Gantry Crane Device Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for gantry crane device

In today’s fast-paced global market, sourcing a reliable gantry crane device can be a daunting challenge for international B2B buyers. The need for efficient material handling solutions is paramount, especially in industries such as construction, manufacturing, and logistics. This comprehensive guide aims to equip businesses from Africa, South America, the Middle East, and Europe—countries like Saudi Arabia and Germany—with the knowledge necessary to make informed purchasing decisions.

We will explore various types of gantry cranes, including adjustable and fixed-height models, and discuss their applications across different sectors. Additionally, the guide will provide insights on how to effectively vet suppliers to ensure quality and reliability, as well as an overview of cost considerations and potential financing options.

By navigating the complexities of the gantry crane market, this resource empowers buyers to identify the best solutions tailored to their specific operational needs. Whether you’re looking to enhance productivity, ensure workplace safety, or streamline logistics, understanding the nuances of gantry cranes will be instrumental in making strategic procurement choices that can drive your business forward.

Understanding gantry crane device Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Adjustable Height Gantry Crane | Height adjustable in increments, portable design | Warehousing, manufacturing, construction | Pros: Flexible height; easy transport. Cons: May require assembly. |

| Fixed Height Gantry Crane | Set height, robust construction, high load capacity | Heavy-duty lifting in factories | Pros: Stability and strength; ideal for heavy loads. Cons: Limited height flexibility. |

| Aluminum Gantry Crane | Lightweight, corrosion-resistant, adjustable spans | Outdoor applications, temporary setups | Pros: Easy to transport; resistant to weather. Cons: Lower load capacity than steel. |

| A-Frame Gantry Crane | Unique A-frame design, allows for greater clear spans | Industrial applications, shipping yards | Pros: Space-efficient; suitable for narrow aisles. Cons: May not support as much weight as traditional designs. |

| Portable Gantry Crane | Compact, easy to move, often with wheels for mobility | Small workshops, maintenance tasks | Pros: Versatile and mobile; ideal for limited spaces. Cons: Generally lower lifting capacity. |

What Are the Key Characteristics of Adjustable Height Gantry Cranes?

Adjustable Height Gantry Cranes are designed for versatility, allowing users to modify the height in six-inch increments. This feature is particularly beneficial for businesses needing to accommodate various load sizes and uneven flooring. The cranes are typically lightweight and portable, making them suitable for different job sites. When considering purchasing, buyers should evaluate the crane’s capacity, the ease of height adjustment, and whether the design meets their specific lifting requirements.

How Do Fixed Height Gantry Cranes Compare in Performance?

Fixed Height Gantry Cranes are characterized by their robust construction and high load capacities, making them ideal for heavy-duty applications in factories and warehouses. Unlike adjustable models, these cranes provide stability for consistent lifting tasks. Buyers should consider the maximum weight the crane can handle and the operational environment, as these cranes are best suited for permanent installations where height adjustments are unnecessary.

