Heat Exchanger Cover Plate Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for heat exchanger cover plate

In today’s competitive global landscape, sourcing high-quality heat exchanger cover plates presents a significant challenge for B2B buyers. As industries increasingly prioritize efficiency and reliability, understanding the nuances of cover plate procurement is crucial. This guide serves as a comprehensive resource, detailing various types of heat exchanger cover plates, their applications across different sectors, and essential considerations for supplier vetting.

International buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—will find valuable insights tailored to their unique procurement needs. The guide not only outlines the critical attributes that define quality heat exchanger cover plates but also addresses factors such as cost-effectiveness and maintenance requirements.

By equipping decision-makers with actionable strategies and a thorough understanding of the global market dynamics, this guide empowers B2B buyers to make informed purchasing decisions. Whether you are involved in manufacturing, energy production, or HVAC systems, navigating the complexities of heat exchanger cover plate sourcing has never been more accessible. Prepare to enhance your operational efficiency and reduce downtime through effective procurement practices tailored for a global audience.

Understanding heat exchanger cover plate Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Cover Plate | Basic design, typically flat, made from stainless steel | General industrial applications | Pros: Cost-effective; Cons: Limited customization options. |

| Double Wall Cover Plate | Two layers for enhanced safety, leak detection | Chemical processing, oil & gas sectors | Pros: Increased safety; Cons: Higher initial cost. |

| Gasketed Cover Plate | Integrated gaskets for improved sealing | HVAC systems, refrigeration | Pros: Better leak prevention; Cons: Requires regular maintenance. |

| Custom Fabricated Plate | Tailored dimensions and materials as per specifications | Specialized industrial applications | Pros: Perfect fit for unique systems; Cons: Longer lead times. |

| High-Temperature Cover Plate | Designed to withstand extreme temperatures | Power generation, waste heat recovery | Pros: Durable under stress; Cons: Typically more expensive. |

What Are the Characteristics of Standard Cover Plates?

Standard cover plates are the most commonly used type in various industrial applications. They are typically flat and constructed from durable materials like stainless steel, ensuring a balance between cost and functionality. Their simplicity makes them easy to manufacture and replace, making them suitable for general industrial applications where customization is not a priority. Buyers should consider the compatibility of these plates with existing systems, as they may not offer advanced features found in more specialized designs.

How Do Double Wall Cover Plates Enhance Safety?

Double wall cover plates consist of two layers, providing an additional safety measure against leaks. This design is particularly beneficial in industries such as chemical processing and oil & gas, where fluid containment is critical. The space between the walls can act as a leak detection area, alerting operators to potential issues before they escalate. While the initial investment may be higher, the long-term benefits in safety and reduced risk of environmental contamination can outweigh these costs.

Why Choose Gasketed Cover Plates for HVAC Systems?

Gasketed cover plates incorporate integrated gaskets, enhancing their sealing capabilities and minimizing the risk of leaks. They are commonly used in HVAC systems and refrigeration applications, where maintaining temperature control is vital. Regular maintenance is necessary to ensure the gaskets remain effective, making them a consideration for buyers who prioritize long-term performance. The added sealing benefits can lead to lower operational costs and increased system efficiency.

