Flexible Baseboard: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for flexible baseboard

In the ever-evolving landscape of construction and interior design, sourcing flexible baseboard solutions that meet diverse aesthetic and functional requirements can be a daunting task for international B2B buyers. Flexible baseboards not only offer the adaptability to fit curved surfaces but also provide a seamless finish that enhances the visual appeal of any space. This comprehensive guide delves into the myriad options available, covering the different types of flexible baseboards, their applications across various sectors, and the factors influencing cost.

Moreover, the guide emphasizes the importance of supplier vetting processes, ensuring buyers can confidently select reputable manufacturers and distributors who adhere to quality standards. With a focus on empowering B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Brazil—this resource equips decision-makers with actionable insights for informed purchasing. By addressing common challenges faced in the sourcing process, such as compatibility with local building codes and material durability, this guide serves as an invaluable tool for navigating the global market for flexible baseboard solutions.

Whether you’re looking to enhance residential interiors or commercial spaces, understanding the nuances of flexible baseboard options will enable you to make strategic purchasing decisions that align with your project goals.

Understanding flexible baseboard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Flexible Baseboard | Lightweight, moisture-resistant, and easy to install. | Commercial buildings, retail spaces. | Pros: Cost-effective, versatile. Cons: Limited aesthetic appeal. |

| Polyurethane Flexible Baseboard | Durable, paintable, and suitable for interior/exterior. | Residential projects, high-end designs. | Pros: High durability, attractive finish. Cons: Higher cost than PVC. |

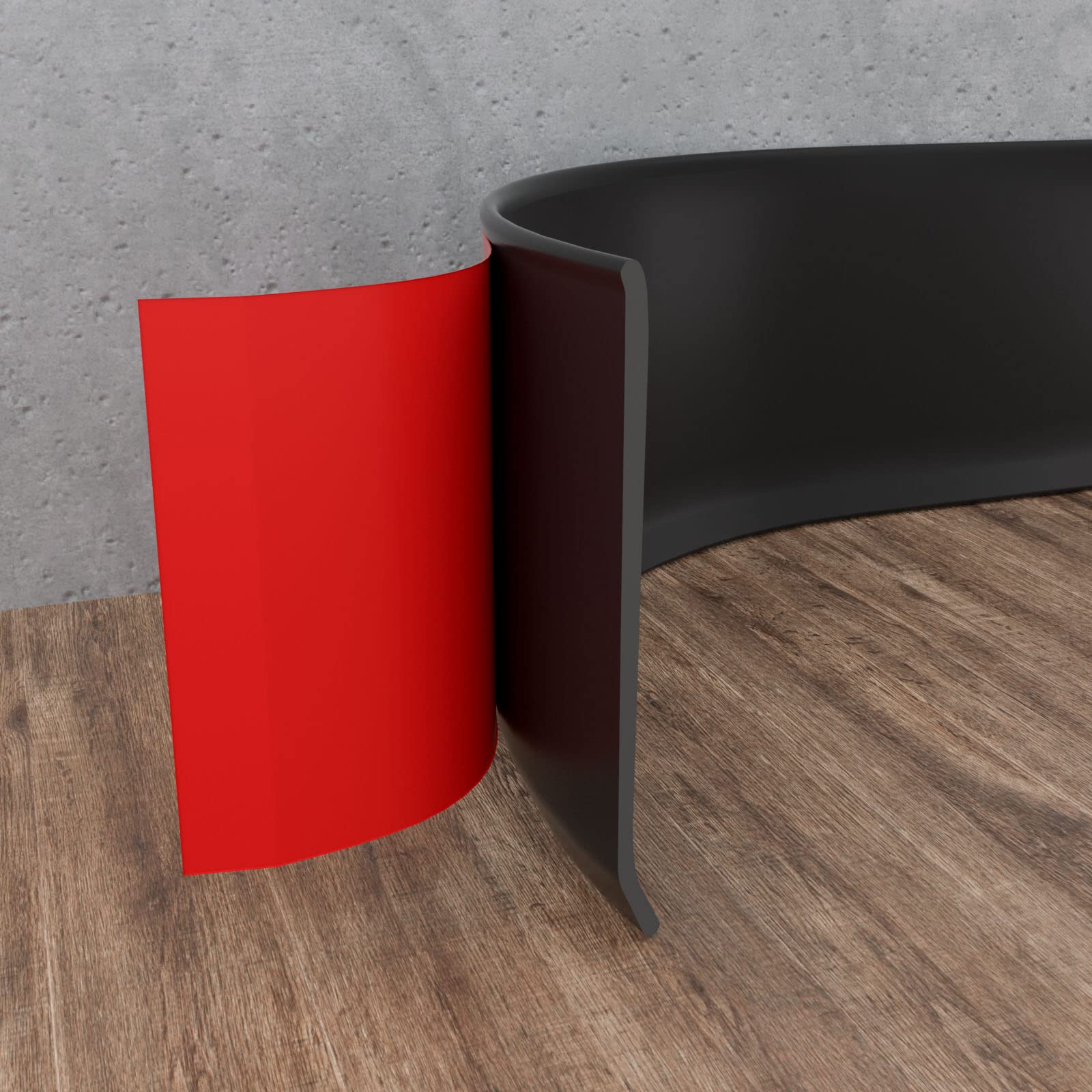

| Self-Adhesive Flexible Baseboard | Quick installation with adhesive backing. | DIY projects, temporary installations. | Pros: Easy to install, no tools required. Cons: Less durable over time. |

| Resin Flexible Baseboard | Strong and impact-resistant, available in various styles. | High-traffic areas, industrial settings. | Pros: Excellent durability, customizable. Cons: Heavier and may require professional installation. |

| MDF Flexible Baseboard | Affordable, can be painted or stained, good for curves. | Residential renovations, commercial spaces. | Pros: Cost-effective, versatile design options. Cons: Susceptible to moisture damage. |

What Are the Characteristics of PVC Flexible Baseboard?