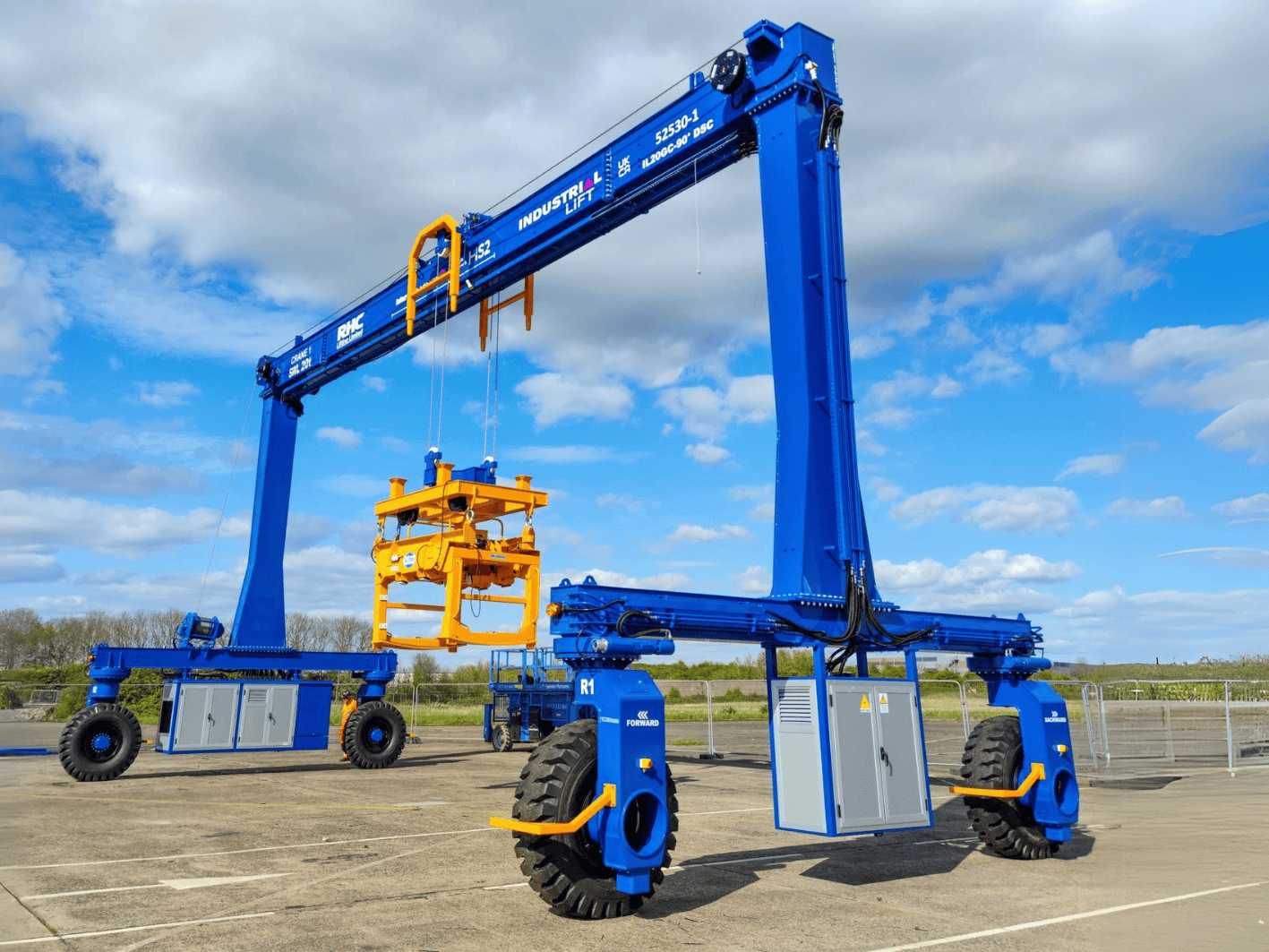

Illustrative image related to gantry crane device

What Advantages Do Aluminum Gantry Cranes Offer for B2B Buyers?

Aluminum Gantry Cranes are lightweight and resistant to corrosion, making them ideal for outdoor or temporary applications. They often feature adjustable spans, allowing for easy transport and storage in tight spaces. Businesses looking for mobility and flexibility, especially in environments where weight is a concern, will find these cranes advantageous. However, potential buyers should note that aluminum cranes typically have lower load capacities compared to their steel counterparts.

Why Choose A-Frame Gantry Cranes for Industrial Applications?

A-Frame Gantry Cranes feature a unique design that allows for greater clear spans without the need for four brace legs. This design is particularly beneficial in industrial settings where space is limited, such as shipping yards or narrow aisles. When considering an A-frame crane, buyers should assess the crane’s load capacity and the specific layout of their workspace to ensure optimal functionality.

What Makes Portable Gantry Cranes Ideal for Small Workspaces?

Portable Gantry Cranes are designed for mobility, often equipped with wheels for easy transport. These cranes are perfect for small workshops or maintenance tasks where space is limited. Buyers should look for features such as weight capacity, ease of assembly, and overall portability when selecting a portable gantry crane to meet their specific operational needs.

Illustrative image related to gantry crane device

Key Industrial Applications of gantry crane device

| Industry/Sector | Specific Application of gantry crane device | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly line support for heavy machinery | Increases efficiency and safety in assembly tasks | Consider load capacity, adjustability, and portability |

| Construction | Lifting and positioning building materials | Enhances workflow and reduces manual handling risks | Assess environmental durability and mobility features |

| Automotive | Engine and parts assembly line operations | Streamlines production processes and reduces downtime | Evaluate compatibility with existing systems and tools |

| Warehousing & Logistics | Loading and unloading of goods in storage facilities | Optimizes space utilization and improves productivity | Check for adjustable spans and ease of transport |

| Energy & Utilities | Maintenance of heavy equipment in power plants | Ensures safety and efficiency in maintenance tasks | Focus on crane stability and adaptability for various loads |

How Are Gantry Cranes Used in Manufacturing and What Problems Do They Solve?

In the manufacturing sector, gantry cranes are primarily used to support assembly lines, particularly for heavy machinery. These cranes facilitate the movement of large components, reducing the risk of injuries associated with manual lifting. For international buyers, it is crucial to consider the crane’s load capacity and adjustability to accommodate various assembly tasks and floor layouts. The ability to transport these cranes easily within the facility further enhances operational efficiency.

What Role Do Gantry Cranes Play in Construction Projects?

In construction, gantry cranes are invaluable for lifting and positioning heavy building materials, such as steel beams and concrete blocks. Their sturdy design allows for safe and efficient material handling, significantly enhancing workflow on job sites. Buyers in regions like Africa and South America should prioritize sourcing cranes that are durable and can withstand diverse environmental conditions. Features such as adjustable heights and spans are also essential for navigating tight spaces and uneven ground.

How Are Gantry Cranes Essential in the Automotive Industry?

In the automotive industry, gantry cranes are extensively used in engine and parts assembly line operations. They help in efficiently lifting and positioning heavy vehicle components, thereby streamlining production processes and minimizing downtime. For B2B buyers, particularly in Europe, evaluating the compatibility of gantry cranes with existing assembly systems is vital. Additionally, features that support ergonomic lifting can enhance worker safety and productivity.

Why Are Gantry Cranes Important in Warehousing and Logistics?

In warehousing and logistics, gantry cranes are employed for loading and unloading goods, improving space utilization and overall productivity. Their ability to maneuver in narrow aisles and adjust spans makes them ideal for various storage configurations. Buyers should consider the crane’s portability and ease of operation to maximize efficiency in fast-paced environments. Furthermore, assessing the durability of materials used in the crane’s construction is essential for long-term reliability.

What Benefits Do Gantry Cranes Provide in Energy and Utilities?

In the energy and utilities sector, gantry cranes are utilized for the maintenance of heavy equipment in power plants and other facilities. They ensure safe lifting and handling of large machinery, significantly reducing the risks associated with maintenance tasks. Buyers should focus on sourcing cranes with high stability and adaptability to accommodate different load types and maintenance scenarios. This ensures safety and efficiency, critical in high-stakes environments like energy production.

