Fork Truck Classes Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for fork truck classes

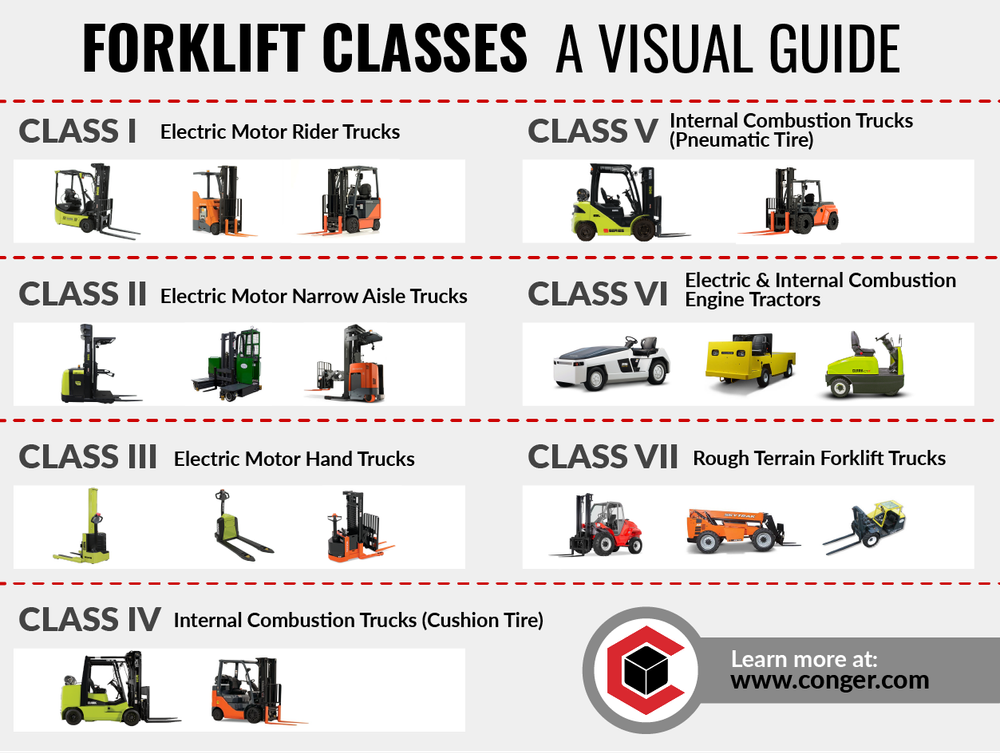

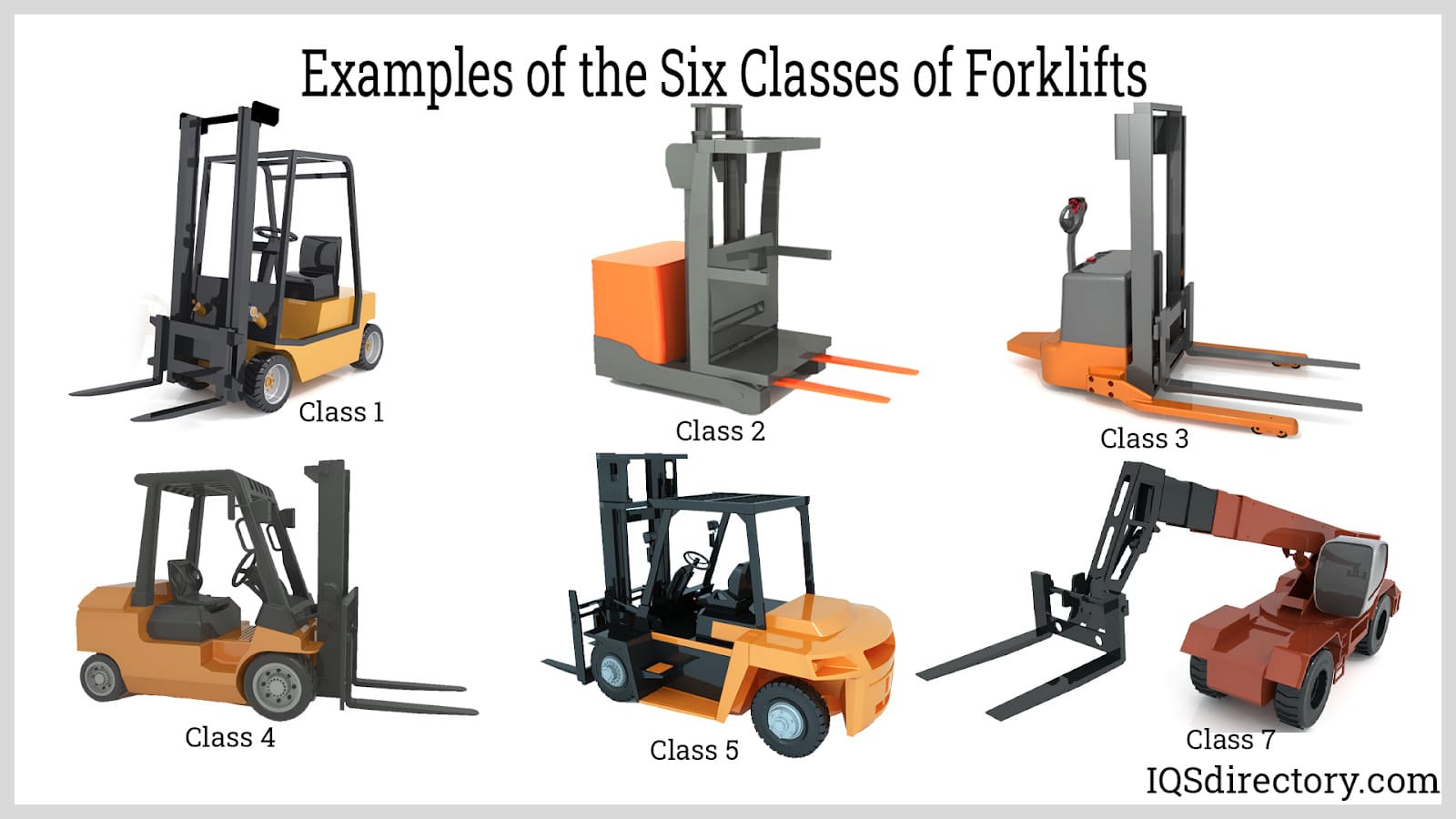

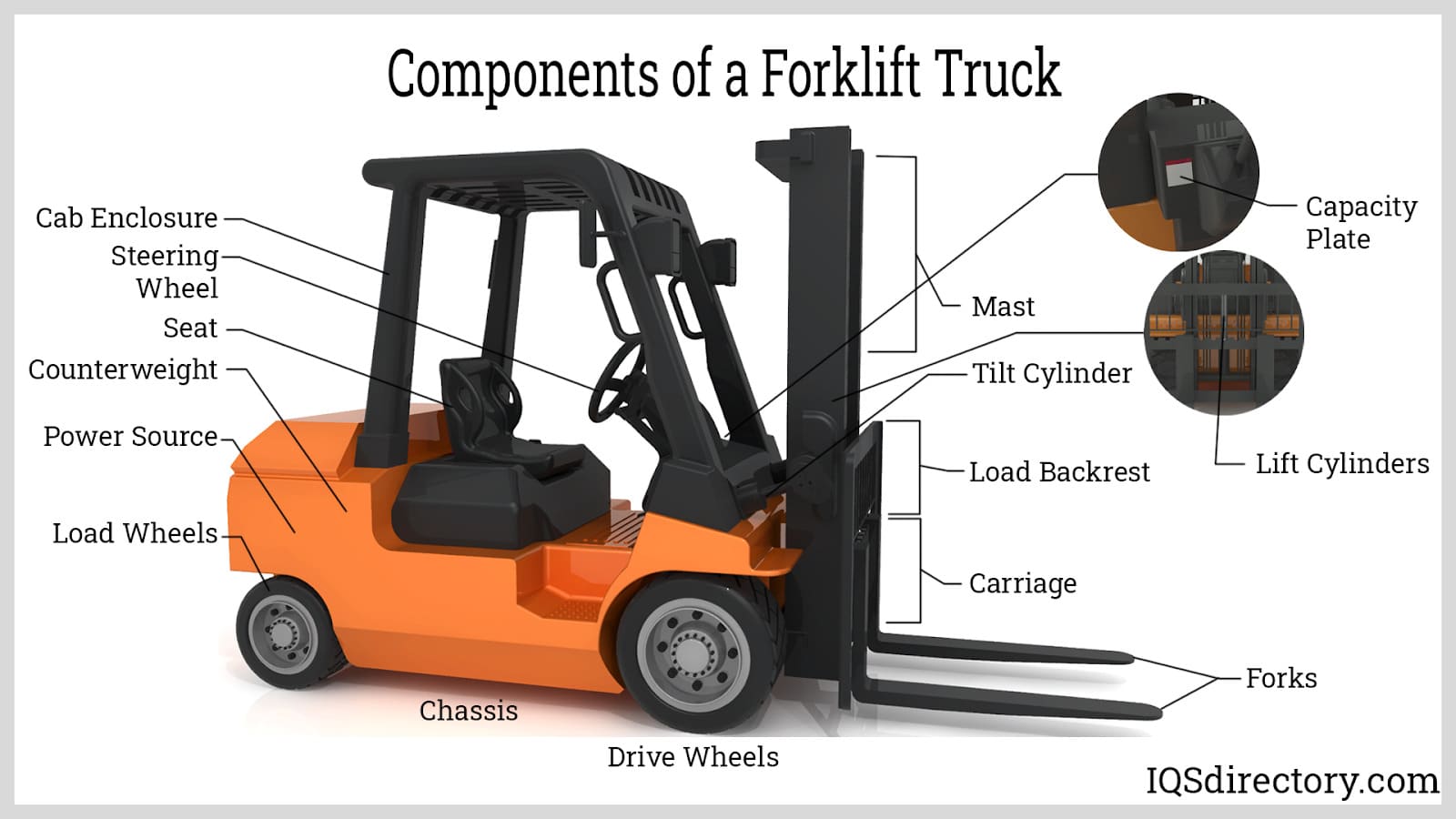

In the ever-evolving landscape of material handling, navigating the global market for fork truck classes presents a significant challenge for B2B buyers. With diverse options available, selecting the right forklift can be a daunting task, particularly for businesses operating across varied terrains and applications. This comprehensive guide delves into the seven distinct classes of forklifts, outlining their specific uses, operational advantages, and suitability for different environments. From electric motor rider trucks ideal for indoor tasks to rough-terrain forklifts designed for rugged outdoor conditions, understanding these classifications is essential for making informed purchasing decisions.

Moreover, this guide goes beyond mere classification. It equips international buyers—especially those from Africa, South America, the Middle East, and Europe—with actionable insights on supplier vetting, cost considerations, and compliance with safety regulations. By providing a thorough analysis of each forklift type, including their load capacities, fuel options, and operational requirements, we empower businesses to select the most effective equipment tailored to their unique needs. Ultimately, this resource aims to streamline your sourcing process, ensuring that you invest wisely in the right fork truck class to enhance operational efficiency and safety in your operations.

Understanding fork truck classes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Class I: Electric Motor Rider Trucks | Electric-powered, quiet operation, counterbalanced design | Warehouses, distribution centers | Pros: Low emissions, versatile indoor use; Cons: Limited outdoor capability. |

| Class II: Electric Motor Narrow Aisle Trucks | Compact design, high lift capabilities, designed for tight spaces | Retail stockrooms, narrow aisles | Pros: Excellent maneuverability; Cons: Lower load capacity compared to larger models. |