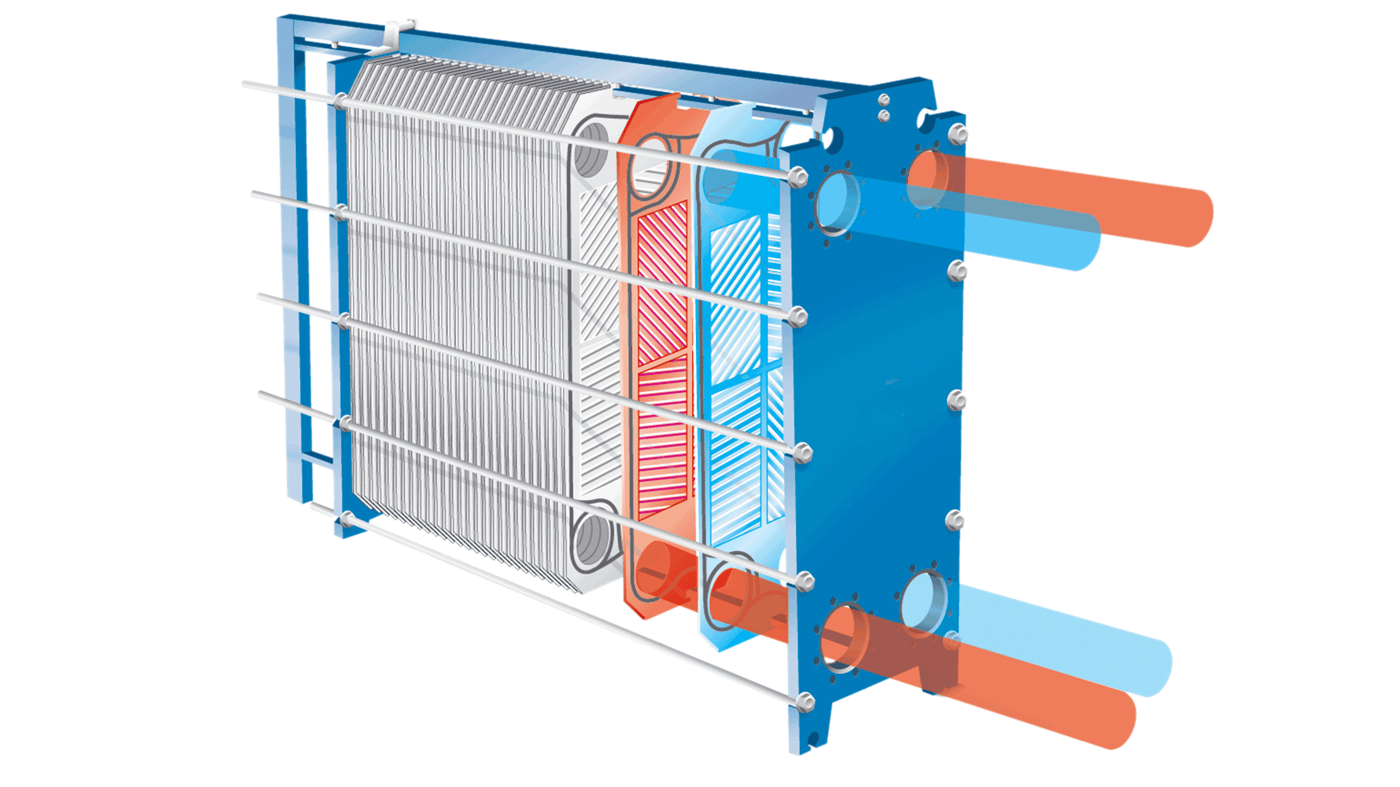

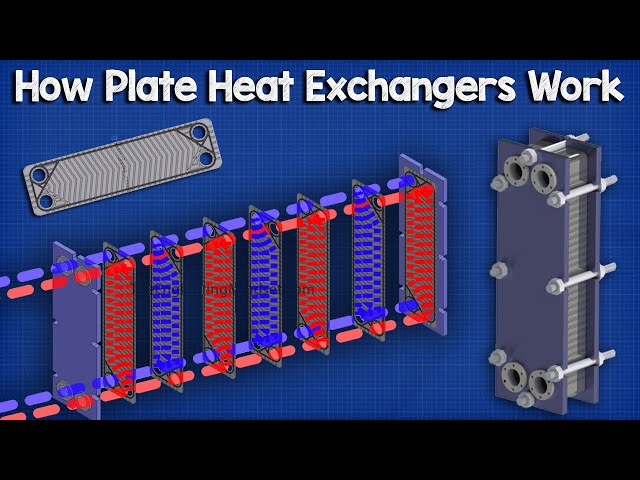

Illustrative image related to heat exchanger cover plate

What Are the Advantages of Custom Fabricated Plates?

Custom fabricated cover plates are designed to meet specific dimensions and material requirements, making them ideal for specialized industrial applications. This type of cover plate ensures a perfect fit for unique systems, providing enhanced performance and reliability. Buyers should be aware that while custom solutions offer significant benefits, they often come with longer lead times and higher costs compared to standard options. Therefore, careful planning and budgeting are essential for businesses considering this route.

How Do High-Temperature Cover Plates Perform Under Stress?

High-temperature cover plates are engineered to withstand extreme conditions, making them suitable for applications in power generation and waste heat recovery. These plates are made from materials that can endure high thermal stress, ensuring longevity and reliability in demanding environments. While they typically come at a higher price point, the investment can be justified by their durability and the operational efficiency they provide in high-temperature applications. Buyers must assess their specific temperature requirements to ensure optimal performance.

Key Industrial Applications of heat exchanger cover plate

| Industry/Sector | Specific Application of heat exchanger cover plate | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Cover plates in heat exchangers for refining processes | Enhances efficiency and safety during high-temperature operations | Material compatibility with corrosive substances; certifications for safety standards |

| Food & Beverage | Sanitary heat exchanger cover plates for pasteurization | Ensures hygiene and prevents contamination in food processing | Compliance with food safety regulations; ease of cleaning and maintenance |

| Power Generation | Cover plates in cooling systems for thermal power plants | Improves thermal efficiency and reduces operational costs | Durability against high pressure; compatibility with existing systems |

| HVAC Systems | Heat exchanger cover plates in air conditioning systems | Optimizes energy consumption and improves system reliability | Temperature ratings; energy efficiency certifications |

| Chemical Processing | Cover plates in heat exchangers for reaction cooling | Prevents overheating and maintains reaction stability | Resistance to chemical corrosion; precise fit for OEM systems |

How Are Heat Exchanger Cover Plates Used in the Oil & Gas Sector?

In the oil and gas industry, heat exchanger cover plates are critical components in refining processes where high temperatures and pressures are prevalent. These plates ensure the safe containment of fluids, minimizing leaks that could lead to costly downtime or environmental hazards. Buyers from this sector must consider the material’s compatibility with corrosive substances and ensure that cover plates meet industry safety certifications to maintain operational integrity.

What Role Do Heat Exchanger Cover Plates Play in Food & Beverage Processing?

In the food and beverage sector, heat exchanger cover plates are essential for pasteurization processes, ensuring that products are heated to safe temperatures without compromising quality. These plates must comply with stringent food safety regulations to prevent contamination. Buyers should prioritize materials that facilitate easy cleaning and maintenance, as well as those that meet hygiene standards, ensuring product safety and consumer trust.

