Gas Springs Applications Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for gas springs applications

In today’s competitive landscape, sourcing the right gas springs for various applications can be a daunting challenge for international B2B buyers, particularly those in rapidly developing markets like Africa, South America, the Middle East, and Europe. Gas springs, also known as gas struts or gas lift supports, play a critical role in enhancing the functionality and safety of products across diverse industries—from automotive and aerospace to medical equipment and furniture design. However, the key to successful integration lies in understanding their specific applications, performance characteristics, and the nuances of sourcing from reliable suppliers.

This comprehensive guide aims to empower B2B buyers by providing in-depth insights into gas spring types and applications, supplier vetting processes, and cost considerations. By navigating through the various facets of gas spring applications, buyers will gain the knowledge necessary to make informed purchasing decisions that meet their project requirements and budget constraints. Whether you are looking to improve the ergonomics of medical equipment in Nigeria or enhance the functionality of furniture in Saudi Arabia, this guide serves as a valuable resource to help you identify the best solutions for your needs.

Armed with actionable insights and expert recommendations, you can confidently embark on your sourcing journey, ensuring that your investments in gas springs contribute to the overall success of your business operations.

Understanding gas springs applications Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compression Gas Springs | Provide constant force through their stroke. | Automotive, furniture, medical devices | Pros: Reliable, adjustable force; Cons: Limited to compression applications. |

| Tension Gas Springs | Designed to provide force in tension. | Industrial machinery, safety gates | Pros: Effective for lifting and holding; Cons: Less common than compression springs. |

| Locking Gas Springs | Feature a locking mechanism to maintain height. | Office furniture, adjustable equipment | Pros: Stable at set heights; Cons: More complex and potentially higher cost. |

| Damped Gas Springs | Equipped with damping features for controlled motion. | Aerospace, automotive, heavy machinery | Pros: Smooth operation, reduces shock; Cons: Can be more expensive due to additional features. |

| Multi-Stage Gas Springs | Offer adjustable lengths for versatile applications. | Automotive, furniture, custom machinery | Pros: Flexible and adaptable; Cons: More complex design can lead to higher costs. |

What are Compression Gas Springs and Their Key Features?

Compression gas springs are the most commonly used type, characterized by their ability to exert a consistent force throughout their stroke. They are widely utilized in the automotive sector for applications such as hood supports and in furniture for adjustable chairs. Buyers should consider the required force and stroke length when selecting compression gas springs, ensuring they meet specific application needs while providing reliable performance.

How Do Tension Gas Springs Function in Industrial Applications?

Tension gas springs operate by providing force in a pulling motion, making them ideal for applications like safety gates and industrial machinery. These springs are less common than their compression counterparts but are essential in scenarios where controlled lifting and holding are necessary. When purchasing tension gas springs, businesses should assess the required force and installation space to ensure compatibility with their equipment.

What Advantages Do Locking Gas Springs Offer for Office Furniture?

Locking gas springs are designed to maintain a set height, making them ideal for office furniture and adjustable equipment. They provide stability and safety, allowing users to lock the desired height with ease. For B2B buyers, it’s crucial to evaluate the locking mechanism’s reliability and the gas spring’s overall durability, as these factors directly impact user experience and safety.

How Do Damped Gas Springs Enhance Aerospace and Heavy Machinery Performance?

Damped gas springs incorporate features that control the speed of extension and retraction, providing smooth operation in applications such as aerospace and heavy machinery. Their ability to reduce shock and vibration makes them invaluable in environments where precision and comfort are paramount. Buyers should consider the specific damping characteristics required for their application to ensure optimal performance.

What Makes Multi-Stage Gas Springs Versatile for Various Applications?

Multi-stage gas springs can be adjusted to different lengths, offering versatility in applications ranging from automotive to custom machinery. Their adaptability allows for greater functionality in limited spaces. When purchasing multi-stage gas springs, businesses should focus on the range of adjustment and ensure that the spring can handle the required load without compromising stability or safety.

Key Industrial Applications of gas springs applications

| Industry/Sector | Specific Application of gas springs applications | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Trunk and hood supports | Enhanced safety and convenience for users, improving vehicle usability | Compatibility with vehicle models, load capacity, and durability |

| Furniture | Adjustable office chairs and reclining furniture | Improved ergonomics leading to increased employee productivity and comfort | Customization options, longevity, and aesthetic integration |

| Medical Equipment | Hospital beds and examination tables | Facilitates patient comfort and ease of use, enhancing service quality | Compliance with health regulations and reliability in performance |

| Aerospace | Aircraft cargo doors and overhead compartments | Increased efficiency in loading/unloading, enhancing operational safety | Weight considerations, durability under varying pressures |

| Industrial Machinery | Safety gates and access panels in manufacturing setups | Improved safety and operational efficiency, reducing workplace accidents | Load ratings, stroke length, and environmental resistance |

How Are Gas Springs Used in the Automotive Industry?

In the automotive sector, gas springs are integral for trunk and hood supports, providing controlled lifting and lowering mechanisms. They enhance user convenience by ensuring that hoods and trunks open smoothly and remain securely in place. For international B2B buyers, sourcing gas springs requires attention to compatibility with specific vehicle models, ensuring they meet load capacity and durability standards essential for automotive safety regulations.

What Role Do Gas Springs Play in Furniture Design?

Gas springs are widely used in the design of adjustable office chairs and reclining furniture, allowing users to modify height and angle effortlessly. This adaptability contributes to better ergonomics, which can significantly boost employee productivity and comfort. Buyers should consider customization options for aesthetics and functionality, as well as the longevity of the gas springs to ensure a worthwhile investment in quality furniture.

Why Are Gas Springs Essential in Medical Equipment?

In healthcare, gas springs are critical for hospital beds and examination tables, facilitating smooth adjustments that enhance patient comfort and accessibility. This adaptability is vital in medical environments where ease of use can significantly impact patient care quality. Buyers must ensure that the gas springs comply with health regulations and are reliable under frequent use, as performance and safety are paramount in medical applications.

How Do Gas Springs Enhance Aerospace Operations?

