Gato Para Carro: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for gato para carro

In the competitive landscape of automotive equipment, sourcing the right gato para carro (car jack) can pose significant challenges for B2B buyers. With a myriad of options available, ranging from hydraulic floor jacks to compact bottle jacks, understanding the nuances of each type is critical. This guide offers a thorough exploration of the global market for car jacks, addressing essential considerations such as product types, applications, supplier vetting processes, and cost implications.

International buyers, particularly those from Africa, South America, the Middle East, and Europe—regions with diverse automotive needs—will find actionable insights tailored to their unique market dynamics. The comprehensive nature of this guide is designed to empower you in making informed purchasing decisions, ensuring that you not only select the right products but also establish fruitful relationships with reliable suppliers.

As you navigate this guide, you will gain clarity on the various functionalities of car jacks, enabling you to match specific products with your operational requirements. Whether you are enhancing your product portfolio or seeking to optimize your supply chain, this resource serves as a valuable tool in your sourcing strategy, fostering confidence and efficiency in your procurement processes.

Understanding gato para carro Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic Floor Jack | Operates using hydraulic fluid; typically has a low profile for easy access | Automotive repair shops, garages | Pros: High lifting capacity, stable base. Cons: Heavier and less portable. |

| Bottle Jack | Compact design; uses a hydraulic mechanism, often with a higher lifting capacity | Construction, heavy machinery maintenance | Pros: High lifting power, space-efficient. Cons: Limited lifting height, can be unstable. |

| Scissor Jack | Manual operation; compact and lightweight; often included with vehicles | Roadside assistance, emergency kits | Pros: Lightweight, easy to store. Cons: Lower lifting capacity, requires more physical effort. |

| Off-Road Jack | Designed for rugged terrains; often features a larger base and higher lift range | Off-road vehicle repair, outdoor events | Pros: Versatile for uneven surfaces, durable. Cons: Bulkier, may require more storage space. |

| Transmission Jack | Specialized for lifting transmissions; typically features adjustable arms | Automotive repair, specialized workshops | Pros: Precision lifting, safe for heavy components. Cons: Limited to specific tasks, usually more expensive. |

What Are the Key Characteristics of a Hydraulic Floor Jack?

Hydraulic floor jacks are favored in automotive repair settings due to their ability to lift heavy vehicles effortlessly. They utilize hydraulic fluid to generate lifting power, allowing for a stable and controlled lift. This type of jack is ideal for garages and repair shops where heavy lifting is routine. When purchasing, consider the weight capacity, height range, and durability, ensuring it meets the specific demands of your operations.

How Does a Bottle Jack Compare to Other Types?

Bottle jacks are compact and powerful, making them suitable for construction and heavy machinery maintenance. They are often used in scenarios where space is limited, yet high lifting capacity is required. While they provide significant lifting power, buyers should be aware of their limitations in height and stability, particularly on uneven surfaces. Evaluating the weight and size in relation to your operational space is crucial for effective purchasing.

Why Choose a Scissor Jack for Emergency Situations?

Scissor jacks are lightweight and easy to store, making them a common choice for emergency roadside assistance. Their manual operation means they do not rely on power sources, enhancing reliability in unexpected situations. However, their lower lifting capacity and the physical effort required to operate them should be considered, especially for businesses that frequently assist vehicles in distress.

What Makes an Off-Road Jack Essential for Rugged Terrain?

Off-road jacks are specifically designed for use on uneven surfaces, making them indispensable for off-road vehicle repairs. They usually feature a larger base for stability and a higher lift range to accommodate various vehicle heights. While they offer versatility and durability, their bulkiness may require additional storage considerations. Businesses involved in outdoor events or off-road vehicle repairs should prioritize this type for its specialized functionality.

How Can a Transmission Jack Benefit Automotive Workshops?

Transmission jacks are tailored for lifting transmissions and similar components, featuring adjustable arms for precise lifting. They are essential for automotive workshops that handle transmission repairs, ensuring safety during heavy lifts. However, their specialized nature means they may be more expensive and limited to specific tasks. Assessing the volume of transmission work in your operations can help justify the investment in this type of jack.

Key Industrial Applications of gato para carro

| Industry/Sector | Specific Application of gato para carro | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Lifting vehicles for maintenance and repairs | Increases efficiency and safety during vehicle servicing | Durability, load capacity, and compatibility with various vehicle types |

| Construction | Supporting heavy machinery and equipment | Enhances productivity and reduces downtime | Weight capacity, stability, and ease of transport |

| Logistics and Transport | Assisting in loading and unloading operations | Streamlines operations and minimizes handling injuries | Portability, lifting height, and safety features |

| Agriculture | Elevating agricultural equipment for servicing | Reduces maintenance time and increases equipment lifespan | Terrain adaptability, load capacity, and ease of use |

| Mining | Supporting machinery maintenance and repairs | Ensures operational efficiency and worker safety | Robustness, load capacity, and resistance to harsh environments |

How is ‘gato para carro’ utilized in the automotive repair industry?

In the automotive repair sector, a ‘gato para carro’ is essential for lifting vehicles during maintenance and repairs. Mechanic shops rely on hydraulic jacks to facilitate tire changes, brake repairs, and undercarriage inspections. The efficiency gained through the use of these jacks reduces service time and enhances safety by providing a stable lifting solution. International buyers should consider durability and load capacity to accommodate various vehicle sizes and types, particularly in regions with diverse automotive fleets.

