Forging Brass: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for forging brass

Navigating the complexities of sourcing quality forging brass can be a daunting challenge for B2B buyers in today’s global market. The unique properties of brass, primarily composed of copper and zinc, make it a preferred material for a variety of applications, from valve components to plumbing fixtures. However, understanding the nuances of this alloy, including its mechanical properties and the various forging processes, is crucial for making informed purchasing decisions. This guide aims to demystify the world of forging brass by exploring its types, applications, and the critical factors to consider when vetting suppliers.

As international buyers from regions such as Africa, South America, the Middle East, and Europe (including key markets like Germany and Saudi Arabia) navigate their procurement strategies, they face the challenge of ensuring quality, cost-effectiveness, and reliability in their sourcing decisions. Our comprehensive guide provides actionable insights into evaluating supplier capabilities, understanding pricing structures, and identifying the best applications for forged brass products. By empowering buyers with essential knowledge and strategies, this guide not only facilitates informed decisions but also fosters successful partnerships in the global market for forging brass. Equip yourself with the insights needed to streamline your sourcing process and enhance your competitive edge in this dynamic landscape.

Understanding forging brass Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leaded Brass | Contains lead for enhanced machinability and wear resistance | Fasteners, fittings, electrical connectors | Pros: Excellent machinability; durable. Cons: Lead content raises health concerns; may be restricted in some regions. |

| Free-Cutting Brass | High machinability due to the inclusion of sulfur or lead | Precision components, automotive parts | Pros: Ideal for high-volume machining; cost-effective. Cons: Not suitable for high-stress applications. |

| Naval Brass | Contains tin for improved corrosion resistance | Marine fittings, valve components | Pros: Superior corrosion resistance; strong. Cons: Higher cost due to alloying elements. |

| Cartridge Brass | Good ductility and strength, with low zinc content | Ammunition casings, plumbing fixtures | Pros: Excellent forming capabilities; versatile. Cons: Lower corrosion resistance compared to other brass types. |

| Yellow Brass | Balanced copper and zinc content, typically 60-70% copper | Plumbing, HVAC components | Pros: Good corrosion resistance; widely available. Cons: Limited high-temperature applications. |

What Are the Characteristics of Leaded Brass for B2B Buyers?

Leaded brass is characterized by the addition of lead, which significantly enhances its machinability, making it a preferred choice for components requiring intricate designs. It is commonly used in fasteners, fittings, and electrical connectors where durability and precise machining are paramount. B2B buyers should consider the potential health risks associated with lead content and check regional regulations regarding its use, particularly in Europe and North America, where lead restrictions are more stringent.

How Does Free-Cutting Brass Benefit High-Volume Production?

Free-cutting brass is specifically formulated for high machinability, incorporating elements like sulfur or lead to facilitate rapid machining processes. This type of brass is ideal for precision components in the automotive and manufacturing sectors. For B2B buyers, the cost-effectiveness of free-cutting brass makes it attractive for high-volume production runs, though its mechanical strength may limit its application in high-stress environments.

Why Choose Naval Brass for Marine Applications?

Naval brass is distinguished by its tin content, which provides exceptional corrosion resistance, making it ideal for marine environments. It is commonly used in fittings and valve components exposed to seawater and harsh conditions. B2B buyers should weigh the higher costs associated with naval brass against its longevity and performance in corrosive environments, ensuring that the investment aligns with their operational needs.

What Makes Cartridge Brass Suitable for Versatile Applications?

Cartridge brass, with its lower zinc content, offers good ductility and strength, making it suitable for applications such as ammunition casings and plumbing fixtures. Its excellent forming capabilities allow for efficient production of complex shapes. However, B2B buyers should note that while cartridge brass is versatile, its corrosion resistance is not as strong as other brass types, which may limit its use in certain environments.

What Are the Advantages and Disadvantages of Yellow Brass?

Yellow brass is a popular alloy that typically contains 60-70% copper, offering a balanced combination of strength and corrosion resistance. It is widely used in plumbing and HVAC components. B2B buyers appreciate its availability and reasonable cost, but should be aware that yellow brass may not perform well under high-temperature conditions, potentially limiting its applications in heat-intensive environments.

Key Industrial Applications of forging brass

| Industry/Sector | Specific Application of forging brass | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Plumbing and HVAC | Valves and Fittings | Durability and corrosion resistance ensure long-lasting performance in fluid systems. | Compliance with local plumbing standards and certifications. |

| Electrical Engineering | Electrical Connectors | High conductivity and corrosion resistance enhance the reliability of electrical systems. | Ensuring precision machining capabilities for complex designs. |

| Construction and Machinery | Fasteners (Nuts, Bolts, Screws) | Strength and reliability reduce maintenance needs and improve structural integrity. | Sourcing lead-free options for compliance with health regulations. |

| Automotive | Engine Components | Enhanced strength and thermal conductivity improve engine efficiency and performance. | Availability of custom forging services to meet specific design requirements. |

| Marine and Offshore | Marine Hardware | Corrosion resistance in harsh environments ensures longevity and reduces replacement costs. | Understanding regional environmental regulations and certifications. |

