Fruit Slicer Watermelon: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for fruit slicer watermelon

In the competitive landscape of the global market, sourcing high-quality fruit slicers, particularly for watermelon, poses a significant challenge for B2B buyers. The demand for efficient, durable, and user-friendly slicing tools is on the rise, especially in regions like Africa, South America, the Middle East, and Europe, where watermelon consumption is prevalent. This guide aims to equip international buyers with the insights necessary to navigate the complexities of sourcing watermelon slicers, ensuring they make informed purchasing decisions that align with market trends and consumer preferences.

Throughout this comprehensive guide, we will explore various types of watermelon slicers available in the market, ranging from electric models to ergonomic handheld options. We will also delve into their specific applications, highlighting how these tools can enhance operational efficiency in both commercial and domestic settings. Additionally, we will provide essential tips on supplier vetting, helping buyers identify reliable manufacturers that adhere to quality standards. Cost considerations will also be addressed, offering insights into pricing strategies and bulk purchasing options that can optimize procurement budgets.

By the end of this guide, B2B buyers will be empowered to select the right fruit slicer that meets their unique requirements, ultimately enhancing their product offerings and customer satisfaction in a thriving market.

Understanding fruit slicer watermelon Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Watermelon Slicer | Hand-operated, typically features a stainless steel blade | Restaurants, catering services | Pros: Cost-effective, easy to use. Cons: Labor-intensive, slower slicing. |

| Electric Watermelon Slicer | Powered by electricity, offers rapid slicing capabilities | Large-scale food processing, event catering | Pros: Fast and efficient, consistent results. Cons: Higher initial investment, requires power source. |

| Multi-blade Watermelon Cutter | Multiple blades for simultaneous slicing | Buffets, party rentals | Pros: Saves time, produces uniform slices. Cons: May require more cleaning, can be bulky. |

| Ergonomic Watermelon Slicer | Designed for comfortable grip and ease of use | Home kitchens, small cafes | Pros: Reduces hand strain, enhances user experience. Cons: May be less durable than metal options. |

| Portable Watermelon Slicer | Compact design for easy transport | Food trucks, outdoor events | Pros: Lightweight, convenient for on-the-go use. Cons: Limited slicing capacity, may not handle large melons. |

What Are the Characteristics of Manual Watermelon Slicers?

Manual watermelon slicers are typically hand-operated tools featuring a sharp stainless steel blade. They are easy to use and often require minimal maintenance, making them a popular choice for restaurants and catering services. However, they can be labor-intensive, requiring time and effort to slice larger quantities, which may not be ideal for high-volume operations. B2B buyers should consider the balance between cost-effectiveness and labor efficiency when selecting this type of slicer.

Why Choose Electric Watermelon Slicers for Large Operations?

Electric watermelon slicers are designed for high efficiency and speed, making them suitable for large-scale food processing and event catering. These machines can slice multiple watermelons in a fraction of the time it takes manual slicers, ensuring consistent results. While the initial investment is higher, the time saved and increased productivity can justify the cost in a busy kitchen environment. B2B buyers should assess their volume needs to determine if the electric option aligns with their operational goals.

