges are often employed to create seamless cabinet doors and foldable furniture designs. These hinges allow for smooth operation while maintaining a clean aesthetic, as they are concealed within the door structure. This not only enhances the visual appeal of the furniture but also significantly reduces maintenance needs, as the hinge is protected from dust and debris. Buyers in this industry should consider factors such as material compatibility, weight capacity, and design flexibility to ensure that the hinges meet their specific product requirements.

What are the benefits of hidden piano hinges in transportation?

In the transportation industry, hidden piano hinges are crucial for heavy-duty truck and trailer doors. They provide enhanced security and durability, which is vital for vehicles that operate under harsh conditions. The continuous design of these hinges distributes the weight of the door evenly, reducing wear and tear over time. For international buyers, sourcing hinges that offer corrosion resistance and meet specific load-bearing capacities is essential, as these factors directly impact the longevity and reliability of the vehicle.

Why choose hidden piano hinges for construction applications?

Hidden piano hinges find extensive use in high-traffic commercial building doors, where durability and safety compliance are paramount. These hinges are designed to withstand frequent use, extending the lifespan of the doors and minimizing maintenance costs. For buyers in the construction industry, it is important to consider fire ratings, material choices (such as stainless steel or aluminum), and ease of installation to ensure that the hinges meet building codes and safety standards.

How do hidden piano hinges enhance marine applications?

In marine applications, hidden piano hinges are utilized for access hatches and compartment doors, where resistance to harsh marine environments is critical. These hinges must be able to withstand exposure to saltwater and other corrosive elements, making material selection crucial. Additionally, safety features such as secure locking mechanisms are often required. Buyers should prioritize sourcing hinges that offer custom sizes and weight considerations to ensure they fit seamlessly into their specific vessel designs.

What role do hidden piano hinges play in healthcare environments?

In healthcare settings, hidden piano hinges are commonly used in hospital room doors and equipment access panels. Their design allows for smooth operation while promoting hygiene compliance, as they can be manufactured from sterilizable materials. This is particularly important in environments where cleanliness is paramount. Buyers in the healthcare sector should look for hinges that offer durability and noise reduction features to create a more comfortable environment for patients and staff alike.

Illustrative image related to hidden piano hinge

3 Common User Pain Points for ‘hidden piano hinge’ & Their Solutions

Scenario 1: Ensuring Durability in Harsh Environments

The Problem: For B2B buyers in industries such as marine, construction, or food processing, sourcing hinges that can withstand extreme conditions is a significant challenge. Hidden piano hinges are often subjected to corrosive elements, moisture, or heavy use, leading to premature failure. Buyers may face costly repairs and replacements, impacting their project timelines and budgets. They need a reliable solution that can endure these harsh conditions without sacrificing performance or aesthetics.

The Solution: When specifying hidden piano hinges for environments with extreme conditions, it is crucial to opt for materials designed for durability, such as stainless steel or high-grade aluminum. Buyers should seek out suppliers who provide hinges with coatings or finishes that enhance corrosion resistance. Additionally, consider the hinge’s load-bearing capacity and ensure it is rated for heavy-duty applications. Implementing regular maintenance checks can also prolong the lifespan of the hinges, so establishing a maintenance schedule with your facilities team is advisable. By prioritizing quality and appropriate material selection, buyers can mitigate the risk of hinge failure and ensure long-term performance.

Scenario 2: Achieving Seamless Aesthetic Integration

The Problem: Many architects and designers face the challenge of maintaining a clean and modern aesthetic in their projects. Hidden piano hinges can enhance the visual appeal of doors and cabinetry by providing a seamless look; however, if not properly specified, they can become visible or misaligned, disrupting the intended design. This misalignment can lead to dissatisfaction from end-users and may require costly rework, creating a significant pain point for B2B buyers in the construction and interior design sectors.

The Solution: To achieve a seamless integration of hidden piano hinges, it is essential to work closely with manufacturers who understand the aesthetic requirements of your project. Specify hinges that are designed for flush mounting and ensure they fit the door and frame precisely. Detailed measurements are critical; therefore, investing time in accurate architectural drawings and consulting with hinge specialists can prevent misalignment issues. Additionally, using adjustable hinges can offer flexibility during installation, allowing for fine-tuning that ensures perfect alignment. By focusing on precision and collaboration with manufacturers, buyers can achieve the desired aesthetic without compromising functionality.

Scenario 3: Managing Supply Chain and Lead Time Challenges

The Problem: B2B buyers often grapple with supply chain disruptions and extended lead times, especially when sourcing specialized components like hidden piano hinges. This can lead to project delays, increased costs, and frustration among stakeholders. For international buyers, navigating different suppliers and logistics can further complicate the procurement process, resulting in uncertainty about delivery timelines and product availability.