What role does ‘gato para carro’ play in construction projects?

In construction, ‘gato para carro’ serves as a reliable solution for lifting heavy machinery and equipment during installation and maintenance tasks. This application is critical for enhancing productivity, as it allows workers to safely access machinery for repairs without extensive downtime. Buyers in this sector should prioritize jacks with high weight capacities and stability to handle the rigors of construction sites, especially in regions with varying terrain and equipment types.

How does ‘gato para carro’ benefit logistics and transport operations?

Logistics and transport companies utilize ‘gato para carro’ for loading and unloading operations, particularly when dealing with heavy cargo. These jacks streamline the handling process, reducing the risk of workplace injuries associated with manual lifting. For B2B buyers in this industry, key considerations include the jack’s portability, lifting height, and safety features to ensure compliance with international safety standards.

In what ways is ‘gato para carro’ significant for agricultural applications?

In agriculture, ‘gato para carro’ assists in elevating agricultural equipment for maintenance, such as tractors and harvesters. This application minimizes downtime during critical planting and harvesting seasons, ultimately leading to higher productivity. Buyers should focus on jacks that are adaptable to various terrains and have sufficient load capacities to support heavy machinery, particularly in rural areas where equipment reliability is paramount.

Why is ‘gato para carro’ crucial in mining operations?

In the mining industry, ‘gato para carro’ is employed for the maintenance of heavy machinery, ensuring that equipment remains operational and safe for workers. This application is vital for operational efficiency and worker safety, as machinery failures can lead to costly delays. Buyers should consider jacks that are robust and capable of withstanding harsh environments, as well as those with high load capacities to meet the demands of heavy mining equipment.

Illustrative image related to gato para carro

3 Common User Pain Points for ‘gato para carro’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right ‘Gato para Carro’ for Different Vehicle Types

The Problem: Many B2B buyers struggle with selecting the appropriate type of ‘gato para carro’ (car jack) for the diverse range of vehicles in their fleet. For instance, a company managing a mixed fleet of cars, SUVs, and trucks may find it challenging to determine which jacks are suitable for each vehicle type. This can lead to purchasing the wrong equipment, which not only wastes money but also jeopardizes safety during maintenance tasks.

The Solution: To effectively address this issue, B2B buyers should conduct a thorough analysis of their vehicle specifications, including weight and clearance levels. It’s crucial to categorize vehicles into different segments based on their weight class and operational needs. Once categorized, buyers should look for jacks that explicitly indicate compatibility with their vehicle types, such as hydraulic floor jacks for sedans and bottle jacks for heavier vehicles like trucks. Additionally, sourcing from reputable suppliers that provide detailed product specifications and recommendations can ensure informed purchasing decisions. Using a standardized checklist during procurement can streamline the selection process, ensuring that the right jack is chosen for each vehicle type.

Scenario 2: Safety Concerns Regarding Jack Stability and Load Capacity

The Problem: Safety is a paramount concern for B2B buyers when it comes to using ‘gato para carro’. Many buyers may overlook the importance of load capacity and stability features, especially when dealing with heavier vehicles. The risk of accidents due to jack failure can lead to significant liability issues and harm workers, making it essential to prioritize safety in equipment selection.

The Solution: B2B buyers should prioritize jacks that come with comprehensive safety features, such as safety locks and wide bases for enhanced stability. It is advisable to always purchase jacks with a load capacity exceeding the weight of the heaviest vehicle in the fleet. Buyers can also implement a regular maintenance schedule for their jacks, including inspections for wear and tear, which is critical for maintaining safety standards. Training employees on proper jack usage, including weight distribution and jack placement, can further minimize risks. Collaborating with suppliers who provide detailed safety guidelines and usage instructions will enhance overall safety awareness.

Scenario 3: Challenges with Portability and Storage of Jacks

The Problem: For businesses that operate in various locations or have limited storage space, the bulkiness and weight of traditional jacks can present significant logistical challenges. B2B buyers often find themselves needing jacks that are easy to transport and store without sacrificing functionality, which can be a balancing act.

The Solution: To navigate this challenge, buyers should consider lightweight, compact jack options that do not compromise on performance. Portable jacks, such as aluminum floor jacks or scissor jacks, offer a great solution due to their ease of transport and storage efficiency. When evaluating options, buyers should look for models with foldable designs and integrated carrying handles. Additionally, creating a designated storage area that maximizes vertical space can enhance organization and accessibility. Engaging with suppliers who specialize in innovative, space-saving designs can also provide buyers with the flexibility they need in their operations. Providing training to staff on efficient packing and unpacking techniques will further streamline operations and enhance productivity.

Strategic Material Selection Guide for gato para carro

What Are the Key Materials Used in Manufacturing Gato para Carro?

When selecting materials for ‘gato para carro’ (car jacks), it is essential to consider their properties, advantages, disadvantages, and suitability for various applications. Here, we analyze four common materials used in the manufacturing of car jacks: steel, aluminum, composite materials, and plastic. Each material has unique characteristics that can influence the performance and marketability of the product.

How Does Steel Perform as a Material for Gato para Carro?

Steel is the most widely used material for car jacks due to its high strength and durability. It typically has excellent temperature and pressure ratings, making it suitable for heavy-duty applications. Steel jacks can withstand significant loads without deformation, which is crucial for safety.