PVC flexible baseboard is recognized for its lightweight nature and moisture-resistant properties, making it ideal for various environments, especially in commercial settings. Its ease of installation is a significant advantage, allowing for quick application in retail spaces and offices. However, while it is cost-effective and versatile, its aesthetic appeal may not meet the expectations of high-end projects.

How Does Polyurethane Flexible Baseboard Stand Out?

Polyurethane flexible baseboard offers a blend of durability and aesthetic appeal, suitable for both interior and exterior applications. Its ability to be painted allows for customization, making it a preferred choice for residential projects and upscale designs. While it carries a higher price point compared to PVC, the long-term investment in quality and appearance can justify the cost for many B2B buyers.

Why Choose Self-Adhesive Flexible Baseboard?

Self-adhesive flexible baseboard is designed for quick and easy installation, making it an attractive option for DIY enthusiasts and temporary setups. The adhesive backing eliminates the need for tools, speeding up the application process. However, its longevity may be compromised in high-traffic areas, making it less suitable for permanent installations in commercial environments.

What Are the Benefits of Resin Flexible Baseboard?

Resin flexible baseboard is known for its strength and impact resistance, making it ideal for high-traffic areas and industrial applications. Its availability in various styles allows for customization to fit specific project needs. While it offers excellent durability, its heavier weight may necessitate professional installation, which could increase overall project costs.

What Makes MDF Flexible Baseboard a Popular Choice?

MDF flexible baseboard is favored for its affordability and versatility, allowing for easy painting or staining to match any decor. It is particularly useful in residential renovations where curves and angles are present. However, B2B buyers should consider its susceptibility to moisture damage, which could limit its use in certain environments.

Key Industrial Applications of flexible baseboard

| Industry/Sector | Specific Application of Flexible Baseboard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Curved wall designs in hotels and resorts | Enhances aesthetic appeal and allows for seamless integration in unique architectural designs | Durability, moisture resistance, and availability in custom lengths |

| Retail | Retail store displays and merchandising setups | Provides a polished look, protecting walls from damage while enhancing product presentation | Cost-effectiveness, flexibility in design, and ease of installation |

| Healthcare | Hospitals and clinics with complex room layouts | Ensures hygienic environments by minimizing dust accumulation and facilitating easy cleaning | Compliance with health regulations, material safety, and finish options |

| Residential Construction | Custom home interiors with unique architectural features | Adds value through enhanced design flexibility, allowing for creative finishes and styles | Compatibility with various wall types, ease of painting, and color options |

| Commercial Spaces | Office buildings with intricate layouts and designs | Improves workspace aesthetics while ensuring durability against wear and tear | Sourcing from reliable suppliers for consistent quality and delivery timelines |

How is Flexible Baseboard Used in Hospitality Settings?

In the hospitality sector, flexible baseboard is commonly used to create visually appealing curved wall designs in hotels and resorts. Its ability to bend along contours allows for seamless integration with unique architectural features, enhancing the overall aesthetic of guest areas. This flexibility not only elevates the design but also protects walls from damage in high-traffic areas. For buyers in this sector, sourcing durable and moisture-resistant materials is crucial to ensure longevity and maintain hygiene standards.

What Role Does Flexible Baseboard Play in Retail Environments?

In retail, flexible baseboard is utilized in merchandising setups and display designs. Its clean lines and ability to fit around irregular shapes contribute to a polished and professional appearance, which is vital for attracting customers. Additionally, it protects walls from scuff marks and damage caused by carts and foot traffic. B2B buyers should consider the cost-effectiveness and installation ease of flexible baseboard, as well as its compatibility with various display designs.

How is Flexible Baseboard Beneficial in Healthcare Facilities?

Healthcare facilities, including hospitals and clinics, benefit from flexible baseboard due to its adaptability in complex room layouts. It minimizes dust accumulation, which is critical for maintaining hygienic environments. The smooth surface of flexible baseboard facilitates easy cleaning, thereby supporting infection control measures. Buyers in this sector must prioritize compliance with health regulations, ensuring that the materials used are safe and suitable for medical settings.

Why Choose Flexible Baseboard in Residential Construction?

In residential construction, flexible baseboard is favored for custom interiors, particularly in homes with unique architectural features. Its versatility allows homeowners and builders to achieve creative finishes that enhance the property’s value and appeal. Buyers should focus on sourcing flexible baseboard that is compatible with various wall types and easy to paint, ensuring that it meets both aesthetic and practical requirements.

How Does Flexible Baseboard Enhance Commercial Spaces?

In commercial spaces, flexible baseboard is essential for accommodating intricate layouts often found in office buildings. Its durability protects against wear and tear, while its design flexibility allows for a tailored look that reflects the brand’s identity. When sourcing for commercial applications, it is important to partner with reliable suppliers to ensure consistent quality and timely delivery, enabling businesses to maintain their operational standards.