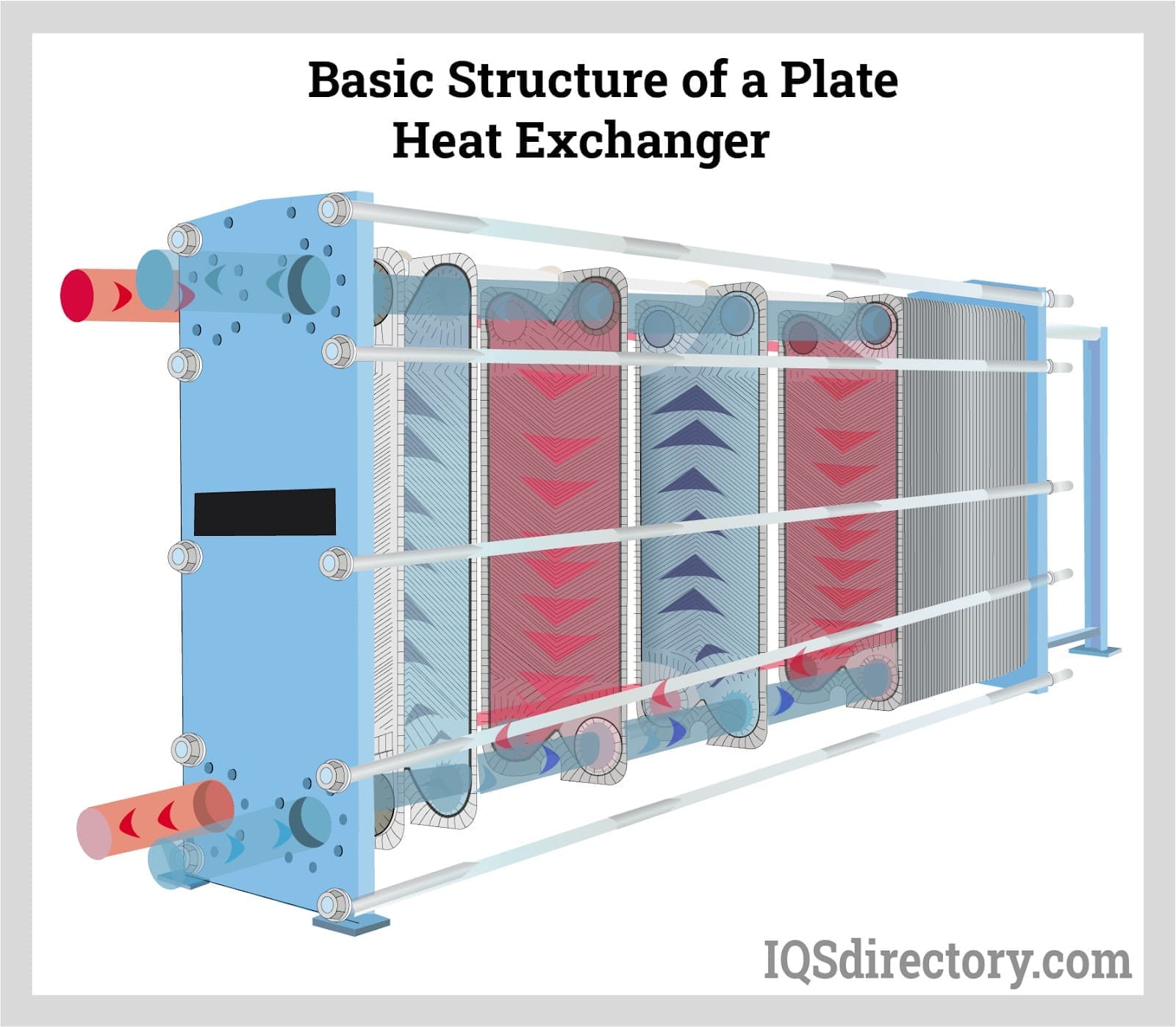

Illustrative image related to heat exchanger cover plate

How Do Heat Exchanger Cover Plates Improve Efficiency in Power Generation?

In thermal power plants, heat exchanger cover plates are utilized in cooling systems to enhance thermal efficiency. These plates help maintain optimal operating temperatures, which can significantly reduce fuel consumption and operational costs. For international buyers, particularly in regions with varying climates, sourcing durable plates that can withstand high pressure and temperature fluctuations is essential for ensuring long-term performance and reliability.

Why Are Heat Exchanger Cover Plates Important in HVAC Systems?

In HVAC systems, heat exchanger cover plates play a pivotal role in optimizing energy consumption and improving system reliability. They help manage airflow and thermal transfer, contributing to overall energy efficiency. Buyers should look for cover plates that meet specific temperature ratings and energy efficiency certifications, as these factors directly impact operational costs and system longevity.

What Are the Sourcing Considerations for Chemical Processing Applications?

In chemical processing, heat exchanger cover plates are vital for maintaining the stability of reactions by preventing overheating. These plates must resist chemical corrosion and be designed for precise fitment in existing systems to avoid leaks. Buyers in this sector should prioritize sourcing from manufacturers who provide detailed specifications and certifications, ensuring that the plates meet rigorous industry standards for safety and performance.

3 Common User Pain Points for ‘heat exchanger cover plate’ & Their Solutions

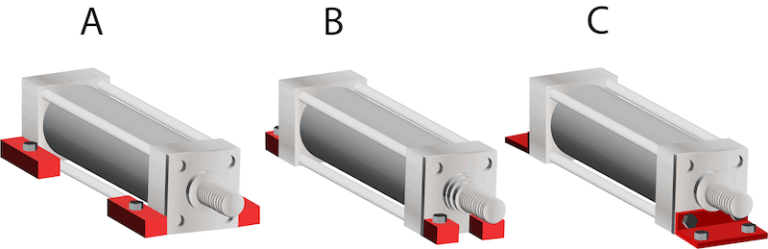

Scenario 1: Difficulty in Finding Compatible Replacement Cover Plates

The Problem: B2B buyers often encounter challenges when searching for compatible replacement cover plates for their heat exchangers. This issue is particularly pronounced in regions with less established supply chains, where buyers may have limited access to OEM parts. Mismatched specifications can lead to improper fits, resulting in leaks, inefficiencies, and potential equipment failures. In industries where downtime translates to significant financial loss, this situation creates an urgent need for reliable sourcing options.

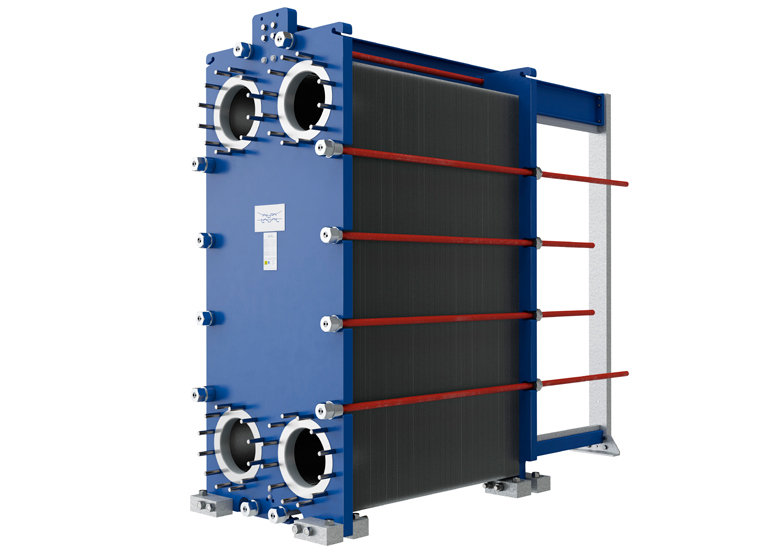

Illustrative image related to heat exchanger cover plate

The Solution: To effectively source compatible heat exchanger cover plates, buyers should prioritize working with manufacturers or suppliers that offer reverse-engineered parts tailored to match OEM specifications. Engaging with suppliers who provide detailed product catalogs, including dimensional data and material specifications, can simplify the selection process. Additionally, establishing a relationship with a trusted supplier can facilitate quicker turnaround times for replacement parts, ensuring that businesses minimize operational disruptions. Buyers should also consider investing in a comprehensive inventory management system that tracks the specifications and lifespan of their current cover plates, enabling proactive replacements before issues arise.

Scenario 2: Frequent Maintenance and Replacement Challenges

The Problem: Regular maintenance and timely replacement of heat exchanger cover plates are critical to ensuring optimal performance. However, many B2B buyers struggle with the frequency of maintenance due to inadequate product durability or poor quality of the replacement parts. Buyers may experience frustration when cover plates fail prematurely, leading to unplanned downtime and costly repairs. This issue is often compounded by a lack of clear maintenance guidelines from suppliers.

The Solution: Buyers can mitigate these challenges by selecting high-quality cover plates made from robust materials designed to withstand extreme operational conditions. It is essential to consult with manufacturers who provide detailed maintenance guidelines and recommended replacement intervals based on real-world usage data. Implementing a scheduled maintenance program that aligns with these recommendations can help extend the lifespan of cover plates and improve overall system efficiency. Additionally, investing in training for maintenance personnel on proper installation and care of cover plates can further reduce the risk of premature failure.