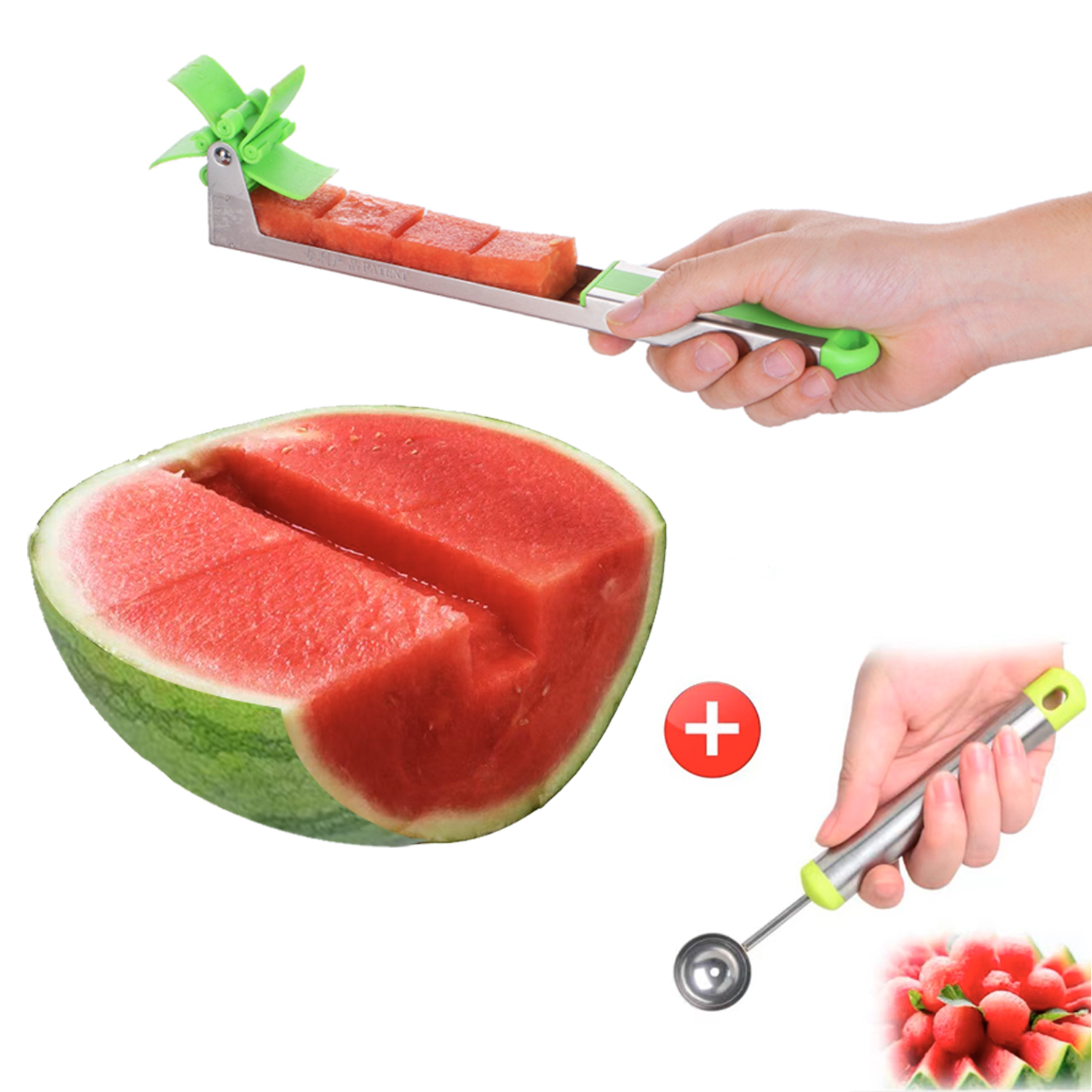

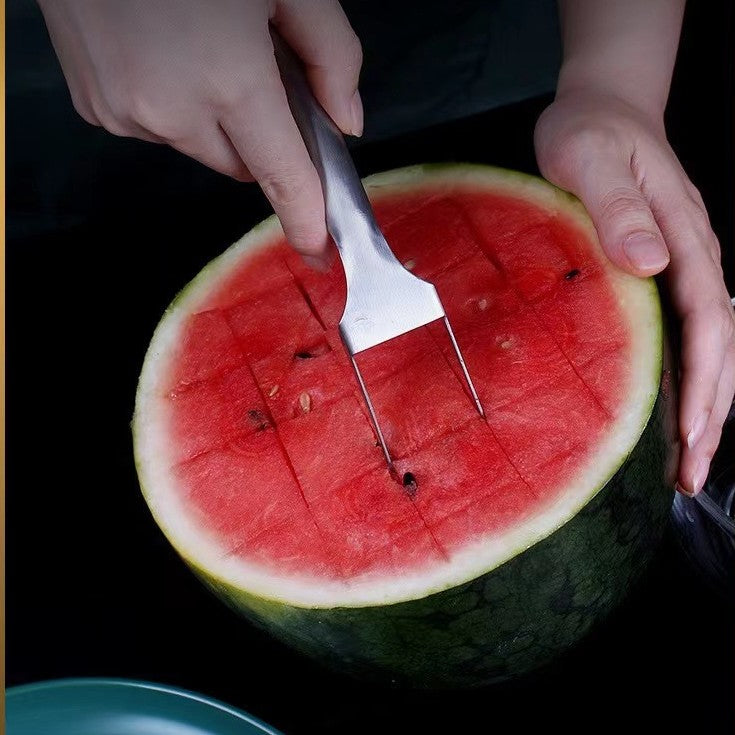

Illustrative image related to fruit slicer watermelon

What Are the Benefits of Multi-blade Watermelon Cutters?

Multi-blade watermelon cutters are engineered to slice multiple pieces simultaneously, making them ideal for buffets and party rentals. They produce uniform slices quickly, enhancing presentation and reducing preparation time. However, these slicers can be bulkier and require more cleaning than simpler models. Buyers should evaluate their space and cleaning capabilities when considering this type of slicer for their business.

How Do Ergonomic Watermelon Slicers Improve User Experience?

Ergonomic watermelon slicers are designed with user comfort in mind, featuring grips that reduce hand strain during use. These slicers are suitable for home kitchens and small cafes where ease of use is essential. While they may not be as durable as their metal counterparts, they offer a better user experience. B2B buyers should consider the target market and expected usage frequency when choosing this type of slicer.

What Makes Portable Watermelon Slicers Ideal for Mobile Vendors?

Portable watermelon slicers are compact and lightweight, making them easy to transport for food trucks and outdoor events. While they offer convenience, their slicing capacity may be limited compared to larger models, which could affect efficiency during peak times. B2B buyers should consider their operational needs and the types of events they cater to when selecting a portable option.

Key Industrial Applications of fruit slicer watermelon

| Industry/Sector | Specific Application of fruit slicer watermelon | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service & Catering | High-volume fruit preparation for events and banquets | Increases efficiency and reduces labor costs in food prep | Durability, ease of cleaning, and safety features |

| Retail Grocery Stores | Demonstration and sale of pre-sliced fruit for consumer convenience | Enhances customer experience and boosts sales of fresh produce | Product size, slicing efficiency, and safety compliance |

| Restaurants & Cafés | Quick preparation of fruit dishes, salads, and desserts | Saves time in food prep, allowing for faster service delivery | Ergonomic design, ease of use, and ability to handle large fruits |

| Juice and Smoothie Bars | Efficient slicing for juice extraction and smoothie preparation | Maximizes yield from fruits, reducing waste | Blade quality, slicing speed, and ease of cleaning |

| Food Processing Industry | Automation of fruit slicing in production lines | Increases production speed and consistency in product quality | Compatibility with existing machinery and operational efficiency |

How is a Fruit Slicer Watermelon Used in the Food Service & Catering Industry?