3 Common User Pain Points for ‘flexible baseboard’ & Their Solutions

Scenario 1: Navigating Complex Curves in Design Projects

The Problem: For many B2B buyers, particularly those in architectural and interior design sectors, the challenge lies in achieving seamless transitions around complex curves in spaces like retail environments or high-end residential projects. Traditional baseboards often fail to fit these unique contours, leading to unsightly gaps or the need for extensive custom work. This not only delays project timelines but also inflates costs, creating frustration for both the buyers and their clients.

The Solution: Sourcing flexible baseboard specifically designed for curved applications can alleviate this issue significantly. Buyers should look for products that are manufactured from materials such as PVC or polyurethane, which are inherently more pliable. When specifying flexible baseboard, ensure to select options that come in longer lengths (e.g., 12-foot rolls) to minimize seams. Additionally, consider pre-finished or primed options that can be painted on-site, reducing labor costs and time. Collaboration with suppliers who understand the specific demands of curved installations can also yield tailored solutions, enhancing both aesthetic appeal and project efficiency.

Illustrative image related to flexible baseboard

Scenario 2: Ensuring Durability in Challenging Environments

The Problem: Buyers operating in environments with high moisture levels, such as bathrooms, kitchens, or coastal regions, often face concerns regarding the durability of flexible baseboard. Many products may warp, rot, or deteriorate over time, leading to costly replacements and maintenance issues. This is particularly problematic for B2B buyers who need to uphold the integrity of their installations and satisfy client expectations for longevity and performance.

The Solution: To counteract these challenges, buyers should prioritize flexible baseboards that are explicitly labeled as moisture-resistant or rot-resistant. Materials like PVC and certain high-grade polyurethane are excellent choices for such applications. When procuring these products, it’s beneficial to request detailed specifications regarding their resistance properties. Additionally, implementing proper installation techniques—such as ensuring a tight seal against the wall and using appropriate adhesives—can further enhance durability. Regular maintenance checks can help identify early signs of wear, allowing for timely interventions that preserve the baseboard’s integrity.

Scenario 3: Balancing Cost with Quality in Bulk Purchases

The Problem: International buyers, especially those operating in price-sensitive markets like parts of Africa and South America, often struggle with the dual pressures of maintaining quality while controlling costs. When dealing with flexible baseboard, the risk of choosing cheaper options that compromise on quality can result in increased long-term expenses due to replacements or repairs. This creates a tough balancing act, as businesses need to stay competitive while ensuring client satisfaction.

The Solution: To navigate this cost-quality dilemma, buyers should establish relationships with reputable suppliers who offer flexible baseboards at competitive rates without sacrificing quality. Engaging in bulk purchasing agreements can also secure better pricing while ensuring consistency in material quality. It’s advisable to conduct thorough market research and request samples before committing to large orders. Additionally, leveraging technology such as project management software can streamline inventory management and reduce waste, ultimately leading to cost savings. Establishing a quality assurance process that includes regular evaluations of the products received can further mitigate risks associated with bulk purchases, ensuring that only high-quality materials are utilized in projects.

Strategic Material Selection Guide for flexible baseboard

When selecting materials for flexible baseboard, it is essential to consider various factors that impact performance, durability, and overall suitability for specific applications. Here, we analyze four common materials used in the production of flexible baseboards: PVC, polyurethane, MDF, and resin. Each material offers unique properties and benefits, making them suitable for different environments and requirements.

Illustrative image related to flexible baseboard

What are the Key Properties of PVC Flexible Baseboard?

PVC (Polyvinyl Chloride) is a widely used material for flexible baseboards, known for its versatility and durability. It exhibits excellent moisture resistance, making it suitable for both interior and exterior applications. PVC can withstand a range of temperatures without losing its shape, which is crucial for environments that experience temperature fluctuations.

Pros: PVC is cost-effective and lightweight, making it easy to handle and install. It is also resistant to rot, termites, and corrosion, ensuring longevity in various settings.

Cons: While PVC is durable, it may not offer the same aesthetic appeal as wood or resin options. Additionally, it can be less flexible than other materials, which may limit its use in highly curved applications.

International Considerations: Buyers from regions like Africa and South America should ensure that PVC products comply with local environmental regulations regarding plastic use. Standards such as ASTM can guide quality assurance.

How Does Polyurethane Compare as a Material for Flexible Baseboard?

Polyurethane is another popular choice for flexible baseboards, particularly in applications requiring a more decorative finish. This material is known for its exceptional flexibility, allowing it to bend around curves and corners easily.

Pros: Polyurethane baseboards can be painted or stained, providing versatility in design. They are also resistant to moisture and can withstand impacts better than some other materials.

Cons: The primary drawback is the higher cost compared to PVC. Additionally, polyurethane can be more complex to manufacture, which may affect lead times for international buyers.

International Considerations: Compliance with standards such as DIN or JIS is crucial for ensuring product quality. Buyers should also consider the availability of polyurethane products in their local markets.

What Role Does MDF Play in Flexible Baseboard Applications?

Medium Density Fiberboard (MDF) is a composite material made from wood fibers and resin. While it is not inherently flexible, specially engineered MDF products can be designed to provide some degree of flexibility.

Illustrative image related to flexible baseboard

Pros: MDF is highly customizable and can be easily painted or finished, making it ideal for aesthetic applications. It is also relatively inexpensive compared to other materials.

Cons: MDF is less durable than PVC or polyurethane, particularly in humid environments, where it can swell or deteriorate over time. Its lower resistance to moisture limits its use in certain applications.

International Considerations: Buyers should be aware of moisture levels in their regions, especially in tropical climates like Nigeria or Brazil, where MDF may not perform as well. Compliance with local building standards is also essential.

