Heavy Duty Coil Springs: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for heavy duty coil springs

In the competitive landscape of industrial manufacturing, sourcing heavy duty coil springs poses unique challenges, particularly for international B2B buyers seeking reliable and high-performance components. As industries across Africa, South America, the Middle East, and Europe (notably Brazil and Nigeria) expand, the demand for durable and efficient coil springs has surged. This guide serves as a comprehensive resource, addressing crucial aspects such as types of heavy duty coil springs, their diverse applications, and effective supplier vetting techniques.

Navigating this market involves understanding the specifications that best meet operational needs, the cost implications of different materials and designs, and the nuances of international procurement. With varying standards and practices across regions, informed decision-making is essential for successful sourcing. This guide empowers buyers by providing actionable insights and expert recommendations, ensuring that they can confidently select the right heavy duty coil springs for their specific applications.

By delving into the intricacies of spring manufacturing, material choices, and market dynamics, this resource aims to facilitate strategic purchasing decisions that enhance operational efficiency and drive business growth. Whether you are in the transportation, construction, or agriculture sectors, this guide is designed to help you navigate the complexities of sourcing heavy duty coil springs in a global marketplace.

Understanding heavy duty coil springs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

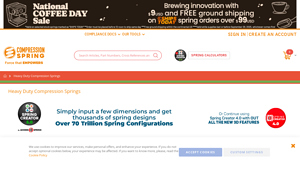

| Heavy Duty Compression Spring | Designed to resist compressive forces; can be straight, conical, or variable rate | Manufacturing, automotive, construction | Pros: Excellent load-bearing capacity; customizable. Cons: May require specific design considerations for optimal performance. |

| Heavy Duty Tension Spring | Coils wound to provide pull force when extended; features loops or end fittings | Elevators, garage doors, agricultural machinery | Pros: Versatile application; strong tensile strength. Cons: Limited in applications requiring compressive force. |

| Heavy Duty Torsion Spring | Provides rotational force; designed for high torque applications | Machinery, automotive tailgates, industrial equipment | Pros: Ideal for applications requiring twisting motion; robust construction. Cons: More complex design may increase costs. |

| Heavy Duty Variable Rate Spring | Allows for variable spring rates; adjusts resistance based on load | Automotive suspension, industrial machinery | Pros: Adaptable to changing loads; improved ride comfort. Cons: More intricate design can lead to higher manufacturing costs. |

| Heavy Duty Disc Spring | Flat, disc-shaped spring providing high force in compact space | Aerospace, automotive, and machinery applications | Pros: Space-efficient; can handle high loads. Cons: May have limited displacement compared to coil springs. |

What Are the Characteristics of Heavy Duty Compression Springs?

Heavy duty compression springs are characterized by their ability to withstand and resist compressive forces. They can come in various forms, including straight, conical, and variable rate designs. These springs are widely used in sectors like manufacturing, automotive, and construction, where they provide essential support and stability. When purchasing, buyers should consider load requirements, space constraints, and the specific application to ensure optimal performance.

How Do Heavy Duty Tension Springs Function in B2B Applications?

Heavy duty tension springs, also known as extension springs, are designed to exert a pulling force when extended. Their construction includes tightly wound coils and end fittings that facilitate attachment. Commonly used in elevators, garage doors, and agricultural machinery, these springs are valued for their versatility and strength. Buyers should evaluate the initial tension, material choices, and compatibility with existing systems when selecting tension springs.

What Are the Key Features of Heavy Duty Torsion Springs?

Heavy duty torsion springs are engineered to provide rotational force, making them essential in applications requiring torque. These springs are typically larger and constructed to handle significant pressure. They are frequently found in automotive tailgates and various industrial equipment. When considering torsion springs, buyers should focus on torque specifications, space availability, and the operational environment to ensure they meet the application’s demands.

How Do Variable Rate Springs Enhance Performance?

Heavy duty variable rate springs are designed to adjust their resistance based on the load applied. This adaptability makes them ideal for automotive suspensions and industrial machinery, where load conditions can change frequently. Buyers should assess the spring’s design complexity, load variability, and cost implications when considering these springs, as they can offer enhanced performance but may require a more intricate manufacturing process.

What Are the Advantages of Heavy Duty Disc Springs?

Heavy duty disc springs are unique in their flat, disc-like shape, allowing them to provide significant force in a compact form. They are commonly used in aerospace, automotive, and machinery applications, where space is at a premium. When purchasing disc springs, buyers should consider load requirements, space limitations, and the specific performance characteristics needed for their application to ensure effective integration.

Key Industrial Applications of heavy duty coil springs

| Industry/Sector | Specific Application of heavy duty coil springs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension systems in trucks and heavy vehicles | Improved load capacity and vehicle stability | Material quality, load rating, and compliance with safety standards |

| Construction | Load-bearing components in cranes and heavy machinery | Enhanced performance under extreme conditions | Custom design capabilities and corrosion resistance |

| Agriculture | Equipment such as tractors and harvesters | Increased durability and performance in rugged environments | Compatibility with existing machinery and environmental factors |

| Mining and Quarrying | Tension and compression springs in drilling rigs | Reliability in harsh conditions, reducing downtime | Sourcing from manufacturers with experience in mining applications |

| Energy Production | Support structures in power generation systems | Higher efficiency and reduced maintenance costs | Material specifications for temperature and pressure resistance |

How Are Heavy Duty Coil Springs Utilized in the Automotive Industry?

