Fryer Oil: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for fryer oil

In the dynamic landscape of the global food service industry, sourcing high-quality fryer oil presents a critical challenge for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With varying culinary traditions and health regulations, selecting the right type of fryer oil—be it canola, peanut, or specialty blends—can significantly impact food quality, customer satisfaction, and operational efficiency. This guide aims to empower buyers by providing a comprehensive overview of the different types of fryer oils available, their specific applications, and the nuances of supplier vetting, pricing strategies, and quality assurance.

As the demand for fried foods continues to rise globally, understanding the complexities of fryer oil sourcing becomes imperative. This guide will delve into the essential factors to consider when choosing fryer oils, including smoke points, flavor profiles, and cost-effectiveness. Additionally, it will offer insights into how to identify reliable suppliers who can meet the rigorous demands of busy kitchens while adhering to international safety standards.

By leveraging the information contained within this guide, B2B buyers from regions like Brazil and Saudi Arabia will be equipped to make informed purchasing decisions that not only enhance their culinary offerings but also optimize their operational costs and ensure compliance with local regulations. This strategic approach to sourcing fryer oil is essential for maintaining a competitive edge in the fast-paced food service market.

Understanding fryer oil Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Canola Oil | Neutral flavor, high smoke point (~400°F) | Restaurants, catering, food processing | Pros: Cost-effective, versatile; Cons: May require frequent changes due to flavor degradation. |

| Peanut Oil | High smoke point (450°F), subtle flavor | Asian cuisine, frying foods with high heat | Pros: Excellent stability, enhances flavor; Cons: Higher cost, potential allergy concerns. |

| Soybean Oil | Light flavor, commonly blended with other oils | General frying, food manufacturing | Pros: Economical, good for high-volume use; Cons: Lower smoke point than peanut oil. |

| Blended Oil | Combination of different oils for cost and stability | Fast food chains, large-scale kitchens | Pros: Cost-effective, customizable; Cons: May compromise flavor quality compared to pure oils. |

| Extra Virgin Olive Oil | Rich flavor, lower smoke point (~375°F) | Gourmet cooking, dressings | Pros: High-quality taste, health benefits; Cons: More expensive, less suited for frying. |

What Are the Characteristics of Canola Oil for Frying?

Canola oil is derived from the rapeseed plant and is favored for its neutral flavor and high smoke point of around 400°F. This makes it ideal for a variety of frying applications, from deep-frying to sautéing. For B2B buyers, canola oil is often a cost-effective choice, especially for restaurants and catering services that require large quantities. However, its flavor can degrade over time, necessitating regular monitoring and replacement to maintain food quality.

Illustrative image related to fryer oil

Why Choose Peanut Oil for High-Temperature Cooking?

Peanut oil stands out for its high smoke point of 450°F, making it particularly suitable for high-temperature frying. Its subtle flavor profile allows the natural taste of food to shine through, which is crucial for Asian cuisine and other fried dishes. For businesses, while peanut oil may be more expensive than canola, its stability and performance can justify the investment. However, buyers should consider potential allergy issues and ensure they source highly refined peanut oil to mitigate risks.

How Does Soybean Oil Fit into the Frying Landscape?

Soybean oil is a versatile option commonly used in commercial kitchens for frying and food manufacturing. Its light flavor allows it to blend seamlessly with various foods, while its cost-effectiveness makes it a popular choice for businesses operating on tight budgets. However, soybean oil has a lower smoke point compared to peanut oil, which can affect its performance in high-heat cooking. B2B buyers should assess their specific frying needs and volume requirements when considering soybean oil.

What Are the Advantages of Using Blended Oils?

Blended oils combine various oil types to maximize benefits, such as stability and cost-effectiveness. This approach is particularly favored in fast food chains and large-scale kitchens where budget constraints are critical. Blended oils can achieve desirable smoke points while minimizing flavor transfer between food and oil. However, businesses should be aware that blending may compromise the flavor quality compared to using pure oils. Therefore, understanding the specific blend composition is essential for making informed purchasing decisions.

Is Extra Virgin Olive Oil Suitable for Frying?

Extra virgin olive oil is renowned for its rich flavor and health benefits, making it a preferred choice for gourmet cooking and dressings. With a lower smoke point of around 375°F, it is less suitable for high-temperature frying but can be used for sautéing and light frying applications. B2B buyers in the upscale dining sector may find the investment worthwhile for its unique flavor profile. However, its higher cost and limited frying capability should be factored into purchasing decisions, especially in high-volume environments.

Key Industrial Applications of fryer oil

| Industry/Sector | Specific Application of Fryer Oil | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Deep Frying in Restaurants | Ensures consistent taste and texture in fried foods, enhancing customer satisfaction and repeat business. | High smoke point, neutral flavor, bulk purchasing options. |

| Snack Manufacturing | Production of Snack Foods | Facilitates the frying of chips and other snacks, maintaining quality while optimizing production costs. | Quality control, bulk supply, and oil stability. |

| Catering and Events | Frying for Large-Scale Events | Provides efficient cooking solutions for large volumes, ensuring timely service and quality food. | High-volume supply, oil longevity, and cost-effectiveness. |

| Food Processing | Oil Blending for Commercial Products | Allows for tailored flavor profiles and cost management in food products. | Consistency, sourcing of blended oils, and regulatory compliance. |

| Bakery and Confectionery | Frying for Pastries and Doughnuts | Enhances product quality and extends shelf life through proper frying techniques. | Quality of oil, health regulations, and flavor neutrality. |

How is Fryer Oil Used in the Food Service Industry?

In the food service sector, fryer oil is essential for deep frying various menu items, such as French fries, chicken, and doughnuts. The high smoke point of oils like canola and peanut oil ensures that they can withstand the heat without degrading, which is crucial for maintaining food quality. For international buyers, particularly in regions like Africa and the Middle East, sourcing reliable suppliers who can provide bulk quantities at competitive prices is vital to manage operational costs and maintain flavor consistency.