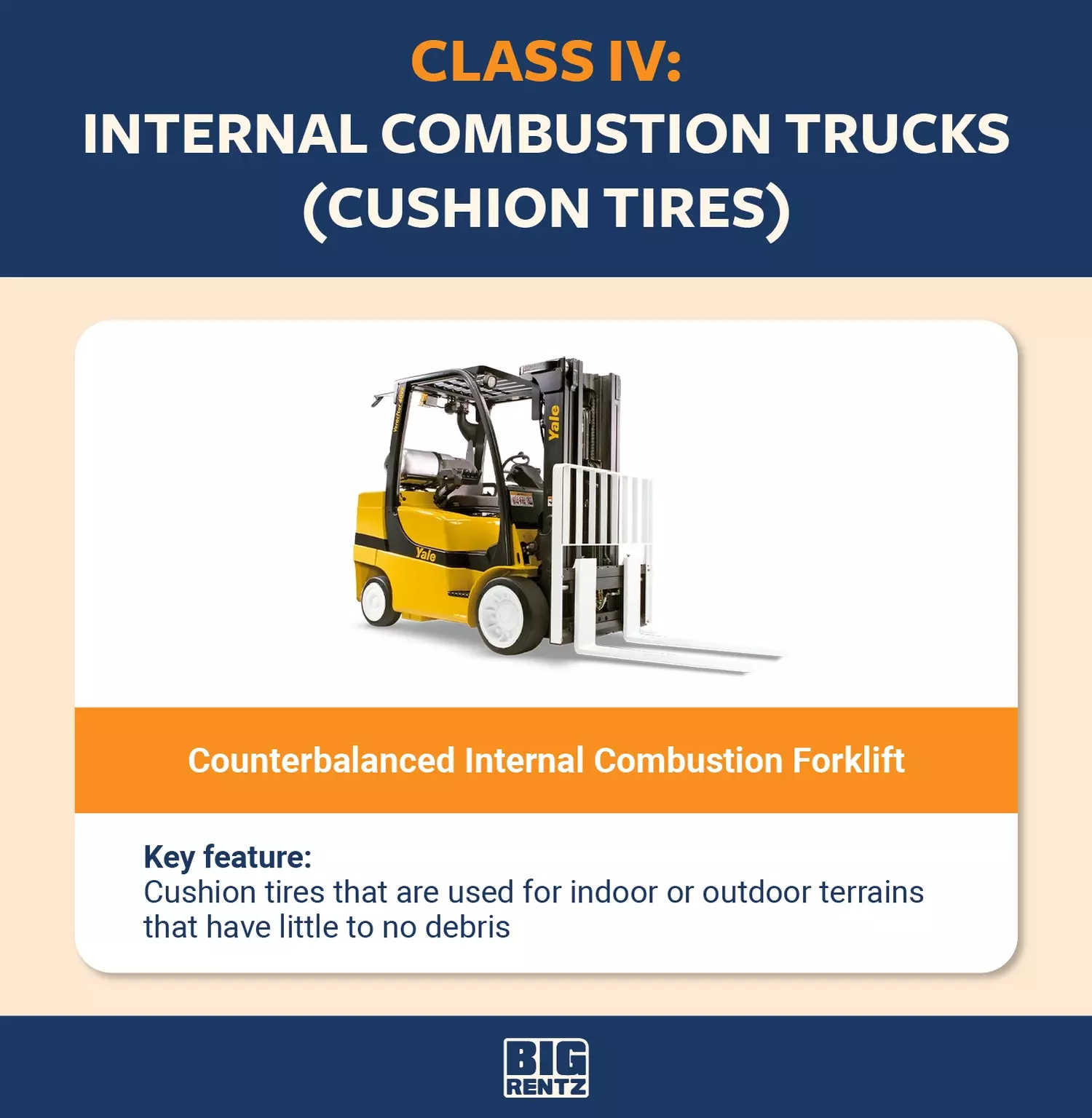

| Class IV: Internal Combustion Trucks (Cushion Tires) | Gas-powered, cushion tires for smooth surfaces | Indoor warehouses, loading docks | Pros: High load capacity, suitable for heavy materials; Cons: Higher emissions, limited outdoor use. |

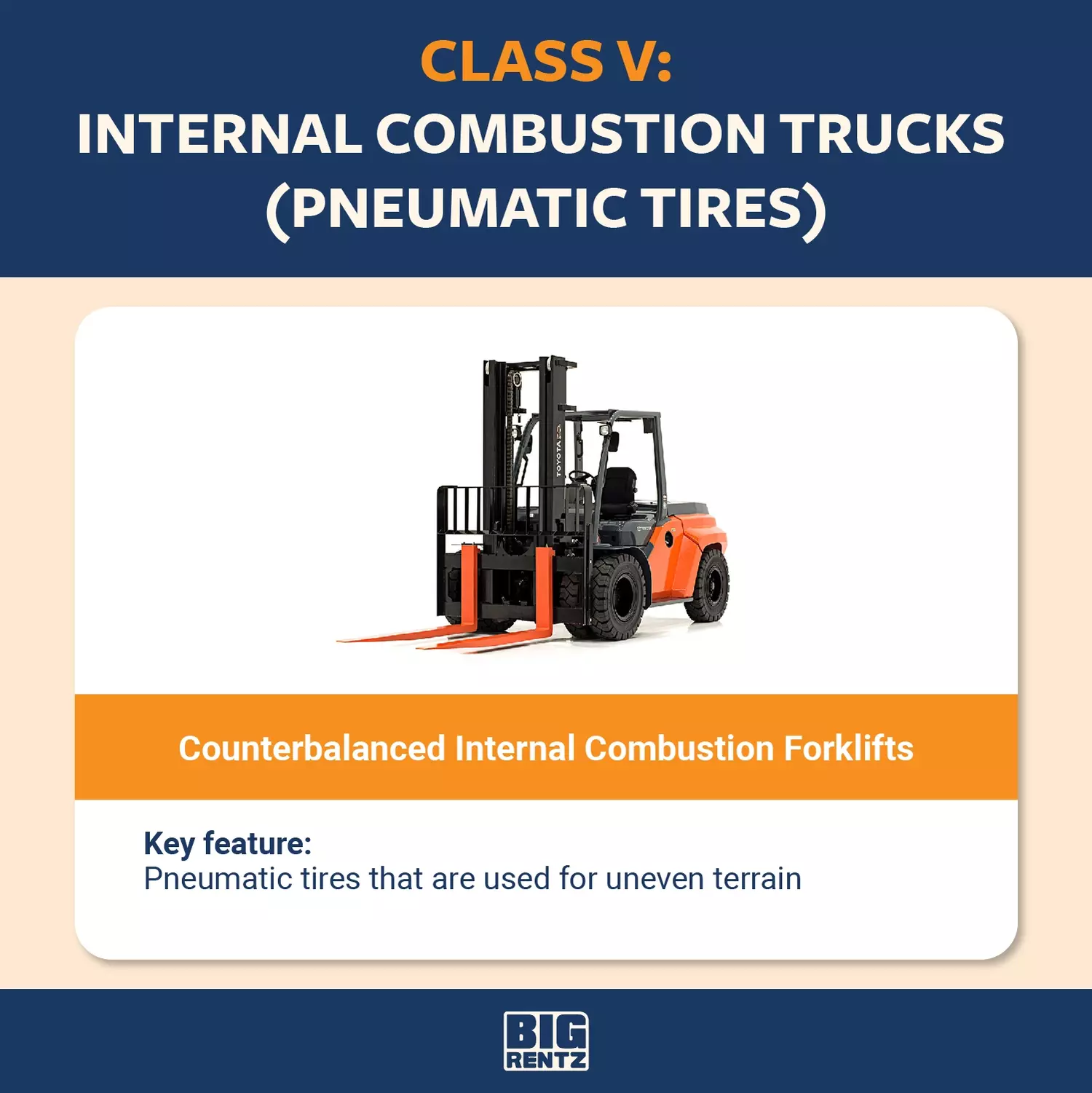

| Class V: Internal Combustion Trucks (Pneumatic Tires) | Gas-powered, pneumatic tires for rough terrain | Construction sites, outdoor applications | Pros: Good traction on uneven surfaces; Cons: Higher operational costs, more maintenance needed. |

| Class VII: Rough-Terrain Forklift Trucks | Large tires, designed for uneven and outdoor surfaces | Lumber yards, construction sites | Pros: Excellent stability on rough terrain; Cons: Typically more expensive and less maneuverable in tight spaces. |

What Are the Key Characteristics of Class I Forklifts?

Class I forklifts are electric motor rider trucks, recognized for their quiet operation and environmental friendliness. They are primarily used in warehouses and distribution centers where air quality is a concern. These forklifts are equipped with counterbalanced designs, allowing them to handle various material handling tasks. When considering a Class I forklift, B2B buyers should assess the indoor versus outdoor application, as these units are best suited for indoor environments with limited outdoor capabilities.

How Do Class II Forklifts Stand Out in Narrow Spaces?

Class II forklifts, or electric motor narrow aisle trucks, are specifically engineered for operation in tight spaces. Their compact design and high lift capabilities make them ideal for retail stockrooms and narrow aisles. Buyers should note that while these forklifts excel in maneuverability, they generally have lower load capacities. This makes them suitable for businesses that prioritize space efficiency over heavy lifting.

What Makes Class IV Forklifts Ideal for Indoor Use?

Class IV forklifts utilize internal combustion engines and cushion tires, making them suitable for transporting heavy loads across smooth, flat surfaces like loading docks and warehouses. These forklifts offer high load capacities, which can be advantageous for businesses dealing with heavy materials. However, potential buyers should be aware of the higher emissions associated with gas-powered models and their limited outdoor applicability.

Why Choose Class V Forklifts for Outdoor Applications?

Class V forklifts are designed with pneumatic tires, providing excellent traction on both indoor and outdoor surfaces. They are particularly effective in construction sites and other outdoor environments where rough terrain is prevalent. While they offer versatility, buyers should consider the higher operational costs and maintenance requirements associated with internal combustion engines.

Illustrative image related to fork truck classes

How Do Class VII Forklifts Handle Rough Terrain?

