Harbor Freight Plate Compactor: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for harbor freight plate compactor

In today’s competitive landscape, sourcing reliable and cost-effective equipment like the Harbor Freight plate compactor can pose significant challenges for international B2B buyers. With the growing demand for efficient compaction solutions in construction and landscaping projects, it becomes crucial to navigate the complexities of product selection, supplier reliability, and market pricing. This comprehensive guide aims to equip decision-makers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—with the necessary insights to make informed purchasing decisions.

Throughout this guide, we will explore various types of Harbor Freight plate compactors, their applications in diverse industries, and key factors to consider when evaluating suppliers. We will also delve into pricing structures, warranty options, and best practices for maintenance, ensuring that you not only choose the right equipment but also maximize its longevity and performance.

By addressing critical aspects of the sourcing process, this guide empowers B2B buyers to confidently assess their options, negotiate better deals, and ultimately enhance their operational efficiencies. Whether you are looking to invest in a single unit or bulk orders, understanding the intricacies of the Harbor Freight plate compactor market will enable you to make strategic decisions that align with your business objectives.

Understanding harbor freight plate compactor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CENTRAL MACHINERY 6.5 HP | Compact design, 5,500 vibrations per minute, 350 sq. m/hr | Gravel compaction for patios and driveways | Pros: Cost-effective, efficient; Cons: Limited depth of compaction. |

| CENTRAL MACHINERY 7 HP with Wheel Kit | Foldaway wheel kit for mobility, 3600 lb impact force | Heavy-duty soil compaction | Pros: High impact force, easy transport; Cons: Heavier, higher price point. |

| Plate Compactor with Water Tank | Integrated water tank for dust control | Asphalt and soil compaction | Pros: Reduces dust, improves surface finish; Cons: More complex maintenance. |

| Electric Plate Compactor | Lightweight, quieter operation, suitable for indoor use | Indoor projects and landscaping | Pros: Environmentally friendly, low noise; Cons: Limited power for heavy-duty tasks. |

| Reversible Plate Compactor | Can move forward and backward, versatile for various terrains | Road construction and trenching | Pros: Increased maneuverability; Cons: More expensive due to added features. |

What Are the Key Characteristics of CENTRAL MACHINERY 6.5 HP Plate Compactor?

The CENTRAL MACHINERY 6.5 HP Plate Compactor is designed for efficiency with a compact size, capable of delivering up to 5,500 vibrations per minute. It is ideal for B2B applications involving gravel compaction for patios, paths, and driveways, covering approximately 350 square meters per hour. Buyers should consider its affordability and effectiveness for light to medium tasks, but be aware of its limitations in depth of compaction, making it less suitable for heavy-duty applications.

Illustrative image related to harbor freight plate compactor

How Does the CENTRAL MACHINERY 7 HP with Wheel Kit Stand Out?

The CENTRAL MACHINERY 7 HP Plate Compactor features a foldaway wheel kit for enhanced mobility, making it easier to transport to job sites. With a powerful impact force of 3600 lbs, it is suitable for heavy-duty soil compaction tasks, covering over 9,500 sq. ft. per hour. While its robust capabilities are a significant advantage, potential buyers should consider the higher weight and price, which may impact budget constraints and ease of use on smaller projects.

What Advantages Does the Plate Compactor with Water Tank Offer?

The Plate Compactor with an integrated water tank is specifically designed for applications requiring dust control, making it particularly useful in asphalt and soil compaction tasks. By reducing airborne dust, it improves the working environment and surface finish. However, the added complexity of maintenance due to the water system may deter some buyers, particularly those looking for straightforward operations.

Why Choose an Electric Plate Compactor for Indoor Projects?

Electric Plate Compactors are lightweight and operate quietly, making them well-suited for indoor projects and sensitive environments such as landscaping. They provide an environmentally friendly option with lower emissions compared to gas-powered models. However, their limited power may restrict their effectiveness for heavy-duty tasks, which could be a consideration for buyers focusing on larger projects.

What Makes Reversible Plate Compactors a Versatile Choice?

Reversible Plate Compactors offer the unique ability to move both forward and backward, enhancing their versatility for various terrains and applications like road construction and trenching. This feature increases maneuverability, making them suitable for confined spaces. While they can be more expensive due to their advanced capabilities, the investment can be justified for businesses requiring flexibility and efficiency in their compaction tasks.

Illustrative image related to harbor freight plate compactor

Key Industrial Applications of harbor freight plate compactor

| Industry/Sector | Specific Application of Harbor Freight Plate Compactor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Soil compaction for foundations and roadways | Ensures stability and durability of structures, reducing future repair costs | Equipment reliability and maintenance support |

| Landscaping | Compacting gravel for pathways and patios | Provides a smooth, even surface for aesthetic and functional outdoor spaces | Availability of spare parts and service in local markets |

| Infrastructure Development | Compaction of base layers for asphalt and concrete | Enhances load-bearing capacity and extends lifespan of pavement | Compliance with local regulations and standards |

| Utility Installation | Compaction of backfill around utility lines | Prevents settling and damage to utilities, ensuring long-term functionality | Ease of transport and maneuverability in tight spaces |

| Agricultural Construction | Compaction of soil for agricultural buildings and structures | Improves soil structure and drainage, enhancing crop productivity | Adaptability to various soil types and conditions |

How is the Harbor Freight Plate Compactor Used in Construction Projects?