In the aerospace industry, gas springs are used in aircraft cargo doors and overhead compartments to facilitate efficient loading and unloading processes. They contribute to operational safety by ensuring that these heavy components can be managed with minimal effort. For buyers in this sector, weight considerations and the durability of gas springs under varying pressure conditions are critical factors in sourcing decisions.

What Benefits Do Gas Springs Provide in Industrial Machinery?

Gas springs are essential in industrial settings for applications such as safety gates and access panels, where they provide controlled motion and enhance workplace safety. By improving operational efficiency and reducing the risk of accidents, gas springs play a crucial role in maintaining a safe working environment. Buyers should focus on load ratings, stroke lengths, and the springs’ resistance to environmental factors when sourcing gas springs for industrial machinery applications.

3 Common User Pain Points for ‘gas springs applications’ & Their Solutions

Scenario 1: Sourcing Quality Gas Springs for Diverse Applications

The Problem: B2B buyers often struggle with sourcing high-quality gas springs suitable for various applications, such as automotive, furniture, or medical equipment. Many suppliers may not provide detailed specifications or compatibility information, leading to uncertainty about whether the gas springs will meet the specific requirements of their projects. This can result in costly delays, increased operational risks, and potential safety issues if the wrong components are used.

The Solution: To effectively source gas springs, buyers should partner with reputable suppliers that offer comprehensive technical data, including pressure ratings, stroke lengths, and material specifications. It’s crucial to engage in a thorough consultation with the supplier to discuss the specific application needs, such as load capacity and environmental conditions (e.g., humidity, temperature fluctuations). Utilizing tools like gas spring calculators available on supplier websites can help determine the correct size and specifications needed for each application. Additionally, requesting samples or prototypes can provide a practical insight into the product’s performance before making bulk orders. By adopting a meticulous sourcing strategy, buyers can ensure they acquire reliable gas springs that enhance their product functionality and safety.

Scenario 2: Ensuring Longevity and Reliability of Gas Springs

The Problem: Many B2B buyers experience issues with the premature failure of gas springs in their applications, leading to maintenance challenges and unexpected replacement costs. Factors such as poor-quality materials, incorrect installation, and inadequate maintenance can contribute to reduced lifespan and performance. This not only affects productivity but also raises concerns about user safety and satisfaction.

The Solution: To extend the lifespan of gas springs, buyers should focus on selecting products made from high-quality materials, such as corrosion-resistant alloys, and ensure they meet industry standards. Proper installation is equally essential; therefore, buyers should invest in training for their staff or engage experienced professionals to perform the installation. Regular maintenance checks should be scheduled to inspect for signs of wear, leaks, or pressure loss. Implementing a monitoring system that tracks the performance of gas springs can also help identify issues before they lead to failure. By prioritizing quality and maintenance, businesses can significantly reduce replacement costs and enhance the reliability of their applications.

Scenario 3: Adapting Gas Springs to Evolving Design Requirements

The Problem: As industries evolve, so do design requirements for gas spring applications. B2B buyers often face challenges when their existing gas springs do not align with new product designs or functionalities, leading to inefficiencies and the need for redesigns. This can create a bottleneck in the development process, delaying product launches and increasing costs.

The Solution: To adapt gas springs to evolving design requirements, buyers should consider flexible sourcing strategies that include custom solutions. Engaging with manufacturers that offer bespoke services allows for the design of gas springs tailored to specific dimensions, load requirements, and damping characteristics. Additionally, buyers should stay informed about industry trends and innovations, which can provide insights into emerging technologies that could enhance gas spring applications. Collaborating with engineers early in the design phase can also facilitate the integration of gas springs into new products effectively. By taking a proactive approach to customization and collaboration, businesses can ensure their gas springs meet the dynamic demands of their applications, ultimately leading to improved product performance and customer satisfaction.

Strategic Material Selection Guide for gas springs applications

What Are the Key Materials Used in Gas Springs Applications?

Gas springs are engineered components that benefit from a variety of materials, each offering distinct properties that influence performance, durability, and cost. Understanding these materials is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, where specific compliance and standards may apply.

How Does Steel Contribute to Gas Springs Performance?

Steel is the most commonly used material for gas springs, particularly in the construction of the cylinder and piston rod. Its high tensile strength allows for the safe containment of high-pressure gas, typically nitrogen. Steel can withstand significant temperature and pressure variations, making it suitable for applications ranging from automotive to industrial machinery.

Pros: Steel’s durability and strength make it ideal for high-load applications. It is also relatively cost-effective, allowing for competitive pricing in mass production.

Illustrative image related to gas springs applications

Cons: However, steel is prone to corrosion if not properly treated or coated, which can impact its longevity in humid or corrosive environments. Additionally, manufacturing processes for steel components can be complex, potentially increasing lead times.

Impact on Application: The choice of steel can affect the compatibility of the gas spring with various media, particularly in industries like automotive and aerospace, where specific standards must be met.

What Role Does Aluminum Play in Gas Springs?

Aluminum is another popular material used in gas springs, particularly for applications where weight reduction is critical, such as in aerospace and automotive sectors. Aluminum’s lightweight nature combined with good corrosion resistance makes it a favorable choice for applications requiring mobility and ease of handling.

Pros: The primary advantage of aluminum is its lightweight property, which can significantly reduce the overall weight of the assembly. It also offers good resistance to corrosion, especially when anodized.

Illustrative image related to gas springs applications

Cons: On the downside, aluminum generally has lower tensile strength compared to steel, which may limit its use in high-load applications. The cost of aluminum can also be higher than that of steel, impacting budget considerations.

Impact on Application: Aluminum gas springs are particularly suitable for environments where weight is a critical factor, but care must be taken to ensure they meet the necessary load requirements.

How Do Composite Materials Enhance Gas Spring Applications?

Composite materials, such as carbon fiber reinforced polymers, are increasingly being explored for gas springs, particularly in specialized applications. These materials offer a unique combination of lightweight properties and high strength.

Illustrative image related to gas springs applications

Pros: Composites provide excellent corrosion resistance and can be engineered to meet specific performance criteria, making them versatile for various applications.

Cons: However, the manufacturing process for composites can be complex and costly, which may limit their use in standard applications. Additionally, they may not be as widely accepted or understood in all markets.