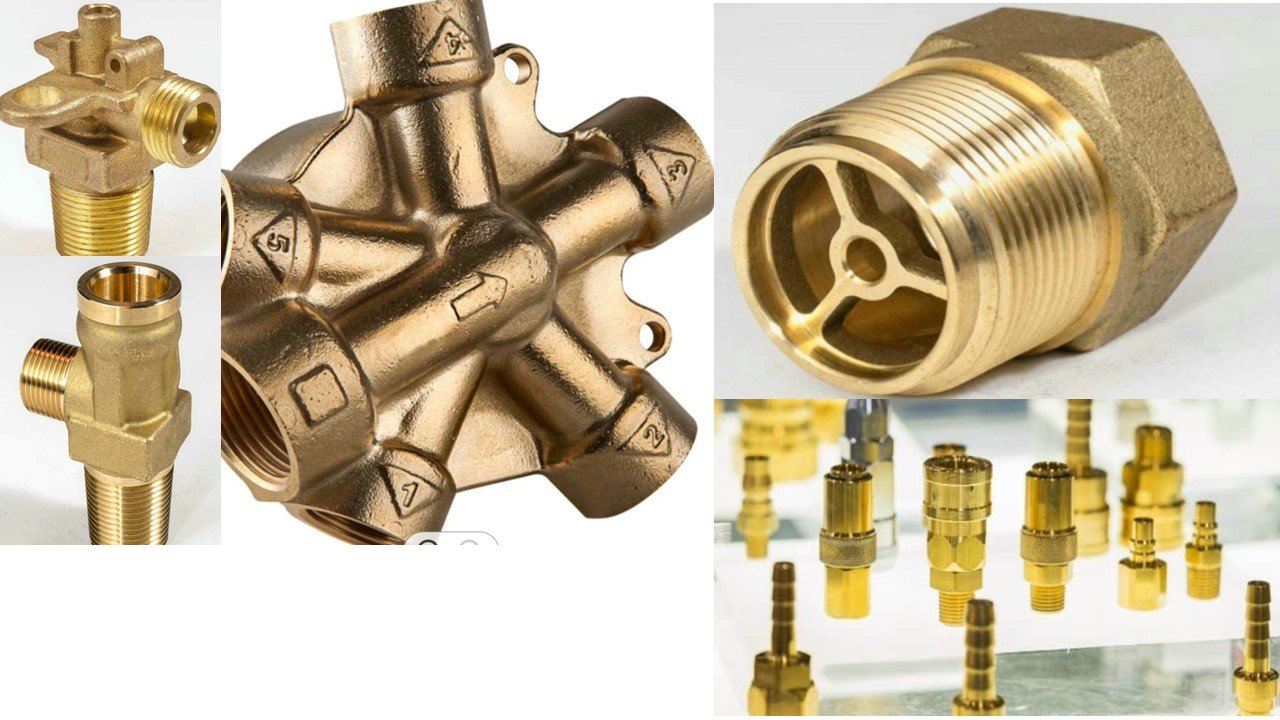

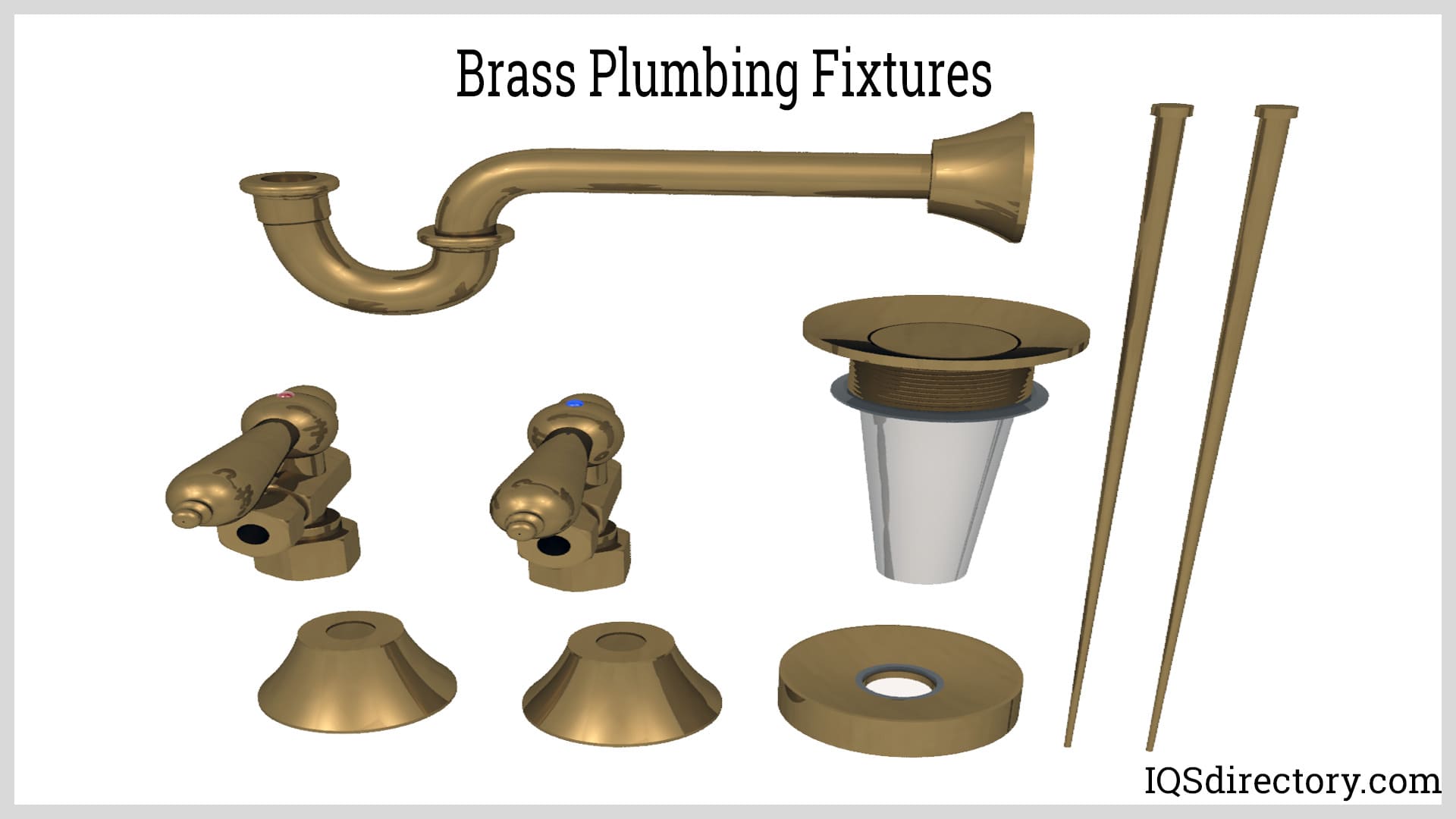

How is Forging Brass Used in Plumbing and HVAC Industries?

In the plumbing and HVAC sectors, forging brass is predominantly utilized for manufacturing valves and fittings. These components require durability and exceptional corrosion resistance to withstand exposure to water and various chemicals. Forged brass components help prevent leaks and failures, which can lead to costly repairs and downtime. International buyers should consider sourcing products that comply with local plumbing standards and certifications to ensure quality and reliability.

