Flexible Baseboard Trim: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for flexible baseboard trim

In the fast-evolving landscape of construction and interior design, sourcing flexible baseboard trim can be a pivotal challenge for B2B buyers looking to enhance aesthetic appeal while ensuring functionality. Flexible baseboard trim is increasingly sought after for its ability to conform to curved surfaces, making it a versatile solution for diverse applications, from residential renovations to commercial projects. However, navigating the global market requires a nuanced understanding of product types, material specifications, and supplier reliability.

This comprehensive guide aims to equip international B2B buyers—especially those in Africa, South America, the Middle East, and Europe (including key markets like Germany and Brazil)—with essential insights into the flexible baseboard trim market. We will delve into various types of flexible baseboard trims available, their applications in different environments, and the factors influencing pricing. Additionally, we’ll cover critical aspects of supplier vetting, ensuring that buyers can make informed decisions that align with their project requirements and budget constraints.

By exploring the intricacies of sourcing flexible baseboard trim, this guide empowers businesses to not only enhance their offerings but also to foster strong partnerships with reliable suppliers. With actionable insights and expert recommendations, you will be well-prepared to navigate the complexities of this dynamic market and elevate your procurement strategy.

Understanding flexible baseboard trim Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Flexible Baseboard | Made from PVC, moisture-resistant, easy to install | Commercial spaces, retail environments | Pros: Durable, low maintenance; Cons: Limited color options. |

| Polyurethane Flexible Trim | Lightweight, paintable, available in various profiles | Residential and commercial interiors | Pros: Aesthetic appeal, versatile; Cons: Higher cost compared to PVC. |

| MDF Flexible Baseboard | Medium-density fiberboard, smooth finish, cost-effective | Budget-conscious projects | Pros: Economical, easy to paint; Cons: Less durable in high-moisture areas. |

| Rubber Baseboard Trim | Flexible and durable, ideal for high-traffic areas | Schools, hospitals, and industrial settings | Pros: Impact-resistant, long-lasting; Cons: Heavier, may require specialized installation. |

| Self-Adhesive Flexible Trim | Easy installation with adhesive backing, flexible for curves | DIY projects, quick renovations | Pros: User-friendly, no tools required; Cons: Adhesive may weaken over time. |

What Are the Key Characteristics of PVC Flexible Baseboard Trim?

PVC flexible baseboard trim is renowned for its durability and moisture resistance, making it a preferred choice for high-humidity environments like bathrooms and kitchens. Its ease of installation is another significant advantage, appealing to contractors and builders who prioritize efficiency. B2B buyers should consider the limited color options available, which may restrict design flexibility in custom projects.

How Does Polyurethane Flexible Trim Stand Out in the Market?

Polyurethane flexible trim is lightweight and offers a variety of profiles, allowing for creative design applications in both residential and commercial settings. Its paintable surface can be customized to match any décor, enhancing its aesthetic appeal. However, B2B buyers should be aware that the higher cost may be a consideration for budget-sensitive projects, despite its long-term value.

Why Choose MDF Flexible Baseboard for Cost-Effective Solutions?

MDF flexible baseboard trim is an economical option that provides a smooth finish, making it easy to paint and integrate into various interior designs. It is particularly appealing for budget-conscious projects where aesthetics are still a priority. However, its lower durability in high-moisture areas could be a drawback for buyers looking for longevity in demanding environments.

What Are the Benefits of Rubber Baseboard Trim in High-Traffic Areas?

Rubber baseboard trim is designed for high-traffic environments, making it ideal for schools, hospitals, and industrial settings. Its flexibility and impact resistance ensure longevity, which is a vital consideration for B2B buyers in these sectors. While it is more durable, the weight of rubber trim may necessitate specialized installation techniques, which could impact overall project costs.

How Do Self-Adhesive Flexible Trims Simplify Installation?

Self-adhesive flexible trims offer a user-friendly installation process, making them perfect for DIY projects and quick renovations. The adhesive backing allows for easy application without the need for tools, appealing to contractors looking for efficiency. However, B2B buyers should consider the potential for the adhesive to weaken over time, which may affect the longevity of the installation.

Key Industrial Applications of flexible baseboard trim

| Industry/Sector | Specific Application of flexible baseboard trim | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Curved wall installations in residential and commercial buildings | Enhances aesthetic appeal while providing a seamless finish | Ensure flexibility for various curves; consider local climate impacts on materials |

| Hospitality | Decorative trim in hotels and resorts | Adds luxury and improves guest experience | Look for moisture and wear resistance; sourcing should align with design themes |

| Retail & Merchandising | Display setups in retail environments | Creates visually appealing product displays that attract customers | Consider customizable options to match branding; durability for high foot traffic areas |

| Healthcare | Trim in hospitals and clinics | Facilitates easy cleaning and maintenance, ensuring hygienic environments | Compliance with health regulations; materials should be easy to sanitize |

| Manufacturing & Warehousing | Trim for factory and warehouse interiors | Protects walls from damage and minimizes maintenance costs | Focus on durability and impact resistance; sourcing should consider local availability |

How is Flexible Baseboard Trim Utilized in Construction & Renovation?