Class VII forklifts are specialized for rough terrain, featuring large tires and robust designs to navigate uneven surfaces. Commonly used in lumber yards and construction sites, they provide stability and reliability in challenging conditions. However, B2B buyers should factor in the typically higher costs and reduced maneuverability in tight spaces when selecting this type of forklift for their operations.

Key Industrial Applications of fork truck classes

| Industry/Sector | Specific Application of fork truck classes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Warehousing and Distribution | Class I Electric Motor Rider Trucks for indoor operations | Enhanced efficiency in material handling and reduced emissions | Ensure the forklift meets load capacity and indoor air quality standards |

| Manufacturing | Class IV Internal Combustion Trucks for heavy lifting | Ability to transport heavy materials on production floors | Look for models with high durability and low maintenance costs |

| Construction | Class VII Rough-Terrain Forklift Trucks for site logistics | Effective material transport in uneven terrains | Consider tire type and engine power for specific job site conditions |

| Retail | Class II Electric Motor Narrow Aisle Trucks for inventory management | Maximized space utilization in tight aisles | Evaluate maneuverability and lift height for specific warehouse layouts |

| Agriculture | Class V Internal Combustion Trucks for outdoor operations | Improved efficiency in transporting goods across farms | Assess fuel type and terrain capability based on agricultural needs |

How Are Fork Truck Classes Used in Warehousing and Distribution?

In warehousing and distribution, Class I Electric Motor Rider Trucks are commonly utilized for indoor operations. These forklifts facilitate the efficient movement of goods, especially in high-density storage environments. The zero-emission feature makes them suitable for indoor use, addressing air quality concerns. International buyers should prioritize sourcing models with adequate load capacities and features that comply with local safety regulations to ensure optimal performance.

What Role Do Fork Truck Classes Play in Manufacturing?

In the manufacturing sector, Class IV Internal Combustion Trucks are essential for heavy lifting tasks. These forklifts are designed to transport bulky materials across production floors, enhancing workflow efficiency. Businesses benefit from their robust construction and ability to operate on smooth surfaces. Buyers in regions with varying fuel availability should consider the engine type (diesel, gas, or natural gas) and the overall durability of the forklift to minimize downtime.

Illustrative image related to fork truck classes

Why Are Fork Truck Classes Important in Construction?

Class VII Rough-Terrain Forklift Trucks are invaluable in construction environments, where uneven surfaces are common. These forklifts are designed to navigate challenging terrains, making them ideal for transporting materials on job sites. Their robust design and powerful engines enable efficient logistics management. Buyers should evaluate the tire type and engine specifications to ensure suitability for specific construction conditions, especially in remote areas.

How Do Fork Truck Classes Benefit Retail Operations?

In the retail sector, Class II Electric Motor Narrow Aisle Trucks are frequently used for inventory management. Their compact design allows for navigation in tight aisles, maximizing storage space and improving operational efficiency. This is particularly beneficial for retailers looking to optimize their warehouse layouts. B2B buyers should assess the maneuverability and lift height of these trucks to meet their specific inventory needs.

What Are the Key Applications of Fork Truck Classes in Agriculture?

In agriculture, Class V Internal Combustion Trucks are utilized for outdoor operations, facilitating the transportation of goods across farms. These forklifts are equipped with pneumatic tires, providing the traction needed for rugged agricultural terrain. Efficiency in moving products directly impacts productivity. When sourcing, buyers should consider the fuel type and overall capability of the forklift to handle the specific challenges faced in agricultural settings.

Illustrative image related to fork truck classes

3 Common User Pain Points for ‘fork truck classes’ & Their Solutions

Scenario 1: Choosing the Right Fork Truck Class for Specific Tasks

The Problem: One of the most common challenges B2B buyers face is selecting the appropriate fork truck class for their specific operational needs. With multiple classes available, each designed for different environments and tasks, it can be overwhelming. For instance, a company operating in a narrow warehouse might mistakenly choose a Class IV internal combustion truck instead of a Class II electric motor narrow aisle truck, leading to inefficiencies and potential safety hazards. This not only impacts productivity but can also result in costly accidents or equipment damage.

The Solution: To effectively choose the right fork truck class, buyers should conduct a thorough assessment of their operational environment and material handling requirements. Start by evaluating the following factors: the maximum load capacity needed, the height of racking systems, the width of aisles, and whether the operations are indoor or outdoor. Create a checklist that includes these parameters and engage with suppliers to discuss your specific needs. Use this information to narrow down your options to the most suitable classes, such as Class II for narrow aisles or Class V for outdoor rough terrains. Additionally, consider renting different models for trial periods to ascertain their performance before making a purchase.

Scenario 2: Ensuring Compliance with Safety Regulations

The Problem: B2B buyers often struggle with ensuring that their operations comply with safety regulations related to fork truck classes, especially in industries with strict operational standards. The Occupational Safety and Health Administration (OSHA) mandates that all operators must be trained and certified to handle forklifts. Non-compliance can lead to heavy fines, legal liabilities, and an unsafe working environment, which can severely impact company reputation and financial stability.

Illustrative image related to fork truck classes

The Solution: To mitigate compliance issues, companies should implement a comprehensive training program that aligns with OSHA standards. This includes investing in certified training courses for all forklift operators. Additionally, buyers should document all training sessions and maintain records of operator certifications. Regular refresher courses can help ensure that operators stay up-to-date with safety protocols. Furthermore, consider establishing a safety audit system to regularly review operations and equipment, ensuring that they meet regulatory requirements. Collaborating with suppliers who offer training resources can also streamline this process and provide peace of mind.

Scenario 3: Managing Equipment Maintenance and Downtime

The Problem: Another prevalent pain point for B2B buyers is the challenge of managing equipment maintenance and minimizing downtime. Fork trucks, regardless of class, require regular maintenance to operate efficiently and safely. Unexpected breakdowns can lead to significant operational delays, lost revenue, and disrupted supply chains. Buyers often struggle to establish effective maintenance schedules and may overlook minor issues until they escalate into major problems.

The Solution: To effectively manage maintenance and reduce downtime, buyers should develop a proactive maintenance plan that includes regular inspections and servicing according to the manufacturer’s guidelines. Implement a tracking system that alerts management when maintenance is due based on usage hours or calendar time. Additionally, train staff to recognize early signs of wear or malfunction in fork trucks, encouraging a culture of proactive maintenance. Establish relationships with reliable service providers who can respond quickly to repairs and offer emergency services when needed. By prioritizing maintenance and fostering a preventative approach, companies can extend the lifespan of their equipment and maintain smooth operations.

Strategic Material Selection Guide for fork truck classes

What Are the Key Properties of Common Materials Used in Fork Truck Classes?

When selecting materials for fork truck classes, it’s essential to consider their properties, advantages, and limitations to ensure optimal performance. Here, we analyze four common materials: steel, aluminum, plastic, and rubber.

Illustrative image related to fork truck classes

How Does Steel Perform in Fork Truck Applications?

Steel is a primary material used in the construction of fork truck frames and components due to its high strength and durability. It has excellent temperature and pressure ratings, making it suitable for heavy-duty applications. Steel also offers good corrosion resistance when treated with coatings or galvanization.

Pros: Steel’s high tensile strength allows it to withstand heavy loads and impacts, making it ideal for demanding environments. It is relatively cost-effective compared to other materials, especially for large-scale production.