What are the Benefits of Forging Brass in Electrical Engineering?

Forging brass is essential in electrical engineering for creating connectors that require high conductivity and resistance to corrosion. These properties are crucial for maintaining the integrity and performance of electrical systems. The ability to produce precise components through forging allows for intricate designs that meet specific technical requirements. Buyers should ensure that their suppliers have advanced machining capabilities to deliver the necessary precision and quality.

How Does Forging Brass Enhance Fasteners in Construction and Machinery?

In the construction and machinery industries, forging brass is commonly used for producing fasteners such as nuts, bolts, and screws. The mechanical properties of forged brass, including its strength and resistance to deformation, contribute to the structural integrity of various assemblies. This reliability minimizes maintenance needs and enhances safety. Buyers should prioritize sourcing lead-free options to comply with health regulations and ensure the safety of their projects.

Why is Forging Brass Important for Automotive Engine Components?

Forged brass finds significant application in automotive engine components due to its enhanced strength and thermal conductivity. These characteristics improve engine efficiency and performance, making forged brass a preferred material for critical parts. Buyers in the automotive sector should seek suppliers that offer custom forging services to meet specific design requirements, ensuring optimal performance in their applications.

How Does Forging Brass Benefit Marine Hardware Applications?

In the marine and offshore industries, forging brass is utilized to manufacture marine hardware that must withstand harsh environmental conditions. The corrosion-resistant properties of forged brass significantly extend the lifespan of components, reducing replacement costs and enhancing reliability. International buyers should familiarize themselves with regional environmental regulations and certifications to ensure compliance and performance in their marine applications.

3 Common User Pain Points for ‘forging brass’ & Their Solutions

Scenario 1: Challenges with Corrosion Resistance in Forging Brass Components

The Problem: B2B buyers often encounter issues with corrosion resistance when sourcing brass components for applications exposed to harsh environments. Industries such as plumbing, HVAC, and marine applications require materials that can withstand moisture, chemicals, and other corrosive agents. Without adequate corrosion resistance, brass components may fail prematurely, leading to costly repairs and downtime. Buyers may also struggle to find suppliers that provide consistent quality and performance in these challenging environments, resulting in uncertainty and risk.

The Solution: To address corrosion resistance concerns, buyers should prioritize sourcing lead-free brass alloys, which offer enhanced durability against environmental factors. When specifying materials, inquire about the exact composition and any protective coatings that may be available. It’s also beneficial to collaborate closely with suppliers who understand your specific application requirements, ensuring they provide brass that meets industry standards for corrosion resistance. Regular testing and validation of components should be a standard practice, enabling buyers to monitor performance and make informed decisions about their suppliers.

Scenario 2: Inconsistent Quality and Mechanical Properties in Forged Brass

The Problem: Another common challenge for B2B buyers is the inconsistency in the quality and mechanical properties of forged brass products. Variability in tensile strength, yield strength, and elongation can lead to component failures, which jeopardize the integrity of the entire assembly. This inconsistency is often exacerbated by differences in manufacturing processes across suppliers, making it difficult for buyers to maintain quality control and predict performance.

The Solution: Buyers should establish clear specifications and standards that outline the desired mechanical properties for their forged brass components. Engage with suppliers who can provide detailed documentation of their manufacturing processes, including material certifications and quality assurance protocols. Implementing a rigorous quality control program that includes third-party inspections or audits can help ensure that the materials received consistently meet the required standards. Additionally, fostering long-term relationships with reliable suppliers can lead to improved communication and collaboration, allowing for better quality assurance and product consistency over time.

Scenario 3: High Production Costs Due to Inefficient Forging Processes

The Problem: B2B buyers frequently face high production costs when sourcing forged brass components, which can arise from inefficient forging processes, excessive waste, and high labor costs. These factors can erode profit margins, particularly in industries where cost competitiveness is critical. Furthermore, suboptimal forging techniques may lead to longer lead times and delays in getting products to market, impacting overall business operations and customer satisfaction.

Illustrative image related to forging brass

The Solution: To mitigate high production costs, buyers should consider working with suppliers that utilize advanced forging techniques, such as closed-die forging or precision forging. These methods can enhance material utilization, minimize waste, and reduce labor costs. Additionally, conducting a thorough cost analysis that includes not only the initial purchase price but also the total cost of ownership can help buyers make more informed decisions. Collaborating with suppliers to optimize the design of components can also reduce material usage and simplify production processes, resulting in lower costs and improved efficiency. Regularly reviewing and streamlining the supply chain can further enhance cost-effectiveness, ensuring that buyers remain competitive in their respective markets.

Strategic Material Selection Guide for forging brass

What Are the Key Materials Used in Forging Brass?

When selecting materials for forging brass, understanding the composition and properties of various brass alloys is crucial. The most common materials used in forging brass are C36000, C37700, and C46400. Each of these alloys has distinct characteristics that affect performance, manufacturability, and suitability for specific applications.

What Are the Key Properties of C36000 Brass Alloy?

C36000, also known as Free-Cutting Brass, is primarily composed of 61% copper and 35% zinc, with small amounts of lead. This alloy is renowned for its excellent machinability, making it ideal for precision components.

- Key Properties: C36000 has a tensile strength of approximately 50,000 psi and a yield strength of around 25,000 psi. It also offers good corrosion resistance, particularly in freshwater environments, and performs well under moderate temperatures and pressures.

- Pros & Cons: Its high machinability reduces manufacturing complexity and costs, making it a popular choice for fittings and connectors. However, the presence of lead raises health and environmental concerns, leading to restrictions in certain markets.

- Impact on Application: C36000 is suitable for applications that require intricate shapes, such as valve components and electrical connectors, but may not be ideal for environments with aggressive chemical exposure.

- Considerations for International Buyers: Buyers in regions like Europe and the Middle East must ensure compliance with regulations regarding lead content, such as RoHS in the EU. Understanding local standards is essential for market entry.

How Does C37700 Brass Alloy Compare?