In the automotive sector, heavy duty coil springs play a crucial role in the suspension systems of trucks and heavy vehicles. They are engineered to support greater loads while maintaining vehicle stability, which is vital for transporting heavy cargo. Buyers in this sector should prioritize sourcing springs that meet stringent safety standards and provide high load ratings to ensure vehicle performance under various conditions. Additionally, understanding the material properties, such as fatigue resistance, is essential for long-term reliability.

What Role Do Heavy Duty Coil Springs Play in Construction Equipment?

Heavy duty coil springs are integral to load-bearing components in cranes and heavy machinery used in construction. These springs are designed to withstand extreme conditions, providing enhanced performance and safety when lifting heavy loads. For B2B buyers in construction, sourcing springs with custom design capabilities can help meet specific project requirements. Furthermore, considering factors like corrosion resistance is important, especially in outdoor environments where equipment is exposed to the elements.

How Are Heavy Duty Coil Springs Used in Agriculture?

In the agriculture industry, heavy duty coil springs are utilized in various equipment, including tractors and harvesters, to enhance durability and performance in rugged environments. These springs absorb shocks and vibrations, ensuring smoother operation during fieldwork. Buyers from agricultural sectors should focus on compatibility with existing machinery and the ability of springs to perform under specific environmental conditions. This ensures that the equipment remains operational during critical harvesting periods.

What Applications Are There for Heavy Duty Coil Springs in Mining and Quarrying?

In mining and quarrying, heavy duty coil springs are essential components in drilling rigs, providing tension and compression support. They are designed to perform reliably in harsh environments, which helps minimize downtime and increase productivity. For international buyers in this sector, it is crucial to source springs from manufacturers experienced in mining applications, as they will understand the unique challenges and requirements, such as resistance to abrasive materials and extreme temperatures.

How Do Heavy Duty Coil Springs Enhance Energy Production Systems?

Heavy duty coil springs are used in the support structures of power generation systems, where they contribute to higher efficiency and reduced maintenance costs. These springs help absorb vibrations and support heavy components, ensuring operational stability. B2B buyers in the energy sector should consider sourcing springs that meet specific material specifications for temperature and pressure resistance, as these factors are critical for the longevity and performance of energy production equipment.

3 Common User Pain Points for ‘heavy duty coil springs’ & Their Solutions

Scenario 1: Sourcing Quality Heavy Duty Coil Springs for Unique Applications

The Problem:

B2B buyers often encounter difficulties when sourcing heavy duty coil springs that meet specific application requirements. For instance, a construction equipment manufacturer may need springs that withstand extreme loads while maintaining performance over extended periods. Suppliers may offer a range of products, but buyers might struggle to find springs tailored to their unique specifications, leading to operational inefficiencies and potential safety hazards. The consequences of using inadequate springs can result in costly downtime and repairs, impacting the overall productivity of the business.

The Solution:

To effectively source high-quality heavy duty coil springs, buyers should engage in a detailed consultative process with manufacturers. Begin by clearly defining the application requirements, including load specifications, environmental conditions, and desired lifespan. Collaborate with engineers from potential suppliers who can provide insights into material choices and spring design. For example, if the application involves exposure to corrosive environments, opt for springs made from stainless steel or coated with protective finishes. Additionally, requesting prototypes or samples can help verify the springs’ performance before bulk orders are placed, ensuring that they meet the necessary specifications and quality standards.

Scenario 2: Understanding the Impact of Spring Specifications on Performance

The Problem:

Another common challenge B2B buyers face is misunderstanding how different specifications, such as wire diameter, coil diameter, and material type, impact the performance of heavy duty coil springs. A logistics company might purchase springs based solely on price, neglecting to consider that a thicker wire or a different material could significantly enhance durability and load capacity. This oversight can lead to premature spring failure, resulting in unexpected maintenance costs and vehicle downtime.

The Solution:

To navigate the complexities of spring specifications, buyers should invest time in understanding the engineering principles behind coil springs. Engage with technical experts or use resources provided by manufacturers to learn how varying dimensions and materials affect spring performance. For instance, a spring with a larger wire diameter can better handle heavy loads but may require a specific coil design to maintain flexibility. Requesting detailed technical data sheets and performance charts from suppliers can help in making informed decisions. Furthermore, conducting a total cost of ownership analysis that includes maintenance and replacement costs can justify the investment in higher-quality springs that offer better performance over time.

Scenario 3: Managing Lead Times and Supply Chain Reliability

The Problem:

B2B buyers often experience frustration with long lead times and unreliable supply chains when procuring heavy duty coil springs. A company in the agricultural sector may face delays in receiving critical components, jeopardizing their production schedules and contract obligations. Unforeseen supply chain disruptions can arise from material shortages, logistical challenges, or manufacturing delays, leading to a cascade of operational setbacks.

The Solution:

To mitigate lead time issues, buyers should proactively establish relationships with multiple suppliers and explore local manufacturing options. Diversifying the supplier base not only reduces dependency on a single source but also enhances flexibility in responding to demand fluctuations. Additionally, implementing a Just-In-Time (JIT) inventory system can help maintain optimal stock levels, reducing the risk of overordering while ensuring that essential components are available when needed. Regularly communicating with suppliers about production schedules and potential delays can foster transparency and allow for better planning. Lastly, consider investing in strategic partnerships with manufacturers that offer expedited shipping options or have a track record of reliability to ensure timely delivery of critical components.