In the food service and catering sector, a fruit slicer watermelon is essential for efficiently preparing large quantities of fruit for events and banquets. By enabling quick and uniform slicing, it minimizes labor costs and ensures consistent presentation. Buyers in this sector should prioritize durability and ease of cleaning, as the equipment will be used frequently in high-volume settings.

What Role Does a Fruit Slicer Watermelon Play in Retail Grocery Stores?

Retail grocery stores leverage fruit slicers to offer pre-sliced watermelon and other fruits, enhancing customer convenience. This not only improves the shopping experience but also increases sales of fresh produce. When sourcing, retailers must consider the size of the slicer, its efficiency in slicing, and compliance with safety standards to ensure a seamless integration into their operations.

Illustrative image related to fruit slicer watermelon

Why is a Fruit Slicer Watermelon Important for Restaurants & Cafés?

Restaurants and cafés use fruit slicers to quickly prepare ingredients for fruit dishes, salads, and desserts, significantly reducing food preparation time. This efficiency allows staff to focus on service, enhancing customer satisfaction. Key considerations for buyers include ergonomic design for user comfort, ease of use, and the ability to handle large fruits without compromising safety.

How Do Juice and Smoothie Bars Benefit from Using a Fruit Slicer Watermelon?

Juice and smoothie bars utilize fruit slicers to streamline the slicing process, maximizing yield while minimizing waste. This is particularly crucial in high-demand settings where speed and efficiency directly impact profitability. Buyers should focus on blade quality, slicing speed, and the ease of cleaning to maintain hygiene standards in their operations.

What is the Significance of a Fruit Slicer Watermelon in the Food Processing Industry?

In the food processing industry, fruit slicers are vital for automating the slicing process on production lines. This automation increases production speed and ensures consistent product quality, which is essential for maintaining brand standards. When sourcing, businesses should ensure compatibility with existing machinery and assess the overall operational efficiency of the slicer to enhance productivity.

3 Common User Pain Points for ‘fruit slicer watermelon’ & Their Solutions

Scenario 1: Difficulty in Ensuring Consistent Quality of Slices

The Problem: For B2B buyers, particularly those in the food service industry, ensuring that watermelon slices are uniformly cut is crucial for presentation and portion control. Inconsistent slicing can lead to customer dissatisfaction, as uneven portions may appear unprofessional and can complicate serving logistics. Additionally, using subpar tools may result in waste due to jagged cuts that leave excess fruit on the rind.

The Solution: To address this issue, buyers should invest in high-quality fruit slicers designed specifically for watermelons. Look for slicers that feature multiple blades, like the 12-blade models, which can create uniform slices in one motion. This not only speeds up the slicing process but also minimizes waste. When sourcing these tools, consider materials such as stainless steel for durability and easy cleaning. Ensure to include ergonomic handles for safety and comfort during operation, which can significantly reduce fatigue during high-volume service periods.

Scenario 2: Inefficient Cleanup and Maintenance Post-Use

The Problem: One common frustration among B2B buyers is the time and effort required for cleaning and maintaining fruit slicers after use. Many slicers can accumulate juices and residues that are hard to clean, leading to potential hygiene issues and increased labor costs. This can be especially burdensome in busy kitchen environments where time is of the essence.

The Solution: To mitigate cleanup challenges, buyers should opt for fruit slicers with easy-to-clean designs, such as those featuring non-stick surfaces or detachable components. Stainless steel slicers are often easier to wipe down and resist staining, making them ideal for a high-volume setting. Additionally, consider implementing a regular maintenance schedule that includes thorough cleaning after each use and periodic inspections for wear and tear. This proactive approach not only extends the lifespan of the slicers but also ensures a consistently hygienic kitchen environment.

Scenario 3: Safety Concerns During Use

The Problem: Safety is a significant concern in any food service operation, and using sharp tools like watermelon slicers can pose risks if not handled correctly. B2B buyers often worry about the potential for cuts or accidents, particularly when training new staff who may not be accustomed to using specialized kitchen equipment.

Illustrative image related to fruit slicer watermelon

The Solution: To enhance safety, buyers should prioritize slicers that come with safety features, such as protective covers for blades and non-slip handles. Ergonomic designs that facilitate a secure grip can reduce the likelihood of accidents. Additionally, investing in staff training is essential; conducting workshops on safe slicing techniques and proper equipment handling can greatly reduce risks. Suppliers should be consulted to provide demonstrations or materials that can help train staff effectively, ensuring everyone is well-prepared to operate the slicers safely and efficiently.

Strategic Material Selection Guide for fruit slicer watermelon

When selecting materials for watermelon slicers, it is essential to consider various factors that affect performance, durability, and compliance with international standards. Here, we analyze four common materials used in the manufacturing of watermelon slicers, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Stainless Steel in Watermelon Slicers?

Stainless steel is a popular choice for watermelon slicers due to its excellent corrosion resistance and durability. It can withstand high temperatures and is less prone to rust, making it suitable for various environments, including humid climates. Stainless steel typically has a high tensile strength, which ensures that the blades maintain their sharpness over time.

Pros & Cons:

The primary advantage of stainless steel is its long lifespan and ease of cleaning, as it does not retain food particles or odors. However, it can be more expensive than other materials and may require more complex manufacturing processes, which can increase production costs.

Impact on Application:

Stainless steel is compatible with food-grade standards, making it safe for food contact. It is essential for manufacturers to ensure compliance with international food safety regulations, particularly in regions like Europe and the Middle East.

