Fractional Horsepower Electric Motors: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for fractional horsepower electric motors

In the dynamic landscape of global commerce, sourcing fractional horsepower electric motors (FHP motors) presents a unique challenge for B2B buyers, particularly those operating across diverse markets in Africa, South America, the Middle East, and Europe. These compact yet powerful motors are essential components in various applications, ranging from industrial automation to consumer electronics, making their selection critical for operational efficiency and cost-effectiveness. However, the multitude of options available can overwhelm decision-makers seeking reliable suppliers and optimal performance.

This comprehensive guide serves as a vital resource for international buyers, outlining the various types of fractional horsepower motors, their specific applications, and key design considerations. It delves into supplier vetting processes, providing insights into how to evaluate manufacturers based on quality, reliability, and compliance with regional standards. Additionally, we cover cost factors, helping buyers understand pricing structures and negotiate effectively in their respective markets.

By equipping decision-makers with actionable insights and practical strategies, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints. Whether you are seeking to enhance your production capabilities or improve energy efficiency in your applications, understanding the nuances of fractional horsepower electric motors is pivotal to achieving sustainable growth and competitive advantage in today’s global marketplace.

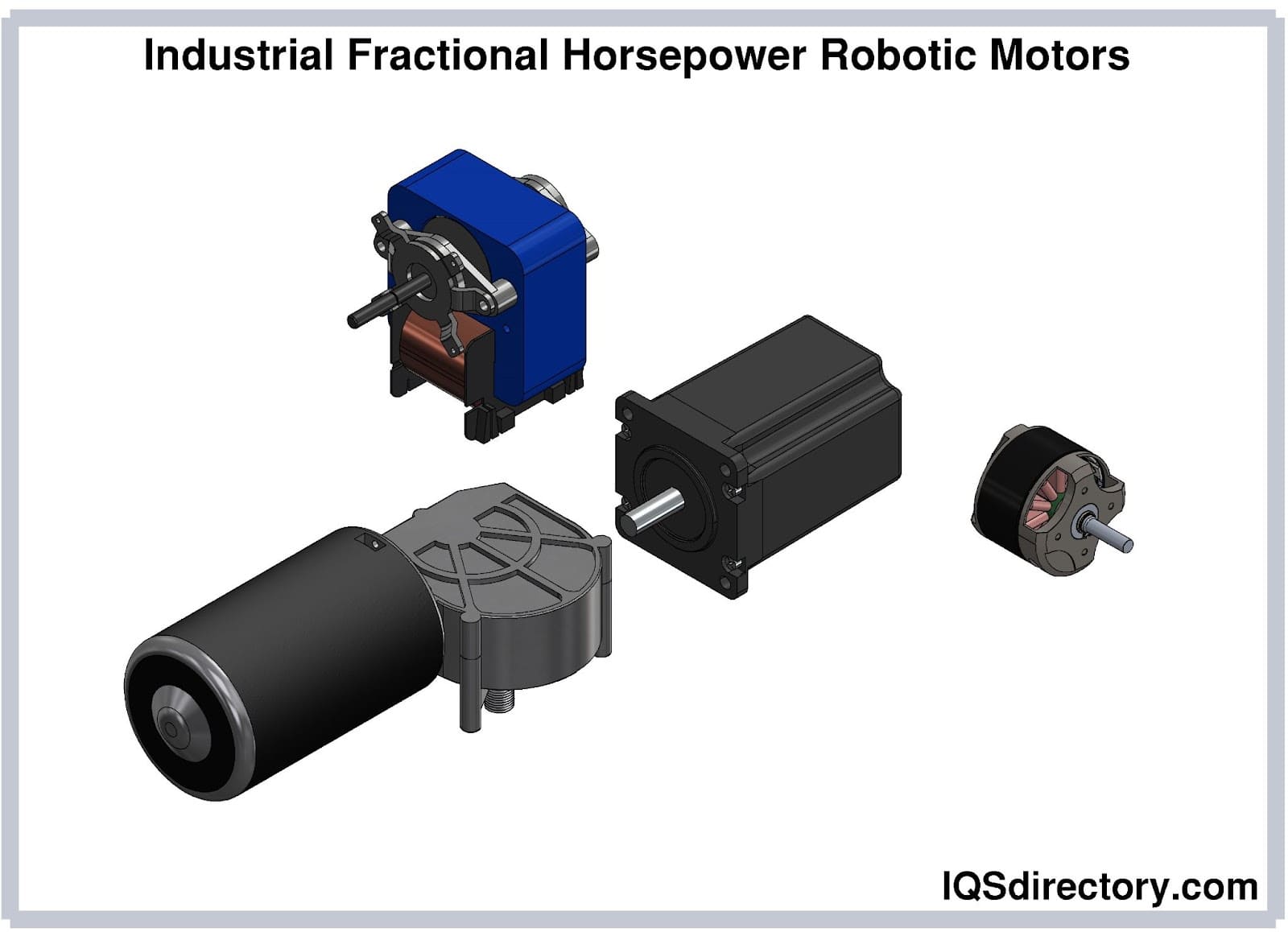

Understanding fractional horsepower electric motors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Induction Motors | Operate on alternating current, robust and low maintenance | Industrial machinery, HVAC systems | Pros: Durable, efficient; Cons: Less torque at low speeds. |

| DC Permanent Magnet Motors | Use permanent magnets for efficient operation | Robotics, automotive systems | Pros: High efficiency, good torque; Cons: Higher cost. |

| Universal Motors | Can operate on both AC and DC, versatile in application | Household appliances, power tools | Pros: Flexible, compact; Cons: Limited lifespan under heavy load. |

| Gear Motors | Incorporate gears for increased torque output | Conveyor systems, automated machinery | Pros: High torque, precise control; Cons: Bulkier design. |

| Brushless DC Motors | Utilize electronic commutation for efficiency | Medical devices, drones, renewable energy systems | Pros: Low maintenance, high efficiency; Cons: Higher initial cost. |