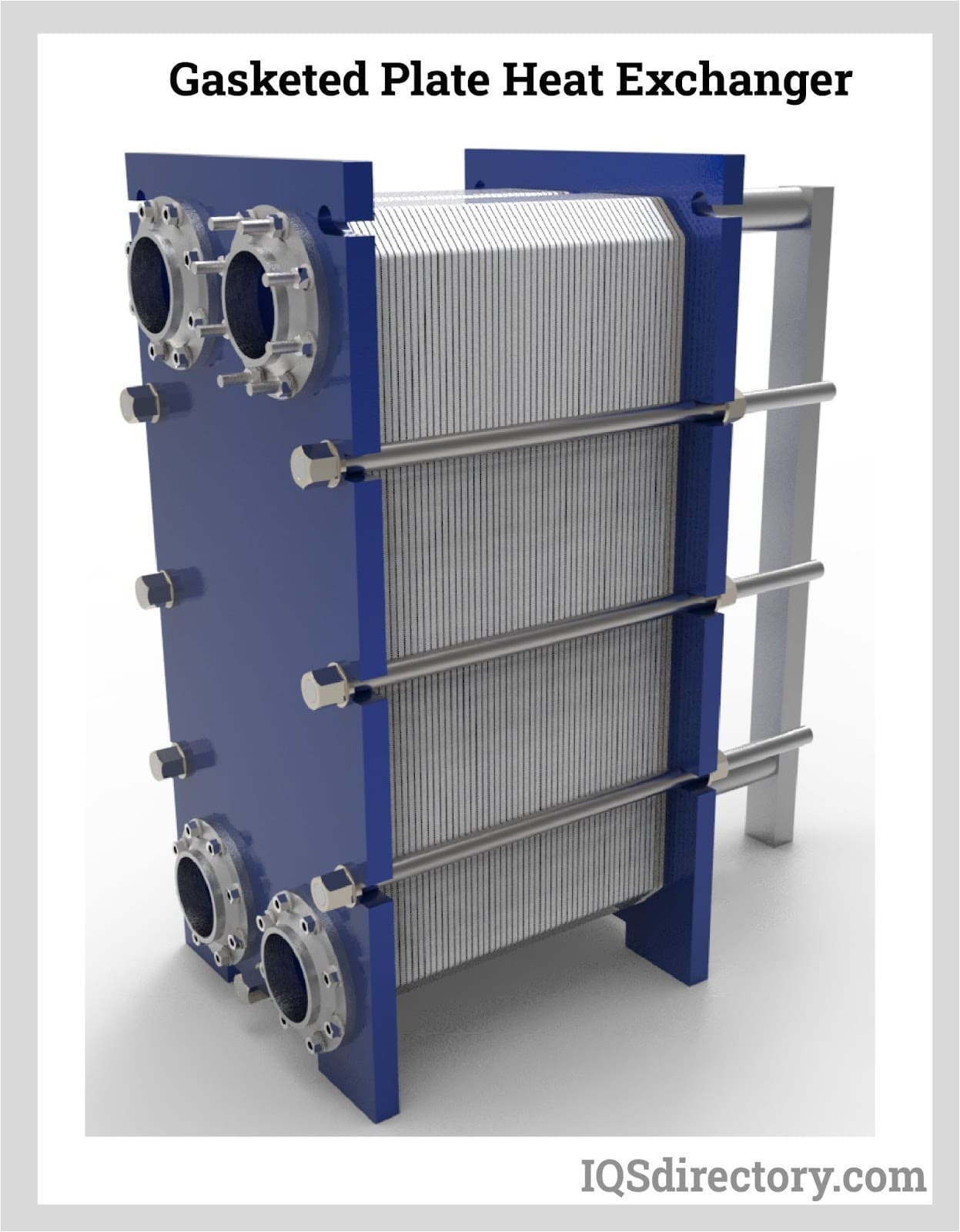

Illustrative image related to heat exchanger cover plate

Scenario 3: Inadequate Technical Support and Guidance

The Problem: Technical support is often a significant pain point for B2B buyers of heat exchanger cover plates. Many buyers find themselves lacking the necessary technical expertise to make informed decisions on installation, compatibility, and maintenance. This gap can lead to improper installation, operational inefficiencies, and safety risks, particularly in complex industrial applications where precision is vital.

The Solution: To address this issue, buyers should seek suppliers that offer comprehensive technical support, including installation guides, troubleshooting resources, and direct access to engineering teams. Participating in supplier-led training sessions or webinars can also enhance the technical knowledge of buyers’ teams. Furthermore, leveraging online resources such as product videos or detailed FAQs can empower buyers to make better-informed decisions. Establishing a feedback loop with suppliers can also facilitate continuous improvement in product offerings and support services, ultimately leading to enhanced operational efficiency and safety.

Strategic Material Selection Guide for heat exchanger cover plate

What Are the Key Properties of Common Materials for Heat Exchanger Cover Plates?

When selecting materials for heat exchanger cover plates, it is essential to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. The choice of material can significantly affect the performance and longevity of the heat exchanger, making it crucial for international B2B buyers to understand the implications of their selections.

Which Materials Are Commonly Used for Heat Exchanger Cover Plates?

1. Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand high temperatures and pressures, making it suitable for various heat transfer applications.

Pros & Cons: Its durability and resistance to oxidation are significant advantages. However, stainless steel can be more expensive than other materials, and its manufacturing complexity can lead to higher production costs.

Illustrative image related to heat exchanger cover plate

Impact on Application: Stainless steel is compatible with a wide range of media, including water, oils, and chemicals. Its robustness makes it ideal for industries such as food processing and pharmaceuticals, where hygiene is paramount.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel is crucial. Buyers from Europe, particularly Germany, may prefer materials that meet DIN standards, while those in Africa and South America should consider local regulations regarding corrosion resistance.

2. Carbon Steel

Key Properties: Carbon steel is known for its strength and ability to handle high pressure, though it is less resistant to corrosion compared to stainless steel.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for large-scale applications. However, its susceptibility to rust and corrosion limits its use in harsh environments, necessitating protective coatings or treatments.

Illustrative image related to heat exchanger cover plate

Impact on Application: Carbon steel is suitable for applications involving non-corrosive fluids. It is commonly used in oil and gas industries but may require additional maintenance to prevent degradation.

Considerations for International Buyers: Buyers should ensure that carbon steel components comply with relevant standards such as ASTM A36. In regions with high humidity or corrosive environments, additional protective measures may be necessary.

3. Aluminum

Key Properties: Aluminum is lightweight and has good thermal conductivity, making it an excellent choice for heat exchangers that require efficient heat transfer.

Pros & Cons: Its lightweight nature can reduce overall system weight, leading to lower shipping costs. However, aluminum has a lower melting point and is less durable under extreme conditions compared to stainless steel.

