Harbor Freight Car Ramps: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for harbor freight car ramps

In the competitive landscape of automotive tools and equipment, sourcing high-quality Harbor Freight car ramps is a critical challenge for international B2B buyers. Whether you are a distributor in Africa, a retailer in South America, or a service provider in the Middle East and Europe, understanding the nuances of these essential tools can significantly impact your purchasing decisions. This comprehensive guide delves into the diverse types of Harbor Freight car ramps available, including loading ramps and lifting ramps, along with their various applications, capacities, and materials.

Our exploration extends to vital considerations such as supplier vetting processes, pricing strategies, and market trends across different regions, including Germany and Saudi Arabia. By equipping buyers with actionable insights and best practices, this guide aims to empower you to make informed purchasing decisions that align with your business needs. From ensuring safety during vehicle maintenance to optimizing logistics for heavy equipment loading, understanding the right car ramp solution can enhance operational efficiency and customer satisfaction.

Dive into this resource to navigate the complexities of the global market for Harbor Freight car ramps, ensuring you find the perfect solutions tailored to your specific requirements.

Understanding harbor freight car ramps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

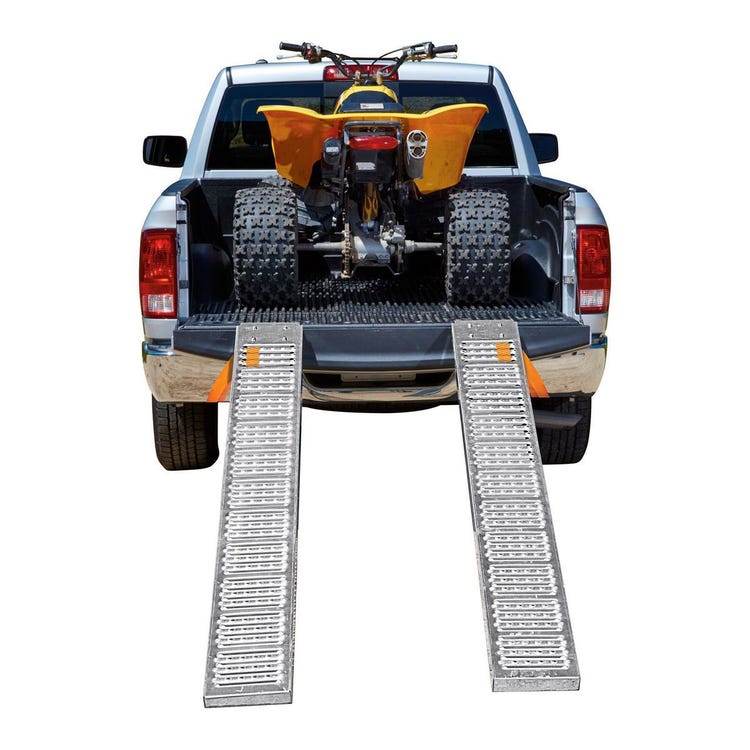

| Loading Ramps | Typically made from aluminum or steel, designed for loading vehicles onto trailers or trucks. | Transporting motorcycles, ATVs, and lawn equipment. | Pros: Lightweight, portable, and easy to store. Cons: May not support heavier vehicles without additional support. |

| Lifting Ramps | Engineered for vehicle maintenance, providing ample clearance for repairs. | Automotive workshops and DIY enthusiasts performing maintenance. | Pros: Stable design for safety, allows easy access to undercarriage. Cons: Requires sufficient space for setup. |

| Heavy-Duty Ramps | Constructed from high-strength materials, often with higher weight capacities. | Industrial applications and heavy vehicle servicing. | Pros: Can support larger vehicles and heavier loads. Cons: Bulkier and less portable than lighter options. |

| Adjustable Ramps | Feature adjustable heights to accommodate various vehicle sizes and ground clearance. | Versatile use across different vehicle types and maintenance tasks. | Pros: Customizable for specific needs. Cons: More complex design may require additional setup time. |

| Plastic Ramps | Made from durable plastic, often lightweight and resistant to rust. | Ideal for lighter vehicles and casual use. | Pros: Easy to handle and store, rust-resistant. Cons: Lower weight capacity compared to metal options. |

What Are the Key Characteristics of Loading Ramps?

Loading ramps are primarily designed for facilitating the safe and efficient loading of vehicles onto trailers or trucks. Typically constructed from aluminum or steel, these ramps are lightweight yet robust enough to handle equipment such as motorcycles, ATVs, and lawnmowers. B2B buyers in the transport and logistics sector should consider the ramp’s weight capacity, length, and surface traction, ensuring they meet the specific needs of their operations without compromising safety.

How Do Lifting Ramps Enhance Vehicle Maintenance?

Lifting ramps are specifically engineered to provide ample clearance for automotive maintenance tasks. They allow mechanics and DIY enthusiasts to access the underside of vehicles easily, making oil changes and inspections more straightforward. When purchasing lifting ramps, B2B buyers should evaluate the stability and safety features, as these are critical for preventing accidents in busy workshops. The design should also accommodate various vehicle types to maximize utility.

What Advantages Do Heavy-Duty Ramps Offer for Industrial Use?

Heavy-duty ramps are built from high-strength materials and are designed to support larger vehicles, making them ideal for industrial applications. These ramps are essential for businesses that deal with heavy machinery or vehicles requiring regular servicing. Buyers should assess the weight capacity and durability of the ramp, as well as its compatibility with different types of vehicles. The initial investment may be higher, but the long-term value in safety and efficiency often justifies the cost.