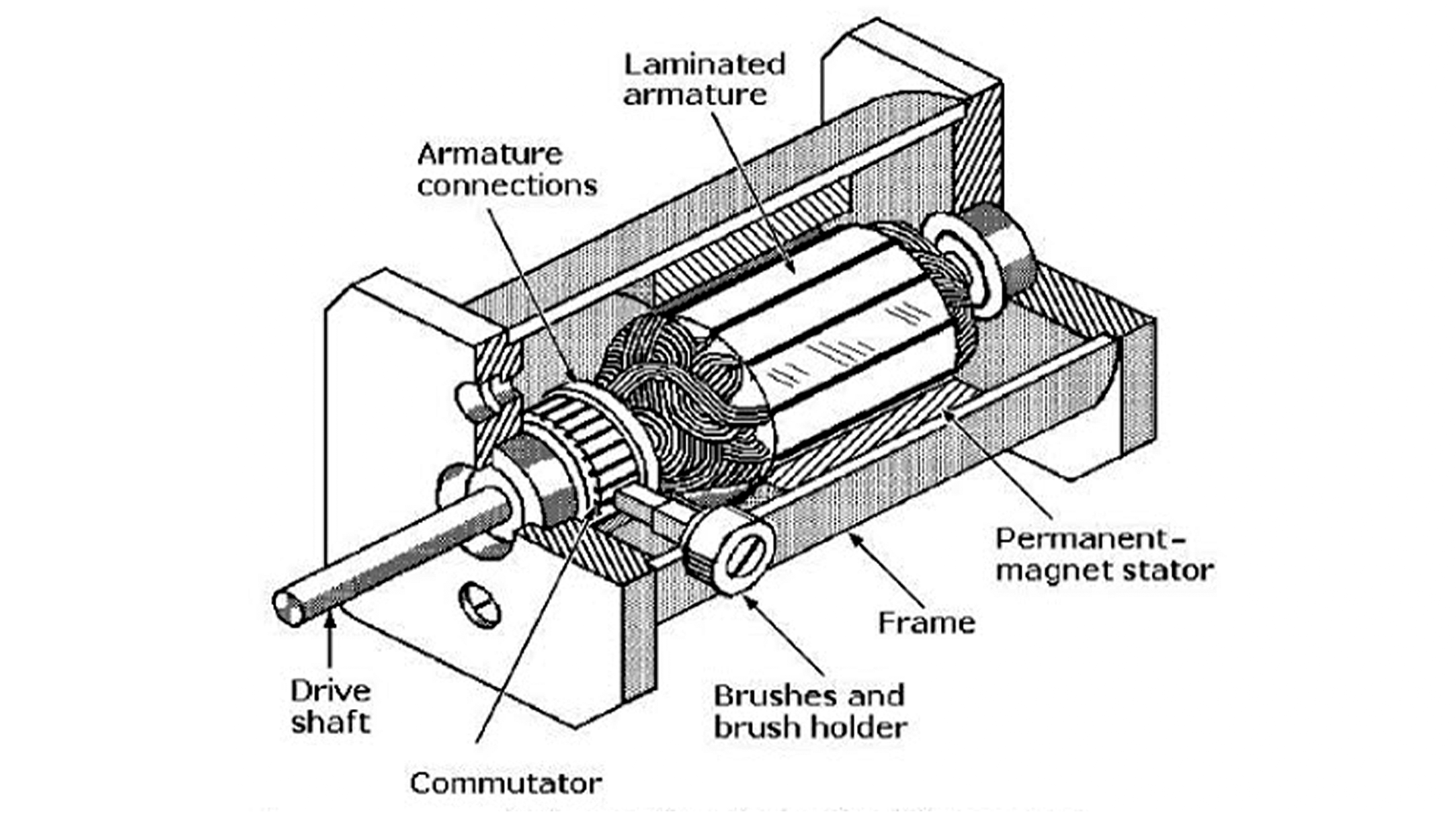

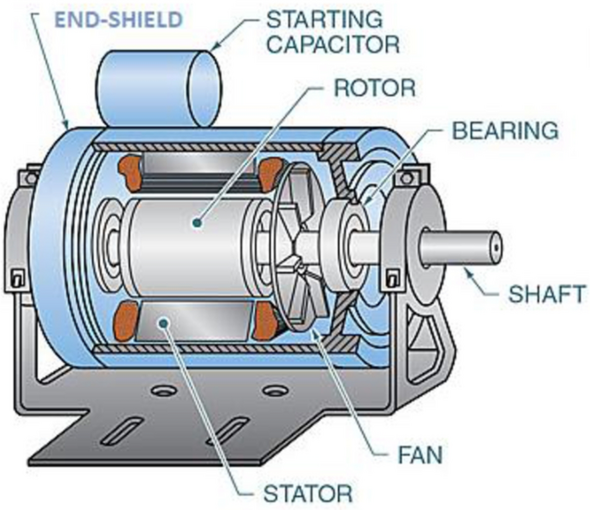

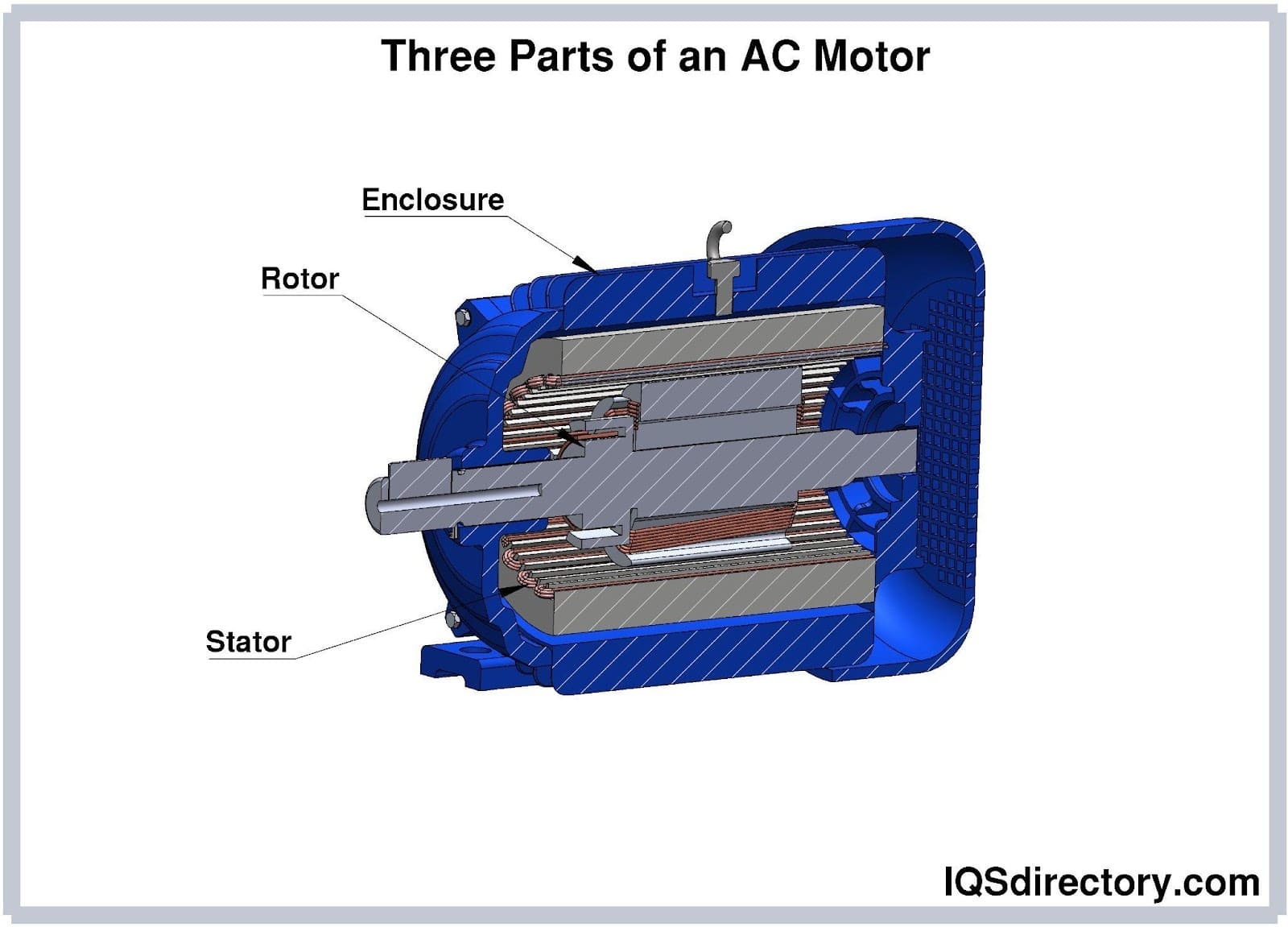

What Are the Characteristics of AC Induction Motors?

AC induction motors are widely recognized for their durability and low maintenance requirements, making them ideal for industrial applications. They operate on alternating current and are often used in HVAC systems and various types of machinery. When considering an AC induction motor for B2B applications, buyers should assess the motor’s efficiency, power output, and suitability for specific operational environments, as these factors directly influence performance and operational costs.

Why Choose DC Permanent Magnet Motors for Your Applications?

DC permanent magnet motors are characterized by their high efficiency and good torque characteristics, making them suitable for applications in robotics and automotive systems. These motors use permanent magnets to generate the magnetic field, which enhances their performance. B2B buyers should consider the cost-to-performance ratio, as while they may be more expensive than other types, their efficiency can lead to long-term savings in energy costs and maintenance.

How Do Universal Motors Benefit Various Industries?

Universal motors are versatile, capable of running on both AC and DC power, which makes them suitable for a wide range of applications, including household appliances and power tools. Their compact design allows for easy integration into various devices. Buyers should weigh the benefits of flexibility against the potential limitations in lifespan when used under heavy loads, making it essential to evaluate the intended application carefully.

What Advantages Do Gear Motors Offer for Industrial Use?

Gear motors are designed to provide increased torque output through the incorporation of gears, making them particularly valuable in conveyor systems and automated machinery. Their ability to deliver precise control over speed and torque is crucial in many industrial applications. Buyers should consider the balance between size and torque output, as gear motors tend to be bulkier than other types, which may impact design and space considerations.

When Should You Consider Brushless DC Motors?

Brushless DC motors are known for their low maintenance needs and high efficiency, making them increasingly popular in applications like medical devices, drones, and renewable energy systems. By utilizing electronic commutation, these motors eliminate the wear associated with traditional brushes. B2B buyers should evaluate the initial investment against long-term operational savings, as the higher upfront cost can be offset by reduced maintenance and energy costs over time.

Key Industrial Applications of fractional horsepower electric motors

| Industry/Sector | Specific Application of fractional horsepower electric motors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Industrial Automation | Driving conveyor systems and assembly line equipment | Enhances production efficiency and reduces operational downtime | Reliability, energy efficiency, and adaptability to varying loads |

| Automotive | Powering vehicle components like power windows and HVAC systems | Improves vehicle functionality and user comfort | Compact design, precise speed control, and durability |

| Medical Devices | Operating infusion pumps and diagnostic equipment | Ensures reliable and precise patient care | Low noise operation, reliability, and compliance with medical standards |

| HVAC Systems | Powering fans, compressors, and blowers | Optimizes energy consumption and maintains indoor air quality | Energy efficiency, adaptability, and noise levels |

| Consumer Electronics & Appliances | Operating kitchen appliances and personal care devices | Enhances user experience through improved performance and reduced noise | Size, power output, and compatibility with various devices |

How Are Fractional Horsepower Electric Motors Used in Industrial Automation?

In the industrial automation sector, fractional horsepower electric motors are essential for driving equipment such as conveyor systems and assembly lines. These motors provide the necessary torque and speed to facilitate smooth operations, contributing to enhanced production efficiency. For international B2B buyers, particularly from regions like Africa and South America, sourcing reliable FHP motors that can withstand varying load conditions and offer energy efficiency is crucial. Additionally, the compact design of these motors allows for integration into limited spaces without compromising performance.