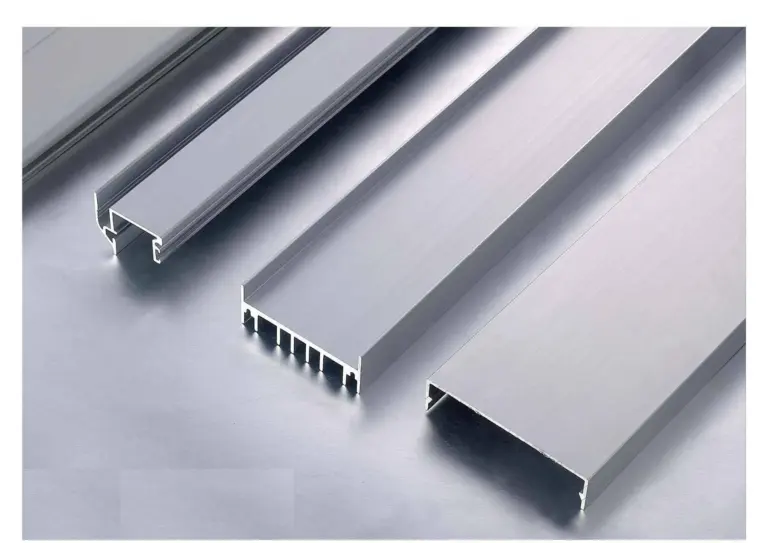

Illustrative image related to gantry crane device

3 Common User Pain Points for ‘gantry crane device’ & Their Solutions

Scenario 1: Adjusting Crane Heights for Varied Tasks

The Problem: Many B2B buyers in industries such as manufacturing and construction struggle with the need for adjustable lifting heights. Fixed-height gantry cranes often fall short when it comes to handling items of varying dimensions or working in environments with uneven floors. This limitation can lead to inefficiencies, increased labor costs, and even safety hazards when workers attempt to maneuver heavy loads at improper heights. Buyers may find themselves investing in multiple cranes to accommodate different tasks, which can inflate budgets and complicate logistics.

The Solution: To address this challenge, buyers should consider investing in adjustable height gantry cranes, which allow for seamless height modifications in 6-inch increments. When sourcing these cranes, look for models that feature spring-loaded locking pins to ensure secure adjustments. Additionally, inquire about cranes equipped with height-extension kits for increased versatility under no-load conditions. By selecting a crane with adjustable features, businesses can optimize their lifting operations for diverse applications without the need for multiple pieces of equipment, ultimately reducing costs and enhancing safety.

Scenario 2: Ensuring Stability and Safety in Dynamic Environments

The Problem: In fast-paced work environments, stability and safety are paramount. B2B buyers often face challenges with gantry cranes that can become unstable during operations, especially when handling heavy loads or navigating uneven surfaces. This instability can lead to accidents, damaging both personnel and equipment, and can result in costly downtime. Buyers need a reliable solution that enhances operational safety without sacrificing efficiency.

The Solution: To ensure stability, buyers should prioritize gantry cranes with robust design features, such as heavy-duty casters and a low center of gravity. Opt for cranes that allow for adjustable spans; this feature not only enables better maneuverability in confined spaces but also enhances stability during lifting tasks. Additionally, investing in anti-collision systems can further mitigate risks when cranes are operated in crowded environments. Comprehensive training for operators on how to use these features effectively can also significantly reduce the risk of accidents, ensuring a safer workplace.

Illustrative image related to gantry crane device

Scenario 3: Managing Logistics and Space Constraints

The Problem: Logistics play a critical role in the efficiency of operations involving gantry cranes. Many B2B buyers encounter challenges related to space constraints, particularly in facilities with narrow aisles or limited room for maneuvering equipment. The inability to easily transport cranes can result in lost time and increased operational costs, as teams may struggle to reposition cranes for various tasks.

The Solution: Buyers should consider portable gantry cranes designed for easy transport and setup. Look for cranes that feature adjustable spans, allowing them to be shortened for transport through narrow aisles. Investing in cranes with lightweight materials, such as aluminum, can further facilitate mobility without compromising on load capacity. Additionally, incorporating modular designs that can be easily disassembled and reassembled can provide flexibility in various work environments. By selecting equipment tailored for efficient logistics, businesses can streamline their operations and maximize productivity.

Strategic Material Selection Guide for gantry crane device

What Are the Key Materials Used in Gantry Crane Devices?

When selecting materials for gantry cranes, several common options come into consideration, each with unique properties that affect performance, durability, and cost. Understanding these materials is crucial for B2B buyers, particularly those in diverse regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to gantry crane device

How Does Steel Perform as a Material for Gantry Cranes?

Steel is one of the most widely used materials for gantry cranes due to its exceptional strength and durability. It typically has a high tensile strength, making it suitable for heavy lifting and demanding applications. Steel cranes can withstand high temperatures and pressures, which is advantageous in industrial settings.

Pros: Steel’s primary advantage is its robustness, allowing for heavy loads and extended service life. It also offers good resistance to deformation under load.

Cons: However, steel is susceptible to corrosion if not properly treated or coated, which can be a significant drawback in humid or corrosive environments. Its weight can also complicate transport and installation.

Impact on Application: Steel is compatible with a wide range of lifting applications, including construction and manufacturing. Its strength makes it ideal for lifting heavy machinery or materials.

Considerations for International Buyers: Buyers must consider compliance with local standards such as ASTM in the U.S. or DIN in Germany. In regions with high humidity, additional corrosion protection measures may be necessary.

Why Choose Aluminum for Gantry Cranes?

Aluminum is another popular choice, particularly for portable gantry cranes. It is lightweight, which facilitates easier transport and setup. Aluminum cranes are often used in environments where mobility is essential.

Illustrative image related to gantry crane device

Pros: The primary advantage of aluminum is its lightweight nature, which allows for easy maneuverability. It also has good corrosion resistance, making it suitable for outdoor applications.

Cons: However, aluminum has a lower tensile strength compared to steel, which limits its load-bearing capacity. This can be a significant limitation for heavy-duty applications.

Impact on Application: Aluminum cranes are often used in warehouses and for lighter lifting tasks, making them ideal for operations that require frequent relocation.

Considerations for International Buyers: Buyers should ensure that aluminum cranes meet local safety standards and regulations. In regions with strict weight restrictions, aluminum’s lightweight nature can be beneficial.

What Role Does Composite Material Play in Gantry Cranes?

Composite materials, often used in specialized applications, combine lightweight properties with high strength. While not as common as steel or aluminum, they are gaining traction in specific niche markets.

