Fibre Plastic Sheet Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for fibre plastic sheet

In today’s global marketplace, sourcing high-quality fibre plastic sheets can pose significant challenges for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. As industries increasingly rely on these versatile materials for applications ranging from electrical insulation to durable packaging, understanding the nuances of fibre plastic sheets becomes crucial. This guide aims to demystify the complexities associated with sourcing fibre plastic sheets by providing a comprehensive overview of the various types available, their specific applications, and insights into supplier vetting processes.

B2B buyers will find actionable insights into the cost structures associated with fibre plastic sheets, including bulk pricing strategies and shipping considerations tailored to different markets. The guide empowers decision-makers by equipping them with the knowledge to identify reliable suppliers, negotiate better terms, and ensure compliance with international standards. By addressing common pain points and offering strategic solutions, this resource serves as an indispensable tool for businesses seeking to enhance their procurement processes and optimize their supply chains. Whether you’re a manufacturer in Brazil or an importer in Germany, understanding the global landscape of fibre plastic sheets is essential for making informed purchasing decisions that drive business success.

Understanding fibre plastic sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vulcanized Fibre | Durable, chemically pure cellulose, hard texture | Electrical insulation, mechanical parts | Pros: High strength, thermal resistance. Cons: Limited color options, may require specific handling. |

| Commercial Grade Fibre | Flexible, available in various thicknesses, cost-effective | Packaging, gaskets, seals | Pros: Versatile, economical. Cons: May not withstand extreme conditions. |

| Electrical Insulation | High dielectric strength, flame retardant | Insulation for electrical components | Pros: Excellent electrical properties. Cons: More expensive than standard grades. |

| Reinforced Fibre Sheet | Composite material, enhanced strength and durability | Automotive, construction materials | Pros: Superior strength, lightweight. Cons: Higher cost, may require specialized processing. |

| Specialty Fibre Sheets | Custom formulations for specific applications (e.g., food grade) | Food packaging, medical applications | Pros: Tailored properties for specific uses. Cons: Often has longer lead times and higher costs. |

What are the Characteristics of Vulcanized Fibre Sheets?

Vulcanized fibre sheets are a robust, chemically pure cellulose product known for their hardness and durability. They are primarily utilized in applications requiring electrical insulation and mechanical strength, making them ideal for industries like automotive and electronics. Buyers should consider the specific thickness and dimensions needed for their applications, as well as the handling requirements due to their rigidity. The cost-effectiveness of vulcanized fibre sheets is an added advantage, but their limited color options may not suit all aesthetic needs.

How Does Commercial Grade Fibre Differ from Other Types?

Commercial grade fibre sheets are designed for flexibility and come in various thicknesses, making them suitable for a wide range of applications, including packaging and seals. Their cost-effective nature appeals to businesses looking for versatile materials without compromising quality. However, potential buyers should assess whether these sheets can withstand the specific environmental conditions of their intended use, as they may not perform well under extreme temperatures or pressures.

Why Choose Electrical Insulation Fibre Sheets for Your Business?

Electrical insulation fibre sheets are characterized by their high dielectric strength and flame-retardant properties. They are essential in protecting electrical components from short circuits and overheating. Businesses in the electrical and electronics sectors should prioritize these sheets for applications where safety and reliability are paramount. While they tend to be more expensive than other grades, their performance justifies the investment, particularly in critical applications.

What Advantages Do Reinforced Fibre Sheets Offer?

Reinforced fibre sheets are composites that provide enhanced strength and durability, making them suitable for demanding applications in the automotive and construction sectors. Their lightweight nature does not compromise structural integrity, offering significant advantages in design and manufacturing. Buyers should consider the higher cost associated with these sheets, as well as the potential need for specialized processing techniques. The investment can yield long-term benefits in performance and reliability.

What are Specialty Fibre Sheets and When Should They Be Used?

Specialty fibre sheets are custom formulations designed for specific applications, such as food packaging or medical uses. These sheets offer tailored properties, ensuring compliance with regulatory standards in sensitive industries. While they provide unique advantages, businesses should be prepared for longer lead times and potentially higher costs. When selecting specialty sheets, it is crucial to clearly define the requirements and ensure the supplier can meet those specific needs.