C37700, or Architectural Bronze, consists of about 60% copper and 40% zinc with trace elements of lead and tin. This alloy is favored for its balance of strength and corrosion resistance.

- Key Properties: C37700 features a tensile strength of around 70,000 psi and excellent resistance to corrosion, making it suitable for outdoor applications.

- Pros & Cons: Its durability and aesthetic appeal make it a preferred choice for architectural applications. However, its higher cost compared to C36000 can be a limiting factor for budget-conscious projects.

- Impact on Application: This alloy is particularly effective in environments exposed to moisture and chemicals, such as plumbing fixtures and marine applications.

- Considerations for International Buyers: Compliance with local standards, such as ASTM and DIN, is critical. Buyers should also consider the aesthetic requirements of their markets, as C37700 offers a distinct appearance.

What About C46400 Brass Alloy?

C46400, often referred to as Naval Brass, contains approximately 60% copper, 39% zinc, and 1% tin. This alloy is specifically designed for marine applications due to its superior corrosion resistance.

- Key Properties: C46400 has a tensile strength of about 70,000 psi and excellent resistance to saltwater corrosion, making it ideal for marine environments.

- Pros & Cons: Its exceptional durability and resistance to corrosion are significant advantages. However, the manufacturing process can be more complex due to its higher melting point, leading to increased costs.

- Impact on Application: This alloy is particularly suited for marine hardware, ship fittings, and other applications exposed to harsh environments.

- Considerations for International Buyers: Buyers should be aware of maritime regulations and standards that govern the use of materials in marine applications, ensuring compliance with international maritime safety standards.

Summary Table of Brass Alloys for Forging

| Material | Typical Use Case for forging brass | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| C36000 | Fittings and connectors | Excellent machinability | Lead content may restrict use | Medium |

| C37700 | Architectural applications | High corrosion resistance | Higher cost than C36000 | High |

| C46400 | Marine hardware | Superior saltwater resistance | Complex manufacturing process | High |

In conclusion, selecting the right brass alloy for forging applications involves careful consideration of mechanical properties, application suitability, and compliance with international standards. Understanding these factors will enable B2B buyers to make informed decisions that align with their operational needs and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for forging brass

What Are the Main Stages of the Manufacturing Process for Forging Brass?

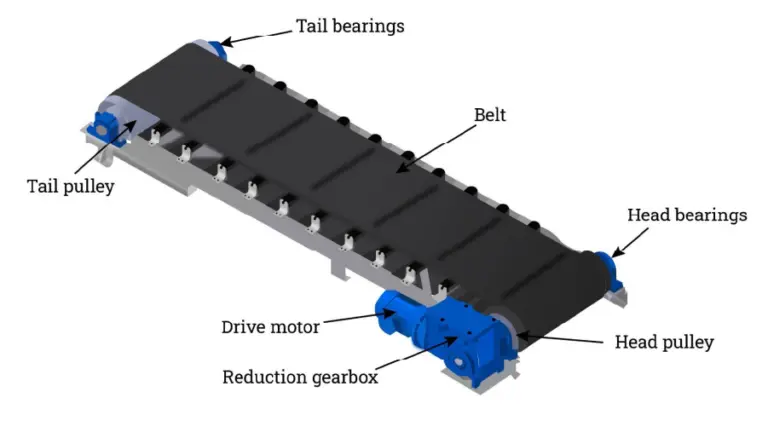

The manufacturing process of forging brass is a meticulous procedure that ensures the production of high-quality components suitable for various industrial applications. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Forging Brass?