Why Choose Adjustable Ramps for Versatile Applications?

Adjustable ramps offer a unique advantage by allowing users to modify the height, making them suitable for various vehicle sizes and maintenance tasks. This flexibility is particularly beneficial for businesses that handle a diverse fleet of vehicles. When considering adjustable ramps, B2B buyers should focus on the ease of adjustment and the stability of the ramp at different heights to ensure safe operation across all applications.

What Are the Benefits of Plastic Ramps for Casual Use?

Plastic ramps are a lightweight and rust-resistant option, making them ideal for casual use with lighter vehicles. They are easy to handle and store, appealing to businesses with limited space or those that require portable solutions. While they may not support as much weight as their metal counterparts, plastic ramps can be a cost-effective choice for small businesses or individual contractors needing reliable loading solutions. Buyers should weigh the ramp’s weight capacity against their specific usage requirements.

Key Industrial Applications of harbor freight car ramps

| Industry/Sector | Specific Application of Harbor Freight Car Ramps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Routine vehicle maintenance and inspections | Enhances safety and efficiency during oil changes and repairs | Consider weight capacity, ramp material, and durability |

| Logistics and Transport | Loading and unloading vehicles and heavy equipment | Streamlines operations and reduces risk of injury | Ensure compatibility with vehicle types and weight limits |

| Construction | Accessing machinery for maintenance and repairs | Improves accessibility for equipment servicing | Look for ramps that can support heavy machinery and tools |

| Agriculture | Loading farm equipment onto trailers | Facilitates safe and efficient transportation of equipment | Evaluate ramp length and incline for specific equipment types |

| Recreational Vehicle | Loading ATVs and motorcycles onto trailers or trucks | Increases convenience for outdoor recreational activities | Assess ramp width and traction features for specific vehicles |

How Are Harbor Freight Car Ramps Used in Automotive Repair?

In the automotive repair industry, Harbor Freight car ramps are essential tools for routine maintenance and inspections. Mechanics utilize these ramps to elevate vehicles, providing safe access to the underside for oil changes, brake inspections, and other repairs. The ramps enhance safety by offering a stable platform compared to traditional jack stands, minimizing the risk of accidents. For international buyers, especially in regions like Africa and the Middle East, sourcing ramps with appropriate weight capacities and durable materials is crucial to withstand diverse working conditions.

What Role Do Car Ramps Play in Logistics and Transport?

In logistics and transport, Harbor Freight car ramps facilitate the loading and unloading of vehicles and heavy equipment. These ramps allow for a smooth transition when moving items onto trucks or trailers, significantly reducing the risk of injury associated with manual lifting. For businesses in South America and Europe, it is vital to consider the ramp’s compatibility with various vehicle types and its weight limits to ensure safe operations during transport.

How Are Car Ramps Beneficial in Construction?

Construction companies often utilize Harbor Freight car ramps to access machinery for maintenance and repairs. These ramps provide an effective solution for elevating equipment, allowing workers to perform necessary checks without the need for complex lifting devices. In regions such as Germany, where safety regulations are stringent, sourcing high-quality ramps that meet local standards is essential to maintain compliance and ensure worker safety.

In What Ways Do Car Ramps Assist in Agriculture?

In the agricultural sector, loading ramps are employed to transport farm equipment onto trailers efficiently. This application is crucial for farmers who need to move machinery between fields or to maintenance facilities. For international buyers, particularly in Africa, evaluating ramp length and incline is important to accommodate various types of agricultural equipment, ensuring safe and effective loading practices.

How Do Car Ramps Enhance Recreational Vehicle Use?

For recreational vehicle enthusiasts, Harbor Freight car ramps are invaluable for loading ATVs and motorcycles onto trucks or trailers. These ramps simplify the process, allowing users to quickly and safely transport their vehicles for outdoor activities. Buyers in regions with a strong outdoor culture, such as parts of South America and Europe, should assess the width and traction features of the ramps to ensure compatibility with specific vehicle types, enhancing usability and safety during transport.

3 Common User Pain Points for ‘harbor freight car ramps’ & Their Solutions

Scenario 1: Inadequate Weight Capacity for Heavy Vehicles

The Problem: Many B2B buyers, particularly those in industries that deal with heavy machinery or vehicles, often find that the weight capacity of standard Harbor Freight car ramps is insufficient for their needs. For example, a fleet maintenance company may require ramps that can support vehicles weighing over 3,000 pounds for routine inspections and repairs. When ramps are not rated for the required weight, it can lead to safety hazards, damage to the vehicles, and increased downtime for repairs. This scenario not only affects operational efficiency but can also result in costly accidents.

The Solution: To overcome this challenge, B2B buyers should conduct a thorough assessment of their vehicle weight requirements and match them against the specifications of available Harbor Freight ramps. It’s advisable to opt for heavy-duty ramps designed for higher capacities, ensuring they are rated well above the heaviest vehicle in the fleet. Buyers should also consider purchasing ramps with additional safety features, such as rubberized feet or a wider surface area, which can enhance stability and reduce the risk of slipping. Additionally, creating a comprehensive maintenance schedule for the ramps can help ensure they remain in good condition and continue to meet safety standards.

Scenario 2: Compatibility Issues with Vehicle Clearance

The Problem: A common pain point for buyers is the compatibility of Harbor Freight car ramps with various vehicle models, especially those with low ground clearance or unique designs. For instance, automotive repair shops may encounter vehicles that scrape the ramp during loading, leading to potential damage and operational delays. This issue is particularly prevalent in regions where vehicles are modified for performance, resulting in lower ride heights that standard ramps cannot accommodate.