Strategic Material Selection Guide for heavy duty coil springs

What Are the Key Materials Used for Heavy Duty Coil Springs?

When selecting materials for heavy duty coil springs, it is crucial to consider properties such as strength, durability, and resistance to environmental factors. Here, we analyze four common materials used in manufacturing heavy duty coil springs, highlighting their key properties, advantages, disadvantages, and implications for international buyers.

How Do Different Steel Alloys Perform in Heavy Duty Applications?

1. Chrome Silicon Steel (CrSi)

Chrome silicon steel is a popular choice for heavy duty coil springs due to its excellent fatigue resistance and high tensile strength. This alloy can withstand high temperatures, making it suitable for applications in automotive and industrial sectors where heat is a concern.

- Pros: Exceptional strength and fatigue resistance, good temperature tolerance, and relatively low cost.

- Cons: Moderate corrosion resistance; may require protective coatings in corrosive environments.

- Impact on Application: Ideal for automotive and machinery applications where high stress and temperature fluctuations occur.

- Considerations for International Buyers: Compliance with ASTM standards is common, and buyers should ensure that suppliers can provide certifications for material quality and performance.

2. Oil-Tempered Steel

Oil-tempered steel is another widely used material for heavy duty coil springs. This material undergoes a heat treatment process that enhances its strength and elasticity, making it suitable for dynamic applications.

- Pros: High resilience, good fatigue properties, and cost-effective.

- Cons: Limited corrosion resistance; may require additional treatment for harsh environments.

- Impact on Application: Commonly used in automotive suspensions and industrial machinery where dynamic loads are prevalent.

- Considerations for International Buyers: Buyers should be aware of regional standards such as DIN or JIS that may apply to oil-tempered steel specifications.

3. Stainless Steel

Stainless steel is renowned for its corrosion resistance, making it a prime choice for applications exposed to moisture and chemicals. This material is particularly beneficial in marine and agricultural environments.

- Pros: Excellent corrosion resistance, durability, and aesthetic appeal.

- Cons: Higher cost compared to carbon steels; may have lower fatigue strength.

- Impact on Application: Suitable for applications in corrosive environments, such as agricultural equipment and marine applications.

- Considerations for International Buyers: Buyers should verify compliance with international standards such as ASTM A313, especially when sourcing from different regions.

4. Music Wire

Music wire is a high-carbon steel that is often used for precision springs. It offers high tensile strength and is commonly used in applications that require tight tolerances.

- Pros: High strength-to-weight ratio, excellent fatigue resistance, and good formability.

- Cons: Limited corrosion resistance; typically requires coating for protection.

- Impact on Application: Commonly used in precision applications such as aerospace and automotive components where performance is critical.

- Considerations for International Buyers: Buyers should ensure that the music wire meets specific international standards, and they may need to consider local sourcing for better logistics.

Summary Table of Material Properties for Heavy Duty Coil Springs

| Material | Typical Use Case for heavy duty coil springs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Chrome Silicon Steel | Automotive and industrial applications | Exceptional strength and fatigue resistance | Moderate corrosion resistance | Medium |

| Oil-Tempered Steel | Automotive suspensions, industrial machinery | High resilience and cost-effective | Limited corrosion resistance | Low |

| Stainless Steel | Marine and agricultural applications | Excellent corrosion resistance | Higher cost, lower fatigue strength | High |

| Music Wire | Precision aerospace and automotive components | High strength-to-weight ratio | Limited corrosion resistance | Medium |

Understanding the properties and applications of these materials will help international B2B buyers make informed decisions when selecting heavy duty coil springs. By considering factors such as compliance with local standards and environmental conditions, buyers can ensure the longevity and performance of their spring solutions.

In-depth Look: Manufacturing Processes and Quality Assurance for heavy duty coil springs

What Are the Main Stages in the Manufacturing Process of Heavy Duty Coil Springs?

Manufacturing heavy duty coil springs is a complex process that involves several key stages, each critical for ensuring the quality and performance of the final product.

How is Material Prepared for Heavy Duty Coil Springs?

The manufacturing journey begins with material selection, where manufacturers typically choose high-strength steel alloys like chrome silicon or chrome vanadium due to their durability and fatigue resistance. These materials are available in various wire diameters, ranging from 3mm to 65mm, to meet specific application requirements.

Once the material is selected, it undergoes preparation, which may include processes like straightening and cutting to ensure uniformity. The wire is then treated to enhance its mechanical properties, often involving processes such as heat treatment or surface hardening to increase strength and resistance to wear.

What Techniques Are Used in Forming Heavy Duty Coil Springs?

The forming stage is where the raw material is transformed into coil springs. This involves either hot or cold coiling techniques, depending on the required specifications.

-

Hot Coiling: This method is typically used for larger diameter springs. The wire is heated to a specific temperature, making it malleable. It is then coiled into the desired shape, which allows for greater flexibility in design.

-

Cold Coiling: This technique is preferred for smaller diameter springs and involves coiling the wire at room temperature. Cold coiling often results in springs with superior dimensional accuracy and surface finish.

Advanced CNC (Computer Numerical Control) machines are employed to ensure precision in the coiling process. These machines can produce complex geometries and maintain consistency across large production runs.