Impact on Application: Aluminum is best suited for applications with lower pressure and temperature requirements. It is often used in HVAC systems and automotive applications.

Considerations for International Buyers: Compliance with international standards such as ASTM B221 is essential. Buyers in the Middle East, where temperatures can be extreme, should carefully evaluate the application conditions to ensure aluminum’s suitability.

4. Titanium

Key Properties: Titanium is known for its exceptional corrosion resistance and strength-to-weight ratio, making it suitable for aggressive environments.

Pros & Cons: The primary advantage of titanium is its longevity and resistance to corrosion, particularly in seawater and chemical applications. However, it is one of the most expensive materials, and its manufacturing processes can be complex.

Impact on Application: Titanium is ideal for applications in chemical processing and marine environments where corrosion is a significant concern.

Illustrative image related to heat exchanger cover plate

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM B348. In regions with stringent environmental regulations, titanium may be the preferred choice despite its higher cost.

Summary Table of Material Selection for Heat Exchanger Cover Plates

| Material | Typical Use Case for heat exchanger cover plate | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Oil and gas industries | Cost-effective | Susceptible to rust and corrosion | Low |

| Aluminum | HVAC systems, automotive | Lightweight and good thermal conductivity | Lower durability under extreme conditions | Medium |

| Titanium | Chemical processing, marine environments | Exceptional corrosion resistance | High cost and complex manufacturing | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for heat exchanger cover plate

What Are the Main Stages of the Manufacturing Process for Heat Exchanger Cover Plates?

The manufacturing process for heat exchanger cover plates involves several critical stages that ensure durability and efficiency. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is selecting the right materials. Commonly used materials include stainless steel, aluminum, and high-grade plastics, depending on the application requirements such as corrosion resistance, thermal conductivity, and strength. The raw materials undergo rigorous inspection to ensure they meet the necessary specifications. This includes checking for impurities, dimensional accuracy, and compliance with international standards.

How Are Heat Exchanger Cover Plates Formed?

Once the materials are prepared, the forming stage begins. Techniques such as stamping, laser cutting, or CNC machining are employed to shape the cover plates. Each method has its advantages: stamping allows for high-volume production with consistent quality, while CNC machining offers precision for custom designs. The choice of technique often depends on the order size and specific design requirements.

What Does the Assembly Process Entail?

After forming, the components are assembled. This may involve welding or bolting different parts together, depending on the design. The assembly stage is crucial for ensuring that the heat exchanger cover plate fits correctly and functions as intended. Manufacturers must also consider thermal expansion and contraction during this stage to prevent future issues.

How Is the Finishing Process Conducted?

Finishing processes such as surface treatment, painting, or anodizing are applied to enhance the cover plate’s durability and aesthetic appeal. These treatments provide additional protection against corrosion and wear, extending the lifespan of the product. Quality manufacturers will conduct thorough inspections during this stage to ensure that the finishing meets the established standards.

What Quality Assurance Standards Are Relevant for Heat Exchanger Cover Plates?

Quality assurance is paramount in the manufacturing of heat exchanger cover plates, particularly for international B2B transactions. Buyers should look for manufacturers that comply with established international standards such as ISO 9001, which focuses on quality management systems.

Which Industry-Specific Standards Should Buyers Be Aware Of?

In addition to ISO standards, industry-specific certifications such as CE marking for products sold within the European Union and API standards for petroleum and natural gas industries can be critical. These certifications ensure that the products meet safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch any defects early. Key stages include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested for dimensional accuracy and quality consistency. This stage is critical for maintaining production standards.

-

Final Quality Control (FQC): Before shipping, the finished products undergo a thorough inspection. This includes tests for strength, durability, and compliance with specified standards.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance processes is essential. Here are several methods to ensure that you partner with a reliable manufacturer:

What Role Do Audits and Reports Play in Quality Verification?

Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. Requesting detailed quality assurance reports can also help buyers understand how a manufacturer maintains its standards.

Why Are Third-Party Inspections Important?

Engaging third-party inspection services can further enhance confidence in a supplier’s quality claims. These independent assessments can validate that the manufacturing process aligns with international standards and that the products meet the required specifications.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers should be aware of the nuances in quality control that may vary by region. For instance, some countries have more stringent regulations regarding material safety and environmental impact than others. Understanding these differences can help buyers navigate the complexities of international procurement.

Illustrative image related to heat exchanger cover plate

How Do Regional Standards Affect Product Quality?

In regions like Europe, the emphasis on CE marking reflects a strong commitment to product safety and performance. In contrast, regions in Africa and South America may have different regulatory frameworks, which can impact the quality and reliability of heat exchanger cover plates. Buyers should familiarize themselves with these standards to ensure compliance and product reliability.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance

In conclusion, understanding the manufacturing processes and quality assurance measures for heat exchanger cover plates is vital for international B2B buyers. By focusing on material selection, forming techniques, and rigorous quality control, manufacturers can produce high-quality products that meet industry standards. Buyers should prioritize suppliers who demonstrate a commitment to these processes, ensuring they receive reliable and efficient heat exchanger cover plates for their applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heat exchanger cover plate’

Introduction

Sourcing a heat exchanger cover plate can be a complex process, especially for international B2B buyers. This guide provides a structured checklist to help streamline your procurement process, ensuring you find the right products that meet your operational needs while maintaining quality and compliance.

Illustrative image related to heat exchanger cover plate

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, clearly outline the technical specifications required for your heat exchanger cover plate. This includes dimensions, material type, pressure ratings, and thermal performance characteristics.

- Why It Matters: Having precise specifications helps in identifying suitable suppliers and ensures that the product will integrate seamlessly with existing systems.

- What to Look For: Ensure compatibility with your current heat exchangers and any specific industry standards your equipment must meet.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of heat exchanger cover plates. Utilize industry-specific directories, trade shows, and online platforms to compile a list of reputable manufacturers.

- Why It Matters: A diverse supplier pool increases your chances of finding competitive pricing and quality products.

- What to Look For: Check supplier credentials, industry experience, and customer reviews to gauge reliability.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that validate their quality management systems, such as ISO 9001 or equivalent.

Illustrative image related to heat exchanger cover plate

- Why It Matters: Certifications ensure that suppliers adhere to international quality standards, reducing the risk of defects and operational failures.

- What to Look For: Request copies of certifications and audit reports to confirm compliance with industry regulations.

Step 4: Request Samples for Quality Assessment

Once you have narrowed down your list of suppliers, request samples of the heat exchanger cover plates for quality evaluation.

- Why It Matters: Testing samples allows you to assess product durability, fit, and performance under operational conditions.

