Hat Eyelets: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for hat eyelets

The global market for hat eyelets presents a unique set of challenges for international B2B buyers, especially when considering factors such as material quality, functionality, and design aesthetics. Sourcing reliable hat eyelets that meet specific requirements—such as ventilation, durability, and style—can be a daunting task, particularly for businesses operating in diverse markets like Africa, South America, the Middle East, and Europe, including regions like Saudi Arabia and Vietnam. This comprehensive guide is designed to equip you with the insights needed to navigate these complexities effectively.

Within this guide, you will discover a variety of hat eyelet types and their applications, from ventilation grommets to decorative options. We delve into the intricacies of supplier vetting, ensuring you can identify trustworthy manufacturers who uphold quality standards. Additionally, we provide a detailed overview of cost considerations, enabling you to make informed decisions that align with your budgetary constraints.

By leveraging the information in this guide, B2B buyers can confidently approach their sourcing strategies, ensuring they select the right eyelets that not only enhance product functionality but also resonate with their target market’s preferences. Ultimately, this resource empowers you to streamline your purchasing process, paving the way for successful procurement in the competitive hat industry.

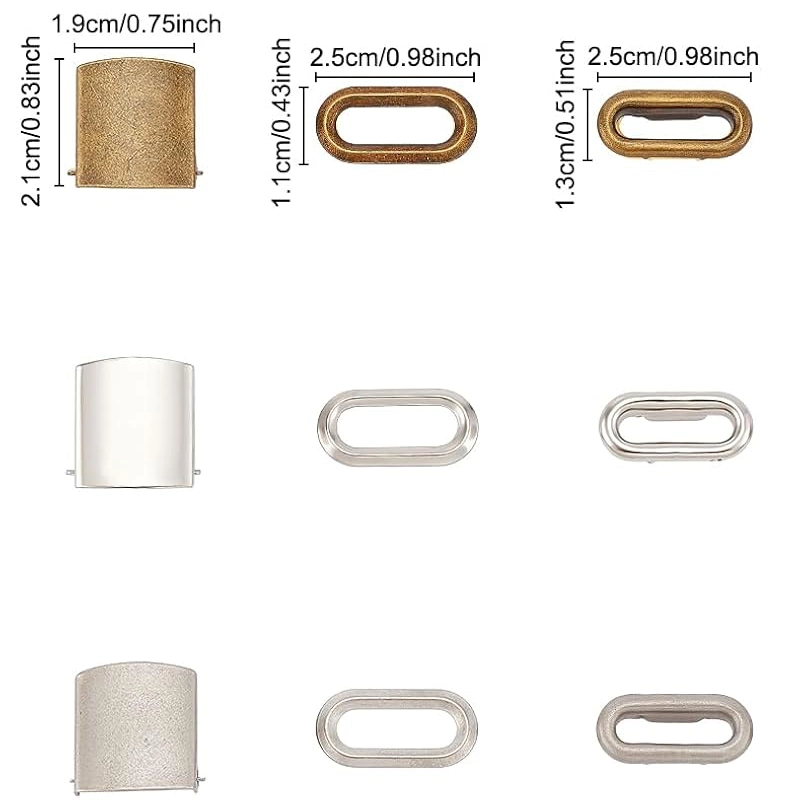

Understanding hat eyelets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Crown Eyelets | Small size for ventilation; typically 1/8″ diameter | Used in hats requiring airflow; popular in warm climates | Pros: Enhances breathability; lightweight. Cons: Limited strength for heavy-duty applications. |

| Stampede Eyelets | Larger size (1/4″ diameter) for chin straps; often reinforced | Ideal for rodeo hats; prevents loss in windy conditions | Pros: Durable; secures hats effectively. Cons: May require additional installation tools. |

| Ventilation Grommets | Available in various shapes; waterproof and mesh options | Used in hats for enhanced airflow; suitable for outdoor activities | Pros: Versatile; moisture-resistant options. Cons: More complex installation process. |

| Decorative Eyelets | Aesthetic designs; various finishes and colors | Fashion hats and promotional items; enhances visual appeal | Pros: Customizable; enhances branding. Cons: May compromise structural integrity if not used properly. |

| Custom Eyelets | Tailored specifications; can be made in different materials | Specialized applications; unique branding opportunities | Pros: Fully customizable; meets specific needs. Cons: Higher cost and longer lead times. |

What Are Crown Eyelets and Their Key Benefits for B2B Buyers?

Crown eyelets are small, typically 1/8″ in diameter, and are primarily used for ventilation in hats. Their design allows for airflow, making them particularly suitable for hats intended for warm climates, such as those used in Africa and South America. For B2B buyers, the lightweight nature of crown eyelets contributes to overall comfort, especially in casual and outdoor hats. However, they may not be ideal for heavy-duty applications, as they lack the strength of larger eyelets.

How Do Stampede Eyelets Secure Hats in Windy Conditions?

Stampede eyelets are larger, generally measuring 1/4″ in diameter, and are designed to accommodate chin straps, providing a secure fit in windy environments. They are particularly favored in rodeo and outdoor hats, where loss of headgear is a concern. For B2B buyers, these eyelets offer durability and reliability, ensuring that hats remain in place during vigorous activities. However, they may require specialized installation tools, adding complexity to the procurement process.

What Are the Advantages of Using Ventilation Grommets in Hats?