The Solution: To effectively manage supply chain challenges, buyers should establish relationships with multiple suppliers, ensuring a diverse sourcing strategy that can mitigate risks associated with delays. It’s also beneficial to engage with local manufacturers who may offer shorter lead times and lower shipping costs. Implementing a just-in-time inventory system can help align hinge procurement with project timelines, reducing excess inventory and associated costs. Moreover, clear communication with suppliers about project needs and timelines is crucial; setting expectations upfront can lead to more reliable delivery schedules. By proactively managing supply chain relationships and logistics, buyers can reduce delays and keep projects on track.

Strategic Material Selection Guide for hidden piano hinge

What Are the Key Properties of Stainless Steel for Hidden Piano Hinges?

Stainless steel is a popular choice for hidden piano hinges due to its excellent corrosion resistance, durability, and aesthetic appeal. It can withstand high temperatures and pressures, making it suitable for various applications, including marine environments and heavy-duty doors. The material’s non-reactive nature ensures that it maintains its integrity even when exposed to harsh chemicals or salty air, which is particularly beneficial in coastal regions.

Pros and Cons of Stainless Steel:

– Pros: High durability, excellent corrosion resistance, low maintenance, and a polished finish that enhances aesthetic appeal.

– Cons: Higher cost compared to other materials and potential for scratching, which may require additional protective coatings.

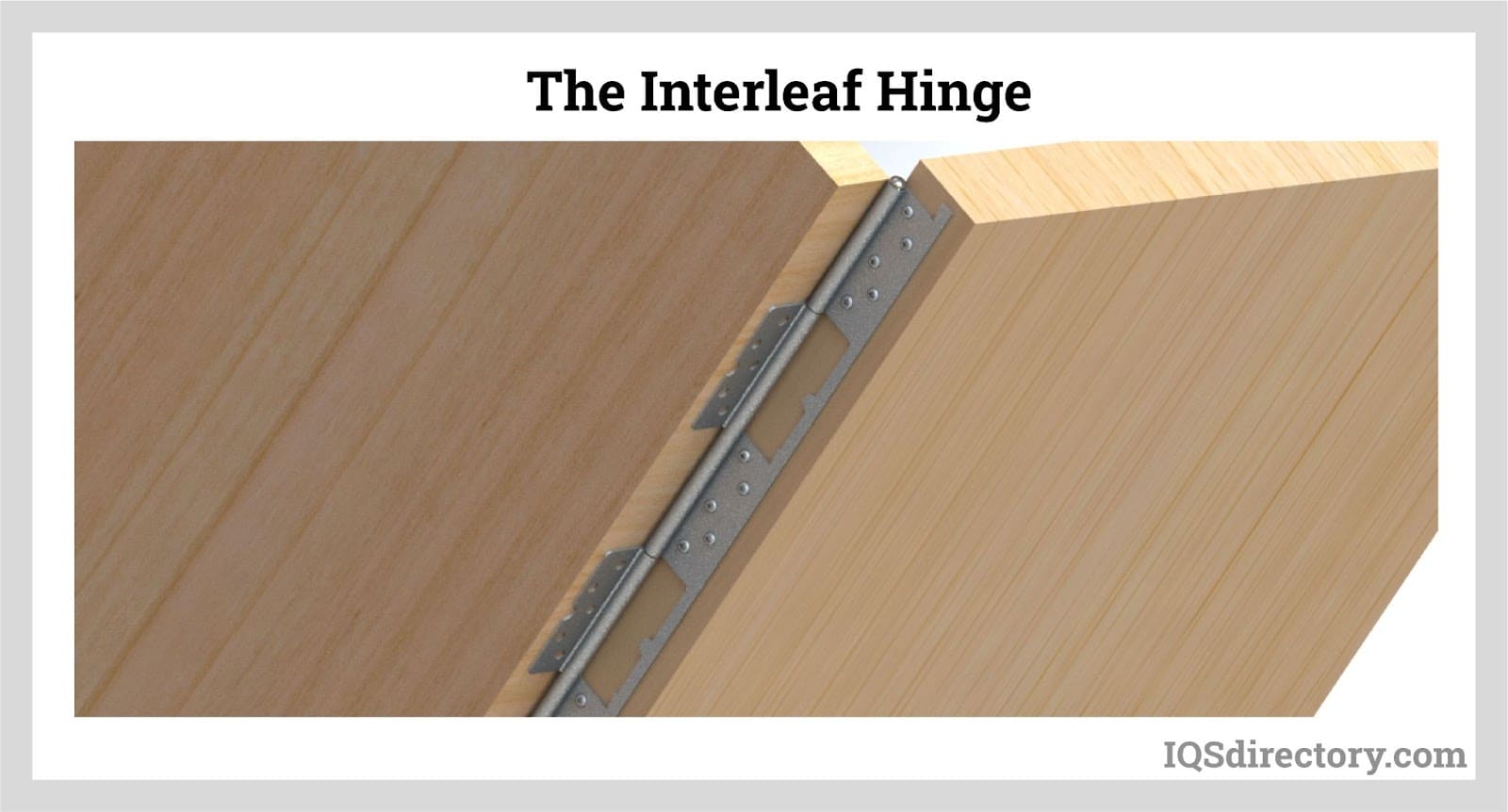

Illustrative image related to hidden piano hinge

For international buyers, especially in regions like Africa and the Middle East, compliance with standards such as ASTM and ISO is crucial. Buyers should also consider local climatic conditions that may affect the longevity of stainless steel products.