What Role Does Fryer Oil Play in Snack Manufacturing?

Snack manufacturers rely on fryer oil for producing items such as potato chips and other fried snacks. The oil not only contributes to the desired texture and taste but also plays a critical role in the efficiency of production processes. Buyers in South America, for example, must consider the stability and quality of the oil to minimize production downtime due to oil degradation. Ensuring a consistent supply of high-quality oil is key to meeting production demands and maintaining product standards.

How is Fryer Oil Utilized in Catering and Events?

In the catering industry, fryer oil is indispensable for preparing large quantities of fried foods for events and gatherings. Efficient frying is crucial to meet service timelines while ensuring that the food retains its flavor and quality. International buyers from regions like Europe should focus on sourcing oils that offer both longevity and cost-effectiveness, as these factors directly impact their ability to deliver high-quality service at competitive prices.

What is the Importance of Fryer Oil in Food Processing?

Food processing companies often utilize fryer oil for blending and creating commercial food products. By combining various oils, manufacturers can achieve specific flavor profiles while managing costs effectively. Buyers need to ensure that the oils sourced meet quality standards and regulatory requirements, especially in diverse markets like Brazil and Saudi Arabia, where food safety regulations can vary significantly. Understanding local regulations and sourcing reliable suppliers is critical for success in this sector.

How Does Fryer Oil Benefit the Bakery and Confectionery Sector?

In bakeries and confectioneries, fryer oil is essential for frying pastries, doughnuts, and other fried confections. The quality of the oil directly affects the final product’s taste and shelf life. Buyers must prioritize sourcing high-quality oils that have a neutral flavor to avoid altering the taste of their baked goods. Additionally, compliance with health regulations is paramount, especially in international markets, where consumer preferences and safety standards may differ.

Illustrative image related to fryer oil

3 Common User Pain Points for ‘fryer oil’ & Their Solutions

Scenario 1: Managing Oil Quality and Consistency for High-Volume Cooking

The Problem: In the fast-paced environment of commercial kitchens, many B2B buyers struggle with maintaining the quality and consistency of fryer oil. High-volume cooking, particularly in busy restaurants, can lead to rapid degradation of oil quality, resulting in off-flavors and compromised food quality. Buyers often face the dilemma of balancing cost savings with the need for high-quality oil, which can lead to inconsistent cooking results and customer dissatisfaction. Furthermore, the frequent need to change fryer oil can disrupt operations, leading to wasted time and resources.

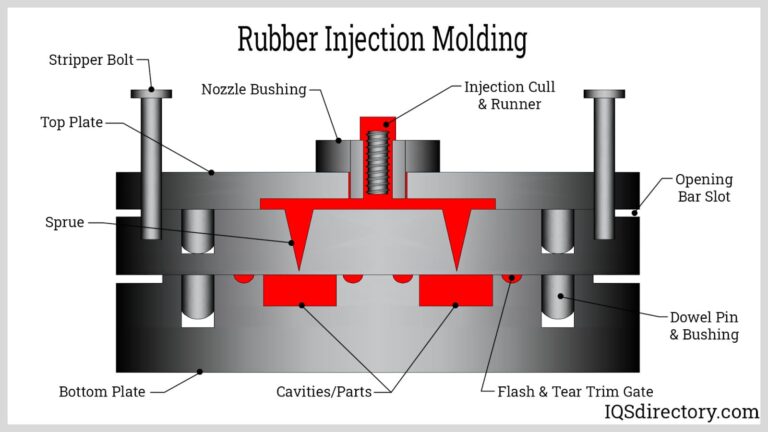

The Solution: To tackle this issue, buyers should invest in high-quality oils with superior stability, such as refined canola or peanut oil, which have higher smoke points and longer lifespans. Establishing a regular oil filtration schedule can also extend the life of fryer oil. Investing in an oil management system that monitors oil quality and usage can provide data-driven insights to inform when to change the oil, preventing unnecessary waste. Additionally, suppliers can offer bulk purchasing options, allowing for consistent supply without frequent reordering, which can streamline operations and reduce costs.

Scenario 2: Dealing with Flavor Transfer Issues in Frying

The Problem: Another common pain point for B2B buyers is the issue of flavor transfer in fryer oil. When different types of food are fried in the same oil, it can lead to undesirable flavors that affect the overall dish. This is particularly critical in establishments that pride themselves on unique flavor profiles, such as gourmet restaurants or food trucks. Buyers may also face the challenge of managing oil used for allergenic foods, leading to potential health risks and customer complaints.

The Solution: To mitigate flavor transfer, buyers should consider using blended oils designed specifically for high-temperature frying. These oils are formulated to reduce flavor transfer between different foods, ensuring that the integrity of each dish is preserved. Suppliers can provide information on oil blends that include canola and soybean oils, which are known for their neutral flavors and high smoke points. Additionally, implementing a rotation system where oils are designated for specific food types can help maintain flavor integrity and minimize cross-contamination.

Scenario 3: Navigating Cost-Effectiveness While Ensuring Quality

The Problem: For many B2B buyers, especially those operating in emerging markets, the challenge of managing oil costs while ensuring quality is significant. Fluctuating prices and the need for bulk purchasing can strain budgets, particularly for small to medium-sized businesses. Buyers may feel pressured to opt for cheaper oils that ultimately do not deliver the desired cooking performance, leading to higher food waste and customer dissatisfaction.