- What to Look For: Inspect the material quality, craftsmanship, and any specific features that are critical to your application.

Step 5: Compare Pricing and Terms

Gather detailed quotes from your shortlisted suppliers and compare pricing structures, payment terms, and delivery timelines.

- Why It Matters: Understanding the total cost of ownership, including shipping and potential tariffs, is crucial for budget management.

- What to Look For: Look for transparency in pricing and any hidden costs that may affect your overall expenditure.

Step 6: Negotiate and Finalize Contracts

Engage in negotiations to finalize contracts with the selected supplier. Ensure all terms, including warranties, return policies, and maintenance support, are clearly defined.

- Why It Matters: A well-defined contract protects your interests and establishes clear expectations regarding product quality and supplier responsibilities.

- What to Look For: Pay attention to the terms of warranty coverage and the process for handling defective products or returns.

Step 7: Plan for Ongoing Maintenance and Support

After procurement, develop a maintenance plan that includes regular inspections and replacement schedules for the cover plates.

- Why It Matters: Regular maintenance extends the lifespan of your heat exchangers and prevents unexpected downtimes.

- What to Look For: Ensure your supplier offers support and readily available replacement parts for long-term operational efficiency.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing heat exchanger cover plates, ensuring a successful procurement process that aligns with their business needs.

Comprehensive Cost and Pricing Analysis for heat exchanger cover plate Sourcing

When sourcing heat exchanger cover plates, understanding the comprehensive cost structure is crucial for B2B buyers. This section delves into the various components of cost, factors influencing pricing, and essential tips for buyers to optimize their procurement process.

What Are the Key Cost Components for Heat Exchanger Cover Plates?

-

Materials: The primary cost driver in manufacturing heat exchanger cover plates is the raw materials used. Common materials include stainless steel, aluminum, and specialized alloys, which can vary significantly in price based on global market trends and supplier availability. Fluctuations in metal prices can lead to daily changes in overall costs.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process. This includes both skilled labor for assembly and unskilled labor for basic tasks. Labor costs can vary by region, with higher wages typically found in Europe compared to Africa or South America.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, maintenance, and administrative expenses. Efficient production practices can help minimize overhead costs, thus impacting the final price.

-

Tooling: Initial tooling costs, which involve creating the molds and dies necessary for manufacturing, can be significant. These costs are typically amortized over production runs, making them a crucial consideration for buyers looking at both small and large orders.

-

Quality Control (QC): Ensuring that the cover plates meet specified quality standards involves additional costs for inspections, testing, and certifications. Buyers should consider these QC costs when evaluating supplier proposals.

-

Logistics: Transportation and shipping costs can significantly impact overall pricing, especially for international buyers. Factors such as distance, mode of transport, and customs duties play a vital role in determining logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on market competition, supplier reputation, and relationship with buyers.

What Influences the Pricing of Heat Exchanger Cover Plates?

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their usage patterns to maximize cost efficiency.

-

Specifications and Customization: Custom designs or unique specifications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Materials and Quality Certifications: The choice of materials and the level of quality certification (e.g., ISO, ASME) can influence pricing. Higher-quality materials and certifications typically command higher prices, which may be justified by improved durability and performance.

-

Supplier Factors: The reliability, reputation, and location of suppliers can affect pricing. Established suppliers may offer better quality and service but at a premium price, while newer or less-known suppliers may provide lower costs but with potential risks.

-

Incoterms: The terms of shipping (Incoterms) agreed upon can greatly impact the total cost. Understanding who bears the cost of shipping and insurance can help buyers better estimate their total expenses.

What Are Some Essential Tips for Buyers to Optimize Costs?

-

Negotiate Terms: Engage in discussions with suppliers to negotiate better pricing, especially for large orders. Flexibility in payment terms or delivery schedules may also yield cost benefits.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, potential downtime, and operational efficiency. A higher-quality cover plate may have a higher upfront cost but could save money in the long run.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and import regulations that can affect the final cost. Conducting thorough market research can help mitigate these risks.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better pricing and terms over time. Suppliers may be more willing to offer discounts or favorable terms to trusted customers.

In conclusion, a comprehensive understanding of cost components, pricing influencers, and strategic procurement practices will empower B2B buyers to make informed decisions when sourcing heat exchanger cover plates. It is essential to remain vigilant about market trends and maintain open communication with suppliers to achieve the best possible outcomes.

Alternatives Analysis: Comparing heat exchanger cover plate With Other Solutions

Exploring Alternatives to Heat Exchanger Cover Plates

When considering heat exchanger solutions, buyers often seek alternatives to traditional heat exchanger cover plates. These alternatives may provide varying benefits in terms of performance, cost, and maintenance, thereby influencing decision-making in a B2B context. Below, we compare heat exchanger cover plates with two viable alternatives: double-wall heat exchanger plates and shell-and-tube heat exchangers.

| Comparison Aspect | Heat Exchanger Cover Plate | Double-Wall Heat Exchanger Plates | Shell-and-Tube Heat Exchangers |

|---|---|---|---|

| Performance | High thermal efficiency, designed for specific applications | Excellent for preventing leaks, maintains integrity under pressure | Versatile, good for high flow applications |

| Cost | Moderate initial cost, potential for regular replacement | Higher initial investment, but longer lifespan reduces long-term costs | Generally more expensive due to complexity |

| Ease of Implementation | Simple installation, typically requires minimal tooling | Moderate installation effort, may need specialized skills | Complex installation, requires professional setup |

| Maintenance | Regular maintenance needed, particularly gasket replacements | Low maintenance, durable design limits wear | Moderate maintenance, requires periodic inspection |

| Best Use Case | Ideal for compact systems needing high efficiency | Suitable for applications where leak prevention is critical | Best for industrial applications with high flow rates |

Double-Wall Heat Exchanger Plates: Pros and Cons

Double-wall heat exchanger plates offer a robust alternative to traditional cover plates. Their primary advantage lies in their ability to prevent fluid mixing, which is crucial in applications where contamination is a concern. The dual-wall design ensures that even if one wall fails, the second provides a backup, enhancing safety. However, the initial cost is typically higher compared to standard heat exchanger cover plates, which may deter some buyers. Moreover, while they require less frequent maintenance, installation can be more complex, necessitating skilled labor.