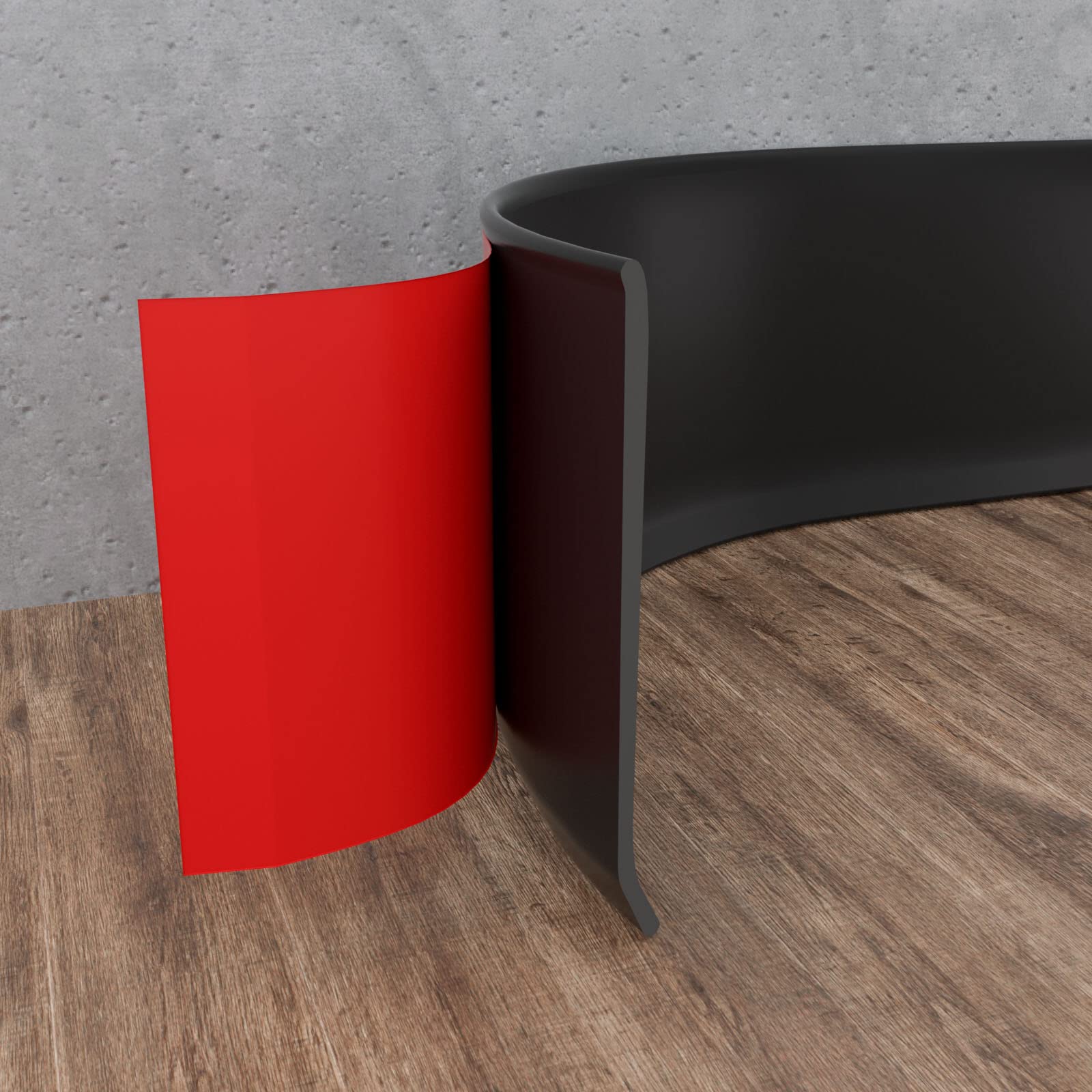

In the construction and renovation sector, flexible baseboard trim is primarily used for curved wall installations in both residential and commercial buildings. This application allows builders to create seamless transitions around rounded surfaces, enhancing the overall aesthetic of the space. For international buyers, especially those from regions with diverse architectural styles, sourcing flexible baseboard trim that can withstand local climate conditions is crucial. Additionally, they must ensure that the materials are compliant with regional building codes to avoid costly modifications during installation.

What Role Does Flexible Baseboard Trim Play in the Hospitality Industry?

In the hospitality sector, flexible baseboard trim is often employed in hotels and resorts to add decorative elements that enhance luxury and comfort. The ability to bend and fit around various architectural features allows for more creative designs, contributing to a memorable guest experience. For B2B buyers in this industry, sourcing options that are both aesthetically pleasing and durable is essential, particularly in high-traffic areas. Additionally, materials should exhibit moisture resistance to maintain appearance and longevity in environments where cleaning and upkeep are frequent.

Illustrative image related to flexible baseboard trim

How is Flexible Baseboard Trim Used in Retail & Merchandising?

Retail environments utilize flexible baseboard trim to create attractive product displays, enhancing visual merchandising efforts. Its flexibility allows for creative designs that can adapt to various display formats, making products more appealing to customers. For international buyers, it’s important to consider customizable options that align with their branding strategies. Durability is also a key factor, as the trim must withstand the wear and tear of high foot traffic while maintaining its visual appeal.

What Benefits Does Flexible Baseboard Trim Offer in Healthcare Settings?

In healthcare facilities, flexible baseboard trim is critical for maintaining hygienic environments. It is used in hospitals and clinics to create smooth transitions between walls and floors, facilitating easier cleaning and minimizing dust accumulation. For B2B buyers in this sector, compliance with health regulations is paramount. They should seek materials that are easy to sanitize and resistant to moisture and stains, ensuring a safe environment for patients and staff alike.

Why is Flexible Baseboard Trim Important for Manufacturing & Warehousing?

In manufacturing and warehousing, flexible baseboard trim serves to protect walls from damage caused by equipment and foot traffic. This application helps to minimize maintenance costs and prolong the lifespan of interior finishes. International buyers in this industry should focus on sourcing durable options that can withstand impact and wear. It’s also important to consider local availability and pricing to ensure cost-effective procurement while maintaining quality standards.

3 Common User Pain Points for ‘flexible baseboard trim’ & Their Solutions

Scenario 1: Difficulty with Installation on Curved Surfaces

The Problem:

B2B buyers often encounter challenges when installing flexible baseboard trim on curved surfaces, such as arches or rounded walls. This installation difficulty can lead to misalignment, visible gaps, and unsightly finishes, which are particularly problematic for contractors working on high-end residential or commercial projects. The need for precise installation can be stressful, especially when tight deadlines are in play and mistakes can lead to costly delays.

