Furnace Pressure Switch Wiring: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for furnace pressure switch wiring

In today’s global market, sourcing reliable furnace pressure switch wiring is crucial for businesses seeking to optimize their heating systems and ensure operational efficiency. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe face unique challenges—such as varying standards, accessibility to quality components, and fluctuating costs—this guide aims to demystify the complexities of selecting the right wiring solutions.

This comprehensive resource will cover the various types of furnace pressure switches, their applications across different heating systems, and the importance of understanding the specific requirements for each application. Additionally, we will provide valuable insights into supplier vetting processes, enabling buyers to identify reputable manufacturers and distributors that meet their quality and compliance standards. Cost considerations will also be explored, helping businesses weigh their options and make informed financial decisions.

By equipping decision-makers with the knowledge needed to navigate the nuances of furnace pressure switch wiring, this guide empowers companies to enhance their purchasing strategies. Whether you’re a procurement officer in Nigeria or a facilities manager in Vietnam, understanding these critical components will lead to improved reliability and safety in your heating systems, ultimately driving better performance and customer satisfaction.

Understanding furnace pressure switch wiring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard SPST Switch | Simple open/closed mechanism with two terminals | Residential and light commercial furnaces | Pros: Cost-effective, easy to install. Cons: Limited functionality for advanced systems. |

| High-Pressure Switch | Designed for two-stage heating systems, varying suction | Industrial and high-efficiency residential units | Pros: Versatile for different heating demands. Cons: More complex installation and higher cost. |

| Dual Pressure Switch | Offers both high and low-pressure settings for flexibility | Large-scale HVAC systems | Pros: Enhances operational efficiency. Cons: Requires careful calibration and maintenance. |

| Integrated Pressure Switch | Combines pressure sensing with electronic control | Modern HVAC systems | Pros: Improved safety and automation. Cons: Higher initial investment and potential compatibility issues. |

| Adjustable Pressure Switch | Allows manual adjustments of pressure settings | Custom HVAC applications | Pros: Tailored performance for specific needs. Cons: May require specialized knowledge for setup. |

What are the Characteristics of Standard SPST Switches?

Standard Single Pole Single Throw (SPST) switches are the most common type of furnace pressure switches used in residential applications. These switches feature a straightforward design with two terminals and operate on a simple open/closed mechanism. They are ideal for basic heating systems where a direct connection to the inducer fan is required. B2B buyers often prefer these switches due to their affordability and ease of installation. However, businesses should consider that their limited functionality may not meet the needs of more complex systems.

How Do High-Pressure Switches Differ from Standard Options?

High-pressure switches are specifically designed for two-stage heating systems, which require different levels of suction for low and high heat output. This variation makes them suitable for both industrial and high-efficiency residential applications. For B2B buyers, the advantage of high-pressure switches lies in their ability to optimize heating efficiency, but the complexity of installation and higher costs can be a drawback. Proper training and knowledge of HVAC systems are essential for effective implementation.

What Advantages Do Dual Pressure Switches Provide?

Dual pressure switches allow for both high and low-pressure settings, providing flexibility in large-scale HVAC systems. These switches are particularly useful in environments where varying heating demands are present. B2B purchasers value dual pressure switches for their ability to enhance operational efficiency and safety. However, they require careful calibration and regular maintenance, which may increase operational costs over time.

What are Integrated Pressure Switches and Their Benefits?

Integrated pressure switches combine the functionality of pressure sensing with electronic control systems, making them a staple in modern HVAC setups. These switches improve safety by preventing furnace ignition when proper ventilation is not detected. B2B buyers appreciate the automation and reliability these switches offer, although the higher initial investment and potential compatibility issues with older systems can be a concern.

Why Consider Adjustable Pressure Switches?

Adjustable pressure switches provide businesses with the ability to manually set pressure levels according to specific operational needs. This customization makes them suitable for unique HVAC applications that may require tailored performance. While B2B buyers benefit from the flexibility and adaptability of these switches, they may also need specialized knowledge for installation and adjustment, which can add to the overall cost of ownership.

Key Industrial Applications of furnace pressure switch wiring

| Industry/Sector | Specific Application of furnace pressure switch wiring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC Systems | Integration in residential and commercial heating systems | Ensures safety and efficiency in heating operations | Availability of compatible models and local support |

| Industrial Manufacturing | Monitoring combustion processes in furnaces and boilers | Enhances operational safety and prevents equipment damage | Compliance with industry standards and regulations |

| Oil & Gas | Pressure monitoring in heating units for fluid processing | Mitigates risks of hazardous emissions and system failures | Durability in extreme conditions and reliability under pressure |

| Power Generation | Usage in gas turbine systems for pressure regulation | Optimizes performance and increases energy efficiency | Sourcing from trusted manufacturers with proven track records |

| Food Processing | Control of heating elements in ovens and drying systems | Maintains product quality and prevents overheating | Need for food-grade materials and certifications |

How is Furnace Pressure Switch Wiring Used in HVAC Systems?

In HVAC systems, furnace pressure switch wiring is critical for integrating safety mechanisms that control heating operations. These switches ensure that the furnace ignites only when there is adequate pressure, thereby preventing dangerous gas leaks or system malfunctions. International buyers in regions such as Africa and South America must consider the compatibility of pressure switches with local furnace models, as well as the availability of technical support for installation and maintenance.

What Role Does Furnace Pressure Switch Wiring Play in Industrial Manufacturing?

In industrial manufacturing, furnace pressure switches are vital for monitoring combustion processes in furnaces and boilers. They help maintain optimal pressure levels, thus enhancing operational safety and preventing equipment damage. For businesses in the Middle East and Europe, sourcing pressure switches that comply with local safety regulations is essential. Buyers should also prioritize suppliers who can provide reliable technical documentation and support.

How Does Furnace Pressure Switch Wiring Benefit the Oil & Gas Industry?

In the oil and gas sector, furnace pressure switch wiring is used for pressure monitoring in heating units that process fluids. This application is crucial for mitigating risks associated with hazardous emissions and potential system failures. Buyers in this industry, particularly from regions with stringent safety standards, should focus on sourcing durable and reliable pressure switches that can withstand extreme conditions.

Why is Furnace Pressure Switch Wiring Important in Power Generation?

In power generation, especially in gas turbine systems, furnace pressure switch wiring regulates pressure to optimize performance. This ensures energy efficiency and reduces operational costs. Buyers from South America and Africa should look for manufacturers that offer proven products with certifications, ensuring reliability under varied operational conditions.