Cons: While steel is durable, it can be heavy, which may affect the overall weight of the forklift. Additionally, untreated steel is prone to rust and corrosion, particularly in humid or wet environments.

Impact on Application: Steel’s robustness makes it suitable for Class IV and V forklifts, which often operate in industrial settings. However, buyers in regions with high humidity, such as parts of Africa and South America, should consider corrosion-resistant coatings.

What Advantages Does Aluminum Offer Fork Truck Manufacturers?

Aluminum is increasingly used in fork truck design due to its lightweight nature and resistance to corrosion. It is particularly beneficial in applications requiring lower weight for better fuel efficiency and maneuverability.

Pros: Aluminum’s lightweight characteristic improves fuel efficiency and reduces operational costs. It also has a high strength-to-weight ratio, making it suitable for various components without compromising structural integrity.

Cons: Aluminum can be more expensive than steel, impacting overall manufacturing costs. It is also less durable under heavy loads compared to steel, which may limit its application in high-capacity forklifts.

Impact on Application: Aluminum is often used in Class I and II forklifts, where weight reduction is critical. Buyers from Europe and the Middle East may prefer aluminum for its corrosion resistance, especially in coastal areas.

Illustrative image related to fork truck classes

How Do Plastics Enhance Fork Truck Functionality?

Plastics are commonly used for non-structural components, such as covers, handles, and some internal parts of forklifts. They are lightweight and can be engineered for specific applications.

Pros: Plastics are resistant to corrosion and chemicals, making them suitable for various environments. They are also lightweight and can be molded into complex shapes, providing design flexibility.

Cons: While plastics are durable, they may not withstand high loads or extreme temperatures as effectively as metals. They can also be more susceptible to wear and tear over time.

Impact on Application: Plastics are ideal for Class III forklifts, where lighter components can enhance maneuverability. Buyers should consider the specific chemical environments in which the forklift will operate, especially in industries like food processing or pharmaceuticals.

What Role Does Rubber Play in Fork Truck Performance?

Rubber is primarily used for tires and grips on fork trucks, providing essential traction and shock absorption. Its properties can significantly impact the performance of the forklift, especially in varied terrains.

Illustrative image related to fork truck classes

Pros: Rubber tires offer excellent traction and shock absorption, enhancing stability and safety. They are versatile and can be used on both indoor and outdoor surfaces.

Cons: Rubber can wear down faster than other materials, especially on rough surfaces. It may also require more frequent replacement, adding to maintenance costs.

Impact on Application: Class V and VII forklifts benefit from rubber tires, particularly in outdoor applications where terrain varies. Buyers in regions with rough terrain, such as parts of Africa and South America, should prioritize high-quality rubber tires for better performance.

Illustrative image related to fork truck classes

Summary Table of Material Selection for Fork Truck Classes

| Material | Typical Use Case for fork truck classes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components in Class IV and V forklifts | High strength and durability | Heavy and prone to corrosion | Medium |

| Aluminum | Lightweight components in Class I and II forklifts | Lightweight and corrosion-resistant | More expensive and less durable under heavy loads | High |

| Plastic | Non-structural parts in Class III forklifts | Corrosion-resistant and flexible | Less durable under high loads | Medium |

| Rubber | Tires for Class V and VII forklifts | Excellent traction and shock absorption | Wears down faster on rough surfaces | Medium |

This guide serves as a strategic resource for international B2B buyers, helping them make informed decisions about material selection for fork truck classes based on their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for fork truck classes

The manufacturing processes and quality assurance protocols for fork truck classes are critical for ensuring operational efficiency and safety. Understanding these processes can help B2B buyers make informed decisions when sourcing forklifts from international suppliers. Here’s a detailed look at the stages of manufacturing, quality control measures, and what buyers should consider when verifying supplier standards.

What Are the Main Stages of Fork Truck Manufacturing?

How is Material Prepared for Fork Trucks?

The manufacturing process for fork trucks begins with material preparation. This stage involves sourcing high-quality raw materials such as steel, aluminum, and composite materials. These materials are selected based on their durability, weight capacity, and resistance to environmental factors.

Once sourced, materials undergo various treatments to enhance their properties, such as heat treatment for steel, which increases strength and toughness. Additionally, surface treatments may be applied to prevent corrosion, especially for trucks intended for outdoor use in challenging terrains.

Illustrative image related to fork truck classes

What Techniques Are Used in Forming Fork Trucks?

The forming stage involves transforming raw materials into usable components. This includes processes such as:

- Cutting: Raw materials are cut into specific shapes and sizes using laser cutting or water jet cutting technologies for precision.

- Bending: Components like frames and chassis are bent into shape using hydraulic presses, ensuring they meet design specifications.

- Welding: Various parts are joined together through welding techniques, including MIG and TIG welding, which provide strong and lasting bonds.

Advanced manufacturing technologies like robotic welding may be employed to enhance consistency and reduce human error.

How Are Fork Trucks Assembled?

The assembly stage is where all the formed components come together to create the final product. This process typically includes:

- Sub-assembly: Individual components such as the engine, mast, and hydraulic systems are assembled separately before being brought together.

- Main assembly: All sub-assemblies are integrated into the fork truck. This stage often involves intricate tasks such as wiring electrical systems and connecting hydraulic lines.

- Final assembly: The finishing touches are added, such as installing safety features, attachments, and aesthetic components.

What Are the Finishing Processes for Fork Trucks?

The finishing stage enhances both the functionality and appearance of fork trucks. It typically includes:

- Painting and Coating: Fork trucks are coated with protective paints or powder coatings to enhance durability and resist environmental damage.

- Inspection and Testing: Before leaving the factory, each fork truck undergoes a series of tests to ensure that all systems function correctly, including load tests and safety checks.

How Is Quality Assurance Implemented in Fork Truck Manufacturing?

What Are the Relevant International Standards for Fork Truck Quality?

Quality assurance in fork truck manufacturing is governed by several international standards. The most notable among these is ISO 9001, which sets criteria for a quality management system and ensures consistent quality across products and services. Other industry-specific standards include:

Illustrative image related to fork truck classes

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Specifications: For companies producing fork trucks for the oil and gas industry, adherence to API standards is critical to ensure the equipment can withstand harsh environments.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that each stage meets quality standards. These checkpoints typically include:

- Incoming Quality Control (IQC): Raw materials are inspected for quality and compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Ongoing inspections occur during the manufacturing process to detect any defects early on. This includes monitoring welding quality, dimensional accuracy, and assembly integrity.

- Final Quality Control (FQC): The finished fork trucks are subjected to rigorous testing procedures, including load testing, safety inspections, and functionality assessments.

What Testing Methods Are Commonly Used for Fork Trucks?

Testing methods for fork trucks are critical to ensuring safety and performance. Common testing protocols include:

- Load Testing: Assessing the fork truck’s ability to lift and move specified loads safely.

- Stability Testing: Evaluating the truck’s stability under various conditions, particularly for models designed for rough terrain.

- Operational Testing: Ensuring that all controls, alarms, and safety features function correctly.

How Can B2B Buyers Verify Supplier Quality Control?

What Steps Should Buyers Take to Verify Quality Control Standards?

B2B buyers must conduct thorough due diligence when selecting suppliers for fork trucks. Here are some actionable steps:

-

Request Documentation: Ask suppliers for their quality control certifications, including ISO 9001 and any relevant industry certifications (e.g., CE marking).