What Role Do Fractional Horsepower Motors Play in Automotive Applications?

Fractional horsepower motors are integral to various automotive components, including power windows, HVAC systems, and seat adjustments. Their compact design and precise speed control enhance vehicle functionality and user comfort. For automotive manufacturers in the Middle East and Europe, sourcing durable and efficient FHP motors is vital to meeting consumer demands for reliability and performance. Buyers must consider factors such as motor size, weight, and the ability to operate effectively in diverse climate conditions, which can impact the longevity and functionality of these components.

Why Are Fractional Horsepower Motors Important in Medical Devices?

In the medical field, fractional horsepower motors are used to operate devices such as infusion pumps and diagnostic equipment. Their low power consumption and quiet operation are critical in healthcare settings where precision and unobtrusiveness are paramount. For B2B buyers in regions like Vietnam and Nigeria, sourcing FHP motors that comply with stringent medical standards is essential. Reliability and the ability to perform consistently under various conditions are key requirements, as these motors directly impact patient care and the effectiveness of medical treatments.

How Do Fractional Horsepower Motors Enhance HVAC Systems?

FHP motors play a significant role in HVAC systems by powering essential components like fans, compressors, and blowers. Their energy efficiency is crucial for optimizing energy consumption while maintaining effective temperature control and air quality in residential and commercial spaces. For businesses in Europe and the Middle East, selecting energy-efficient motors that can adapt to varying loads can lead to significant cost savings and improved environmental compliance. Buyers should prioritize sourcing motors that balance performance with energy efficiency to meet regulatory standards and customer expectations.

In What Ways Are Fractional Horsepower Motors Used in Consumer Electronics?

In the consumer electronics sector, fractional horsepower motors are commonly found in kitchen appliances, vacuum cleaners, and personal care devices. Their compact size and low noise output make them ideal for enhancing user experience in household devices. For B2B buyers from Africa and South America, sourcing FHP motors that align with the latest technology trends while ensuring compatibility with various applications is critical. Buyers must consider the specific power output and design requirements to ensure optimal performance and reliability in consumer products.

3 Common User Pain Points for ‘fractional horsepower electric motors’ & Their Solutions

Scenario 1: Inconsistent Motor Performance in Industrial Applications

The Problem: Many B2B buyers in industries such as manufacturing or automation face the challenge of inconsistent performance from fractional horsepower electric motors. This inconsistency can lead to unplanned downtime, decreased production efficiency, and increased operational costs. Factors contributing to performance issues include improper motor sizing, inadequate power supply, and environmental conditions that affect motor operation, such as temperature and humidity variations. Buyers often struggle to find motors that can maintain reliable operation under varying load conditions, leading to frustration and potential losses.