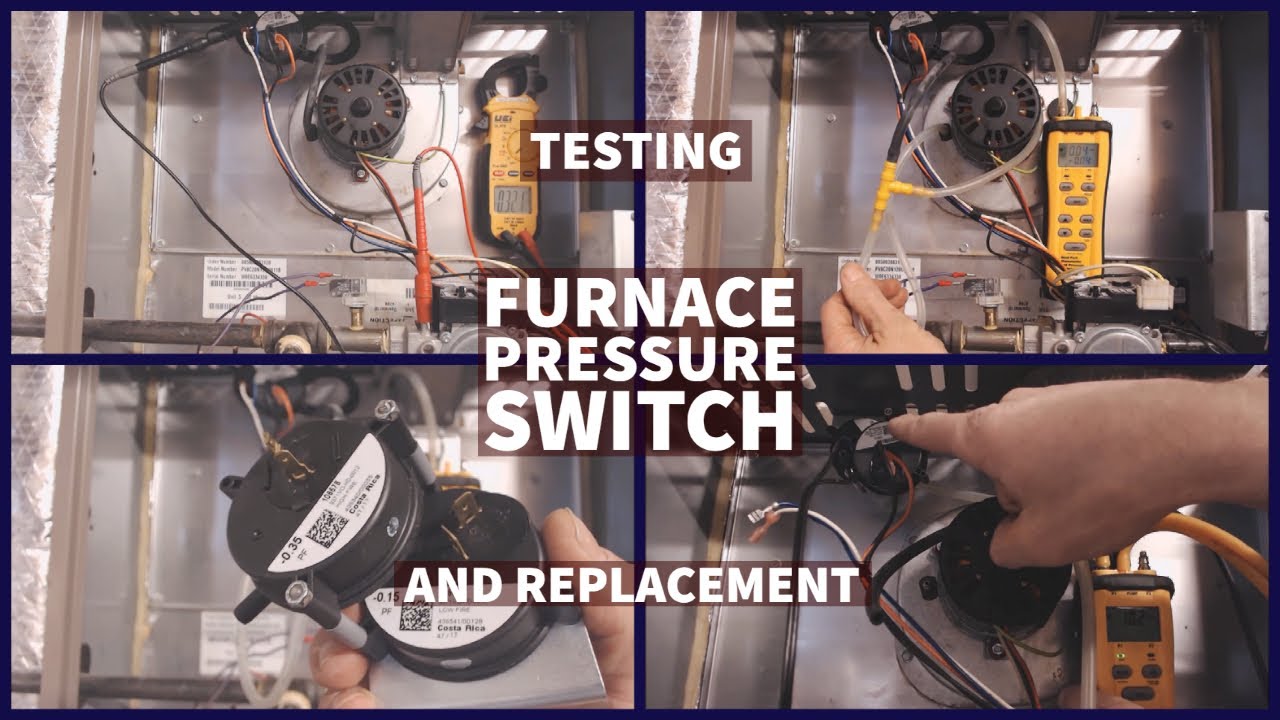

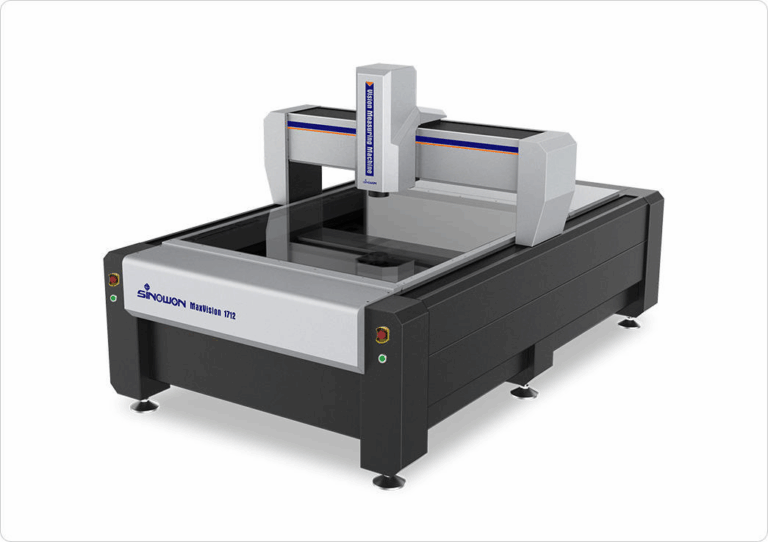

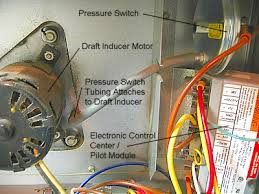

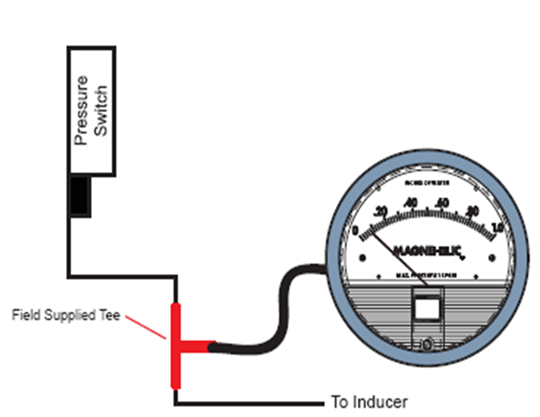

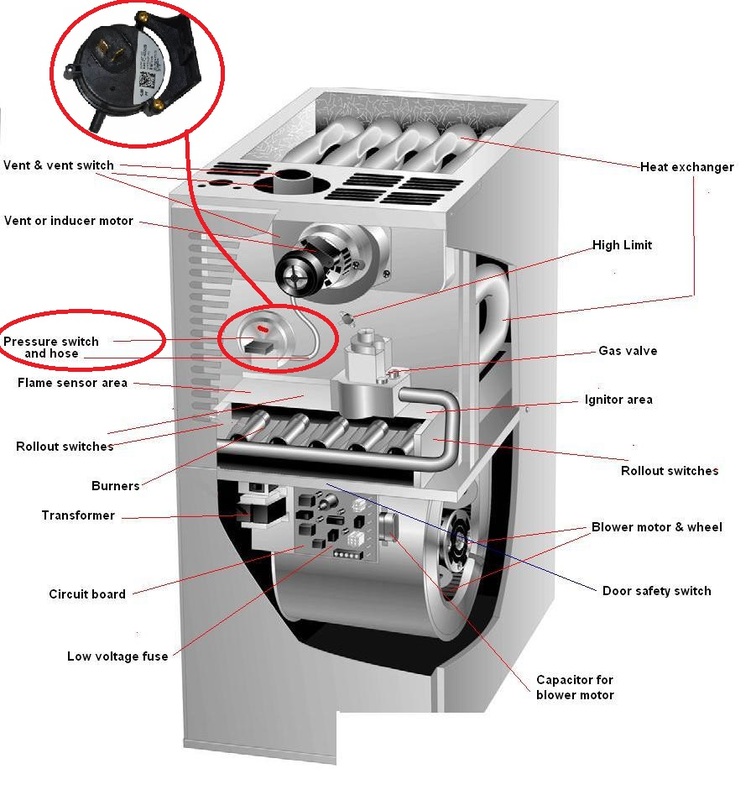

Illustrative image related to furnace pressure switch wiring

How is Furnace Pressure Switch Wiring Applied in Food Processing?

In the food processing industry, furnace pressure switch wiring controls heating elements in ovens and drying systems. Proper functioning is essential to maintain product quality and prevent overheating, which could lead to food spoilage. Buyers in Europe and the Middle East must ensure that the materials used in these switches meet food-grade standards and come with necessary certifications for safety and compliance.

3 Common User Pain Points for ‘furnace pressure switch wiring’ & Their Solutions

Scenario 1: Confusion Over Wiring Connections for Pressure Switches

The Problem: B2B buyers often encounter situations where they need to replace or install a furnace pressure switch but face confusion regarding the proper wiring connections. This is especially common when dealing with different models or aftermarket equivalents that may not have clear documentation. Miswiring can lead to system malfunctions, safety hazards, or even damage to the furnace, leaving buyers frustrated and uncertain about the next steps.

The Solution: To mitigate this issue, buyers should prioritize sourcing pressure switches from reputable manufacturers that provide comprehensive wiring diagrams and technical specifications. When installing a new switch, carefully examine the wiring layout for the specific furnace model in question. If documentation is lacking, buyers can conduct continuity tests using a multimeter to identify terminal functions. For instance, identifying Normally Open (NO) and Common (C) terminals is critical; connecting the +24V AC lead to the NO terminal ensures proper operation. Additionally, engaging with technical support from the manufacturer can provide clarity and confidence in making correct connections, reducing the risk of operational failures.

Scenario 2: Intermittent Operation Leading to Unreliable Performance

The Problem: A common pain point for B2B buyers is dealing with intermittent operation of the furnace due to pressure switch issues. This often manifests as the furnace occasionally failing to ignite or shut down unexpectedly, which can create significant disruptions in heating operations. Buyers may be left guessing the cause, leading to increased maintenance costs and potential downtime.

The Solution: To address this challenge, it is essential to conduct a thorough diagnostic of the furnace’s pressure switch and its related components. Buyers should inspect the inducer fan for blockages and ensure that the tubing connecting the switch to the inducer is intact and free from cracks or leaks. Implementing a regular maintenance schedule that includes testing the pressure switch’s responsiveness to changes in pressure can help identify issues before they escalate. Furthermore, investing in high-quality, durable pressure switches designed for the specific furnace model can enhance reliability and reduce the frequency of replacements or repairs.