Ventilation grommets come in various shapes and sizes, including waterproof and mesh options. They are designed to enhance airflow in hats, making them suitable for outdoor activities where breathability is essential. B2B buyers can benefit from their versatility, as they can be customized for different applications. However, the installation of grommets can be more complex compared to traditional eyelets, which may require additional considerations during the manufacturing process.

Why Choose Decorative Eyelets for Fashion Hats?

Decorative eyelets serve a dual purpose: they enhance the aesthetic appeal of hats while providing functional benefits. Available in various finishes and colors, these eyelets are ideal for fashion hats and promotional items. B2B buyers can leverage decorative eyelets to strengthen branding efforts and differentiate products in competitive markets. However, it’s essential to ensure that their use does not compromise the hat’s structural integrity, particularly in high-stress applications.

How Can Custom Eyelets Meet Specific Business Needs?

Custom eyelets offer the flexibility to tailor specifications according to unique business requirements. Whether it’s for branding or specialized applications, these eyelets can be made from various materials and designs. For B2B buyers, this customization can lead to unique product offerings that stand out in the market. However, the trade-off may include higher costs and longer lead times, which should be factored into purchasing decisions.

Illustrative image related to hat eyelets

Key Industrial Applications of hat eyelets

| Industry/Sector | Specific Application of hat eyelets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Ventilation in hats | Enhances comfort for wearers in warm climates | Material durability, size options, and color availability |

| Equestrian Equipment | Stampede strings for riding hats | Prevents loss of hats during riding, improving safety | Strength of materials, customization options, and lead times |

| Outdoor and Adventure Gear | Custom hats with eyelets for ventilation | Improves breathability for outdoor activities | Weather resistance, design flexibility, and bulk pricing |

| Safety and Protective Gear | Eyelets in hard hats for ventilation | Ensures worker comfort in high-temperature environments | Compliance with safety standards, material certifications |

| Sports Merchandise | Branding and customization on team hats | Increases brand visibility and team spirit | Customization capabilities, turnaround times, and cost |

How are Hat Eyelets Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, hat eyelets are primarily utilized to provide ventilation in hats. This is particularly important in regions with hot climates, such as parts of Africa and the Middle East, where breathability can significantly enhance wearer comfort. Buyers in this sector should consider the durability of the materials used in eyelets, as well as the variety of sizes and colors available to match different hat designs.

What Role do Hat Eyelets Play in Equestrian Equipment?

Hat eyelets are essential in equestrian equipment, specifically for attaching stampede strings to riding hats. This feature prevents hats from being lost during rides, thereby enhancing safety for riders. Buyers from regions like South America, where equestrian activities are prevalent, should prioritize the strength and reliability of the eyelet materials, as well as customization options to suit various hat styles.

How are Hat Eyelets Beneficial for Outdoor and Adventure Gear?

In the outdoor and adventure gear industry, hat eyelets are used to improve ventilation in custom hats designed for outdoor activities. This is crucial for maintaining comfort during prolonged exposure to heat, making these hats popular among outdoor enthusiasts in Europe and other regions. Buyers should focus on sourcing weather-resistant materials and ensuring design flexibility to cater to different outdoor applications.

Why are Hat Eyelets Important in Safety and Protective Gear?

Hat eyelets are incorporated into hard hats to facilitate ventilation, crucial for worker comfort in high-temperature environments such as construction sites. This application is particularly relevant in regions with extreme weather conditions. Buyers need to ensure that the materials used comply with safety standards and possess the necessary certifications to guarantee worker safety.

Illustrative image related to hat eyelets

How do Hat Eyelets Enhance Sports Merchandise?

In the sports merchandise industry, hat eyelets are used for branding and customization on team hats. This application not only increases brand visibility but also fosters team spirit among fans. B2B buyers should consider customization capabilities, turnaround times, and pricing when sourcing eyelets for sports merchandise, especially when catering to international markets with diverse fan bases.

3 Common User Pain Points for ‘hat eyelets’ & Their Solutions

Scenario 1: Sourcing Quality Hat Eyelets for High-Volume Production

The Problem: For B2B buyers in the hat manufacturing industry, sourcing quality hat eyelets can be a significant challenge, especially when dealing with high-volume production runs. Buyers often face issues with inconsistent quality, which can lead to production delays and increased costs. Inconsistent eyelet sizes or materials may not only affect the final product’s aesthetics but also compromise functionality, such as ventilation and durability. This inconsistency can tarnish brand reputation and lead to customer dissatisfaction, particularly in competitive markets like Europe and the Middle East.

The Solution: To address these challenges, buyers should establish relationships with reputable suppliers who offer consistent quality and can provide certifications for their materials. It is essential to request samples before committing to larger orders to ensure that the eyelets meet the required specifications for size, durability, and finish. Additionally, implementing a quality control process that includes testing the eyelets for strength and fit can mitigate risks associated with production defects. Buyers may also consider bulk purchasing agreements that secure favorable pricing while ensuring supply consistency.

Scenario 2: Choosing the Right Eyelet Type for Specific Hat Designs

The Problem: Different hat designs require different types of eyelets, which can confuse buyers who are not familiar with the nuances of hat accessories. For instance, a buyer might need ventilation eyelets for a summer collection, but mistakenly choose decorative eyelets that do not provide the necessary airflow. This oversight can lead to product failures, customer complaints, and costly returns. Buyers must navigate various options, such as the diameter, material (metal vs. plastic), and design, to ensure they select the right eyelets for their specific hat designs.