Key Industrial Applications of fibre plastic sheet

| Industry/Sector | Specific Application of fibre plastic sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electrical & Electronics | Insulation components in electrical devices | High dielectric strength ensures safety and reliability | Compliance with international electrical standards |

| Automotive | Interior panels and insulation materials | Lightweight and durable, enhancing vehicle efficiency | Material thickness and weight specifications |

| Aerospace | Lightweight structural components | Reduces overall aircraft weight, improving fuel efficiency | Aerospace-grade certifications and testing requirements |

| Construction & Architecture | Wall panels and partitions | Provides thermal insulation and aesthetic appeal | Fire resistance ratings and environmental certifications |

| Manufacturing & Industrial | Gaskets and seals in machinery | Enhances operational efficiency and reduces downtime | Chemical resistance and mechanical property specifications |

How is fibre plastic sheet used in the Electrical & Electronics industry?

In the electrical and electronics sector, fibre plastic sheets serve as insulation components for various devices, including transformers and circuit boards. Their high dielectric strength prevents electrical leakage, ensuring safety and reliability in operations. For international buyers, particularly in regions like Africa and Europe, sourcing materials that comply with international electrical standards is crucial to avoid potential regulatory issues and enhance product safety.

What role does fibre plastic sheet play in the Automotive industry?

Fibre plastic sheets are increasingly utilized in the automotive industry for interior panels and insulation materials. Their lightweight yet durable nature significantly contributes to overall vehicle efficiency by reducing weight, which can lead to improved fuel economy. Buyers should focus on specific material thickness and weight specifications to meet automotive standards, particularly in markets like Brazil and Germany, where regulations around emissions and safety are stringent.

How is fibre plastic sheet applied in Aerospace applications?

In aerospace, fibre plastic sheets are used for lightweight structural components, which are essential for reducing the overall weight of aircraft. This reduction directly correlates with enhanced fuel efficiency and operational cost savings. Buyers in this sector must ensure that the materials sourced are aerospace-grade, meeting rigorous certifications and testing requirements to guarantee safety and performance in flight.

What are the benefits of using fibre plastic sheet in Construction & Architecture?

Fibre plastic sheets are employed in construction for wall panels and partitions, offering both thermal insulation and aesthetic appeal. Their versatility allows for creative architectural designs while maintaining energy efficiency in buildings. For international buyers, particularly in regions with diverse climates, it is essential to consider fire resistance ratings and environmental certifications to ensure compliance with local building codes.

How does fibre plastic sheet enhance Manufacturing & Industrial processes?

In manufacturing, fibre plastic sheets are commonly used for gaskets and seals in machinery. These applications enhance operational efficiency by preventing leaks and reducing downtime due to maintenance. Buyers should prioritize sourcing materials with high chemical resistance and mechanical property specifications to ensure long-lasting performance in various industrial environments.

3 Common User Pain Points for ‘fibre plastic sheet’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Thickness for Specific Applications

The Problem: B2B buyers often struggle to determine the appropriate thickness of fibre plastic sheets required for their specific applications. This challenge is especially pronounced in industries such as electrical insulation, where the thickness can significantly impact performance. For instance, a manufacturer might require sheets for electrical insulation but may not understand how varying thicknesses can affect dielectric strength, durability, and overall safety. This lack of clarity can lead to costly mistakes, including purchasing sheets that are either too thin—resulting in potential failures—or too thick, leading to unnecessary expenses.

The Solution: To address this issue, buyers should collaborate closely with their suppliers to establish clear specifications based on application needs. Conducting a comprehensive assessment of the intended use—such as insulation requirements, mechanical stress, and environmental factors—can help in selecting the right thickness. Additionally, leveraging supplier resources, including technical data sheets and application guidelines, can provide crucial insights. For example, if a buyer is sourcing sheets for high-voltage applications, they should consult with engineers or technical experts from their suppliers to ensure the selected thickness meets the necessary standards. Finally, requesting samples for testing before making bulk purchases can mitigate risks and ensure the right fit.

Scenario 2: Concerns Over Material Quality and Consistency

The Problem: Quality inconsistency is a significant concern for B2B buyers of fibre plastic sheets, particularly for those sourcing from multiple suppliers across different regions. Variability in material composition and manufacturing processes can lead to discrepancies in performance characteristics, which can compromise product integrity. This is especially critical in industries like automotive or aerospace, where precise specifications are mandatory for safety and compliance.