The Solution: Buyers can address this issue by investing in adjustable ramps or those specifically designed for low-clearance vehicles. When sourcing ramps, it’s essential to measure the ground clearance of the vehicles being serviced and compare it with the ramp’s height. Furthermore, utilizing incline extensions or constructing DIY ramps can provide the necessary height to safely load vehicles without scraping. Establishing a clear communication channel with suppliers can also help in acquiring ramps that meet specific vehicle requirements, ensuring that the ramps are appropriate for the intended use.

Scenario 3: Durability and Material Concerns

The Problem: B2B buyers often express concerns regarding the durability of Harbor Freight car ramps, especially in environments that demand frequent use, such as automotive repair shops or warehouses. Ramps made from lower-quality materials may bend, rust, or break over time, leading to safety issues and financial losses. This concern is heightened for international buyers in humid or coastal regions where corrosion can quickly degrade metal products.

The Solution: To combat durability issues, buyers should prioritize ramps constructed from high-quality materials, such as aluminum or galvanized steel, which offer superior resistance to rust and wear. It’s also advisable to verify the manufacturer’s warranty and product reviews to gauge long-term performance. Implementing a regular inspection and maintenance routine for the ramps can help identify wear and tear before it becomes a safety concern. Additionally, when purchasing in bulk, consider negotiating with suppliers for customized solutions that meet specific durability standards tailored to the buyer’s operational environment. This proactive approach not only ensures safety but also extends the life of the ramps, providing better overall value.

Strategic Material Selection Guide for harbor freight car ramps

What Are the Key Materials Used in Harbor Freight Car Ramps?

When selecting car ramps, the material used in their construction plays a crucial role in determining their performance, durability, and suitability for various applications. For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the properties, advantages, and limitations of different ramp materials is essential for making informed purchasing decisions.

How Does Aluminum Perform as a Material for Car Ramps?

Aluminum is a popular choice for car ramps due to its lightweight nature and excellent strength-to-weight ratio. It is resistant to corrosion, making it suitable for environments with high humidity or exposure to chemicals. Aluminum ramps typically have a temperature rating that allows them to perform well in both hot and cold climates.

Pros: The primary advantages of aluminum ramps include their portability, ease of handling, and resistance to rust. They are also relatively easy to manufacture, which can lower production costs.

Cons: However, aluminum ramps can be more expensive than other materials, and they may not support as much weight as heavier steel options. Additionally, they can be prone to bending under excessive loads if not designed correctly.

Impact on Application: Aluminum ramps are ideal for light to medium-duty applications, such as loading motorcycles or ATVs. They are less suitable for heavy vehicles due to their weight capacity limitations.

What Are the Benefits of Steel in Car Ramp Construction?

Steel, particularly high-strength steel, is another common material used in car ramps. Steel ramps are known for their durability and high weight capacity, making them suitable for heavy-duty applications.

Pros: The main advantage of steel ramps is their strength and stability, which allows them to support heavier vehicles without bending or breaking. They are also generally more affordable than aluminum ramps.

Cons: On the downside, steel is heavier, making these ramps less portable. Additionally, steel is susceptible to rust if not properly coated or maintained, which can be a significant concern in humid or corrosive environments.

Impact on Application: Steel ramps are ideal for workshops or garages where heavy vehicles are frequently serviced, as they can handle the weight of trucks and larger cars.

How Do Plastic Car Ramps Compare?

Plastic ramps are often made from high-density polyethylene (HDPE) or similar materials. They are lightweight and resistant to many chemicals, making them suitable for various environments.

Pros: The key advantages of plastic ramps include their lightweight nature, corrosion resistance, and lower cost compared to metal ramps. They are also less likely to scratch vehicle surfaces.

Cons: However, plastic ramps typically have lower weight capacities and may not be suitable for heavy-duty applications. They can also be less stable than metal ramps, particularly on uneven surfaces.

Impact on Application: Plastic ramps are best suited for light-duty applications, such as loading lawn equipment or smaller vehicles.

What Should International Buyers Consider When Choosing Ramp Materials?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, compliance with local standards is crucial. Different countries may have specific regulations regarding material safety, load capacities, and environmental impacts. Familiarity with standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), or JIS (Japanese Industrial Standards) can guide buyers in selecting the right product.

Summary Table of Material Properties for Harbor Freight Car Ramps

| Material | Typical Use Case for harbor freight car ramps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Loading motorcycles, ATVs, and light vehicles | Lightweight and corrosion-resistant | Limited weight capacity compared to steel | Medium |

| Steel | Heavy-duty applications for trucks and larger vehicles | High strength and durability | Heavier and prone to rust without proper maintenance | Low |

| Plastic | Light-duty applications for lawn equipment and smaller vehicles | Lightweight and cost-effective | Lower weight capacity and stability issues | Low |

| Composite | Versatile use in various environments | Resistant to corrosion and chemicals | May have higher manufacturing costs | Medium |

In conclusion, selecting the right material for car ramps is essential for ensuring safety, performance, and cost-effectiveness. International B2B buyers should carefully consider the specific needs of their applications and the environmental conditions in which the ramps will be used.

In-depth Look: Manufacturing Processes and Quality Assurance for harbor freight car ramps

What Are the Key Stages in the Manufacturing Process for Harbor Freight Car Ramps?