In the construction industry, the Harbor Freight plate compactor is essential for achieving proper soil compaction during the foundation laying process. It is particularly effective in compacting granular soils, which are crucial for the stability of structures like buildings and roadways. By using these compactors, contractors can ensure that the soil achieves the desired density, which significantly reduces the likelihood of future subsidence and structural damage. International buyers should consider the reliability and maintenance support of the equipment, especially in regions where access to service may be limited.

What Role Does the Plate Compactor Play in Landscaping?

Landscapers utilize the Harbor Freight plate compactor to create smooth and stable surfaces for pathways, patios, and driveways. By compacting gravel and other materials, landscapers can enhance the aesthetic appeal and functionality of outdoor spaces. This compaction process helps in preventing shifting and settling, which can lead to uneven surfaces over time. For buyers from regions with fluctuating weather conditions, the durability of the equipment and the availability of spare parts in local markets are critical factors to consider.

How Does the Plate Compactor Contribute to Infrastructure Development?

In infrastructure projects, the Harbor Freight plate compactor is used to compact base layers before laying asphalt or concrete. This application is vital for ensuring that the pavement has adequate load-bearing capacity, which directly impacts its longevity and performance. Proper compaction minimizes the risk of cracks and surface failures, which can lead to costly repairs. Buyers in developing regions should be aware of local regulations regarding construction materials and methods, ensuring that the equipment meets these requirements.

Illustrative image related to harbor freight plate compactor

Why is the Plate Compactor Important for Utility Installation?

During utility installations, the Harbor Freight plate compactor is employed to compact backfill around pipes and cables. This practice is crucial in preventing future settling that can damage underground utilities, ensuring they function correctly for years. For international buyers, especially in remote areas, the ease of transport and maneuverability of the compactor in tight spaces can be a decisive factor when selecting equipment.

How Can Agricultural Construction Benefit from Using a Plate Compactor?

In agricultural construction, the Harbor Freight plate compactor is utilized to prepare the ground for various structures such as barns and silos. Proper soil compaction improves drainage and soil structure, which can significantly enhance crop productivity. Buyers should consider the adaptability of the compactor to different soil types and conditions, as well as the long-term benefits it brings to agricultural operations.

3 Common User Pain Points for ‘harbor freight plate compactor’ & Their Solutions

Scenario 1: Difficulty in Operating Heavy Equipment Safely

The Problem: Many B2B buyers, especially those in construction or landscaping, face the challenge of training their operators to use heavy machinery like the Harbor Freight plate compactor safely and effectively. New users may struggle with understanding the mechanics of the machine, leading to improper use that can cause accidents or equipment damage. Additionally, without proper training, workers might not achieve optimal compaction results, wasting time and resources.

The Solution: To mitigate these risks, it is essential to implement a structured training program before introducing the plate compactor to your workforce. Start by conducting hands-on workshops where operators can familiarize themselves with the equipment. Utilize the owner’s manual to guide the training sessions, emphasizing key operational features, such as adjusting the throttle and understanding vibration settings. Consider creating a checklist for daily safety inspections, which includes checking oil levels and ensuring that all parts are functioning correctly. This proactive approach not only ensures safety but also enhances productivity by enabling operators to use the compactor effectively from day one.

Scenario 2: Compaction Performance Below Expectations

The Problem: Some users may find that the compaction performance of their Harbor Freight plate compactor does not meet project requirements, leading to dissatisfaction and potential delays. Factors such as the type of soil or aggregate being compacted, along with the compactor’s specifications, can significantly affect performance. Buyers may feel frustrated if they invested in a product expecting it to handle all types of materials efficiently.

The Solution: To achieve optimal compaction results, it is crucial to match the plate compactor’s specifications with the materials being used. For instance, when working with granular materials like gravel or sand, ensure the compactor has sufficient impact force and vibration frequency. If the project involves cohesive soils, consider using additional methods like moisture control to enhance compaction. Additionally, regularly maintaining the machine—such as checking for wear on the plate and ensuring the engine is well-tuned—will help maximize its performance. For buyers facing consistent issues, reaching out to Harbor Freight’s customer support for technical advice can provide tailored solutions based on specific project needs.

Scenario 3: High Transportation Costs Affecting Profitability

The Problem: B2B buyers in regions with challenging logistics may experience high transportation costs for their Harbor Freight plate compactor, which can impact overall project profitability. Whether it’s moving the equipment between job sites or transporting it across borders, these costs can quickly add up, especially for smaller companies operating on tight margins.