How Are Heavy Duty Coil Springs Assembled and Finished?

Following the coiling process, the springs undergo assembly, where additional components such as end fittings or loops may be attached, depending on the application.

The finishing stage involves several processes aimed at enhancing the spring’s performance and longevity. Common finishing techniques include:

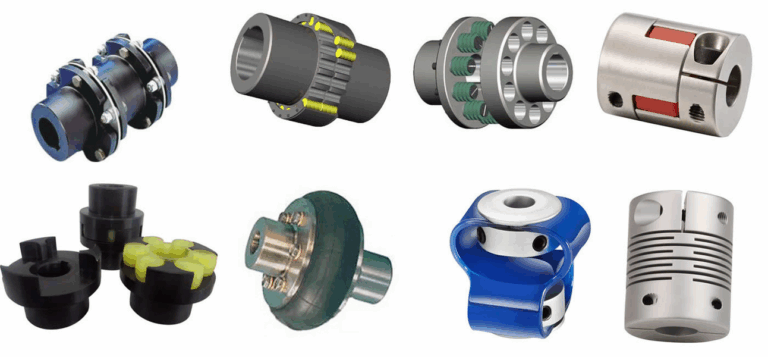

Illustrative image related to heavy duty coil springs

- Shot Peening: This process introduces compressive stresses on the surface, improving fatigue resistance.

- Surface Treatment: Techniques such as zinc phosphating or powder coating are applied to protect against corrosion and enhance aesthetics.

Each of these finishing processes is crucial for ensuring that the springs can withstand extreme operational conditions, which is particularly important for applications in industries like construction, mining, and transportation.

What Quality Assurance Measures Are Commonly Used in Heavy Duty Coil Spring Production?

Quality assurance (QA) is paramount in the manufacturing of heavy duty coil springs to ensure they meet international standards and customer specifications.

Which International Standards Are Relevant for Heavy Duty Coil Springs?

Manufacturers typically adhere to international standards such as ISO 9001, which focuses on quality management systems. In addition, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may be required, particularly for applications in the oil and gas sector.

What Are the Key Quality Control Checkpoints in Heavy Duty Coil Spring Manufacturing?

Quality control is integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before production begins. It ensures that the materials meet specified standards and are free from defects.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs to identify any deviations from set specifications. This includes checking dimensions, coil tightness, and surface finish.

-

Final Quality Control (FQC): After production, springs undergo comprehensive testing to confirm that they meet all performance criteria. This may involve load testing, fatigue testing, and dimensional inspections.

What Common Testing Methods Are Used for Heavy Duty Coil Springs?

Testing methods can vary based on application requirements but commonly include:

- Tensile Testing: Measures the strength of the spring material.

- Fatigue Testing: Assesses the spring’s performance under cyclic loading.

- Dimensional Inspection: Ensures that the springs meet precise specifications in terms of diameter, length, and other critical dimensions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial. Here are some actionable steps:

What Should B2B Buyers Look for in Supplier Audits and Reports?

-

Audits: Request to see recent quality audits conducted by third-party organizations. These audits should evaluate the manufacturing processes, quality systems, and adherence to relevant standards.

-

Quality Reports: Suppliers should provide detailed quality reports that outline testing results, certifications, and any corrective actions taken for non-conformities.

-

References and Case Studies: Ask for references from other clients, particularly those in your industry, to understand the supplier’s reliability and performance history.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an additional layer of assurance. These independent organizations can perform random inspections and audits to verify compliance with international standards and the supplier’s internal quality processes.

What Quality Control Nuances Should International B2B Buyers Be Aware Of?

When dealing with suppliers across different regions, it’s important to be aware of potential quality control nuances:

-

Cultural Differences: Understand that quality perception may vary across cultures. Establish clear communication about quality expectations and standards.

-

Regulatory Compliance: Ensure that suppliers are compliant with both local and international regulations, which can differ significantly between regions.

-

Supply Chain Transparency: Seek suppliers who are open about their supply chain processes, as transparency can significantly influence quality assurance.

By focusing on these manufacturing and quality assurance processes, B2B buyers can make informed decisions when sourcing heavy duty coil springs, ensuring they partner with reliable suppliers who deliver high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heavy duty coil springs’

Introduction

Navigating the procurement of heavy-duty coil springs requires a systematic approach to ensure that you select the right products for your application. This guide provides a step-by-step checklist to help B2B buyers effectively source heavy-duty coil springs, ensuring that you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your application is crucial. Determine the load capacity, dimensions, and type of coil spring needed—compression, tension, or torsion. This step ensures you communicate your needs clearly to potential suppliers, facilitating a smoother procurement process.

Illustrative image related to heavy duty coil springs

- Load Capacity: Identify the maximum weight or force the spring must support.

- Dimensions: Specify the required diameter and length to fit your machinery or vehicle.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in heavy-duty coil springs. Look for companies with a solid reputation in the industry and a proven track record of quality.

- Industry Experience: Prefer suppliers with extensive experience in your sector, such as automotive, agriculture, or construction.

- Global Reach: Consider suppliers with a global presence, especially if you’re sourcing from Africa, South America, or the Middle East.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that potential suppliers hold relevant industry certifications. Certifications can indicate a supplier’s commitment to quality and compliance with international standards.

- ISO Certification: Look for ISO 9001 or similar certifications, which demonstrate adherence to quality management principles.