Illustrative image related to fryer oil

The Solution: To address cost concerns without sacrificing quality, buyers should focus on sourcing oils that offer the best price-to-performance ratio. Engaging with reputable suppliers who provide transparent pricing and quality assurance can help in making informed purchasing decisions. Additionally, buyers should consider establishing long-term partnerships with suppliers for bulk purchasing agreements, which can lead to significant discounts. Implementing a cooking oil inventory management system can also help track usage patterns, allowing for better forecasting and budgeting, thus optimizing purchasing decisions and minimizing waste.

Strategic Material Selection Guide for fryer oil

What Are the Key Properties of Common Fryer Oils?

When selecting fryer oil, understanding the key properties of various oil types is essential for ensuring optimal cooking performance. The most common materials used in fryer oils include canola oil, peanut oil, soybean oil, and blended oils. Each type has unique characteristics that can significantly impact food quality, operational efficiency, and cost-effectiveness.

Canola Oil: A Versatile Choice for Frying

Canola oil is derived from the seeds of the canola plant and is known for its high smoke point, typically around 400°F (204°C). This property makes it suitable for deep frying, allowing for consistent cooking without the risk of burning.

Pros: Canola oil is relatively inexpensive, widely available, and has a neutral flavor, which means it won’t alter the taste of the food. It also has good stability, making it a cost-effective option for high-volume frying operations.

Cons: While canola oil is versatile, it may not provide the same depth of flavor as other oils, such as peanut oil. Additionally, concerns about genetically modified organisms (GMOs) in canola crops may affect buyer preferences in certain markets.

Impact on Application: Canola oil is compatible with a wide range of fried foods, from vegetables to proteins, making it a go-to choice for many restaurants.

International Considerations: Buyers should ensure compliance with local regulations regarding GMOs and food safety standards, which may vary by region, especially in Europe and South America.

Peanut Oil: Flavorful and High-Temperature Resistant

Peanut oil is prized for its high smoke point of about 450°F (232°C), making it ideal for frying at high temperatures. Its subtle flavor enhances the taste of fried foods without overwhelming them.

Pros: The high smoke point offers excellent stability, reducing the need for frequent oil changes. Its natural flavor is often preferred in Asian cuisine, making it a popular choice in diverse culinary applications.

Cons: Peanut oil is generally more expensive than canola oil and may pose allergy risks for some consumers. However, refined peanut oil typically removes allergenic proteins, mitigating this concern.

Illustrative image related to fryer oil

Impact on Application: Peanut oil is particularly well-suited for frying foods like chicken and French fries, where flavor and crispiness are paramount.

International Considerations: Compliance with food safety regulations is critical, especially in regions with strict allergy labeling laws, such as the EU and North America.

Soybean Oil: Cost-Effective and Reliable

Soybean oil is another common frying oil, known for its affordability and versatility. With a smoke point of around 450°F (232°C), it is suitable for various frying applications.

Pros: Soybean oil is cost-effective and has a neutral flavor, making it a popular choice for large-scale operations. Its high smoke point allows for effective frying without significant degradation.

Cons: The flavor profile may not be as appealing for gourmet applications, and it may require blending with other oils to enhance stability and flavor.

Illustrative image related to fryer oil

Impact on Application: Soybean oil is used widely in fast-food operations and food processing due to its low cost and effectiveness in frying.

International Considerations: Buyers should be aware of sourcing practices, as some regions may prefer non-GMO options. Compliance with local food safety standards is also essential.

Blended Oils: Customizable Solutions for Frying Needs

Blended oils combine different types of oils to optimize performance characteristics. For example, a blend of canola and soybean oil can achieve a high smoke point while reducing costs.

Illustrative image related to fryer oil

Pros: Blended oils can be tailored to meet specific frying needs, balancing performance and cost. They often provide improved flavor stability and reduced flavor transfer between foods.

Cons: The complexity of blending may lead to variability in quality, and not all blends are created equal. Buyers must ensure they source from reputable suppliers.

Impact on Application: Blended oils are suitable for a variety of frying tasks, from deep frying to sautéing, making them versatile for different cuisines.

International Considerations: Buyers should verify that blended oils meet local regulations and standards, particularly in regions with strict labeling requirements.

Summary Table of Fryer Oil Materials

| Material | Typical Use Case for fryer oil | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Canola Oil | General frying of various foods | Neutral flavor, cost-effective | May lack flavor depth | Low |

| Peanut Oil | High-temperature frying, Asian cuisine | High smoke point, flavorful | Allergy risk, higher cost | Med |

| Soybean Oil | Fast food frying | Affordable, versatile | Less appealing flavor | Low |

| Blended Oils | Custom frying applications | Tailored performance, cost-saving | Quality variability | Med |

This strategic material selection guide provides valuable insights for B2B buyers to make informed decisions regarding fryer oil, considering both operational needs and regional compliance.

Illustrative image related to fryer oil

In-depth Look: Manufacturing Processes and Quality Assurance for fryer oil

What Are the Main Stages in the Manufacturing Process of Fryer Oil?

The manufacturing process of fryer oil involves several critical stages that ensure the final product meets quality and safety standards. The primary stages include material preparation, refining, blending, and packaging.

1. Material Preparation

The first step in the manufacturing process is sourcing high-quality raw materials, which may include seeds such as canola, soybeans, or peanuts. These seeds undergo thorough cleaning to remove impurities such as dirt, stones, and foreign seeds. This step is crucial because the quality of the raw materials directly affects the final oil’s taste and stability.

2. Refining

Once cleaned, the seeds are subjected to mechanical pressing or solvent extraction to separate the oil from the solids. Mechanical pressing involves crushing the seeds to extract oil, while solvent extraction uses solvents to dissolve and separate the oil. The extracted oil then undergoes refining, which typically includes degumming, neutralization, bleaching, and deodorization. Each of these steps removes undesirable components, such as free fatty acids and odors, ensuring the oil’s taste and stability during frying.