The manufacturing of Harbor Freight car ramps involves several critical stages that ensure durability, safety, and functionality. Understanding these stages can help B2B buyers assess the quality and reliability of the products they intend to purchase.

Material Preparation: What Types of Materials Are Used?

The first step in manufacturing car ramps is selecting the appropriate materials. Harbor Freight ramps are typically made from aluminum, steel, or high-strength plastic. Aluminum ramps are lightweight yet sturdy, making them ideal for easy transport. Steel ramps offer higher weight capacities and durability, while plastic ramps are corrosion-resistant and often used for lighter applications.

Once the materials are selected, they undergo treatment processes such as anodizing for aluminum or galvanization for steel. These processes enhance the resistance to rust and wear, extending the lifespan of the ramps and ensuring they maintain structural integrity under load.

Forming: How Are Ramps Shaped for Optimal Performance?

The forming stage involves shaping the materials into the desired ramp profiles. This is typically achieved through techniques such as extrusion for aluminum or stamping for steel. The goal is to create ramps with the right angle and surface texture to ensure traction and stability.

For instance, ramps may feature perforated surfaces or ladder-style treads to enhance grip. These design elements are essential for safety, particularly in wet or oily conditions. Additionally, the ramps are engineered to distribute weight evenly, preventing deformation during use.

Assembly: What Processes Ensure Structural Integrity?

After the individual components are shaped, they are assembled. This may involve welding, bolting, or riveting, depending on the material used. Quality control is crucial at this stage to ensure that the joints are secure and can withstand the stresses encountered during loading and unloading.

Automated assembly lines may be employed for efficiency, but manual inspection is still necessary. Skilled workers check for alignment and secure fastening, ensuring that each ramp meets the specified design criteria.

Finishing: How Is the Final Product Prepared for Market?

The finishing stage includes surface treatments and coatings that improve aesthetics and functionality. For example, ramps may be powder-coated to provide additional protection against scratches and environmental damage. This step not only enhances the visual appeal but also contributes to the longevity of the ramps.

Quality checks are conducted to ensure that the finish is uniform and free from defects. This stage is essential for meeting international standards that may require specific finish qualities, particularly for export.

What Quality Assurance Standards Are Relevant to Harbor Freight Car Ramps?

Quality assurance (QA) is a vital component of the manufacturing process for Harbor Freight car ramps. B2B buyers should be familiar with the relevant international and industry-specific standards that govern product quality.

Which International Standards Should Buyers Be Aware Of?

ISO 9001 is one of the most recognized quality management standards globally. It sets the framework for maintaining consistent quality in manufacturing processes, focusing on customer satisfaction and continuous improvement. B2B buyers can look for suppliers that hold ISO 9001 certification, indicating a commitment to quality assurance.

In addition to ISO standards, other certifications may be applicable depending on the region. For example, the CE mark in Europe signifies compliance with health, safety, and environmental protection standards, while the API (American Petroleum Institute) certification may be relevant for products used in specific industrial applications.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage assesses raw materials for compliance with specifications before production begins. Suppliers may conduct tests for material strength and composition.

-

In-Process Quality Control (IPQC): During the manufacturing process, inspections are carried out at various stages to ensure adherence to design and quality standards. This may include dimensional checks and functional tests.

-

Final Quality Control (FQC): Once the ramps are assembled, a final inspection verifies that the product meets all specifications and is free from defects. This includes load testing and safety assessments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, it’s essential to verify the quality control processes of potential suppliers to mitigate risks associated with product quality.

What Methods Can Be Used to Assess Supplier QC?

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control systems, and compliance with relevant standards. This firsthand assessment can uncover potential issues that may not be apparent through documentation alone.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes. These reports should outline the results of IQC, IPQC, and FQC activities, including any corrective actions taken in response to identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and product quality. These inspections can be particularly valuable for buyers unfamiliar with local manufacturing standards.

What Are the Quality Control Considerations for International Buyers?

When purchasing from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of certain nuances in quality control:

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers must ensure that the products meet the regulatory requirements of their own country, which may differ from those of the supplier’s country.

-

Cultural Differences: Understanding cultural norms around quality and manufacturing can impact the effectiveness of communication and collaboration. Building strong relationships with suppliers can help bridge these gaps and foster mutual understanding regarding quality expectations.

-

Logistics and Shipping: Quality assurance does not end at manufacturing. The transportation of products can affect quality, especially if not handled properly. Buyers should work with suppliers who have robust logistics processes to ensure that products arrive in optimal condition.

By gaining a thorough understanding of the manufacturing processes and quality assurance standards associated with Harbor Freight car ramps, B2B buyers can make informed purchasing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘harbor freight car ramps’

In the competitive world of automotive tools, sourcing the right car ramps from Harbor Freight is crucial for ensuring efficiency and safety in your operations. This guide offers a step-by-step checklist to assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Begin by identifying the specific requirements for your car ramps. Consider the weight capacity needed based on the types of vehicles you will service, as Harbor Freight ramps come with varying capacities, typically ranging from 1,500 lbs to 3,000 lbs or more. Additionally, assess the material (aluminum, metal, or plastic) and design features that would best suit your operational needs.

Step 2: Research and Compare Product Options

Explore the full range of car ramps available at Harbor Freight. Take note of the different types, such as loading ramps and lifting ramps, and their respective applications. Understanding the product specifications, such as length, width, and weight, will help you determine the best fit for your operations.

- Loading Ramps: Ideal for loading vehicles onto trailers, consider the incline and surface texture for safety.