Impact on Application: For international buyers, the use of composites may require adherence to specific standards and testing protocols, which can vary by region.

What Advantages Do Plastics Offer in Gas Spring Design?

Plastics, particularly engineering-grade polymers, are sometimes used in non-structural components of gas springs, such as seals and end fittings. These materials can provide excellent resistance to chemicals and environmental factors.

Pros: Plastics are lightweight and can be produced at a lower cost, making them suitable for applications where weight and cost are critical factors.

Cons: The main limitation is their lower mechanical strength compared to metals, which can restrict their use in high-stress applications. Additionally, plastics may have temperature limitations that could affect performance.

Impact on Application: Buyers should consider the environmental conditions in which the gas springs will operate, as certain plastics may degrade under extreme temperatures or exposure to specific chemicals.

Summary Table of Material Selection for Gas Springs

| Material | Typical Use Case for gas springs applications | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive and industrial machinery | High tensile strength and durability | Prone to corrosion without treatment | Medium |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Lower tensile strength than steel | High |

| Composite | Specialized applications requiring high strength-to-weight ratio | Excellent corrosion resistance | Complex and costly manufacturing | High |

| Plastic | Non-structural components like seals | Lightweight and cost-effective | Lower mechanical strength and temperature limits | Low |

This strategic material selection guide provides insights into the various materials used in gas springs, helping B2B buyers make informed decisions based on performance, cost, and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for gas springs applications

What Are the Key Stages in the Manufacturing Process of Gas Springs?

The manufacturing of gas springs involves several critical stages that ensure quality and performance. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

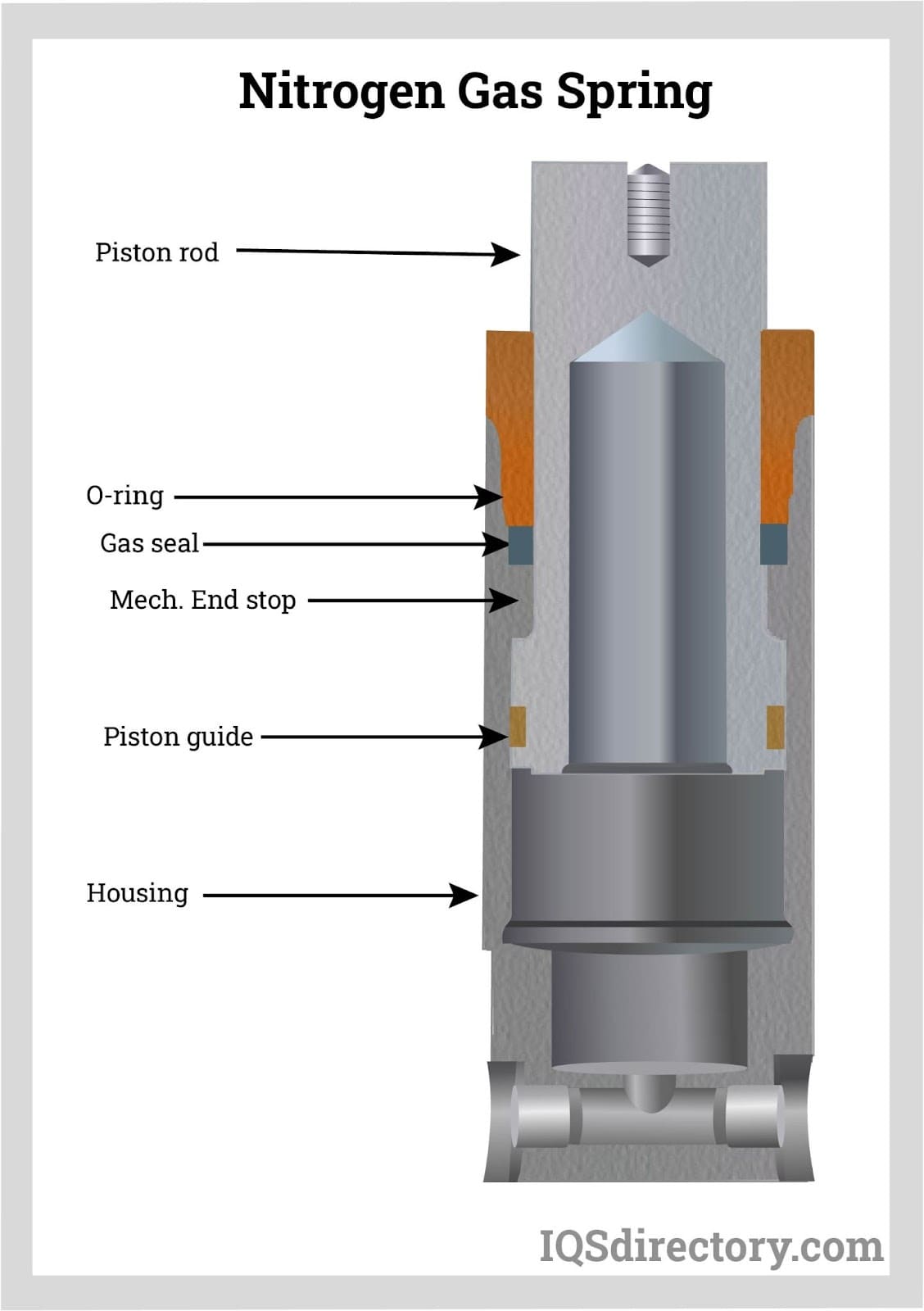

Material Preparation: What Materials Are Used and How Are They Processed?

The foundation of any gas spring lies in its materials. Typically, gas springs are constructed from high-strength steel or stainless steel, chosen for their durability and resistance to corrosion. The manufacturing process begins with material selection and preparation, which includes cutting, bending, and machining the metal into specific shapes.

Advanced techniques such as laser cutting or CNC machining are often employed to achieve precise dimensions. This is crucial as the fit and finish of components like the piston and cylinder significantly impact the gas spring’s performance. After cutting, the surfaces are polished to reduce friction and wear, ensuring smooth operation during compression and extension.

How Are Gas Springs Formed and Assembled?