- Material Certifications: Ensure that the materials used meet industry standards for durability and performance.

Step 4: Request Samples for Testing

Request samples of the coil springs to test their performance under your specific conditions. This step is vital to ensure the springs meet your technical specifications and operational demands.

Illustrative image related to heavy duty coil springs

- Test Conditions: Conduct tests that mimic the actual operating environment of the springs.

- Performance Metrics: Evaluate key performance indicators such as elasticity, fatigue resistance, and load-bearing capacity.

Step 5: Compare Pricing and Terms

Once you have a shortlist of suppliers, compare their pricing structures and payment terms. Understanding the total cost of ownership will help you make a financially sound decision.

- Bulk Discounts: Inquire about discounts for bulk purchases or long-term contracts.

- Payment Flexibility: Look for suppliers who offer flexible payment terms that align with your cash flow.

Step 6: Assess Customer Support and After-Sales Service

Consider the level of customer support and after-sales service offered by the supplier. A reliable supplier should be able to assist you throughout the procurement process and beyond.

- Technical Support: Ensure that the supplier offers engineering support for installation and maintenance.

- Warranty and Returns: Check the warranty policy and return options in case the springs do not meet your expectations.

Step 7: Finalize Your Order and Establish Communication

After selecting a supplier, finalize your order with clear communication regarding delivery timelines and expectations. Establishing a strong line of communication can help address any potential issues that may arise.

- Order Confirmation: Ensure all specifications are confirmed in writing.

- Regular Updates: Request regular updates on the order status to avoid delays.

By following this checklist, B2B buyers can enhance their procurement strategy for heavy-duty coil springs, ensuring they choose the right products from reputable suppliers while minimizing risks and maximizing value.

Illustrative image related to heavy duty coil springs

Comprehensive Cost and Pricing Analysis for heavy duty coil springs Sourcing

What Are the Key Cost Components in Sourcing Heavy Duty Coil Springs?

When sourcing heavy duty coil springs, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

Materials: The choice of material significantly impacts costs. Common materials such as chrome silicon and chrome vanadium are preferred due to their strength and durability. The price of these materials can fluctuate based on market conditions and availability.

Labor: Labor costs encompass the wages of skilled workers involved in the design, production, and quality assurance of the springs. Advanced manufacturing techniques may require specialized skills, which can increase labor costs.

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and general administrative costs. Efficient manufacturing processes can help minimize these overhead costs.

Tooling: Tooling costs are associated with the creation of molds and dies necessary for spring production. Custom designs may incur higher tooling costs due to the need for specialized equipment.

Quality Control (QC): Implementing rigorous QC processes ensures that the springs meet industry standards and customer specifications. While this adds to the cost, it is essential for maintaining product reliability and minimizing returns.

Logistics: Transportation and handling costs are critical, especially for international shipments. Factors such as shipping methods, distances, and customs duties can significantly influence overall logistics expenses.

Margin: Supplier margins vary based on market positioning and competition. Understanding the margin can help buyers assess whether they are receiving a fair price.

How Do Price Influencers Affect Heavy Duty Coil Springs Pricing?

Several factors influence pricing for heavy duty coil springs, making it essential for buyers to consider these elements when negotiating.

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower unit prices. Suppliers may offer discounts for bulk purchases, making it beneficial for companies that require high quantities.

Specifications and Customization: Custom designs tailored to specific applications often come with a premium. Buyers should weigh the need for customization against the potential cost implications.

Material Quality and Certifications: Springs manufactured from high-grade materials or those that comply with specific certifications (e.g., ISO, AS9100) may command higher prices. Buyers should prioritize quality to ensure long-term performance.

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers with proven track records may charge more but offer better service and quality assurance.

Incoterms: Understanding international commercial terms (Incoterms) is crucial for buyers engaging in cross-border transactions. Incoterms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

What Are Effective Buyer Tips for Sourcing Heavy Duty Coil Springs?

To optimize sourcing strategies, B2B buyers should adopt several best practices.

Negotiation: Engage in discussions with multiple suppliers to establish a competitive pricing environment. Leverage quotes and terms to negotiate favorable conditions, especially for larger orders.

Cost-Efficiency: Analyze the total cost of ownership (TCO) rather than just the purchase price. Consider factors such as maintenance, durability, and potential downtime when evaluating the overall value of the springs.

Pricing Nuances for International Buyers: When sourcing from regions such as Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, tariffs, and regional compliance standards. These factors can significantly influence pricing and delivery timelines.

Supplier Relationship Management: Building long-term relationships with suppliers can lead to better pricing, improved service, and priority handling. Regular communication and feedback are key to nurturing these partnerships.

Illustrative image related to heavy duty coil springs

Disclaimer on Indicative Prices: Prices for heavy duty coil springs can vary widely based on the aforementioned factors. Buyers should conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

By considering these aspects, international B2B buyers can effectively navigate the complexities of sourcing heavy duty coil springs and secure the best possible deals.