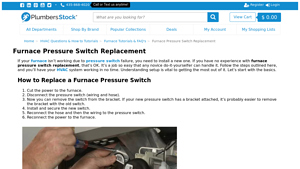

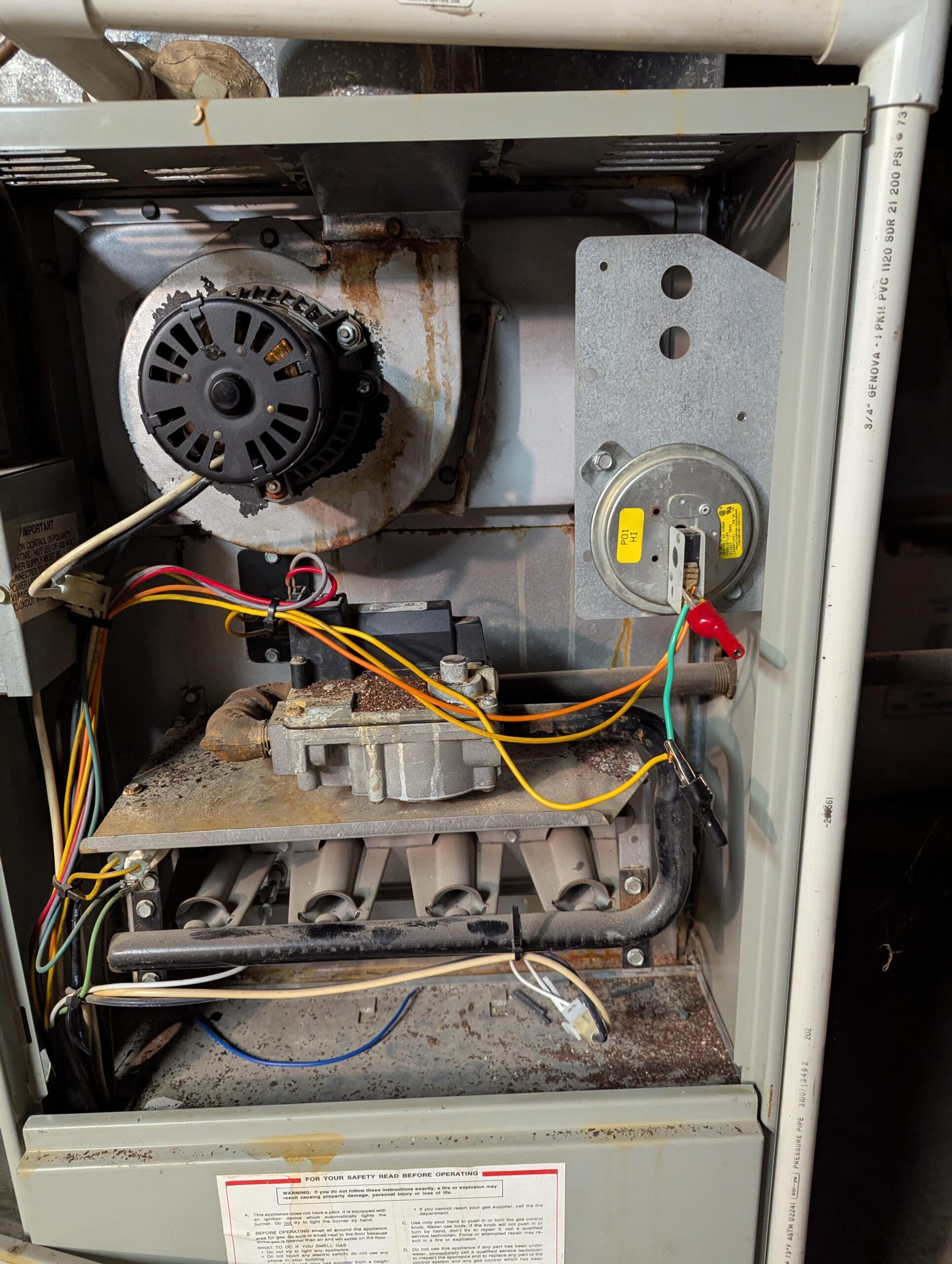

Illustrative image related to furnace pressure switch wiring

Scenario 3: Challenges with Sourcing Compatible Pressure Switches

The Problem: B2B buyers operating in regions with limited access to furnace parts often struggle to find compatible pressure switches for their systems. This can lead to extended lead times for repairs and increased operational costs. In some cases, buyers may resort to using incompatible parts, which can compromise the system’s efficiency and safety.

The Solution: To effectively address sourcing challenges, buyers should build relationships with multiple suppliers who specialize in HVAC components, including pressure switches. Utilizing online platforms that aggregate suppliers can streamline the search process for compatible parts. When evaluating potential replacements, it is crucial to cross-reference part numbers and specifications against the furnace’s manual or manufacturer guidelines. Buyers can also consider investing in dual-pressure switches, which provide flexibility for different heating demands and may be more readily available. Establishing a proactive inventory management system that includes critical components like pressure switches can further minimize downtime and improve operational efficiency.

Strategic Material Selection Guide for furnace pressure switch wiring

What Are the Key Materials for Furnace Pressure Switch Wiring?

When selecting materials for furnace pressure switch wiring, it is crucial to consider properties that directly impact performance, durability, and compliance with international standards. Here, we analyze four common materials used in this application: copper, aluminum, PTFE (Polytetrafluoroethylene), and silicone. Each material has distinct characteristics that influence its suitability for various environments and applications.

How Does Copper Perform in Furnace Pressure Switch Wiring?

Copper is a widely used conductor in electrical applications due to its excellent electrical conductivity and thermal properties. It typically has a high temperature rating, making it suitable for environments with significant heat fluctuations.

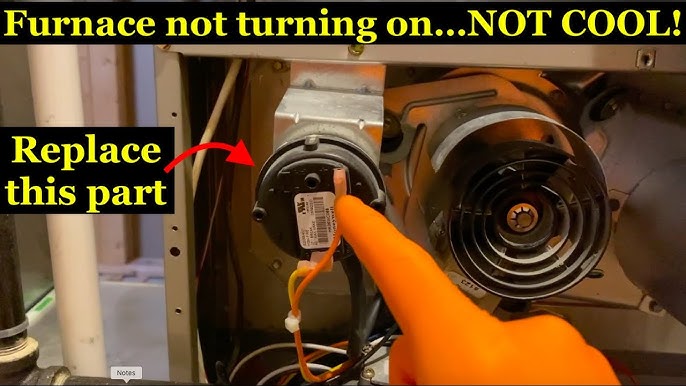

Illustrative image related to furnace pressure switch wiring

Pros: Copper’s durability and resistance to corrosion make it ideal for long-term use in furnace applications. It is also relatively easy to work with, allowing for straightforward manufacturing processes.

Cons: The primary drawback of copper is its cost, which can be higher than alternatives like aluminum. Additionally, copper wiring can be susceptible to oxidation if not properly insulated, which may affect performance over time.

Impact on Application: Copper is compatible with various media and can withstand high-pressure environments, making it a reliable choice for furnace pressure switch wiring.

Considerations for International Buyers: Buyers should ensure that copper wiring complies with international standards such as ASTM and IEC. Countries in Africa and South America may have specific regulations regarding material sourcing and environmental impact that need to be considered.

What Role Does Aluminum Play in Furnace Pressure Switch Wiring?

Aluminum is another common material used in wiring due to its lightweight nature and good conductivity, though it is slightly less conductive than copper.

Pros: The main advantage of aluminum is its lower cost compared to copper, making it an attractive option for budget-conscious projects. Additionally, aluminum’s lightweight properties can reduce shipping costs and ease installation.

Cons: However, aluminum is more prone to oxidation, which can lead to electrical resistance over time if not properly treated. It also has a lower tensile strength, which may limit its applications in high-stress environments.

Impact on Application: Aluminum is suitable for low to medium-pressure applications but may not be ideal for high-temperature environments where copper would perform better.

Illustrative image related to furnace pressure switch wiring

Considerations for International Buyers: Buyers should ensure compliance with local standards, as some regions may have restrictions on aluminum use in electrical applications due to safety concerns.

Why Is PTFE a Preferred Insulation Material for Furnace Pressure Switch Wiring?

PTFE is often used as insulation for wiring due to its excellent chemical resistance and thermal stability.

Pros: PTFE can withstand high temperatures and is resistant to a wide range of chemicals, making it ideal for harsh environments. Its non-stick properties also prevent the buildup of contaminants.

Cons: The primary limitation of PTFE is its cost, as it can be significantly more expensive than traditional insulation materials. Additionally, the manufacturing process can be complex, which may lead to longer lead times.

Illustrative image related to furnace pressure switch wiring

Impact on Application: PTFE is particularly useful in applications where exposure to aggressive chemicals or extreme temperatures is expected, ensuring the longevity and reliability of the wiring.

Considerations for International Buyers: Buyers should verify that PTFE insulation meets local safety and environmental regulations, particularly in regions with strict chemical handling laws.

How Does Silicone Contribute to Furnace Pressure Switch Wiring?

Silicone is increasingly used in wiring applications due to its flexibility and resistance to extreme temperatures.

Illustrative image related to furnace pressure switch wiring

Pros: Silicone’s flexibility allows for easy installation in tight spaces, and its high-temperature resistance makes it suitable for applications where heat is a concern. It also exhibits good electrical insulation properties.