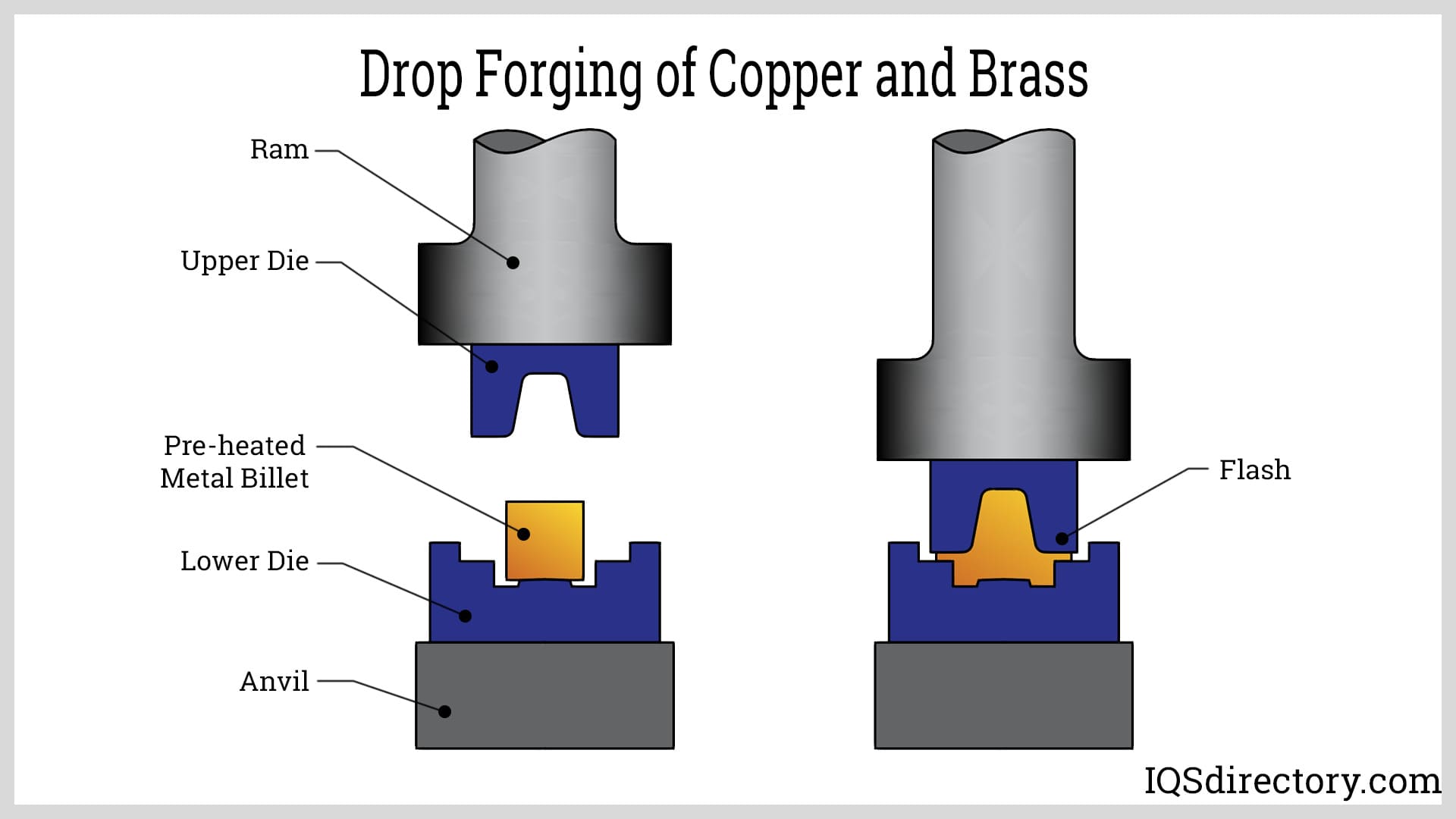

Material preparation begins with selecting the appropriate brass alloy, which typically consists of 60-70% copper and 30-40% zinc, along with trace elements that enhance specific properties. The chosen alloy is then processed into billets or ingots, which are heated to a temperature conducive for forging. This heating phase is critical, as it reduces the metal’s yield strength, allowing for easier deformation during the forging process.

What Techniques Are Used in the Forming Process of Forging Brass?

The forming stage involves applying mechanical force to shape the brass into the desired configuration. There are two primary techniques used in forging brass: hot forging and cold forging.

-

Hot Forging: This method involves heating the brass above its recrystallization temperature, allowing for significant deformation without cracking. Hot forging is ideal for creating complex shapes and is commonly used for components such as valve bodies and fittings.

-

Cold Forging: In contrast, cold forging takes place at room temperature. It is advantageous for producing precise dimensions and enhanced surface finishes. This method is often used for manufacturing small fasteners and electrical connectors, where tight tolerances are essential.

Both techniques ensure that the forged brass exhibits superior mechanical properties, including excellent tensile strength and corrosion resistance.

How Are Forged Brass Components Assembled?

Once the brass components are formed, the assembly stage may involve additional processes such as machining, welding, or threading. These processes ensure that the components fit together accurately and function as intended in their final applications. For instance, fittings and connectors often require precise threading to ensure leak-proof joints in plumbing systems.

What Quality Assurance Measures Are Implemented in Forging Brass?

Quality assurance is a critical aspect of the forging brass manufacturing process, ensuring that the final products meet international standards and customer specifications. Various quality control (QC) measures are implemented throughout the production stages.

Which International Standards Are Relevant for Brass Forging Quality Assurance?

Manufacturers typically adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific standards may apply, such as CE marking for products sold in the European Economic Area and API specifications for components used in the oil and gas sector. Compliance with these standards is essential for establishing credibility and trust with international B2B buyers.

What Are the Key QC Checkpoints in the Brass Forging Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure consistent quality. These include:

Illustrative image related to forging brass

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any subpar materials are rejected before the forging process begins.

-

In-Process Quality Control (IPQC): During the forging and assembly stages, random sampling and testing are conducted to verify that the components meet design specifications. This may include dimensional checks and visual inspections.

-

Final Quality Control (FQC): Once the components are completed, they undergo a final inspection that may involve non-destructive testing methods such as ultrasonic or magnetic particle testing to detect internal flaws.

How Can B2B Buyers Verify the Quality Control of Brass Forging Suppliers?

For B2B buyers, particularly those sourcing from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several strategies to ensure reliability:

What Auditing Procedures Should Buyers Consider?

Conducting audits of potential suppliers is an effective way to assess their quality assurance practices. Buyers can request access to the supplier’s quality management documentation, including their ISO certifications and internal audit reports.

How Can Buyers Access Quality Control Reports?

Buyers should request quality control reports that detail the results of inspections and tests conducted at various stages of production. These reports provide transparency and assurance regarding the quality of the final products.

What Role Do Third-Party Inspections Play in Ensuring Quality?

Engaging third-party inspection services can provide an independent assessment of the manufacturing process and product quality. This is particularly important for international transactions, where buyers may not have the capability to inspect products on-site.

Illustrative image related to forging brass

What Are the Nuances of Quality Control Certifications for International Buyers?

Understanding the nuances of quality control certifications is essential for international B2B buyers. For example, in Europe, compliance with CE marking indicates that a product meets EU safety, health, and environmental protection requirements. In contrast, API certification is vital for products intended for the oil and gas industry, ensuring they meet specific operational standards.

Buyers should also be aware of regional differences in quality expectations and standards. For instance, while German manufacturers may emphasize precision and reliability, Middle Eastern buyers may prioritize durability in harsh environments. Understanding these nuances helps buyers make informed decisions when selecting suppliers.

Conclusion

The manufacturing processes and quality assurance measures for forging brass are critical components that determine the reliability and performance of the final products. By understanding the intricacies of material preparation, forming techniques, and quality control standards, B2B buyers can make informed choices when sourcing forged brass components. Ensuring adherence to international standards and engaging in thorough verification processes will foster trust and long-term partnerships in the global marketplace.

Illustrative image related to forging brass

Practical Sourcing Guide: A Step-by-Step Checklist for ‘forging brass’

To successfully procure forging brass for your business needs, it’s essential to follow a systematic approach. This guide outlines key steps to ensure you select the right materials and suppliers, optimizing quality and cost-effectiveness in your sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the cornerstone of your procurement process. Consider the specific properties you need from the brass, such as tensile strength, yield strength, and corrosion resistance. Determine the alloy composition, typically a mix of copper and zinc, and any additional elements that may enhance performance for your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in forging brass. Look for companies with a proven track record in the industry, as well as those that offer the specific grades of brass you require. Utilize online directories, industry forums, and trade shows to gather a list of potential partners.