The Solution: To minimize transportation expenses, consider investing in a model that includes a mobility kit, such as the Harbor Freight plate compactor with a wheel kit. This feature facilitates easier transport, allowing operators to move the machine quickly between sites without needing additional vehicles or equipment. Furthermore, evaluate the possibility of consolidating deliveries when transporting multiple units or tools at once to save on shipping costs. For international buyers, exploring local distributors or partners can also reduce import fees and logistical challenges. Establishing relationships with local suppliers may lead to better pricing and reduced transportation costs, ultimately enhancing profitability on projects.

Strategic Material Selection Guide for harbor freight plate compactor

When selecting materials for Harbor Freight plate compactors, it’s essential to consider their properties, advantages, disadvantages, and suitability for various applications. This analysis focuses on four common materials used in the construction of these machines: steel, aluminum, rubber, and composite materials. Each material has unique characteristics that can impact performance, durability, and cost, which are crucial for international B2B buyers.

What Are the Key Properties of Steel in Plate Compactors?

Steel is a primary material used in the construction of plate compactors, particularly for the base plate and frame. Its key properties include high tensile strength, excellent durability, and resistance to deformation under heavy loads. Steel can withstand high temperatures and pressures, making it suitable for various compaction tasks.

Pros: Steel’s durability ensures a long lifespan, which is beneficial for operations in harsh environments. It is also cost-effective, as it is widely available and relatively inexpensive to manufacture.

Cons: However, steel is prone to corrosion if not properly treated, which can be a significant concern in humid or coastal regions. Additionally, the weight of steel can make the compactor less maneuverable.

Illustrative image related to harbor freight plate compactor

Impact on Application: Steel plate compactors are ideal for compacting soil, gravel, and asphalt. However, buyers in regions with high humidity should consider models with corrosion-resistant coatings.

How Does Aluminum Compare as a Material for Plate Compactors?

Aluminum is increasingly being used in plate compactors due to its lightweight nature and resistance to corrosion. This material is particularly advantageous for portable models where ease of transport is a priority.

Pros: Aluminum’s lightweight characteristic allows for better maneuverability and reduces operator fatigue during transport. It also has excellent corrosion resistance, making it suitable for humid or coastal environments.

Illustrative image related to harbor freight plate compactor

Cons: The primary drawback of aluminum is its lower tensile strength compared to steel, which may limit its use in heavy-duty applications. Additionally, aluminum can be more expensive than steel.

Impact on Application: Aluminum plate compactors are suitable for smaller jobs and residential applications. B2B buyers should consider the specific compaction needs of their projects to determine if aluminum is a viable option.

What Role Does Rubber Play in Plate Compactor Design?

Rubber is commonly used in plate compactors, primarily in the form of vibration isolators and pads. Its key properties include excellent shock absorption and flexibility, which enhance operator comfort and machine stability.

Pros: Rubber components significantly reduce vibrations, improving operator comfort and extending the life of the machine. They also provide a non-slip surface, which is beneficial for safety during operation.

Illustrative image related to harbor freight plate compactor

Cons: Rubber can degrade over time, especially when exposed to harsh environmental conditions or chemicals. This degradation can lead to increased maintenance costs.

Impact on Application: The use of rubber in plate compactors is crucial for applications requiring prolonged use. Buyers in warmer climates should ensure that the rubber components are rated for high temperatures to avoid premature wear.

How Do Composite Materials Enhance Plate Compactor Performance?

Composite materials, often a blend of polymers and other materials, are gaining traction in the manufacturing of plate compactors. Their properties include lightweight, high strength-to-weight ratio, and resistance to environmental factors.

Pros: Composites can provide significant weight savings while maintaining strength, making them ideal for portable equipment. They are also resistant to corrosion and chemicals, which enhances durability.

Cons: The primary limitation of composite materials is their higher manufacturing costs compared to traditional materials like steel and aluminum. Additionally, they may not be suitable for extremely heavy-duty applications.

Impact on Application: Composite materials are well-suited for compactors used in diverse environments, including construction sites and landscaping. Buyers should assess the specific requirements of their applications to determine the suitability of composite materials.

Summary Table of Material Selection for Harbor Freight Plate Compactors

| Material | Typical Use Case for harbor freight plate compactor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty soil and gravel compaction | High durability and strength | Prone to corrosion | Low |

| Aluminum | Portable and residential applications | Lightweight and corrosion-resistant | Lower strength than steel | Med |

| Rubber | Vibration isolation and operator comfort | Excellent shock absorption | Degrades over time | Low |

| Composite | Versatile applications in various environments | Lightweight and durable | Higher manufacturing costs | High |

This guide provides actionable insights for international B2B buyers, emphasizing the importance of material selection in achieving optimal performance and longevity for Harbor Freight plate compactors.

In-depth Look: Manufacturing Processes and Quality Assurance for harbor freight plate compactor

What Are the Main Stages of Manufacturing for Harbor Freight Plate Compactors?

The manufacturing process for Harbor Freight plate compactors involves several key stages, each critical for ensuring quality and performance. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to harbor freight plate compactor

-

Material Preparation: The first stage involves sourcing high-quality raw materials, primarily heavy-gauge steel for the plates and robust components for the engines. Suppliers are typically vetted to ensure compliance with international standards such as ISO 9001, which signifies a commitment to quality management systems. The materials undergo initial inspections to confirm that they meet the specifications required for durability and performance.