The Solution:

To overcome installation challenges, buyers should first assess the specific curvature of the surfaces they are working with. Opt for flexible baseboard trims that are designed for easy bending; these should be available in various materials such as PVC or polyurethane, which can conform to curves without breaking. Additionally, employing a heat gun can make the trim more pliable, allowing for smoother application along curved surfaces. It’s also advisable to utilize adhesive specifically designed for flexible materials to ensure a strong bond. Finally, training your installation team on best practices for working with flexible trim will enhance their confidence and efficiency, leading to a superior finish.

Scenario 2: Concerns About Material Durability and Longevity

The Problem:

Another common pain point for B2B buyers is the concern regarding the durability and longevity of flexible baseboard trim. In regions with high humidity or temperature fluctuations, inferior materials may warp, crack, or deteriorate over time. Buyers, especially those in the construction and renovation sectors, need assurance that their investment in flexible baseboard trim will withstand the test of time and environmental challenges.

The Solution:

To address durability concerns, buyers should prioritize sourcing flexible baseboard trims made from high-quality, moisture-resistant materials such as treated MDF, polyurethane, or PVC. These materials not only resist environmental damage but also provide a robust finish that can endure wear and tear. Conducting thorough supplier evaluations and requesting product samples can help ensure that the chosen materials meet industry standards for durability. Additionally, consider implementing a warranty policy that covers defects or failures, which can provide added peace of mind for both the buyer and their clients.

Scenario 3: Inconsistent Supply and Availability Issues

The Problem:

Supply chain disruptions can significantly impact B2B buyers looking for flexible baseboard trim, leading to delays in project timelines. Inconsistent availability can force buyers to settle for lower-quality alternatives or rush orders that inflate costs. This is particularly problematic for international buyers from regions such as Africa or South America, where logistics can complicate procurement.

Illustrative image related to flexible baseboard trim

The Solution:

To mitigate supply chain issues, buyers should establish strong relationships with multiple suppliers to create a diversified sourcing strategy. This approach not only ensures consistent availability but also enhances negotiation leverage for better pricing. Implementing an inventory management system can help track stock levels and predict future needs, allowing for proactive ordering. Additionally, buyers should explore local manufacturers or distributors to reduce shipping times and costs. Developing a robust supply chain plan that includes contingency measures for unexpected delays can further safeguard against disruptions, ensuring that projects remain on schedule.

Strategic Material Selection Guide for flexible baseboard trim

What Are the Key Materials Used in Flexible Baseboard Trim?

Flexible baseboard trim is available in various materials, each with distinct properties that affect performance, durability, and suitability for specific applications. Understanding these materials can help international B2B buyers make informed decisions that align with their project requirements and regional standards.

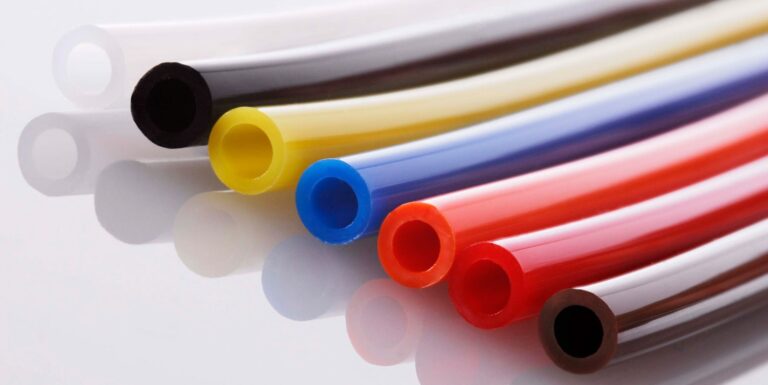

How Does PVC Perform as a Material for Flexible Baseboard Trim?

Polyvinyl Chloride (PVC) is a popular choice for flexible baseboard trim due to its excellent flexibility and resistance to moisture. It is particularly suited for curved applications and can be easily painted or finished to match interior designs. PVC is also resistant to rot, termites, and corrosion, making it ideal for both indoor and outdoor use.

Pros: PVC is lightweight, cost-effective, and easy to install. Its durability against environmental factors makes it a long-lasting option for various climates.

Cons: While PVC is generally durable, it may not withstand extreme temperatures, leading to potential warping in high-heat environments. Furthermore, its aesthetic appeal may not match that of natural materials.

Illustrative image related to flexible baseboard trim

Impact on Application: PVC is compatible with a wide range of adhesives and paints, making it versatile for different design needs.

Considerations for International Buyers: Buyers should ensure that the PVC products comply with local regulations, such as ASTM standards in the U.S. or DIN standards in Germany. Additionally, the availability of PVC may vary by region, affecting supply chains.

What Are the Advantages of Polyurethane for Flexible Baseboard Trim?

Polyurethane is another widely used material for flexible baseboard trim, known for its robustness and aesthetic versatility. This material can be molded into intricate designs and is often used in decorative applications.

Pros: Polyurethane is highly durable, resistant to impacts, and can handle temperature fluctuations without significant deformation. It also offers a high-quality finish, making it suitable for upscale projects.

Cons: The manufacturing process for polyurethane can be more complex and costly than for PVC. It may also require specialized adhesives for installation.

Impact on Application: Polyurethane’s compatibility with various paints and finishes allows for a broad range of design possibilities.

Considerations for International Buyers: Buyers should verify that polyurethane products meet local fire safety and environmental regulations, as these can vary significantly across regions, especially in Europe and the Middle East.

Why Choose MDF for Flexible Baseboard Trim?