Pros: Composites offer excellent corrosion resistance and can be designed to withstand specific environmental conditions. Their lightweight nature allows for easy handling and transport.

Cons: The primary drawback is cost; composites are generally more expensive than traditional materials. Additionally, manufacturing processes can be complex, requiring specialized knowledge.

Impact on Application: Composites are suitable for applications in corrosive environments, such as chemical plants or marine settings, where traditional materials may fail.

Considerations for International Buyers: Buyers should be aware of the specific certifications and standards applicable to composite materials in their region. This may include compliance with industry-specific regulations.

Illustrative image related to gantry crane device

How Does Plastic Factor into Gantry Crane Design?

Plastic, particularly high-density polyethylene (HDPE), is sometimes used for components of gantry cranes, especially in non-load-bearing applications.

Pros: Plastics are lightweight and resistant to many chemicals, making them suitable for specific environments. They are also less expensive than metals.

Cons: The primary limitation is their lower strength and load capacity compared to metals. Plastics can also degrade under UV exposure unless treated.

Impact on Application: Plastic components can be useful in environments where corrosion is a concern, but they are generally not suitable for structural applications.

Illustrative image related to gantry crane device

Considerations for International Buyers: Buyers should verify that plastic components meet relevant safety and performance standards in their region.

Summary Table of Material Selection for Gantry Cranes

| Material | Typical Use Case for gantry crane device | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy lifting in industrial applications | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Portable lifting solutions | Lightweight and easy to transport | Lower load capacity than steel | Medium |

| Composite | Specialized applications in corrosive environments | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Non-load-bearing components | Lightweight and chemical resistant | Low strength and UV degradation | Low |

This guide serves as a strategic resource for international B2B buyers looking to make informed decisions regarding material selection for gantry cranes, ensuring compliance with regional standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for gantry crane device

What Are the Main Stages of Manufacturing a Gantry Crane Device?

The manufacturing of gantry cranes involves a series of well-defined stages, each critical to ensuring the final product meets the necessary specifications and quality standards. Understanding these stages helps B2B buyers make informed decisions when sourcing from suppliers.

Illustrative image related to gantry crane device

-

Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials used include high-strength steel and aluminum, chosen for their durability and load-bearing capabilities. The materials undergo cutting and shaping to prepare them for the next stages. This preparation may involve CNC machining, where precision is paramount to ensure that components fit correctly during assembly. -

Forming

After material preparation, the next stage is forming. This process includes bending, welding, and machining the materials into their final shapes. For steel gantries, techniques like hot-rolling and cold-rolling are often used to create beams and frames that can withstand heavy loads. Advanced welding techniques, such as TIG and MIG welding, are employed to ensure strong, durable joints that can endure the stresses of lifting operations. -

Assembly

The assembly stage involves bringing together all the formed components. This includes attaching the gantry’s vertical supports to the horizontal beam, installing wheels, and integrating lifting mechanisms. During this stage, it is essential to follow specific assembly protocols to maintain structural integrity. Quality checks are often conducted at this stage to verify alignment and fit before moving to the next phase. -

Finishing

The final manufacturing stage is finishing, which involves surface treatments and coatings to enhance durability and aesthetics. Processes such as sandblasting, powder coating, or galvanizing are commonly used to protect against corrosion and wear. The finishing stage also includes inspection for surface defects, ensuring that the gantry crane meets both functional and visual standards.

How Is Quality Assurance Implemented in Gantry Crane Manufacturing?

Quality assurance (QA) is a critical component in the manufacturing process of gantry cranes. It ensures that products meet international standards and client specifications, which is particularly important for B2B buyers seeking reliable suppliers.

-

International Standards Compliance

Gantry crane manufacturers often adhere to international standards like ISO 9001, which outlines quality management principles. Compliance with these standards ensures a systematic approach to quality, focusing on continuous improvement and customer satisfaction. Additionally, products may need to meet industry-specific certifications such as CE marking for the European market or API standards for certain lifting equipment. -

Quality Control Checkpoints

Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Checks are conducted during various stages of production to identify issues early and prevent defects.

– Final Quality Control (FQC): A thorough inspection of the completed gantry crane is conducted to ensure all specifications are met before shipment. -

Common Testing Methods

Various testing methods are utilized to validate the quality and safety of gantry cranes. Load testing is one of the most significant tests, where cranes are subjected to maximum load conditions to verify structural integrity and performance. Non-destructive testing (NDT) methods, such as ultrasonic and magnetic particle inspections, are also used to detect internal flaws without damaging the material.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure reliable and safe products.

-

Supplier Audits

Conducting supplier audits is one of the most effective ways to verify quality assurance processes. Audits can assess compliance with international standards, review quality management systems, and examine production capabilities. Buyers should request audit reports and certifications as part of their due diligence. -

Requesting Quality Reports

Suppliers should be able to provide documentation of their quality control processes, including testing results and compliance certifications. Regular quality reports can give insight into the supplier’s commitment to maintaining high standards and addressing any issues promptly. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality control processes. These services can conduct inspections at various stages of production, ensuring that the cranes meet the required specifications before they are shipped.

What Are the Quality Control and Certification Nuances for International Buyers?

B2B buyers operating in different regions must be aware of specific quality control and certification nuances that may affect their procurement process.

Illustrative image related to gantry crane device

-

Regional Compliance Requirements

Different regions may have varying compliance requirements. For instance, the European Union has stringent regulations for machinery safety, necessitating CE marking. Buyers in the Middle East might need to ensure compliance with local standards, which can differ significantly from those in Europe or the Americas. -

Understanding Certification Bodies

Familiarizing oneself with recognized certification bodies in the target market can help buyers assess supplier credibility. Certifications from reputable organizations can serve as a quality assurance indicator, especially for buyers unfamiliar with local suppliers. -

Cultural Considerations

Understanding cultural attitudes toward quality and safety can influence supplier relationships. In some regions, informal agreements may be common, while in others, formal contracts and stringent adherence to specifications are expected. Buyers should adapt their approaches accordingly to ensure successful partnerships.