Forming Techniques: What Methods Are Used to Shape Gas Springs?

Once the materials are prepared, the next step involves forming the components of the gas spring. This usually entails processes like deep drawing, where a sheet metal blank is transformed into a cylindrical shape. The forming technique chosen will depend on the design specifications and performance requirements of the gas spring.

After forming, components are subjected to heat treatment to enhance their mechanical properties. This treatment ensures that the gas spring can withstand the high-pressure environment created by the compressed gas within.

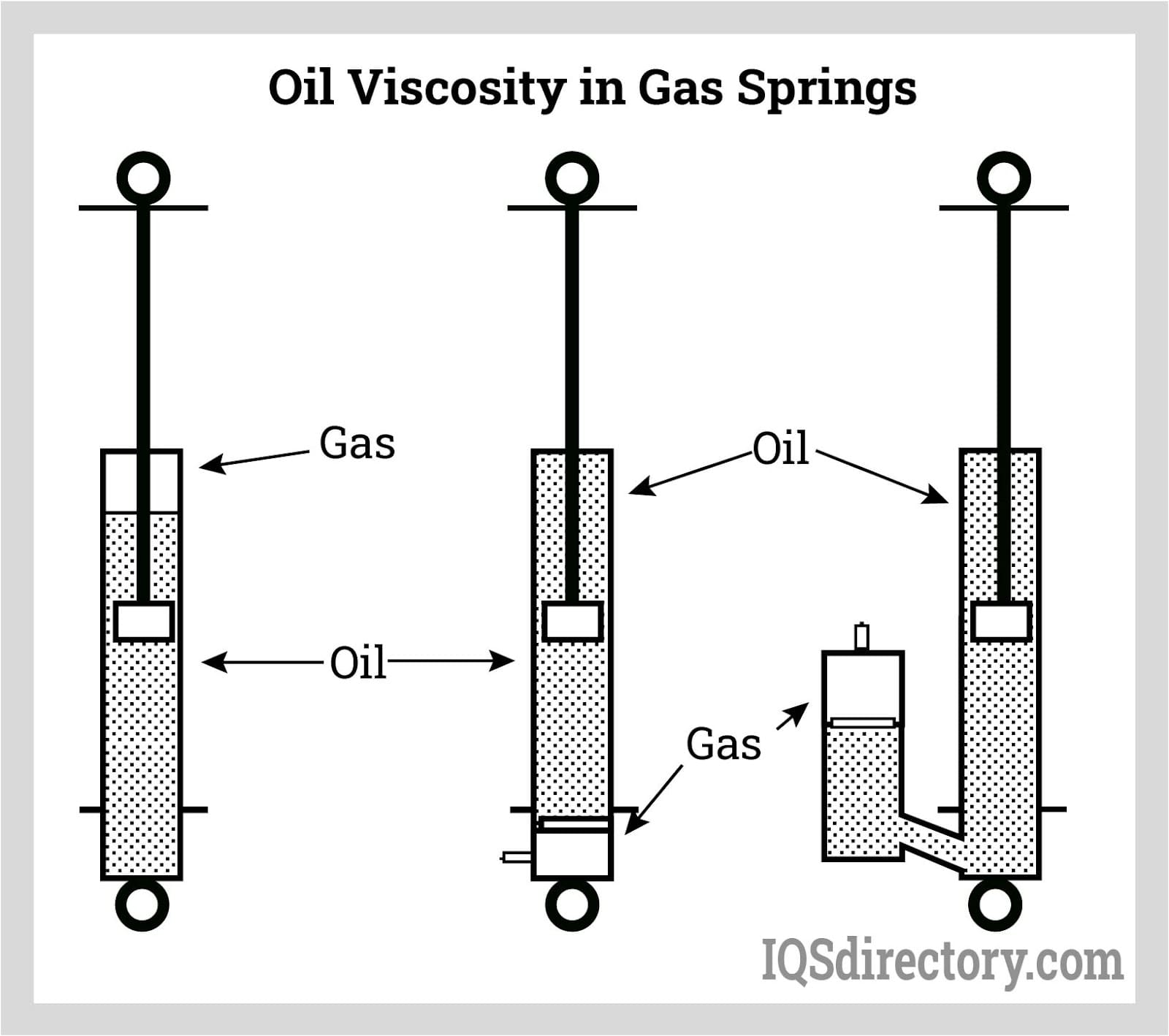

Assembly Process: How Are Components Brought Together?

The assembly of gas springs is a meticulous process that requires precision. During assembly, components such as the piston, rod, and cylinder are joined. The piston rod is inserted into the cylinder, and a specified amount of nitrogen gas is filled under high pressure.

This step is critical as the pressure within the gas spring directly correlates with its lifting force. After filling, the assembly is sealed to prevent gas leakage. Quality checks are implemented at this stage to ensure that the assembly meets specified tolerances.

What Finishing Techniques Are Applied to Gas Springs?

Finishing processes enhance the durability and aesthetic appeal of gas springs. Common techniques include surface treatments like coating or plating, which provide corrosion resistance and improve wear characteristics.

Additionally, gas springs may undergo a final inspection for visual defects and dimensional accuracy. This ensures that only products meeting the highest standards are dispatched to clients.

How Is Quality Assurance Conducted in Gas Spring Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of gas springs, particularly for B2B buyers who require reliability and safety in their applications.

What Are the Relevant International and Industry-Specific Standards?

Manufacturers of gas springs typically adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards demonstrates a commitment to consistent quality and continuous improvement.

For specific industries, additional certifications may be necessary. For example, gas springs used in the automotive sector might require compliance with automotive quality standards like IATF 16949, while those in the aerospace industry may need to meet AS9100 standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage ensures that all raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): During manufacturing, components are regularly inspected for dimensional accuracy and quality. This might involve using gauges or other measuring devices.

- Final Quality Control (FQC): Once the gas springs are assembled, they undergo a final inspection to verify that they meet all performance and safety criteria.

What Testing Methods Are Commonly Used for Gas Springs?

Testing is an essential part of the quality assurance process for gas springs. Common methods include:

Illustrative image related to gas springs applications

- Functional Testing: Evaluating the spring’s performance under load to ensure it meets specified force requirements.