Medium Density Fiberboard (MDF) is a composite material that offers a smooth surface for painting and finishing. It is less flexible than PVC or polyurethane but can still be used in certain applications where slight bends are required.

Pros: MDF is economical and provides a uniform surface that is easy to paint. It is also readily available in many markets.

Cons: MDF is susceptible to moisture damage, which limits its use in humid environments. It is also less durable than PVC and polyurethane in terms of impact resistance.

Impact on Application: While MDF can be used for interior applications, it is not recommended for outdoor use due to its moisture sensitivity.

Considerations for International Buyers: Buyers should check for compliance with local standards regarding formaldehyde emissions, as MDF can release VOCs. This is particularly important in markets with strict environmental regulations.

What Role Does Wood Play in Flexible Baseboard Trim?

Natural wood, including softwoods and hardwoods, is sometimes used for flexible baseboard trim, especially in high-end applications. Wood offers a classic aesthetic and can be stained or painted to match various decors.

Pros: Wood is durable and can provide a warm, natural look that is difficult to replicate with synthetic materials. It can also be sanded and refinished.

Illustrative image related to flexible baseboard trim

Cons: Wood is more expensive than synthetic options and can be prone to warping and splitting if not properly treated. It also requires regular maintenance to preserve its appearance.

Impact on Application: Wood is compatible with a variety of adhesives and finishes, but care must be taken to ensure it is adequately protected from moisture.

Considerations for International Buyers: Buyers should ensure that the wood products comply with local forestry and sustainability standards, especially in regions that prioritize eco-friendly practices.

Illustrative image related to flexible baseboard trim

Summary Table of Material Selection for Flexible Baseboard Trim

| Material | Typical Use Case for flexible baseboard trim | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Curved applications in residential settings | Moisture and rot resistance | Limited high-temperature tolerance | Low |

| Polyurethane | Decorative trim in upscale interiors | High durability and aesthetic appeal | Complex manufacturing process | High |

| MDF | Interior applications in budget projects | Economical and easy to paint | Susceptible to moisture damage | Low |

| Wood | High-end decorative applications | Natural aesthetic and durability | Expensive and requires maintenance | High |

This analysis provides a comprehensive overview of the materials available for flexible baseboard trim, enabling B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for flexible baseboard trim

What Are the Main Stages of Manufacturing Flexible Baseboard Trim?

The manufacturing process for flexible baseboard trim involves several critical stages, each designed to ensure that the final product meets both functional and aesthetic requirements. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Processed?

The primary materials used in flexible baseboard trim include PVC, polyurethane, and other composite materials. The process begins with sourcing high-quality raw materials that meet international standards. After procurement, these materials undergo a rigorous preparation phase, where they are cleaned and, if necessary, pre-treated to enhance adhesion and flexibility.

For example, PVC is often processed through a series of thermal and chemical treatments to improve its elasticity and durability. This is crucial for applications that require the trim to bend around curves or unique architectural features. B2B buyers should look for suppliers who use high-grade materials, as the quality directly impacts the product’s longevity and performance.

How Is Flexible Baseboard Trim Formed?

The forming stage is pivotal in shaping the flexible baseboard trim. Techniques such as extrusion and molding are commonly employed. During extrusion, the prepared material is heated and forced through a die to create a continuous profile that matches the desired dimensions of the trim. This method is particularly effective for maintaining uniformity in thickness and flexibility.

In contrast, molding involves pouring the material into a pre-designed mold where it sets and takes the shape of the trim. This method is often used for more intricate designs. B2B buyers should inquire about the forming techniques used by their suppliers, as this can affect not only the cost but also the design capabilities and the trim’s overall aesthetic appeal.

What Happens During the Assembly Stage?

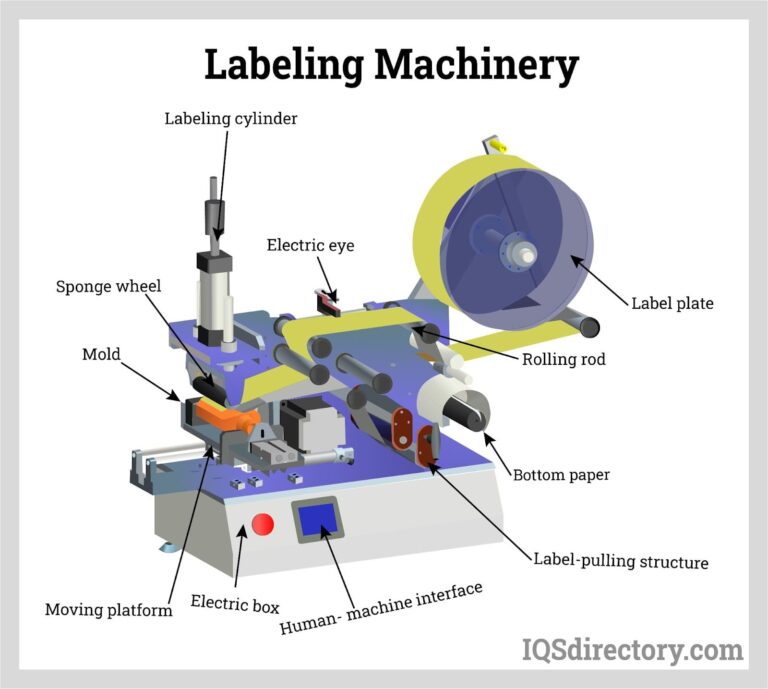

In the assembly stage, different components of the flexible baseboard trim are brought together. This may include attaching pre-fabricated elements, such as corner pieces or connectors, which are crucial for installations that require seamless transitions. Some manufacturers may also incorporate adhesive backing during this stage, allowing for easier installation.

Quality control checkpoints are essential during assembly. Any discrepancies in dimensions or alignment can lead to installation issues down the line. B2B buyers should ensure that their suppliers have a structured assembly process that includes checks for dimensional accuracy and overall product integrity.