3. Blending

After refining, the oil may be blended with other oils to achieve desired characteristics such as flavor, smoke point, and cost-effectiveness. For instance, blending canola and soybean oils can enhance the smoke point while reducing production costs. Manufacturers often formulate specific blends tailored to different frying applications, allowing B2B buyers to choose oils that best suit their culinary needs.

4. Packaging

The final stage involves packaging the oil in suitable containers that prevent contamination and degradation. Packaging materials must be food-safe and protect the oil from light and air, which can cause rancidity. Proper labeling is also essential, providing buyers with information on the oil type, processing methods, and nutritional content.

Illustrative image related to fryer oil

How Is Quality Assurance Implemented in Fryer Oil Production?

Quality assurance (QA) in fryer oil manufacturing is vital to ensure safety, consistency, and compliance with international standards. Manufacturers typically implement a comprehensive QA system that includes various checkpoints and testing methods.

1. Relevant International and Industry Standards

To maintain high-quality standards, manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can demonstrate compliance with safety and quality benchmarks. These certifications are particularly important for B2B buyers seeking assurance that the products meet rigorous safety and performance criteria.

2. Key Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step ensures that raw materials meet specified standards before processing begins. Suppliers are often required to provide certificates of analysis (CoA) for their products.

-

In-Process Quality Control (IPQC): During production, samples are taken at various stages to monitor quality parameters such as acidity, moisture content, and flavor stability. This real-time monitoring helps to identify issues before they escalate.

-

Final Quality Control (FQC): After packaging, products undergo final inspection, where samples are tested for compliance with established specifications. This includes sensory evaluation (taste and smell) and chemical analysis to ensure the oil’s quality.

What Common Testing Methods Are Used for Fryer Oil Quality Assurance?

Several testing methods are commonly employed to assess the quality of fryer oil. These methods help verify that the oil meets industry standards and is safe for consumption.

-

Peroxide Value (PV): This test measures the extent of oxidation in the oil. High peroxide values indicate rancidity, which is unacceptable for fryer oil.

-

Free Fatty Acids (FFA): The FFA test determines the level of free fatty acids in the oil, providing insight into its freshness. Lower FFA levels are preferred as they indicate better quality.

-

Smoke Point Testing: This test measures the temperature at which the oil begins to smoke. Oils with higher smoke points are more stable for frying and are preferred by foodservice operators.

-

Sensory Evaluation: Trained panels may conduct sensory evaluations to assess the oil’s aroma, flavor, and overall quality. This qualitative analysis is essential for ensuring that the oil does not adversely affect the taste of fried foods.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control practices of suppliers is crucial in ensuring product reliability. Here are several strategies:

1. Conduct Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes, quality assurance systems, and compliance with international standards. Buyers should develop a checklist based on their specific needs and industry standards.

2. Request Quality Reports

Buyers should request detailed quality reports, including CoA, testing results, and certifications. These documents can provide evidence of the supplier’s commitment to quality and safety.

3. Utilize Third-Party Inspections

Engaging third-party inspection services can add an additional layer of verification. Independent inspectors can evaluate the manufacturing facilities, processes, and final products to ensure compliance with agreed standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance and certification. Here are some nuances to consider:

-

Understanding Regional Standards: Different countries may have varying regulatory requirements. Buyers should familiarize themselves with local food safety standards and certifications required in their respective markets.

-

Language and Documentation: Ensure that all quality documents are available in a language that is easily understood. Misinterpretations can lead to compliance issues.

-

Cultural Considerations: Cultural differences can impact the understanding of quality and safety. Engaging local experts or consultants can help bridge these gaps and ensure that buyers are informed about local practices and expectations.

-

Sustainability and Ethical Sourcing: Increasingly, B2B buyers are focusing on sustainability and ethical sourcing. Suppliers should be able to provide evidence of responsible sourcing practices, including certifications related to environmental sustainability and fair trade.

By understanding the manufacturing processes and quality assurance measures for fryer oil, B2B buyers can make informed decisions that enhance their operational efficiency and product quality.

Illustrative image related to fryer oil

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fryer oil’

To assist B2B buyers in procuring fryer oil effectively, this practical sourcing guide provides a structured checklist that outlines essential steps to follow. By adhering to this guide, buyers can ensure they select the right type of fryer oil that meets their culinary needs while maintaining quality and cost-efficiency.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in sourcing fryer oil. This includes determining the type of oil required—such as canola, peanut, or blended oils—based on your cooking methods and menu offerings. Consider factors like smoke point, flavor profile, and oil stability under high temperatures, as these will significantly affect the quality of your fried products.

Step 2: Conduct Market Research for Suppliers

Engage in thorough market research to identify potential suppliers that specialize in fryer oil. Analyze their product offerings, pricing structures, and market reputation. Utilize online platforms, trade shows, and industry publications to gather insights about suppliers and their reliability in fulfilling large orders consistently.

Illustrative image related to fryer oil

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capabilities, quality control measures, and adherence to food safety standards to ensure they can meet your operational demands.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers possess relevant certifications that affirm their commitment to quality and safety, such as ISO, HACCP, or local food safety regulations. Compliance with international standards is especially important when sourcing from suppliers in different regions, as it guarantees product safety and quality.

Step 5: Request Samples for Testing

Before making a bulk purchase, always request samples of the fryer oil. Conduct a series of tests to evaluate the oil’s performance, including smoke point tests and flavor assessments. This step helps you verify that the oil meets your specifications and will perform well in your cooking processes.

Step 6: Negotiate Terms and Pricing

Engage in negotiations with your selected suppliers to discuss pricing, payment terms, and delivery schedules. Consider the total cost of ownership, including shipping and storage, to ensure that you are getting a competitive deal. Establishing clear terms can help mitigate potential misunderstandings and ensure a smooth procurement process.