Pros: Steel jacks are highly durable and resistant to wear and tear. They are generally less expensive than other materials, making them cost-effective for manufacturers. Additionally, steel can be easily sourced and formed into various shapes.

Cons: However, steel is prone to corrosion if not properly treated or coated, which can limit its lifespan, especially in humid or salty environments. The manufacturing process can also be complex, requiring more energy and resources compared to lighter materials.

Impact on Application: Steel jacks are compatible with most automotive fluids, making them versatile for various applications. However, international buyers should ensure compliance with standards such as ASTM for structural integrity.

What Advantages Does Aluminum Offer for Gato para Carro?

Aluminum is increasingly popular in the automotive industry due to its lightweight properties and resistance to corrosion. It typically has a lower density than steel, which can be advantageous for portable jacks.

Pros: Aluminum jacks are easier to transport and handle, making them ideal for emergency kits and mobile repair services. They are also resistant to rust, which is beneficial in regions with high humidity or coastal climates.

Cons: The main drawback of aluminum is its lower load-bearing capacity compared to steel, which may limit its use in heavy-duty applications. Additionally, aluminum tends to be more expensive, impacting the overall cost of the product.

Impact on Application: Aluminum jacks are suitable for lighter vehicles and applications where weight is a crucial factor. Buyers in regions like Europe, where lightweight materials are favored, may prefer aluminum options.

How Do Composite Materials Enhance Gato para Carro Performance?

Composite materials, which often combine plastics and fibers, are gaining traction in the automotive sector for their lightweight and high-strength properties. These materials can be engineered to meet specific performance criteria.

Pros: Composites offer excellent corrosion resistance and can be molded into complex shapes, providing design flexibility. They are also lightweight, which enhances portability.

Cons: However, composites can be more expensive to manufacture and may require specialized production techniques. Their load-bearing capacity can also vary significantly based on the specific formulation used.

Impact on Application: Composites are suitable for applications where weight reduction is essential, such as in racing or high-performance vehicles. International buyers should consider compliance with local standards for composite materials.

What Role Does Plastic Play in Gato para Carro Manufacturing?

Plastic is often used in non-load-bearing components of car jacks, such as handles or casings. It is lightweight and can be produced at a low cost.

Pros: The primary advantage of plastic is its low cost and ease of manufacturing. It can be molded into intricate shapes and is resistant to many chemicals.

Cons: However, plastics typically have lower strength and durability compared to metals, which limits their use in critical load-bearing applications. They can also degrade under UV exposure, impacting longevity.

Impact on Application: Plastic components can enhance user experience by reducing weight but should be used cautiously in structural applications. Buyers should ensure that plastics meet relevant safety standards.

Illustrative image related to gato para carro

Summary Table of Material Selection for Gato para Carro

| Material | Typical Use Case for gato para carro | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty jacks | High strength and durability | Prone to corrosion | Low |

| Aluminum | Portable jacks | Lightweight and corrosion-resistant | Lower load capacity | Med |

| Composite | High-performance jacks | Design flexibility and lightweight | Higher manufacturing costs | High |

| Plastic | Non-load-bearing components | Low cost and easy to mold | Low strength and durability | Low |

This analysis provides B2B buyers with essential insights into material selection for ‘gato para carro,’ helping them make informed purchasing decisions based on performance, cost, and application suitability.

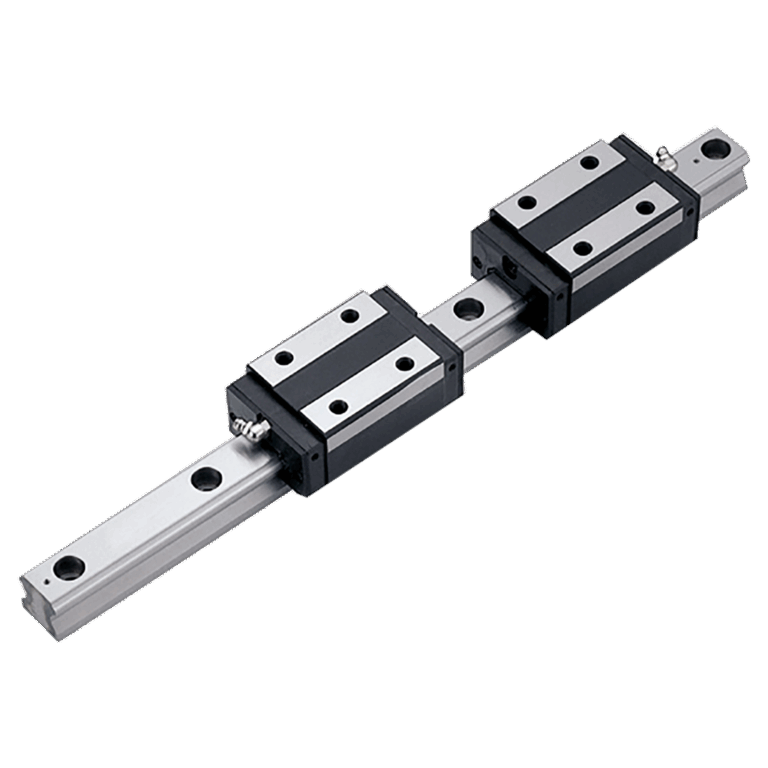

In-depth Look: Manufacturing Processes and Quality Assurance for gato para carro

What Are the Key Stages in the Manufacturing Process of Gato para Carro?