-

Forming: In this stage, the prepared materials are shaped into the necessary components. Techniques such as cutting, bending, and welding are employed to create the heavy-duty plates and frames. Advanced machinery and skilled labor are utilized to ensure precision in forming, which directly impacts the compactor’s effectiveness and longevity.

-

Assembly: Once the components are formed, they move to the assembly line. Here, skilled technicians assemble the parts, including the engine, vibration isolators, and mobility kits. This stage is crucial as it requires both manual dexterity and knowledge of mechanical systems to ensure that every unit is constructed to the highest standards.

-

Finishing: After assembly, the compactors undergo finishing processes such as powder coating, which provides a protective layer against wear and environmental factors. This finishing touch not only enhances the aesthetics of the product but also contributes to its durability, making it suitable for various applications in diverse climates.

How Is Quality Assurance Implemented in the Manufacturing of Plate Compactors?

Quality assurance is integral to the manufacturing process, ensuring that each plate compactor meets stringent performance and safety standards. The quality control (QC) process includes several checkpoints and adheres to both international and industry-specific standards.

-

International Standards Compliance: Harbor Freight plate compactors are manufactured in accordance with ISO 9001 standards, which focus on maintaining quality management systems. In addition to ISO certifications, products often comply with CE standards, particularly for the European market, ensuring they meet safety and environmental requirements.

-

Quality Control Checkpoints: Quality assurance is conducted at various stages of production:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are performed to monitor the quality of assembly and the precision of components.

– Final Quality Control (FQC): Once the compactors are fully assembled, they undergo rigorous testing, including operational tests to assess vibration frequency and compaction efficiency. -

Common Testing Methods: Testing methodologies include performance testing under simulated operating conditions, vibration analysis, and durability testing to ensure that the products can withstand heavy use. These tests verify that the compactors can achieve the advertised performance metrics, such as compaction depth and area coverage per hour.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for making informed purchasing decisions. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits of manufacturing facilities can provide valuable insights into the supplier’s quality assurance processes. During these audits, buyers should assess the production workflow, quality control checkpoints, and adherence to safety standards.

-

Requesting Quality Assurance Documentation: Buyers can request detailed quality assurance reports, including inspection records, test results, and certifications. These documents should outline compliance with relevant international standards and demonstrate a commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing processes and quality controls in place. This service is particularly beneficial for buyers unfamiliar with local manufacturing practices and standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating quality control and certification nuances can be complex for international buyers. Here are some key considerations:

-

Regional Compliance Requirements: Different markets have varying compliance requirements. For instance, products sold in Europe must meet CE certification, while in the U.S., compliance with OSHA standards may be necessary. Understanding these nuances helps buyers ensure that the products will be legally marketable in their regions.

-

Cultural and Communication Considerations: Effective communication with suppliers about quality expectations is crucial. Cultural differences may affect how quality is perceived and managed. B2B buyers should ensure that their quality standards are clearly articulated and understood.

-

Ongoing Quality Monitoring: Once a partnership is established, ongoing monitoring of quality assurance practices is vital. Regular communication regarding product performance and quality feedback can foster a collaborative relationship and ensure that standards remain high.

By understanding the manufacturing processes and quality assurance measures in place for Harbor Freight plate compactors, B2B buyers can make informed decisions, ensuring they procure reliable and high-quality equipment suited to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘harbor freight plate compactor’

Introduction

This practical sourcing guide is designed for international B2B buyers looking to procure Harbor Freight plate compactors. By following this step-by-step checklist, you can ensure that you make informed decisions that align with your operational needs and budget constraints.

Illustrative image related to harbor freight plate compactor

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline the technical specifications required for your projects. This includes parameters such as engine horsepower, vibration frequency, and compaction depth.

- Key Considerations:

- For instance, a 7 HP model may be necessary for larger projects, while a 6.5 HP model could suffice for smaller tasks.

- Determine the material types you will be compacting, such as gravel or soil, as this impacts the compactor’s performance.

Step 2: Research Supplier Reputation

Investigate the reputation of Harbor Freight as a supplier. Look for reviews, ratings, and testimonials from other businesses that have purchased their equipment.

- Why This Matters:

- Understanding the experiences of previous buyers can provide insights into product reliability and customer service.

- Utilize platforms such as industry forums or trade publications for unbiased feedback.

Step 3: Evaluate Product Availability and Lead Times

Assess the availability of the specific plate compactor models you are interested in and inquire about lead times for delivery.

- Action Items:

- Confirm whether the supplier can meet your timeline, especially if you have upcoming projects that require immediate equipment.

- Check if there are any shipping restrictions, particularly if you are sourcing from regions with specific import regulations.

Step 4: Request Detailed Quotations

Obtain detailed quotations from Harbor Freight, including pricing, shipping costs, and any applicable taxes or tariffs.

- Why It’s Essential:

- A comprehensive quote helps you understand the total cost of ownership and allows for better budgeting.

- Ensure that the quote includes warranty information and after-sales support options, which are crucial for maintenance and repairs.