-

Conduct Audits: If feasible, perform site audits to evaluate the manufacturing processes and quality control systems firsthand. This can provide insights into their operational standards and commitment to quality.

-

Review Quality Reports: Suppliers should be able to provide quality assurance reports detailing their QC processes, results of inspections, and testing outcomes.

-

Third-Party Inspections: Consider engaging third-party inspection services that specialize in industrial equipment. These services can provide impartial assessments of the supplier’s quality control measures.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several nuances in quality control must be considered:

-

Regulatory Compliance: Be aware of local regulations and standards that may differ from international norms. Ensure that the fork trucks comply with both the supplier’s and the buyer’s country regulations.

-

Cultural Differences in Quality Perception: Different cultures may have varying standards of quality and expectations. Clear communication about quality requirements is essential to avoid misunderstandings.

-

Logistical Considerations: Shipping and transport can introduce risks to quality. Ensure that suppliers have robust packaging and handling procedures to maintain product integrity during transit.

By understanding the manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing fork trucks, ensuring they invest in reliable, high-quality equipment that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fork truck classes’

In the competitive landscape of material handling, selecting the right fork truck class is crucial for operational efficiency and safety. This guide provides a step-by-step checklist for B2B buyers to streamline the procurement process and ensure that they choose the most suitable forklifts for their specific needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical specifications. This includes determining the load capacity, the type of materials to be handled, and the operational environment (indoor vs. outdoor). Identifying these parameters will help narrow down the options and ensure that the selected fork truck class can effectively meet your operational demands.

Illustrative image related to fork truck classes

Step 2: Assess the Terrain and Application Needs

Understanding the working conditions is essential in choosing the right fork truck class. Evaluate the terrain where the forklifts will operate—smooth surfaces may require different machines compared to rough or uneven grounds. Consider the specific applications, such as narrow aisle operations or heavy lifting, as this will dictate whether you need a Class I electric motor rider truck or a Class VII rough-terrain forklift.

Step 3: Evaluate Potential Suppliers

Before committing to any purchase, conduct a thorough evaluation of potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Pay attention to their experience with the specific fork truck classes you are interested in, as well as their reputation for customer service and support.

Step 4: Check for Compliance with Safety Standards

Ensure that any fork trucks you consider comply with relevant safety regulations and standards, such as those set by OSHA. Verify that the models are certified and that the supplier provides necessary documentation, including operator training and safety certifications. Compliance is not only a legal requirement but also critical for the safety of your workforce.

Illustrative image related to fork truck classes

Step 5: Consider Total Cost of Ownership (TCO)

When evaluating fork trucks, consider the total cost of ownership, which includes purchase price, maintenance, fuel or energy costs, and potential resale value. Electric forklifts may have a higher upfront cost but lower operational expenses over time. Assessing TCO will help you make a financially sound decision that aligns with your budget and operational needs.

Step 6: Review Warranty and Service Agreements

Before finalizing your purchase, review the warranty and service agreements offered by the supplier. A comprehensive warranty can protect your investment and provide peace of mind. Additionally, consider the availability of service support and spare parts, as reliable after-sales service is crucial for minimizing downtime.

Step 7: Plan for Operator Training and Certification

Ensure that your team is adequately trained to operate the chosen fork trucks safely and efficiently. Check if the supplier provides training programs and certifications, as OSHA mandates that all operators receive proper training. Investing in training will enhance operational efficiency and promote a culture of safety within your organization.

By following this checklist, B2B buyers can make informed decisions when procuring fork trucks, ensuring they select the right class that meets their operational needs while enhancing safety and productivity.

Comprehensive Cost and Pricing Analysis for fork truck classes Sourcing

When sourcing fork trucks, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. The complexities involved in purchasing these industrial vehicles necessitate a comprehensive analysis of various cost components and price influencers.

What Are the Key Cost Components in Fork Truck Classes?

The cost of fork trucks is influenced by several components:

-

Materials: The primary material costs include steel and other metals used in the chassis, along with components like the engine and electrical systems. High-quality materials ensure durability and performance, impacting the overall cost.

-

Labor: Labor costs involve wages for skilled workers involved in assembly, welding, and finishing processes. Labor rates can vary significantly based on geographic location and the skill level required.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, factory rent, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, allowing for more competitive pricing.

-

Tooling: Tooling costs can be substantial, especially for custom or specialized fork truck designs. Investing in advanced tooling can enhance production efficiency and quality.

-

Quality Control (QC): Ensuring that each fork truck meets safety and performance standards involves quality control measures. These costs are essential but can influence the final price based on the level of testing and certification required.

-

Logistics: Transportation of finished products to the buyer’s location adds to the cost. Factors like shipping distance, mode of transport, and customs duties can significantly impact logistics expenses.

-

Margin: Suppliers will typically add a margin to cover their costs and generate profit. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Fork Truck Sourcing?

Several factors can influence the pricing of fork trucks, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts. Understanding a supplier’s MOQ can help in negotiating better prices.

-

Specifications and Customization: Custom features or specific performance requirements can increase the base price. Buyers should clearly outline their needs to avoid unexpected costs.

-

Material Quality and Certifications: Fork trucks with higher quality materials or specific safety certifications may command a premium. Certifications can also be essential for compliance in certain regions.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer better warranties and after-sales support, justifying higher prices.

-

Incoterms: The chosen Incoterms (International Commercial Terms) affect the total cost. Buyers should be aware of who is responsible for shipping, insurance, and duties to avoid hidden costs.

What Are the Best Negotiation Tips for Buyers?

To maximize value when sourcing fork trucks, international buyers should consider these negotiation strategies:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, repair, and operational costs over the vehicle’s lifespan. This perspective can influence buying decisions.

-

Leverage Competitive Quotes: Obtain quotes from multiple suppliers to create a competitive environment. This can lead to better pricing and terms.

-

Negotiate Payment Terms: Flexible payment terms can ease financial pressure. Discuss options like installment payments or deferred payments based on delivery milestones.

-

Assess After-Sales Support: Ensure that the supplier offers robust after-sales support and warranty options. A slightly higher initial price may be worth it for better service and support.

-

Be Aware of Regional Pricing Nuances: Prices may vary significantly across regions due to local market conditions, tariffs, and currency fluctuations. Understanding these nuances can provide leverage during negotiations.

Conclusion and Disclaimer

While this analysis provides a framework for understanding the costs and pricing of fork trucks, it is essential to note that prices can fluctuate based on market conditions and specific buyer needs. Always conduct thorough market research and engage in discussions with multiple suppliers to ensure the best possible terms for your purchase.