The manufacturing process of a gato para carro (car jack) typically encompasses several critical stages, each contributing to the overall quality and reliability of the product.

1. Material Preparation

The initial stage involves selecting the right materials, which are crucial for the jack’s strength and durability. Common materials include high-grade steel for structural integrity and aluminum for lightweight designs. Suppliers must ensure that the raw materials meet international standards such as ASTM or EN specifications. This stage often includes:

Illustrative image related to gato para carro

- Material Inspection: Verification of the quality and specifications of incoming materials.

- Cutting and Shaping: Raw materials are cut to size and shaped using techniques such as laser cutting or stamping, which ensures precision.

2. Forming and Machining

After preparation, the forming process begins. This involves several methods such as:

- Forging: Used for components that require high strength, where metal is heated and shaped under pressure.

- Casting: Suitable for complex shapes, where molten metal is poured into molds.

Machining processes like milling, turning, and drilling follow to create precise dimensions and features. CNC (Computer Numerical Control) machines are commonly employed for high accuracy.

3. Assembly

The assembly stage is where different components come together. This can include:

- Welding: For joining parts, particularly in hydraulic jacks where strength is paramount.

- Bolting and Screwing: For parts that may need to be disassembled for maintenance.

Robotics and automated systems are increasingly used in assembly lines to improve consistency and reduce human error.

4. Finishing

Finishing processes enhance the aesthetic and protective qualities of the jack. This includes:

- Surface Treatment: Processes like powder coating or galvanizing provide corrosion resistance and durability.

- Quality Inspection: Each finished product undergoes visual inspections and may be subjected to testing to ensure it meets design specifications.

How is Quality Assurance Implemented in Gato para Carro Manufacturing?

Quality assurance (QA) is integral to the manufacturing of gato para carro, ensuring that each product is safe and effective. Various international and industry-specific standards guide this process.

Relevant International Standards for Quality Assurance

B2B buyers should be aware of various standards that influence the quality of car jacks:

- ISO 9001: This standard focuses on quality management systems and is applicable across industries. Manufacturers adhering to ISO 9001 demonstrate a commitment to consistent quality and continuous improvement.

- CE Marking: In Europe, products must meet health, safety, and environmental protection standards, making CE marking essential for compliance.

- API Standards: For hydraulic jacks, API (American Petroleum Institute) standards may apply, ensuring that products meet specific safety and performance criteria.

What Are the QC Checkpoints in Gato para Carro Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to catch defects early and ensure compliance with standards.

1. Incoming Quality Control (IQC)

At this stage, raw materials are inspected upon arrival. This includes:

- Material Certification: Verifying that materials meet specified standards.

- Visual and Dimensional Checks: Ensuring there are no visible defects or discrepancies in dimensions.

2. In-Process Quality Control (IPQC)

During manufacturing, ongoing inspections are crucial:

- Process Monitoring: Regular checks during machining and assembly help catch issues before they escalate.

- Dimensional Verification: Parts are measured against specifications at various points in the process.

3. Final Quality Control (FQC)

Once production is complete, a thorough inspection occurs:

- Functional Testing: Jacks are tested for lifting capacity and stability.

- Safety Checks: Verification that safety features are functional and meet regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control practices of suppliers is essential for ensuring product reliability.

1. Supplier Audits

Conducting audits is a proactive approach to assessing a supplier’s quality management system. Buyers should look for:

- Documentation Review: Ensuring suppliers maintain detailed records of their QC processes.

- Facility Inspection: Visiting the manufacturing site to observe operations firsthand.

2. Quality Reports

Requesting quality assurance reports can provide insights into a supplier’s performance over time. This may include:

- Defect Rates: Historical data on product defects can indicate reliability.

- Compliance Certifications: Proof of adherence to relevant standards, such as ISO 9001 or CE.

3. Third-Party Inspections

Engaging third-party inspection services offers an independent assessment of a supplier’s quality practices. These services can conduct:

- Random Sampling: Testing a selection of products for compliance with specifications.

- Certification Verification: Ensuring that suppliers hold necessary certifications for international trade.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing gato para carro from international suppliers, buyers must navigate various quality control nuances, particularly in regions like Africa, South America, the Middle East, and Europe.

1. Regional Standards and Compliance

Different regions may have unique regulatory requirements. For instance, European markets may demand more stringent compliance with CE standards, while Middle Eastern buyers might require adherence to local safety regulations. Understanding these nuances is crucial for ensuring market acceptance.

2. Cultural Considerations in Quality Assurance

Cultural attitudes towards quality and compliance can vary significantly. In some regions, there may be a greater emphasis on face-to-face relationships and trust, while in others, documented processes and certifications may be prioritized. Building strong relationships with suppliers can facilitate better communication regarding quality expectations.

3. Logistics and Supply Chain Management

Lastly, logistical challenges can impact quality control. Delays in shipping or variations in handling can affect product quality upon arrival. Buyers should consider working with suppliers who have robust logistics and quality management systems to mitigate these risks.