How Does Plastic Compare for Watermelon Slicer Manufacturing?

Plastic, particularly high-density polyethylene (HDPE) or polypropylene, is another common material for watermelon slicers. These plastics are lightweight and can be molded into various shapes, allowing for ergonomic designs.

Illustrative image related to fruit slicer watermelon

Pros & Cons:

The main advantage of plastic is its lower cost and ease of manufacturing, which can lead to reduced retail prices. However, plastic may not offer the same durability as metal options and can be susceptible to wear and tear over time, especially under high-pressure applications.

Impact on Application:

Plastic slicers must comply with food safety standards, but they may not be as robust in high-temperature environments. Buyers from regions with extreme temperatures, such as parts of Africa and the Middle East, should consider the potential for warping or degradation.

What Role Does Silicone Play in Watermelon Slicer Design?

Silicone is often used for handles or grips on watermelon slicers due to its excellent non-slip properties and comfort. It can withstand a wide range of temperatures and is generally resistant to chemicals.

Pros & Cons:

Silicone provides a soft touch and enhances user experience by reducing hand fatigue. However, it is typically not used for the blades themselves, which limits its application. The cost of silicone can also be higher than that of standard plastics.

Impact on Application:

Silicone must meet certain food safety standards, particularly in Europe, where regulations are stringent. Manufacturers should ensure that their silicone products are free from harmful additives.

Why is Aluminum an Attractive Option for Watermelon Slicers?

Aluminum is lightweight and has good thermal conductivity, making it another viable option for watermelon slicers. It is often anodized to enhance corrosion resistance and durability.

Pros & Cons:

The lightweight nature of aluminum makes it easy to handle, while its cost is generally lower than stainless steel. However, aluminum can be prone to scratching and denting, which may affect the product’s longevity.

Impact on Application:

Aluminum slicers must comply with food safety regulations, and buyers should verify that the anodization process meets international standards. This is particularly important for B2B buyers in Europe and the Middle East, where compliance is rigorously enforced.

Illustrative image related to fruit slicer watermelon

Summary Table of Material Selection for Watermelon Slicers

| Material | Typical Use Case for fruit slicer watermelon | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Blades and cutting edges | Excellent durability and corrosion resistance | Higher manufacturing cost | High |

| Plastic | Handles and body of slicers | Lightweight and cost-effective | Less durable, potential wear over time | Low |

| Silicone | Handles and grips | Comfortable, non-slip properties | Limited use for blades, higher cost | Medium |

| Aluminum | Blades and body of slicers | Lightweight, good thermal conductivity | Prone to scratching and denting | Medium |

This comprehensive analysis provides B2B buyers with valuable insights into material selection for watermelon slicers, helping them make informed purchasing decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for fruit slicer watermelon

What Are the Main Stages in the Manufacturing Process of Watermelon Slicers?

The manufacturing of watermelon slicers involves several critical stages that ensure the final product meets quality and performance expectations.

-

Material Preparation: The first step involves sourcing high-quality materials, primarily stainless steel for blades and durable plastics (like ABS and TPE) for handles. Sourcing from reliable suppliers who adhere to international standards is essential to ensure the materials are non-toxic and environmentally friendly. Manufacturers often conduct preliminary tests on raw materials to verify their suitability for production.

-

Forming: This stage involves shaping the materials into the desired components. For stainless steel blades, techniques such as stamping or laser cutting are commonly used to ensure precision and sharpness. The handles are typically molded using injection molding technology, which allows for ergonomic designs that enhance user comfort.

-

Assembly: After forming, the components are assembled. This process can be manual or automated, depending on the scale of production. Manual assembly often allows for better quality control, as skilled workers can ensure that each slicer is assembled correctly, while automated processes can increase efficiency in larger manufacturing facilities.

-

Finishing: The final stage includes polishing the blades for sharpness, applying any necessary coatings to prevent corrosion, and quality checks on aesthetics and functionality. Proper finishing not only enhances the product’s appearance but also its durability, which is crucial for B2B buyers looking for long-lasting tools.

How Is Quality Assurance Implemented in Watermelon Slicer Manufacturing?

Quality assurance is critical in the production of watermelon slicers to ensure safety, functionality, and customer satisfaction. Various international and industry-specific standards guide these processes.

-

International Standards: Manufacturers often adhere to ISO 9001, a widely recognized quality management standard that ensures consistent quality and customer satisfaction. Compliance with CE marking standards is also crucial for products sold in Europe, indicating that they meet safety, health, and environmental protection standards.

-

Industry-Specific Certifications: Certifications like API (American Petroleum Institute) are less common in the kitchenware industry but can indicate the manufacturer’s commitment to quality and safety in their production processes.

What Are the Key Quality Control Checkpoints in the Production Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects and ensure compliance with standards:

Illustrative image related to fruit slicer watermelon

-

Incoming Quality Control (IQC): This is the first checkpoint where raw materials are inspected upon arrival. Key aspects include verifying material specifications, checking for damage, and ensuring that suppliers provide the necessary documentation for compliance.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC involves continuous monitoring of the production process. This may include measuring dimensions, checking blade sharpness, and ensuring that assembly processes are followed correctly. This stage is crucial for identifying issues early and minimizing waste.

-

Final Quality Control (FQC): Once the watermelon slicers are assembled, they undergo final inspections where functionality tests are performed. This includes testing the slicer’s ability to cut through the watermelon efficiently and checking for any sharp edges that could pose safety risks.