Step 3: Evaluate Supplier Certifications

Before finalizing any deals, it’s crucial to verify that suppliers hold relevant certifications. Check for ISO certifications, which indicate adherence to international quality standards. Additionally, inquire about compliance with local regulations, particularly in regions like Europe and the Middle East, where standards can vary significantly.

Step 4: Request Samples and Test Quality

Always request samples before placing large orders. Evaluate the quality of the forging brass by conducting tests on mechanical properties such as hardness and elongation. This step is vital to ensure that the materials meet your specifications and perform reliably in their intended applications.

Step 5: Assess Pricing Structures

Analyze the pricing models offered by your shortlisted suppliers. Consider not only the cost of the material but also any additional fees related to shipping, handling, and customization. Negotiate terms that align with your budget while ensuring that quality is not compromised.

Step 6: Review Lead Times and Delivery Options

Understanding lead times is essential for effective project planning. Discuss delivery schedules with suppliers and ensure they can meet your timeline requirements. Evaluate their logistics capabilities, particularly if you’re sourcing from international suppliers, to avoid delays that could impact your production.

Step 7: Establish Clear Communication Channels

Finally, establish effective communication channels with your chosen supplier. Clarity in communication helps prevent misunderstandings and ensures that any issues can be addressed promptly. Regular updates on order status and any changes in specifications can significantly enhance your sourcing experience.

Illustrative image related to forging brass

By following this structured checklist, B2B buyers can streamline the procurement of forging brass, ensuring they obtain high-quality materials that meet their operational needs.

Comprehensive Cost and Pricing Analysis for forging brass Sourcing

What Are the Key Cost Components in Forging Brass Sourcing?

When sourcing forged brass, understanding the cost structure is crucial for B2B buyers. The primary components that contribute to the overall cost include:

-

Materials: The main cost driver in forging brass is the raw materials, primarily copper and zinc. The prices of these metals can fluctuate significantly based on global market conditions, geopolitical factors, and supply chain disruptions. Buyers should consider the percentage of copper and zinc in the alloy, as variations can affect both price and performance.

-

Labor: Labor costs encompass wages for skilled workers involved in the forging process, from initial setup to finishing. Skilled labor is particularly important in regions with high-quality manufacturing standards. In places like Germany and Saudi Arabia, labor costs may be higher, reflecting the skill level and regulatory environment.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs, impacting the final pricing of forged brass components.

-

Tooling: The tooling costs depend on the complexity of the parts being produced. Custom tooling can be expensive but is necessary for intricate designs. Buyers should be aware of how tooling costs are amortized over production volume.

-

Quality Control (QC): Ensuring that forged brass components meet industry standards requires investment in quality control processes. Certifications and testing can add to the cost but are vital for ensuring reliability, especially in critical applications.

-

Logistics: Shipping and handling costs can vary based on distance, mode of transport, and Incoterms agreed upon in the contract. International buyers should factor in potential tariffs and customs fees.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. This margin can vary widely based on the supplier’s positioning in the market and the competitive landscape.

How Do Price Influencers Impact Forging Brass Costs?

Several factors can influence the pricing of forged brass components:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQ). Higher volumes can lead to lower per-unit costs due to economies of scale. Buyers should negotiate volume commitments to secure better pricing.

-

Specifications and Customization: Custom designs or specific material requirements can significantly affect pricing. More complex specifications typically require additional tooling and labor, which can raise costs.

-

Material Quality and Certifications: High-quality materials and certifications (e.g., ISO, ASTM) may come at a premium but are essential for applications requiring stringent compliance.

-

Supplier Factors: The supplier’s reputation, experience, and location can impact pricing. Established suppliers with a track record of quality may charge more but offer better reliability.

-

Incoterms: The chosen Incoterms can affect the final price. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight), as they dictate who bears the costs and risks during transportation.

What Are the Best Buyer Tips for Cost-Efficiency in Forging Brass?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, here are key strategies to enhance cost-efficiency:

Illustrative image related to forging brass

-

Negotiate Terms: Engage in discussions about pricing, payment terms, and delivery schedules. Building a good relationship with suppliers can lead to better terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, reliability, and performance of the components.

-

Understand Pricing Nuances: Be aware of the pricing landscape in different regions. For instance, sourcing from suppliers in Europe might provide quality assurance but could be more expensive compared to sourcing from emerging markets.

-

Stay Informed: Keep abreast of market trends affecting raw materials and labor costs. This knowledge can empower buyers to make informed decisions and timing for purchases.

-

Seek Multiple Quotes: Don’t settle for the first quote. Obtain multiple quotes from different suppliers to compare prices, quality, and delivery terms.

Disclaimer

The pricing and cost components mentioned above are indicative and can vary based on numerous factors including market conditions, supplier negotiations, and specific project requirements. Buyers are encouraged to conduct thorough due diligence and seek tailored quotes to ensure accurate pricing for their specific needs.

Alternatives Analysis: Comparing forging brass With Other Solutions

Introduction: Understanding Alternatives in Brass Forging

In the competitive landscape of industrial manufacturing, selecting the right material or process is crucial for optimizing performance, cost, and longevity. While forging brass is a popular choice due to its unique mechanical properties, several alternative solutions exist that can cater to similar applications. This analysis will compare forging brass with other viable methods, including forging steel and casting aluminum, providing B2B buyers with actionable insights to make informed decisions.

Comparison Table

| Comparison Aspect | Forging Brass | Forging Steel | Casting Aluminum |

|---|---|---|---|

| Performance | High tensile and yield strength; excellent corrosion resistance | Superior strength and hardness; versatile | Good strength; lower durability than steel and brass |

| Cost | Moderate; higher than steel but lower than some specialty alloys | Generally lower; cost-effective for large volumes | Lower than brass and steel; economical for large parts |

| Ease of Implementation | Requires specialized equipment and expertise | Well-established processes; widely available | Easier for complex shapes; less skill required |

| Maintenance | Low; corrosion-resistant | Moderate; may require protective coatings | Low; generally corrosion-resistant but can deform under stress |

| Best Use Case | Valves, fittings, and electrical connectors | Heavy machinery, automotive components | Large, intricate parts in consumer goods |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Forging Steel?