Illustrative image related to gato para carro

In summary, understanding the manufacturing processes and quality assurance practices for gato para carro is crucial for B2B buyers. By focusing on the key stages of production, relevant standards, and effective verification methods, buyers can make informed decisions that ensure product reliability and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gato para carro’

Introduction

Sourcing the right ‘gato para carro’ (car jack) is crucial for businesses involved in automotive repairs, maintenance, or manufacturing. This practical checklist is designed to guide B2B buyers through the key steps to ensure they procure high-quality, reliable jacks that meet their specific operational needs. By following these steps, you can minimize risks and maximize value in your purchasing decisions.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements of the jacks you need, including load capacity, type (hydraulic, bottle, scissor), and intended use (e.g., for cars, SUVs, or heavy-duty vehicles). This step is essential because different applications require different jack specifications.

- Load Capacity: Ensure the jack can support the weight of the vehicles in your fleet.

- Type of Jack: Choose between hydraulic, mechanical, or pneumatic options based on your operational workflow.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers who specialize in ‘gato para carro.’ Look for manufacturers or distributors with a solid reputation in the market. This research is critical to finding reliable partners who can deliver quality products on time.

- Industry Experience: Prioritize suppliers with a proven track record in the automotive sector.

- Product Range: Ensure they offer a variety of jacks to meet diverse needs.

Step 3: Evaluate Potential Suppliers

Before making any commitments, assess potential suppliers thoroughly. Request company profiles, product catalogs, and customer testimonials to gauge their reliability and quality of service.

- References: Ask for references from other B2B clients who have purchased similar products.

- Case Studies: Review case studies to understand how they have supported other businesses.

Step 4: Verify Compliance with Standards

Ensure that the jacks comply with relevant safety and quality standards in your region. This step is essential to mitigate risks associated with product failures that could lead to injuries or damages.

- Certifications: Check for ISO or other relevant certifications that verify quality control processes.

- Safety Standards: Confirm compliance with local safety regulations, especially in high-risk environments.

Step 5: Request Samples or Demonstrations

Whenever possible, request samples or arrange for demonstrations of the jacks. This allows you to assess the product’s quality and usability before making a bulk purchase.

- Hands-On Evaluation: Test the jacks under realistic conditions to ensure they meet your operational needs.

- Feedback from Technicians: Involve your maintenance staff in the evaluation to get their insights on usability.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, negotiate pricing, payment terms, and delivery schedules. This step is vital to ensure that you receive the best possible deal while maintaining a solid business relationship.

Illustrative image related to gato para carro

- Volume Discounts: Inquire about discounts for bulk purchases or long-term contracts.

- Payment Flexibility: Discuss payment terms that align with your cash flow needs.

Step 7: Establish a Quality Assurance Process

After procurement, set up a quality assurance process to monitor the performance of the jacks in your operations. This ongoing assessment is crucial for maintaining safety and efficiency in your workflows.

- Regular Inspections: Implement a schedule for regular inspections to identify any issues promptly.

- Feedback Loop: Create a feedback mechanism for your team to report any problems or suggestions for improvement.

By following this checklist, you can streamline the sourcing process for ‘gato para carro’ and ensure that your business is equipped with reliable, high-quality tools to support your operations.

Comprehensive Cost and Pricing Analysis for gato para carro Sourcing

Analyzing the cost structure and pricing for sourcing “gato para carro” (car jacks) involves understanding various components that contribute to the overall expense and factors influencing market prices. This information is essential for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Sourcing Gato Para Carro?

When evaluating the cost structure for car jacks, several key components come into play:

-

Materials: The primary materials used in manufacturing car jacks include steel, aluminum, and hydraulic components. The choice of materials directly impacts the durability and weight capacity of the jack. Higher quality materials generally lead to increased costs.

-

Labor: Labor costs vary significantly depending on the manufacturing location. In regions with higher wages, such as Western Europe, labor costs will be more substantial compared to areas in Southeast Asia or Eastern Europe.

-

Manufacturing Overhead: This encompasses costs associated with facility operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thus lowering overall costs.

-

Tooling: Investment in specialized tooling for production can be significant. This cost is often amortized over the production run, making it crucial for buyers to consider the volume of their orders.

-

Quality Control (QC): Ensuring that each jack meets safety and performance standards can incur additional costs. Certifications and testing can add to the initial expense but are essential for maintaining product integrity.

-

Logistics: Transportation costs, including freight and insurance, can vary based on distance and shipping methods. Incoterms also play a crucial role in determining who bears these costs.

-

Margin: Suppliers will factor in their profit margins, which can fluctuate based on market competition and demand.

How Do Price Influencers Affect Gato Para Carro Pricing?

Several factors influence the pricing of car jacks in the B2B market:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Larger orders often lead to volume discounts, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Custom features, such as enhanced lifting capacity or unique designs, can increase costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and compliance with international safety standards can lead to premium pricing. Buyers should ensure that the certifications align with their market requirements.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more due to their proven track record and superior service.

-

Incoterms: Different shipping terms can lead to variations in total costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital for accurate cost estimation.

What Are the Best Buyer Tips for Sourcing Gato Para Carro?

Navigating the complexities of sourcing car jacks requires strategic planning. Here are some essential tips for buyers:

-

Negotiation: Always negotiate prices and terms with suppliers. Building a relationship can lead to better deals and future discounts.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance costs, and potential replacement expenses. This approach helps buyers make informed decisions.

-

Pricing Nuances for International Markets: Understand the economic and regulatory environment in the target market. For example, import tariffs in South America or compliance regulations in Europe can significantly impact overall costs.