What Are the Benefits of Using Resin for Flexible Baseboard?

Resin-based flexible baseboards are known for their strength and durability. They are particularly suitable for high-traffic areas due to their resistance to scratches and impacts.

Pros: Resin baseboards offer excellent aesthetic appeal and can mimic the look of wood while providing superior durability. They are also resistant to moisture and chemicals.

Cons: The cost of resin materials is typically higher, and they may require specialized installation techniques. Additionally, the manufacturing process can be more complex.

International Considerations: Buyers should ensure that resin products meet local safety and environmental standards. Understanding the supply chain and availability in regions like the Middle East is also crucial for timely procurement.

Summary Table of Material Selection for Flexible Baseboard

| Material | Typical Use Case for flexible baseboard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Residential and commercial interiors | Cost-effective and moisture-resistant | Less aesthetic appeal | Low |

| Polyurethane | Decorative applications in interiors | Highly flexible and paintable | Higher cost and complex to manufacture | High |

| MDF | Custom designs in low-humidity areas | Customizable and inexpensive | Less durable in humid environments | Med |

| Resin | High-traffic and aesthetic applications | Strong and durable | Higher cost and specialized installation | High |

This strategic material selection guide provides essential insights for B2B buyers looking to make informed decisions regarding flexible baseboard materials, ensuring they choose the best options for their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for flexible baseboard

What Are the Main Stages in the Manufacturing Process of Flexible Baseboard?

The manufacturing of flexible baseboards involves several critical stages that ensure the final product meets both functional and aesthetic requirements. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of suitable materials, commonly thermoplastics like PVC or polyurethane. These materials are chosen for their flexibility, durability, and resistance to moisture and wear. Raw materials are then processed into pellets or sheets, which are inspected for quality to ensure they meet the necessary specifications.

-

Forming: The next step is forming, where the prepared materials are heated and shaped. Techniques such as extrusion are frequently used, where the material is forced through a die to create long strips of baseboard. This process allows for continuous production and can accommodate varying profiles to suit different architectural styles.

-

Assembly: After forming, the individual pieces are cut to size and assembled. This stage may include additional components such as adhesive backing for easy installation or reinforcing elements to enhance stability. Automated machinery often assists in this process to improve efficiency and precision.

-

Finishing: The final stage involves applying finishes that enhance the product’s appearance and durability. This can include priming, painting, or coating to provide a smooth, attractive surface. Quality checks are performed at this stage to ensure that the finish adheres well and meets color specifications.

How Is Quality Assurance Implemented in Flexible Baseboard Manufacturing?

Quality assurance (QA) is essential in manufacturing flexible baseboards to ensure the product meets international standards and customer expectations. The QA process is typically structured around relevant standards such as ISO 9001, which governs quality management systems.

Illustrative image related to flexible baseboard

-

International Standards: Compliance with ISO 9001 helps manufacturers establish a quality management framework that enhances customer satisfaction and operational efficiency. Other certifications, such as CE marking in Europe, signify that the product conforms to health, safety, and environmental protection standards.

-

Quality Control Checkpoints: Various checkpoints are established throughout the manufacturing process to identify defects early. These include:

– Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Monitoring production processes to catch any deviations in real-time.

– Final Quality Control (FQC): Conducting thorough inspections of finished products to ensure they meet all quality standards before shipment. -

Common Testing Methods: Manufacturers use a range of testing methods to verify the quality of flexible baseboards. This includes:

– Flexibility Tests: Assessing how well the baseboard can bend without breaking.

– Adhesion Tests: Evaluating the effectiveness of any adhesive backing.

– Durability Tests: Simulating wear and tear to ensure longevity in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial for ensuring product reliability.

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess their quality management systems and manufacturing processes. This can be done in-person or through virtual audits, where buyers review documentation and quality control procedures.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports that outline testing methods, results, and any corrective actions taken for non-conformities. These documents provide insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspectors can offer an unbiased evaluation of a supplier’s manufacturing processes and product quality. This can be particularly valuable when entering new markets or working with unfamiliar suppliers.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing flexible baseboards internationally, buyers must navigate various quality control and certification nuances that differ by region.

-

Regulatory Compliance: Each region has its own regulatory frameworks. For instance, in Europe, CE marking is mandatory, while in the U.S., products may need to comply with specific building codes. Understanding these regulations is essential for compliance and market access.

-

Cultural Considerations: Different regions may have varying expectations regarding quality and safety standards. B2B buyers should familiarize themselves with local market requirements and cultural perceptions of quality to ensure products meet consumer expectations.

-

Documentation and Traceability: Buyers should ensure that suppliers provide comprehensive documentation for each batch of products, including material certifications and test results. This traceability is vital for addressing any quality issues that may arise post-purchase.

In conclusion, understanding the manufacturing processes and quality assurance measures for flexible baseboards is crucial for B2B buyers seeking reliable suppliers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control practices, buyers can ensure they procure high-quality products that meet their specific needs. Moreover, verifying supplier practices through audits, reports, and third-party inspections will facilitate successful international transactions, particularly in diverse markets such as Africa, South America, the Middle East, and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘flexible baseboard’

To effectively source flexible baseboard, a structured approach is essential for B2B buyers. This guide provides a step-by-step checklist to help you navigate the procurement process efficiently, ensuring you select the right products and suppliers for your business needs.