How Does Aluminum Compare for Hidden Piano Hinges?

Aluminum is another viable option for hidden piano hinges, known for its lightweight nature and resistance to corrosion. It is particularly advantageous in applications where weight reduction is critical, such as in aviation or mobile units. Aluminum hinges can also be anodized for additional protection, enhancing their durability and appearance.

Pros and Cons of Aluminum:

– Pros: Lightweight, good corrosion resistance, and lower cost compared to stainless steel.

– Cons: Less durable than steel, may not withstand heavy loads as effectively, and can be prone to deformation under high stress.

International buyers should note that aluminum hinges are often compliant with various international standards, including JIS and DIN. However, they may not be suitable for high-temperature applications, which is a consideration for buyers in regions with extreme climates.

What Are the Benefits of Using Brass for Hidden Piano Hinges?

Brass offers a unique combination of strength and aesthetic appeal, making it a favored choice for decorative applications. Its natural resistance to corrosion and tarnishing makes it suitable for environments where appearance is essential, such as in luxury furnishings or high-end cabinetry.

Pros and Cons of Brass:

– Pros: Attractive appearance, good corrosion resistance, and antimicrobial properties.

– Cons: Higher cost and less strength compared to steel, making it unsuitable for heavy-duty applications.

For buyers in Europe and South America, brass hinges may need to meet specific standards for quality and performance. The aesthetic appeal of brass can also be a selling point in markets where design is a priority.

Illustrative image related to hidden piano hinge

When Should You Choose Plastic for Hidden Piano Hinges?

Plastic hinges are gaining traction in specific applications due to their lightweight and cost-effective nature. They are resistant to corrosion and can be molded into various shapes, making them versatile for different designs. However, they are generally not suitable for heavy-duty applications.

Pros and Cons of Plastic:

– Pros: Low cost, lightweight, and resistant to corrosion.

– Cons: Limited strength and durability, not suitable for high-stress applications.

International buyers should be aware of the varying quality standards for plastic materials. In some regions, such as Africa and South America, the availability of high-quality plastics may be limited, which could affect the performance of plastic hinges.

Summary Table of Material Selection for Hidden Piano Hinges

| Material | Typical Use Case for hidden piano hinge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty doors in marine environments | Excellent corrosion resistance | Higher cost and potential for scratching | High |

| Aluminum | Lightweight applications in aviation | Lightweight and lower cost | Less durable under heavy loads | Medium |

| Brass | Decorative applications in luxury furniture | Attractive appearance and antimicrobial | Higher cost and less strength | High |

| Plastic | Cost-sensitive applications with low stress | Low cost and lightweight | Limited strength and durability | Low |

This guide provides a comprehensive overview of material selection for hidden piano hinges, assisting international B2B buyers in making informed decisions based on their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hidden piano hinge

What Are the Key Manufacturing Processes for Hidden Piano Hinges?

The manufacturing of hidden piano hinges involves a series of meticulously coordinated processes designed to ensure durability and precision. The main stages include material preparation, forming, assembly, and finishing.

Illustrative image related to hidden piano hinge

How Is Material Prepared for Hidden Piano Hinges?

The journey begins with material selection, where manufacturers typically choose high-grade stainless steel, aluminum, or brass. These materials are selected based on their strength, corrosion resistance, and suitability for specific applications. Once the material is selected, it undergoes preparation, which includes cutting it into specified lengths and thicknesses. This stage is crucial, as precise measurements are essential for the hinge’s functionality and compatibility with doors or panels.

What Forming Techniques Are Used in Hidden Piano Hinge Production?

Once the material is prepared, it proceeds to the forming stage. This involves several techniques, including stamping and bending. Stamping machines are used to create the intricate shapes of the hinge leaves, while bending machines ensure the correct angles and curves. Advanced manufacturers may also employ CNC (Computer Numerical Control) machining for enhanced precision. The forming process not only shapes the hinge but also determines its load-bearing capacity, making it critical for heavy-duty applications.

How Are Hidden Piano Hinges Assembled?

The assembly stage combines the formed components into a functional hinge. This typically involves aligning the hinge leaves and attaching them using rivets, screws, or welding, depending on the design and material. Manufacturers often utilize automated assembly lines to improve efficiency and reduce human error. The assembly must maintain tight tolerances to ensure smooth operation, especially in high-frequency applications like heavy doors or industrial machinery.