-

Disclaimer for Indicative Prices: It’s important to remember that prices can fluctuate based on market conditions, supplier changes, and raw material availability. Always seek updated quotes before finalizing any orders.

By carefully analyzing these components and factors, international B2B buyers can make informed decisions when sourcing “gato para carro,” ensuring they achieve the best value for their investments.

Alternatives Analysis: Comparing gato para carro With Other Solutions

Understanding Alternatives to Gato Para Carro

When it comes to lifting vehicles for repairs or maintenance, ‘gato para carro’ (car jack) is a widely utilized tool. However, various alternative solutions exist that can offer similar functionalities, each with its unique advantages and drawbacks. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational needs, budget constraints, and performance expectations.

Comparison Table

| Comparison Aspect | Gato Para Carro | Hydraulic Lift Table | Pneumatic Jack |

|---|---|---|---|

| Performance | Effective for small to medium vehicles; limited height | Excellent for larger vehicles; customizable height | Fast lifting; high weight capacity |

| Cost | Generally affordable (varies by type) | Higher initial investment | Moderate to high cost |

| Ease of Implementation | Simple to use; requires minimal training | Requires space and setup | Needs compressed air source; training may be needed |

| Maintenance | Low; occasional lubrication needed | Moderate; regular checks required | Higher; air system maintenance needed |

| Best Use Case | General automotive repairs and maintenance | Professional auto shops; heavy-duty use | Racing environments; quick tire changes |

Detailed Breakdown of Alternatives

Hydraulic Lift Table

Hydraulic lift tables are robust devices designed to lift vehicles for extensive repairs and servicing. They provide a stable platform and can be adjusted to various heights, making them ideal for professional auto shops. The primary advantage of hydraulic lifts is their ability to handle larger vehicles and offer a safer working environment due to the stability they provide. However, they come with a higher initial cost and require significant space, which may not be feasible for smaller operations. Additionally, they necessitate regular maintenance checks to ensure safe operation.

Illustrative image related to gato para carro

Pneumatic Jack

Pneumatic jacks utilize compressed air to lift vehicles quickly, making them a popular choice in racing environments where speed is essential for quick tire changes. The main advantage is their rapid lifting capability and high weight capacity, which can accommodate larger vehicles. However, pneumatic jacks require a reliable air source and can have higher operational costs due to the need for compressed air systems. Furthermore, they may require training for proper usage, which can be a consideration for businesses with less experienced staff.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the right lifting solution, B2B buyers should assess their specific operational needs, including the types of vehicles they service, the frequency of use, and available space. For those requiring a versatile and cost-effective solution for general maintenance, a ‘gato para carro’ remains a strong choice. However, for businesses engaged in heavy-duty repairs or needing speed in high-pressure environments, investing in hydraulic lift tables or pneumatic jacks might be more beneficial. Ultimately, understanding the advantages and limitations of each option will guide buyers toward the most suitable investment for their operations.

Essential Technical Properties and Trade Terminology for gato para carro

What are the Essential Technical Properties of a Gato para Carro?

When sourcing a gato para carro (car jack), understanding its technical properties is crucial for ensuring safety and performance. Here are some key specifications to consider:

-

Weight Capacity (Ton Rating)

The weight capacity, typically measured in tons, indicates the maximum load a jack can lift. Common ratings include 1, 2, 3, and even 20 tons. For B2B buyers, selecting the appropriate weight capacity is essential to match the vehicles being serviced, ensuring safety and preventing equipment failure. -

Type of Jack (Pneumatic, Hydraulic, or Mechanical)

Gatos para carro come in various types, including hydraulic floor jacks, bottle jacks, and scissor jacks. Hydraulic jacks are favored for their efficiency and ease of use, making them ideal for professional garages. Understanding the type helps buyers choose the right equipment for their operational needs. -

Material Composition

The material used in the jack construction, such as steel or aluminum, impacts both durability and weight. Steel jacks are typically more robust, while aluminum models are lighter and easier to maneuver. Buyers must consider the balance between strength and portability based on their specific applications. -

Lift Range (Minimum and Maximum Height)

The lift range specifies how low the jack can go (minimum height) and how high it can lift (maximum height). This is critical for compatibility with different vehicle models, especially in workshops that service a variety of automobiles. A wider lift range offers more versatility. -

Safety Features

Safety features such as overload protection, automatic safety locks, and non-slip rubber pads are essential for preventing accidents during operation. Buyers should prioritize jacks with robust safety mechanisms to enhance workplace safety.

What are Common Trade Terms Related to Gato para Carro?

Familiarity with industry terminology is vital for effective communication and negotiation in B2B transactions. Here are some common terms related to gatos para carro:

-

OEM (Original Equipment Manufacturer)

OEM refers to products made by the original manufacturer of the equipment. In the context of gatos para carro, purchasing OEM parts ensures compatibility and reliability. Buyers should verify if the jacks they consider are OEM to maintain quality standards. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to gauge inventory levels and manage cash flow. Suppliers may set MOQs based on production costs, so negotiating favorable terms can lead to better pricing. -

RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to solicit price quotes from suppliers. It typically includes details about specifications, quantities, and delivery timelines. By issuing RFQs, buyers can compare offers and negotiate better terms, ensuring they get competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that define the responsibilities of buyers and sellers during transportation. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for understanding shipping costs and responsibilities in international transactions. -

Warranty and Support Services

Warranty terms specify the duration and coverage of the manufacturer’s commitment to repair or replace defective products. Understanding warranty conditions is essential for B2B buyers to mitigate risks associated with faulty equipment and ensures long-term support.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing gatos para carro, leading to improved operational efficiency and safety.