Shell-and-Tube Heat Exchangers: Pros and Cons

Shell-and-tube heat exchangers are renowned for their versatility and ability to handle large flow rates, making them suitable for various industrial applications. They generally provide excellent thermal performance, particularly in high-capacity systems. However, their complexity can lead to higher upfront costs and more extensive installation requirements. Maintenance can also be more involved, as the design necessitates periodic inspections and potential cleaning of the tubes. This makes them less appealing for smaller or less demanding applications.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate heat exchanger solution, buyers must consider their specific operational requirements, budget constraints, and maintenance capabilities. For compact systems requiring efficient heat transfer, heat exchanger cover plates may be ideal. In contrast, double-wall plates are preferable for applications where leak prevention is paramount, while shell-and-tube exchangers excel in high-flow industrial settings. Ultimately, understanding the unique benefits and limitations of each alternative will empower B2B buyers to make informed decisions that align with their operational goals and financial plans.

Essential Technical Properties and Trade Terminology for heat exchanger cover plate

When considering the procurement of heat exchanger cover plates, understanding their essential technical properties and the relevant trade terminology is critical for making informed purchasing decisions. This knowledge not only aids in selecting the right product but also ensures compliance with industry standards and enhances operational efficiency.

What Are the Key Technical Properties of Heat Exchanger Cover Plates?

-

Material Grade

Heat exchanger cover plates are typically manufactured from materials like stainless steel, aluminum, or specialized alloys. The material grade impacts the durability, corrosion resistance, and thermal conductivity of the plates. For instance, stainless steel (like 316L) is often preferred for its high resistance to corrosion in aggressive environments, making it ideal for chemical processing applications. -

Thickness Tolerance

The thickness of a cover plate can significantly affect its structural integrity and heat transfer efficiency. Tolerances are often specified in millimeters or inches, indicating the allowable variation from the nominal thickness. Maintaining tight tolerances is crucial for ensuring proper fit and function within the heat exchanger system, which helps to prevent leaks and maintain efficiency. -

Surface Finish

The surface finish of the cover plate can influence both performance and aesthetic appeal. A smoother finish can enhance heat transfer and reduce the likelihood of fouling, while a rougher finish may be beneficial in certain applications to promote fluid turbulence. Understanding the required finish helps buyers align their products with operational needs. -

Operating Temperature and Pressure Ratings

Each cover plate is designed to withstand specific temperature and pressure ranges. Knowing these ratings is essential for ensuring that the cover plate can operate safely within the intended application. Exceeding these limits can lead to catastrophic failures, making this property a top priority for buyers. -

Weight and Dimensions

The weight and dimensions of the cover plate are critical for installation and compatibility with existing systems. Buyers must ensure that the selected plates fit within the spatial constraints of their equipment while also considering the ease of handling and installation. -

Compatibility with Gaskets and Seals

Many heat exchanger cover plates require gaskets or seals for proper functioning. Understanding the compatibility between the cover plate and the specific gasket materials is vital to prevent leaks and maintain system integrity. This consideration can also affect maintenance schedules and overall operational costs.

What Are Common Trade Terms Related to Heat Exchanger Cover Plates?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components used in another company’s end products. For heat exchanger cover plates, sourcing from OEMs ensures that the parts meet the original specifications and performance standards, which can be critical for system reliability. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to ensure they are making a cost-effective purchase without overcommitting to inventory that may not be immediately needed. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of goods. This process is vital for B2B buyers to compare prices and terms across different suppliers, ensuring they secure the best deal for heat exchanger cover plates. -

Incoterms

International Commercial Terms (Incoterms) are standardized trade terms used in international contracts. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers manage shipping risks and costs effectively. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is crucial for effective project management, especially in industries where equipment downtime can lead to significant financial losses. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and longevity of the product. Knowing the warranty terms can help buyers assess the long-term value of their investment in heat exchanger cover plates and plan for potential future expenses.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when purchasing heat exchanger cover plates, ensuring they select the right products for their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the heat exchanger cover plate Sector

What Are the Key Trends Shaping the Heat Exchanger Cover Plate Market?

The heat exchanger cover plate market is experiencing significant growth, driven by several global factors. Increasing demand for energy-efficient systems across industries, particularly in manufacturing and HVAC, has led to a heightened focus on the performance and longevity of heat exchangers. Buyers in regions like Africa, South America, the Middle East, and Europe are particularly interested in advanced materials and technologies that can enhance efficiency while reducing operational costs.

Emerging technologies, such as digital monitoring systems and predictive maintenance analytics, are also influencing sourcing decisions. These innovations help buyers anticipate maintenance needs, thereby minimizing downtime and prolonging the lifespan of heat exchangers. Additionally, the trend toward customization is gaining traction, with manufacturers offering bespoke solutions tailored to specific operational requirements. This shift is particularly relevant for international buyers who require equipment that meets local standards and operational conditions.

Moreover, fluctuating raw material prices are a critical concern for buyers, necessitating a proactive approach to sourcing. Establishing strong relationships with suppliers who can provide transparent pricing models and consistent quality is essential. As the industry evolves, buyers must remain agile, adapting to market dynamics and leveraging technology to optimize their sourcing strategies.

How Does Sustainability Impact the Sourcing of Heat Exchanger Cover Plates?

Sustainability is increasingly becoming a central consideration for B2B buyers in the heat exchanger cover plate sector. The environmental impact of manufacturing processes, particularly concerning carbon emissions and resource consumption, is under scrutiny. Buyers are now prioritizing suppliers who demonstrate a commitment to reducing their environmental footprint through sustainable practices.

Ethical sourcing is another critical factor, as businesses are held accountable for their supply chain decisions. Buyers are looking for suppliers that adhere to ethical labor practices and environmentally friendly sourcing of materials. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming essential benchmarks for evaluating suppliers. These certifications not only signify compliance with environmental standards but also enhance the credibility of suppliers in the eyes of conscientious buyers.

Using “green” materials in the manufacturing of heat exchanger cover plates is gaining momentum, with options such as recycled metals and biodegradable coatings being explored. This shift towards sustainability not only meets regulatory requirements but also aligns with the growing consumer demand for environmentally responsible products. As such, international buyers must consider these factors when selecting suppliers to enhance their brand reputation and ensure compliance with increasingly stringent regulations.

What Is the Historical Context of Heat Exchanger Cover Plates in B2B?

The evolution of heat exchanger cover plates is tied closely to advancements in thermal management technology. Initially, cover plates were designed primarily for functionality, focusing on preventing leaks and maintaining pressure within heat exchangers. However, as industries began to prioritize efficiency and sustainability, the design and material selection for these components evolved significantly.

Over the past few decades, the introduction of high-performance materials, such as stainless steel and advanced composites, has improved the durability and efficiency of cover plates. Manufacturers have increasingly adopted computer-aided design (CAD) and simulation technologies to optimize the geometry and thermal performance of these components. This evolution has led to significant enhancements in energy efficiency, reducing operational costs for end-users.