How Is the Finishing Process Conducted?

The finishing stage enhances the aesthetic and functional properties of the flexible baseboard trim. This may involve painting, priming, or applying protective coatings to ensure durability against environmental factors. For instance, exterior trims often receive additional weather-resistant finishes, while interior trims may be painted in various colors to match customer preferences.

B2B buyers should prioritize suppliers who offer customizable finishing options, as this can provide significant value in terms of meeting specific project requirements and enhancing the visual appeal of installations.

What Quality Assurance Measures Are Essential for Flexible Baseboard Trim?

Quality assurance (QA) is a non-negotiable aspect of manufacturing flexible baseboard trim. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain a systematic approach to quality management, which is crucial for consistency and reliability.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is a widely recognized standard that focuses on quality management systems. Additionally, suppliers may need to comply with regional standards such as CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards.

For buyers in Africa, South America, and the Middle East, understanding local compliance requirements is vital. Different regions may have specific regulations that affect product specifications, so B2B buyers should work closely with suppliers to ensure compliance.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integral to the manufacturing process of flexible baseboard trim. These checkpoints typically include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the quality of the ongoing production. This can include measuring dimensions, checking for defects, and ensuring the proper functioning of machinery.

- Final Quality Control (FQC): Before the product is packaged and shipped, a final inspection is conducted to verify that the finished trim meets all specified requirements and standards.

B2B buyers should request detailed reports on these quality control processes from suppliers to ensure that all products adhere to the required specifications.

Illustrative image related to flexible baseboard trim

How Can B2B Buyers Verify Supplier Quality Control?

To verify a supplier’s quality control processes, B2B buyers can adopt several strategies:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and quality assurance practices. This allows buyers to assess compliance with international standards firsthand.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes, including results from IQC, IPQC, and FQC stages. Regular reports can help buyers track quality trends and identify potential issues.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures. This is particularly beneficial for international transactions where buyers may not have direct access to suppliers.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is crucial. Different countries may have varying requirements, and certifications recognized in one region may not hold the same value in another.

For instance, European buyers often prioritize CE marking, while buyers in South America may look for compliance with local safety standards. Buyers should engage with suppliers who understand these nuances and can provide appropriate certifications for their target markets.

In conclusion, the manufacturing and quality assurance processes for flexible baseboard trim are multifaceted and require careful consideration. By understanding these processes and implementing thorough verification strategies, B2B buyers can ensure they source high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flexible baseboard trim’

To effectively procure flexible baseboard trim, B2B buyers must navigate a range of considerations that impact both product quality and supply chain efficiency. This guide provides a structured checklist to ensure a successful sourcing process, tailored for international buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

Illustrative image related to flexible baseboard trim

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before sourcing flexible baseboard trim. Determine the material type, dimensions, and flexibility requirements based on your project needs. Consider factors such as moisture resistance and durability, particularly if the trim will be used in varying climates or environments.

Step 2: Research Market Trends and Standards

Understanding current market trends and industry standards can significantly influence your sourcing decisions. Investigate what materials are favored in your target markets and any relevant compliance certifications. This knowledge will help ensure that the products you source meet both regional regulations and customer expectations.

Step 3: Evaluate Potential Suppliers

Thoroughly vetting suppliers is crucial to securing high-quality products. Request detailed company profiles, product samples, and case studies showcasing their past work in similar projects. Look for testimonials or references from clients within your industry to gauge their reliability and service quality.

- Tip: Check if suppliers have established partnerships with reputable manufacturers to ensure product authenticity.

Step 4: Request and Compare Quotes

Once you have identified potential suppliers, request detailed quotations that include pricing, delivery times, and payment terms. Comparing multiple quotes allows for a better understanding of the market rates and helps identify any hidden costs. Ensure that the quotes reflect the specific product specifications you require.

Step 5: Assess Shipping and Logistics Options

Logistics can significantly impact your procurement process, especially when sourcing from international suppliers. Evaluate shipping options, lead times, and customs regulations that may apply to your imports. Consider working with suppliers that offer transparent shipping policies and reliable delivery schedules to avoid disruptions.

Step 6: Verify Quality Assurance Processes

Quality assurance is critical in maintaining product standards. Inquire about the supplier’s quality control measures, including any testing and certification processes their products undergo. A reliable supplier should be willing to share information about their quality assurance protocols to assure you of their commitment to excellence.

Step 7: Establish Clear Communication Channels

Effective communication with your supplier is vital throughout the sourcing process. Ensure that you have established clear channels for discussing orders, addressing concerns, and providing feedback. A responsive supplier will enhance your overall purchasing experience and foster a long-term partnership.

By following this checklist, B2B buyers can streamline their sourcing process for flexible baseboard trim, ensuring that they secure quality products while navigating the complexities of international procurement.

Comprehensive Cost and Pricing Analysis for flexible baseboard trim Sourcing

What Are the Key Cost Components in Sourcing Flexible Baseboard Trim?

When sourcing flexible baseboard trim, understanding the cost structure is essential for effective budget management and supplier negotiations. The primary cost components include:

Illustrative image related to flexible baseboard trim

-

Materials: The choice of materials significantly impacts pricing. Common materials for flexible baseboard trim include PVC, polyurethane, and MDF. Each material has varying costs, durability, and aesthetic qualities, which can influence the overall price.

-

Labor: Labor costs encompass the workforce involved in manufacturing the trim. This includes skilled labor for production as well as the labor costs associated with installation if applicable. Depending on the region, labor costs can vary widely, affecting the final price.

-

Manufacturing Overhead: This includes costs related to the production facility, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can lower these overhead costs, thus impacting the pricing strategy.

-

Tooling: Custom tooling may be required for specific designs or profiles, which adds to the initial investment. This is particularly relevant for buyers seeking unique or branded profiles that require specialized production setups.