Step 1: Define Your Technical Specifications

Clearly outlining your requirements is crucial for successful sourcing. Determine the material (e.g., PVC, polyurethane), dimensions (length, width, and thickness), and finish (paintable or pre-finished) of the flexible baseboard you need. This clarity will help you communicate effectively with suppliers and avoid costly mistakes.

- Material Considerations: Different materials offer varying durability and aesthetic appeal. Choose based on your project needs and environmental factors.

- Dimensions: Ensure that the dimensions align with your project specifications, especially if you are dealing with curved installations.

Step 2: Research Potential Suppliers

Identifying reliable suppliers is a key step in the sourcing process. Look for manufacturers and distributors with a solid reputation in the industry. Utilize online platforms, industry directories, and trade shows to gather a list of potential partners.

- Supplier Reputation: Check reviews and testimonials from other businesses to gauge reliability.

- Product Range: Ensure the supplier offers a variety of flexible baseboard options to meet diverse project requirements.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. This is particularly important for international purchases to ensure that products meet regional regulations.

- Quality Certifications: Look for ISO certifications or other relevant quality assurance marks.

- Sustainability Standards: If environmental considerations are important for your project, check if the supplier adheres to sustainable practices.

Step 4: Request Samples

Once you have shortlisted suppliers, request samples of the flexible baseboard. This allows you to assess the quality, finish, and flexibility of the materials firsthand.

- Testing for Fit and Finish: Evaluate how well the sample fits your design needs and whether it matches your aesthetic requirements.

- Durability Assessment: Consider the physical properties of the material, such as moisture resistance and flexibility, especially for curved installations.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare not only the prices but also the terms of service, including shipping costs, lead times, and payment terms. This will help you find the best overall value.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Shipping Considerations: Factor in the logistics costs and delivery timelines when evaluating offers.

Step 6: Negotiate and Finalize the Purchase

Once you’ve selected a supplier, engage in negotiations to secure favorable terms. Discuss price, payment methods, and delivery timelines to ensure both parties are aligned.

- Contract Clarity: Ensure that all terms are clearly documented in a contract to avoid misunderstandings later.

- Payment Security: Consider using secure payment methods that protect your investment.

Step 7: Plan for Installation and Aftercare

Finally, prepare for the installation process and any necessary aftercare. Ensure that your team is trained or informed about the best practices for installing flexible baseboard, particularly if it requires specific techniques for curved applications.

- Installation Guidelines: Obtain installation instructions from the supplier to ensure proper application.

- Maintenance Information: Understanding how to care for the flexible baseboard will enhance its longevity and performance.

By following this structured checklist, B2B buyers can confidently source flexible baseboard that meets their project requirements, ensuring quality and satisfaction in their procurement process.

Comprehensive Cost and Pricing Analysis for flexible baseboard Sourcing

What Are the Key Cost Components in Flexible Baseboard Sourcing?

When evaluating the cost structure for flexible baseboard, several components come into play. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: Flexible baseboards are commonly made from materials such as PVC, polyurethane, and resin. The choice of material significantly affects the overall cost; for instance, premium materials like polyurethane may yield higher durability but come at a steeper price.

-

Labor: Labor costs can vary depending on the region of production. In countries with lower labor costs, such as some South American and African nations, the overall cost of manufacturing flexible baseboard may be reduced, making these regions attractive for sourcing.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and equipment depreciation. Manufacturers with advanced technologies or eco-friendly practices may have higher overhead, impacting the final price.

-

Tooling: Custom tooling for unique designs or specifications can require significant investment. Buyers looking for customized flexible baseboards should be prepared for higher upfront costs associated with this tooling.

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection processes can add to costs. However, investing in quality can lead to reduced returns and improved customer satisfaction.

-

Logistics: The costs of shipping and handling are crucial, especially for international buyers. Factors like distance, mode of transport, and customs duties can significantly affect the total logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Understanding the average market margins can help buyers identify reasonable pricing.

How Do Price Influencers Affect Flexible Baseboard Pricing?

Several factors influence the pricing of flexible baseboard, particularly for B2B buyers in diverse international markets.

-

Volume/MOQ: Suppliers often provide discounts for bulk orders. Understanding the minimum order quantities (MOQ) can help buyers negotiate better rates.

-

Specifications and Customization: Custom designs or specific dimensions can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Selection: Different materials have varying costs, durability, and aesthetics. Buyers should weigh the benefits of higher-quality materials against their budget constraints.

-

Quality and Certifications: Products that meet international quality standards or carry certifications may be priced higher. However, these can be vital for ensuring compliance and customer satisfaction.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their experience and market presence, while newer suppliers may offer lower prices to gain market share.

-

Incoterms: Understanding the terms of trade (Incoterms) is essential for international transactions. They dictate who is responsible for shipping costs, insurance, and liabilities, which can significantly influence the overall price.

What Are the Best Buyer Tips for Sourcing Flexible Baseboard?

-

Negotiate Effectively: Develop a strong relationship with suppliers and be prepared to negotiate terms. Utilize your understanding of cost components and market trends to achieve favorable pricing.

-

Focus on Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes purchase price, shipping, and potential maintenance costs. A cheaper initial price may lead to higher long-term costs if quality is compromised.

-

Understand Pricing Nuances for International Buyers: International transactions can introduce complexities such as currency fluctuations, tariffs, and shipping delays. Buyers from regions like Africa or South America should factor these into their budgeting.

-

Evaluate Supplier Reliability: Conduct due diligence on suppliers to assess their reliability and product quality. This can prevent costly mistakes and ensure timely delivery.