Navigating Market Dynamics and Sourcing Trends in the gato para carro Sector

What Are the Current Market Dynamics and Key Trends in the Gato Para Carro Sector?

The global market for ‘gato para carro’ (car jacks) is experiencing significant growth, driven by several factors. Increased vehicle ownership, particularly in emerging markets in Africa and South America, is a primary driver, as more consumers and businesses seek efficient and reliable tools for vehicle maintenance. Technological advancements in manufacturing processes are leading to improved product quality, with innovative features such as lightweight materials and enhanced safety mechanisms gaining traction among buyers.

Furthermore, digital transformation is reshaping sourcing trends. B2B buyers are increasingly utilizing e-commerce platforms for procurement, allowing for better price comparisons and access to a wider range of products. In Europe, particularly in Germany, there is a growing preference for online marketplaces that facilitate direct interactions between manufacturers and buyers. This trend is mirrored in the Middle East, where digital solutions streamline the sourcing process, reducing lead times and costs.

Sourcing strategies are also evolving, with buyers seeking suppliers that can offer customized solutions tailored to specific vehicle types and usage scenarios. This shift is particularly relevant for businesses that operate fleets or specialize in automotive services. As the market continues to grow, international buyers must stay informed about regional regulatory changes and standards that can affect product availability and compliance.

How Is Sustainability Influencing Sourcing Decisions in the Gato Para Carro Industry?

Sustainability is becoming an essential consideration for B2B buyers in the ‘gato para carro’ sector. The environmental impact of manufacturing and distributing car jacks is prompting companies to seek out sustainable practices within their supply chains. Buyers are increasingly prioritizing suppliers that adhere to ethical sourcing standards and demonstrate a commitment to reducing their carbon footprint.

The use of eco-friendly materials and processes is gaining importance, with many manufacturers exploring options for recyclable or biodegradable components in their products. Green certifications, such as ISO 14001, are becoming critical for suppliers aiming to differentiate themselves in a competitive market. Buyers are encouraged to inquire about the sustainability practices of potential suppliers, including waste management, energy efficiency, and the sourcing of raw materials.

Additionally, the demand for transparency in the supply chain is rising, with buyers wanting to ensure that their suppliers follow ethical labor practices and provide fair working conditions. This trend is particularly relevant in regions where labor regulations may vary significantly. By aligning with suppliers that prioritize sustainability, B2B buyers not only contribute to environmental preservation but also enhance their brand reputation among increasingly eco-conscious consumers.

What Is the Historical Context of the Gato Para Carro Market?

The ‘gato para carro’ market has evolved significantly over the past few decades. Initially, car jacks were predominantly basic mechanical devices, primarily made from heavy metals and designed for simple lifting tasks. However, with the advent of hydraulic technology in the late 20th century, the industry began to see substantial improvements in efficiency and safety.

As vehicle designs became more complex, the demand for specialized jacks increased, leading to the development of various types, including bottle jacks, floor jacks, and scissor jacks. Manufacturers began to innovate, focusing on lightweight materials and ergonomic designs to enhance usability. Today, the market is characterized by a diverse array of products that cater to different vehicle types and user needs, reflecting the ongoing evolution of automotive technology and consumer preferences.

In summary, understanding the market dynamics, sustainability considerations, and the historical evolution of the ‘gato para carro’ sector is crucial for international B2B buyers. By leveraging these insights, businesses can make informed sourcing decisions that align with current trends and future demands.

Frequently Asked Questions (FAQs) for B2B Buyers of gato para carro

-

How do I choose the right gato para carro for my business needs?

When selecting a gato para carro, consider the weight capacity required for your typical vehicles, as well as the type of lifting mechanism (hydraulic, mechanical, etc.). Assess the operational environment—whether you need a low-profile jack for sports cars or a heavy-duty model for larger vehicles. Additionally, look for durability and ease of use, as these factors will influence long-term productivity. Consulting with suppliers regarding the specifications can also help you find the best fit for your operational requirements. -

What is the best type of gato para carro for heavy-duty applications?

For heavy-duty applications, a hydraulic floor jack or a bottle jack is typically recommended. Hydraulic jacks provide greater lifting power and stability, making them suitable for lifting heavier vehicles or equipment. Ensure the jack has a high-tonnage rating, ideally exceeding the weight of the heaviest vehicle you plan to service. Brands with a reputation for quality and safety should be prioritized to avoid accidents and ensure reliability. -

What are the typical minimum order quantities (MOQs) for gato para carro when sourcing internationally?

MOQs for gato para carro can vary widely depending on the supplier and the type of jack. Generally, you might encounter MOQs ranging from 50 to 100 units for standard models. However, some suppliers may offer flexible terms for larger orders or custom designs. It’s advisable to discuss your specific needs with suppliers to negotiate MOQs that align with your purchasing strategy while ensuring cost-effectiveness. -

What payment terms should I expect when sourcing gato para carro from international suppliers?

Payment terms can vary significantly by supplier and region. Common options include advance payment, letters of credit, or payment upon delivery. It’s essential to clarify these terms before finalizing orders to ensure both parties are protected. Some suppliers may offer discounts for early payments or bulk purchases, so exploring these options can lead to cost savings. Always ensure that payment methods are secure and provide a clear record of transactions. -

How do I vet suppliers for gato para carro to ensure quality and reliability?