As the market continues to evolve, it is essential for B2B buyers to stay informed about historical trends and technological advancements. Understanding the development of heat exchanger cover plates can provide valuable insights into current and future sourcing strategies, ensuring that buyers are equipped to make informed decisions in a competitive landscape.

Illustrative image related to heat exchanger cover plate

Frequently Asked Questions (FAQs) for B2B Buyers of heat exchanger cover plate

-

How do I solve issues related to heat exchanger cover plate leaks?

To address leaks in heat exchanger cover plates, first inspect the gaskets and seals for wear or damage. If they are compromised, replace them with high-quality, OEM-compatible gaskets to ensure a proper seal. Regular maintenance is crucial; schedule periodic checks to identify potential issues before they escalate. Consider implementing a monitoring system to track performance metrics and detect leaks early. If problems persist, consult with your supplier for technical support or replacement options tailored to your specific heat exchanger model. -

What is the best material for heat exchanger cover plates?

The optimal material for heat exchanger cover plates typically includes stainless steel, aluminum, or specialized alloys, depending on the operating conditions. Stainless steel is favored for its corrosion resistance and durability, while aluminum offers a lightweight alternative with good thermal conductivity. For high-temperature or high-pressure applications, consider custom alloys designed to withstand extreme environments. Always verify that the material meets industry standards and is compatible with the fluids being processed to ensure long-lasting performance. -

How can I customize a heat exchanger cover plate for my specific application?

Customizing a heat exchanger cover plate involves collaborating with your supplier to specify dimensions, materials, and design features that meet your operational needs. Provide detailed technical drawings or specifications, including any unique requirements such as pressure ratings or thermal performance. Many manufacturers offer engineering support to help refine your design for optimal functionality. Remember to confirm lead times and costs associated with customization, as these can vary significantly based on complexity and material choice. -

What are the minimum order quantities (MOQs) for heat exchanger cover plates?

Minimum order quantities for heat exchanger cover plates can vary widely among suppliers, typically ranging from a few units to several hundred. Factors influencing MOQs include manufacturing capabilities, material availability, and the complexity of the design. When sourcing internationally, it’s advisable to discuss your needs with potential suppliers upfront to negotiate favorable terms that align with your project requirements. Smaller orders may incur higher per-unit costs, so consider consolidating orders for better pricing. -

What payment terms should I expect when purchasing heat exchanger cover plates?

Payment terms for heat exchanger cover plates can vary depending on the supplier and the nature of your transaction. Common terms include upfront payment, partial payment upon order confirmation, and the balance upon delivery. For larger orders, suppliers may offer more flexible financing options or credit terms. It’s essential to clarify payment expectations before finalizing contracts to avoid potential disputes. Additionally, consider using secure payment methods and escrow services for international transactions to mitigate risk. -

How can I vet suppliers for heat exchanger cover plates?

To effectively vet suppliers for heat exchanger cover plates, start by researching their industry reputation, certifications, and years of experience. Request references from previous clients and review case studies that demonstrate their capabilities. Evaluate their manufacturing processes and quality assurance practices to ensure they meet international standards. Additionally, consider visiting their facilities if possible, or arranging virtual meetings to assess their operations. A thorough vetting process will help ensure a reliable partnership and high-quality products. -

What quality assurance processes should I expect from heat exchanger cover plate manufacturers?

Reputable heat exchanger cover plate manufacturers implement rigorous quality assurance processes to ensure product reliability and performance. Expect to see measures such as material inspections, in-process quality checks, and final product testing, including pressure and leak tests. Certifications like ISO 9001 may also indicate a commitment to quality management. Request documentation of their QA processes and results to ensure they align with your expectations and industry standards. -

What logistics considerations should I keep in mind for international shipping of heat exchanger cover plates?

When planning for international shipping of heat exchanger cover plates, consider factors such as shipping methods, customs regulations, and lead times. Choose a logistics partner experienced in handling industrial components to ensure proper packaging and documentation for customs clearance. Be aware of any tariffs, duties, or taxes that may apply to your shipment. Additionally, confirm that the supplier provides tracking information and offers insurance options to protect your investment during transit.

Top 2 Heat Exchanger Cover Plate Manufacturers & Suppliers List

1. Boiler Supplies – Plate and Frame Heat Exchanger Gaskets and Plates

Domain: boilersupplies.com

Registered: 2002 (23 years)

Introduction: Plate and Frame Heat Exchanger Gaskets and Plates

– Replacement Gaskets: In Stock

– Replacement Plates: In Stock

– Key Features and Benefits:

– Exact Fit: Reverse-engineered to match OEM specifications for seamless integration and performance.

– High Quality: Manufactured with top-grade materials and cutting-edge technology for durability and efficiency.

– Guaranteed Performance: Precision-e…

2. Weil-McLain – Heat Exchanger Cover Plate Kit

Domain: unitedsupplyusa.com

Registered: 2013 (12 years)

Introduction: {“Product Name”: “Weil-McLain 383-500-395 Gas Boiler Heat Exchanger Cover Plate Kit”, “Description”: “Heat Exchanger Cover Plate Kit for Ultra-155/230 Residential Gas Boiler”, “UPC”: “672619162532”, “Part Number”: “383-500-395”, “UNSPSC”: “40101851”, “Includes”: [“Cover Plate”, “Cover Plate Gasket”, “Burner Gasket”, “Hardware”], “Used On”: {“Item”: “Residential Gas Boiler”, “Part No”: “Ultra-155/2…

Strategic Sourcing Conclusion and Outlook for heat exchanger cover plate

What Are the Key Insights for Strategic Sourcing of Heat Exchanger Cover Plates?

In conclusion, effective strategic sourcing of heat exchanger cover plates is vital for optimizing operational efficiency and minimizing downtime. By focusing on high-quality materials and precise engineering, businesses can ensure that replacement parts maintain the original equipment manufacturer’s (OEM) performance standards. Regular maintenance and timely replacement of these components not only enhance the reliability of heat exchangers but also lead to significant cost savings by preventing unexpected failures.

International B2B buyers, especially those in Africa, South America, the Middle East, and Europe, should prioritize partnerships with suppliers who offer comprehensive support, including reverse-engineered products that guarantee compatibility and performance. As the demand for efficient thermal management solutions continues to grow, investing in reliable cover plates will be crucial for maintaining competitive advantage in various industries.

Looking ahead, companies should remain proactive in assessing their sourcing strategies and engaging with suppliers who demonstrate a commitment to quality and innovation. By doing so, businesses can position themselves to meet evolving market demands and enhance their operational resilience. Now is the time to evaluate your sourcing partnerships and ensure you are equipped for future challenges in heat exchanger technology.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to heat exchanger cover plate