Illustrative image related to fork truck classes

Alternatives Analysis: Comparing fork truck classes With Other Solutions

When evaluating material handling solutions, it’s essential for B2B buyers to consider various alternatives to fork truck classes. While fork trucks are versatile and widely used in industrial settings, other technologies and methods may offer specific advantages based on the operational environment, budget constraints, and project requirements. This analysis will compare fork truck classes against two viable alternatives: Automated Guided Vehicles (AGVs) and Manual Pallet Jacks.

| Comparison Aspect | Fork Truck Classes | Automated Guided Vehicles (AGVs) | Manual Pallet Jacks |

|---|---|---|---|

| Performance | High load capacity; versatile for various environments | Efficient for repetitive tasks; limited load capacity | Low load capacity; manual operation requires physical effort |

| Cost | Higher initial investment; ongoing maintenance costs | Moderate to high initial costs; lower operational costs over time | Low initial investment; minimal maintenance costs |

| Ease of Implementation | Requires training and certification for operators | Requires programming and integration into existing systems | Simple to implement; no special training needed |

| Maintenance | Regular maintenance required; higher costs for repairs | Lower maintenance; often requires software updates | Minimal maintenance required; easy to repair |

| Best Use Case | Warehousing, construction, and heavy-duty applications | Automated warehousing and assembly lines | Small warehouses, retail, and light-duty applications |

What Are the Advantages and Disadvantages of Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles (AGVs) are increasingly popular for material handling, especially in large warehouses and manufacturing facilities. They offer the advantage of automation, which can significantly reduce labor costs and increase efficiency in repetitive tasks such as transporting goods from one location to another. However, AGVs typically have a higher initial investment and require integration into existing systems, which can complicate implementation. Furthermore, their load capacity is often limited compared to fork trucks, making them less suitable for heavy-duty applications.

How Do Manual Pallet Jacks Compare to Fork Truck Classes?

Manual pallet jacks are a cost-effective alternative for transporting goods over short distances, especially in small warehouses or retail environments. They are easy to use and require no special training, making them accessible for a wide range of employees. However, they have a significantly lower load capacity than fork trucks and require physical effort to operate, which can lead to worker fatigue and limit productivity. Additionally, they are not suitable for tasks that require lifting goods to elevated heights or transporting heavy loads over long distances.

How Can B2B Buyers Choose the Right Material Handling Solution?

Choosing the right material handling solution depends on several factors, including the specific operational environment, load requirements, and budget. B2B buyers should assess the scope of their operations and determine whether the efficiency and versatility of fork trucks outweigh the initial investment and maintenance costs. For businesses focused on automation and efficiency, AGVs may provide long-term savings despite higher upfront costs. Conversely, for smaller operations with limited budgets, manual pallet jacks may be the most practical solution. Ultimately, aligning the chosen technology with the business’s operational needs and future growth plans will lead to the most effective material handling strategy.

Essential Technical Properties and Trade Terminology for fork truck classes

What Are the Key Technical Properties of Fork Truck Classes?

When selecting a fork truck for your business needs, understanding the essential technical specifications is crucial. Here are some of the most important properties to consider:

Illustrative image related to fork truck classes

Load Capacity

Load capacity refers to the maximum weight a forklift can safely lift and carry. This specification is critical for B2B buyers, as it directly impacts operational efficiency and safety. Choosing a forklift with insufficient capacity can lead to accidents and equipment damage, resulting in costly downtime.

Lift Height

Lift height indicates how high a forklift can raise its load. This is particularly important for warehouses or storage facilities with vertical space constraints. Understanding lift height ensures that you select a model that can effectively operate within your site’s parameters, maximizing storage capabilities.

Fuel Type

Fork trucks can be powered by electricity, diesel, or gas, each offering distinct advantages. Electric forklifts are quieter and produce zero emissions, making them suitable for indoor use. Conversely, diesel and gas-powered forklifts are often preferred for outdoor applications due to their greater power and longevity. Knowing the fuel type helps businesses align their equipment choices with operational needs and environmental considerations.

Tire Type

The type of tires on a forklift affects its traction and stability, especially in various terrains. Cushion tires are designed for smooth surfaces, while pneumatic tires are better suited for rough or uneven ground. Selecting the appropriate tire type is vital for ensuring operational safety and efficiency, particularly in diverse environments.

Illustrative image related to fork truck classes

Turning Radius

The turning radius is the minimum space required for a forklift to make a complete turn. This property is essential for operations in tight spaces, such as narrow aisles in warehouses. A smaller turning radius enhances maneuverability, allowing for more efficient material handling.

Battery Life

For electric forklifts, battery life is a significant factor that impacts operational efficiency. Longer battery life means less frequent charging and downtime, which is critical for maintaining productivity levels in high-demand environments.

What Are Common Trade Terms in Fork Truck Procurement?

Understanding industry jargon can enhance communication and negotiation during the procurement process. Here are several common terms:

Illustrative image related to fork truck classes

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. When buying forklifts, knowing whether you are dealing with an OEM can ensure you receive authentic and high-quality equipment.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers who need to understand the scale of their purchase and how it aligns with their budget and operational needs.

RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to submit price proposals for specific products or services. Crafting a detailed RFQ can help businesses compare multiple suppliers effectively and secure the best deal.

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international trade. Familiarity with these terms helps B2B buyers understand shipping logistics, costs, and risks associated with their purchases, ensuring smoother transactions.

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with purchasing and operating a fork truck, including maintenance, fuel, and depreciation. Understanding TCO is vital for making informed purchasing decisions that align with long-term financial goals.

Illustrative image related to fork truck classes

Lead Time

Lead time is the period between placing an order and receiving the product. Knowing the lead time is crucial for B2B buyers to plan operations and inventory management effectively, especially in industries where timely delivery is critical.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting fork trucks, ensuring they meet operational requirements while optimizing costs and efficiency.

Navigating Market Dynamics and Sourcing Trends in the fork truck classes Sector

What Are the Current Market Dynamics and Key Trends Influencing Fork Truck Classes?

The fork truck classes sector is experiencing transformative shifts driven by technological advancements, increased demand for efficiency, and changing regulations. As global supply chains become more integrated, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must navigate a complex landscape marked by fluctuating market dynamics. Key trends include the growing adoption of electric forklifts, spurred by their lower emissions and operational costs. This trend is particularly relevant in regions with stringent environmental regulations, such as Europe, where sustainability is a priority.

Moreover, the rise of automation in material handling is reshaping sourcing strategies. Advanced technologies such as telematics and IoT are increasingly being integrated into fork truck designs, enhancing operational visibility and efficiency. Buyers are now looking for forklifts that not only meet their immediate logistical needs but also align with long-term operational goals, such as reducing downtime and maintenance costs. In markets like Brazil and Vietnam, where infrastructure challenges persist, the demand for versatile and robust forklift classes, especially rough-terrain models, is on the rise.

Additionally, the current geopolitical landscape has introduced uncertainties in supply chains, compelling buyers to seek local suppliers or diversify their sourcing strategies. This trend is evident in emerging markets, where buyers are increasingly investing in local partnerships to mitigate risks associated with international logistics and tariffs. Understanding these dynamics allows B2B buyers to make informed decisions that align with their operational objectives and market conditions.

How Does Sustainability and Ethical Sourcing Impact the Fork Truck Classes Sector?

In today’s environmentally conscious market, sustainability and ethical sourcing are paramount considerations for B2B buyers in the fork truck classes sector. The environmental impact of material handling equipment extends beyond operational emissions; it encompasses the entire lifecycle of the product, from manufacturing to disposal. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their carbon footprint through sustainable practices, such as using recycled materials and minimizing waste during production.

Furthermore, the importance of ethical supply chains cannot be overstated. B2B buyers are scrutinizing their suppliers’ sourcing practices, ensuring they comply with labor laws and environmental regulations. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for suppliers aiming to attract conscientious buyers. In regions like Africa and South America, where resource extraction can often lead to environmental degradation, ethical sourcing practices are critical for fostering long-term relationships with buyers who prioritize social responsibility.