Cons: The main drawback of silicone is its relatively high cost compared to other insulation materials. Additionally, while silicone is durable, it may not be as chemically resistant as PTFE.

Impact on Application: Silicone is well-suited for applications with fluctuating temperatures and where flexibility is essential, such as in compact furnace designs.

Illustrative image related to furnace pressure switch wiring

Considerations for International Buyers: Buyers should check for compliance with international standards and certifications, as silicone products may vary in quality and performance across different manufacturers.

Summary Table of Material Selection for Furnace Pressure Switch Wiring

| Material | Typical Use Case for furnace pressure switch wiring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance electrical connections | Excellent conductivity and durability | Higher cost and oxidation risk | High |

| Aluminum | Budget-friendly wiring solutions | Lightweight and cost-effective | Prone to oxidation and lower strength | Medium |

| PTFE | Insulation in harsh environments | High chemical resistance and thermal stability | Expensive and complex manufacturing | High |

| Silicone | Flexible wiring applications | High-temperature resistance and flexibility | Higher cost and lower chemical resistance | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers considering furnace pressure switch wiring, helping them make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for furnace pressure switch wiring

What Are the Main Stages of the Manufacturing Process for Furnace Pressure Switch Wiring?

The manufacturing process for furnace pressure switch wiring involves several critical stages, each of which contributes to the final product’s quality and reliability. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

How Is Material Preparation Conducted for Furnace Pressure Switch Wiring?

Material preparation is the first step in the manufacturing process. This stage typically involves selecting high-quality materials, such as copper for wiring, thermoplastics for the switch housing, and rubber for seals. The materials undergo rigorous inspection to ensure they meet specific standards.

Illustrative image related to furnace pressure switch wiring

During this phase, suppliers may utilize advanced technologies like laser cutting and precision machining to prepare components for assembly. By sourcing materials that comply with international standards, manufacturers reduce the risk of defects and ensure that the end product is durable and effective.

What Techniques Are Used in the Forming Stage of Furnace Pressure Switch Manufacturing?

The forming stage involves shaping the prepared materials into the necessary components of the furnace pressure switch. Techniques such as injection molding for plastic parts and stamping for metal components are commonly employed.

Injection molding allows for complex geometries and ensures uniformity, while stamping provides high precision for metal parts. Manufacturers may also use automated processes to enhance efficiency and minimize human error, ensuring that each component is produced consistently according to specifications.

How Are Components Assembled in the Manufacturing Process?

Assembly is a critical stage in the manufacturing of furnace pressure switch wiring. This process often involves integrating various components, such as the pressure switch, wiring, connectors, and housing.

Skilled technicians or automated assembly lines perform the assembly, ensuring that each component is securely fitted and that electrical connections are properly made. Quality control measures, such as visual inspections and functional tests, are implemented during assembly to identify any issues before the product moves to the finishing stage.

What Finishing Processes Are Involved in Producing Furnace Pressure Switch Wiring?

Finishing processes enhance the durability and functionality of the furnace pressure switch wiring. These processes may include surface treatments, such as coating or plating, to protect against corrosion and wear.

Additionally, manufacturers may perform final inspections to ensure that all components meet the required specifications and standards. This final quality check is essential for identifying any defects that may have occurred during earlier stages of production.

Which International Standards Govern Quality Assurance in Furnace Pressure Switch Manufacturing?

Quality assurance is paramount in the manufacturing of furnace pressure switch wiring. International standards, such as ISO 9001, provide a framework for quality management systems and ensure that manufacturers consistently produce high-quality products.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the application and regional requirements. These certifications ensure compliance with safety and performance standards, which is especially crucial for B2B buyers operating in diverse markets.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials and components before they enter the production process.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that the assembly and forming processes adhere to established standards.

-

Final Quality Control (FQC): The final inspection assesses the completed products for functionality, safety, and compliance with specifications before shipping.

By implementing these checkpoints, manufacturers can identify and rectify issues early in the production process, ultimately improving the quality of the final product.

What Testing Methods Are Commonly Used for Furnace Pressure Switch Wiring?

Testing methods play a crucial role in verifying the functionality and safety of furnace pressure switch wiring. Common testing methods include:

-

Electrical Testing: This ensures that the electrical components function correctly and meet voltage and current specifications.

-

Pressure Testing: This assesses the pressure switch’s ability to operate under various pressure conditions, simulating real-world scenarios.

-

Environmental Testing: This evaluates the product’s performance under different environmental conditions, such as temperature and humidity, to ensure reliability in diverse operating environments.

B2B buyers should inquire about the specific testing methods employed by suppliers to ensure that the products meet their operational requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying a supplier’s quality control practices is vital to ensuring product reliability. Here are some actionable steps:

-

Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes, quality control measures, and adherence to international standards.

-

Request Quality Reports: Ask suppliers for documentation related to quality control, including inspection reports, test results, and compliance certificates.

-

Third-Party Inspections: Consider engaging third-party inspection services to evaluate the quality and reliability of the products before shipment.

-

Customer References: Request references from other customers to gain insights into the supplier’s quality management practices and product performance.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances. These may include:

-

Regional Compliance Requirements: Different regions may have unique compliance requirements and standards. Buyers should ensure that their suppliers are knowledgeable about and compliant with local regulations.

-

Cultural Considerations: Understanding cultural differences in business practices and communication can facilitate smoother transactions and foster stronger supplier relationships.

-

Logistical Challenges: Consider the logistical implications of sourcing from international suppliers, including shipping times, customs regulations, and potential delays.

By being informed about these nuances, B2B buyers can navigate the complexities of international procurement more effectively and secure high-quality furnace pressure switch wiring for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘furnace pressure switch wiring’

To assist B2B buyers in the procurement of furnace pressure switch wiring, this guide provides a comprehensive checklist that outlines essential steps for effective sourcing. Whether you are sourcing for industrial applications or residential projects, understanding the specifics of furnace pressure switch wiring is crucial for ensuring safety and functionality.

Illustrative image related to furnace pressure switch wiring

1. Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the furnace pressure switch wiring. This includes voltage ratings, wire gauge, insulation type, and connection types. Understanding these specifications ensures that the components will be compatible with your existing systems and meet operational standards.

- Voltage Rating: Confirm the voltage requirements (e.g., 24V AC) to ensure safe operation.

- Wire Gauge: Select an appropriate gauge to handle the necessary current without overheating.