- Leak Testing: Checking for gas leaks, which can compromise performance.

- Endurance Testing: Subjecting the gas spring to repeated cycles of compression and extension to assess durability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, equipment, and quality control systems directly.

- Reviewing Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QA performance over time, including defect rates and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s quality control measures and product reliability.

What Are the Quality Certification Nuances for International Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality certifications is crucial. Different regions may have specific requirements or standards that need to be adhered to.

For example, buyers in Europe may require CE marking, which indicates compliance with health, safety, and environmental protection standards. In contrast, buyers in the Middle East may prioritize suppliers with certifications recognized in their local markets.

In conclusion, gas springs are sophisticated components whose manufacturing processes and quality assurance systems significantly influence their performance and reliability. B2B buyers should prioritize suppliers that demonstrate robust manufacturing practices, adherence to international standards, and a commitment to quality control. By doing so, they can ensure they procure high-quality gas springs that meet their specific application needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gas springs applications’

The purpose of this guide is to equip B2B buyers with a practical checklist for sourcing gas springs effectively. By following these steps, you can ensure that you select the right gas springs for your applications, enhancing product performance and reliability.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your gas springs. This includes understanding the force needed, the length when extended, and the type of damping required. Clear specifications help suppliers provide accurate options and prevent misalignment with your project needs.

- Force Requirements: Determine the weight and load that the gas spring will support.

- Length and Stroke: Specify the extended and compressed lengths to ensure compatibility with your application.

Step 2: Research Industry Standards

Investigate the relevant industry standards and certifications for gas springs in your sector. Compliance with these standards ensures quality and safety, which is crucial for applications in industries such as automotive, aerospace, and medical equipment.

- ISO Certifications: Look for suppliers who adhere to ISO 9001 or similar quality management standards.

- Material Specifications: Ensure that the materials used meet industry-specific regulations, especially for medical or food-related applications.

Step 3: Evaluate Potential Suppliers

Before making a decision, thoroughly vet potential suppliers. Assess their experience, reputation, and reliability in delivering gas springs that meet your specifications. This diligence can save you from future complications and ensure a steady supply chain.

- Request Documentation: Ask for company profiles, case studies, and references from similar projects.

- Customer Reviews: Look for testimonials from other businesses in your industry to gauge satisfaction levels.

Step 4: Analyze Pricing and Terms

Obtain detailed quotes from multiple suppliers to compare pricing structures and payment terms. Understanding the financial implications of your purchase is essential for budget management and long-term planning.

Illustrative image related to gas springs applications

- Unit Pricing vs. Bulk Discounts: Inquire about pricing for different order quantities and whether bulk purchases yield significant savings.

- Payment Terms: Clarify payment conditions, including deposits and credit options, to ensure they align with your financial policies.

Step 5: Assess Customization Options

Determine whether you need customized gas springs for specific applications. Many suppliers offer customization, which can enhance functionality and efficiency but may also affect lead times and costs.

- Custom Features: Inquire about options for variable damping, locking mechanisms, or specific rod sizes.

- Lead Times: Understand how customization impacts delivery schedules and plan accordingly.

Step 6: Verify Supplier Support and Warranty

Ensure that the supplier provides adequate support and a warranty for their products. This support can be crucial for resolving issues quickly and minimizing downtime in your operations.

- Technical Support: Check if the supplier offers technical assistance during installation or operation.

- Warranty Policies: Review warranty coverage to ensure protection against defects or performance issues.

Step 7: Make an Informed Decision

After completing the evaluation, weigh all factors, including technical specifications, supplier reliability, pricing, and support. Making a well-informed decision will enhance your project’s success and ensure the longevity of your gas spring applications.

By following this comprehensive checklist, you can streamline the sourcing process for gas springs, ensuring that you select the best options for your business needs.

Comprehensive Cost and Pricing Analysis for gas springs applications Sourcing

What Are the Key Cost Components in Gas Springs Applications?

Understanding the cost structure for sourcing gas springs is crucial for B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. The main cost components include:

-

Materials: The primary materials used in gas springs are high-strength metals for the cylinder and rod, along with nitrogen gas for compression. The choice of materials can significantly impact the overall cost. Higher quality materials might increase upfront costs but can lead to better performance and longevity, reducing the Total Cost of Ownership (TCO).

-

Labor: Labor costs vary by region and the complexity of manufacturing processes. Skilled labor is essential for the assembly of gas springs, especially for custom applications that require precision.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, which can be a point of negotiation for buyers.

-

Tooling: Custom tooling can be a significant investment, especially for bespoke gas spring solutions. Buyers should consider the amortization of these costs over the expected volume of production to better understand their impact on pricing.

-

Quality Control (QC): Quality assurance processes are vital to ensure that gas springs meet safety and performance standards. Enhanced QC measures can lead to higher costs but are essential for maintaining product reliability.

-

Logistics: Shipping and handling costs can vary widely depending on geographic location and chosen shipping methods. International buyers must consider tariffs, freight charges, and potential delays when assessing total logistics costs.

-

Margin: Supplier profit margins can vary based on market competition and the uniqueness of the product offering. Understanding the supplier’s pricing strategy can aid in negotiations.

How Do Price Influencers Affect Gas Springs Sourcing?

Several factors influence the pricing of gas springs, particularly in international B2B transactions:

-

Volume/MOQ: Minimum order quantities can significantly affect pricing. Higher volumes typically lead to lower per-unit costs, making it beneficial for buyers to consolidate orders when possible.

-

Specifications and Customization: Custom specifications can lead to increased costs due to additional engineering and manufacturing requirements. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: The presence of certifications (e.g., ISO, CE) for materials can justify higher prices. Buyers in regulated industries must ensure compliance with relevant standards, which may necessitate higher upfront costs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Well-established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: Understanding the terms of delivery can greatly influence the total cost. Buyers should be clear on whether costs include freight, insurance, and duties to avoid surprises.

What Are the Best Negotiation Tips for International B2B Buyers?

B2B buyers should adopt strategic approaches when negotiating gas spring prices:

-

Leverage Volume Discounts: When placing larger orders, negotiate for volume discounts. Suppliers often have more flexibility in pricing for bulk purchases.