The Solution: To make informed decisions, buyers should conduct thorough research on the specific requirements of their hat designs. Engaging with design teams to understand the functional needs of the hats, such as breathability or style, can help in selecting the appropriate eyelet type. Additionally, collaborating with suppliers who offer customization options can provide tailored solutions that enhance both functionality and aesthetics. Buyers should also leverage digital tools, such as CAD software, to visualize how different eyelet types will appear on their hat designs, ensuring a seamless integration of accessories.

Illustrative image related to hat eyelets

Scenario 3: Managing Inventory and Reducing Lead Times for Hat Eyelets

The Problem: Many B2B buyers struggle with inventory management and lead times when sourcing hat eyelets, particularly when faced with unpredictable demand fluctuations. Long lead times can disrupt production schedules, forcing manufacturers to rush orders or use subpar materials. This can lead to production bottlenecks, increased operational costs, and missed delivery deadlines, ultimately affecting customer satisfaction and loyalty.

The Solution: Implementing an efficient inventory management system can help buyers maintain optimal stock levels of eyelets and reduce lead times. This system should include forecasting tools that analyze past sales data to predict future demand accurately. Buyers can also establish a just-in-time inventory approach, collaborating closely with suppliers to ensure they can quickly restock eyelets as needed. Building strong relationships with multiple suppliers can provide flexibility and alternative sourcing options when lead times become extended. Additionally, considering local suppliers can significantly cut down on shipping times and costs, further streamlining the production process.

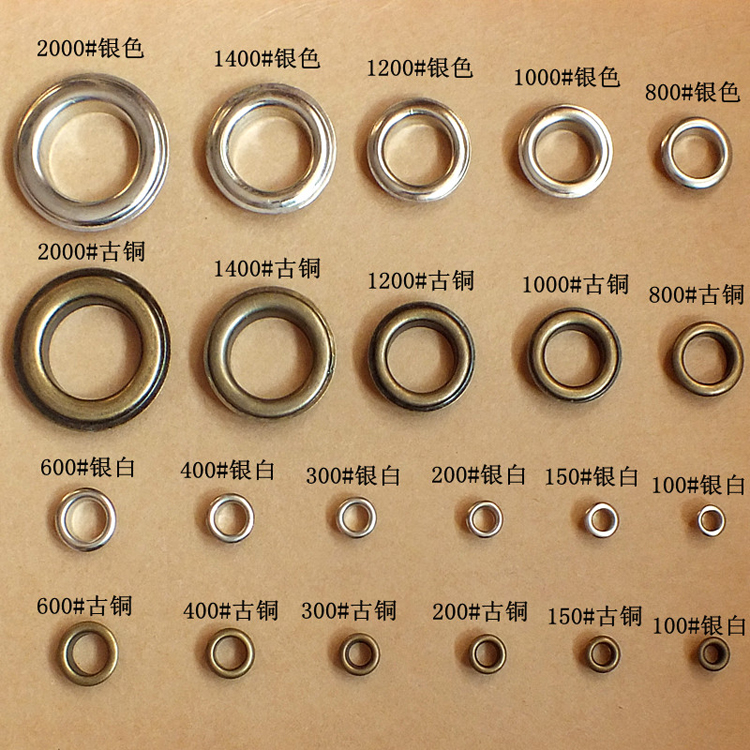

Strategic Material Selection Guide for hat eyelets

When selecting materials for hat eyelets, it is essential to consider the performance characteristics, durability, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of hat eyelets: brass, stainless steel, aluminum, and plastic. Each material has unique properties that can influence the choice for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Brass for Hat Eyelets?

Brass is a popular choice for hat eyelets due to its excellent corrosion resistance and aesthetic appeal. It can withstand moderate temperatures and pressures, making it suitable for various environmental conditions. Brass eyelets are often used in hats designed for outdoor activities, where exposure to moisture and humidity is common.

Pros and Cons: Brass eyelets are durable and have a pleasing appearance, which can enhance the overall look of the hat. However, they can be more expensive than other materials, and their manufacturing process may involve intricate machining, increasing production complexity.

Impact on Application: Brass is compatible with a wide range of media, including water and air, making it ideal for ventilation eyelets. However, it may not be suitable for applications requiring high-temperature resistance.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM for metals. Brass may be preferred in markets where aesthetics are crucial, such as in high-end fashion hats.

How Does Stainless Steel Perform as a Material for Hat Eyelets?

Stainless steel is renowned for its exceptional strength and resistance to corrosion and rust. It is suitable for high-stress applications and can withstand extreme temperatures, making it a versatile option for hat eyelets.

Pros and Cons: The durability of stainless steel eyelets ensures a long lifespan, reducing the need for replacements. However, this material can be more costly than brass and aluminum, and its manufacturing process may require specialized equipment.

Illustrative image related to hat eyelets

Impact on Application: Stainless steel is ideal for hats used in harsh environments, such as industrial settings or outdoor activities in humid regions. Its robustness allows it to maintain structural integrity under varying conditions.

Considerations for International Buyers: Compliance with international standards like DIN or JIS is critical, especially in regions with strict regulations. Buyers in the Middle East and Europe may prefer stainless steel for its durability and reliability.

What Advantages Does Aluminum Offer for Hat Eyelets?

Aluminum is lightweight and resistant to corrosion, making it a practical choice for hat eyelets. It is easy to manufacture and can be anodized for enhanced durability and aesthetic appeal.