Vetting suppliers involves several steps: check their industry reputation, review customer testimonials, and request product samples. Verify their manufacturing capabilities and compliance with international safety standards. Consider visiting their facilities if possible or using third-party inspection services for quality assurance. Additionally, engaging in direct communication about their production processes and warranties can provide further insights into their reliability. -

What customization options are available for gato para carro?

Customization options may include specific weight capacities, color preferences, or additional features like built-in safety locks or extended lifting heights. Many suppliers offer tailored solutions to meet unique operational needs, particularly for businesses with specialized vehicle types. When discussing customization, provide clear specifications and inquire about any associated costs or lead times to ensure the solution aligns with your requirements. -

What logistics considerations should I keep in mind when importing gato para carro?

Logistics considerations include understanding shipping methods, customs regulations, and potential tariffs. Evaluate the best shipping options based on urgency and cost, whether by air or sea. Ensure that the supplier can provide necessary documentation for customs clearance, including invoices and certificates of origin. Working with a freight forwarder can help streamline the process and mitigate risks associated with international shipping. -

How can I ensure quality assurance (QA) for gato para carro before accepting delivery?

To ensure QA, establish a clear inspection process with your supplier before shipment. Request quality inspection reports and consider implementing third-party inspections for additional assurance. During the acceptance phase, verify that the products meet the agreed specifications and standards. If possible, conduct a pre-shipment inspection to address any issues before the products reach your facility, minimizing potential disruptions to your operations.

Top 6 Gato Para Carro Manufacturers & Suppliers List

1. Facebook – Herramienta Preferida de Mecánicos

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Herramienta Preferida de Mecánicos, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Husky – Gato Hidraulico Para Carro

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Gato Hidraulico Para Carro available on eBay with various options including:

– Types: Floor Jack, Scissor Jack

– Capacity per Stand: 3000lbs, 4000lbs, 6000lbs, 8000lbs

– Brands: Husky, Torin, Unbranded, VEVOR

– Materials: Steel, Aluminum

– Price Range: Under $75.00, $75.00 to $125.00, Over $125.00

– Condition: New

– Buying Formats: Auction, Buy It Now, Accepts Offers

– Shipping: Free delivery opti…

3. Gatos Hidráulicos – Variedad y Capacidades

Domain: ar.ebay.com

Registered: 1995 (30 years)

Introduction: Gatos hidráulicos y soportes de gato disponibles en eBay. Tipos de gatos: Gato de piso, Gato de botella, Gato tipo tijera, Gato de transmisiones, Juego de soporte y gato, Grúa. Capacidades: 1000 lb, 2000 lb, 3000 lb, 4000 lb, 5000 lb, 6000 lb, 7000 lb, 8000 lb, 9000 lb, 10,000 lb, 12,000 lb. Marcas: ARB, ATD Tools, Blackhawk by Proto, Black Jack, Craftsman, Duralast, Esco, Hein-Werner Automotive, …

4. Vaqueiros – Gatos Hidráulicos y Torres para Auto

5. USAS – Gato para Levantar Autos

Domain: us.as.com

Registered: 1997 (28 years)

Introduction: Gato para levantar autos: Herramienta esencial para levantar vehículos, ya sea para cambiar llantas o realizar mantenimiento. Funciona mediante sistemas hidráulicos o mecánicos. Tipos de gatos: 1. Gato de tijera: Compacto, ligero, fácil de usar, pero con capacidad de elevación limitada. 2. Gato hidráulico de botella: Potente y estable, pero más voluminoso. 3. Gato hidráulico de piso: Grande, poten…

6. Tullanta – Gato Hidráulico para Carro

Domain: tullanta.com

Registered: 2009 (16 years)

Introduction: Gato hidráulico para carro: herramienta indispensable para levantar vehículos pesados. Tipos: gatos de botella (compactos, ideales para vehículos pesados), gatos de tijera (comunes para automóviles de pasajeros, fáciles de almacenar), gatos de piso (mayor estabilidad, rango de elevación amplio). Capacidad: debe levantar al menos el 75% del peso del vehículo, medido en toneladas. Altura y rango de …

Strategic Sourcing Conclusion and Outlook for gato para carro

How Can Strategic Sourcing Enhance Your Gato Para Carro Procurement?

In conclusion, strategic sourcing for gato para carro is essential for international B2B buyers aiming to optimize costs and ensure quality in their automotive equipment procurement. By identifying reliable suppliers and leveraging bulk purchasing agreements, businesses can enhance their supply chain resilience and mitigate risks associated with fluctuating market conditions.

Investing in thorough supplier evaluations and market analysis enables buyers to make informed decisions that align with their operational needs and growth objectives. Additionally, focusing on sustainability and innovative solutions in sourcing can differentiate your offerings in competitive markets across Africa, South America, the Middle East, and Europe.

Illustrative image related to gato para carro

As we look ahead, the demand for high-quality lifting equipment will only grow, driven by advancements in automotive technology and an expanding global vehicle market. Now is the time to refine your sourcing strategies and establish partnerships that can support your business goals. Engage with suppliers who can provide tailored solutions and ensure a steady supply of high-quality gato para carro. By taking proactive steps today, you can secure a competitive advantage and position your business for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.