-

Stay Informed on Market Trends: Regularly monitor market trends and price fluctuations in the flexible baseboard industry. Being informed will empower you to make strategic purchasing decisions.

Disclaimer on Pricing

The prices for flexible baseboard materials and sourcing can vary widely based on the factors mentioned above. The figures provided are indicative and should be validated with suppliers for accurate quotations tailored to specific needs.

Alternatives Analysis: Comparing flexible baseboard With Other Solutions

Exploring Alternative Solutions to Flexible Baseboard

When evaluating options for wall protection and aesthetic enhancement, flexible baseboard stands out for its adaptability and ease of installation. However, various alternatives may suit different projects or preferences. This section compares flexible baseboard with two viable alternatives: traditional rigid baseboards and wall paneling, providing B2B buyers with insights to make informed decisions.

| Comparison Aspect | Flexible Baseboard | Traditional Rigid Baseboard | Wall Paneling |

|---|---|---|---|

| Performance | Excellent for curved surfaces, durable | Strong, stable; limited to straight lines | Versatile design options, durable |

| Cost | Moderate cost per linear foot | Generally lower upfront cost | Higher initial investment |

| Ease of Implementation | Easy to install, often requires less cutting | Requires precise measurements and cutting | Can be complex; may need professional installation |

| Maintenance | Low maintenance, easy to clean | Low maintenance, may require painting | Moderate; depends on material choice |

| Best Use Case | Ideal for unique architectural designs | Suitable for standard applications | Great for creating feature walls |

What Are the Advantages and Disadvantages of Traditional Rigid Baseboard?

Traditional rigid baseboards are typically made from wood or MDF and are a common choice in many commercial and residential settings. Their primary advantage lies in their cost-effectiveness and straightforward installation. However, they lack the flexibility of their counterparts, making them unsuitable for curved or irregular surfaces. Moreover, rigid baseboards may require regular maintenance, such as repainting or refinishing, especially in high-traffic areas.

How Does Wall Paneling Compare to Flexible Baseboard?

Wall paneling offers a distinct aesthetic appeal, allowing for various designs that can enhance a room’s character. It can serve both functional and decorative purposes, providing insulation and soundproofing. However, wall paneling generally involves a higher upfront investment and may require more complex installation processes. Additionally, maintaining wall paneling can be more labor-intensive, depending on the material used, such as wood or PVC.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between flexible baseboard, traditional rigid baseboards, and wall paneling, B2B buyers should consider their specific project requirements, including budget, design preferences, and installation capabilities. Flexible baseboard is ideal for projects requiring adaptability and ease of installation, particularly in spaces with curves or unique architectural features. In contrast, traditional rigid baseboards offer a cost-effective solution for standard applications, while wall paneling caters to those seeking a more elaborate and visually striking design. Ultimately, understanding the strengths and limitations of each option will empower buyers to make the best choice for their projects.

Essential Technical Properties and Trade Terminology for flexible baseboard

What Are the Key Technical Properties of Flexible Baseboard?

Understanding the technical specifications of flexible baseboard is essential for B2B buyers to make informed purchasing decisions. Here are several critical specifications to consider:

-

Material Composition

Flexible baseboards are commonly made from materials such as PVC, polyurethane, and medium-density fiberboard (MDF). Each material has distinct characteristics affecting durability, flexibility, and resistance to moisture and pests. For instance, PVC is known for its water resistance and low maintenance, making it suitable for humid environments, while polyurethane offers superior flexibility and a higher-end finish. -

Flexibility and Bend Radius

The flexibility of baseboard determines its suitability for various architectural applications, particularly in spaces with curves or irregular shapes. The bend radius specification indicates the minimum curve the baseboard can accommodate without damage. This property is crucial for projects involving rounded walls or unique design elements. -

Durability Ratings

Durability is a key consideration, particularly in high-traffic areas. Ratings for moisture resistance, rot resistance, and scratch resistance help buyers gauge how well the product will perform over time. A product with high durability ratings is less likely to require frequent replacements, thereby reducing long-term costs. -

Finish Type

Baseboards come in various finishes, including primed, painted, or unfinished. The finish type can affect installation time and the overall aesthetic appeal. For B2B buyers, specifying the desired finish can streamline the procurement process and ensure that the product meets the project’s design requirements. -

Dimensions and Tolerance

Accurate dimensions and tolerances are critical for ensuring a proper fit during installation. Specifications such as width, height, and length should align with project needs. Tolerances indicate how much variation is acceptable, which is particularly important in large orders where uniformity is essential.

What Are Common Trade Terms Used in the Flexible Baseboard Industry?

Familiarity with industry-specific terminology is essential for effective communication and negotiation. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are sold under another company’s brand. Understanding OEM relationships can help buyers identify reliable suppliers and the quality of the products being offered. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. This term is crucial for budgeting and inventory management, as it helps buyers determine if they can meet the supplier’s requirements while still fulfilling their project needs. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers. This term is vital for buyers seeking competitive pricing and ensuring they are making cost-effective decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding shipping costs, insurance, and transportation risks. Familiarity with these terms is critical for international B2B transactions, as they help clarify who is responsible for various aspects of the shipping process. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is essential for project planning and ensuring that materials arrive on schedule to avoid delays in construction or installation.

By grasping these technical properties and trade terminology, B2B buyers can enhance their procurement strategies, ensuring they select the right flexible baseboard solutions for their projects.