What Common Testing Methods Are Used for Watermelon Slicers?

Manufacturers employ various testing methods to ensure product performance and safety:

- Functional Testing: This involves testing the slicer with actual watermelons to assess cutting efficiency and ease of use.

- Durability Testing: Slicers are subjected to stress tests to determine their longevity and resistance to wear and tear.

- Safety Testing: This includes checking for sharp edges, ensuring that handles are securely attached, and verifying that materials are non-toxic.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, ensuring supplier quality is paramount. Here are actionable steps to verify QC practices:

-

Supplier Audits: Conducting on-site audits allows buyers to observe manufacturing processes, quality control systems, and compliance with international standards firsthand.

-

Requesting Quality Reports: Suppliers should provide detailed QC reports that outline testing results, inspection processes, and any corrective actions taken to address issues. Regular reporting can help build trust in the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s production quality. These inspections can be particularly useful when dealing with new suppliers or when entering new markets.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances when dealing with suppliers across different regions:

-

Regulatory Compliance: Understanding the local regulations regarding product safety and environmental standards is crucial. For example, products sold in Europe must meet stringent CE marking requirements, while Middle Eastern countries may have different standards.

-

Cultural Considerations: Different regions may have varying expectations regarding quality and customer service. Building strong relationships with suppliers can facilitate better communication and understanding of these differences.

-

Logistics and Shipping: Quality can also be affected by how products are packaged and shipped. Ensuring that suppliers follow best practices in logistics can help maintain product integrity during transit.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions, ensuring they source high-quality watermelon slicers that meet their operational needs and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fruit slicer watermelon’

In the competitive landscape of food preparation equipment, sourcing the right watermelon slicer is crucial for businesses in the food service industry. This guide aims to assist B2B buyers in navigating the procurement process efficiently, ensuring they select the best product for their needs.

Step 1: Define Your Technical Specifications

Understanding your specific needs is the first step in sourcing a watermelon slicer. Consider the volume of fruit you need to slice, the types of melons you’ll be working with, and the desired slice thickness. This will help you narrow down options that meet your operational requirements.

- Capacity: Assess whether a manual or electric slicer is more suitable for your volume.

- Size and Design: Ensure the slicer can handle larger melons if required, and that its design fits your kitchen layout.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers. Look for manufacturers with a solid reputation in the market, especially those that specialize in fruit preparation tools.

- Market Presence: Suppliers with a long-standing presence are often more reliable.

- Product Variety: Evaluate if they offer multiple models to meet different slicing needs.

Step 3: Evaluate Product Quality and Materials

The durability and effectiveness of a watermelon slicer largely depend on the materials used in its construction. High-quality stainless steel blades, for example, provide longevity and sharpness, which is essential for efficient slicing.

- Material Standards: Verify that the materials used are food-safe and non-toxic.

- Ergonomics: A well-designed handle can enhance user experience and safety.

Step 4: Check for Certifications and Compliance

Before finalizing your supplier, ensure they comply with international standards and certifications relevant to food safety and equipment manufacturing. This is particularly important for buyers in regions with strict regulations.

- Certifications: Look for ISO certifications or compliance with local health and safety regulations.

- Product Testing: Inquire about the quality control processes in place.

Step 5: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples for hands-on evaluation. Testing the product will allow you to assess its performance and ease of use firsthand.

Illustrative image related to fruit slicer watermelon

- Performance Evaluation: Check the slicer’s efficiency in cutting through different types of melons.

- User Feedback: Gather opinions from staff who will be using the slicer regularly.

Step 6: Negotiate Pricing and Terms

Price negotiation is a critical step in the sourcing process. Consider not just the unit price but also shipping costs, bulk discounts, and payment terms.

- Volume Discounts: Discuss pricing structures based on order quantities.

- Payment Flexibility: Look for suppliers that offer favorable payment terms to manage cash flow effectively.

Step 7: Establish a Relationship with Your Supplier

Building a strong relationship with your chosen supplier can lead to better service, support, and future collaboration opportunities. Regular communication and feedback are key.

- Ongoing Support: Ensure they provide adequate after-sales support and warranty options.

- Feedback Loop: Share your experiences to help them improve their offerings.

By following these steps, B2B buyers can confidently navigate the sourcing process for watermelon slicers, ensuring they make informed decisions that align with their operational needs and standards.

Comprehensive Cost and Pricing Analysis for fruit slicer watermelon Sourcing

What Are the Key Cost Components for Watermelon Slicer Production?

When sourcing watermelon slicers, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

Illustrative image related to fruit slicer watermelon

-

Materials: The choice of materials significantly influences the cost. Common materials include stainless steel for blades, ABS plastic for handles, and silicone for grips. Higher quality materials typically lead to increased durability and performance, which can justify a higher price point.

-

Labor: Labor costs vary by region and can impact the overall price. Countries with higher wage standards may produce slicers at a higher cost, but this can be offset by better craftsmanship and quality assurance.

-

Manufacturing Overhead: This encompasses expenses related to the manufacturing facility, equipment maintenance, utilities, and administrative costs. Efficient operations can minimize overhead, which is beneficial for pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. These costs are often amortized over larger production runs, making it essential to consider minimum order quantities (MOQs).

-

Quality Control (QC): Investing in quality control is vital for ensuring product reliability. Suppliers who adhere to international quality standards may charge more but can reduce the risk of defects and returns.

-

Logistics: Shipping and transportation costs are influenced by the geographic location of suppliers and buyers. Understanding Incoterms is essential for managing these costs effectively.