Forging steel is widely recognized for its remarkable strength and versatility. It is often the preferred choice for heavy machinery and automotive components, where durability is paramount. The cost-effectiveness of steel forging makes it an attractive option for large-scale production. However, it may not offer the same level of corrosion resistance as brass, making it less suitable for applications exposed to harsh environments. Additionally, the need for protective coatings can lead to increased long-term maintenance costs.

How Does Casting Aluminum Compare?

Casting aluminum presents a compelling alternative, particularly for producing large and intricate parts. The process is generally simpler and requires less specialized skill, making it more accessible for manufacturers. Furthermore, aluminum’s lightweight properties can lead to energy savings in applications where weight reduction is critical. On the downside, aluminum may not provide the same strength and durability as forged brass or steel, making it less ideal for high-stress applications. Its susceptibility to deformation under heavy loads can also limit its usability in certain environments.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a solution for your manufacturing needs, it is essential to weigh the specific requirements of your applications against the advantages and disadvantages of each alternative. Forging brass excels in applications demanding excellent corrosion resistance and precise mechanical properties, making it ideal for components like valves and electrical connectors. However, if cost-effectiveness or lighter weight is a priority, forging steel or casting aluminum may be more suitable. Ultimately, understanding the unique characteristics of each option will empower B2B buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for forging brass

What Are the Key Technical Properties of Forging Brass Important for B2B Buyers?

Understanding the technical properties of forging brass is crucial for B2B buyers to ensure they select the right material for their applications. Here are some essential specifications to consider:

1. Material Grade

Material grades for forging brass typically refer to the specific alloy composition, such as C36000 (free-cutting brass) or C28000 (common brass). Each grade has distinct mechanical properties that dictate its suitability for various applications. For instance, higher copper content generally enhances corrosion resistance and conductivity, making it preferable for electrical components. Selecting the appropriate material grade can significantly impact product performance and longevity.

2. Tensile Strength

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before failing. Forging brass generally exhibits high tensile strength, which is essential for components subjected to mechanical loads. For B2B applications, ensuring that the brass can handle the required tensile strength is vital for maintaining structural integrity and safety in end-use products.

3. Yield Strength

Yield strength indicates the maximum stress a material can endure without permanent deformation. A high yield strength in forging brass ensures that components retain their shape under operational stress. This property is particularly important in applications like valves and fittings, where maintaining precise dimensions is crucial for functionality and efficiency.

4. Elongation

Elongation refers to the degree to which a material can be stretched before breaking, typically expressed as a percentage. Forging brass with good elongation properties allows manufacturers to create complex shapes without compromising the material’s integrity. This flexibility is advantageous in intricate designs, reducing the risk of defects during the forging process.

5. Corrosion Resistance

Brass is known for its corrosion-resistant properties, which are critical for components exposed to moisture and chemicals. This resistance extends the service life of products made from forging brass, making it an ideal choice for plumbing fixtures, marine applications, and outdoor hardware. B2B buyers should prioritize corrosion resistance to minimize maintenance costs and enhance product reliability.

What Are Common Trade Terms in the Forging Brass Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the forging brass market. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of forging brass, B2B buyers often work with OEMs to source custom components tailored to specific applications. Understanding the OEM’s role can help buyers ensure compatibility and quality in the final product.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and procurement strategies. Knowing the MOQ helps buyers plan their purchasing effectively, ensuring they meet production needs without overcommitting resources.

Illustrative image related to forging brass

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers asking for price estimates for specific quantities of products or services. In the forging brass industry, an RFQ helps buyers gather competitive pricing and understand lead times, allowing for informed decision-making when selecting suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers engaged in global trade, as they clarify shipping responsibilities, risk management, and cost allocation, ensuring smoother transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the products. In the forging brass industry, lead times can vary significantly based on production schedules and material availability. B2B buyers should consider lead times when planning projects to avoid delays that could impact production schedules.

By understanding these key properties and terminology, B2B buyers can navigate the forging brass market more effectively, ensuring that their procurement decisions align with their operational requirements and business goals.

Navigating Market Dynamics and Sourcing Trends in the forging brass Sector

What Are the Key Market Dynamics and Trends in the Forging Brass Sector?

The global forging brass market is experiencing significant growth driven by various factors, including industrial expansion, rising demand in the automotive and plumbing sectors, and increasing infrastructure investments, particularly in emerging markets such as Africa and South America. Key trends influencing the market include the adoption of advanced manufacturing technologies, such as automation and digitalization, which enhance production efficiency and precision. International B2B buyers, especially from regions like Europe and the Middle East, are increasingly focused on sourcing high-quality brass components that offer superior mechanical properties, durability, and corrosion resistance.

Additionally, as industries strive for greater operational efficiency, there is a growing trend towards just-in-time (JIT) inventory management. This approach reduces lead times and minimizes costs, making it essential for B2B buyers to establish strong relationships with reliable suppliers. The rise of e-commerce platforms is also transforming the sourcing landscape, providing buyers with access to a broader range of suppliers and enabling them to compare prices and quality easily. Furthermore, sustainability is becoming a critical factor in sourcing decisions, pushing manufacturers to adopt greener practices and materials.

How Is Sustainability and Ethical Sourcing Influencing the Forging Brass Sector?

Sustainability is increasingly pivotal in the forging brass sector, driven by environmental concerns and regulatory pressures. The production of brass, primarily composed of copper and zinc, can have significant environmental impacts if not managed responsibly. Consequently, buyers are prioritizing suppliers that demonstrate commitment to sustainable practices, including recycling initiatives, energy-efficient manufacturing processes, and reduced carbon footprints.

Illustrative image related to forging brass

Ethical sourcing is equally important, as companies aim to ensure that their supply chains are free from unethical practices such as child labor and exploitation. Certifications such as ISO 14001 for environmental management and Fair Trade certification for ethical sourcing are becoming essential benchmarks for B2B buyers. Additionally, the use of lead-free brass is gaining traction, particularly in plumbing applications, as health concerns regarding lead exposure push for safer alternatives. By prioritizing suppliers that adhere to sustainability and ethical standards, international buyers can enhance their brand reputation and align with consumer expectations for responsible sourcing.