Navigating Market Dynamics and Sourcing Trends in the flexible baseboard Sector

What Are the Current Market Dynamics and Key Trends in the Flexible Baseboard Sector?

The flexible baseboard market is witnessing a robust growth trajectory, driven by several global factors. Increased urbanization and a booming construction sector, particularly in regions like Africa and South America, are fueling demand for versatile building materials that can adapt to various design specifications. The rise of open-concept living spaces, which often feature curved walls and unique architectural designs, has heightened the need for flexible baseboard solutions that can seamlessly fit into these environments.

Emerging B2B technology trends are also reshaping the sourcing landscape. E-commerce platforms are becoming vital for international buyers, allowing them to compare products, prices, and suppliers with ease. Additionally, the use of digital supply chain management tools is enhancing transparency and efficiency in sourcing. Buyers are increasingly looking for suppliers that can provide real-time inventory data and facilitate quick order fulfillment, particularly in regions where logistics can be challenging.

Furthermore, sustainability is becoming a focal point for B2B buyers. As regulatory pressures increase and consumer demand for eco-friendly materials rises, suppliers are adapting their offerings. Products that boast attributes like moisture resistance, durability, and low environmental impact are gaining traction. This shift is particularly evident in Europe, where stringent environmental regulations are influencing purchasing decisions.

Illustrative image related to flexible baseboard

How Important Is Sustainability and Ethical Sourcing in the Flexible Baseboard Market?

Sustainability and ethical sourcing are no longer optional considerations for B2B buyers in the flexible baseboard market; they are essential elements of procurement strategies. The environmental impact of manufacturing processes and the materials used in products has become a primary concern. Buyers are increasingly aware of the carbon footprint associated with their purchases and are actively seeking materials that are recyclable or sourced from sustainable forests.

Certifications such as Forest Stewardship Council (FSC) and Greenguard are gaining importance as buyers look to validate their sourcing decisions. These certifications assure that products meet specific environmental and health criteria, thereby reducing the risk of non-compliance with local regulations. In addition, suppliers who prioritize ethical labor practices and transparency in their supply chains are becoming more attractive to B2B buyers, as these factors contribute to corporate social responsibility initiatives.

In regions like the Middle East and Africa, where natural resources may be limited, the focus on sustainability can also drive innovation. Suppliers are developing new materials that reduce waste and utilize renewable resources, thus creating a more circular economy within the construction sector.

What Is the Evolution and History of Flexible Baseboard in the B2B Context?

The flexible baseboard has evolved significantly over the past few decades, transitioning from a niche product to a mainstream solution in construction and interior design. Initially, flexible baseboards were primarily used in commercial settings where adaptability was essential. However, as design trends shifted towards more fluid and organic forms in residential spaces, the demand for flexible baseboards surged.

Advancements in materials technology have played a crucial role in this evolution. Early versions of flexible baseboards were often limited in terms of durability and aesthetic appeal. Today, products made from PVC, polyurethane, and other innovative materials offer enhanced flexibility, moisture resistance, and aesthetic versatility. This evolution has positioned flexible baseboards as not just functional elements, but also as key design features that can enhance the overall aesthetic of a space.

As international B2B buyers navigate the complexities of sourcing flexible baseboard solutions, understanding these market dynamics, sustainability considerations, and the historical context can empower them to make informed decisions that align with both their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of flexible baseboard

-

How do I solve issues with flexible baseboard installation?

To address installation challenges with flexible baseboards, ensure that the surface is clean and dry before application. Use a high-quality adhesive suitable for the baseboard material to enhance bonding. For curved applications, pre-bend the baseboard slightly before affixing it to the wall, which can help avoid cracking. Additionally, consider utilizing a professional installer with experience in flexible materials, especially for complex designs or larger projects, to ensure a seamless finish. -

What is the best material for flexible baseboard applications?

The best material for flexible baseboards depends on the specific application. Polyurethane is highly recommended for its durability and resistance to moisture, making it suitable for both interior and exterior uses. PVC is another popular option due to its affordability and ease of maintenance. For high-end finishes, consider resin materials that offer superior aesthetics and flexibility. Evaluate your project’s environmental conditions and aesthetic requirements to choose the ideal material. -

What should I consider when vetting suppliers for flexible baseboard?

When vetting suppliers for flexible baseboard, check their industry experience and reputation. Request samples to assess product quality and flexibility. Ensure they can provide documentation for compliance with international standards, particularly for safety and environmental regulations. Additionally, inquire about their production capacity and lead times to ensure they can meet your project timelines. Reviews and testimonials from other B2B buyers can provide insights into their reliability and service quality. -

What are typical minimum order quantities (MOQs) for flexible baseboard?

Minimum order quantities for flexible baseboard can vary significantly based on the supplier and the material type. Generally, MOQs can range from 100 to 500 linear feet, depending on the supplier’s production capabilities and inventory policies. For customized orders, MOQs may be higher. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms that align with your project requirements. -

What payment terms should I expect when sourcing flexible baseboard internationally?

Payment terms for international purchases of flexible baseboard typically include options such as 30% upfront deposit and 70% before shipment or upon delivery. Some suppliers may offer letters of credit or escrow services for larger orders to enhance security. Always clarify payment methods accepted (e.g., wire transfer, PayPal) and ensure they align with your financial practices. Be aware of any additional fees related to currency conversion or international transactions. -

How can I ensure quality assurance (QA) for flexible baseboard products?