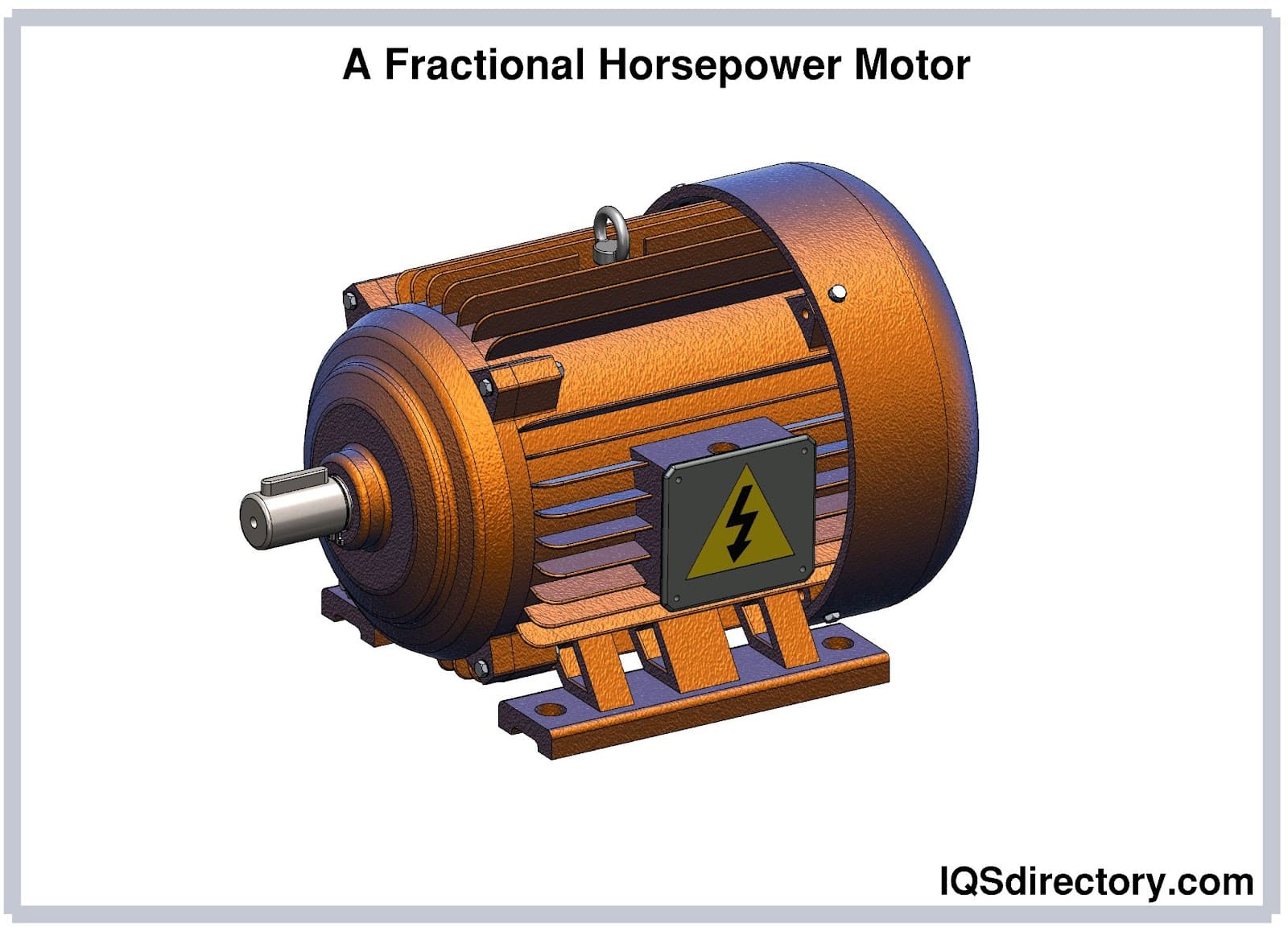

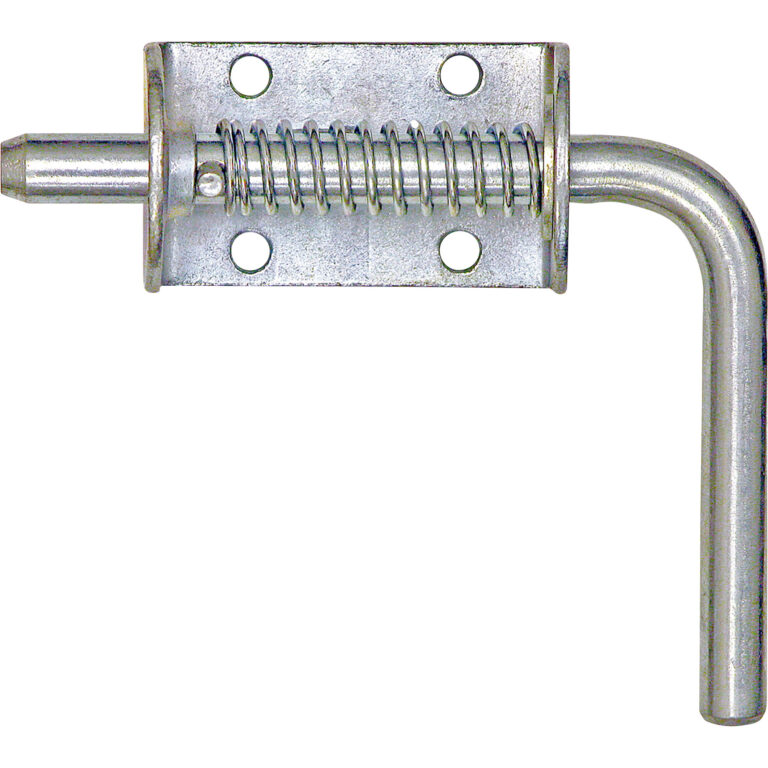

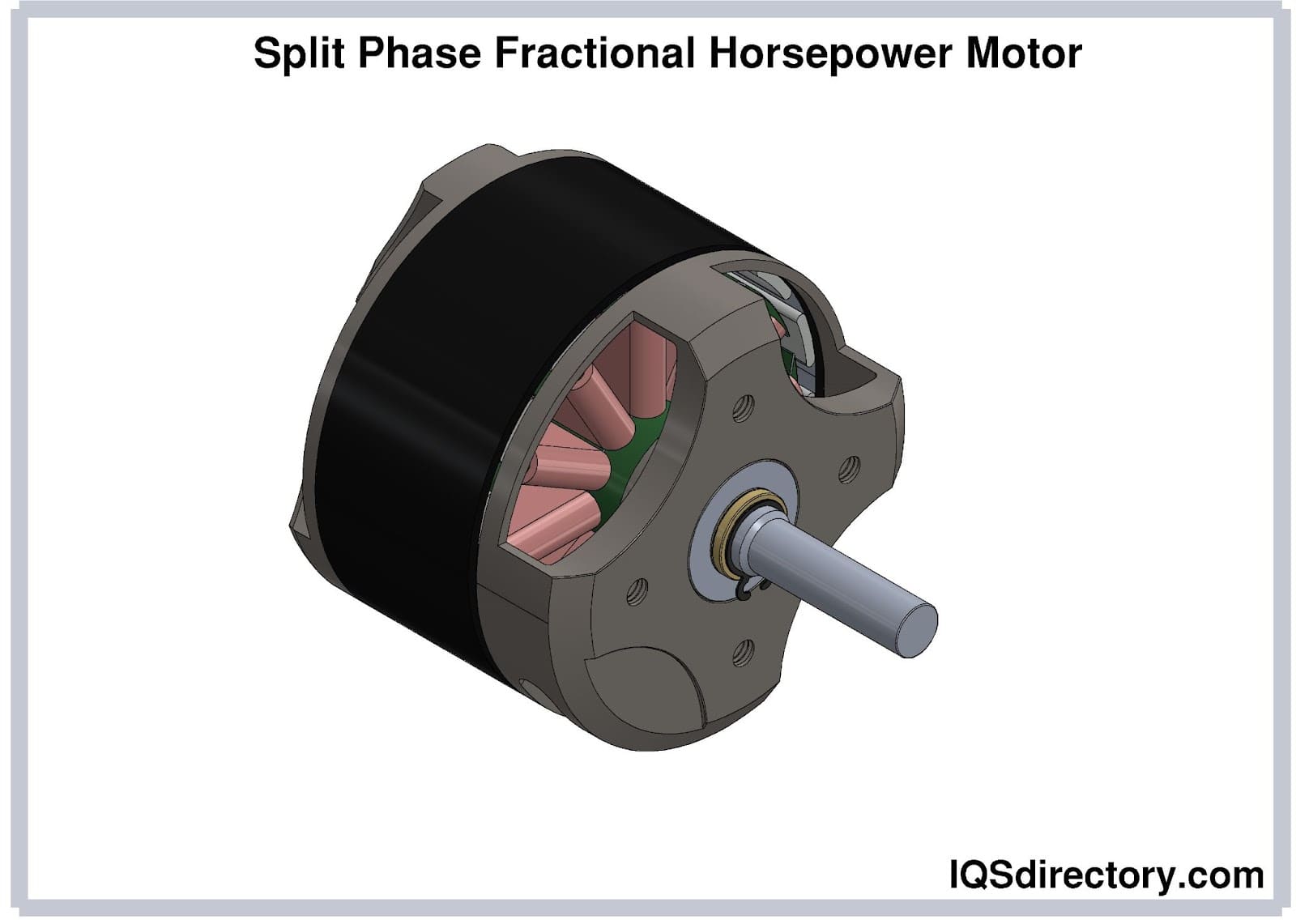

Illustrative image related to fractional horsepower electric motors

The Solution: To address performance inconsistencies, buyers should prioritize proper motor selection and sizing. Begin by conducting a thorough analysis of the application requirements, including load characteristics, duty cycle, and environmental factors. Collaborate with motor manufacturers to obtain detailed specifications and recommendations tailored to specific operational needs. Additionally, consider motors with built-in features such as overload protection and speed control that can adapt to changing conditions. Regular maintenance and monitoring systems can also be implemented to ensure that motors are functioning optimally and to predict when service is needed, thereby minimizing downtime.

Scenario 2: High Energy Costs Due to Inefficient Motors

The Problem: Energy efficiency is a critical concern for B2B buyers, especially in regions with rising electricity costs. Fractional horsepower electric motors that are not energy-efficient can lead to significant increases in operational expenses, particularly in high-usage applications like HVAC systems, industrial machinery, and consumer appliances. Buyers may find themselves faced with the decision to either absorb these costs or invest in newer, more efficient technology, which can be a significant financial burden.

The Solution: To combat high energy costs, buyers should look for fractional horsepower motors that meet or exceed the latest energy efficiency standards, such as NEMA Premium efficiency ratings. Conduct a cost-benefit analysis to determine the potential savings from investing in energy-efficient motors compared to the current operational costs. Additionally, consider integrating variable frequency drives (VFDs) to optimize motor performance and reduce energy consumption based on load demand. Collaborating with suppliers who provide energy audits can also help identify specific areas for improvement and tailor solutions that maximize efficiency while minimizing costs.

Scenario 3: Limited Availability of Replacement Parts

The Problem: B2B buyers often encounter difficulties in sourcing replacement parts for fractional horsepower electric motors, leading to extended downtimes and interruptions in production. This issue is particularly prevalent in regions where manufacturers may have limited distribution networks or where specific motor models are no longer in production. The inability to quickly replace or repair motors can significantly impact productivity and profitability, causing frustration for both management and operational teams.

The Solution: To mitigate challenges related to the availability of replacement parts, buyers should establish strong relationships with multiple suppliers and manufacturers. This network can provide access to a wider range of replacement parts and quicker turnaround times for repairs. Additionally, consider investing in modular motor designs that allow for easier part replacements and upgrades without the need to replace the entire motor. It’s also beneficial to maintain an inventory of critical spare parts based on usage patterns and historical data, ensuring that essential components are readily available when needed. Regular communication with suppliers regarding upcoming changes in product lines can also help anticipate future needs and prevent last-minute sourcing challenges.

Strategic Material Selection Guide for fractional horsepower electric motors

When selecting materials for fractional horsepower electric motors, it is crucial to consider their properties and how they align with the specific requirements of various applications. The choice of material can significantly impact performance, durability, and cost-effectiveness, which are vital factors for international B2B buyers.

What Are the Key Materials Used in Fractional Horsepower Electric Motors?

1. Steel

Key Properties: Steel is known for its high tensile strength and durability, making it an excellent choice for motor frames and shafts. It typically has good temperature resistance and can withstand significant mechanical stress.

Pros & Cons: Steel’s primary advantage is its strength and ability to handle heavy loads, which is essential in industrial applications. However, it is susceptible to corrosion unless treated or coated, which can increase manufacturing complexity and costs. Additionally, the weight of steel can be a disadvantage in applications where weight savings are critical.

Impact on Application: Steel is suitable for high-torque applications where durability is paramount. However, its susceptibility to rust in humid environments may require additional protective measures, particularly in regions with high moisture levels, such as parts of Africa and South America.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM or DIN for steel grades. In regions like Nigeria, where corrosion can be a significant issue, selecting galvanized or stainless steel may be necessary.

2. Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, making it a popular choice for motor housings and components.

Pros & Cons: The primary advantage of aluminum is its low weight, which can enhance the overall efficiency of the motor by reducing energy consumption. However, it is generally less strong than steel and may not be suitable for high-torque applications without reinforcement. Additionally, aluminum can be more expensive than steel.

Impact on Application: Aluminum is ideal for applications requiring lightweight solutions, such as portable tools and consumer electronics. Its corrosion resistance makes it suitable for humid environments, which is beneficial for buyers in the Middle East and coastal areas of South America.

Illustrative image related to fractional horsepower electric motors

Considerations for International Buyers: Buyers must consider local manufacturing capabilities and the availability of aluminum alloys that meet specific standards. Compliance with JIS standards is also essential in markets like Vietnam.

3. Plastic Composites

Key Properties: Plastic composites are known for their lightweight nature and resistance to corrosion and chemicals. They can be molded into complex shapes, providing design flexibility.

Pros & Cons: The advantages of plastic composites include low weight, resistance to environmental factors, and lower manufacturing costs compared to metals. However, they may not withstand high temperatures or mechanical stress as effectively as metals, limiting their use in high-performance applications.

Impact on Application: These materials are suitable for low-power applications, such as small appliances and consumer electronics, where weight and corrosion resistance are critical. However, they may not be appropriate for heavy-duty industrial applications.

Considerations for International Buyers: Buyers should ensure that the selected plastic composites comply with relevant safety and performance standards, especially in regulated markets like Europe. Understanding the local climate’s impact on material performance is also crucial.

Illustrative image related to fractional horsepower electric motors

4. Copper

Key Properties: Copper is an excellent conductor of electricity and is often used in windings and electrical connections within motors. It has good thermal conductivity and resistance to corrosion.

Pros & Cons: The key advantage of copper is its superior electrical conductivity, leading to improved motor efficiency. However, copper is relatively expensive compared to alternatives like aluminum, which can increase overall motor costs. Additionally, it is heavier than aluminum.