-

Emphasize Long-Term Relationships: Building a long-term partnership can lead to better pricing terms. Suppliers are more likely to offer favorable conditions to clients they view as stable, repeat customers.

-

Focus on Total Cost of Ownership: Rather than solely concentrating on initial costs, consider the TCO, which includes maintenance, longevity, and performance. Presenting this analysis can lead to more informed negotiations.

-

Be Aware of Pricing Nuances: Different markets may have varying pricing dynamics. For instance, suppliers in Europe may have different cost structures compared to those in Africa or South America. Understanding these nuances can provide leverage in negotiations.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This can also serve as a negotiation point regarding quality assurance.

Conclusion

Navigating the complexities of gas springs sourcing requires an understanding of the cost structure and pricing influencers. By leveraging strategic negotiation techniques and focusing on the Total Cost of Ownership, B2B buyers can secure favorable terms that meet their operational needs while ensuring product reliability and performance. Always seek out multiple quotes and evaluate suppliers based on quality, service, and long-term potential to make the most informed purchasing decisions.

Alternatives Analysis: Comparing gas springs applications With Other Solutions

Exploring Alternative Solutions to Gas Springs Applications

When evaluating the optimal mechanisms for controlled force and motion in various applications, gas springs have established themselves as a reliable choice across multiple industries. However, other alternatives exist that can also fulfill similar roles. This section compares gas springs applications against alternative solutions, allowing B2B buyers to make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Gas Springs Applications | Pneumatic Cylinders | Coil Springs |

|---|---|---|---|

| Performance | Provides consistent force throughout the stroke; adjustable damping available | High force output with rapid actuation; may require complex control systems | Variable force depending on compression; less control over motion |

| Cost | Moderate initial investment; long-term savings due to durability | Higher upfront costs; ongoing costs for air supply and maintenance | Generally low-cost; limited lifespan due to wear |

| Ease of Implementation | Relatively easy to install and integrate into existing systems | Requires specialized installation; complex systems may need additional controls | Simple installation; widely understood technology |

| Maintenance | Low maintenance requirements; generally long-lasting | Requires regular maintenance of air supply and potential leaks | Requires periodic checks and replacements due to fatigue |

| Best Use Case | Ideal for applications requiring precise control and consistent performance | Best for applications needing high speed and force, such as automated machinery | Suitable for simple applications with less critical performance needs |

What Are the Advantages and Disadvantages of Pneumatic Cylinders?

Pneumatic cylinders utilize compressed air to produce linear motion, making them suitable for applications that require rapid actuation and high force output. They excel in environments where speed is critical, such as automated manufacturing processes. However, their complexity can lead to increased costs due to the need for air supply systems and maintenance. Additionally, pneumatic systems may require more control components, which can complicate integration into existing setups.

How Do Coil Springs Compare to Gas Springs Applications?

Coil springs are a traditional solution for providing resistance and motion in various applications. They are generally lower in cost and easier to implement, making them a popular choice for straightforward applications. However, coil springs lack the precise control and damping capabilities that gas springs offer, leading to variable performance based on compression. Their lifespan can also be shorter due to fatigue and wear, requiring more frequent replacements and potentially increasing long-term costs.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Choosing the right solution for controlled force and motion depends on various factors, including the specific requirements of the application, budget constraints, and long-term maintenance considerations. Gas springs are ideal for applications demanding precision and consistency, particularly in industries like automotive, aerospace, and medical equipment. On the other hand, pneumatic cylinders may be better suited for high-speed applications, while coil springs can serve well in simpler, cost-sensitive environments. By assessing these alternatives against their operational needs, B2B buyers can make informed decisions that enhance their product offerings and operational efficiency.

Essential Technical Properties and Trade Terminology for gas springs applications

What Are the Key Technical Properties of Gas Springs?

Understanding the technical specifications of gas springs is crucial for B2B buyers looking to optimize product design and functionality. Here are some essential properties that should be considered:

Illustrative image related to gas springs applications

-

Material Grade

– Gas springs are typically made from high-grade steel or aluminum, which ensures durability and resistance to corrosion. The material choice affects the spring’s weight, strength, and longevity, making it a vital consideration for applications in automotive, aerospace, and industrial machinery. -

Force Rating

– The force rating indicates the amount of load a gas spring can support. It is usually expressed in pounds or Newtons and is determined by the internal gas pressure and the piston area. Selecting the correct force rating is essential to ensure safety and functionality, as an inadequate rating can lead to mechanical failure or operational inefficiency. -

Stroke Length

– Stroke length refers to the distance a gas spring can extend or compress. It is critical for applications that require precise movement control, such as in adjustable furniture or automotive hoods. Buyers need to match the stroke length with their specific application requirements to ensure optimal performance. -

Damping Characteristics

– Some gas springs come with variable damping features that allow for controlled motion, reducing the risk of abrupt movements. This is particularly important in applications involving delicate components or user interaction, such as medical devices or ergonomic furniture. Understanding damping properties can enhance user experience and safety. -

Operating Temperature Range

– Gas springs must perform effectively within specific temperature ranges. Extreme temperatures can affect gas pressure and material integrity, potentially leading to failure. Buyers should consider the environmental conditions in which the gas spring will operate to ensure reliability. -

Tolerance Levels

– Tolerance levels refer to the allowable variation in dimensions and force ratings. Tight tolerances are crucial in applications where precision is paramount, such as in aerospace or medical equipment. Understanding tolerance requirements helps buyers ensure compatibility with other components.

What Are Common Trade Terms Related to Gas Springs?

Familiarity with industry jargon can facilitate smoother transactions and better communication with suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the role of OEMs is essential for buyers looking to integrate gas springs into existing systems or products. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest order size that a supplier is willing to accept. This is crucial for budget-conscious buyers, as it can significantly impact inventory management and cash flow. Knowing the MOQ helps in planning purchases effectively. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to request pricing information from suppliers for specific products or services. It is a critical step in the procurement process, allowing buyers to compare costs and terms from different vendors. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for buyers engaged in cross-border trade, as they outline shipping, insurance, and tariffs. -

Lead Time

– Lead time refers to the time taken from placing an order to its delivery. This is crucial for project planning, as long lead times can affect production schedules and inventory levels. Buyers should inquire about lead times to ensure timely project execution. -

Custom Specifications

– Custom specifications refer to tailored requirements for gas springs, including unique force ratings, sizes, or features. Knowing how to communicate custom needs is essential for buyers seeking specialized solutions that meet specific application requirements.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they select the right gas springs for their applications while navigating the complexities of procurement effectively.