The Solution: To mitigate quality concerns, buyers should prioritize sourcing from reputable suppliers who provide detailed certifications and quality assurance processes. Establishing a robust supplier evaluation process, which includes reviewing manufacturing practices, materials sourcing, and previous client testimonials, can help ensure reliability. Furthermore, implementing a quality control protocol that includes in-house testing of incoming materials can help detect inconsistencies before they affect production. Utilizing advanced technologies, such as spectroscopic analysis, can also provide objective data on material composition, ensuring that the sheets meet the required standards consistently.

Scenario 3: Navigating Cost Fluctuations and Bulk Pricing Challenges

The Problem: B2B buyers frequently face challenges related to cost fluctuations and bulk pricing when purchasing fibre plastic sheets. The pricing structure can vary widely based on order quantity, material type, and supplier location, which can complicate budgeting and financial forecasting. Additionally, buyers may find themselves pressured to meet minimum order requirements, leading to overstock and increased storage costs.

The Solution: To effectively manage costs, buyers should engage in strategic purchasing practices. This includes analyzing historical pricing trends and establishing long-term relationships with suppliers to negotiate better pricing based on projected demand. Implementing a just-in-time inventory strategy can also help reduce storage costs while ensuring that the necessary materials are on hand when needed. Additionally, exploring alternative suppliers in different regions can provide leverage in negotiations and help mitigate the impact of local price fluctuations. Lastly, buyers should consider forming purchasing cooperatives with other businesses in similar industries to increase order volumes collectively, which can lead to significant discounts and more favorable terms.

Strategic Material Selection Guide for fibre plastic sheet

What Are the Key Materials for Fibre Plastic Sheets in B2B Applications?

When selecting fibre plastic sheets for various applications, understanding the properties and implications of different materials is crucial for international B2B buyers. This guide analyzes four common materials used in fibre plastic sheets: Vulcanized Fibre, Phenolic Resin, Polycarbonate, and Fiberglass Reinforced Plastic (FRP). Each material offers unique advantages and limitations that can significantly impact performance, cost, and compliance with international standards.

How Does Vulcanized Fibre Perform in Various Applications?

Vulcanized Fibre is a cellulose-based material known for its excellent electrical insulation properties and mechanical strength. It is resistant to moisture and offers good dimensional stability, making it suitable for applications in electrical insulation and mechanical components.

Pros: Durable and lightweight, Vulcanized Fibre is cost-effective for bulk applications. It is also easy to machine and can be produced in various thicknesses and sizes.

Cons: While it performs well under moderate temperatures, it is not suitable for high-temperature applications. Additionally, it may not withstand harsh chemical environments.

Impact on Application: Vulcanized Fibre is ideal for electrical insulation in transformers and switchgear, where moisture resistance and electrical properties are critical.

Considerations for International Buyers: Buyers should ensure compliance with electrical insulation standards, such as ASTM D149, and consider local manufacturing capabilities for cost-effective sourcing.

What Advantages Does Phenolic Resin Offer?

Phenolic Resin is a thermosetting polymer known for its high strength, heat resistance, and chemical stability. It is often used in applications requiring high thermal resistance and durability.

Pros: Phenolic sheets are highly resistant to heat and chemicals, making them suitable for harsh environments. They also have excellent mechanical properties and can be produced in various colors and finishes.

Cons: The manufacturing process can be more complex and costly compared to other materials. Additionally, they may require specialized machining tools due to their hardness.