Step 7: Establish a Quality Assurance Process

Once you start receiving shipments, implement a quality assurance process to monitor the oil’s condition and performance over time. Regularly check for signs of degradation, such as off odors or excessive foaming during frying. Keeping a close eye on oil quality will help maintain the integrity of your dishes and prevent costly errors.

By following this structured checklist, B2B buyers can make informed decisions when sourcing fryer oil, ensuring that they select the best products for their culinary needs while optimizing costs and maintaining quality.

Comprehensive Cost and Pricing Analysis for fryer oil Sourcing

Understanding the cost structure of fryer oil sourcing is essential for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This section will delve into the various components of cost, pricing influencers, and practical tips for buyers to optimize their sourcing strategy.

What Are the Key Cost Components in Fryer Oil Sourcing?

Materials: The primary cost driver in fryer oil sourcing is the raw materials used to produce the oil. Different types of oils—such as canola, peanut, and soybean—have varying costs influenced by market demand, agricultural yields, and regional availability.

Labor: Labor costs encompass the wages of workers involved in the extraction, refining, and packaging of oil. In regions with higher labor costs, such as parts of Europe, this can significantly impact the overall price.

Illustrative image related to fryer oil

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these costs, leading to more competitive pricing.

Tooling and Quality Control (QC): Investment in specialized equipment and quality control processes is necessary to ensure high-grade oil production that meets safety and health standards. These costs can vary based on the level of automation and the certifications required (e.g., ISO, HACCP).

Logistics: Transportation and storage costs are crucial, particularly for international buyers. Factors such as shipping methods, distance, and local infrastructure can affect logistics expenses. Incoterms chosen by buyers can also influence the final landed cost.

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on their operational efficiencies, market competition, and brand reputation.

Illustrative image related to fryer oil

How Do Volume and Customization Influence Pricing?

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers may offer significant discounts for larger orders, making it economically advantageous for businesses that can commit to higher volumes. Understanding the minimum order quantity (MOQ) is critical for negotiating better prices.

Specifications and Customization: Custom blends of oils or oils with specific certifications may incur additional costs. Buyers should assess whether these specifications justify the price difference compared to standard offerings.

Quality and Certifications: Oils that meet higher quality standards or possess special certifications (e.g., organic, non-GMO) often come at a premium. Buyers should weigh the benefits of these certifications against their budget constraints.

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers with a proven track record may charge higher prices, but they often provide better quality assurance and customer service.

What Are the Best Practices for B2B Buyers in Fryer Oil Sourcing?

Negotiation: Leverage your buying power by negotiating prices based on volume commitments, long-term contracts, or multi-product purchases. Establishing a strong relationship with suppliers can lead to favorable terms and discounts.

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, storage, and potential wastage due to oil degradation. Choose oils with higher smoke points and longer shelf lives to maximize value.

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, import tariffs, and local regulations that can affect pricing. Understanding the specific market conditions in your region can help in making informed purchasing decisions.

Final Thoughts on Fryer Oil Pricing

It’s important to note that prices for fryer oil can fluctuate based on global market conditions, seasonal factors, and regional supply chains. Buyers should conduct thorough market research and maintain flexibility in their sourcing strategies to adapt to these dynamics effectively. By understanding the cost components and pricing influencers, international B2B buyers can make more informed decisions, ensuring they receive quality products at competitive prices.

Alternatives Analysis: Comparing fryer oil With Other Solutions

Exploring Alternatives to Fryer Oil in Commercial Kitchens

When it comes to deep frying, fryer oil has long been the standard choice for many commercial kitchens. However, emerging technologies and methods present viable alternatives that can meet the same culinary needs while potentially offering additional benefits. This analysis will compare fryer oil with two alternatives: air frying and oil-free frying technologies, helping B2B buyers make informed decisions.

| Comparison Aspect | Fryer Oil | Air Frying | Oil-Free Frying Technology |

|---|---|---|---|

| Performance | Excellent for deep frying; maintains flavor and texture. | Good for crispy textures, but may lack the same flavor depth. | Efficient cooking with even heat distribution; retains moisture but may not achieve the same crispiness. |

| Cost | Moderate to high, especially for quality oils; ongoing replenishment needed. | Lower operating costs; initial equipment investment can be high. | Generally high initial costs but lower operating costs due to reduced energy consumption and no need for oil replenishment. |

| Ease of Implementation | Widely understood and easy to integrate into existing kitchens. | Requires training staff on new equipment and techniques. | Installation can be complex; staff training is essential. |

| Maintenance | Regular oil filtration and replacement needed; can be labor-intensive. | Low maintenance; minimal cleaning required. | Requires regular maintenance of technology but no oil disposal. |

| Best Use Case | Ideal for high-volume frying operations, such as restaurants and food trucks. | Suitable for smaller operations or health-conscious establishments. | Excellent for commercial kitchens focusing on healthy cooking without oil. |

In-Depth Evaluation of Alternatives

1. Air Frying

Air frying has gained popularity due to its health benefits and ease of use. This method utilizes rapid air circulation to cook food, resulting in a crispy texture similar to traditional frying but with significantly less oil. While air fryers are ideal for smaller batches, they may struggle to replicate the rich flavors achieved with fryer oil. For businesses focused on healthy eating or smaller-scale operations, air frying presents a compelling option, especially considering the lower ongoing costs.

Illustrative image related to fryer oil

2. Oil-Free Frying Technology

Oil-free frying technology employs innovative cooking methods, such as hot air or infrared radiation, to achieve desired cooking results without the use of oil. This approach not only reduces calorie content but also eliminates the complexities associated with oil management, such as disposal and oil degradation. However, the initial investment in oil-free frying equipment can be high, making it more suitable for larger establishments that prioritize health and efficiency. While this technology can yield moisture-rich foods, some culinary applications may still require the unique crispiness provided by traditional frying methods.