Step 5: Verify Compliance with Local Regulations

Ensure that the plate compactors you intend to purchase comply with local regulations and standards in your region.

- Considerations:

- Check for certifications such as EPA compliance, which may be required in certain areas.

- Understanding local emissions regulations can prevent potential issues during operation and resale.

Step 6: Assess After-Sales Support and Warranty Options

Evaluate the after-sales support offered by Harbor Freight, including warranty terms and availability of replacement parts.

- Key Points:

- A strong warranty can significantly reduce long-term costs associated with repairs or replacements.

- Ensure that replacement parts are easily accessible, as this can impact your equipment’s operational uptime.

Step 7: Finalize Purchase and Establish Payment Terms

Once you are satisfied with the supplier’s responses and product details, finalize the purchase agreement and clarify payment terms.

- Important Actions:

- Negotiate payment terms that align with your cash flow needs, whether that involves upfront payments or installment options.

- Ensure that all agreements are documented to avoid any misunderstandings in the future.

By following this checklist, B2B buyers can effectively navigate the procurement process for Harbor Freight plate compactors, ensuring they select the right equipment for their operational needs while securing favorable terms.

Comprehensive Cost and Pricing Analysis for harbor freight plate compactor Sourcing

What Are the Key Cost Components for Harbor Freight Plate Compactors?

When sourcing Harbor Freight plate compactors, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The quality of materials directly affects the performance and durability of the compactors. Heavy-gauge steel plates and high-performance engines, like the 6.5 HP or 7 HP models from Harbor Freight, contribute significantly to the material costs.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembly, and quality control. Skilled labor is essential for ensuring that each unit meets stringent quality standards, which can influence the final pricing.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: The initial investment in tools and molds necessary for producing plate compactors can be substantial. These costs are often amortized over the production run, affecting pricing.

-

Quality Control (QC): Implementing strict QC measures ensures that each plate compactor functions as intended. This includes testing for vibration levels, durability, and safety, which adds to the overall cost.

-

Logistics: Shipping and handling costs, especially for bulky items like plate compactors, can be significant. Factors such as distance from the manufacturing facility and shipping methods can impact logistics expenses.

-

Margin: The profit margin set by the manufacturer or distributor is a final factor in the pricing structure. This margin may vary based on competition, market demand, and the perceived value of the product.

How Do Price Influencers Impact Harbor Freight Plate Compactor Sourcing?

Several price influencers play a critical role in determining the final pricing for plate compactors:

-

Volume/MOQ: Bulk orders often lead to lower prices per unit. Understanding the minimum order quantities (MOQ) can help buyers negotiate better terms.

-

Specifications and Customization: Customizing features, such as additional wheels or specific engine types, can lead to increased costs. Buyers should assess whether the additional investment aligns with their operational needs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as EPA compliance) can justify higher prices. Buyers should evaluate whether the added cost translates into better performance and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer higher prices due to their reliability and service quality.

-

Incoterms: Understanding shipping terms is vital. Costs associated with duties, taxes, and insurance can significantly affect total expenditures for international buyers.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Plate Compactors?

International B2B buyers can adopt several strategies to enhance cost-efficiency:

-

Negotiate Effectively: Leverage volume purchases to negotiate better prices. Building a relationship with suppliers can also lead to favorable terms over time.

-

Consider Total Cost of Ownership (TCO): Beyond the purchase price, assess maintenance, operational efficiency, and longevity of the equipment. A higher initial investment may yield savings in the long run if the equipment lasts longer and requires less maintenance.

-

Understand Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should consider currency fluctuations, local regulations, and import tariffs that may affect overall costs.

-

Request Multiple Quotes: Obtaining quotes from different suppliers can provide insight into competitive pricing and help identify the best value.

Disclaimer on Indicative Prices

Prices mentioned, such as $499.99 for the CENTRAL MACHINERY 6.5 HP Plate Compactor or $699.99 for the 7 HP model, are indicative and may vary based on location, shipping costs, and market conditions. Buyers should confirm current pricing directly with suppliers for the most accurate and relevant information.

Alternatives Analysis: Comparing harbor freight plate compactor With Other Solutions

In the competitive landscape of construction equipment, particularly for soil compaction, it’s essential for B2B buyers to evaluate various solutions available in the market. The Harbor Freight plate compactor offers an economical choice, but there are alternative technologies that may better suit specific operational needs or project demands. This analysis compares the Harbor Freight plate compactor with two viable alternatives: the Tomahawk HZR80 plate compactor and a hydraulic compactor.

| Comparison Aspect | Harbor Freight Plate Compactor | Tomahawk HZR80 Plate Compactor | Hydraulic Compactor |

|---|---|---|---|

| Performance | 5,500 vibrations per minute; covers 350 sq. m/hr | 6,500 vibrations per minute; covers 300 sq. m/hr | Variable; often adjustable based on hydraulic pressure |

| Cost | $499.99 – $699.99 | $1,169.99 | $2,000 – $5,000 |

| Ease of Implementation | Requires minimal setup | Moderate; needs fuel and maintenance | High; requires hydraulic connections and setup |

| Maintenance | Low; basic oil changes | Moderate; regular maintenance needed | High; complex systems require specialized knowledge |

| Best Use Case | Small to medium projects; DIY | Medium to large projects; professional use | Large-scale projects; heavy-duty applications |

What are the Advantages and Disadvantages of the Tomahawk HZR80 Plate Compactor?