2. Research Industry Standards and Regulations

Investigate the relevant industry standards and regulations that govern the installation and operation of furnace pressure switches. Compliance with these standards is vital to ensure safety and performance.

- Local Codes: Familiarize yourself with local electrical codes in your region to avoid legal issues.

- International Standards: Check if the products meet international standards such as IEC or UL certifications, especially if sourcing from overseas suppliers.

3. Evaluate Potential Suppliers

Before finalizing your supplier, conduct thorough evaluations to ensure reliability and quality. Look for suppliers with a strong reputation in the HVAC industry.

- Company Profiles: Review supplier backgrounds, including years in business and market presence.

- References and Case Studies: Request references or case studies from previous clients to gauge customer satisfaction and product performance.

4. Request Samples for Testing

Always request samples of the wiring and associated components before placing bulk orders. Testing samples allows you to verify compatibility and quality.

- Quality Assurance: Inspect the samples for defects or inconsistencies in wiring and insulation.

- Performance Testing: Conduct tests under controlled conditions to ensure they meet your operational needs.

5. Verify Supplier Certifications

Confirm that your chosen suppliers possess the necessary certifications that attest to their product quality and safety standards. This is particularly important for electrical components.

- ISO Certifications: Look for ISO certifications that indicate a commitment to quality management systems.

- Safety Certifications: Ensure that the products are certified by recognized safety organizations to mitigate risks.

6. Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, delivery timelines, and warranty provisions. Clear agreements can help prevent misunderstandings later.

- Pricing Structure: Discuss bulk pricing options and payment terms to optimize costs.

- Warranty Policies: Ensure the supplier provides warranties for their products to protect your investment.

7. Plan for Installation and Maintenance

Finally, consider the installation and maintenance of the furnace pressure switch wiring. Ensure that you have the necessary resources and expertise for proper installation.

- Installation Guides: Request installation manuals or guides from the supplier to facilitate the process.

- Maintenance Schedule: Establish a maintenance schedule to monitor the performance of the pressure switches over time.

By following this checklist, B2B buyers can streamline the sourcing process for furnace pressure switch wiring, ensuring they acquire reliable and compliant components that meet their operational needs.

Illustrative image related to furnace pressure switch wiring

Comprehensive Cost and Pricing Analysis for furnace pressure switch wiring Sourcing

What Are the Key Cost Components of Furnace Pressure Switch Wiring?

When sourcing furnace pressure switch wiring, understanding the cost structure is crucial for effective budgeting and decision-making. The primary components influencing costs include:

-

Materials: The quality and type of materials used in the wiring significantly affect pricing. High-quality copper wiring, for example, can be more expensive but offers better conductivity and longevity. Additionally, insulation materials and connectors can vary in cost based on their specifications and durability.

-

Labor: Labor costs encompass the wages of skilled technicians involved in manufacturing and installation. This can vary by region, with labor rates typically higher in developed markets compared to emerging economies. For international buyers, understanding local labor costs can provide insights into potential savings.

-

Manufacturing Overhead: This includes all costs associated with the production process, such as utilities, rent, and maintenance of manufacturing facilities. Efficient production processes can help reduce overhead costs, thus lowering the final price.

-

Tooling: The initial setup for manufacturing furnace pressure switch wiring can require specialized tooling, which adds to the overall cost. Buyers should consider whether suppliers have advanced manufacturing capabilities that can yield cost savings through efficiency.

-

Quality Control (QC): Implementing a robust QC process ensures the reliability and safety of the wiring products. However, these quality checks also incur costs. Buyers must weigh the benefits of stringent quality assurance against their budget constraints.

-

Logistics: The cost of shipping and handling can vary greatly depending on the distance, shipping method, and volume of the order. Buyers should be aware of potential extra costs, such as customs duties and taxes, especially for international shipments.

-

Margin: Supplier margins vary based on market positioning and demand. Understanding typical margins in the industry can help buyers negotiate more effectively.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of furnace pressure switch wiring, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for bulk orders. Understanding the MOQ can aid in planning purchases and negotiating favorable terms.

-

Specifications and Customization: Customized wiring solutions may incur additional costs. Buyers should evaluate whether the added expense is justified based on their specific needs.

-

Material Quality and Certifications: Wiring that meets international standards or comes with certifications may be priced higher. However, these certifications often ensure better performance and safety, which can justify the cost.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their experience and quality assurance, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms can significantly affect the total cost of ownership. Buyers should understand the implications of shipping terms on responsibilities, costs, and risk exposure during transit.

What Are the Best Negotiation Strategies for Buyers?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings:

-

Leverage Volume Discounts: Consolidating orders can help negotiate better rates with suppliers. Consider forming buying groups with other businesses to increase order volumes.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the upfront price, consider the TCO, which includes installation, maintenance, and potential downtime costs. This approach can lead to better long-term investments.

-

Understand Market Trends: Being aware of market fluctuations and demand trends can provide leverage in negotiations. Timing purchases during off-peak seasons may yield better pricing.

-

Request Multiple Quotes: Gathering quotes from various suppliers can provide a clearer picture of the market rate and help in negotiating terms more effectively.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Suppliers may be more willing to offer discounts or favorable terms to trusted clients.

Disclaimer on Pricing

Pricing for furnace pressure switch wiring can fluctuate due to various market factors, including raw material costs and geopolitical events. Buyers should conduct thorough market research and obtain updated quotes from multiple suppliers to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing furnace pressure switch wiring With Other Solutions

Exploring Alternatives to Furnace Pressure Switch Wiring

When evaluating solutions for controlling furnace operations, understanding the alternatives to furnace pressure switch wiring is crucial for B2B buyers. This analysis compares furnace pressure switch wiring with two viable alternatives: smart thermostats and gas valve control systems. Each option has unique advantages and considerations that can affect operational efficiency and maintenance requirements.

| Comparison Aspect | Furnace Pressure Switch Wiring | Smart Thermostat | Gas Valve Control System |

|---|---|---|---|

| Performance | Reliable for basic pressure monitoring; ensures safe furnace operation | Advanced control with programmable settings; optimizes energy usage | Provides direct control over gas flow; ensures efficient heating |

| Cost | Generally low cost; installation may require professional help | Higher initial investment; potential for long-term energy savings | Moderate cost; may require specialized installation |

| Ease of Implementation | Straightforward installation for basic models; more complex for dual-stage systems | Installation can be complex; requires Wi-Fi and programming | Requires professional installation; integration with existing systems can be challenging |

| Maintenance | Low maintenance; occasional testing needed | Requires software updates; may need recalibration | Regular inspection needed; mechanical parts may wear out |

| Best Use Case | Ideal for traditional furnaces needing basic safety measures | Best for energy-conscious users wanting customizable heating | Suitable for systems requiring precise gas control and efficiency |

In-Depth Analysis of Alternatives

Smart Thermostats

Smart thermostats represent a modern approach to furnace management. These devices allow for remote control and programming, enabling users to optimize their heating systems based on real-time data and schedules. The key advantage is their ability to reduce energy consumption significantly, leading to cost savings over time. However, the initial investment can be higher than traditional systems, and installation may require technical expertise, particularly for integration with existing HVAC systems.