-

Margin: Suppliers will typically add a profit margin to the total cost, which can vary based on market conditions and competition.

How Do Price Influencers Affect Watermelon Slicer Sourcing?

Several factors can influence the pricing of watermelon slicers, making it imperative for buyers to consider these when negotiating.

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Suppliers often have set MOQs to justify production runs, so aligning orders with supplier capabilities can create cost efficiencies.

-

Specifications/Customization: Custom features or specific design requests can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials: As mentioned earlier, the choice of materials can greatly affect pricing. Premium materials, while more expensive, can enhance the product’s lifespan and performance.

-

Quality/Certifications: Products that meet specific certifications (e.g., FDA, CE) may come at a premium but can be essential for compliance in certain markets, particularly in Europe and the Middle East.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their experience and quality assurance processes.

-

Incoterms: Understanding shipping terms (like FOB, CIF) can help buyers manage logistics costs effectively and avoid unexpected fees.

What Are the Best Negotiation Tips for B2B Buyers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing.

-

Leverage Volume: Highlighting the potential for larger orders can encourage suppliers to offer better pricing.

-

Evaluate Total Cost of Ownership: Consider long-term costs, including durability and maintenance, rather than just the initial purchase price. This perspective can justify spending more upfront for higher-quality products.

-

Research Market Prices: Understanding the average market price for watermelon slicers in the supplier’s region can provide leverage during negotiations.

-

Flexible Payment Terms: Offering upfront payment or shorter payment cycles can incentivize suppliers to lower prices.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better service, pricing, and priority during production.

Are There Pricing Nuances for International B2B Buyers?

Yes, international buyers face unique challenges and opportunities in pricing. Currency fluctuations, import tariffs, and varying shipping costs can all affect final pricing. Buyers should factor in these elements when budgeting for purchases to ensure comprehensive cost assessments.

Disclaimer

The prices and costs discussed are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure the best sourcing decisions.

Illustrative image related to fruit slicer watermelon

Alternatives Analysis: Comparing fruit slicer watermelon With Other Solutions

Exploring Alternatives to the Fruit Slicer Watermelon

In the competitive landscape of food preparation tools, particularly in the fruit slicing niche, the fruit slicer watermelon stands out for its specialized design and efficiency. However, B2B buyers may benefit from evaluating alternative solutions that could meet similar needs, offering distinct advantages in various contexts. This section explores two viable alternatives to the fruit slicer watermelon: the traditional knife method and the electric fruit slicer.

| Comparison Aspect | Fruit Slicer Watermelon | Traditional Knife Method | Electric Fruit Slicer |

|---|---|---|---|

| Performance | High – cuts multiple slices quickly | Moderate – requires skill for uniformity | Very High – provides consistent slices with speed |

| Cost | $25-$30 | Low – cost of a good knife (approx. $10-$50) | High – typically $100 and above |

| Ease of Implementation | Simple – requires minimal training | Moderate – requires practice to master | Easy – plug and play with minimal setup |

| Maintenance | Low – easy to clean by hand | Moderate – requires regular sharpening | Moderate to High – requires regular cleaning and maintenance |

| Best Use Case | Ideal for parties and events | Versatile for various fruits, suitable for home use | Best for commercial kitchens or high-volume settings |

What Are the Pros and Cons of Using a Traditional Knife Method?

The traditional knife method is perhaps the most common alternative to the fruit slicer watermelon. While it offers versatility in slicing different types of fruits, it demands a certain level of skill and experience to achieve uniform slices. The initial investment is low, making it accessible for many businesses, but ongoing costs include maintenance such as sharpening. Additionally, this method can be time-consuming, particularly in settings where large quantities of watermelon need to be prepared quickly, thus affecting efficiency.

How Does an Electric Fruit Slicer Compare?

The electric fruit slicer is a powerful alternative designed for high-volume slicing. It excels in performance, offering speed and uniformity in slicing, which can significantly reduce preparation time in commercial environments. However, the initial investment is considerably higher than that of a fruit slicer watermelon or a knife, which could deter smaller businesses. Maintenance can also be more demanding, requiring regular cleaning and potential repairs. Despite these considerations, its efficiency makes it an ideal choice for businesses that prioritize high output and consistency.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right slicing solution, B2B buyers should assess their specific operational needs, including volume requirements, budget constraints, and the skill level of their staff. For businesses focused on high-volume fruit preparation, an electric fruit slicer may be the most efficient choice despite its higher cost. Conversely, smaller operations or those seeking a versatile tool may find the traditional knife method sufficient. The fruit slicer watermelon offers a balance of efficiency and affordability, making it a strong contender for events and casual gatherings. Ultimately, understanding the unique demands of their business will guide buyers in making an informed decision that aligns with their goals.

Essential Technical Properties and Trade Terminology for fruit slicer watermelon

What Are the Key Technical Properties of a Fruit Slicer for Watermelon?