Alternatives Analysis: Comparing heavy duty coil springs With Other Solutions

Exploring Alternatives to Heavy Duty Coil Springs

When considering heavy duty coil springs for industrial applications, it’s essential to evaluate alternative solutions that may offer similar benefits. This analysis will compare heavy duty coil springs against two viable alternatives: leaf springs and air suspension systems. Each solution has unique attributes that could align with specific operational requirements, making it crucial for B2B buyers to assess their options carefully.

| Comparison Aspect | Heavy Duty Coil Springs | Leaf Springs | Air Suspension Systems |

|---|---|---|---|

| Performance | High load capacity; durable; ideal for heavy loads. | Good load distribution; effective in off-road applications. | Adjustable stiffness; superior comfort and handling. |

| Cost | Moderate initial investment; long-term durability can lower total cost of ownership. | Generally lower upfront cost; limited lifespan may increase long-term costs. | Higher initial cost; maintenance can be expensive. |

| Ease of Implementation | Straightforward installation; requires specific mounting points. | Simple installation; adaptable to various vehicles. | Complex installation; requires skilled technicians. |

| Maintenance | Low maintenance; periodic inspections recommended. | Moderate maintenance; prone to wear and tear. | Regular maintenance needed; air leaks can be problematic. |

| Best Use Case | Heavy-duty trucks, construction equipment, and industrial applications. | Commercial vehicles, light trucks, and off-road vehicles. | Luxury vehicles, specialized transport, and adjustable load applications. |

Understanding the Pros and Cons of Leaf Springs

Leaf springs are a traditional suspension solution known for their simplicity and cost-effectiveness. They consist of multiple layers of metal (leaves) stacked together, providing a robust means of load support and excellent durability. One of the key advantages of leaf springs is their ability to handle heavy loads while maintaining vehicle stability, particularly in off-road scenarios. However, they tend to offer a rougher ride compared to coil springs and may require more frequent maintenance due to wear and fatigue.

Evaluating Air Suspension Systems

Air suspension systems utilize air-filled bags instead of traditional springs, allowing for adjustable ride height and improved comfort. This adaptability is particularly beneficial for vehicles that frequently change loads, as the system can automatically adjust to maintain optimal performance. While air suspension systems provide superior ride quality and handling, they come with a higher upfront cost and potential long-term maintenance challenges, such as air leaks and the need for air compressor upkeep.

Making the Right Choice for Your Business Needs

Selecting the appropriate suspension system for your operations depends on several factors, including budget, application, and performance requirements. Heavy duty coil springs excel in heavy-load scenarios, offering a balance of cost and longevity, making them an excellent choice for industrial applications. Leaf springs may be more suitable for businesses focused on cost and simplicity, particularly in commercial and off-road environments. On the other hand, air suspension systems are ideal for those prioritizing ride comfort and adjustability, albeit at a higher price point.

In conclusion, B2B buyers should carefully evaluate their operational needs and budget constraints when choosing between heavy duty coil springs, leaf springs, and air suspension systems. By understanding the strengths and weaknesses of each option, businesses can make informed decisions that enhance their operational efficiency and vehicle performance.

Essential Technical Properties and Trade Terminology for heavy duty coil springs

What Are the Key Technical Properties of Heavy Duty Coil Springs?

When selecting heavy duty coil springs for industrial applications, understanding their critical specifications is essential for ensuring performance and longevity. Here are several key properties that B2B buyers should consider:

1. Material Grade

The material used for coil springs significantly impacts their strength, flexibility, and resistance to fatigue. Common materials include chrome silicon and chrome vanadium, known for their exceptional tensile strength and durability. Selecting the appropriate material grade ensures that the springs can withstand the specific operational stresses they will encounter in their application, thereby reducing the risk of failure and enhancing safety.

2. Wire Diameter

The wire diameter of a coil spring is a vital specification that affects its load-bearing capacity and overall performance. Heavier loads require thicker wire diameters to prevent deformation. Understanding the wire diameter helps buyers select springs that will maintain structural integrity under expected loads, which is particularly crucial in sectors like construction and transportation.

3. Spring Rate

The spring rate is defined as the amount of force required to compress the spring by a certain distance (typically measured in pounds per inch or N/mm). This property is critical in applications where precise load handling is essential, such as in automotive suspension systems. A proper understanding of the spring rate allows businesses to ensure that the spring will perform as intended under varying load conditions.

4. Tolerance

Tolerance refers to the allowable variation in the dimensions of the spring, including its length, diameter, and shape. Tight tolerances are essential for applications requiring precision, such as in machinery or aerospace components. Understanding tolerance specifications helps buyers ensure that the springs will fit correctly and function efficiently in their intended applications.

5. Surface Finish

The surface finish of coil springs can affect their durability and resistance to corrosion. Common finishes include zinc plating and powder coating, which protect against environmental factors. Selecting the right surface finish is crucial for applications exposed to harsh conditions, as it can extend the lifespan of the springs and reduce maintenance costs.

What Are Common Trade Terms Used in the Heavy Duty Coil Springs Industry?

Familiarity with industry terminology is essential for effective communication and negotiation. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM produces components or products that are used in another company’s end product. In the context of coil springs, understanding whether a supplier is an OEM can help buyers assess the quality and compatibility of the springs with their machinery or vehicles.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases and manage inventory effectively. This is particularly important for companies operating in regions where shipping costs can significantly impact profitability.

Illustrative image related to heavy duty coil springs

3. RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to potential suppliers requesting pricing and terms for specific products. Understanding how to properly formulate an RFQ can help buyers obtain competitive pricing and ensure that their needs are met.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risks, and responsibilities, which can be crucial for cross-border procurement of heavy duty coil springs.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is essential for effective project management and inventory control, especially in industries with tight deadlines.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing heavy duty coil springs, ensuring they select the right products for their specific applications while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the heavy duty coil springs Sector

What Are the Current Market Dynamics and Key Trends in Heavy Duty Coil Springs?