Navigating Market Dynamics and Sourcing Trends in the gas springs applications Sector

What Are the Global Drivers Influencing the Gas Springs Applications Market?

The gas springs applications market is experiencing significant growth, driven by increasing demand across various sectors such as automotive, healthcare, aerospace, and furniture. In regions like Africa, South America, the Middle East, and Europe, buyers are focusing on innovative solutions that enhance product efficiency and user experience. The automotive industry, in particular, is witnessing a surge in the adoption of gas springs for applications like trunk lids and tailgates, fueled by rising vehicle production and a growing emphasis on vehicle safety and comfort.

Emerging technologies, such as automation and IoT integration, are transforming how gas springs are designed and utilized. For instance, smart gas springs equipped with sensors can provide real-time feedback on performance, allowing manufacturers to optimize their products and improve maintenance processes. Furthermore, the trend towards lightweight materials in manufacturing is driving the development of more efficient gas springs that enhance the performance of various applications.

International buyers are also navigating fluctuating supply chains and pricing dynamics. Factors such as geopolitical tensions, trade regulations, and fluctuating raw material costs are influencing sourcing strategies. As a result, companies are increasingly looking for reliable suppliers who can offer both quality and flexibility in their product offerings.

How Is Sustainability Impacting the Sourcing of Gas Springs?

Sustainability is becoming a pivotal consideration for B2B buyers in the gas springs applications sector. The environmental impact of manufacturing processes, including emissions and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers that adopt sustainable practices, such as using eco-friendly materials and minimizing resource consumption.

Ethical sourcing is also gaining traction, particularly in regions where labor practices may be questionable. Buyers are encouraged to verify that their suppliers adhere to fair labor practices and are committed to corporate social responsibility. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can guide buyers in selecting ethical suppliers.

Moreover, the use of recycled materials in the production of gas springs is becoming more common. Suppliers that incorporate ‘green’ certifications or utilize sustainable materials can not only appeal to environmentally conscious buyers but also contribute to broader sustainability goals. This trend not only enhances brand reputation but can also lead to cost savings in the long run, making it a win-win for businesses.

What Is the Historical Context of Gas Springs in B2B Applications?

The evolution of gas springs dates back to the mid-20th century when they were first introduced as an innovative solution for various mechanical applications. Initially, these components were primarily used in the automotive sector, providing support for hoods and trunks. Over the decades, advancements in materials and manufacturing processes have expanded their applications significantly.

By the 1990s, gas springs began to find their way into the furniture industry, enhancing user experience with features like adjustable height and soft-closing mechanisms. The aerospace sector soon followed, recognizing the benefits of gas springs in improving passenger comfort and operational efficiency.

Today, gas springs are integral to numerous industries, reflecting a shift towards more versatile and efficient engineering solutions. This historical context underscores the importance of innovation and adaptability in meeting the evolving needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of gas springs applications

1. How do I select the right gas spring for my application?

Choosing the right gas spring involves assessing the specific requirements of your application, such as load capacity, stroke length, and mounting style. Start by determining the weight that the gas spring needs to support and the distance it must travel. Consider the environment where the gas spring will be used, as factors like temperature and humidity can affect performance. Consulting with suppliers for technical specifications and utilizing gas spring calculators can help ensure that you select a spring that meets your needs efficiently.

Illustrative image related to gas springs applications

2. What are the advantages of using gas springs over traditional springs?

Gas springs offer numerous benefits compared to traditional coil or leaf springs. They provide a nearly constant force throughout their stroke, which ensures smooth operation and controlled movement. Additionally, gas springs can be engineered with features like variable damping, enhancing their functionality for specific applications. They are also typically more compact and can be designed to fit into tighter spaces, making them ideal for a variety of industries, including automotive and furniture design.

3. What industries primarily utilize gas springs?

Gas springs are utilized across several industries, including automotive, aerospace, furniture manufacturing, medical equipment, and industrial machinery. In the automotive sector, they assist in opening and supporting hoods and tailgates. In furniture, they enable adjustable mechanisms in chairs and desks. Their adaptability and reliability make them essential components in enhancing user experience and operational efficiency across these varied applications.

4. What is the typical lead time for custom gas springs?

Lead times for custom gas springs can vary significantly depending on the supplier, complexity of the design, and current production capacity. Generally, standard products may ship within a few days, while customized solutions might take anywhere from two to six weeks. It’s advisable to communicate your timeline needs early in the process and confirm with the supplier to ensure that your project deadlines are met.

5. How can I ensure the quality of gas springs from suppliers?

To ensure the quality of gas springs, it is crucial to conduct thorough supplier vetting. Look for suppliers with industry certifications, such as ISO 9001, which indicates adherence to quality management standards. Request samples to assess performance and reliability. Additionally, inquire about the supplier’s quality assurance processes, including testing methods and warranty policies, to ensure that you receive high-quality, durable products.

Illustrative image related to gas springs applications

6. What are the minimum order quantities (MOQs) for gas springs?

Minimum order quantities for gas springs can vary widely among suppliers, typically ranging from a few units to several hundred, depending on the product type and customization level. Many suppliers may offer flexibility in MOQs for large projects or long-term partnerships. It’s best to discuss your specific needs with potential suppliers and explore options that align with your procurement strategy.

7. What payment terms should I expect when sourcing gas springs internationally?

Payment terms can differ based on the supplier’s policies and the nature of your business relationship. Common arrangements include payment in advance, net 30 or 60 days after delivery, and letter of credit for larger orders. Always clarify payment terms before finalizing contracts and consider negotiating terms that safeguard your interests, especially for international transactions where currency fluctuations may impact costs.