When sourcing a fruit slicer for watermelon, understanding its technical properties is crucial for ensuring efficiency, durability, and user satisfaction. Here are some critical specifications to consider:

Illustrative image related to fruit slicer watermelon

-

Material Composition

The most common materials used in watermelon slicers include stainless steel, ABS plastic, and TPE (thermoplastic elastomer). Stainless steel is favored for its durability and resistance to corrosion, which is essential for food safety. ABS plastic provides lightweight and robust construction, while TPE offers a comfortable grip. Selecting the right material can influence the slicer’s longevity and ease of cleaning, factors that are vital for B2B buyers in the food service industry. -

Blade Sharpness and Configuration

The blade’s sharpness is a critical property that determines cutting efficiency. Watermelon slicers typically feature multiple blades, often 12 or more, designed to cut through tough rind and flesh simultaneously. A well-configured blade set minimizes wastage and maximizes yield, which is particularly important for businesses looking to enhance productivity and reduce food costs. -

Ergonomic Design

Ergonomics play a significant role in user satisfaction and safety. A slicer with an ergonomic handle reduces strain during use, making it easier for staff to operate over extended periods. This aspect is crucial for B2B buyers, as it can lead to increased employee efficiency and reduced workplace injuries, ultimately impacting operational costs. -

Cleaning and Maintenance

Ease of cleaning is another important specification. Slicers that can be easily disassembled or have non-stick surfaces can significantly reduce labor time in food preparation environments. For international buyers, ensuring that the slicer meets local health and safety regulations is essential, as non-compliance can lead to costly fines and damage to brand reputation. -

Dimensions and Weight

The size and weight of a watermelon slicer can affect its usability and storage. Compact, lightweight models are often preferred in commercial kitchens with limited space. Understanding the dimensional specifications helps businesses optimize their kitchen layout and equipment storage.

What Are Common Trade Terms Related to Fruit Slicers?

Navigating the B2B market involves understanding specific trade terminology that is commonly used in transactions. Here are some key terms to familiarize yourself with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For businesses sourcing watermelon slicers, working with OEM suppliers can allow for customization and branding opportunities, ensuring that products meet specific market demands. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. For watermelon slicers, understanding the MOQ is vital for budgeting and inventory management. Buyers must evaluate their needs against the supplier’s MOQ to ensure that they are making a financially sound decision. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request a price quote for specific products. When looking to purchase watermelon slicers, submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, facilitating better negotiation and decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping agreements. Understanding these terms is crucial for B2B buyers to clarify shipping costs, risk, and delivery responsibilities, especially when importing watermelon slicers from different countries. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is essential for planning inventory levels and ensuring that products are available when needed, thus maintaining smooth operations. -

Warranty and Support

Warranties cover repairs and replacements for defective products. Knowing the warranty terms can significantly impact a buyer’s decision-making process, as robust support can mitigate risks associated with equipment failure in a commercial setting.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market expectations.

Navigating Market Dynamics and Sourcing Trends in the fruit slicer watermelon Sector

What Are the Key Market Dynamics and Trends in the Fruit Slicer Watermelon Sector?

The global market for fruit slicers, particularly those designed for watermelons, is experiencing notable growth driven by increasing consumer demand for convenience in food preparation. As busy lifestyles lead to a preference for quick and easy meal solutions, innovative kitchen tools like watermelon slicers are becoming essential for both domestic and commercial use. In emerging markets across Africa and South America, the rising middle class is significantly influencing purchasing decisions, with an increasing focus on high-quality, user-friendly products.

Technologically, the integration of advanced materials and ergonomic designs is gaining traction. Electric and stainless steel options are particularly appealing to international buyers who prioritize durability and efficiency. Additionally, online sales channels are expanding, allowing B2B buyers in regions such as the Middle East and Europe, including Germany and Saudi Arabia, to access a broader range of products. This shift is complemented by the growth of e-commerce platforms that facilitate bulk purchasing, enabling businesses to streamline their supply chain processes.

Illustrative image related to fruit slicer watermelon

How Is Sustainability and Ethical Sourcing Impacting the Fruit Slicer Watermelon Market?

As global awareness of environmental issues rises, sustainability has become a pivotal factor in the sourcing of fruit slicers. B2B buyers are increasingly seeking suppliers who prioritize eco-friendly materials and practices. The use of non-toxic, recyclable materials in the production of watermelon slicers is not just a trend but a necessity for companies looking to enhance their brand reputation. Certifications such as FSC (Forest Stewardship Council) for wood products or ISO certifications for sustainable manufacturing processes are becoming essential credentials for suppliers.

Moreover, ethical sourcing is crucial in today’s market. Businesses are increasingly scrutinizing their supply chains to ensure fair labor practices and minimal environmental impact. By partnering with manufacturers that demonstrate a commitment to ethical practices, B2B buyers can not only meet regulatory requirements but also appeal to a growing segment of environmentally-conscious consumers. This shift towards sustainability not only benefits the planet but can also lead to cost savings through efficient resource use.

What Is the Historical Context of the Fruit Slicer Watermelon Sector?

The evolution of fruit slicers can be traced back several decades, with early designs focusing primarily on manual tools that required significant effort and time. Over the years, innovations in design and materials have transformed these tools into efficient kitchen gadgets. The introduction of stainless steel blades and ergonomic handles has significantly improved user experience, making slicing watermelons quicker and less wasteful.

In recent years, the market has shifted towards electric slicers, reflecting broader trends in kitchen automation. This evolution is particularly relevant for B2B buyers who cater to the food service industry, where efficiency and speed are paramount. As consumer preferences continue to evolve towards convenience and quality, the fruit slicer watermelon sector is poised for further innovation and growth, offering ample opportunities for international buyers to capitalize on emerging trends.

Frequently Asked Questions (FAQs) for B2B Buyers of fruit slicer watermelon

-

How do I choose the right fruit slicer for watermelons?