Illustrative image related to hat eyelets

Pros and Cons: The lightweight nature of aluminum makes it suitable for hats designed for comfort. However, it may not be as durable as brass or stainless steel, particularly under heavy stress, which could limit its application in certain markets.

Impact on Application: Aluminum eyelets are often used in casual hats and can be effective for ventilation. However, they may not be suitable for high-end applications where strength is paramount.

Considerations for International Buyers: Buyers should consider the cost-effectiveness of aluminum, especially in price-sensitive markets in Africa and South America. Compliance with local standards is essential to ensure product acceptance.

Why Choose Plastic for Hat Eyelets?

Plastic eyelets are an economical option that offers decent durability and resistance to moisture. They are lightweight and can be produced in various colors, making them appealing for fashion-forward designs.

Illustrative image related to hat eyelets

Pros and Cons: The primary advantage of plastic is its low cost and versatility in design. However, plastic eyelets may not provide the same level of durability as metal options and can be susceptible to wear over time.

Impact on Application: Plastic is suitable for hats used in casual settings and those designed for children. However, they may not perform well in extreme temperatures or conditions.

Considerations for International Buyers: Buyers should evaluate the environmental impact of plastic materials, especially in regions with strict regulations on plastic use. Compliance with safety standards is crucial for market acceptance.

Summary Table of Material Selection for Hat Eyelets

| Material | Typical Use Case for hat eyelets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Fashion hats, outdoor hats | Corrosion resistance, aesthetic | Higher cost, complex manufacturing | Medium |

| Stainless Steel | Industrial and outdoor hats | High strength, durability | Higher cost, specialized equipment | High |

| Aluminum | Casual hats, lightweight designs | Lightweight, corrosion resistant | Less durable under stress | Low |

| Plastic | Fashion hats, children’s hats | Low cost, versatile designs | Less durable, temperature sensitive | Low |

This analysis provides a comprehensive overview of material options for hat eyelets, enabling B2B buyers to make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for hat eyelets

What Are the Key Stages in the Manufacturing Process of Hat Eyelets?

The manufacturing process of hat eyelets involves several crucial stages designed to ensure that the final product is durable and functional. Understanding these stages can help B2B buyers assess the quality and reliability of potential suppliers.

Material Preparation: What Materials Are Commonly Used?

The first stage in the manufacturing of hat eyelets is material preparation. Typically, manufacturers use metals such as brass, aluminum, or stainless steel due to their strength and corrosion resistance. High-quality eyelets are often made from materials that can withstand environmental stresses, particularly for outdoor hats. Manufacturers may also opt for plastic eyelets for lighter hats, ensuring that the material choice aligns with the intended use of the hat.

Illustrative image related to hat eyelets

How Are Hat Eyelets Formed?

Once the materials are prepared, the next step is forming. This can involve several techniques, including stamping, extrusion, or molding, depending on the material used. Stamping is a popular method for metal eyelets, where a die cuts the desired shape from a sheet of metal. For plastic eyelets, injection molding is commonly used, allowing for intricate designs and cost-effective production runs.

The choice of forming technique impacts the eyelet’s strength, appearance, and functionality, making it essential for buyers to understand the methods used by their suppliers.

What Assembly Techniques Are Employed in Eyelet Production?

After forming, assembly techniques come into play. This stage often involves attaching the eyelet to the hat fabric. Some manufacturers utilize a setting tool that flares the eyelet around the fabric, ensuring a secure fit. This process is critical, as poorly set eyelets can lead to functionality issues, such as tearing or detachment.

Additionally, some suppliers may offer custom assembly options, allowing B2B buyers to specify features like eyelet size and color, which can enhance the product’s appeal to their market.

What Finishing Processes Are Commonly Applied?

Finishing is the final stage of eyelet production, focusing on enhancing durability and aesthetics. This may include processes such as plating, anodizing, or painting. For metal eyelets, a protective coating can prevent rust and corrosion, which is particularly important for hats used in outdoor environments.

Finishing also plays a role in the eyelet’s visual appeal; manufacturers can apply different colors or finishes to match various hat designs. B2B buyers should inquire about the finishing processes used by suppliers to ensure they meet their quality standards.

How Is Quality Assurance Implemented During the Manufacturing Process?

Quality assurance (QA) is a critical component in the production of hat eyelets, ensuring that they meet international standards and customer expectations. Understanding the QA processes can help buyers make informed decisions about their suppliers.

What Are the Relevant International Standards for Eyelet Production?

Most reputable manufacturers adhere to international quality standards such as ISO 9001, which specifies requirements for a quality management system. Compliance with these standards indicates that a manufacturer consistently meets customer and regulatory requirements. Additionally, industry-specific certifications, such as CE marking for European markets, may be relevant for certain types of eyelets, particularly those used in safety or protective gear.

What QC Checkpoints Are Essential in Eyelet Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process. These include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter production. Suppliers should verify that materials meet specified standards, reducing defects in the final product.

-

In-Process Quality Control (IPQC): During production, various tests and inspections ensure that the manufacturing process is consistent and that any defects are caught early.

-

Final Quality Control (FQC): This final inspection checks the finished eyelets for defects in dimensions, finish, and functionality.

Buyers should inquire about the specific QC measures their suppliers implement at each stage to ensure product quality.

What Common Testing Methods Are Used to Ensure Eyelet Quality?

Several testing methods are commonly employed to assess the quality of hat eyelets. These may include:

-

Tensile Strength Tests: To evaluate how much force the eyelet can withstand before failure.