-

Quality Control (QC): Ensuring product quality involves additional costs. Rigorous QC processes help maintain standards but can increase the price. Certifications for quality assurance can also add to costs but may be necessary for compliance in certain markets.

-

Logistics: Shipping and handling costs, including freight and customs duties for international transactions, are critical components of total cost. These costs can fluctuate based on shipping distance, volume, and chosen transport methods.

-

Margin: Suppliers will include a profit margin on top of their costs. Understanding typical margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Impact Flexible Baseboard Trim Pricing?

Several factors influence the pricing of flexible baseboard trim, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to lower per-unit costs. Suppliers may offer significant discounts for large orders, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Custom specifications can drive up costs due to the need for specialized production processes. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., eco-friendly certifications) typically result in higher prices. Buyers should consider the long-term benefits of investing in quality versus cheaper alternatives.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their proven quality and service, while less reputable suppliers might offer lower prices but with increased risk.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall costs.

What Tips Can Help Buyers Optimize Costs in Flexible Baseboard Trim Sourcing?

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Highlighting your purchasing power and potential for future business can lead to favorable terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just upfront costs. A higher initial investment in durable, quality materials may yield savings over time through reduced maintenance and replacement needs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, trade tariffs, and local market conditions that may affect pricing. Establishing relationships with local suppliers can also mitigate some of these risks.

-

Market Research: Conduct thorough market research to understand prevailing prices and trends in different regions, especially in target markets like Africa, South America, the Middle East, and Europe. This knowledge will enhance negotiation power and supplier selection.

-

Disclaimer on Indicative Prices: Always approach pricing with the understanding that quoted prices can fluctuate based on market conditions, demand, and availability. Request updated quotes regularly to ensure budget accuracy.

By understanding these cost structures and price influencers, B2B buyers can make informed decisions that optimize their sourcing strategies for flexible baseboard trim.

Alternatives Analysis: Comparing flexible baseboard trim With Other Solutions

In the realm of interior design and construction, selecting the right baseboard trim solution is crucial for aesthetic appeal and functionality. While flexible baseboard trim is a popular choice for its adaptability to curved surfaces, various alternative solutions can also meet similar needs. This analysis will compare flexible baseboard trim with two viable alternatives: rigid baseboard trim and wall paneling systems, providing insights that can assist B2B buyers in making informed decisions.

| Comparison Aspect | Flexible Baseboard Trim | Rigid Baseboard Trim | Wall Paneling Systems |

|---|---|---|---|

| Performance | Excellent for curves; adaptable to various designs | Strong and durable; limited to straight applications | Versatile; can cover large areas and add texture |

| Cost | Moderate cost per linear foot | Typically lower cost; varies by material | Higher initial cost due to installation complexity |

| Ease of Implementation | Requires specific tools for installation | Generally easier; standard installation methods | Complex; often requires professional installation |

| Maintenance | Low maintenance; paintable and stainable | Low maintenance; durable finishes available | Moderate; may need periodic repainting or touch-ups |

| Best Use Case | Ideal for custom designs and curved walls | Best for traditional designs and straight walls | Suitable for creating feature walls and large-scale applications |

What Are the Pros and Cons of Rigid Baseboard Trim?

Rigid baseboard trim is a classic choice, often made from wood, MDF, or PVC. Its primary advantage lies in its durability and the ability to provide a clean, finished look to straight walls. Installation is typically straightforward, requiring fewer specialized tools compared to flexible options. However, it falls short in applications involving curves or intricate designs, as it cannot bend to fit unconventional wall shapes. Additionally, while rigid trims can be cost-effective, the cost can increase significantly with high-quality materials or custom profiles.

Illustrative image related to flexible baseboard trim

How Do Wall Paneling Systems Compare to Flexible Baseboard Trim?

Wall paneling systems offer a unique approach to interior design, allowing for the coverage of entire walls rather than just the base. They can add significant texture and character to a space. Their versatility means they can be designed to fit various styles, from traditional to contemporary. However, wall paneling often comes with a higher initial cost due to the complexity of installation, which may necessitate professional help. Maintenance can also be more demanding, as panels may require repainting or repairs over time, especially in high-traffic areas.

Making the Right Choice: How Should B2B Buyers Decide?

When evaluating baseboard trim solutions, B2B buyers should consider their specific project requirements, including design aesthetics, budget constraints, and installation capabilities. Flexible baseboard trim is an excellent choice for projects requiring adaptability and custom design features, particularly in spaces with curves. Rigid trim offers a more traditional solution for straightforward applications at a lower cost, while wall paneling systems can provide an impactful design element for larger areas. Ultimately, the best choice will depend on balancing these factors to align with the project’s overall goals and the buyer’s long-term vision.

Essential Technical Properties and Trade Terminology for flexible baseboard trim

What Are the Key Technical Properties of Flexible Baseboard Trim?

Understanding the technical properties of flexible baseboard trim is crucial for B2B buyers looking to make informed purchasing decisions. Here are some essential specifications to consider:

-

Material Composition

– Flexible baseboard trim is often made from materials like polyurethane, PVC, or medium-density fiberboard (MDF). Each material has unique properties, such as moisture resistance or durability. Buyers should choose based on the intended application—whether for interior or exterior use—and the environmental conditions the trim will face. -

Flexibility Rating

– This property indicates how well the trim can bend without breaking. A higher flexibility rating is essential for applications involving curves or irregular surfaces. Understanding this rating helps buyers select the right trim for specific architectural designs, ensuring a seamless fit. -

Length and Width Specifications

– Flexible baseboard trim typically comes in various lengths (e.g., 12 ft or 20 ft) and widths (e.g., 3-1/2 in or 5-1/4 in). These dimensions are critical for calculating material requirements for projects. Buyers should ensure the selected dimensions align with their project specifications to avoid excess waste or shortages. -

Finish Type

– The trim can be unfinished, primed, or pre-finished. A pre-finished option saves time during installation, while an unfinished option allows for customization. Understanding the finish type helps buyers align their choices with project timelines and aesthetic requirements. -

Durability Features

– Many flexible baseboard trims come with properties like scratch resistance, rot resistance, and UV stability. These features are vital for ensuring long-lasting performance, particularly in high-traffic or outdoor environments. Buyers should prioritize durability to reduce maintenance and replacement costs. -

Moisture Resistance

– This property is crucial for areas prone to humidity or water exposure, such as bathrooms and kitchens. Flexible trims with moisture-resistant properties can prevent warping or deterioration, making them a more reliable choice for such environments.