The global heavy-duty coil springs market is experiencing significant growth, driven by the increasing demand for robust suspension systems in various industries, including automotive, construction, and mining. The rise of electric vehicles (EVs) is also influencing market dynamics, as manufacturers seek lightweight yet durable components to enhance efficiency and performance. In regions such as Africa, South America, the Middle East, and Europe, there is a growing focus on local sourcing and partnerships, leading to a shift in supply chain strategies. International B2B buyers are increasingly leveraging digital platforms for procurement, utilizing advanced technologies like AI and data analytics to optimize their sourcing processes.

Emerging trends include the customization of heavy-duty coil springs to meet specific application requirements. This trend is particularly important for industries facing unique challenges, such as extreme temperatures or heavy loads. Manufacturers are investing in advanced manufacturing technologies, such as CNC coiling and automated production lines, to enhance precision and reduce lead times. As competition intensifies, suppliers are also emphasizing customer service, offering consultative support to help buyers identify the best solutions for their needs.

How Is Sustainability Influencing Sourcing in the Heavy Duty Coil Springs Industry?

Sustainability is becoming a cornerstone of sourcing strategies in the heavy-duty coil springs sector. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmental responsibility. This includes evaluating the lifecycle impact of products, from raw material extraction to production and eventual disposal. The use of recycled materials and sustainable manufacturing practices is gaining traction, as businesses seek to minimize their carbon footprint.

The importance of ethical supply chains cannot be overstated. Companies are expected to adhere to social responsibility standards, ensuring fair labor practices and transparency in their operations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential for suppliers aiming to attract global buyers. Furthermore, the use of ‘green’ materials, such as chrome silicon and chrome vanadium, known for their durability and performance, is increasingly favored. By aligning with sustainable practices, businesses not only comply with regulations but also appeal to environmentally conscious consumers, enhancing their market reputation.

What Is the Historical Context of Heavy Duty Coil Springs?

The evolution of heavy-duty coil springs dates back to the industrial revolution when the need for durable and reliable components became paramount for machinery and transportation. Early designs primarily focused on functionality, but as industries advanced, so did the technology and materials used in spring manufacturing. Over the decades, the introduction of high-strength alloys and advanced coiling techniques has allowed for the production of springs that can withstand extreme loads and harsh environments.

The emergence of the automotive industry in the early 20th century marked a significant turning point. Manufacturers began to prioritize suspension systems that provided better ride quality and safety, leading to innovations in spring design. Today, heavy-duty coil springs are integral to numerous applications, from commercial vehicles to industrial machinery, reflecting a rich history of engineering excellence and continuous improvement. As the industry moves forward, the focus remains on enhancing performance while embracing sustainable practices, ensuring that heavy-duty coil springs will continue to play a vital role in global supply chains.

Frequently Asked Questions (FAQs) for B2B Buyers of heavy duty coil springs

-

1. How do I select the right heavy-duty coil spring for my application?

Choosing the right heavy-duty coil spring requires a clear understanding of your application’s specific needs. Consider factors such as load capacity, spring type (compression, tension, or torsion), and environmental conditions (temperature, corrosion, etc.). Consult with manufacturers who can offer technical assistance and help you determine the appropriate wire diameter and material. Providing detailed specifications will enable suppliers to recommend the most suitable options, ensuring optimal performance and durability. -

2. What are the key differences between compression, tension, and torsion springs?

Compression springs are designed to resist axial loads and are commonly used in applications where space is limited. Tension springs, or extension springs, exert a pulling force and are often used in mechanisms like garage doors and machinery. Torsion springs store energy when twisted and are typically found in applications requiring rotational movement, such as tailgates. Understanding these differences will help you choose the right type for your specific application. -

3. What customization options are available for heavy-duty coil springs?

Many manufacturers offer extensive customization options for heavy-duty coil springs, including variations in size, material, and design specifications. You can request specific wire diameters, coil configurations, and surface treatments to meet unique application requirements. Collaborating with a supplier during the design phase can ensure that your custom springs meet performance expectations and industry standards. Be sure to provide detailed engineering drawings or specifications to facilitate the customization process. -

4. What is the typical minimum order quantity (MOQ) for heavy-duty coil springs?

Minimum order quantities for heavy-duty coil springs can vary significantly among suppliers and depend on factors such as material type and manufacturing complexity. Generally, MOQs can range from a few dozen to several hundred units. It’s crucial to discuss your needs with potential suppliers to understand their MOQ policies, especially if you are looking for a customized solution. Some manufacturers may offer flexibility for initial orders or prototyping. -

5. How do I vet potential suppliers of heavy-duty coil springs?

When vetting suppliers, consider their industry experience, certifications, and production capabilities. Request references or case studies from previous clients to assess their reliability and quality standards. Additionally, evaluate their customer service responsiveness and willingness to collaborate on design and engineering challenges. Establishing clear communication and understanding their logistics capabilities will also contribute to a successful partnership. -

6. What payment terms are commonly offered by suppliers?

Payment terms can vary widely among suppliers, but common options include upfront payment, net 30, or net 60 days. Some suppliers may offer discounts for early payments or flexible financing options for larger orders. It’s important to negotiate payment terms that align with your cash flow needs while ensuring that you establish a trustworthy relationship with the supplier. Always review the terms in the contract to avoid misunderstandings. -