Impact on Application: Copper is essential in applications where high electrical efficiency is required, such as in precision medical devices and high-performance automotive systems. Its durability is beneficial in harsh environments.

Considerations for International Buyers: Buyers should be aware of the fluctuating prices of copper and consider sourcing strategies to mitigate costs. Compliance with international electrical standards is also critical for markets in Europe and the Middle East.

Summary Table of Material Selection for Fractional Horsepower Electric Motors

| Material | Typical Use Case for fractional horsepower electric motors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial machinery, high-torque applications | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Portable tools, consumer electronics | Lightweight and corrosion-resistant | Less strength than steel | High |

| Plastic Composites | Small appliances, consumer electronics | Low weight and design flexibility | Limited temperature and stress resistance | Low |

| Copper | Medical devices, high-performance automotive systems | Superior electrical conductivity | Higher cost and weight compared to aluminum | High |

This material selection guide provides actionable insights for international B2B buyers, enabling them to make informed decisions based on application needs, environmental factors, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fractional horsepower electric motors

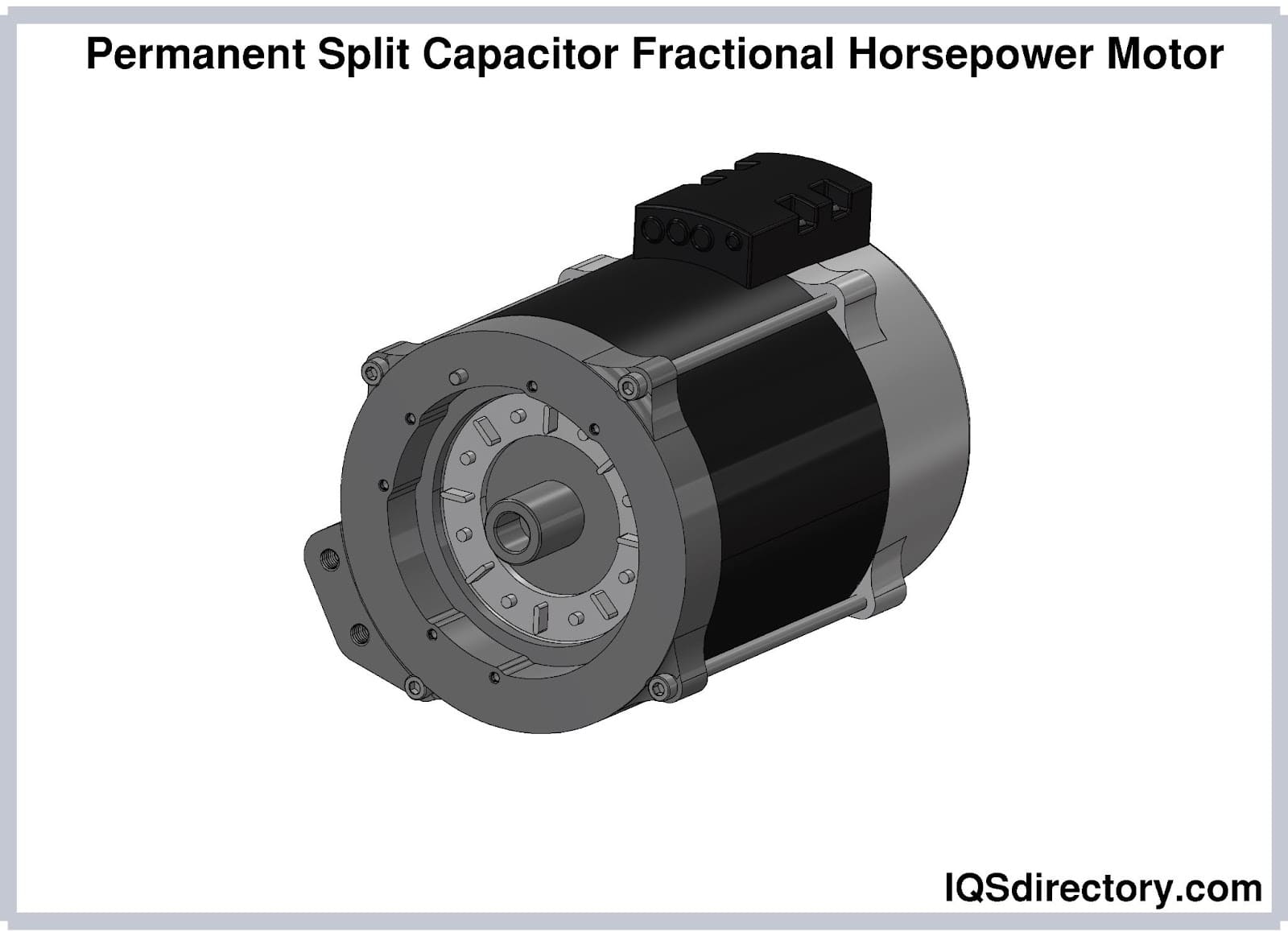

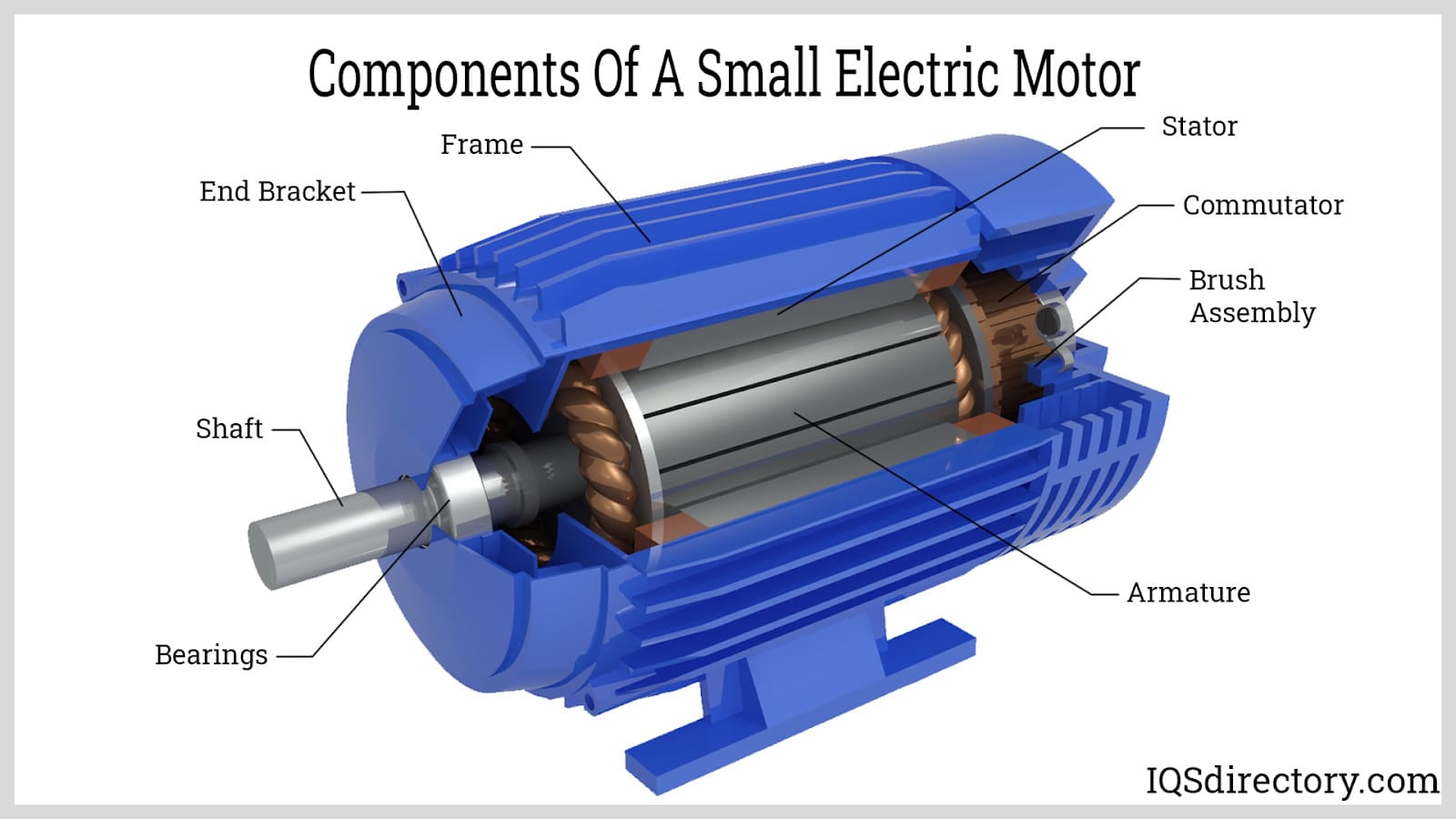

What Are the Main Stages of Manufacturing Fractional Horsepower Electric Motors?

The manufacturing of fractional horsepower (FHP) electric motors involves several critical stages, each designed to ensure that the final product meets performance and quality standards. Understanding these stages can empower B2B buyers to make informed decisions when sourcing from manufacturers.