-

Corrosion Resistance Tests: Essential for eyelets intended for outdoor use, assessing their durability against environmental factors.

-

Dimensional Inspections: Ensuring that the eyelets meet specified measurements for a proper fit.

-

Visual Inspections: Checking for surface defects or inconsistencies in finish.

B2B buyers should request documentation or reports detailing the testing methods used by their suppliers to verify compliance with quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are some actionable steps buyers can take:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request access to quality audits and reports from potential suppliers. These documents should detail the supplier’s adherence to international standards, quality control measures, and any certifications obtained. Regular audits provide insights into the supplier’s commitment to quality and their ability to maintain consistent standards over time.

How Can Third-Party Inspections Enhance Supplier Reliability?

Utilizing third-party inspection services can add an extra layer of assurance for B2B buyers. These independent entities can conduct audits and inspections at various stages of production, providing unbiased assessments of quality and compliance. Buyers should consider incorporating third-party inspections, especially for larger orders or when entering new markets.

What Nuances Should International Buyers Consider Regarding Quality Control?

For international buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, there are additional nuances to consider:

-

Cultural and Regulatory Differences: Different regions may have varying standards for quality and safety. Buyers should be aware of these differences and ensure that their suppliers can comply with local regulations.

-

Communication Barriers: Language and cultural differences can impact the clarity of quality expectations. Establishing clear communication channels is vital to avoid misunderstandings.

-

Logistical Challenges: Shipping and handling can affect product quality. Buyers should discuss logistics with suppliers to ensure products are handled properly throughout the supply chain.

By understanding these aspects of the manufacturing processes and quality assurance for hat eyelets, B2B buyers can make informed decisions that align with their quality expectations and market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hat eyelets’

To assist B2B buyers in effectively sourcing hat eyelets, this guide provides a structured checklist that highlights essential steps in the procurement process. By following these steps, buyers can ensure they secure high-quality products that meet their specific needs.

Illustrative image related to hat eyelets

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, it is critical to outline the technical specifications of the hat eyelets you require. Consider factors such as size, material, and design, which will impact both functionality and aesthetic appeal. For instance, small eyelets are often used for ventilation, while larger ones may be necessary for attaching strings or straps.

Step 2: Research Potential Suppliers

Take the time to investigate various suppliers that specialize in hat eyelets. Look for companies that have a strong reputation in the market and offer a diverse range of products. A thorough review of their website, product catalogs, and customer testimonials can provide insight into their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Ensure that potential suppliers hold relevant certifications that demonstrate compliance with industry standards. This may include ISO certifications or adherence to environmental regulations. Valid certifications not only assure quality but also indicate that the supplier is committed to ethical manufacturing practices.

Step 4: Request Samples for Quality Assessment

Before placing a large order, request samples of the eyelets you are considering. This allows you to assess the material quality, finish, and functionality firsthand. Pay attention to details such as the durability of the eyelets and how well they fit into the intended hats, as these factors will affect customer satisfaction.

Step 5: Compare Pricing and Payment Terms

Once you have identified suitable suppliers, compare their pricing structures and payment terms. Look for transparency in costs, including shipping and handling fees. Additionally, evaluate payment options; some suppliers may offer favorable credit terms or discounts for bulk orders, which could be advantageous for your budget.

Step 6: Review Shipping and Delivery Options

Understanding the logistics involved in receiving your order is crucial. Check the supplier’s shipping policies, including estimated delivery times and options for international shipping, especially if you are sourcing from regions like Africa or South America. Timely delivery is essential for maintaining your production schedules.

Illustrative image related to hat eyelets

Step 7: Establish a Communication Plan

Effective communication with your supplier can prevent misunderstandings and ensure that your requirements are met. Set up a clear plan for regular updates and establish points of contact for any queries or issues that may arise. This proactive approach can foster a better working relationship and facilitate smoother transactions.

By following this checklist, B2B buyers can navigate the sourcing process for hat eyelets with confidence, ensuring they find reliable suppliers who provide high-quality products tailored to their needs.

Comprehensive Cost and Pricing Analysis for hat eyelets Sourcing

What Are the Key Cost Components in Hat Eyelet Sourcing?

When sourcing hat eyelets, understanding the cost structure is crucial for B2B buyers. The primary components of costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. Metal eyelets, for instance, typically have a higher price point than plastic alternatives due to durability and aesthetic appeal. Buyers should consider the long-term benefits of investing in higher-quality materials that offer better performance and longevity.

-

Labor: Labor costs can vary depending on the location of the manufacturing facility. Regions with lower labor costs, such as parts of South America and Asia, might offer more competitive pricing. However, the trade-off may be in quality and craftsmanship, which are critical for products like hat eyelets that must withstand wear and tear.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production. Suppliers with streamlined operations may offer more competitive prices. Buyers should inquire about the manufacturing processes to assess efficiency.

-

Tooling: Initial setup costs for production tools can be significant, especially for custom designs. A one-time investment in tooling can lead to lower per-unit costs for larger orders, making it essential for buyers to negotiate minimum order quantities (MOQs) that justify this investment.

-

Quality Control: Implementing QC processes adds to the overall cost but is essential for ensuring product reliability. Suppliers who prioritize QC may charge a premium, but this can save buyers from costly returns and defects.

-

Logistics: Shipping costs can vary widely based on distance and shipping terms (Incoterms). For international buyers, understanding these logistics costs upfront can prevent unexpected budget overruns.