- Lifting Ramps: Used for maintenance tasks, ensure they provide sufficient clearance for vehicle inspections.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet suppliers thoroughly. Request company profiles and references from other businesses that have previously sourced from Harbor Freight. Assess their track record for reliability, quality of products, and customer service.

- Check Reviews: Look for user feedback on product performance and supplier responsiveness.

- Request Samples: If feasible, obtain samples or demo units to assess quality firsthand.

Step 4: Verify Compliance with Local Regulations

Ensure that the car ramps meet any applicable safety and regulatory standards in your region. Different countries may have specific requirements regarding load capacities and materials. Compliance not only ensures safety but also protects your business from potential legal issues.

- Safety Certifications: Look for ramps with safety certifications that align with your local regulations.

- Material Standards: Ensure that materials used are suitable for the environment in which they will be used.

Step 5: Analyze Pricing and Payment Terms

Review the pricing structure and payment terms offered by the supplier. Harbor Freight generally offers competitive pricing, but it’s essential to understand the total cost of ownership, including shipping and customs duties if applicable.

- Bulk Discounts: Inquire about bulk purchasing options, which can significantly reduce costs.

- Payment Flexibility: Discuss payment terms that suit your cash flow needs, such as net 30 or net 60 terms.

Step 6: Plan for Logistics and Delivery

Once you’ve selected a supplier, coordinate logistics for the delivery of your ramps. Consider lead times, shipping methods, and any potential customs delays that may affect the arrival of your products.

- Local Shipping Providers: Identify reliable local logistics partners to facilitate smooth delivery.

- Inventory Management: Ensure you have a plan for storing the ramps upon arrival, considering space and accessibility.

Step 7: Establish a Maintenance and Inspection Routine

After procurement, develop a routine for inspecting and maintaining the ramps. Regular checks can prevent accidents and extend the lifespan of your equipment.

- User Training: Ensure that staff are trained on proper usage to maximize safety and efficiency.

- Documentation: Keep records of inspections and maintenance for accountability and compliance.

Following this checklist will ensure that you make informed decisions when sourcing Harbor Freight car ramps, enhancing your operational efficiency and safety standards in your automotive business.

Comprehensive Cost and Pricing Analysis for harbor freight car ramps Sourcing

What Are the Key Cost Components in Sourcing Harbor Freight Car Ramps?

When considering the procurement of Harbor Freight car ramps, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials—such as aluminum, steel, or plastic—affects both durability and cost. For instance, aluminum ramps are lightweight and rust-resistant but typically more expensive than their plastic counterparts.

-

Labor: Labor costs vary by region and can significantly influence the final pricing. Manufacturing locations with lower labor costs may provide a competitive edge, especially for bulk orders.

-

Manufacturing Overhead: This encompasses costs related to production facilities, utilities, and other operational expenses. Higher overhead can be indicative of quality assurance measures and advanced manufacturing processes.

-

Tooling: Initial investments in tooling for specialized ramp designs can increase upfront costs. However, these expenses are often amortized over large production runs, making them less significant on a per-unit basis for larger orders.

-

Quality Control (QC): Implementing stringent QC protocols ensures product reliability and safety. While this may add to the costs, it also enhances the product’s perceived value, particularly in markets where safety standards are paramount.

-

Logistics: Shipping costs, including freight charges and customs duties, are critical considerations, especially for international buyers. The choice of shipping method and Incoterms can affect lead times and overall costs.

-

Margin: Suppliers typically apply a profit margin to cover risks and ensure sustainability. Understanding the margin expectations can help buyers negotiate better prices.

What Influences the Pricing of Harbor Freight Car Ramps?

Several factors influence the pricing of car ramps, particularly for bulk B2B orders:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced unit pricing. Establishing a good relationship with suppliers can lead to flexible MOQ terms.

-

Specifications and Customization: Custom ramps designed for specific vehicles or applications may incur additional costs. Buyers should weigh the benefits of customization against standard options.

-

Material Quality and Certifications: Higher quality materials typically come with a higher price tag. Certifications related to safety and performance can also influence pricing, as they may require additional testing and compliance measures.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Well-established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market entry.

-

Incoterms: The chosen Incoterms can significantly impact the total landed cost. Terms such as CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can change the responsibility for shipping and insurance, thus affecting the final price.

How Can Buyers Negotiate and Ensure Cost-Efficiency?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency:

-

Negotiation Tactics: Leverage volume discounts and establish long-term relationships with suppliers to negotiate better pricing. Be prepared to discuss terms of payment and delivery to find a mutually beneficial agreement.

-

Total Cost of Ownership (TCO): Consider the TCO, which includes not just the purchase price but also maintenance, logistics, and potential resale value. A lower upfront cost may lead to higher operational costs if the ramps are of inferior quality.

-

Pricing Nuances for International Buyers: Understand the local market conditions, currency fluctuations, and economic factors that may affect pricing. Utilize local contacts or agents who can provide insights into regional pricing trends.

-

Research and Comparison: Conduct thorough market research to compare prices from different suppliers. Utilize online platforms and trade shows to gather information on available options and pricing structures.

By understanding these cost components and pricing influencers, international B2B buyers can make informed decisions when sourcing Harbor Freight car ramps, ensuring they achieve both quality and value in their procurement strategies.