Illustrative image related to fractional horsepower electric motors

How Is Material Preparation Conducted in FHP Motor Manufacturing?

Material preparation is the foundational step in the manufacturing process. This stage includes sourcing high-quality raw materials such as copper for windings, steel for the motor frame, and various plastics for insulation and components. Manufacturers often prioritize materials that meet industry specifications to enhance durability and efficiency.

Once sourced, materials undergo inspection to ensure they meet quality standards. This may include checking for defects, measuring dimensions, and assessing material properties. Adopting stringent material preparation protocols helps manufacturers avoid defects in later stages, reducing waste and improving overall product quality.

What Forming Techniques Are Used in the Production of FHP Motors?

The forming stage encompasses several processes, including stamping, molding, and machining. Stamping is often used for creating the motor’s frame and rotor components from metal sheets. This technique allows for high precision and consistency in dimensions, which is vital for the motor’s performance.

Molding techniques, particularly for plastic components, involve injecting molten plastic into molds to form the necessary shapes. Machining processes, such as turning and milling, are employed to refine components and achieve the required tolerances. Each of these methods is designed to ensure that parts fit together seamlessly, which is crucial for the efficiency and longevity of the motor.

How Is Assembly Conducted in FHP Motor Manufacturing?

The assembly stage is where all components come together to form the complete motor. This process typically involves the following steps:

- Winding: Copper wire is wound around the stator and rotor to create electromagnetic fields.

- Component Integration: Various parts, including bearings, end shields, and housings, are assembled in a systematic manner.

- Connection: Electrical connections are made, ensuring that the motor can operate effectively.

Automated assembly lines are increasingly common in FHP motor manufacturing, enabling high-speed production while maintaining precision. However, skilled technicians are essential for overseeing the assembly process, particularly for quality-critical tasks.

What Finishing Processes Are Essential for FHP Motors?

Finishing processes enhance the motor’s durability and aesthetic appeal. Common techniques include:

- Surface Treatment: Coatings are applied to metal parts to resist corrosion and wear.

- Balancing: Rotors are balanced to minimize vibrations during operation, which is crucial for performance and longevity.

- Testing: Initial testing occurs at this stage to ensure that the motor meets specified performance criteria before it moves to quality control.

Finishing processes not only contribute to the motor’s functionality but also help in meeting international standards.

Illustrative image related to fractional horsepower electric motors

What Quality Assurance Standards Are Relevant to FHP Motor Manufacturing?

Quality assurance (QA) is integral to the manufacturing of fractional horsepower motors. Various international and industry-specific standards guide manufacturers in maintaining high-quality output.

Which International Standards Should B2B Buyers Be Aware Of?

One of the most recognized standards is ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO 9001 ensures that manufacturers consistently meet customer requirements and enhance satisfaction.

In addition to ISO standards, regional certifications such as CE marking in Europe and API standards for specific industrial applications may be relevant. These certifications not only validate the safety and efficiency of the motors but also enhance marketability in international markets.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. These typically include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify issues as they arise, allowing for immediate corrections.

- Final Quality Control (FQC): The final product undergoes rigorous testing to confirm that it meets performance, safety, and quality standards before shipping.

Each checkpoint is crucial for maintaining product integrity and ensuring that the motors perform reliably in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is vital for B2B buyers, especially when sourcing internationally.

What Methods Can Buyers Use to Assess Supplier Quality?

-

Audits: Conducting on-site audits can provide insight into a supplier’s manufacturing processes and quality management systems. This is particularly beneficial for buyers in Africa, South America, the Middle East, and Europe, where different standards may apply.

-

Quality Reports: Requesting documentation of quality control processes and results can help buyers gauge a supplier’s commitment to maintaining standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices and adherence to international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of the nuances that come with sourcing from different regions. For example, compliance with local regulations in countries like Nigeria or Vietnam may differ significantly from those in Europe or the Middle East.

Understanding these differences is critical for ensuring that the sourced motors will meet local market requirements and customer expectations. Building relationships with suppliers who are familiar with these regulations can facilitate smoother transactions and compliance.

In conclusion, the manufacturing and quality assurance processes for fractional horsepower electric motors are complex and multifaceted. By understanding these processes, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fractional horsepower electric motors’

This guide serves as a practical checklist for B2B buyers seeking to procure fractional horsepower electric motors (FHP motors). Given the diverse applications of these motors across various industries, it’s essential to approach sourcing with a clear strategy. The following steps will help you make informed decisions, ensuring you select the right motor for your needs.

Illustrative image related to fractional horsepower electric motors

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to outline the technical requirements of the fractional horsepower motors you need. Consider factors such as power output, voltage, and speed ratings. Be specific about the application—whether it’s for industrial automation, HVAC systems, or consumer electronics—as this will guide your selection and help suppliers understand your needs.

Step 2: Research and Identify Reputable Suppliers

Start by compiling a list of potential suppliers that specialize in FHP motors. Look for manufacturers with a proven track record in your industry. Research their reputation through customer reviews, industry forums, and third-party ratings. This foundational step will help you avoid potential pitfalls and ensure you are engaging with credible suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, product catalogs, and case studies that showcase their experience with similar applications. It’s also beneficial to ask for references from other businesses in your region or sector to gauge their reliability and customer service.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers meet industry standards and certifications relevant to fractional horsepower motors. This may include ISO certifications, CE marking, or compliance with local regulations, depending on your region. Compliance not only ensures product quality but also reflects the supplier’s commitment to safety and environmental responsibility.

Step 5: Assess Product Customization Options

In many cases, standard FHP motors may not fully meet your specific requirements. Discuss customization options with potential suppliers, such as modifications to size, output, or features. Understanding the flexibility of a supplier to adapt their products can be a key differentiator in your sourcing decision.

Step 6: Request Samples for Testing

Before finalizing your order, request samples of the motors you are considering. Testing samples in your actual application environment allows you to evaluate performance, efficiency, and compatibility. This step is crucial for ensuring that the motor will meet your operational needs and expectations.

Step 7: Negotiate Terms and Conditions

Once you have identified a preferred supplier, engage in negotiations regarding pricing, lead times, and payment terms. Be clear about your expectations and any potential volume discounts. Establishing favorable terms can significantly impact your overall procurement costs and ensure a smooth purchasing process.

By following these steps, B2B buyers can navigate the complexities of sourcing fractional horsepower electric motors effectively. A well-planned approach will not only streamline procurement but also enhance the operational efficiency of your applications.

Illustrative image related to fractional horsepower electric motors

Comprehensive Cost and Pricing Analysis for fractional horsepower electric motors Sourcing

What Are the Key Cost Components for Fractional Horsepower Electric Motors?

When sourcing fractional horsepower electric motors, understanding the cost structure is crucial for effective budgeting and decision-making. The cost components generally include:

-

Materials: This is the largest cost component, encompassing the raw materials such as copper, aluminum, and plastics used in motor construction. The quality and sourcing of these materials can significantly influence overall costs.

-

Labor: Labor costs include wages for skilled workers involved in the manufacturing process. High-quality production often requires specialized labor, which can increase costs.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: The initial investment in tooling for production can be substantial, especially for custom designs. However, these costs can be amortized over larger production runs.

-

Quality Control (QC): Ensuring that motors meet specific standards incurs additional costs. Rigorous QC processes are necessary for maintaining reliability, especially in critical applications like medical devices.

-

Logistics: Transportation and warehousing costs are essential considerations, particularly for international shipments. Proximity to suppliers and distribution centers can reduce these expenses.

-

Margin: Manufacturers typically add a profit margin on top of their costs, which can vary based on market conditions and competition.

How Do Price Influencers Impact Sourcing Decisions for Fractional Horsepower Motors?

Several factors can influence the pricing of fractional horsepower electric motors, which buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with larger order quantities due to economies of scale. Buyers should negotiate MOQs that align with their operational needs.

-

Specifications and Customization: Custom motors tailored to specific applications may incur higher costs due to the additional engineering and design work involved. Standard models typically offer better pricing.

-

Material Quality and Certifications: Higher quality materials and compliance with international standards (like ISO certifications) can lead to increased costs but often result in better performance and reliability.

-

Supplier Factors: Supplier reputation, financial stability, and production capabilities can also affect pricing. Building long-term relationships with reliable suppliers can lead to better terms and pricing.

-

Incoterms: The agreed-upon Incoterms can significantly affect the final price. Understanding responsibilities for shipping, insurance, and customs clearance can help buyers avoid unexpected costs.

What Are the Best Negotiation Tips for B2B Buyers of Fractional Horsepower Motors?

Effective negotiation can yield significant savings when sourcing fractional horsepower motors. Consider the following strategies:

-

Understand Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factors such as energy efficiency, maintenance costs, and lifespan can impact the TCO. Emphasizing these aspects during negotiations can justify a higher upfront cost for a more reliable motor.

-

Leverage Market Research: Knowledge of current market trends, competitor pricing, and technological advancements can provide leverage in negotiations. Suppliers are more likely to offer favorable terms when they know you are informed.