What Is the Historical Context of Forging Brass in the B2B Landscape?

The history of forging brass dates back thousands of years, with its origins rooted in the early metallurgical practices of ancient civilizations. Initially, brass was created through the natural alloying of copper and zinc, which was later replicated through controlled processes as metallurgy advanced. The industrial revolution marked a significant turning point, where the introduction of mechanical forging techniques allowed for the mass production of brass components, enhancing their availability and application across various industries.

Over the decades, the forging brass sector has evolved with technological advancements, leading to improved methods such as hot and cold forging, which optimize the material properties and production efficiency. Today, forging brass is integral to numerous applications, from plumbing fixtures to electrical connectors, and continues to adapt to the changing demands of global markets. Understanding this evolution is crucial for B2B buyers, as it underscores the reliability and enduring relevance of forged brass components in modern manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of forging brass

-

How do I select the right supplier for forging brass components?

Choosing the right supplier for forging brass involves assessing several key factors. Start by evaluating the supplier’s reputation through reviews and references from past clients. It’s essential to verify their certifications and quality management systems, such as ISO 9001, to ensure adherence to international standards. Additionally, inquire about their production capabilities and experience with specific brass alloys relevant to your needs. Establish communication to gauge their responsiveness and willingness to collaborate on custom requirements, which can be crucial for building a long-term partnership. -

What are the key properties of forging brass that make it suitable for industrial applications?

Forging brass is valued for its excellent mechanical properties, including high tensile and yield strength, which provide structural integrity under stress. Its good elongation allows for intricate shaping during the forging process without compromising strength. Additionally, brass exhibits superior corrosion resistance, making it ideal for applications in harsh environments, such as plumbing and valve components. The alloy’s machinability also facilitates the production of precise components, making it a preferred choice across various industries, including aerospace, automotive, and electronics. -

What customization options are available when sourcing forging brass components?

Most suppliers offer a range of customization options for forging brass components, including variations in alloy composition, dimensions, and surface finishes. Buyers can specify requirements for mechanical properties, such as hardness or tensile strength, tailored to specific applications. Additionally, suppliers may provide design assistance to optimize components for performance and manufacturability. When discussing customization, it’s important to communicate your needs clearly and work collaboratively with the supplier to ensure that the final product meets your specifications. -

What is the minimum order quantity (MOQ) for forging brass components?

The minimum order quantity for forging brass components can vary significantly between suppliers and is influenced by factors such as the complexity of the component, production processes, and material costs. Typically, MOQs may range from a few hundred to several thousand pieces. It’s advisable to discuss your requirements with the supplier upfront to understand their MOQ policies. For smaller orders, some suppliers may offer flexibility or alternative solutions, such as stock items or batch production, which can help meet your needs without incurring excessive costs. -

What payment terms should I expect when sourcing forging brass?

Payment terms for forging brass can vary widely depending on the supplier and the nature of the transaction. Common practices include a percentage upfront as a deposit (typically 30-50%) with the balance due upon delivery or acceptance of the goods. Some suppliers may also offer net payment terms, such as net 30 or net 60 days, allowing buyers time to settle invoices after receipt. It’s crucial to negotiate payment terms that align with your cash flow requirements while ensuring they are clearly outlined in the purchase agreement to avoid any misunderstandings. -

How can I ensure quality assurance for my forging brass components?

To ensure quality assurance, request that your supplier provides detailed information about their quality control processes. Look for suppliers who utilize rigorous testing methods, including dimensional inspections, mechanical property tests, and surface finish evaluations. Certifications such as ISO 9001 can indicate a commitment to quality management. Additionally, consider implementing a quality audit process where you can perform inspections at various stages of production or request third-party inspections to verify that the components meet your specifications before shipping. -

What logistical considerations should I keep in mind when sourcing forging brass internationally?

When sourcing forging brass internationally, consider shipping costs, lead times, and customs regulations. Ensure you understand the Incoterms (International Commercial Terms) that define the responsibilities of buyers and sellers in shipping arrangements. It’s also important to plan for potential delays due to customs clearance, especially in regions with strict import regulations. Collaborating with a logistics partner experienced in international shipping can help streamline the process, ensuring timely delivery and compliance with all legal requirements. -

What are the common applications of forging brass in various industries?

Forging brass is widely used across numerous industries due to its favorable properties. Common applications include manufacturing valve components, fittings and connectors for plumbing and HVAC systems, fasteners such as nuts and bolts, and electrical connectors due to its conductivity. Additionally, forging brass is employed in creating precision parts for the automotive and aerospace industries, where reliability and strength are paramount. Understanding these applications can help buyers identify suitable products for their specific needs and industries.

Top 1 Forging Brass Manufacturers & Suppliers List

1. Brass – Cold Working Insights

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Brass is generally not forgeable, despite being a copper alloy. It is usually cold worked and then annealed. Brass has a large range of cold work motion compared to steel. It can become ‘hot short’, meaning it may crumble if hot worked at the wrong temperature. Hot working brass usually requires getting close to its melting point, which is typically done industrially with specialized equipment.

Strategic Sourcing Conclusion and Outlook for forging brass

Why is Strategic Sourcing Crucial for Forging Brass?

In the competitive landscape of forging brass, strategic sourcing emerges as a critical factor for success. By prioritizing high-quality materials and reliable suppliers, businesses can enhance the mechanical properties of their brass components, ensuring superior performance in applications ranging from plumbing fixtures to electrical connectors. The unique characteristics of forging brass, such as its excellent tensile strength, corrosion resistance, and machinability, make it a highly valuable material across diverse industries.

Moreover, the global demand for forged brass components is on the rise, particularly in regions like Africa, South America, the Middle East, and Europe. Buyers in these markets should leverage strategic sourcing to not only secure the best prices but also to foster long-term partnerships with suppliers who understand the local market dynamics. This approach can lead to significant cost savings and improved product quality, ultimately driving business growth.

As we look to the future, the emphasis on sustainability and innovation in the forging industry will only increase. International B2B buyers are encouraged to adopt a proactive sourcing strategy that aligns with evolving market trends. Engage with trusted suppliers today to explore the full potential of forging brass and position your business for success in an ever-changing landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.