The Tomahawk HZR80 plate compactor stands out for its superior performance, offering 6,500 vibrations per minute, making it suitable for medium to large-scale projects. Its construction is robust, allowing for effective compaction of denser materials. However, its higher price point at $1,169.99 may deter budget-conscious buyers. Additionally, the maintenance requirements are moderate, necessitating regular fuel checks and mechanical upkeep that could lead to downtime if not managed properly.

What Benefits Does a Hydraulic Compactor Provide?

Hydraulic compactors are designed for heavy-duty applications, making them ideal for large-scale construction projects. They offer variable performance based on hydraulic pressure settings, allowing for tailored compaction based on material types and site conditions. However, the initial investment is significantly higher, ranging from $2,000 to $5,000. They also require a more complex setup and maintenance routine, as hydraulic systems can be intricate and may necessitate specialized knowledge for repairs and service.

How Should B2B Buyers Decide on the Right Compaction Solution?

When choosing the right compaction solution, B2B buyers should assess their specific project requirements, including the scale of the job, the type of materials being compacted, and budget constraints. The Harbor Freight plate compactor is a solid choice for smaller tasks or DIY projects due to its affordability and ease of use. In contrast, if the project demands higher performance and durability, investing in a Tomahawk or hydraulic compactor may provide better long-term value despite the higher upfront costs. Understanding the trade-offs in performance, cost, and maintenance will empower buyers to make informed decisions tailored to their operational needs.

Essential Technical Properties and Trade Terminology for harbor freight plate compactor

What Are the Essential Technical Properties of Harbor Freight Plate Compactors?

When considering the procurement of Harbor Freight plate compactors, it’s crucial to understand their key technical specifications. Here are several critical properties that impact performance, durability, and operational efficiency:

-

Engine Power (HP)

– The engine power, typically measured in horsepower (HP), is a vital specification. For example, the CENTRAL MACHINERY 7 HP plate compactor is designed to deliver superior compaction force, making it suitable for heavy-duty applications. Higher HP means better performance on tough materials, which is essential for projects requiring substantial ground stabilization. -

Vibration Rate (VPM)

– Measured in vibrations per minute (VPM), this metric indicates how many times the plate compactor’s plate vibrates in a minute. For instance, models like the 6.5 HP variant can achieve up to 5,500 VPM. A higher vibration rate translates to more effective compaction, enabling faster completion of large areas, which is particularly beneficial for contractors looking to optimize productivity. -

Compaction Depth

– The maximum compaction depth is critical for understanding how deeply the compactor can densify materials. A model capable of compacting soil to a depth of 13 inches, like the 7 HP version, is advantageous for projects involving thick layers of gravel or soil, ensuring stable foundations for roads or buildings. -

Plate Size and Weight

– The size and weight of the compactor’s plate affect its efficiency and suitability for different tasks. A larger plate size can cover more ground per pass, while a heavier weight ensures better compaction. Knowing the dimensions and weight, such as a 205 lb. unit, helps buyers evaluate its maneuverability and suitability for specific job sites. -

Material Construction

– The construction material, often heavy-gauge steel, determines the durability and resistance to wear and tear. A powder-coated finish is an additional feature that protects against corrosion, which is particularly important in harsh environments. Understanding material specifications helps buyers assess the long-term value and maintenance needs of their equipment. -

Mobility Features

– Features like foldaway mobility kits enhance the transportability of plate compactors, making them easier to move between job sites. This is particularly relevant for B2B buyers in construction and landscaping, where equipment mobility can significantly affect operational efficiency.

What Common Trade Terminology Should B2B Buyers Know for Plate Compactors?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some key terms relevant to plate compactors:

Illustrative image related to harbor freight plate compactor

-

OEM (Original Equipment Manufacturer)

– This refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers ensure they are sourcing high-quality components for their plate compactors. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budget management and inventory planning, particularly for businesses in regions with fluctuating demand. -

RFQ (Request for Quotation)

– An RFQ is a document used to solicit price quotes from suppliers. For B2B buyers, submitting an RFQ can lead to better pricing and terms, especially when considering bulk purchases of plate compactors. -

Incoterms (International Commercial Terms)

– These are international standards for shipping and freight, defining the responsibilities of buyers and sellers. Understanding Incoterms is vital for ensuring clarity on shipping costs, risks, and delivery timelines, especially when importing equipment from manufacturers like Harbor Freight. -

Warranty Period

– This term refers to the duration for which the manufacturer guarantees the product against defects. Knowing warranty terms helps buyers assess potential costs related to repairs or replacements, which is essential for budgeting in projects. -

Lead Time

– This is the time between placing an order and receiving the product. Understanding lead times helps businesses plan their project schedules effectively, ensuring they have the necessary equipment on-site when needed.