-

Margin: Suppliers will apply a margin based on their cost structure and market conditions. Understanding the average margins in the industry can help buyers negotiate better terms.

How Do Price Influencers Affect Hat Eyelet Costs?

Several factors influence the pricing of hat eyelets, and being aware of these can help buyers make informed decisions.

Illustrative image related to hat eyelets

-

Volume/MOQ: Larger orders often lead to reduced per-unit costs. Buyers should assess their purchasing patterns to maximize savings through bulk orders.

-

Specifications and Customization: Custom eyelet designs or specific specifications can significantly increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Eyelets made from high-grade materials and certified for quality will generally command higher prices. Buyers should prioritize suppliers who can provide certifications to ensure product reliability.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with proven track records may charge more but offer better service and quality assurance.

-

Incoterms: Understanding the shipping terms can have significant implications for total costs. Buyers should clarify whether costs cover freight, insurance, and duties, as these can affect the total cost of ownership.

What Are the Best Negotiation Tips for International Buyers of Hat Eyelets?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation and strategic purchasing can lead to significant savings.

-

Build Relationships: Establishing a rapport with suppliers can lead to better pricing and terms. Long-term partnerships often result in better service and flexibility.

-

Assess Total Cost of Ownership: Look beyond the initial purchase price. Consider shipping, handling, and potential duties to understand the true cost of sourcing hat eyelets.

-

Leverage Market Research: Knowledge of market prices and competitor offerings can empower buyers during negotiations. Utilize industry benchmarks to support your pricing discussions.

-

Be Open to Alternative Suppliers: Diversifying your supplier base can enhance competition and lead to better pricing. Evaluate suppliers from various regions to find the best fit for your needs.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow. Discussing options like partial upfront payments or extended payment periods can be beneficial.

Disclaimer on Pricing

Pricing for hat eyelets can fluctuate based on market conditions, material costs, and supplier capabilities. The figures mentioned in this analysis are indicative and should be verified through direct consultation with suppliers to obtain the most accurate and current pricing.

Alternatives Analysis: Comparing hat eyelets With Other Solutions

In the realm of hat manufacturing and accessory design, hat eyelets serve a crucial purpose, primarily for ventilation and attachment of chin straps. However, there are alternative solutions that can achieve similar functionality. This section explores these alternatives, helping B2B buyers make informed decisions regarding their hat production needs.

| Comparison Aspect | Hat Eyelets | Ventilation Grommets | Mesh Ventilation Panels |

|---|---|---|---|

| Performance | Excellent for airflow and stability | Good airflow, less secure | Superior airflow, requires attachment |

| Cost | Low cost per unit (approx. $0.10) | Moderate cost (approx. $0.50) | Higher cost (approx. $2.00) |

| Ease of Implementation | Simple installation with a punch | Requires specific installation tools | May require sewing or adhesive |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance (cleaning) |

| Best Use Case | Traditional hats, cowboy hats | Casual hats, fashion caps | High-performance sports or outdoor hats |

How Do Ventilation Grommets Compare to Hat Eyelets?

Ventilation grommets offer a viable alternative to traditional hat eyelets. These grommets provide good airflow and are often used in a variety of headwear, particularly casual hats. The installation process is slightly more complex than that of eyelets, often requiring specific tools for proper fitting. While they can be moderately priced, the enhanced airflow and aesthetic appeal they offer can justify the investment in certain markets. However, they may not provide the same level of security for chin straps, which is a key feature for hats designed for outdoor activities.

What Are the Benefits of Using Mesh Ventilation Panels?

Mesh ventilation panels are another alternative that significantly enhances airflow compared to traditional eyelets. They are typically used in high-performance headwear, such as sports caps and outdoor gear, where breathability is crucial. While mesh panels provide superior ventilation, they can be more costly and may require sewing or adhesive for attachment. This complexity can increase production time and costs, making them less ideal for low-budget hat manufacturing. Additionally, mesh panels may require more maintenance to keep clean, particularly in outdoor environments.

Illustrative image related to hat eyelets

Conclusion: How to Choose the Right Solution for Hat Design?

When selecting between hat eyelets and alternative solutions like ventilation grommets or mesh panels, B2B buyers should consider their specific needs. If the primary goal is simple ventilation and ease of installation, hat eyelets are a cost-effective choice. Conversely, if the design calls for enhanced airflow or if the hat will be used in high-performance scenarios, exploring grommets or mesh panels may be beneficial despite the higher costs and complexity. Ultimately, understanding the target market and the intended use of the hats will guide buyers in choosing the right solution for their production needs.

Essential Technical Properties and Trade Terminology for hat eyelets

What Are the Key Technical Properties of Hat Eyelets?

When sourcing hat eyelets for manufacturing or retail, understanding their technical properties is crucial for ensuring product quality and performance. Here are several critical specifications:

-

Material Grade

Hat eyelets are typically made from materials like brass, aluminum, or stainless steel. The choice of material influences durability, resistance to corrosion, and overall aesthetic appeal. Brass eyelets, for example, offer excellent resistance to rust and are often favored for outdoor hats. In contrast, aluminum is lightweight and cost-effective, making it suitable for mass production. -

Diameter and Hole Size

The diameter of the eyelet and the corresponding hole size are essential for functionality. Common dimensions include 1/8 inch and 1/4 inch, each serving specific purposes, such as ventilation or accommodating stampede strings. Ensuring the right size is critical for maintaining the structural integrity of the hat and preventing damage during use. -

Flange Length

The flange length refers to the part of the eyelet that extends beyond the hole. A longer flange can provide better grip and support, especially in high-stress applications. This feature is vital for ensuring that the eyelet remains securely in place, preventing it from pulling out under tension. -

Finish Type

The finish of the eyelet affects its appearance and functionality. Options include polished, matte, or coated finishes, each offering different aesthetic qualities and levels of corrosion resistance. A high-quality finish can enhance the product’s appeal and longevity, which is particularly important for premium hats sold in competitive markets. -

Tensile Strength

This property indicates the maximum stress that the eyelet can withstand without breaking. High tensile strength is crucial for eyelets used in active or outdoor hats, where exposure to elements and physical stress is common. For B2B buyers, understanding tensile strength helps in selecting eyelets that meet the performance standards required by their customers.