Gas Valve Control Systems

Gas valve control systems provide a more direct method of managing furnace operations. These systems regulate the flow of gas to the burner, ensuring that the furnace operates efficiently and safely. The main benefit of this approach is its ability to offer precise control over heating output, which is essential for larger or more complex systems. However, these systems typically require professional installation and ongoing maintenance, as mechanical components can wear out and affect performance.

Making the Right Choice for Your Business Needs

When choosing between furnace pressure switch wiring and its alternatives, B2B buyers should consider their specific operational needs, budget constraints, and maintenance capabilities. For businesses operating in regions with basic heating requirements, traditional furnace pressure switches may suffice. However, companies looking to enhance energy efficiency and control may benefit from investing in smart thermostats or gas valve control systems. Ultimately, the right solution will depend on the balance between upfront costs, long-term savings, and the level of control required for optimal furnace performance.

Essential Technical Properties and Trade Terminology for furnace pressure switch wiring

What Are the Essential Technical Properties of Furnace Pressure Switch Wiring?

Understanding the technical properties of furnace pressure switch wiring is crucial for B2B buyers in ensuring optimal performance and reliability in heating systems. Here are some key specifications to consider:

1. Material Grade

The materials used in the construction of furnace pressure switches and their wiring are vital for durability and performance. Common materials include high-grade plastics and metals that can withstand high temperatures and corrosive environments. Selecting the right material grade helps prevent premature failure and ensures compliance with industry standards, which is especially important in regions with extreme weather conditions.

2. Electrical Rating

This specification indicates the maximum voltage and current that the pressure switch can handle. Typically rated in volts (V) and amperes (A), this property ensures that the switch can safely operate within the electrical parameters of the furnace system. Understanding the electrical rating is essential for B2B buyers to prevent electrical failures that could lead to costly downtime or safety hazards.

3. Pressure Differential Range

Furnace pressure switches operate based on pressure differentials. This property defines the minimum and maximum pressure that the switch can detect before activating or deactivating the furnace system. A precise pressure differential range is critical for ensuring that the furnace operates efficiently and safely, particularly in regions with varying atmospheric conditions.

4. Tolerance Levels

Tolerance levels specify the allowable deviation from the specified pressure or electrical ratings. High tolerance levels ensure that the pressure switch can maintain performance even with minor fluctuations in pressure or voltage. This reliability is crucial for B2B buyers looking to maintain consistent heating operations in their facilities, minimizing the risk of system failures.

5. Response Time

The response time indicates how quickly the pressure switch can react to changes in pressure. A faster response time enhances the safety and efficiency of the furnace system by ensuring that it can quickly shut down in case of a malfunction. For B2B operations, especially in high-demand environments, this property can significantly impact overall system performance.

Illustrative image related to furnace pressure switch wiring

What Are Common Trade Terms Related to Furnace Pressure Switch Wiring?

Familiarity with industry jargon is essential for effective communication and procurement in the B2B sector. Here are some common terms to understand:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of furnace pressure switches, understanding OEM specifications can help buyers ensure compatibility and reliability in their heating systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and inventory management, especially when sourcing pressure switches from manufacturers.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and availability for specific products. Utilizing RFQs effectively can streamline the procurement process and ensure that buyers receive competitive pricing for furnace pressure switches.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, risk, and insurance. Understanding Incoterms is vital for B2B buyers involved in importing pressure switches from different countries, as it helps clarify the terms of delivery and payment.

Illustrative image related to furnace pressure switch wiring

5. SPST (Single Pole Single Throw)

An SPST switch is a type of pressure switch with two terminals. It operates as a simple on/off switch, commonly used in furnace applications. Knowing this term helps buyers identify the right type of switch for their specific needs.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing furnace pressure switches, ultimately enhancing the efficiency and safety of their heating systems.

Navigating Market Dynamics and Sourcing Trends in the furnace pressure switch wiring Sector

What Are the Key Market Dynamics Affecting Furnace Pressure Switch Wiring?

The furnace pressure switch wiring sector is currently influenced by several global drivers, including technological advancements and regulatory pressures. As industries increasingly adopt smart technologies, the demand for advanced furnace systems equipped with high-efficiency pressure switches is rising. This trend is particularly notable in regions like Africa, South America, the Middle East, and Europe, where energy efficiency regulations are becoming more stringent. For instance, countries in Europe are pushing for higher efficiency standards in HVAC systems, which directly impacts the sourcing of components like pressure switches.

Emerging trends in sourcing include the increased use of digital platforms for procurement, which allow B2B buyers to compare products and suppliers easily. This shift is essential for international buyers seeking reliable sources in remote areas, such as those in Nigeria or Vietnam, where access to local suppliers may be limited. Additionally, the integration of IoT (Internet of Things) in HVAC systems is changing how pressure switches are wired and monitored, fostering greater demand for components that can support connectivity and data analytics.

How Is Sustainability and Ethical Sourcing Influencing the Furnace Pressure Switch Wiring Market?

Sustainability is becoming a critical consideration in the furnace pressure switch wiring sector, driven by both consumer demand and regulatory requirements. The environmental impact of manufacturing processes for wiring components can be significant, prompting buyers to seek suppliers who prioritize eco-friendly practices. Ethical sourcing is also gaining traction, with businesses increasingly focused on ensuring their supply chains are free from exploitation and environmentally damaging practices.

B2B buyers should look for suppliers that offer “green” certifications, such as ISO 14001, which indicates a commitment to minimizing environmental impact. Additionally, the use of recyclable materials in the production of wiring components is becoming more common. Buyers can enhance their sustainability profiles by choosing suppliers that adhere to these practices, which not only benefits the environment but also aligns with the growing consumer preference for socially responsible products.