-

Establish Long-Term Relationships: Building rapport with suppliers can lead to better pricing and terms over time. Regular orders and consistent communication can foster loyalty and preferential pricing.

-

Be Open to Alternative Solutions: If a supplier cannot meet your price expectations, consider discussing alternative products or specifications that may lower costs while still meeting your requirements.

What Are the Pricing Nuances for International B2B Buyers in Regions Like Africa, South America, the Middle East, and Europe?

International buyers face unique challenges when sourcing fractional horsepower motors. Understanding regional nuances can aid in better purchasing decisions:

-

Currency Fluctuations: Be aware of exchange rate volatility, which can impact pricing. Consider pricing in a stable currency or hedging against currency risks.

-

Import Duties and Taxes: Different countries impose varying import tariffs and taxes. Buyers should factor these costs into their total budget when sourcing internationally.

-

Logistical Considerations: Shipping times and costs can vary significantly by region. Buyers should assess the reliability of shipping options and plan accordingly to avoid delays in production.

-

Regulatory Compliance: Each region may have specific regulations regarding motor performance and safety. Ensure that sourced motors comply with local standards to avoid costly rework or penalties.

In summary, understanding the cost structure and pricing dynamics of fractional horsepower electric motors is crucial for B2B buyers. By focusing on negotiation strategies and regional nuances, buyers can achieve more favorable outcomes in their sourcing efforts.

Illustrative image related to fractional horsepower electric motors

Alternatives Analysis: Comparing fractional horsepower electric motors With Other Solutions

Understanding Alternative Solutions to Fractional Horsepower Electric Motors

In the quest for effective power solutions, fractional horsepower electric motors (FHP motors) have established themselves as reliable and versatile options for various applications. However, businesses may find themselves considering alternative technologies that can fulfill similar operational needs. This section explores two notable alternatives: stepper motors and servo motors, providing a comprehensive comparison to help B2B buyers make informed decisions.

| Comparison Aspect | Fractional Horsepower Electric Motors | Stepper Motors | Servo Motors |

|---|---|---|---|

| Performance | Good for low-power applications; reliable torque and speed control | Excellent for precise positioning and repeatable motion | High torque and speed with advanced feedback control |

| Cost | Generally affordable, with low operational costs | Moderate initial cost; economical for low-volume applications | Higher initial investment; costs justified by performance |

| Ease of Implementation | Simple installation and integration into existing systems | Requires careful programming and tuning | More complex setup; requires controller integration |

| Maintenance | Low maintenance due to robust design; occasional checks needed | Moderate maintenance; wear on components can occur | Low maintenance, but requires skilled technicians for repairs |

| Best Use Case | Ideal for small machinery, HVAC systems, and consumer appliances | Best for 3D printers, CNC machines, and robotics needing precise control | Suitable for industrial automation, robotics, and applications requiring dynamic movement |

Stepper Motors: Advantages and Disadvantages

Stepper motors are known for their precise control and ability to maintain position without the need for feedback systems. This makes them particularly suitable for applications requiring accurate movement, such as in 3D printing and CNC machinery. The primary advantage of stepper motors is their ability to achieve high precision with simple control systems. However, they can be less efficient than FHP motors in terms of power consumption and may require more complex programming and tuning to ensure optimal performance. Additionally, stepper motors can experience wear on components over time, necessitating more frequent maintenance.

Servo Motors: Pros and Cons

Servo motors stand out for their high performance and accuracy, making them ideal for applications in industrial automation and robotics. They utilize feedback mechanisms to adjust their operation, resulting in excellent torque and speed control. While servo motors provide superior performance, they come with a higher initial cost and a more complex installation process, requiring specialized controllers and programming expertise. Despite these challenges, their efficiency and effectiveness in dynamic applications often justify the investment for businesses seeking advanced solutions.

Choosing the Right Solution for Your Needs

When considering alternatives to fractional horsepower electric motors, it is essential for B2B buyers to evaluate their specific application requirements, budget constraints, and operational environments. Fractional horsepower motors offer a balance of performance and cost-effectiveness for many low-power applications, while stepper and servo motors provide enhanced precision and control for specialized tasks. By carefully assessing the unique needs of their operations and the capabilities of each motor type, buyers can select the most suitable solution that aligns with their strategic goals and operational efficiency.

Essential Technical Properties and Trade Terminology for fractional horsepower electric motors

What Are the Key Technical Properties of Fractional Horsepower Electric Motors?

Understanding the technical specifications of fractional horsepower (FHP) electric motors is crucial for B2B buyers who aim to select the right motor for their applications. Here are essential properties to consider:

1. Power Output and Horsepower Rating

Power output, measured in horsepower (HP) or watts, is a critical specification that defines the motor’s capability. FHP motors typically operate at less than one horsepower (746 watts). For B2B buyers, this specification helps in determining whether the motor can meet the demands of specific applications, such as small machinery, HVAC systems, or automotive components.

2. Frame Size

The frame size of a motor indicates its physical dimensions and mounting specifications. Common frame sizes for FHP motors include 42, 48, and 56. Buyers need to consider frame size when ensuring compatibility with existing equipment and space limitations. An accurate frame size selection also influences performance, efficiency, and ease of installation.

3. Efficiency Rating

Efficiency ratings, often expressed as a percentage, indicate how effectively a motor converts electrical energy into mechanical energy. Higher efficiency ratings lead to reduced energy consumption and lower operational costs, making them particularly appealing for businesses focused on sustainability and cost savings. Selecting an efficient motor can significantly impact long-term operational expenses.

Illustrative image related to fractional horsepower electric motors

4. Insulation Class

Insulation class refers to the motor’s ability to withstand temperature extremes, influencing its lifespan and reliability. Common classes include Class A, B, F, and H, with Class H being the most heat-resistant. For B2B buyers, understanding insulation class is vital for ensuring that the motor can operate safely and effectively in specific environments, especially those involving high temperatures or heavy workloads.

5. Torque Characteristics

Torque, measured in pound-feet (lb-ft) or Newton-meters (Nm), is a measure of the rotational force produced by the motor. Different applications require different torque levels, and understanding these characteristics helps buyers choose a motor that meets their operational requirements. Torque performance is particularly crucial in applications involving variable loads or starting conditions.

What Are Common Trade Terms Related to Fractional Horsepower Electric Motors?

Familiarity with industry jargon can enhance communication between buyers and suppliers. Here are some essential terms:

Illustrative image related to fractional horsepower electric motors

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are used in another company’s end products. In the context of FHP motors, understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with their machinery.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management, especially when dealing with specialized motors that may not be readily available.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and other details for a specific quantity of goods. B2B buyers use RFQs to compare costs and terms from different manufacturers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global transactions. Understanding these terms is essential for B2B buyers engaged in international trade, as they clarify shipping responsibilities, costs, and risk management.

Illustrative image related to fractional horsepower electric motors

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. In the context of FHP motors, a clear understanding of lead times is essential for project planning and ensuring that production schedules are met.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing fractional horsepower electric motors, ultimately enhancing operational efficiency and product performance.

Navigating Market Dynamics and Sourcing Trends in the fractional horsepower electric motors Sector

What Are the Key Market Dynamics and Trends Affecting Fractional Horsepower Electric Motors?

The fractional horsepower electric motors sector is experiencing dynamic changes influenced by various global drivers. Rapid industrialization in regions such as Africa, South America, the Middle East, and Europe is increasing demand for efficient and compact motor solutions across industries. The rise of automation and smart technologies is propelling the need for fractional horsepower (FHP) motors, particularly in manufacturing, automotive, and healthcare applications. Additionally, advancements in motor technology, including brushless designs and improved energy efficiency, are enhancing performance and reliability, making FHP motors more appealing to international B2B buyers.

Emerging trends such as the integration of IoT and AI technologies are reshaping sourcing strategies. Buyers are increasingly seeking motors equipped with smart capabilities that can provide real-time data and diagnostics, enhancing operational efficiency and predictive maintenance. Furthermore, the push towards sustainable manufacturing practices is leading to an increased focus on energy-efficient motors that comply with global energy standards. As a result, international buyers are prioritizing suppliers who offer innovative solutions that align with both performance and sustainability goals.

How Is Sustainability and Ethical Sourcing Impacting the Fractional Horsepower Electric Motors Market?

The environmental impact of manufacturing processes in the fractional horsepower electric motors sector is under scrutiny as companies face pressure to adopt sustainable practices. Energy efficiency is a core selling point for FHP motors, as they contribute to reduced energy consumption in various applications. Buyers are increasingly looking for suppliers that prioritize eco-friendly materials and production techniques, which can significantly lower the carbon footprint of motor manufacturing.

Illustrative image related to fractional horsepower electric motors

Moreover, ethical sourcing has become a critical consideration for B2B buyers. Companies are now seeking to ensure that their supply chains are transparent and responsible, minimizing environmental harm and ensuring fair labor practices. Certifications such as ISO 14001 (Environmental Management) and compliance with RoHS (Restriction of Hazardous Substances) are becoming essential for suppliers to demonstrate their commitment to sustainability. By choosing manufacturers who prioritize ethical sourcing and sustainability, B2B buyers can enhance their brand reputation while contributing to a more sustainable future.