Making an Informed Choice for Your Business Needs

When selecting the right frying solution for your business, consider factors such as the volume of food prepared, desired flavor profiles, and operational costs. If maintaining traditional tastes and textures is paramount, fryer oil may still be the best choice. However, for establishments prioritizing health and efficiency, air frying or oil-free technology could offer significant advantages. Assessing your specific culinary goals and operational capabilities will ensure you choose the most suitable method for your kitchen, ultimately enhancing your service offerings and customer satisfaction.

Essential Technical Properties and Trade Terminology for fryer oil

What Are the Key Technical Properties of Fryer Oil for B2B Buyers?

When purchasing fryer oil, understanding its technical properties is crucial for ensuring optimal performance in food preparation. Here are some essential specifications to consider:

1. Smoke Point

The smoke point is the temperature at which oil begins to break down and produce smoke. It is a critical property for fryer oil, as oils with higher smoke points can withstand the high temperatures typically used in frying without degrading. For instance, peanut oil has a smoke point of about 450°F, making it ideal for high-temperature cooking. B2B buyers should prioritize oils with higher smoke points to maintain food quality and reduce the need for frequent oil changes.

Illustrative image related to fryer oil

2. Flavor Profile

The flavor profile of fryer oil can significantly affect the taste of fried foods. Neutral oils, such as canola and soybean oil, allow the natural flavors of the food to shine through, while oils like olive oil can impart distinct flavors. Understanding the flavor profile is essential for restaurants aiming to maintain consistency in their dishes. B2B buyers must choose oils that align with their culinary goals and customer preferences.

3. Refinement Level

The level of refinement affects both the smoke point and flavor stability of fryer oils. Highly refined oils tend to have higher smoke points and fewer flavor transfer issues. For example, refined peanut oil is less likely to trigger allergies compared to cold-pressed variants. Buyers should inquire about the refinement process to ensure they are selecting oils that meet food safety standards and maintain culinary integrity.

4. Shelf Life

Shelf life indicates how long the oil can be stored without losing its quality. Fryer oils typically have a shelf life of several months when stored properly. However, exposure to heat, light, and air can accelerate degradation. B2B buyers should consider purchasing oils with longer shelf lives to minimize waste and optimize inventory management, particularly in high-demand environments.

Illustrative image related to fryer oil

5. Packaging Options

Fryer oil is available in various packaging options, including bulk containers and smaller bottles. Understanding packaging needs is essential for logistics and storage. Bulk purchasing can lead to cost savings and ensure a steady supply, especially for high-volume operations. Buyers should assess their operational requirements to select appropriate packaging that aligns with their storage capabilities.

What Are Common Trade Terms Related to Fryer Oil?

Familiarity with trade terminology is vital for effective communication and negotiation in the fryer oil market. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

In the context of fryer oil, an OEM refers to a company that produces oils or oil blends specifically for another brand. Understanding OEM partnerships can help buyers identify trusted suppliers and ensure product quality.

Illustrative image related to fryer oil

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to gauge the feasibility of their purchasing plans and budget constraints. Suppliers often set MOQs to ensure cost-effectiveness in production and logistics.

3. RFQ (Request for Quotation)

An RFQ is a formal request from a buyer to suppliers asking for pricing and terms for a specific quantity of fryer oil. This process helps buyers compare offers and negotiate better deals, ensuring they secure the best value for their purchases.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in a transaction, including shipping, risk, and insurance. Familiarity with Incoterms is essential for B2B buyers to understand their obligations and protect their interests when sourcing fryer oil from international suppliers.

Illustrative image related to fryer oil

5. Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times is crucial for inventory management and ensuring that operations run smoothly, especially in the food service industry where timely supply is critical.

In summary, grasping the essential technical properties and trade terminology related to fryer oil is vital for B2B buyers. These insights not only facilitate informed purchasing decisions but also enhance operational efficiency and product quality in the food service industry.

Navigating Market Dynamics and Sourcing Trends in the fryer oil Sector

What Are the Key Market Dynamics and Trends in the Fryer Oil Sector?

The fryer oil market is experiencing significant growth driven by rising consumer demand for fried foods across various regions, particularly in Africa, South America, the Middle East, and Europe. The increasing prevalence of quick-service restaurants (QSRs) and fast-casual dining establishments has amplified the demand for bulk fryer oil. Notably, emerging markets like Brazil and Saudi Arabia are witnessing a surge in foodservice activities, contributing to the expansion of the fryer oil sector.