By comprehensively understanding the manufacturing processes and quality assurance practices for gantry cranes, B2B buyers can make informed decisions, ensuring they source reliable and high-quality equipment that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘gantry crane device’

To assist B2B buyers in procuring a gantry crane device, this guide provides a practical checklist that outlines essential steps to ensure a successful purchase. Whether you are in Africa, South America, the Middle East, or Europe, following these steps will help streamline your sourcing process.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your gantry crane. Consider factors such as lifting capacity, height adjustments, span length, and material type (e.g., aluminum vs. steel). This step is crucial as it informs suppliers about your needs and ensures that you select a crane suitable for your specific applications.

- Lifting Capacity: Determine the maximum weight your crane will need to handle.

- Height and Span: Specify the height and width requirements based on your workspace.

Step 2: Research Compliance and Safety Standards

Investigate the regulatory standards and safety certifications relevant to gantry cranes in your region. Compliance with local and international safety standards is vital to ensure the safety of your operations and to mitigate liability risks.

Illustrative image related to gantry crane device

- ISO Certification: Look for suppliers that comply with ISO standards related to material handling equipment.

- Local Regulations: Check if there are specific safety regulations in your country or region that must be met.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. This evaluation helps ensure you partner with a reputable supplier who can deliver quality products.

- Supplier Experience: Assess how long they have been in the industry and their reputation.

- Customer Reviews: Look for testimonials or feedback from previous clients to gauge reliability.

Step 4: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. While cost is a significant factor, consider the value offered, including warranty, after-sales support, and delivery timelines.

- Total Cost of Ownership: Factor in maintenance, spare parts availability, and operational efficiency.

- Payment Terms: Understand the payment options and any financing available.

Step 5: Request Demonstrations or Trials

If possible, request a demonstration or trial of the gantry crane before purchase. This allows you to assess the crane’s performance, ease of use, and any additional features that may be beneficial for your operations.

- Test Lifting Capacity: Ensure that the crane can handle the specified loads effectively.

- User Experience: Evaluate the ergonomics and control mechanisms to ensure they meet your team’s needs.

Step 6: Confirm After-Sales Support and Warranty

Ensure the supplier provides robust after-sales support and a comprehensive warranty. This is crucial for minimizing downtime and ensuring that you have assistance when needed.

- Technical Support: Verify the availability of customer service and technical support.

- Warranty Coverage: Understand what is covered under the warranty and the duration.

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier, carefully review and finalize the purchase agreement. Ensure that all terms discussed are documented, including delivery dates, installation services, and payment schedules.

Illustrative image related to gantry crane device

- Contract Clarity: Ensure all specifications, costs, and terms are clearly stated to avoid future disputes.

- Sign-off on Deliverables: Confirm the expected deliverables, including any training or installation services.

Following these steps will guide you through the sourcing process for a gantry crane device, ensuring you make informed decisions that align with your operational needs.

Comprehensive Cost and Pricing Analysis for gantry crane device Sourcing

What Are the Key Cost Components in Gantry Crane Device Sourcing?

When sourcing gantry cranes, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Steel and aluminum are common, with aluminum being lighter but often more expensive. The thickness and quality of materials will also influence durability and, consequently, the price.

-

Labor: Labor costs cover both manufacturing and assembly. Skilled labor may be required for custom designs or complex features, which can elevate costs. In regions with higher labor rates, such as parts of Europe, this can be a significant factor.

-

Manufacturing Overhead: This includes factory utilities, equipment maintenance, and other indirect costs associated with production. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Custom tooling for unique designs or specifications can incur additional costs. Standard designs usually have lower tooling costs, while custom features can lead to higher expenses.

-

Quality Control (QC): Ensuring the crane meets safety and performance standards is critical. Rigorous QC processes may increase costs but are necessary to avoid liabilities and ensure product reliability.

-

Logistics: Transporting the cranes from the manufacturer to the buyer’s location can add considerable costs, especially for international shipments. Factors such as distance, mode of transport, and customs duties must be considered.

-

Margin: Suppliers typically add a profit margin to the total cost of production. This margin can vary widely based on market demand, competition, and the supplier’s positioning.

How Do Price Influencers Affect Gantry Crane Costs?

Several factors can influence the pricing of gantry cranes:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Suppliers often have set MOQs that can affect pricing; negotiating these terms can yield better pricing.

-

Specifications and Customization: Customized cranes or those with specific features (like adjustable heights or spans) typically cost more. Buyers should weigh the necessity of these features against their budget.

-

Materials Quality and Certifications: Higher quality materials and certifications (such as ISO standards) can increase costs but may also enhance the crane’s durability and safety. Buyers should consider the long-term benefits of investing in quality.

-

Supplier Factors: The supplier’s reputation, location, and reliability play a crucial role in pricing. Established suppliers may charge more but can offer better service and quality assurance.

-

Incoterms: Understanding shipping terms (like FOB, CIF) is essential for calculating total costs. These terms dictate who pays for shipping and insurance, influencing the final price.

What Negotiation Strategies Can Buyers Use for Cost-Efficiency?

International B2B buyers should employ several strategies to negotiate effectively:

-

Research and Compare: Conduct thorough research on various suppliers, comparing prices and features. This knowledge can strengthen your negotiation position.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield favorable conditions.

-

Discuss Total Cost of Ownership (TCO): Emphasize the importance of TCO, which includes maintenance, operation, and potential downtime. A higher initial investment may be justified if it leads to lower TCO.

-

Be Flexible: If possible, be open to alternative specifications or materials that may reduce costs without compromising essential functionality.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, especially from regions like Africa and South America, should consider specific nuances:

-

Currency Fluctuations: Exchange rates can affect the final cost. Locking in prices or negotiating in your local currency can mitigate risks.