What Is the Historical Context of Fractional Horsepower Electric Motors and Its Relevance for Today’s Buyers?

The evolution of fractional horsepower electric motors dates back to the late 19th century, with Nikola Tesla’s invention of the induction motor laying the groundwork for modern electric motors. The widespread use of FHP motors began in the early 20th century, coinciding with urban electrification and the subsequent automation of household chores. By the 1920s, the proliferation of these motors in various applications—including washing machines and small machinery—demonstrated their versatility and cost-effectiveness.

Post-World War II, the FHP motor industry saw significant growth, driven by the rising demand for consumer goods and industrial automation. This historical context is crucial for B2B buyers today, as it highlights the ongoing importance of FHP motors in various sectors. Understanding this evolution not only sheds light on the current market landscape but also underscores the potential for innovation and growth in the FHP motor sector, encouraging buyers to invest in reliable and advanced motor technologies that align with their operational needs.

Illustrative image related to fractional horsepower electric motors

Frequently Asked Questions (FAQs) for B2B Buyers of fractional horsepower electric motors

-

How do I choose the right fractional horsepower motor for my application?

Choosing the right fractional horsepower motor involves assessing your specific application needs, including the required power output, speed, and torque. Consider the motor’s operational environment, such as temperature, humidity, and exposure to dust or moisture. Additionally, evaluate the motor’s efficiency and energy consumption to ensure it aligns with your operational goals. Collaborating with suppliers who offer customization options can also help tailor the motor specifications to your unique requirements. -

What are the common applications for fractional horsepower motors?

Fractional horsepower motors are widely used across various industries, including HVAC systems, automotive components, medical devices, and consumer electronics. They are essential for powering small machinery, fans, pumps, and conveyor systems. In the automotive industry, these motors drive components like power windows and seat adjustments. Understanding the applications relevant to your industry can help you identify the best motor type for your needs. -

What is the minimum order quantity (MOQ) for fractional horsepower motors?

Minimum order quantities for fractional horsepower motors can vary significantly between suppliers and are often influenced by factors like customization and production capabilities. Typically, MOQs can range from a few units to several hundred. It’s crucial to communicate your requirements with potential suppliers to negotiate favorable terms, especially if you are a small or medium-sized enterprise looking to minimize upfront costs. -

How do I vet suppliers for fractional horsepower motors?

When vetting suppliers, consider their reputation, industry experience, and product quality. Request references and case studies from previous clients to evaluate their reliability. Additionally, verify their compliance with international standards and certifications relevant to your region. Conducting site visits or virtual meetings can also provide insights into their manufacturing processes and quality assurance practices, ensuring you partner with a trustworthy supplier. -

What payment terms are typically offered for international orders?

Payment terms for international orders can vary by supplier but commonly include options such as advance payment, letters of credit, or payment upon delivery. It’s advisable to discuss and agree on terms that provide security for both parties. Additionally, consider the implications of currency fluctuations and transaction fees when negotiating payment terms to ensure a smooth financial process. -

How can I ensure quality assurance for fractional horsepower motors?

To ensure quality assurance, request detailed product specifications and documentation from your supplier, including testing protocols and compliance certifications. Inquire about their quality control processes, including inspections and testing at various production stages. Establishing a clear communication channel for feedback and concerns during the manufacturing process can help address potential issues before the motors are shipped. -

What logistics considerations should I keep in mind when sourcing motors internationally?

When sourcing fractional horsepower motors internationally, consider logistics factors such as shipping methods, lead times, and customs regulations. Evaluate the supplier’s ability to provide reliable shipping options that align with your project timelines. Additionally, familiarize yourself with import duties and taxes in your country to avoid unexpected costs. Partnering with logistics experts can streamline the process and ensure timely delivery. -

How do fractional horsepower motors improve energy efficiency in applications?

Fractional horsepower motors enhance energy efficiency by delivering the necessary power output while minimizing energy consumption. Their compact design allows for optimized performance in various applications, reducing energy waste. Additionally, many modern FHP motors incorporate advanced technologies that enable variable speed control, further enhancing efficiency. By selecting high-efficiency models, businesses can lower operational costs and contribute to sustainability efforts.

Top 7 Fractional Horsepower Electric Motors Manufacturers & Suppliers List

1. Fractional Horsepower Motors – FHP Motors

Domain: fractionalhorsepowermotors.com

Registered: 2000 (25 years)

Introduction: Fractional horsepower motors (FHP motors) are small electric motors with a power rating of less than one horsepower (746 watts). They are categorized by frame size and total fractional horsepower. Common frame sizes include 42, 48, and 56. FHP motors are essential in various applications, including industrial automation, automotive systems, medical devices, HVAC equipment, and consumer electronics…

2. Groschopp – Fractional Horsepower Motors

Domain: groschopp.com

Registered: 1995 (30 years)

Introduction: Fractional horsepower motors are defined as motors with a power rating of less than one horsepower (746 Watts). Groschopp specializes in mid- to large-sized fractional horsepower AC motors and small- to mid-sized DC and BLDC motors. Their Universal motors cover a wider range, with horsepower capabilities from 1/20 to 2 ½ hp. Specific horsepower ranges for Groschopp’s motors include: AC – 1/20 – 1 …

3. RSPSupply – Fractional Horsepower Motors

Domain: rspsupply.com

Registered: 2016 (9 years)

Introduction: Fractional horsepower motors are electric motors that provide less than one horsepower. They are typically used for applications that require less power and for devices that must be compact. These motors are essential for a wide range of residential, commercial, and industrial products. Key characteristics include being compact and lightweight, making them suitable for practical applications where…

4. Tecowe Westinghouse – 3-Phase Fractional HP Electric Motor

Domain: tecowestinghouse.com

Registered: 1999 (26 years)

Introduction: 3-Phase Fractional HP Electric Motor

– Type: Totally Enclosed Fan Cooled (TEFC)

– Horsepower: 1/3 HP through 2 HP

– Speed: 3600, 1800, 1200 RPM

– Voltage: 230/460V (usable on 200 & 208V)

– Frequency: 60 Hz

– Features:

– Three Phase, 60 Hz, 1.15 Service Factor (Continuous)

– Class F Insulation

– Class B Temperature Rise

– NEMA Design B Torques

– Rolled Steel Frame and Main Conduit Box

…

5. Robert Gavora – Fractional Horsepower Electric Motors

Domain: robertgavora.com

Registered: 2001 (24 years)

Introduction: Title: FRACTIONAL HORSEPOWER ELECTRIC MOTORS; WHAT KINDS ARE AVAILABLE; WHAT MAKES THEM RUN AND WHAT THEY WILL DO; HOW TO REPAIR, REWIND, AND RECONNECT THEM

Author: Cyril G. Veinott

Edition: First edition, Eighth printing

Publisher: McGraw-Hill Book Company, Inc.

Publication Year: 1939

Format: Hardcover

Condition: Very good plus

Pages: 431

Features: Includes diagrams, numerous graphs and tables, a…

6. eBay – Fractional and Subfractional Horsepower Motors

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”: “Fractional and Subfractional Horsepower Electric Motors”, “author”: “Cyril G. Veinott”, “edition”: “3rd ED.”, “ISBN”: “9780070673908”, “price”: “$78.00”, “original_price”: “$100.00”, “discount”: “22% off”, “shipping”: “$7.21”, “estimated_total”: “$85.21”, “seller_feedback”: “100% positive feedback”, “seller”: “Untold Sunshine”}

7. ScienceDirect – Fractional Horsepower Motors

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Fractional horsepower motors are electric motors rated at less than 1 horsepower, used for applications requiring lower power output compared to integral horsepower motors. They are commonly utilized in various industries, including elevators, electric railroads, cranes, hoists, and laboratory instruments. Direct current (DC) motors, a type of fractional horsepower motor, are noted for their varyi…

Strategic Sourcing Conclusion and Outlook for fractional horsepower electric motors

As the demand for fractional horsepower (FHP) motors continues to grow across diverse industries, strategic sourcing becomes increasingly vital for B2B buyers. By focusing on reliable suppliers and understanding the unique applications of FHP motors—from industrial automation to consumer electronics—companies can enhance operational efficiency and drive innovation. International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should prioritize partnerships with manufacturers that offer not only quality products but also robust support and customization options.

Investing in FHP motors opens doors to improved energy efficiency, reduced operational costs, and enhanced product performance. With evolving technologies and increasing emphasis on sustainability, the future of fractional horsepower motors is poised for expansion. Buyers are encouraged to stay informed about market trends, emerging applications, and innovations that can further leverage these motors’ capabilities.

In conclusion, fostering strategic sourcing relationships will enable businesses to remain competitive in a rapidly changing landscape. Take the next step by exploring partnerships with reputable manufacturers and suppliers who can meet your specific needs, ensuring your operations are equipped for future challenges and opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.