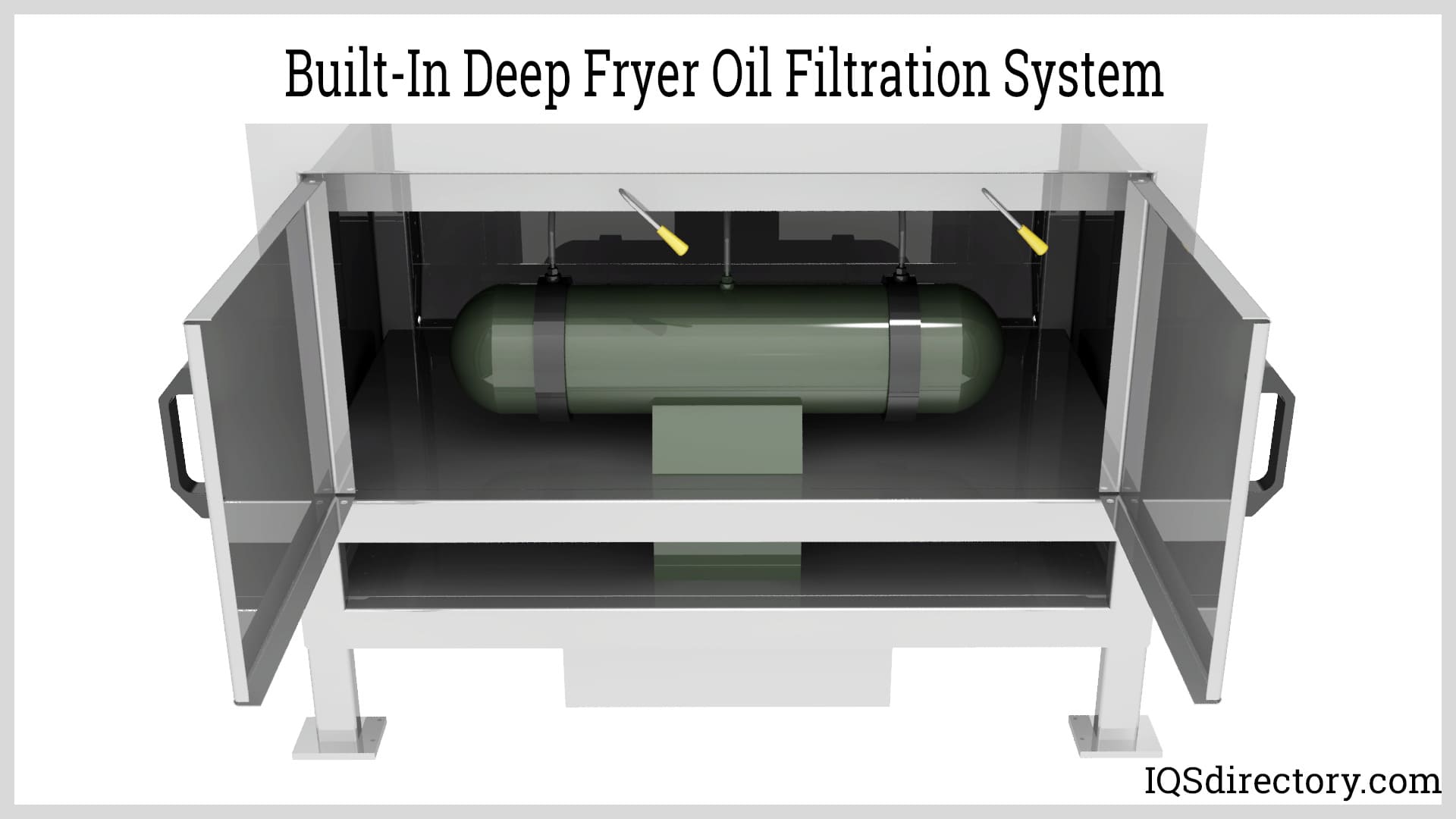

Technological advancements in processing and packaging are also shaping the landscape. Innovations such as oil filtration systems and smart frying technologies enhance oil longevity and quality, appealing to cost-conscious B2B buyers. Additionally, the trend toward oil blends—combining oils like canola and soybean—offers both economic and functional advantages, catering to diverse culinary needs while maintaining high smoke points.

International buyers are increasingly looking for reliable suppliers that can provide consistent quality and competitive pricing. The importance of logistical efficiency cannot be overstated, as timely delivery and bulk purchasing options remain critical factors in supplier selection. As global trade routes continue to evolve, understanding regional dynamics and preferences will be vital for B2B buyers in making informed sourcing decisions.

How Does Sustainability Impact Sourcing in the Fryer Oil Industry?

Sustainability and ethical sourcing are becoming non-negotiable components in the fryer oil sector. The environmental impact of oil production, including deforestation and biodiversity loss, has prompted businesses to reassess their supply chains. B2B buyers are increasingly prioritizing suppliers who can demonstrate commitment to sustainable practices, such as using certified sustainable palm oil or oils sourced from non-GMO crops.

The demand for ‘green’ certifications, such as the Rainforest Alliance or Fair Trade, is on the rise. These certifications not only assure buyers of ethical sourcing but also enhance brand reputation among environmentally-conscious consumers. Furthermore, businesses are exploring waste reduction practices, such as recycling used oil for biodiesel production, thereby closing the loop on the oil lifecycle.

Incorporating sustainability into sourcing strategies can yield competitive advantages. Buyers who engage with suppliers committed to ethical practices may benefit from consumer loyalty, as well as potential cost savings through more efficient resource utilization. Therefore, B2B buyers should actively seek out suppliers that align with their sustainability goals to enhance their market position.

How Has the Fryer Oil Sector Evolved Over Time?

The fryer oil sector has evolved significantly from its early days of using animal fats to the current diverse range of vegetable oils available today. The shift towards healthier frying options began in the late 20th century, with the introduction of oils like canola and sunflower that offer lower saturated fat content.

The emergence of specialty oils, such as avocado and grapeseed oil, has also gained traction, catering to a growing health-conscious demographic. As consumer preferences have shifted, the industry has adapted, leading to innovations in oil refinement and blending techniques that enhance flavor and cooking performance.

Today, the fryer oil market is not just about cooking but also about meeting the demands for quality, sustainability, and ethical sourcing, reflecting broader societal trends. Understanding this evolution is essential for B2B buyers who must navigate an increasingly complex market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of fryer oil

-

How do I determine the right fryer oil for my restaurant?

Choosing the right fryer oil depends on several factors, including the type of food being cooked, the cooking temperature, and flavor considerations. For high-heat applications, oils like peanut or canola are preferred due to their high smoke points. If your menu features fried items that need a neutral flavor, canola oil is an excellent choice. If you want to add a subtle flavor, consider using peanut oil. Additionally, evaluate the oil’s cost-effectiveness and quality, especially when purchasing in bulk. -

What is the best oil to use for deep frying?

The best oils for deep frying include peanut oil, canola oil, and vegetable oil. Peanut oil is favored for its high smoke point (around 450°F) and neutral flavor, making it ideal for various frying applications. Canola oil is also a strong contender due to its affordability and high smoke point (approximately 400°F). Vegetable oil, often a blend, can be a versatile and economical choice, though it may vary in quality. Always consider the specific frying needs of your menu when selecting oil. -

How can I ensure the quality of the fryer oil I purchase?