What Common Trade Terminology Should B2B Buyers Know?

Familiarity with industry jargon can facilitate smoother transactions and communication. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships helps buyers assess the quality and authenticity of the products they are purchasing. -

MOQ (Minimum Order Quantity)

– MOQ represents the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ is vital for budget planning and inventory management, especially for businesses aiming to minimize excess stock. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is a standard practice in B2B transactions that helps buyers compare offers and negotiate terms effectively. -

Incoterms (International Commercial Terms)

– These are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms helps buyers clarify shipping responsibilities, costs, and risk levels. -

Lead Time

– This term refers to the time taken from placing an order to receiving the goods. Knowledge of lead times is essential for project planning and scheduling, ensuring that materials arrive when needed. -

Warranty Period

– This indicates the duration for which the manufacturer guarantees the product’s performance. A longer warranty period often reflects higher product quality and can be a deciding factor for buyers looking for reliable solutions.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing flexible baseboard trim, ultimately enhancing project outcomes and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the flexible baseboard trim Sector

What Are the Key Market Dynamics and Trends Impacting the Flexible Baseboard Trim Sector?

The flexible baseboard trim market is experiencing a transformative phase driven by several global factors. Increased urbanization and rapid construction activities in emerging economies, particularly in Africa, South America, and parts of the Middle East, are propelling demand for versatile and adaptable building materials. These regions are witnessing a surge in residential and commercial projects, creating a significant market for flexible baseboard trims that can accommodate various architectural designs, including curves and intricate layouts.

Technological advancements in manufacturing processes are further enhancing product offerings. Innovations such as automated production lines and improved material formulations are leading to higher quality and more durable products. Additionally, the rise of e-commerce platforms has streamlined the sourcing process for international buyers, providing easier access to a diverse range of flexible baseboard trim options. This trend is particularly notable among B2B buyers from Europe, such as Germany and Brazil, who seek both quality and variety in their procurement strategies.

Emerging trends in design aesthetics are also influencing market dynamics. The growing preference for minimalist and modern interiors is driving demand for sleek and stylish baseboard solutions that can seamlessly blend into various environments. As a result, suppliers are focusing on producing customizable options that cater to specific customer needs, enabling B2B buyers to differentiate their offerings in a competitive marketplace.

How Are Sustainability and Ethical Sourcing Shaping the Flexible Baseboard Trim Market?

Sustainability is increasingly becoming a pivotal factor in the flexible baseboard trim sector. With heightened awareness of environmental issues, B2B buyers are prioritizing products that minimize ecological impact. This shift is prompting manufacturers to explore sustainable materials, such as recycled plastics and responsibly sourced wood, which not only reduce waste but also appeal to environmentally conscious consumers.

Ethical sourcing practices are gaining traction as well. Buyers are now more inclined to partner with suppliers who demonstrate transparency in their supply chains and adhere to fair labor standards. This focus on ethical practices is not only a response to consumer demand but also a strategic move to enhance brand reputation and customer loyalty. Certifications such as FSC (Forest Stewardship Council) for wood products and other ‘green’ certifications are becoming essential for suppliers aiming to meet the expectations of discerning B2B buyers.

Moreover, incorporating sustainable practices into product development is proving beneficial for businesses. Companies that invest in eco-friendly manufacturing processes often experience reduced costs in the long term through energy savings and waste reduction, ultimately leading to a more resilient business model. As sustainability becomes a core value, B2B buyers must consider suppliers that align with these principles to ensure they remain competitive in a rapidly evolving market.

What Is the Historical Context of Flexible Baseboard Trim in B2B?

The evolution of flexible baseboard trim can be traced back to the increasing complexity of architectural designs. Initially used in more straightforward applications, flexible trims have gained popularity as architectural styles have evolved to include curves and unique shapes. The introduction of new materials, such as PVC and polyurethane, has broadened the scope of flexibility, allowing for innovative applications in both interior and exterior environments.

Illustrative image related to flexible baseboard trim

Historically, the flexible baseboard trim sector was primarily dominated by traditional materials like wood, which limited design possibilities. However, the advent of synthetic materials has transformed the landscape, enabling manufacturers to produce lightweight, durable, and moisture-resistant trims that meet diverse aesthetic and functional requirements. This transition has not only expanded the market but has also made flexible baseboard trims a staple in modern construction and renovation projects worldwide.

As the market continues to grow, international B2B buyers are positioned to leverage these advancements, ensuring they remain at the forefront of industry trends and consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of flexible baseboard trim

-

How do I choose the right flexible baseboard trim for my project?

Choosing the right flexible baseboard trim involves considering both the material and design needs of your project. Materials like PVC, polyurethane, and MDF offer varying levels of durability, moisture resistance, and ease of installation. For curves and corners, select a trim that is specifically labeled as flexible. Additionally, consider the finish and color that will best complement your space. Collaborating with your supplier can also provide insights on what has worked best for similar projects in your region. -

What are the common uses for flexible baseboard trim in commercial settings?