Alternatives Analysis: Comparing harbor freight car ramps With Other Solutions

Understanding the Importance of Evaluating Alternatives for Car Ramps

In the automotive industry, selecting the right tools for maintenance and repair is crucial for efficiency and safety. While Harbor Freight car ramps are a popular choice due to their affordability and accessibility, several alternative solutions can also fulfill similar needs. This analysis will compare Harbor Freight car ramps with other viable options, providing insights that can help international B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Harbor Freight Car Ramps | Hydraulic Floor Jacks | Portable Car Lifts |

|---|---|---|---|

| Performance | Good for oil changes and general maintenance | Excellent for heavy lifting and vehicle stability | Versatile; suitable for various vehicle types |

| Cost | $50 – $300 | $100 – $500 | $200 – $800 |

| Ease of Implementation | Easy to set up and use | Requires more setup time | More complex; requires training |

| Maintenance | Minimal upkeep needed | Periodic hydraulic fluid checks | Requires regular maintenance |

| Best Use Case | Routine maintenance tasks | Heavy lifting and repairs | Full vehicle access and service |

Pros and Cons of Alternatives

Hydraulic Floor Jacks

Hydraulic floor jacks are a robust alternative for lifting vehicles, particularly when heavy-duty support is required. They offer superior stability compared to ramps, making them ideal for extensive repair tasks. However, they typically have a higher price point and require more time to set up. Additionally, users must be trained in their operation to ensure safety. For businesses that perform frequent heavy repairs, investing in hydraulic jacks may offer greater long-term value despite the initial cost.

Portable Car Lifts

Portable car lifts provide a versatile solution, accommodating various vehicle sizes and types. They allow for complete access to the vehicle’s underside, making them perfect for comprehensive maintenance and repairs. However, these lifts are generally more expensive and require a higher level of mechanical knowledge for safe operation. They also demand regular maintenance to keep the hydraulic systems functional. For businesses that specialize in auto repair or restoration, the investment in portable lifts can significantly enhance operational efficiency, albeit with a steeper learning curve.

Making the Right Choice: What Should B2B Buyers Consider?

When selecting the right car lifting solution, B2B buyers should evaluate their specific operational needs and budget constraints. Harbor Freight car ramps are a cost-effective choice for routine maintenance tasks, ideal for small shops or personal use. In contrast, hydraulic floor jacks and portable car lifts offer advanced capabilities for heavier tasks and full vehicle access, which may be better suited for larger automotive service centers.

Ultimately, the decision should align with the type of services offered, the volume of work expected, and the skill level of the staff. By carefully considering these factors, international B2B buyers can choose the most effective solution to enhance their automotive operations.

Essential Technical Properties and Trade Terminology for harbor freight car ramps

What Are the Key Technical Properties of Harbor Freight Car Ramps?

Understanding the technical specifications of car ramps is essential for B2B buyers to ensure they select the right products for their needs. Here are critical specifications to consider:

1. Material Composition

Car ramps are typically made from materials such as aluminum, steel, or high-density plastic. Aluminum ramps are lightweight and resistant to corrosion, making them ideal for portable applications. Steel ramps, on the other hand, offer higher weight capacities and durability but can be heavier and prone to rust if not properly coated. Buyers should assess the material based on their intended use and environmental conditions.

2. Weight Capacity

The weight capacity of a ramp is crucial and is often specified in pounds or kilograms. Common capacities range from 1,000 lbs to 3,000 lbs (450 kg to 1,360 kg). Choosing a ramp with an insufficient weight capacity can lead to safety hazards or equipment failure. B2B buyers should match the ramp’s capacity to the weight of the vehicles or equipment they will be using it with.

3. Ramp Length and Angle

The length of the ramp affects the angle of approach and the ease of loading and unloading vehicles. Longer ramps typically provide a gentler incline, reducing the risk of scraping and allowing for smoother transitions. For loading low-profile vehicles, longer ramps are essential. Buyers should consider the height of their loading surfaces to ensure compatibility.

4. Surface Design

The surface design of a ramp plays a significant role in traction and safety. Many ramps feature perforated or textured surfaces that enhance grip and reduce slippage. Buyers should evaluate the surface design based on the specific vehicles being loaded and the environmental conditions, such as wet or slippery surfaces.

5. Foldability and Portability

Some ramps are designed to be foldable, allowing for easier transport and storage. This feature is particularly beneficial for businesses that require mobility, such as those in the automotive service industry. Buyers should assess how often the ramps will be moved and stored when considering this property.

6. Safety Features

Safety features such as rubber feet or stabilizing brackets can prevent movement during use, ensuring a secure loading experience. Safety certifications or compliance with industry standards may also be important. Buyers should look for ramps that prioritize user safety, especially in high-traffic or commercial environments.

What Are the Common Trade Terms Used in the Harbor Freight Car Ramp Industry?

Familiarity with industry terminology can help B2B buyers navigate the procurement process more effectively. Here are some common terms to know:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can be crucial for sourcing high-quality ramps that meet specific requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is essential for buyers to know, as it can impact inventory management and purchasing decisions. Understanding MOQ helps in planning orders that align with business needs.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit pricing and terms from suppliers. It is a critical step in the procurement process, allowing buyers to compare offers and make informed decisions based on pricing and terms.

4. Incoterms (International Commercial Terms)

These are international rules that define the responsibilities of buyers and sellers in global trade. Familiarity with Incoterms can help businesses understand shipping costs, risks, and responsibilities when importing ramps from manufacturers in different countries.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for inventory planning and ensuring that the ramps are available when needed for operations.