What Finishing Processes Enhance the Durability of Hidden Piano Hinges?

The finishing stage is essential for enhancing the hinge’s aesthetic and protective qualities. Common finishing techniques include anodizing, powder coating, or plating. Anodizing is particularly beneficial for aluminum hinges, providing a durable, corrosion-resistant surface. For stainless steel, electropolishing may be employed to achieve a smooth finish that resists tarnishing. These finishing processes not only improve the hinge’s longevity but also ensure it meets the aesthetic requirements of various applications.

What Quality Assurance Practices Are Essential for Hidden Piano Hinges?

Quality assurance (QA) is integral to the manufacturing process of hidden piano hinges, ensuring that each product meets international standards and customer specifications.

Which International Standards Should B2B Buyers Look For?

For hidden piano hinges, adherence to international standards such as ISO 9001 is crucial. This standard focuses on quality management systems and ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for industrial applications may be relevant. B2B buyers should inquire about these certifications when evaluating potential suppliers.

What Are the Key Quality Control Checkpoints During Manufacturing?

Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC monitors critical stages like material forming and assembly to catch any deviations early.

- Final Quality Control (FQC): The final inspection ensures that the completed hinges meet all specifications and quality standards before shipping.

These checkpoints help identify and rectify potential issues, ensuring that only high-quality products reach the market.

What Common Testing Methods Are Used for Hidden Piano Hinges?

Testing methods for hidden piano hinges vary depending on their intended application but often include:

- Load Testing: This assesses the hinge’s load-bearing capacity and ensures it can withstand the intended operational stresses.

- Corrosion Resistance Testing: Essential for hinges used in harsh environments, this test evaluates how well the hinge resists rust and deterioration.

- Cycle Testing: This simulates repeated use to ensure the hinge can endure high-frequency applications without failure.

Manufacturers may also conduct visual inspections to check for surface defects or dimensional inaccuracies.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to stringent quality control practices, B2B buyers should consider several verification methods:

What Audit Processes Are Effective for Supplier Evaluation?

Conducting regular audits is one of the most effective ways to verify a supplier’s quality control measures. These audits can be scheduled or random and should assess the entire manufacturing process, from material sourcing to final inspection. Buyers can also request to review the supplier’s quality management system documentation, including certifications, inspection reports, and test results.

How Can Reports and Third-Party Inspections Aid in Supplier Verification?

Requesting quality assurance reports is another method for buyers to gauge a supplier’s commitment to quality. These reports should detail the results of various tests and inspections conducted throughout the manufacturing process. Additionally, engaging third-party inspection services can provide an unbiased evaluation of the supplier’s production practices and product quality.

What Are the Unique Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. For instance, regulatory compliance can vary significantly across regions. Buyers should familiarize themselves with local standards and requirements to ensure that the hinges not only meet their needs but also comply with local regulations.

Moreover, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear, documented specifications and maintaining open lines of communication with suppliers can mitigate these challenges.

By understanding the manufacturing processes and quality assurance practices specific to hidden piano hinges, B2B buyers can make informed decisions, ensuring they source reliable and durable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hidden piano hinge’

In the intricate world of industrial hardware, sourcing the right hidden piano hinge is crucial for ensuring durability, functionality, and aesthetic appeal in your projects. This guide aims to equip B2B buyers with a comprehensive checklist to streamline the procurement process of hidden piano hinges, particularly for applications in various industries across Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your application is the first step in sourcing hidden piano hinges. Consider factors such as the weight of the door or panel, frequency of use, and environmental conditions (e.g., humidity, exposure to saltwater). Clearly outlining these specifications will help you narrow down your options effectively.

- Material Choices: Stainless steel is ideal for marine applications, while aluminum may be suitable for lighter-duty needs.

- Load Capacity: Ensure the hinge can handle the weight and stress of your application.

Step 2: Research Potential Suppliers

Thorough research is essential in identifying reliable suppliers who specialize in hidden piano hinges. Look for companies with a strong market presence and positive reviews from other B2B clients.

- Supplier Background: Investigate their history, product range, and expertise in your industry.

- Customer Feedback: Seek testimonials or case studies to gauge customer satisfaction and product performance.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their industry certifications and compliance with relevant standards. This is crucial for ensuring the quality and safety of the hinges you intend to purchase.

- Quality Certifications: Look for ISO 9001 or similar certifications that indicate a commitment to quality management.

- Compliance Standards: Ensure the hinges meet specific industry standards applicable in your region (e.g., UL, CE).

Step 4: Request Samples

Once you’ve shortlisted potential suppliers, request samples of the hidden piano hinges. Testing samples in real-world conditions allows you to evaluate their functionality, durability, and fit for your specific applications.