By comprehensively understanding these technical properties and industry terms, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the harbor freight plate compactor Sector

What Are the Current Market Dynamics and Key Trends for Harbor Freight Plate Compactors?

The global market for plate compactors, particularly from brands like Harbor Freight, is influenced by several key drivers. Increasing urbanization and infrastructure development across regions such as Africa, South America, the Middle East, and Europe are propelling demand for construction and landscaping equipment. The need for efficient soil compaction in road construction, landscaping, and foundation laying contributes to the rising adoption of plate compactors. Furthermore, competitive pricing strategies, as seen with Harbor Freight’s offerings, are attracting cost-sensitive B2B buyers looking for reliable yet affordable equipment.

Emerging technologies are reshaping the sourcing landscape. Innovations such as electric and hybrid plate compactors are gaining traction due to their reduced environmental impact and lower operational costs. International buyers are increasingly seeking suppliers that can offer not only competitive pricing but also technological advancements that enhance productivity. Additionally, e-commerce platforms are becoming vital for sourcing, enabling buyers from various regions to access products quickly and efficiently.

Sourcing trends are also leaning towards local procurement as businesses aim to reduce shipping times and costs. This trend is particularly relevant for buyers in regions with developing infrastructure, where rapid project timelines necessitate quick access to equipment. Partnerships with local distributors who understand regional market dynamics can provide significant advantages in terms of logistics and support.

How Does Sustainability and Ethical Sourcing Impact the Harbor Freight Plate Compactor Sector?

Sustainability is becoming a critical focus for B2B buyers in the construction equipment sector. The environmental impact of equipment manufacturing and operation is under scrutiny, prompting buyers to seek out suppliers that prioritize eco-friendly practices. For Harbor Freight plate compactors, this means not only ensuring that the manufacturing processes are sustainable but also that the products themselves are designed for efficiency and minimal environmental impact.

Illustrative image related to harbor freight plate compactor

Ethical sourcing practices are increasingly important as businesses aim to align with corporate social responsibility (CSR) goals. Buyers are encouraged to evaluate suppliers based on their supply chain transparency, labor practices, and environmental certifications. Certifications such as ISO 14001 for environmental management can serve as indicators of a supplier’s commitment to sustainability. Moreover, the use of materials that are recyclable or sourced from sustainable suppliers is becoming a significant consideration for international buyers.

As the market shifts towards greener practices, Harbor Freight and similar companies may benefit from developing and promoting products that meet these sustainability criteria. This not only enhances brand reputation but also appeals to a growing segment of environmentally-conscious buyers.

What Is the Brief History of Harbor Freight’s Plate Compactor Offerings?

Harbor Freight has established itself as a key player in the power tools and equipment sector, particularly known for providing cost-effective solutions for both consumers and B2B buyers. The company has a long history of sourcing and offering a range of construction and landscaping tools, including plate compactors. Over the years, Harbor Freight has focused on enhancing the performance and durability of its products, incorporating feedback from users to refine their offerings.

The introduction of models like the CENTRAL MACHINERY 6.5 HP and 7 HP plate compactors showcases the brand’s commitment to delivering high-quality, reliable equipment at competitive prices. By continually adapting to market demands and technological advancements, Harbor Freight has positioned itself as a go-to supplier for businesses looking to procure essential equipment without compromising on quality. This evolution reflects the broader trends in the construction equipment market, where efficiency, affordability, and sustainability are increasingly prioritized by B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of harbor freight plate compactor

-

How do I choose the right plate compactor for my projects?

Selecting the appropriate plate compactor depends on several factors including the type of material you’ll be compacting, the area size, and your specific project requirements. For instance, if you’re compacting gravel for a driveway, a model like the 7 HP Plate Compactor with a mobility kit may be ideal due to its robust engine and high compaction force. Additionally, consider the compactor’s weight and portability, especially for projects requiring frequent transport. Always verify that the model’s specifications align with your project needs to ensure efficiency and effectiveness. -

What is the best Harbor Freight plate compactor for heavy-duty applications?

For heavy-duty applications, the CENTRAL MACHINERY 7 HP Plate Compactor is highly recommended. It offers an impressive impact force of 3,600 lbs, making it suitable for compacting tough materials like dense soil and gravel. With a travel speed of 65 feet per minute and the ability to compact soil up to 13 inches deep, this model is designed for efficiency. Additionally, its vibration isolators enhance operator comfort, reducing fatigue during extended use, making it perfect for large-scale construction projects. -

What are the minimum order quantities (MOQ) for international purchases?

The minimum order quantities for international buyers can vary based on the supplier and specific model. Typically, Harbor Freight does not publicly list an MOQ, but it’s advisable to contact their sales team directly for detailed information. When negotiating, consider your shipping logistics and potential customs regulations in your region, as these can influence the overall quantity you may need to order for cost-effectiveness and compliance. -

What payment terms are available for B2B purchases?