Flexible baseboard trim is commonly used in commercial environments such as retail spaces, hotels, and healthcare facilities where aesthetics and functionality are crucial. It allows for seamless integration along curved walls and corners, providing a polished look. Additionally, its moisture and impact resistance make it ideal for high-traffic areas, ensuring longevity and minimizing maintenance costs. When sourcing, inquire about specific applications and success stories from suppliers to better understand suitability for your project. -

What customization options are available for flexible baseboard trim?

Many manufacturers offer customization options for flexible baseboard trim, including various lengths, widths, colors, and finishes. Some suppliers can even provide bespoke designs to meet specific architectural requirements. When negotiating with suppliers, discuss your project needs and any unique specifications, such as branding or color matching, to ensure the final product aligns perfectly with your vision. Be sure to confirm lead times for custom orders, as they may vary significantly. -

What are the minimum order quantities (MOQ) for flexible baseboard trim?

Minimum order quantities for flexible baseboard trim can vary widely by supplier and region. Generally, MOQs range from a few hundred to several thousand linear feet, depending on the manufacturer’s production capabilities and the specific trim style. It’s advisable to discuss your projected needs with suppliers early in the sourcing process to ensure they can accommodate your order size without compromising on quality or delivery timelines. -

What payment terms should I expect when sourcing flexible baseboard trim internationally?

Payment terms can vary significantly among international suppliers, typically including options like net 30, net 60, or requiring upfront payments. Some suppliers may offer letters of credit or escrow services for larger orders to ensure security for both parties. It’s crucial to negotiate clear payment terms upfront to avoid misunderstandings. Additionally, consider currency fluctuations and transaction fees when budgeting for your purchase. -

How do I vet suppliers for flexible baseboard trim to ensure quality?

To vet suppliers effectively, start by checking their industry reputation and experience in manufacturing flexible baseboard trim. Request samples of their products to evaluate quality firsthand. It’s also beneficial to read reviews and testimonials from other B2B buyers. Additionally, inquire about their manufacturing processes, certifications, and quality assurance protocols to ensure they adhere to industry standards. Establishing direct communication can also provide insights into their reliability and customer service. -

What logistics considerations should I keep in mind when importing flexible baseboard trim?

When importing flexible baseboard trim, consider shipping methods, costs, and timelines. Sea freight is typically more cost-effective for bulk orders, while air freight offers speed but at a higher cost. Be aware of customs regulations in your country and ensure all necessary documentation is in order to avoid delays. Additionally, factor in potential tariffs and taxes that could affect your overall budget. Collaborating with a logistics partner experienced in international shipping can help streamline this process. -

What quality assurance practices should I look for in flexible baseboard trim suppliers?

Quality assurance practices are vital to ensure the integrity of flexible baseboard trim. Look for suppliers that implement strict quality control measures throughout the production process, including regular inspections and testing for durability, flexibility, and finish quality. Certifications from recognized industry standards, such as ISO 9001, can also indicate a commitment to quality. Request documentation of their QA processes and any third-party inspections to ensure they meet your project requirements.

Top 4 Flexible Baseboard Trim Manufacturers & Suppliers List

1. Next Day Moulding – Flex Baseboard Moulding

Domain: nextdaymoulding.com

Introduction: Flex Baseboard Moulding allows for a bend along an inside or outside curved application. It is stocked in 12 foot rolls, ready to take paint for both interior and exterior applications. Available sizes include: 9/16 X 3-1/2 X 12 FT (Item Code: FLEX-662), 9/16 X 5-1/4 X 12 FT (Item Code: FLEX-L163E), and 5/8 X 7-1/4 X 12 FT (Item Code: FLEX-L163E7). Each product is sold as a pack of 1.

2. Classic Ceilings – Decorative Flexible Baseboards

Domain: crownmoldings.net

Registered: 1999 (26 years)

Introduction: This company, Classic Ceilings – Decorative Flexible Baseboards, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Rubber Baseboard Trim – Durable Solution for Commercial Applications

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Rubber baseboard trim is often used in commercial applications, particularly in healthcare or manufacturing facilities that require frequent washdown procedures. It is noted for its durability and ability to mimic the appearance of MDF while providing the resilience of a through-color rubber body. However, it is important to consider that rubber baseboards may hold mold if not properly maintained….

4. Flexible Moulding Concepts – Flexible Base Moulding

Domain: flexiblemouldingconcepts.com

Registered: 2009 (16 years)

Introduction: Base moulding, also known as “skirting board,” is used to conceal the junction of an interior wall and floor, protecting the wall from impacts while adding a decorative touch. Flexible base moulding comes in various heights and styles, ranging from 3 inches to 9 1/4 inches. Flexible Moulding Concepts offers Duraflex by Resinart, a trusted supplier for over 40 years, with over 18,000 moulding patte…

Strategic Sourcing Conclusion and Outlook for flexible baseboard trim

Flexible baseboard trim presents an exceptional opportunity for international buyers looking to enhance their product offerings in diverse markets. The adaptability of flexible baseboard moulding allows for seamless integration into both interior and exterior applications, catering to a variety of architectural styles and customer preferences. Key considerations in strategic sourcing include evaluating product quality, understanding local market needs, and ensuring reliable supply chains that can meet demand fluctuations.

By prioritizing strategic sourcing, businesses can secure competitive pricing, enhance product availability, and foster strong relationships with manufacturers. This approach not only mitigates risks associated with supply disruptions but also positions companies to respond effectively to emerging market trends.

As the demand for innovative and versatile building materials continues to grow, B2B buyers from Africa, South America, the Middle East, and Europe should take proactive steps to explore partnerships with reputable suppliers. Investing in flexible baseboard trim can significantly elevate your product portfolio, driving customer satisfaction and loyalty. Embrace this opportunity to differentiate your offerings and stay ahead of the competition in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.