8. How do I handle logistics for importing gas springs?

Managing logistics for importing gas springs requires careful planning. Work with suppliers who have experience in international shipping to ensure compliance with customs regulations. Determine the best shipping methods based on cost, speed, and reliability. Consider factors such as duty fees, insurance, and potential delays in customs clearance. Collaborating with a freight forwarder can help streamline the process and mitigate risks associated with international logistics.

Top 9 Gas Springs Applications Manufacturers & Suppliers List

1. Gasspringsshop – Gas Springs Solutions

Domain: gasspringsshop.com

Registered: 2014 (11 years)

Introduction: Gas springs, also known as gas struts or gas lift supports, are versatile components used in various industries. Key details include:

– **Types of Gas Springs:**

– Steel Gas Springs:

– Up to 200N, M3.5 thread

– Up to 450N, M5 thread

– Up to 800N, M8 thread

– Up to 1250N, M8 thread

– Up to 2500N, M10 thread

– Up to 5000N, M14 thread

– Stainless Steel Gas Springs…

2. Albert Jagger – Gas Springs

Domain: albertjagger.co.uk

Registered: 2017 (8 years)

Introduction: Gas springs, also known as gas struts, store energy using compressed gas to create increased pressure. They consist of a sealed cylinder containing a piston that compresses gas to store potential energy, which is released when the piston is moved. Key benefits include not requiring a power source, making them versatile across various industries such as Aerospace, Medical, Furniture, Industrial, an…

3. LST Technologies – Gas Springs

Domain: lstechnologies.ca

Registered: 2003 (22 years)

Introduction: LST gas springs provide controlled damping in automotive, marine, industrial, and domestic applications. They consist of a sealed tubular metallic cylinder, a piston with a metered bore hole, a micro-finished piston rod, oil fill, and a high-pressure nitrogen charge. The rods typically range from 6mm to 14mm in diameter, with a force of 100 pounds requiring about 1400 psi internal pressure. Gas sp…

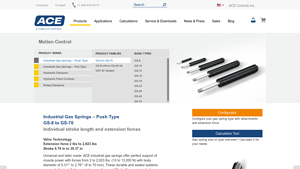

4. Ace Controls – GS Series Industrial Gas Springs

Domain: acecontrols.com

Registered: 1997 (28 years)

Introduction: Product Name: GS-8 to GS-70 – Industrial Gas Springs – Push Type

Extension Force: 2 lbs to 2,923 lbs (10 to 13,000 N)

Stroke Length: 0.79 in to 39.37 in

Piston Rod Diameter: Ø 0.12 in to Ø 1.18 in

Progression: Approx. 13 % to 76 % (depending on size and stroke)

Lifetime: Approx. 32,808 ft

Operating Temperature Range: -4 °F to 176 °F

Material: Outer body – Coated steel; Piston rod – Steel or stainl…

5. Monroe Engineering – Gas Springs

Domain: monroeengineering.com

Registered: 1999 (26 years)

Introduction: Gas springs are versatile components designed for controlled force and motion in mechanical systems, using compressed gas for smoother operation. They are compact, durable, and ideal for various applications across multiple industries. Key applications include: 1. Aerospace: Cargo bay doors, passenger seating adjustments, overhead compartments. 2. Automotive: Trunk and hood supports, seat adjustme…

6. Industrial Gas Springs – Key Products

Domain: industrialgassprings.com

Registered: 2000 (25 years)

Introduction: Gas Spring Applications & Solutions – Industrial Gas Springs, Inc. offers a variety of gas spring products categorized by their functional characteristics. Key product types include: Compression Gas Springs, Safety Shroud Gas Springs, Adjustable Locking Gas Springs, Stainless Steel Gas Springs, Dampers, Tension Gas Springs, and Custom Designed Springs. Applications span across various industries s…

7. Gemini Gas Springs – High-Quality Gas Springs

Domain: geminigassprings.com

Registered: 2008 (17 years)

Introduction: Gemini Gas Springs Inc. is a leading North American manufacturer of high industrial quality gas springs, certified ISO 9001:2015. Their gas springs are used in various applications requiring lift support to ease manual force safely and prevent injuries during the operation of heavy doors, covers, flaps, lids, canopies, and more. Application examples include: Agricultural equipment, Cab doors, Cano…

8. Metrol – High-Performance Gas Springs

Domain: motioncontrol.metrol.com

Registered: 1998 (27 years)

Introduction: Gas springs offer advantages for applications requiring lift, counterbalance, damping, tensioning, clamping, ejection, anti-vibration, and safety-overload. Metrol SAS Gas Springs are designed for high performance and longevity in challenging applications, utilizing advanced technology developed over 35 years. Key features include: high force in less space, built-in damping for controlled movement,…

9. RS Online – Gas Springs

Domain: nz.rs-online.com

Registered: 2001 (24 years)

Introduction: Gas springs, also known as gas struts or gas stays, are lifting mechanisms that utilize pressurized gas to support, lift, or lower heavy objects. They operate using a piston and rod mechanism within a sealed cylinder, creating two chambers: one filled with compressed gas and the other with hydraulic fluid. Common applications include bonnet struts, canopy struts, door gas struts, industrial machin…

Strategic Sourcing Conclusion and Outlook for gas springs applications

In summary, gas springs are essential components across multiple industries, delivering controlled force and enhancing product functionality. Their applications span automotive, furniture, medical, aerospace, and industrial sectors, proving their versatility and reliability. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, leveraging strategic sourcing for gas springs can lead to significant cost savings, improved supply chain efficiency, and enhanced product offerings.

As the demand for innovative and ergonomic solutions continues to grow, businesses must prioritize partnerships with reputable suppliers who can provide high-quality gas springs tailored to specific requirements. Engaging with suppliers that offer customization options and technical expertise will not only ensure compliance with international standards but also foster long-term relationships that drive business success.

Looking ahead, the gas springs market is poised for growth, driven by advancements in technology and increasing applications in emerging industries. International buyers are encouraged to explore these opportunities, ensuring they remain competitive and responsive to market demands. By investing in quality gas springs and cultivating strategic partnerships, businesses can elevate their operations and deliver exceptional value to their customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.