What Are Common Trade Terms Used in the Hat Eyelet Industry?

Navigating the hat eyelet market involves familiarizing oneself with specific industry terminology. Here are several key terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of hat eyelets, an OEM might supply eyelets to hat manufacturers who then sell the finished product under their brand. Understanding OEM relationships can help buyers negotiate better pricing and establish reliable supply chains. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and initial investment. Knowing the MOQ helps businesses plan their purchasing strategies to avoid excess stock or insufficient supply. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. In the context of hat eyelets, submitting an RFQ allows buyers to compare prices, terms, and availability across multiple suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Understanding Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for B2B transactions involving hat eyelets, as they dictate shipping costs, risks, and responsibilities. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. In the hat eyelet industry, lead times can vary based on production schedules and shipping methods. Recognizing lead times helps buyers plan their inventory and ensure timely product availability.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions in the procurement of hat eyelets, optimizing their supply chain management and product offerings.

Navigating Market Dynamics and Sourcing Trends in the hat eyelets Sector

What Are the Current Market Dynamics and Key Trends in the Hat Eyelets Sector?

The global hat eyelets market is experiencing significant growth driven by various factors, including the rising popularity of outdoor activities, fashion trends, and the need for functional accessories in headwear. As consumers increasingly seek hats that provide comfort and utility, eyelets have become essential features for ventilation and securing chin straps, especially in regions with warm climates like Africa and South America. Moreover, the expansion of e-commerce platforms has facilitated international trade, allowing B2B buyers from diverse markets, including the Middle East and Europe, to source high-quality hat eyelets from manufacturers worldwide.

Emerging technologies are also shaping the sourcing landscape. For instance, automated production techniques and rapid prototyping are enabling manufacturers to deliver customized solutions faster. B2B buyers should stay informed about these technological advancements to optimize their sourcing strategies. Additionally, the trend towards personalized products is prompting manufacturers to offer various eyelet designs and materials, catering to niche markets and enhancing brand differentiation.

International buyers should also be aware of market dynamics influenced by fluctuating raw material prices and supply chain disruptions. Geopolitical factors can impact sourcing strategies, especially for buyers in regions like Saudi Arabia and Vietnam, where local regulations may affect import duties and trade agreements. Staying adaptable and maintaining diverse supplier relationships will be crucial for navigating these complexities.

How Does Sustainability and Ethical Sourcing Impact the Hat Eyelets Sector?

Sustainability has become a pivotal focus in the hat eyelets sector, as buyers increasingly prioritize environmentally friendly practices. The production of eyelets, often made from metal or plastic, can have significant environmental impacts, including resource depletion and pollution. Therefore, international B2B buyers are urged to seek suppliers who adhere to sustainable manufacturing practices and utilize recycled or eco-friendly materials.

Ethical sourcing is equally critical. B2B buyers should ensure that their suppliers maintain fair labor practices and transparency in their supply chains. Certifications such as OEKO-TEX and GRS (Global Recycle Standard) can serve as indicators of a supplier’s commitment to sustainability and ethical standards. By partnering with certified manufacturers, businesses not only enhance their brand reputation but also meet the growing consumer demand for ethically produced products.

Furthermore, integrating sustainability into the sourcing process can lead to long-term cost savings. For example, using recyclable materials for eyelets can reduce waste and minimize disposal costs. As markets in Africa and South America become more conscious of environmental issues, aligning with sustainable practices will be essential for B2B buyers aiming to secure a competitive edge.

What Is the Evolution of Hat Eyelets and Its Relevance to B2B Buyers?

The use of eyelets in hats dates back centuries, originally designed to enhance ventilation and provide functionality. Historically, these small, reinforced holes were made from natural materials, evolving into the durable metal and plastic options prevalent today. This evolution reflects broader trends in manufacturing, where advancements in materials and technology have allowed for greater customization and durability.

For B2B buyers, understanding the historical context of hat eyelets can inform sourcing decisions. The shift towards more sustainable materials and production processes signals a growing market demand for innovative and eco-friendly products. Buyers can leverage this knowledge to identify suppliers who are not only aware of these trends but are also actively integrating them into their product lines. This alignment will ensure that their offerings remain relevant and competitive in a rapidly changing marketplace.

Illustrative image related to hat eyelets

Frequently Asked Questions (FAQs) for B2B Buyers of hat eyelets

-

How do I choose the right type of eyelet for my hat production needs?

When selecting eyelets for hat production, consider their primary function—ventilation, aesthetics, or securing attachments like stampede strings. For ventilation, smaller eyelets (approx. 1/8″ diameter) are preferred, while larger ones (1/4″) are suitable for heavier attachments. Assess the materials used in the eyelets, ensuring they are durable and resistant to corrosion, especially for outdoor hats. It’s also beneficial to review samples from suppliers to ensure compatibility with your hat designs. -

What are the advantages of custom eyelets for my hat products?