-

Import Duties and Taxes: Be aware of local regulations regarding import duties, taxes, and compliance costs, as these can significantly increase the total cost.

-

Shipping Delays: Longer shipping times can affect project timelines. Discuss timelines with suppliers to ensure that costs related to delays are accounted for.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier pricing strategies, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure the best deal.

Alternatives Analysis: Comparing gantry crane device With Other Solutions

Introduction to Alternative Lifting Solutions

In the realm of material handling, gantry cranes are a popular choice for their versatility and efficiency. However, various alternative solutions exist that may better suit specific operational needs or budgets. Understanding these alternatives allows B2B buyers to make informed decisions tailored to their unique circumstances, whether they are in Africa, South America, the Middle East, or Europe.

Comparison Table

| Comparison Aspect | Gantry Crane Device | Adjustable Height Jib Crane | Vacuum Lifting Systems |

|---|---|---|---|

| Performance | High load capacity (up to 10 tons) | Moderate load capacity (up to 2 tons) | High efficiency for flat, non-porous surfaces |

| Cost | Mid-range investment | Lower initial cost | Higher upfront investment |

| Ease of Implementation | Requires assembly and space | Simple setup, less space required | Installation may require specialized training |

| Maintenance | Moderate maintenance; regular checks needed | Low maintenance; minimal parts involved | Requires regular checks and maintenance |

| Best Use Case | Heavy lifting in workshops or warehouses | Precision lifting in confined spaces | Lifting large sheets or heavy objects easily |

Detailed Breakdown of Alternatives

Adjustable Height Jib Crane

Adjustable height jib cranes are designed for versatility and ease of use, allowing operators to adjust the height of the lifting arm as needed. This feature is particularly beneficial in environments with varying load sizes or heights. Their lower initial cost makes them accessible for smaller businesses or those just starting with material handling solutions. However, their load capacity is limited compared to gantry cranes, making them less suitable for extremely heavy lifting tasks.

Vacuum Lifting Systems

Vacuum lifting systems offer a highly efficient solution for handling flat, non-porous materials such as glass, metal sheets, or concrete panels. These systems excel in precision and speed, reducing the risk of damage to delicate loads. However, they come with a higher upfront investment and may require specialized training for operators to ensure safe and effective usage. Maintenance can also be more intensive, as the vacuum systems must be regularly checked for leaks and functionality.

Illustrative image related to gantry crane device

Conclusion: Choosing the Right Lifting Solution for Your Business

When selecting the right lifting solution, B2B buyers must consider several factors, including load capacity, cost, ease of implementation, and maintenance requirements. Gantry cranes provide exceptional load capabilities and are suitable for a wide range of heavy lifting tasks, while adjustable height jib cranes offer flexibility and lower costs for lighter loads. On the other hand, vacuum lifting systems are ideal for precision handling of flat materials but require a higher investment and regular maintenance. By carefully evaluating these alternatives against their specific operational needs, businesses can make an informed choice that enhances productivity and efficiency.

Essential Technical Properties and Trade Terminology for gantry crane device

What Are the Key Technical Properties of a Gantry Crane Device?

When evaluating gantry cranes for purchase, understanding critical specifications is essential for making informed decisions. Below are some key properties that should be considered:

-

Load Capacity

Load capacity is the maximum weight a gantry crane can safely lift and transport. This specification is usually measured in tons and varies widely among different models. For B2B buyers, knowing the load capacity is vital to ensure that the crane meets the operational needs of the business, particularly in heavy-duty applications such as manufacturing and construction. -

Span

The span refers to the distance between the crane’s legs, which determines the width of the area it can cover during operations. Spans can be fixed or adjustable, allowing for flexibility depending on the workspace’s constraints. Understanding span is crucial for buyers to ensure that the crane can accommodate the specific layout of their facilities, especially in crowded or narrow spaces. -

Height Adjustment

Height adjustment capabilities allow the crane to be modified for different lifting requirements or to navigate through doorways and uneven surfaces. Many models feature adjustable heights in fixed increments, which can significantly enhance operational versatility. For international buyers, especially in regions with varying floor conditions, this property can be a game-changer in maximizing the crane’s utility. -

Material Grade

The material used in the construction of the gantry crane affects its durability and load-bearing capacity. Common materials include steel and aluminum, each offering distinct advantages. Steel cranes generally provide higher load capacities, while aluminum models are lighter and easier to transport. Buyers should consider the material grade to align with their operational demands and expected lifespan of the equipment. -

Mobility Features

Mobility features, such as heavy-duty casters, are essential for portable gantry cranes. The ability to easily move the crane from one location to another can improve operational efficiency. For industries that require frequent relocation of equipment, understanding these mobility options is critical in selecting the right gantry crane.

Which Trade Terms Should B2B Buyers Know When Purchasing Gantry Cranes?

In the context of purchasing gantry cranes, several industry-specific terms are commonly used. Familiarity with these terms can help buyers navigate the procurement process more effectively:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. For buyers, knowing whether they are dealing with an OEM can indicate the quality and reliability of the equipment, as OEMs typically adhere to stringent manufacturing standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is important for buyers to gauge their purchasing power and budget constraints, especially when sourcing equipment from international suppliers. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. For B2B buyers, issuing an RFQ is a strategic way to obtain competitive pricing and understand the available options. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers for the delivery of goods under sales contracts. Familiarity with Incoterms is essential for international buyers to understand shipping costs, risks, and responsibilities associated with the transportation of gantry cranes. -

Lead Time

Lead time is the time it takes from placing an order to receiving the goods. Understanding lead time is crucial for B2B buyers, particularly in industries where project timelines are tight, as delays can significantly impact operations. -

Warranty Period

The warranty period is the duration during which the manufacturer guarantees the performance of the crane and covers repairs or replacements. Knowing the warranty terms can help buyers assess the long-term value and reliability of their investment.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions when purchasing gantry cranes, ensuring they select the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the gantry crane device Sector

What Are the Current Market Dynamics and Key Trends in the Gantry Crane Device Sector?