To ensure quality, source fryer oil from reputable suppliers who provide detailed product specifications, including purity levels and smoke points. Request samples for testing before making bulk purchases, and consider certifications such as ISO or HACCP, which indicate adherence to safety and quality standards. Additionally, inquire about the oil’s refining process and shelf life, as these factors significantly affect performance and safety in high-heat cooking environments. -

What are the minimum order quantities (MOQ) for fryer oil?

Minimum order quantities for fryer oil can vary significantly based on the supplier and the type of oil. Typically, bulk suppliers may require orders ranging from 200 to 1,000 liters or more. When negotiating with suppliers, clarify the MOQ upfront to ensure it aligns with your operational needs. Some suppliers may offer flexibility, especially for long-term contracts or repeat customers, so it’s beneficial to discuss your purchasing strategy to find the best terms. -

What payment terms should I expect when sourcing fryer oil internationally?

Payment terms for international fryer oil purchases often include options such as advance payment, letters of credit, or payment upon delivery. Common terms range from 30 to 90 days after invoice receipt, depending on the supplier’s policies and your negotiation. It’s crucial to establish clear payment terms before finalizing contracts to avoid disputes. Additionally, consider currency exchange rates and transaction fees if sourcing from overseas suppliers, as these can impact overall costs. -

How do I vet suppliers when sourcing fryer oil internationally?

Vetting suppliers involves several steps: check their industry reputation through reviews and testimonials, assess their production capabilities, and request certifications that demonstrate compliance with safety and quality standards. Conducting site visits, if feasible, or utilizing third-party audit services can provide deeper insights into their operations. Additionally, ask for references from other clients in your region to gauge their reliability and service levels, ensuring you choose a trustworthy partner. -

What logistics considerations should I keep in mind when importing fryer oil?

When importing fryer oil, consider factors such as shipping methods, customs regulations, and lead times. Ensure the supplier can provide proper documentation for customs clearance, including invoices and certificates of origin. Evaluate shipping options to find the most cost-effective and timely method, whether by sea or air. Additionally, consider storage capabilities upon arrival, ensuring you have suitable facilities to maintain oil quality and safety before use. -

How often should I change fryer oil, and what are the signs of degradation?

The frequency of changing fryer oil depends on usage and type of food cooked. Generally, oil should be replaced every 5 to 7 days in moderate-use environments. However, in high-volume settings, daily assessments are crucial. Signs of degradation include off odors, a darkened color, excessive foaming, or a lower smoke point than usual. Regular oil testing can help monitor quality and ensure optimal cooking conditions, ultimately impacting food quality and safety.

Top 4 Fryer Oil Manufacturers & Suppliers List

1. Shop at Dean – Bulk Frying Oil

Domain: shopatdean.com

Registered: 2007 (18 years)

Introduction: This company, Shop at Dean – Bulk Frying Oil, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Gordon – Signature Frying Oils

Domain: gfs.com

Registered: 1994 (31 years)

Introduction: Gordon Signature Premium Soy Blend Liquid Fry Shortening (Cottonseed/Soy Blend), Gordon Signature Simpli-Fry Clear Frying Oil, Gordon Signature High-Oleic Canola Oil, Gordon Signature SunFry Sunflower Oil. Characteristics include: Clear & creamy option, longer fry life than soy, greater crunchiness for mouthfeel, economical option than pure cottonseed oil, proprietary blend designed to simplify oi…

3. WebstaurantStore – Bulk Fryer Oil

Domain: webstaurantstore.com

Registered: 2003 (22 years)

Introduction: Fryer Oil in Bulk: Wholesale at WebstaurantStore. Extensive selection of commercial fryer oils including brands like AAK Foodservice, Bunge, Crisco, Goya, LouAna, and more. Types of oils available: Avocado Oil, Canola Oil, Coconut Oil, Corn Oil, Grapeseed Oil, Peanut Oil, Soybean Oil, Sunflower Oil, and Shortening. Usage options include Deep Frying, Light Frying and Sauteing, Multi-Purpose, Popcor…

4. America’s Test Kitchen – Cooking Oils Guide

Domain: americastestkitchen.com

Registered: 1999 (26 years)

Introduction: 1. Vegetable Oil: Smoking point: 400 to 450 degrees Fahrenheit, great for shallow and deep frying, cheapest option, blend of several oils. 2. Peanut Oil: Smoking point: about 450 degrees Fahrenheit, slightly nutty flavor, suitable for high heat, not for those with peanut allergies. 3. Corn Oil: Smoking point: 450 degrees Fahrenheit, inexpensive, almost no flavor, ideal for frying. 4. Refined Avoca…

Strategic Sourcing Conclusion and Outlook for fryer oil

In conclusion, strategic sourcing of fryer oil is essential for businesses aiming to optimize operational efficiency and maintain high-quality culinary standards. By understanding the various types of fryer oils—such as canola, peanut, and blended oils—international B2B buyers can make informed decisions that align with their specific cooking needs and budget constraints. Bulk purchasing not only ensures a steady supply but also significantly reduces costs, making it an attractive option for restaurants and food service providers across diverse markets.

As the global food industry continues to evolve, the demand for high-quality fryer oil will remain paramount. Buyers from regions like Africa, South America, the Middle East, and Europe should leverage strategic sourcing partnerships to secure reliable suppliers who can meet their unique requirements. Investing in quality oils will enhance food flavor and consistency, ultimately driving customer satisfaction and loyalty.

Now is the time to evaluate your fryer oil sourcing strategy and explore opportunities for improvement. Partner with trusted suppliers to ensure your kitchen remains stocked with the best options available, positioning your business for success in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.