Investing in ‘green’ certifications and materials not only enhances a supplier’s marketability but also positions them as leaders in sustainability within the industry. As buyers increasingly demand transparency in sourcing, suppliers must adapt by incorporating sustainable practices and showcasing their commitment to ethical operations to remain competitive.

Illustrative image related to fork truck classes

How Has the Fork Truck Classes Sector Evolved Over Time?

The evolution of the fork truck classes sector reflects broader changes in industrial practices and technological advancements. Initially, forklifts were predominantly powered by internal combustion engines, which posed challenges in terms of emissions and operational noise. However, the late 20th century saw a significant shift towards electric forklifts, primarily driven by increasing awareness of environmental issues and the need for safer indoor operations.

As technology progressed, innovations such as automated guided vehicles (AGVs) and advanced battery technologies emerged, transforming the functionality and efficiency of forklifts. This evolution has been particularly impactful in regions experiencing rapid industrial growth, such as Southeast Asia and parts of Africa. The focus has now shifted from merely lifting and transporting materials to enhancing overall supply chain efficiency through integrated systems that leverage data analytics and automation.

Today, the fork truck classes sector is characterized by a diverse array of options tailored to specific operational needs, from electric motor rider trucks for indoor use to rough-terrain forklifts designed for challenging environments. As the sector continues to evolve, international B2B buyers must stay informed about these developments to make strategic sourcing decisions that align with their business objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of fork truck classes

-

How do I choose the right fork truck class for my operations?

Choosing the right fork truck class depends on your specific operational needs. First, assess the load capacity required for your tasks and the type of materials you’ll be handling. Consider the environment—indoor settings may benefit from electric motor trucks due to their zero emissions, while rough terrains might require pneumatic tire forklifts. Additionally, evaluate the available space; narrow aisle trucks are ideal for confined areas. Finally, think about the terrain type and select a model with appropriate tires to ensure stability and safety during operation. -

What are the key differences between electric and internal combustion forklifts?

Electric forklifts are typically quieter and produce no emissions, making them suitable for indoor use. They require less maintenance and have lower operational costs over time. In contrast, internal combustion forklifts, powered by diesel or gas, generally offer more power and are better suited for outdoor applications or heavy-duty tasks. They can handle rough terrains but require more maintenance due to engine wear. Ultimately, the choice between the two should reflect your operational environment and specific lifting needs. -

What should I consider when sourcing forklifts from international suppliers?

When sourcing forklifts internationally, consider supplier credibility and experience in the industry. Request certifications and references from previous clients to ensure they comply with safety and quality standards. Evaluate their ability to customize equipment to meet your unique needs, including modifications for specific load capacities or attachments. Additionally, inquire about their logistics capabilities, including shipping times, costs, and terms of delivery to your location, ensuring that they can meet your operational timelines effectively. -

What are the minimum order quantities (MOQs) for fork trucks?

Minimum order quantities for forklifts can vary significantly among suppliers. Some manufacturers may allow single-unit purchases, particularly for specialized or customized models, while others may have higher MOQs to optimize production and shipping costs. When negotiating, consider your current and future needs; securing a larger order can often result in better pricing. Additionally, clarify any terms related to bulk purchases and potential discounts during discussions with suppliers to ensure cost-effectiveness. -

How can I ensure quality assurance (QA) for my fork truck purchase?

To ensure quality assurance when purchasing forklifts, request detailed specifications and performance data from suppliers. Look for internationally recognized certifications such as ISO standards that indicate adherence to quality management systems. It’s beneficial to visit manufacturing facilities, if possible, to observe production processes and quality control measures. Additionally, consider obtaining a warranty or service agreement that covers repairs and maintenance, ensuring that any issues can be addressed promptly after purchase. -

What payment terms should I negotiate when buying forklifts?

When negotiating payment terms for forklift purchases, consider factors such as upfront costs, financing options, and payment schedules. Many suppliers offer flexible payment options, including partial payments upon order confirmation and balance upon delivery. Be sure to discuss any available financing plans that can ease cash flow concerns. Establishing clear payment milestones can help maintain transparency and ensure that both parties are aligned throughout the transaction process. -

How do logistics impact the purchase of forklifts internationally?

Logistics play a crucial role in the successful delivery of forklifts, especially in international transactions. Evaluate the supplier’s shipping capabilities, including options for freight forwarding, customs clearance, and delivery timelines. Consider the potential impact of tariffs and import duties on your total cost. Additionally, ensure that the supplier has a robust tracking system in place for shipments, allowing you to monitor the status and address any potential delays proactively. -

What are the common applications for each fork truck class?

Understanding the applications for each fork truck class can guide your purchasing decision. Class I (Electric Motor Rider Trucks) are ideal for indoor material handling tasks. Class II (Electric Motor Narrow Aisle Trucks) excel in tight spaces. Class III (Electric Motor Hand Trucks) are suited for short-distance pallet transport. Class IV (Internal Combustion Trucks with Cushion Tires) work well on flat surfaces, while Class V (Pneumatic Tire Trucks) are perfect for rough terrains. Class VI (Electric and IC Engine Tractors) are designed for towing, and Class VII (Rough-Terrain Forklifts) are best for outdoor, uneven surfaces.

Top 2 Fork Truck Classes Manufacturers & Suppliers List

1. OSHA Education Center – Forklift Certification Training

Domain: oshaeducationcenter.com

Registered: 2006 (19 years)

Introduction: Forklift Certification Training | 100% Online Course

– Sales Contact: 1-877-978-7246

– Support Contact: 1-855-481-5553

– Course Duration: 2 hours

– Compliance: Fully compliant with OSHA 1910.178(I) and 1926.602(d)

– Certification: Forklift Certificate and Printable Wallet-Sized Forklift Certification Card

– Validity: Certification valid for three years

– Format: 100% Online Course

– Features: Guar…

2. Logisnext Americas – Forklift Class Overview

Domain: logisnextamericas.com

Registered: 2020 (5 years)

Introduction: There are seven basic types of forklift classes ranging from Class I to Class VII, classified based on fuel type, application, and features.

1. **Class I: Electric Motor Rider Trucks** – Electric motor, can be operated standing or sitting, heavy battery acts as counterweight, versatile, available in 3 or 4 wheels, suitable for indoor and outdoor use. Benefits include quieter operation, reduced f…

Strategic Sourcing Conclusion and Outlook for fork truck classes

In navigating the diverse landscape of fork truck classes, international B2B buyers must prioritize strategic sourcing to align operational needs with the right equipment. Understanding the distinct characteristics of each forklift class—from electric motor riders to rough-terrain models—enables companies to enhance efficiency, safety, and productivity in material handling. Key considerations such as load capacity, terrain type, and fuel source are crucial in selecting the appropriate forklift to minimize operational risks and maximize return on investment.

Illustrative image related to fork truck classes

Moreover, as global markets continue to evolve, the demand for versatile and sustainable material handling solutions is on the rise. Buyers in regions like Africa, South America, the Middle East, and Europe should leverage this opportunity to partner with suppliers who offer not only quality equipment but also comprehensive training and support services.

Looking ahead, the integration of advanced technologies and eco-friendly options in fork truck classes will shape the future of material handling. By committing to strategic sourcing now, businesses can position themselves to thrive in a competitive marketplace, ensuring they are equipped to meet both current demands and future challenges. Engage with reliable suppliers today to drive your operational success forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to fork truck classes

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.