The gantry crane device market is experiencing significant growth, driven by the increasing demand for efficient material handling solutions across various industries, including construction, manufacturing, and logistics. Key global drivers include the expansion of infrastructure projects in developing regions, particularly in Africa and South America, as well as the ongoing industrial automation trends in Europe and the Middle East. International B2B buyers are increasingly seeking advanced gantry crane solutions that offer portability, adjustable heights, and robust lifting capacities, catering to diverse operational needs.

Emerging technologies are reshaping sourcing trends in this sector. The integration of IoT (Internet of Things) in gantry cranes is enhancing operational efficiency by enabling real-time monitoring and predictive maintenance. Additionally, automation and robotics are becoming integral, with companies exploring collaborative robots (cobots) that can work alongside gantry cranes to streamline workflows. Buyers from regions like Saudi Arabia and Germany are particularly focused on suppliers that provide customizable solutions, allowing for tailored configurations that meet specific project requirements.

Moreover, the trend toward lightweight materials, such as aluminum, is gaining traction due to their portability and ease of use, making them ideal for urban environments where space is constrained. As companies look to optimize their supply chains, the emphasis is also on sourcing from manufacturers who can offer quick turnaround times and support services, ensuring minimal downtime in operations.

Illustrative image related to gantry crane device

How Are Sustainability and Ethical Sourcing Influencing the Gantry Crane Device Market?

Sustainability is becoming a pivotal consideration for international B2B buyers of gantry crane devices. The environmental impact of manufacturing processes is under scrutiny, with buyers increasingly preferring suppliers that demonstrate a commitment to sustainable practices. This includes the use of recyclable materials and energy-efficient manufacturing processes, which not only reduce carbon footprints but also align with global sustainability goals.

Ethical sourcing is equally important, as companies are held accountable for their supply chain practices. Buyers are prioritizing partnerships with manufacturers that adhere to ethical labor standards and provide transparency in their sourcing processes. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential credentials for suppliers aiming to differentiate themselves in the market.

Additionally, the adoption of ‘green’ materials in the production of gantry cranes is gaining momentum. Buyers are looking for cranes that incorporate environmentally friendly components, which can contribute to a circular economy. This focus on sustainability is not only beneficial for the planet but also enhances brand reputation, as companies that prioritize ethical sourcing are more likely to attract environmentally conscious clients.

What Is the Evolution of the Gantry Crane Device Market and Its Relevance Today?

The evolution of gantry cranes dates back to the early 20th century when they were primarily used in shipyards and heavy industry. Over the decades, their design has transformed significantly, adapting to the needs of various sectors. Early models were predominantly fixed in height and span, limiting their versatility. However, advancements in materials and engineering have led to the development of adjustable height and span gantry cranes, enhancing their applicability in a wider range of environments.

Today, the relevance of gantry cranes continues to grow as industries strive for greater efficiency and flexibility in material handling. The shift towards modular and portable designs reflects changing operational dynamics, particularly in sectors such as construction, where space constraints and mobility are critical. As global markets evolve, the demand for innovative gantry crane solutions that can adapt to diverse operational challenges positions them as indispensable tools in modern industrial applications.

Frequently Asked Questions (FAQs) for B2B Buyers of gantry crane device

1. How do I choose the right gantry crane for my operations?

Selecting the appropriate gantry crane depends on various factors, including the weight capacity required, the height and span needed for lifting, and the environment in which it will operate. Consider if you need an adjustable height model for flexibility or a fixed height for stability. Additionally, assess the mobility needs; portable cranes are beneficial for dynamic workspaces. Collaborate with your supplier to evaluate specific application requirements and ensure compliance with local regulations.

2. What is the best gantry crane type for heavy lifting?

For heavy lifting, steel gantry cranes are often the best choice due to their robustness and ability to support significant loads, typically up to 10 tons or more. Adjustable models allow for versatility in different environments, while fixed height cranes offer enhanced stability. Ensure the crane features heavy-duty casters for mobility if needed, and consult with manufacturers for tailored solutions that meet your specific load requirements.

3. How can I ensure the quality and safety of a gantry crane?

To ensure quality and safety, choose suppliers that comply with international standards such as ISO and CE certifications. Request detailed product specifications, including material quality and load ratings, and inquire about safety features like emergency stop mechanisms and overload protection. Conduct thorough inspections upon delivery and consider hiring a qualified technician for installation and regular maintenance checks to uphold safety standards.

4. What customization options are available for gantry cranes?

Many manufacturers offer customization options to suit specific operational needs. Common customizations include adjustable heights and spans, specialized attachments (like hoists or lifts), and modifications for unique workspace constraints. When discussing your requirements with suppliers, provide detailed information about your operational environment and load specifications to facilitate tailored solutions that enhance efficiency and safety.

5. What are the typical payment terms for purchasing gantry cranes internationally?

Payment terms can vary significantly depending on the supplier and the nature of the transaction. Common practices include a deposit upfront (often 30-50% of the total cost) with the balance due upon shipment or delivery. It’s essential to clarify terms before finalizing the order, including accepted payment methods (e.g., bank transfer, letter of credit) and any applicable taxes or duties, especially for international purchases.

6. How do I vet suppliers for gantry cranes?

To vet suppliers effectively, start by researching their reputation and industry experience. Request references and case studies from previous clients, particularly those in similar industries or regions. Verify their certifications and compliance with local regulations. Additionally, consider visiting their facility or requesting a virtual tour to assess manufacturing capabilities and quality control processes.

7. What are the logistics considerations when importing gantry cranes?

When importing gantry cranes, consider shipping methods, lead times, and customs regulations specific to your country. Ensure your supplier can provide necessary documentation, such as invoices and packing lists, to facilitate smooth customs clearance. Additionally, plan for transportation from the port to your facility, including any special handling requirements due to the crane’s size and weight.