6. Certifications

Many ramps may come with industry-specific certifications that indicate compliance with safety and quality standards. Buyers should look for certifications that align with local regulations and industry best practices to ensure product reliability.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing Harbor Freight car ramps, ensuring they meet operational needs and safety standards.

Navigating Market Dynamics and Sourcing Trends in the harbor freight car ramps Sector

What Are the Key Trends Shaping the Harbor Freight Car Ramps Market?

The market for harbor freight car ramps is experiencing significant growth driven by several global factors. As automotive maintenance and DIY vehicle repair gain traction, especially in emerging markets in Africa and South America, the demand for reliable and cost-effective car ramps is surging. Increased vehicle ownership and a growing middle class in these regions are contributing to a heightened interest in automotive tools. Additionally, the rise of e-commerce is transforming how international buyers source these products, allowing for greater access to a wide range of options from different suppliers.

Emerging technologies, such as smart logistics and advanced inventory management systems, are enhancing sourcing efficiency for B2B buyers. These innovations enable companies to streamline their procurement processes, ensuring timely deliveries and reducing costs. Furthermore, customization options are becoming increasingly popular, allowing buyers to select ramps tailored to specific vehicle types and weights, enhancing safety and usability.

Market dynamics are also influenced by regional preferences. For instance, European buyers often prioritize quality and safety certifications, while Middle Eastern buyers may focus on durability due to harsher environmental conditions. Understanding these regional nuances is crucial for international buyers looking to optimize their sourcing strategies.

How Important Is Sustainability and Ethical Sourcing in the Harbor Freight Car Ramps Market?

Sustainability and ethical sourcing are becoming paramount in the procurement of harbor freight car ramps. As global awareness of environmental issues rises, buyers are increasingly seeking products that minimize ecological impact. This includes the use of recyclable materials and sustainable manufacturing processes. For instance, ramps made from aluminum or high-strength plastics not only offer durability but also align with eco-friendly initiatives.

Ethical supply chains are equally important, as buyers look to partner with manufacturers who prioritize fair labor practices and responsible sourcing. Certifications such as ISO 14001 for environmental management and Fair Trade accreditation can enhance a company’s reputation and appeal to socially conscious consumers.

Investing in ‘green’ certifications and materials not only meets regulatory requirements but also provides a competitive edge in a market that values sustainability. B2B buyers should evaluate potential suppliers based on their environmental impact and ethical practices to align with global sustainability goals.

How Has the Harbor Freight Car Ramps Market Evolved Over Time?

The evolution of the harbor freight car ramps market can be traced back to the increasing need for efficient vehicle maintenance solutions. Initially, the market was dominated by heavy and cumbersome steel ramps, which posed safety risks and were difficult to handle. However, advancements in materials science led to the introduction of lightweight yet robust alternatives, such as aluminum ramps, which offer enhanced portability and ease of use.

Over the years, the design of car ramps has also improved, incorporating features like perforated treads for better traction and safety mechanisms to prevent slippage. The rise of the DIY culture and the growing popularity of automotive maintenance forums have further driven innovation, with manufacturers responding to consumer feedback to refine their products.

As the market continues to grow, the focus is shifting toward incorporating technology in ramp design, such as smart sensors that can assess weight capacity and stability, ensuring a safer experience for users. This trajectory indicates a promising future for harbor freight car ramps, where functionality meets technological advancement.

Frequently Asked Questions (FAQs) for B2B Buyers of harbor freight car ramps

-

How do I determine the right capacity for Harbor Freight car ramps?

When selecting car ramps, it’s essential to match the ramp’s weight capacity with the heaviest vehicle you intend to use. Harbor Freight offers ramps with varying capacities, ranging from 1,000 lbs to over 3,000 lbs. For optimal safety, consider the total weight of the vehicle, including any additional cargo. Always refer to the manufacturer’s specifications to ensure that the ramps can support your specific applications, especially in commercial settings where durability is critical. -

What is the best type of Harbor Freight car ramp for loading vehicles?

The best type of ramp depends on the vehicle and the loading situation. For lighter vehicles, loading ramps made from aluminum or steel with a capacity of 1,000 to 1,500 lbs are sufficient. However, for heavier vehicles or frequent use, consider heavy-duty steel ramps that can support 3,000 lbs or more. Additionally, features like non-slip surfaces and adjustable heights enhance safety and usability, making them ideal for B2B applications in automotive repair and logistics. -

What should I consider when sourcing Harbor Freight car ramps internationally?

When sourcing internationally, consider factors such as compliance with local regulations, shipping costs, and import duties. It’s crucial to verify that the ramps meet safety standards in your region. Additionally, understanding the warranty and return policies can mitigate risks associated with international purchases. Partnering with a reputable distributor can also facilitate smoother transactions and provide local support for any issues that arise post-purchase. -

How can I vet suppliers for Harbor Freight car ramps?

To vet suppliers, start by researching their reputation in the industry. Look for reviews and testimonials from other B2B buyers. Verify their certifications and adherence to safety standards, as this ensures product quality. Request references and conduct background checks to assess their reliability and service history. Establishing communication and asking detailed questions can also provide insight into their customer service and responsiveness. -

What are the typical minimum order quantities (MOQ) for Harbor Freight car ramps?

Minimum order quantities can vary significantly among suppliers. Generally, for bulk purchases of Harbor Freight car ramps, MOQs may range from 10 to 50 units, depending on the supplier’s policies and product availability. Discussing your specific needs with the supplier can lead to customized arrangements, especially for larger orders, which may also provide cost advantages through bulk pricing. -

What payment terms should I expect when purchasing Harbor Freight car ramps?