- Fit and Finish: Inspect the quality of manufacturing and ensure the hinges meet your aesthetic requirements.

- Performance Testing: Conduct load tests to verify the hinge can support the intended use.

Step 5: Negotiate Terms and Conditions

Engaging in negotiations with your selected supplier is essential to ensure favorable terms. Discuss pricing, payment terms, and delivery schedules to align with your project timelines and budget.

- Bulk Discounts: Inquire about pricing structures for larger orders.

- Lead Times: Confirm expected delivery times and any possible delays that could affect your project schedule.

Step 6: Finalize the Order

After agreeing on terms, finalize your order with all necessary details clearly outlined in a purchase agreement. This should include specifications, pricing, delivery dates, and any warranties or return policies.

- Documentation: Ensure that all agreements are documented to avoid misunderstandings later.

- Follow-Up: Establish a communication channel with the supplier for updates on your order status.

Step 7: Post-Purchase Evaluation

After receiving your hinges, conduct a thorough evaluation to ensure they meet your specifications and quality standards. This step is crucial for maintaining long-term supplier relationships and ensuring future orders align with your needs.

- Quality Control: Inspect the hinges upon delivery to ensure they match your specifications.

- Feedback Loop: Provide feedback to the supplier regarding product performance and any issues encountered.

By following this checklist, B2B buyers can enhance their sourcing strategy for hidden piano hinges, ensuring they select the right products that meet their operational needs while fostering productive supplier relationships.

Comprehensive Cost and Pricing Analysis for hidden piano hinge Sourcing

What Are the Key Cost Components of Hidden Piano Hinges?

When sourcing hidden piano hinges, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Stainless steel and aluminum are common for their durability, but they come with varying costs. For instance, stainless steel is often more expensive due to its corrosion resistance, making it suitable for harsh environments.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with higher labor costs may result in increased overall pricing. It is crucial to consider the skill level required for the production of specialized hinges, as this can also affect labor expenses.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. High overhead costs can lead to higher prices for the end product.

-

Tooling: Custom tooling for specific hinge designs can significantly influence the initial cost. If a buyer requires unique specifications, tooling costs can escalate, impacting the overall pricing structure.

-

Quality Control (QC): Rigorous quality assurance processes ensure that the hinges meet international standards. While this adds to the cost, it is essential for maintaining product integrity and reducing the likelihood of returns or replacements.

-

Logistics: Shipping and handling costs can fluctuate based on the distance from the supplier to the buyer, particularly for international transactions. Incoterms also play a crucial role in determining who bears these costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary widely based on the supplier’s market position, brand reputation, and relationship with the buyer.

How Do Price Influencers Impact Hidden Piano Hinge Costs?

Several factors can influence the price of hidden piano hinges, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often qualify for discounts, lowering the per-unit price. Understanding a supplier’s MOQ is vital for optimizing cost efficiency.

-

Specifications and Customization: Customized hinges generally incur higher costs due to additional design and manufacturing processes. Buyers should weigh the benefits of customization against potential cost increases.

-

Material Choices: The selection between standard and premium materials can lead to significant price variations. For example, opting for lightweight aluminum may be more cost-effective than heavy-duty stainless steel.

-

Quality and Certifications: Hinges that meet specific quality standards or certifications may command higher prices. However, investing in certified products can lead to long-term savings by minimizing failures and maintenance.

-

Supplier Factors: The supplier’s reputation, reliability, and market presence can affect pricing. Established suppliers may charge more but offer better warranties and customer service.

-

Incoterms: The choice of Incoterms affects logistics costs and risk. Understanding these terms is essential for accurate cost assessment and negotiation.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

International B2B buyers should consider the following strategies to enhance cost-efficiency when sourcing hidden piano hinges:

-

Negotiate Wisely: Leverage volume purchasing and long-term contracts to negotiate better pricing. Building a relationship with suppliers can also lead to favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Assess not only the purchase price but also maintenance, replacement, and logistics costs over the hinge’s lifecycle. A lower initial price may not always equate to better value.

-

Understand Pricing Nuances for International Buyers: Factors such as currency fluctuations, tariffs, and import duties can significantly impact costs for buyers in Africa, South America, the Middle East, and Europe. Conducting thorough market research and understanding local regulations can mitigate unexpected expenses.

-

Request Samples: Before committing to larger orders, request samples to evaluate quality and compatibility. This can prevent costly mistakes and ensure that the hinges meet your specifications.

-

Stay Informed on Market Trends: Regularly review industry trends and pricing benchmarks to stay competitive. Being informed allows buyers to make strategic decisions that align with their budget and operational needs.

Disclaimer on Pricing

Please note that the prices mentioned in various sources may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence before finalizing any purchase.