To ensure quality assurance for flexible baseboard products, request certifications that demonstrate compliance with industry standards, such as ISO or ASTM. Establish a clear QA process with your supplier, including pre-shipment inspections and testing for durability and flexibility. Consider visiting the manufacturing facility if feasible, or employ third-party inspection services. Regular communication with the supplier about your quality expectations can also help mitigate issues before they arise. -

What logistics considerations should I keep in mind when importing flexible baseboard?

When importing flexible baseboard, consider shipping methods and costs, as these can significantly impact your overall budget. Air freight is faster but more expensive than sea freight. Ensure you understand customs regulations and duties applicable to your products in your destination country. Work with a reliable logistics partner who can handle documentation, track shipments, and navigate any potential delays to ensure timely delivery. -

Can I customize flexible baseboard to match my project specifications?

Yes, many suppliers offer customization options for flexible baseboard, including dimensions, colors, and finishes. Discuss your specific project requirements with potential suppliers and inquire about their capabilities in producing custom orders. Be prepared to provide detailed specifications or samples of desired styles. Customization may require longer lead times and higher MOQs, so plan accordingly to avoid project delays.

Top 7 Flexible Baseboard Manufacturers & Suppliers List

1. Next Day Moulding – Flex Baseboard Moulding

Domain: nextdaymoulding.com

Registered: 2016 (9 years)

Introduction: Flex Baseboard Moulding allows for a bend along an inside or outside curved application. It is stocked in 12-foot rolls that are ready to take paint for either interior or exterior applications. Available sizes include: 9/16 X 3-1/2 X 12 FT (Item Code: FLEX-662), 9/16 X 5-1/4 X 12 FT (Item Code: FLEX-L163E), and 5/8 X 7-1/4 X 12 FT (Item Code: FLEX-L163E7). All products are sold as a pack of 1.

2. Classic Ceilings – Decorative Flexible Baseboards

Domain: crownmoldings.net

Registered: 1999 (26 years)

Introduction: This company, Classic Ceilings – Decorative Flexible Baseboards, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Flexible Moulding Concepts – Flexible Base Moulding

Domain: flexiblemouldingconcepts.com

Registered: 2009 (16 years)

Introduction: Base moulding, also known as “skirting board,” is used to conceal the junction of an interior wall and floor, protect the wall from impacts, and add a decorative touch. Flexible base moulding comes in various heights and styles, ranging from 3 inches to 9 1/4 inches. Flexible Moulding Concepts specializes in Duraflex and Xtraflex products, offering over 18,000 moulding patterns in inventory. Key p…

4. Flexible Millwork – Flex Base Molding

Domain: flexiblemillwork.com

Registered: 2006 (19 years)

Introduction: Collection: Flex Base

– Flexible base board moldings that can be ordered as “straight flexible pieces”.

– Can bend easily around curves as tight as a 6″ radius (normal sized paint can).

– Lengths of 13′ or longer may separate into 2 pieces during transit (less than 2% chance).

– Non-stock items usually ship in 4 to 8 business days.

5. Trimster – Flexible Molding Solutions

Domain: trimster.com

Registered: 2005 (20 years)

Introduction: This company, Trimster – Flexible Molding Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. More Than Moldings – Classic Flexible Baseboard

Domain: morethanmoldings.com

Registered: 2017 (8 years)

Introduction: Classic Flexible Baseboard

– List Price: $545.00

– Sale Price: $436.00 (20% off)

– Dimensions: 7-1/4″H x 3/4″D

– Length: 12′

– Shipping: Allow about 10 days to ship

– SKU: BBJ725

– Description: Flexible molding suitable for round or curved walls, ideal for curved baseboards and crown molding, as well as applications like curved door and window trim, curved staircases, ceiling domes, column wraps, …

7. Elite Trimworks – Flexible Moldings

Domain: elitetrimworks.com

Registered: 2006 (19 years)

Introduction: Flexible Moldings include Flexible Wainscoting, Flexible Cornice, Flexible Baseboards, Flexible Casings, Flexible Panel Mould, Flexible Chair Rails, Flexible Shoe & Quarter Round, and Flexible Dentil Strip. These products are made from durable polyurethane that bends without breaking shape, suitable for arched windows, staircases, and curved walls. They are crafted in the USA and combine strength,…

Strategic Sourcing Conclusion and Outlook for flexible baseboard

What Are the Key Takeaways for B2B Buyers of Flexible Baseboard?

As the demand for flexible baseboard continues to rise across various markets, strategic sourcing becomes crucial for international B2B buyers. The versatility of flexible baseboard, including its ability to accommodate curved applications and diverse materials like PVC and polyurethane, offers significant advantages in design and installation. For buyers in Africa, South America, the Middle East, and Europe, understanding the specific needs of local markets can help in selecting the right products that align with regional preferences and environmental considerations.

How Can Strategic Sourcing Enhance Your Competitive Edge?

Investing in strategic sourcing not only streamlines procurement processes but also fosters long-term partnerships with suppliers. This approach enables buyers to negotiate better pricing, ensure product quality, and access innovative solutions tailored to their unique requirements. As markets evolve, staying ahead of trends and leveraging technology for sourcing can provide a competitive advantage.

What’s Next for B2B Buyers in the Flexible Baseboard Market?

Looking ahead, the flexible baseboard market is poised for growth, driven by ongoing construction and renovation projects globally. Buyers should actively engage with suppliers to explore new offerings and sustainability options. As you navigate this dynamic landscape, consider adopting a proactive sourcing strategy that prioritizes quality and innovation to meet the demands of your customers. Embrace the opportunity to lead in your market by making informed decisions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.