Custom eyelets offer numerous advantages, including the ability to match your branding through specific colors, sizes, and shapes. They can enhance the aesthetic appeal of your hats, making them more marketable. Additionally, custom eyelets can be engineered for specific functionalities, such as improved ventilation or enhanced durability. Sourcing custom options can set your products apart in competitive markets, especially in regions like Africa and South America where unique designs are valued. -

What should I consider regarding minimum order quantities (MOQs) when sourcing eyelets?

Minimum order quantities (MOQs) can vary significantly among suppliers, often influenced by the type of eyelet and the materials used. For bulk production, MOQs typically range from 1,000 to 10,000 pieces. However, some suppliers may offer lower MOQs for custom designs. It’s essential to communicate your needs clearly with potential suppliers and negotiate terms that align with your production scale, especially if you’re testing a new product line. -

How can I ensure quality assurance (QA) when sourcing eyelets internationally?

To ensure quality assurance when sourcing eyelets, establish clear specifications and standards for the products you require. Request samples before placing large orders to evaluate the materials and manufacturing quality. Consider working with suppliers who have ISO certifications or other relevant quality management systems in place. Additionally, employing third-party inspection services can provide an extra layer of confidence in the quality of the eyelets before shipment. -

What payment terms should I negotiate with my eyelet suppliers?

When negotiating payment terms with suppliers, consider options like partial upfront payments (30-50%) and the remainder upon delivery. This arrangement can help mitigate risks for both parties. It’s also wise to discuss payment methods, such as letters of credit, which can provide security in international transactions. Ensure that payment terms are clearly defined in the contract to avoid misunderstandings later. -

How do logistics and shipping impact my sourcing of hat eyelets?

Logistics and shipping are critical components in the sourcing process, especially for international buyers. Consider the shipping methods offered by your supplier—air freight is faster but more expensive, while sea freight is cost-effective but slower. Factor in lead times for production and shipping to ensure timely delivery for your production schedule. Additionally, be aware of customs regulations in your region to avoid delays or additional costs. -

What are common materials used for hat eyelets and their benefits?

Hat eyelets are typically made from materials such as brass, aluminum, or plastic. Brass eyelets are durable and corrosion-resistant, making them ideal for outdoor hats. Aluminum is lightweight and can be coated for aesthetic purposes, while plastic offers flexibility and cost-effectiveness. Understanding the benefits of each material can help you select the most appropriate eyelet type for your specific hat products, based on durability and design requirements. -

How can I vet potential suppliers for hat eyelets effectively?

Effective vetting of potential suppliers involves several key steps. Start by checking their company background and history, including years in business and client testimonials. Request references from previous clients, and assess their production capabilities and quality control processes. Consider visiting their manufacturing facilities if possible, or utilize virtual tours. Additionally, review their compliance with international standards and certifications relevant to your industry to ensure they meet your quality expectations.

Top 3 Hat Eyelets Manufacturers & Suppliers List

1. Sunbody – Eyelet Kit

Domain: sunbody.com

Registered: 1997 (28 years)

Introduction: Eyelet Kit SKU: ek18 Ships Immediately – Within 24 hours Price: $17.75 (incl. Texas Sales Tax) Options: 1/4 in. Eyelet Kit: Punch, Setter, 100 large eyelets – $20.75; 1/8 in. Eyelet Kit: Punch, Setter, 100 small eyelets – $17.75 Features: Eyelet punch, setter, and 100 black eyelets. Small eyelets (1/8″ diameter) for ventilation and stampede string; Large eyelets (1/4″ diameter) for braided horse h…

2. Tandy Leather – Eyelets for Fur Felt Hats

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Eyelets for installation in a fur felt hat; tools available at Tandy Leather.

3. TaylorMade – Newport Retro Metal Eyelet Hat

Domain: taylormadegolf.com

Registered: 1995 (30 years)

Introduction: {“name”:”Newport Retro Metal Eyelet Hat”,”brand”:”TaylorMade”,”price”:”$39.99″,”features”:[“Superior ventilation”,”Modern fit”,”Strategically placed metal eyelets for optimal airflow”,”Keeps head cool and comfortable”,”Durable design”,”Contemporary style”],”sku”:”DW-JE818″}

Strategic Sourcing Conclusion and Outlook for hat eyelets

In summary, the strategic sourcing of hat eyelets presents significant opportunities for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. By focusing on high-quality materials and innovative designs, companies can enhance the functionality and aesthetic appeal of their hat products, catering to diverse market demands. The integration of ventilation and durability features through eyelets not only improves user experience but also positions brands competitively in a growing market.

As the global hat industry evolves, leveraging reliable suppliers who prioritize quality and sustainability will be crucial. Establishing partnerships with manufacturers that offer custom solutions, such as varying sizes and styles of eyelets, can provide a unique selling proposition. Buyers are encouraged to explore these options and engage in discussions with suppliers to tailor their offerings to local preferences.

Looking ahead, the demand for stylish and functional hats will continue to rise, driven by fashion trends and practical needs. Now is the time for international B2B buyers to capitalize on these trends by sourcing quality hat eyelets that meet both aesthetic and functional requirements. Embrace the opportunity to elevate your product line and meet the needs of your customers effectively.

Illustrative image related to hat eyelets

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.