Illustrative image related to hidden piano hinge

Alternatives Analysis: Comparing hidden piano hinge With Other Solutions

Understanding Alternatives to Hidden Piano Hinges

When selecting hardware solutions for doors and cabinetry, businesses often encounter various hinge options that can fulfill similar functions to hidden piano hinges. Understanding the advantages and drawbacks of these alternatives is crucial for making informed purchasing decisions. This analysis compares hidden piano hinges with two other viable solutions: continuous hinges and butt hinges.

| Comparison Aspect | Hidden Piano Hinge | Continuous Hinge | Butt Hinge |

|---|---|---|---|

| Performance | Excellent for concealed applications; smooth operation; distributes weight evenly. | High durability; suitable for heavy-duty doors; good for high-traffic areas. | Standard performance; suitable for light to medium applications; limited weight distribution. |

| Cost | Generally higher initial cost due to manufacturing complexity. | Moderate to high cost, depending on material and length. | Low cost; widely available and economical. |

| Ease of Implementation | Requires precise installation; may need specialized tools. | Straightforward installation; often requires minimal adjustments. | Easy to install; minimal tools needed, suitable for DIY projects. |

| Maintenance | Low maintenance; resistant to wear due to concealed design. | Low maintenance; robust design reduces wear. | Moderate maintenance; exposed parts may require lubrication. |

| Best Use Case | Ideal for high-end cabinetry, furniture, and applications requiring aesthetic appeal. | Best for commercial doors, heavy-duty applications, and environments with frequent use. | Suitable for residential doors, lightweight partitions, and non-critical applications. |

Analyzing Continuous Hinges: Pros and Cons

Continuous hinges, also known as piano hinges, run the entire length of the door, providing uniform support and reducing stress on the door and frame. They are particularly advantageous in heavy-duty applications where doors experience significant wear and tear. The ease of installation, especially in commercial settings, makes them a popular choice for high-traffic areas. However, continuous hinges can be more expensive than traditional options, and their aesthetic appeal may be less favorable in applications requiring a sleek design.

Evaluating Butt Hinges: Pros and Cons

Butt hinges are among the most common types of hinges used in both residential and commercial applications. They are simple to install and cost-effective, making them a popular choice for standard doors and lightweight constructions. While butt hinges can suffice in many situations, their performance may be inadequate for heavier doors or high-frequency use. Additionally, they are more visible when installed, which could detract from the aesthetic of high-end furniture or cabinetry.

How to Choose the Right Hinge for Your Needs

When selecting the right hinge solution for your project, it is essential to consider various factors, including the specific application, door weight, frequency of use, and desired aesthetic. Hidden piano hinges excel in environments where appearance and seamless functionality are paramount, while continuous hinges are ideal for durability and heavy-duty performance. On the other hand, butt hinges offer a practical solution for everyday applications at a lower cost. Ultimately, understanding the unique benefits and limitations of each option will enable B2B buyers to make the best decision tailored to their specific requirements.

Essential Technical Properties and Trade Terminology for hidden piano hinge

What Are the Key Technical Properties of Hidden Piano Hinges?

When sourcing hidden piano hinges, understanding their technical specifications is crucial for ensuring the right fit for your application. Below are some essential properties that B2B buyers should consider:

Illustrative image related to hidden piano hinge

1. Material Grade

Hidden piano hinges are typically constructed from various materials, including stainless steel, aluminum, and brass. Stainless steel is preferred for its corrosion resistance, particularly in harsh environments like marine applications. Aluminum is lightweight and ideal for applications where weight savings are critical. The choice of material affects durability, maintenance needs, and overall performance.

2. Load Capacity

Load capacity refers to the maximum weight that a hinge can support. This is a critical specification for heavy-duty applications, such as commercial doors or industrial equipment. It is essential to select a hinge with a load capacity that exceeds the expected weight of the door or panel to ensure safety and longevity.

3. Length and Leaf Width

The length and width of the hinge leaf determine how well the hinge will distribute the load across the door. Longer hinges provide better weight distribution and reduce stress on the door and frame. Buyers should ensure that the hinge length matches the door dimensions for optimal performance.

4. Tolerance Levels

Tolerance levels indicate the permissible variation in the dimensions of the hinge. High tolerance levels are crucial for precision applications where alignment is critical, such as in high-end cabinetry or custom installations. Understanding tolerance helps in achieving the desired fit and function.

5. Finish Options

The finish of a hidden piano hinge can influence its aesthetic appeal and resistance to environmental factors. Common finishes include brushed, polished, or anodized. Choosing the right finish is important for maintaining the hinge’s appearance and ensuring it complements the surrounding materials.

6. Fire Rating

For applications requiring fire safety compliance, fire-rated hidden piano hinges are essential. These hinges are tested to meet specific fire resistance standards, providing additional safety in commercial and industrial settings.