Illustrative image related to gantry crane device

8. What is the minimum order quantity (MOQ) for gantry cranes?

Minimum order quantities for gantry cranes vary by supplier and product type. Some manufacturers may have a MOQ of one unit, while others may require multiple units for bulk pricing benefits. Discuss your needs with potential suppliers to understand their policies and negotiate terms that align with your purchasing strategy, especially if you are considering a larger fleet of cranes for your operations.

Top 8 Gantry Crane Device Manufacturers & Suppliers List

1. Gorbel – Gantry Cranes

Domain: gorbel.com

Registered: 1996 (29 years)

Introduction: Gantry Cranes provide an economical way to lift materials anywhere in a facility. They are a cost-effective lifting solution for areas of infrequent lifts compared to permanent structures. Key features include:

– Capacity: 1,000 lbs to 5 tons

– Span: Up to 30 ft

– Height: Up to 20 ft

– Coverage Area: Moveable Coverage Area

– Motorization: No

Types of Gantry Cranes:

1. Fixed Height Gantry Cr…

2. Gorbel – Adjustable Height Gantry Crane

Domain: ergonomicpartners.com

Registered: 2006 (19 years)

Introduction: {‘name’: ‘Gorbel Adjustable Height Gantry Crane’, ‘capacity’: ‘5-Ton’, ‘height_adjustable’: ’15-18 ft’, ‘span’: ’30 ft’, ‘manufacturer’: ‘Gorbel’, ‘availability’: ‘In stock’, ‘sku’: ‘AG-5-15/18-30’, ‘lead_time’: ‘typically ships in 13-16 business days’, ‘caster_options’: [‘Phenolic Casters (w/o Cam Brakes)’, ‘Phenolic Casters (w/ Cam Brakes)’, ‘Polyurethane Casters (w/o Cam Brakes)’, ‘Polyurethane…

3. Crane Depot – Gantry Cranes

Domain: cranedepot.com

Registered: 2013 (12 years)

Introduction: Gantry cranes are a subset of cranes with a hoist running horizontally along rails, typically on a single beam. They can lift heavy objects ranging from 250 lbs. to 10 tons, with heavy-duty models handling larger loads. Gantry cranes are equipped with casters and wheels for mobility under heavy loads. Available options include adjustable height and fixed height models, with a variety of capacities…

4. Mazzella Companies – Gantry Cranes

Domain: mazzellacompanies.com

Registered: 1998 (27 years)

Introduction: Gantry cranes are a type of overhead crane with a single or double girder configuration supported by freestanding legs that move on wheels or along a track. They are used when an overhead runway system is not feasible, often in outdoor applications or beneath existing bridge crane systems. There are several types of gantry cranes: 1. Full Gantry Crane Systems: Most popular configuration with two l…

5. LK Goodwin – Adjustable Height Steel Gantry Cranes

Domain: lkgoodwin.com

Registered: 2001 (24 years)

Introduction: Adjustable Height Steel Gantry Cranes (A Series) are portable, lightweight, and affordable lifting solutions with sturdy A-frame designs. They have greater clear spans due to not requiring four brace legs, with capacities available up to 10 tons. Features include:

– Crane Height Adjustments: Adjustable in 6-inch increments using spring-loaded steel locking pins that engage automatically when heig…

6. Konecranes – Industrial Overhead Gantry Cranes

Domain: konecranes.com

Registered: 1999 (26 years)

Introduction: Industrial Overhead Gantry Cranes suitable for various industries, including container handling, general manufacturing, metals production, mining, nuclear, paper and forest, petroleum and gas, power, shipyards, and waste to energy. Features include smart crane technologies, remote operating stations, and predictive maintenance services. Konecranes offers a range of gantry cranes including automate…

7. Reid Lifting – Gantry and Overhead Cranes

Domain: us.reidlifting.com

Registered: 1999 (26 years)

Introduction: Gantry cranes and overhead cranes are both lifting devices used for lifting and lowering operations, available in manual or electric operation. Overhead cranes, or bridge cranes, are mounted to a building’s structure and are permanent installations, ideal for heavy lifting in factories and warehouses. Gantry cranes are self-sufficient, supported by their own A frames, portable, and can be used ind…

8. AM Industries – Gantry Cranes

Domain: insights.am-ind.com

Registered: 1997 (28 years)

Introduction: Gantry cranes are versatile material handling cranes used in various industries such as shipping, construction, warehouses, and manufacturing. They consist of a horizontal girder supported by two A-frame legs, which can be fixed or mobile. Key types include Single Girder Gantry Crane, Double Girder Gantry Crane, Rubber-Tired Gantry Crane (RTG), Rail-Mounted Gantry Crane (RMG), and Adjustable Heigh…

Strategic Sourcing Conclusion and Outlook for gantry crane device

In today’s global marketplace, strategic sourcing of gantry cranes presents a unique opportunity for businesses across Africa, South America, the Middle East, and Europe. By leveraging advanced lifting solutions, such as adjustable height and portable options, companies can enhance operational efficiency while maintaining safety and compliance with industry standards. The ability to customize cranes according to specific needs, such as load capacity and workspace constraints, underscores the importance of selecting the right supplier who understands local market dynamics.

Investing in high-quality gantry cranes not only streamlines material handling processes but also contributes to long-term cost savings through durability and reduced maintenance needs. As industries evolve, the demand for innovative lifting solutions will continue to grow, making it essential for international buyers to stay informed about emerging technologies and supplier capabilities.

Looking ahead, businesses are encouraged to engage with reputable manufacturers and distributors to secure the best possible solutions. By prioritizing strategic sourcing, companies can position themselves for success in an increasingly competitive landscape. Embrace this opportunity to transform your operations and elevate your supply chain efficiency.

Illustrative image related to gantry crane device

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.