When selecting a fruit slicer for watermelons, consider factors such as blade material, ergonomic design, and slicing efficiency. High-quality stainless steel blades ensure durability and smooth cutting through tough skins. Look for ergonomic handles that provide a comfortable grip, especially for high-volume slicing. Additionally, assess whether the slicer can produce uniform slices, as this can enhance presentation for events or retail. Reading reviews from other B2B buyers can also provide insights into the product’s performance. -

What is the best material for a watermelon slicer?

The best materials for a watermelon slicer include stainless steel for the blades and durable plastic or silicone for the handles. Stainless steel is resistant to rust and corrosion, ensuring a long lifespan and sharpness. Handles made from non-slip materials enhance grip and safety during use. Additionally, opting for BPA-free plastics ensures the product is safe for food contact, which is particularly important for suppliers catering to health-conscious markets. -

What are the typical minimum order quantities (MOQ) for fruit slicers?

Minimum order quantities for fruit slicers can vary significantly by supplier and region. Typically, MOQs may range from 100 to 1,000 units, depending on the manufacturer’s production capabilities and the type of slicer. When negotiating with suppliers, consider factors such as your market demand and inventory capacity. Some manufacturers may offer flexible MOQs for first-time buyers or bulk orders, which can be advantageous for establishing a long-term partnership. -

What payment terms should I expect when sourcing fruit slicers?

Payment terms can differ among suppliers, but common practices include options such as a 30% deposit upfront with the balance due before shipment, or payment in full prior to production. Some suppliers may offer net terms (e.g., net 30 or net 60), particularly for established buyers. It’s crucial to discuss and negotiate these terms upfront to ensure clarity and protect your cash flow. Additionally, consider using secure payment methods like letters of credit for larger orders to mitigate risk. -

How can I ensure the quality of watermelon slicers from suppliers?

To ensure quality, request product samples before placing bulk orders. Conduct thorough inspections for blade sharpness, material quality, and overall craftsmanship. Certifications such as ISO or compliance with food safety standards can also be indicators of a reliable supplier. Establishing a quality assurance process, including regular audits and feedback loops, will help maintain product standards over time. Collaborating with suppliers who have a solid reputation in the market can further enhance quality assurance. -

What are the best logistics practices for importing fruit slicers?

Effective logistics practices include selecting reliable freight forwarders and understanding the shipping regulations in your destination country. Consider the mode of transport (air vs. sea) based on cost and urgency. Ensure all documentation, including customs clearance paperwork, is accurate and complete to avoid delays. Additionally, it’s beneficial to track shipments in real-time and maintain communication with suppliers to anticipate any potential disruptions in the supply chain. -

Can I customize watermelon slicers for my brand?

Yes, many manufacturers offer customization options, allowing you to brand the slicers with your logo, choose specific colors, or modify the design to suit your market. Discuss your customization needs during initial negotiations, as this can influence pricing and lead times. Ensure that you have clear specifications and a design mockup to facilitate the production process. Customization can enhance brand visibility and appeal to your target audience, particularly in competitive markets. -

What are the market trends for fruit slicers in international markets?

Current market trends indicate a growing demand for ergonomic and multifunctional fruit slicers that cater to convenience and efficiency. In regions like Africa and South America, there is an increasing focus on health and wellness, driving demand for tools that promote fruit consumption. Eco-friendly materials are also gaining popularity as consumers become more environmentally conscious. Staying informed about these trends will help you align your sourcing strategy with market demands and enhance your competitive edge.

Top 4 Fruit Slicer Watermelon Manufacturers & Suppliers List

1. Target – Watermelon Slicers

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Watermelon Slicers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Götze – Watermelon Slicer with Silicone Handle

Domain: gotzepeeler.com

Registered: 2017 (8 years)

Introduction: Watermelon Slicer with Silicone Handle by Götze

Price: $29.95

SKU: Not specified

Material: ABS, TPE, stainless steel blade

Features:

– Ergonomic rubber handle for secure and safe cutting

– Designed for slicing watermelon, cantaloupe, honeydew, pineapple, and more

– 12 blades for simultaneous separation of core and division into 12 slices

– High-quality stainless steel blades for smooth slicing th…

3. Facebook – Cutting Board

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Cutting Board, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Rick and Ann’s – Double Head Fruit Fork Cutting Knife

Domain: rickandanns.com

Registered: 2002 (23 years)

Introduction: Cutting Tool Double Head Fruit Fork Cutting Knife Summer

Strategic Sourcing Conclusion and Outlook for fruit slicer watermelon

In the competitive landscape of food preparation tools, particularly fruit slicers for watermelons, strategic sourcing emerges as a critical factor for success. International B2B buyers should prioritize suppliers that offer high-quality, ergonomic designs, such as stainless steel blades and user-friendly features that enhance efficiency. By leveraging sourcing strategies that emphasize product quality, sustainability, and innovative design, buyers can ensure they meet the evolving demands of consumers across diverse markets, including Africa, South America, the Middle East, and Europe.

Furthermore, the global trend towards healthier eating habits presents a unique opportunity for businesses in the fruit slicer market. With the increasing popularity of fruits as essential components of diets, investing in versatile and efficient slicing tools can cater to both consumer needs and market trends.

As you consider your sourcing strategies, focus on building relationships with manufacturers that align with your quality standards and market expectations. Engage in proactive discussions about product innovations and supply chain efficiencies. The future of the fruit slicer market is promising, and with the right partnerships, your business can thrive in this growing sector. Embrace this opportunity to enhance your product offerings and meet the demands of your customers head-on.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to fruit slicer watermelon

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.