What Are Common Trade Terms Related to Hidden Piano Hinges?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some key terms associated with hidden piano hinges:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hidden piano hinges, OEM suppliers provide custom solutions tailored to the specifications of original equipment, ensuring compatibility and quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For hidden piano hinges, MOQs can vary significantly depending on the manufacturer and material. Buyers must consider MOQs when planning inventory and supply chain needs.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer submits to suppliers to solicit price quotes for specific products or services. When purchasing hidden piano hinges, submitting an RFQ can help buyers compare prices and terms from different suppliers, leading to better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping costs, risks, and responsibilities associated with the delivery of hidden piano hinges.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For hidden piano hinges, lead times can vary based on production schedules, material availability, and shipping. Knowing the lead time helps buyers plan their projects effectively.

6. Certification Standards

Certification standards ensure that products meet specific quality and safety criteria. For hidden piano hinges, certifications may include ANSI/BHMA (American National Standards Institute/Builders Hardware Manufacturers Association) ratings, which indicate the performance and durability of the hinges in various applications.

Illustrative image related to hidden piano hinge

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing hidden piano hinges, ultimately leading to better project outcomes and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the hidden piano hinge Sector

What Are the Current Market Dynamics and Key Trends for Hidden Piano Hinges?

The hidden piano hinge market is experiencing significant growth driven by the increasing demand for aesthetically pleasing and functional door solutions across various industries, including construction, automotive, and furniture manufacturing. Global drivers include the rise in residential and commercial construction projects, particularly in developing regions like Africa and South America, where urbanization is accelerating. In Europe and the Middle East, there is a notable shift towards modern architectural designs that favor seamless integration of hardware, further propelling the demand for hidden piano hinges.

Emerging B2B technologies are reshaping sourcing trends, with an increasing reliance on digital platforms for procurement. Buyers are leveraging online marketplaces to access a wider range of suppliers and compare products efficiently, fostering competitive pricing. Additionally, advanced manufacturing techniques, such as 3D printing and automated assembly, are enhancing customization options, enabling businesses to meet specific client needs more effectively. As the emphasis on quality and durability grows, buyers are increasingly focusing on product certifications and standards, ensuring that their chosen hinges can withstand varying environmental conditions and usage frequencies.

How Is Sustainability and Ethical Sourcing Influencing the Hidden Piano Hinge Market?

Sustainability is becoming a cornerstone of sourcing strategies in the hidden piano hinge sector. Buyers are increasingly aware of the environmental impact associated with hinge production, including resource extraction, manufacturing processes, and end-of-life disposal. As a result, the demand for hinges made from recycled or sustainably sourced materials is on the rise. Manufacturers are responding by offering products that utilize eco-friendly materials, such as stainless steel and aluminum, which not only provide durability but also reduce the carbon footprint of the production process.

Moreover, ethical supply chains are gaining traction, with buyers prioritizing suppliers who adhere to fair labor practices and responsible sourcing. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) compliance are becoming critical factors in the purchasing decision. By partnering with manufacturers who prioritize sustainability, B2B buyers can enhance their brand reputation and meet the growing consumer expectation for environmentally responsible products.

What Is the Historical Context of Hidden Piano Hinges in B2B?

The evolution of hidden piano hinges can be traced back to the early 20th century when the need for more discreet and functional hardware became apparent in architectural design. Initially used in high-end residential and commercial projects, these hinges gained popularity due to their ability to provide smooth operation without compromising aesthetic appeal. Over the decades, advancements in materials science and manufacturing processes have led to the development of more durable and versatile hinge options, including those designed for heavy-duty applications.

In recent years, the emphasis on minimalistic design and the integration of technology into everyday products have further propelled the adoption of hidden piano hinges. As industries continue to evolve, the historical significance of these hinges serves as a foundation for innovation, enabling manufacturers to create solutions that meet the modern demands of B2B buyers across the globe.

Frequently Asked Questions (FAQs) for B2B Buyers of hidden piano hinge

-

How do I choose the right hidden piano hinge for my application?

Selecting the right hidden piano hinge involves assessing the specific requirements of your application, including door weight, material, and frequency of use. For heavy-duty applications, opt for stainless steel or aluminum hinges, which offer durability and resistance to corrosion, especially in harsh environments. Consider the installation method—full mortise or surface-mounted—based on your project needs. Additionally, evaluate the hinge’s load capacity and dimensions to ensure compatibility with your doors. -

What are the benefits of using hidden piano hinges in my projects?

Hidden piano hinges provide a sleek and aesthetic solution by concealing hardware, enhancing the overall design of doors and furniture. They distribute weight evenly along the door, reducing wear and prolonging lifespan. Their design minimizes gaps, providing better insulation and security. Furthermore, these hinges are versatile and can be used across various industries, including commercial, residential, and automotive applications, making them an ideal choice for many projects. -

What customization options are available for hidden piano hinges?