What Is the Historical Context of Furnace Pressure Switch Wiring?

The evolution of furnace pressure switch wiring has been shaped by advancements in safety and efficiency standards over the decades. Initially, these components were simple mechanical switches designed to operate under basic pressure conditions. However, as HVAC technology progressed, the need for more sophisticated systems emerged, leading to the development of electronic pressure switches capable of providing more precise control and monitoring.

Over time, manufacturers have adapted their wiring solutions to accommodate these changes, resulting in products that are more reliable and easier to integrate into complex systems. This evolution reflects broader trends in the HVAC industry, where the focus is increasingly on energy efficiency and user safety. Today, furnace pressure switch wiring not only serves a functional purpose but is also integral to the overall efficiency and sustainability of heating systems worldwide.

Illustrative image related to furnace pressure switch wiring

Frequently Asked Questions (FAQs) for B2B Buyers of furnace pressure switch wiring

-

How do I solve intermittent issues with furnace pressure switches?

Intermittent problems with furnace pressure switches can often be traced back to improper wiring or faulty components. To resolve these issues, ensure that all connections are secure and that the wiring matches the manufacturer’s specifications. Conduct a thorough inspection for any blockages in the venting system or cracks in the tubing connected to the inducer. If the problem persists, consider replacing the pressure switch with a compatible model, and always refer to the furnace’s wiring diagram to verify proper connections. -

What is the best practice for wiring a furnace pressure switch?

The best practice for wiring a furnace pressure switch involves following the manufacturer’s specifications closely. Generally, the switch has two terminals: Normally Open (NO) and Common (COM). Connect the +24V AC lead to the NO terminal and the return lead to the COM terminal. This configuration ensures that the switch operates correctly, allowing the furnace to function safely and efficiently. Additionally, always use high-quality wiring materials to minimize the risk of electrical failure. -

How can I ensure the quality of furnace pressure switches when sourcing internationally?

To ensure the quality of furnace pressure switches from international suppliers, conduct thorough vetting processes. Request certifications, such as ISO or CE, to verify compliance with international standards. Additionally, ask for product samples to test their performance before committing to a bulk order. Engage with suppliers who have a proven track record and positive reviews from other B2B buyers, and consider using third-party inspection services for quality assurance. -

What are the typical payment terms for purchasing furnace pressure switches?

Payment terms for purchasing furnace pressure switches can vary significantly between suppliers. Common terms include upfront payment, partial payment before shipping, or payment upon delivery. It’s advisable to negotiate terms that protect your interests, such as escrow services or letters of credit, especially for larger orders. Always clarify payment methods accepted, including wire transfers, credit cards, or PayPal, to ensure a smooth transaction. -

What are the minimum order quantities (MOQ) for furnace pressure switch wiring?

Minimum order quantities (MOQ) for furnace pressure switch wiring can differ based on the supplier and the specific product. Typically, MOQs may range from 50 to several hundred units. It’s essential to discuss your requirements upfront with potential suppliers to find flexibility in order quantities, especially if you are testing new products. Some suppliers may offer lower MOQs for first-time customers or for specific product lines. -

How do I find reliable suppliers for furnace pressure switch wiring?

Finding reliable suppliers for furnace pressure switch wiring involves researching and networking within the industry. Utilize online B2B marketplaces, trade shows, and industry associations to connect with reputable manufacturers. Check supplier reviews, request references, and assess their production capabilities. Additionally, consider visiting the supplier’s facility if possible, or arrange for virtual inspections to ensure they meet your quality and compliance standards. -

What logistics considerations should I keep in mind when importing furnace pressure switches?

When importing furnace pressure switches, it’s crucial to consider logistics aspects such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder who can navigate international shipping complexities and ensure compliance with local laws. Additionally, factor in lead times for production and shipping, as well as potential delays at customs. Having clear communication with your supplier about shipping terms (e.g., FOB, CIF) is also vital to avoid unexpected costs. -

How can I customize furnace pressure switches for specific applications?

Customization of furnace pressure switches can be achieved by collaborating closely with your supplier. Provide detailed specifications regarding the pressure settings, wiring configurations, and any unique operational requirements. Many manufacturers offer customization options, such as different pressure ratings or sizes, to meet specific application needs. Ensure that you discuss any additional costs or minimum quantities associated with custom orders, and request samples to validate the modifications before full-scale production.

Top 4 Furnace Pressure Switch Wiring Manufacturers & Suppliers List

1. Terry Love – Furnace Pressure Switch

Domain: terrylove.com

Registered: 1996 (29 years)

Introduction: Furnace pressure switch; connections: Normally Open and Common tabs; operates on a pressure differential; compatible with various furnace models as a replacement; no specific documentation provided; user seeking best practices for wiring configuration.

2. Reddit – Pressure Switch

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The pressure switch is a normally open switch that closes on pressure from the combustion motor. It has 2 terminals and may have similar wire colors piggybacked onto another connection.

3. Rheem – Criterion II Gas Furnace

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: Furnace Pressure Switch, Rheem Criterion II Gas Furnace – model RGLH-07EAMGR, symptoms include intermittent operation, ‘OK’ LED flashing 3 times indicating limit switch is open, potential issues with wiring connections.

4. PlumbersStock – Pressure Switch Replacement

Domain: plumbersstock.com

Registered: 2007 (18 years)

Introduction: This company, PlumbersStock – Pressure Switch Replacement, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for furnace pressure switch wiring

In conclusion, the strategic sourcing of furnace pressure switch wiring is essential for enhancing operational efficiency and ensuring safety in heating systems. By understanding the intricacies of furnace pressure switches—such as their roles, types, and operational parameters—B2B buyers can make informed decisions that align with their specific needs. This knowledge not only aids in selecting the right components but also helps in identifying reliable suppliers who can provide quality products and support.

Investing in strategic sourcing practices can significantly reduce downtime and maintenance costs, which is particularly crucial for businesses operating in remote areas of Africa, South America, the Middle East, and Europe. As global supply chains continue to evolve, staying abreast of emerging technologies and market trends will empower buyers to leverage competitive advantages.

Looking ahead, we encourage international buyers to actively engage with suppliers, share insights, and explore innovative solutions in furnace pressure switch wiring. Embrace the future of heating technology and make strategic sourcing a cornerstone of your operational success. Your proactive approach today will pave the way for a more efficient and sustainable tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to furnace pressure switch wiring

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.