Payment terms can vary widely based on the supplier’s policies and the nature of your business relationship. Common terms include payment upon order, a deposit upfront with the balance due before shipping, or net 30/60 days after delivery. Ensure to clarify these terms before finalizing the transaction and consider negotiating terms that align with your cash flow requirements, especially for larger orders. -

How do I ensure quality assurance for my Harbor Freight car ramps?

To ensure quality assurance, request detailed product specifications and certifications from the supplier. Conduct regular inspections upon receipt of the ramps and before use to check for any damage or defects. Establishing a quality control process that includes both pre-shipment inspections and in-use assessments can help maintain product integrity and safety, which is particularly important in commercial applications. -

What logistics considerations should I keep in mind when importing Harbor Freight car ramps?

When importing, consider shipping methods, lead times, and potential delays at customs. Choosing a reliable logistics partner familiar with international shipping can streamline the process. Additionally, be mindful of packaging to prevent damage during transit, and ensure that all necessary documentation is prepared to facilitate smooth customs clearance. Understanding local import regulations can also help avoid unexpected costs and delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Harbor Freight Car Ramps Manufacturers & Suppliers List

1. Harbor Freight – Car Ramps

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Harbor Freight car ramps are available in plastic and metal options. Users report that the plastic ramps are reliable and have been used for multiple oil changes without feeling unsafe. Some users recommend using wheel chocks and emergency brakes for added safety. However, there are mixed opinions, with some users expressing concerns about the reliability of plastic ramps compared to wooden ramps….

2. Harbor Freight – Pittsburgh Plastic Car Ramps

Domain: torquenews.com

Registered: 2010 (15 years)

Introduction: Harbor Freight’s Pittsburgh plastic car ramps are priced at $60 and were rated as the number one winner in a car ramp comparison test. However, the review indicated that none of the ramps tested, including those from Harbor Freight, were recommended for safe use. Key concerns included potential slipping while driving onto the ramp, the use of lightweight materials, the possibility of the car being…

3. CivicX – Harbor Freight Pittsburgh Automotive Ramps

Domain: civicx.com

Registered: 2015 (10 years)

Introduction: Harbor Freight Pittsburgh automotive ramps, priced at $45, are discussed in relation to their compatibility with the 10th generation Honda Civic Si at stock height. Users confirm that while the ramps work, there is a risk of scraping the two tabs on the bottom of the bumper. Alternatives mentioned include using boards for additional height and custom ramps for better clearance.

4. Harbor Freight – Vehicle Maintenance Ramps

Domain: tacomaworld.com

Registered: 2006 (19 years)

Introduction: Harbor Freight ramps are mentioned as a potential option for vehicle maintenance. Concerns about their safety are raised, with references to past incidents of collapse. Alternatives suggested include Rhino ramps and jack stands from Walmart. The discussion highlights the importance of using multiple safety devices when working under vehicles.

5. PITTSBURGH AUTOMOTIVE – 6500 lb. Capacity Portable Ramp Set

Domain: go.harborfreight.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “PITTSBURGH AUTOMOTIVE 6500 lb. Capacity Portable Ramp Set, 2-Piece”, “price”: “$49.99”, “coupon_code”: “36522551”, “expiration_date”: “6/6/2024”, “item_number”: “63956”, “capacity”: “6500 lb.”, “maximum_lift_height”: “6 inches”, “comparison_price”: “$59.99”, “comparison_model”: “IRONTON 60358”, “savings_percentage”: “16%”, “rating”: “5-star”}

6. Harbor Freight – 2PCS Hydraulic Car Ramps

Domain: lundeenanimalhospital.com

Registered: 2021 (4 years)

Introduction: {“product_name”: “Harbor Freight 2PCS Hydraulic Car Ramps”, “weight_capacity”: “5T (10000lbs)”, “type”: “Low Pro-File”}

7. Harbor Freight – Auto Ramp Sets

Domain: ssforums.com

Registered: 2005 (20 years)

Introduction: Harbor Freight ramps discussed include: 1. Solid Steel Auto Ramp Set (item #63250) 2. 13000 lb Portable Vehicle Ramp Set (item #63956). Users express concerns about low vehicle clearance with these ramps, suggesting alternatives like Race Ramps RR-56 for lower vehicles. Some users have had success using Rhino ramps with modifications, while others recommend investing in higher-quality race ramps f…

Strategic Sourcing Conclusion and Outlook for harbor freight car ramps

As international B2B buyers increasingly seek reliable automotive solutions, the strategic sourcing of Harbor Freight car ramps emerges as a vital component of efficient operations. These ramps, available in various designs and weight capacities, cater to diverse needs—from loading vehicles to facilitating maintenance tasks. Their affordability and robust construction make them an attractive option for businesses in regions such as Africa, South America, the Middle East, and Europe.

To maximize value, buyers should consider the specific applications and material types that best suit their operational requirements. The versatility of aluminum, metal, and plastic ramps allows for tailored solutions based on vehicle types and maintenance needs. Furthermore, prioritizing safety features and stability can significantly enhance operational efficiency and reduce workplace injuries.

Looking ahead, the growing demand for quality automotive tools presents a compelling opportunity for B2B partnerships. By leveraging strategic sourcing practices, businesses can secure high-quality Harbor Freight ramps that align with their operational goals. We encourage buyers to explore these options and consider how integrating these reliable tools can streamline their processes and drive success in their respective markets.