Harbor Freight generally offers several payment options for B2B transactions, including bank transfers, credit terms, and possibly letters of credit for larger orders. Payment terms can vary based on your location and order size, so it’s crucial to discuss these directly with their sales representatives. Additionally, inquire about any discounts for bulk purchases, as this can significantly reduce costs, especially for international buyers. -

How do I ensure the quality of the plate compactors I purchase?

To ensure quality, request product specifications, certifications, and warranty information before finalizing your order. Harbor Freight plate compactors are typically backed by a warranty, which indicates a commitment to quality. Additionally, consider reviewing customer testimonials and seeking third-party reviews for insights into performance and durability. Conducting due diligence will help mitigate risks associated with international purchases. -

What logistics considerations should I keep in mind for international shipping?

When arranging logistics for international shipping, consider factors such as shipping costs, customs duties, and delivery timelines. Ensure you understand the import regulations in your country, as these can affect shipping methods and costs. Collaborating with a reliable freight forwarder can streamline the process, as they can assist with documentation and customs clearance, ensuring your equipment arrives on time and within budget. -

Can I customize the plate compactor features for my specific needs?

Customization options may be limited with standard models like those from Harbor Freight; however, it’s worth discussing your specific requirements with their sales team. They may offer accessories or modifications that can enhance the compactor’s functionality for your project needs, such as different plate sizes or additional attachments. Custom orders may also be available for larger quantities, so be sure to inquire about any potential options. -

What should I do if my plate compactor requires repairs or replacement parts?

If your plate compactor requires repairs or replacement parts, first consult the owner’s manual for troubleshooting guidance and warranty information. Harbor Freight typically offers a selection of replacement parts for their products, which can be ordered directly through their website or customer service. Ensure you have the model number handy to streamline the process. Regular maintenance and timely repairs can extend the lifespan of your equipment, so it’s wise to address issues as they arise.

Top 3 Harbor Freight Plate Compactor Manufacturers & Suppliers List

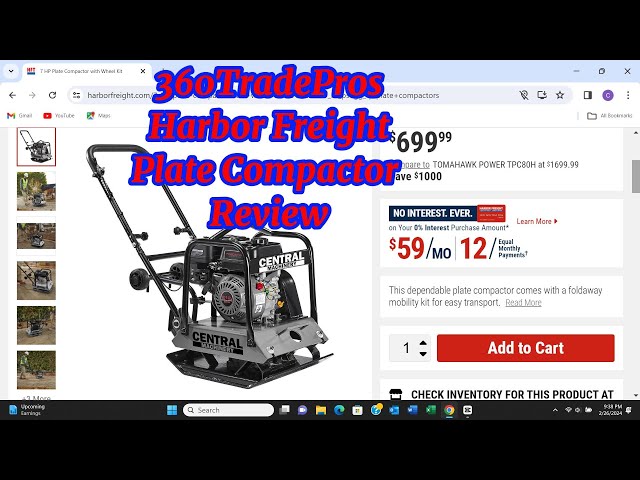

1. Central Machinery – 6.5 HP Plate Compactor

Domain: go.harborfreight.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “CENTRAL MACHINERY 6.5 HP Plate Compactor”, “price”: “$499.99”, “coupon_code”: “36138314”, “valid_until”: “March 31, 2020”, “item_number”: “69738”, “comparison_price”: “$1169.99”, “comparison_model”: “Tomahawk HZR80”, “savings”: “$670”, “vibrations_per_minute”: “5500”, “area_compacted_per_hour”: “350 square meters”, “rating”: “4.5-star”}

2. Harbor Freight – Central Machinery Plate Compactor

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Plate compactor from Harbor Freight, specifically the Central Machinery model. Used for hardscaping work, such as preparing gravel for a concrete driveway and laying paver patios. Users report good performance with around 100-150 hours of use. Some issues noted include rubber hoses rotting and difficulty accessing grease fittings. The engine is a 179cc Predator model, with some users replacing it …

3. Central Machinery – 7 HP Plate Compactor

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: The Central Machinery 7 HP Plate Compactor comes with a foldaway mobility kit.

Strategic Sourcing Conclusion and Outlook for harbor freight plate compactor

In conclusion, the strategic sourcing of Harbor Freight plate compactors presents a unique opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. With competitive pricing, such as the 6.5 HP model available for under $500, companies can achieve significant cost savings compared to alternatives, which may exceed $1,000. The compactors’ efficiency—covering up to 350 square meters per hour with a robust engine capable of delivering 5,500 vibrations per minute—ensures high performance in various applications, from construction to landscaping.

Moreover, the durability and innovative features, including vibration isolators and mobility kits, enhance usability and longevity, making these machines a smart investment for businesses looking to optimize their operational efficiency. As the global demand for reliable construction equipment continues to rise, sourcing from reputable suppliers like Harbor Freight can strengthen supply chains and support sustainable business growth.

International buyers are encouraged to evaluate their sourcing strategies and consider integrating Harbor Freight plate compactors into their operations. By doing so, they not only gain access to quality equipment but also position themselves advantageously in a competitive marketplace. Take the next step—explore your sourcing options today to secure the tools that will drive your projects forward.

Illustrative image related to harbor freight plate compactor

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.