7. What quality assurance measures should I expect from heavy-duty coil spring suppliers?

Reputable suppliers should implement rigorous quality assurance measures, including material inspections, in-process testing, and final product evaluations. Look for manufacturers that adhere to international standards (such as ISO 9001) and provide certifications for their products. Additionally, inquire about their testing methods, such as fatigue testing and load testing, to ensure that the springs meet your specifications and perform reliably in your application. -

8. How can I ensure timely delivery of heavy-duty coil springs?

To ensure timely delivery, establish clear timelines with your supplier from the outset. Discuss their lead times, production schedules, and logistics capabilities. Providing accurate forecasts and placing orders well in advance can help mitigate delays. Additionally, consider working with suppliers who have a robust supply chain and can offer real-time tracking of your order. Regular communication throughout the production and shipping process is key to managing expectations and addressing any potential issues promptly.

Top 6 Heavy Duty Coil Springs Manufacturers & Suppliers List

1. General Spring – Heavy Duty Coil Springs

Domain: generalspringkc.com

Registered: 2005 (20 years)

Introduction: Heavy Duty Coil Springs for various vehicle makes and models including Chevy/GMC, Ford, Dodge, Toyota, and more. Suitable for trucks, vans, and cars. Products include air springs (Rolling Lobe, Double Convoluted, Triple Convoluted), load support systems (Timbrens, SuperSprings), and various suspension components. The company has been in business since 1965 and offers competitive pricing.

2. CargoMaxx – Heavy Duty Rear Coil Springs

Domain: hdcoilsprings.com

Registered: 2020 (5 years)

Introduction: Featured Products: 1. CargoMaxx Heavy Duty 2000-2023 Chevrolet/GMC Suburban/Tahoe/Yukon/Yukon XL Rear Coil Springs (Pair) | +35% Capacity | Price: $270.13 2. CargoMaxx Heavy Duty 2019-2023 Dodge Ram 1500 Rear Coil Springs (Pair) | 2WD / 4WD | +70% Capacity | Price: $291.02 3. CargoMaxx Heavy Duty 2009-2018 Dodge Ram 1500 Rear Coil Springs (Pair) | 2WD / 4WD | +70% Capacity | Price: $253.00 4. Carg…

3. Lesjöfors – Heavy Duty Coil Springs

Domain: lesjoforssprings.com

Registered: 2021 (4 years)

Introduction: Lesjöfors specializes in heavy duty coil springs, including compression springs, torsion springs, and tension springs. They manufacture springs with wire diameters ranging from 3mm to 65mm, utilizing advanced hot and cold coiling technologies. The company has a 170-year manufacturing legacy and operates globally with a focus on quality, accuracy, and customer satisfaction. They offer a wide range …

4. MAD – Reinforced Main Springs

Domain: mad-suspensionsystems.com

Registered: 2017 (8 years)

Introduction: MAD’s reinforced main springs are designed for vehicles that are regularly or continuously loaded, particularly light commercial vehicles. They help maintain ideal ride height, improve driveability and safety, and enhance driver comfort. These springs are suitable when auxiliary springs are not feasible due to constraints like small original coil spring diameter or end stops. Key specifications in…

5. Stengel Bros – CARGOMAXX HD™ Coil Springs

Domain: stengelbros.com

Registered: 2001 (24 years)

Introduction: Heavy Duty Coil Springs – CARGOMAXX HD™ heavy-duty coil springs are custom-designed for increased load handling capability and improved ride quality. Ideal for utility vehicles, pickups, SUVs, vans, and motor homes. HD: Designed to carry 35% more load at stock load height. XHD: Designed to carry 70% more load at stock load height. Benefits include improved handling, ride quality, cornering stabili…

6. Compression Spring Co. – Heavy Duty Compression Springs

Domain: compressionspring.com

Registered: 2000 (25 years)

Introduction: Heavy Duty Compression Springs are designed to withstand large amounts of load due to their physical dimensions. They typically have an outer diameter ranging from 3″ to 9.25″ and a wire diameter between 0.218″ and 0.938″. Customers can find thousands of heavy duty compression spring designs in stock at CompressionSpring.com. If the right spring is not available, users can generate a live instant …

Strategic Sourcing Conclusion and Outlook for heavy duty coil springs

In today’s competitive landscape, strategic sourcing of heavy-duty coil springs is essential for international B2B buyers aiming to enhance operational efficiency and product reliability. By leveraging advanced manufacturing technologies and tapping into a global network of suppliers, businesses can secure high-quality springs tailored to their specific applications, whether in transportation, agriculture, or heavy machinery.

Key takeaways include the importance of selecting reputable manufacturers who prioritize quality and customization. Understanding the nuances of different spring types—compression, tension, and torsion—enables buyers to make informed decisions that align with their operational needs. Furthermore, considering factors such as material selection and manufacturing processes can significantly impact the longevity and performance of coil springs.

Looking ahead, the demand for robust, high-capacity coil springs will only continue to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. B2B buyers should actively engage with suppliers who offer innovative solutions and are committed to sustainability. By prioritizing strategic partnerships, businesses can not only enhance their supply chains but also position themselves for success in an evolving marketplace. Embrace this opportunity to optimize your sourcing strategy and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to heavy duty coil springs