Many manufacturers offer customization options for hidden piano hinges, including specific lengths, finishes, and load capacities. You can request modifications such as special coatings for enhanced corrosion resistance or unique dimensions to fit specific design requirements. When contacting suppliers, provide detailed specifications to ensure the hinges meet your exact needs. Some suppliers may also offer prototype services for testing before committing to bulk orders. -

What is the minimum order quantity (MOQ) for hidden piano hinges?

Minimum order quantities for hidden piano hinges can vary significantly among suppliers. Typically, MOQs range from 100 to 500 pieces, depending on the manufacturer and customization requirements. For smaller projects, some suppliers may accommodate lower quantities or offer stock items. Always inquire about MOQs upfront to ensure they align with your project budget and needs, and consider negotiating terms if you anticipate future orders. -

How do I vet suppliers for hidden piano hinges?

To effectively vet suppliers, start by researching their reputation within the industry. Look for reviews, testimonials, and case studies that demonstrate their experience and reliability. Verify their certifications and compliance with international quality standards, such as ISO 9001. Request samples to evaluate product quality and engage in direct communication to assess their responsiveness and willingness to accommodate your specific requirements. -

What are the typical payment terms for international orders of hidden piano hinges?

Payment terms can vary widely by supplier and region, but common arrangements include a 30% deposit upon order confirmation and the remaining 70% before shipment. Some suppliers may offer flexible terms, such as letters of credit or payment upon delivery, especially for established relationships. Always clarify payment terms during negotiations to avoid misunderstandings and ensure that they align with your cash flow requirements. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers of hidden piano hinges should implement rigorous quality assurance measures, including inspections at multiple production stages. Expect to see documentation of compliance with relevant industry standards, such as ASTM or EN specifications. Inquire about warranty policies and return procedures to ensure that you are protected against defective products. A supplier committed to quality will often provide detailed reports on testing and inspections. -

What logistics considerations should I keep in mind when importing hidden piano hinges?

When importing hidden piano hinges, consider factors such as shipping costs, lead times, and customs regulations specific to your country. Research potential tariffs or duties that may apply to your order, and ensure that your supplier provides the necessary documentation for customs clearance. It’s advisable to work with a freight forwarder who understands international shipping logistics to streamline the process and mitigate potential delays.

Top 4 Hidden Piano Hinge Manufacturers & Suppliers List

1. Qualified Hardware – Pemko CFM83SLF-HD1-M Continuous Hinge

Domain: qualifiedhardware.com

Registered: 2006 (19 years)

Introduction: Continuous Hinges are designed to run along the full length of the door, distributing the weight evenly to reduce wear and prolong lifespan. They are suitable for heavy doors subject to high use. Key products include: 1. Pemko CFM83SLF-HD1-M: Full Mortise Modular Continuous Hinge, starting at $104.00, heavy duty. 2. Pemko CFM95SLF-HD1-M: Full Mortise Modular Continuous Hinge, starting at $148.00, …

2. Reddit – Concealed Bench Hinges

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around finding a way to hide the hinges on a bench lid. Suggestions include using vertical hinges that only show the knuckle when closed, utilizing cabinet hinges, or considering hidden door hinges. There are concerns about the sturdiness of hinges for a plywood lid, with recommendations to frame it with solid wood for better support. Specific hinge types mentioned include …

3. eBay – Heavy Duty Piano Hinges

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: This company, eBay – Heavy Duty Piano Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. HardwareSource – Piano Hinges

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Piano Hinges | HardwareSource

– Types: Single Wrap, Double Wrap, Stainless Steel with Holes, Aluminum with Holes, Dark Plated, Steel with Holes, Brass Plated (72″), Aluminum Blank, Stainless Steel Blank, Heavy Duty Steel Blank, Steel Blank, 316 Stainless Steel Blank, 72″ Nickel Plated, Small Piano Style with Stop, Wrap Around.

– Prices: Ranging from $2.99 to $101.35 depending on the type.

– Featur…

Strategic Sourcing Conclusion and Outlook for hidden piano hinge

In conclusion, the strategic sourcing of hidden piano hinges presents significant opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Understanding the versatility and durability of these hinges is crucial for selecting the right product that aligns with specific applications, whether in high-traffic environments or specialized sectors like marine or automotive.

Leveraging the benefits of stainless steel and aluminum materials can enhance performance and longevity, reducing maintenance costs over time. As demand for innovative and functional design increases, sourcing high-quality hidden piano hinges becomes a vital aspect of ensuring operational efficiency and product reliability.

As you explore sourcing options, consider engaging with reliable suppliers who offer a range of products tailored to your unique needs. The future of hidden piano hinge applications looks promising, and by making informed purchasing decisions today, you can secure a competitive advantage in your respective market. Embrace the potential of hidden piano hinges to enhance your product offerings and elevate your business’s operational standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to hidden piano hinge

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.