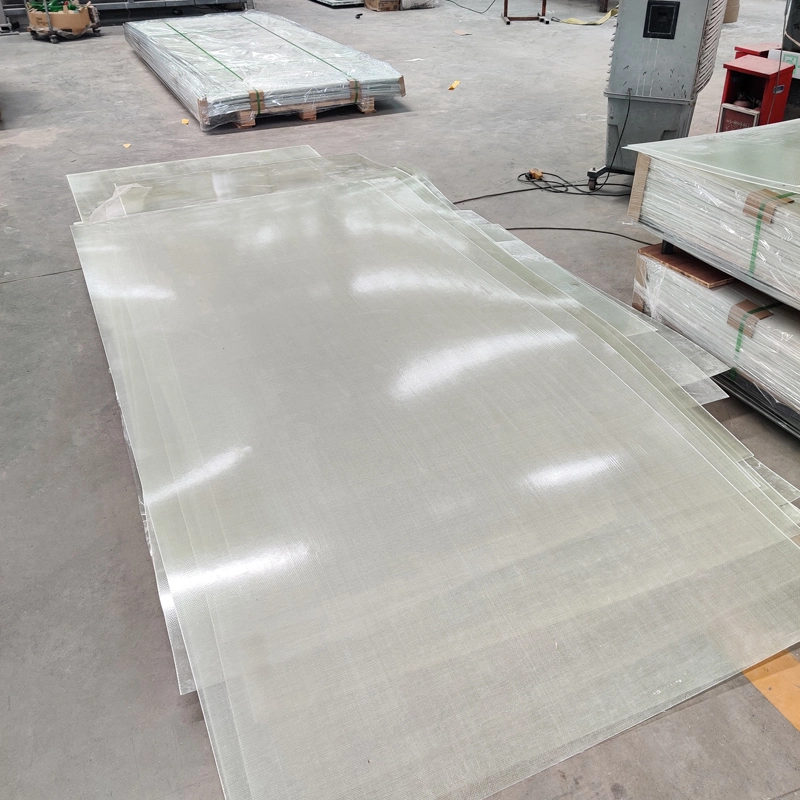

Illustrative image related to fibre plastic sheet

Impact on Application: Ideal for applications in aerospace, automotive, and industrial settings, Phenolic Resin can withstand extreme temperatures and corrosive substances.

Considerations for International Buyers: Compliance with international standards such as ASTM D256 and EN 60893 is essential, particularly for industries like aerospace and automotive in Europe and North America.

How Does Polycarbonate Compare in Terms of Utility?

Polycarbonate is a versatile thermoplastic known for its high impact resistance and transparency. It is often used in applications requiring clarity and durability.

Pros: Polycarbonate sheets are lightweight, shatter-resistant, and can be easily fabricated. They also provide excellent UV protection, making them suitable for outdoor applications.

Cons: While impact-resistant, Polycarbonate can be prone to scratching and may not perform well in high-temperature environments. Its cost is generally higher than other materials.

Impact on Application: Commonly used in safety equipment, signage, and protective barriers, Polycarbonate is ideal for applications where visibility and durability are essential.

Considerations for International Buyers: Buyers should verify compliance with safety standards such as ANSI Z87.1 for eye protection and consider local regulations regarding the use of plastics in construction.

What Role Does Fiberglass Reinforced Plastic (FRP) Play?

Fiberglass Reinforced Plastic (FRP) combines the strength of fiberglass with the versatility of plastic, making it an excellent choice for various industrial applications.

Pros: FRP is highly durable, lightweight, and resistant to corrosion and chemicals. It also offers good thermal insulation properties and can be molded into complex shapes.

Cons: The initial cost can be higher than traditional materials, and the manufacturing process may require specialized equipment. Additionally, FRP can be more challenging to recycle.

Impact on Application: FRP is widely used in construction, transportation, and marine applications due to its strength and resistance to environmental factors.

Considerations for International Buyers: Compliance with standards such as ASTM D638 and ISO 9001 is crucial, especially for industries in Europe and North America where quality assurance is paramount.

Summary Table of Material Properties

| Material | Typical Use Case for fibre plastic sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vulcanized Fibre | Electrical insulation | Lightweight and cost-effective | Limited high-temperature resistance | Low |

| Phenolic Resin | Aerospace and automotive applications | High heat and chemical resistance | More complex manufacturing process | High |

| Polycarbonate | Safety equipment and signage | Impact-resistant and UV protective | Prone to scratching | Medium |

| Fiberglass Reinforced Plastic (FRP) | Construction and marine applications | Highly durable and corrosion-resistant | Higher initial cost | Medium |

This comprehensive material selection guide aims to empower B2B buyers with the insights needed to make informed decisions regarding fibre plastic sheets, ensuring compatibility with their specific applications and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fibre plastic sheet

What Are the Key Stages in the Manufacturing Process of Fibre Plastic Sheets?

The production of fibre plastic sheets involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in manufacturing fibre plastic sheets is the selection and preparation of raw materials, typically cellulose-based fibers. These fibers are treated to enhance their properties, such as strength and durability. The preparation process may involve drying, cutting, and sometimes chemical treatments to improve adhesion and performance in the final product.

-

Forming: Once the materials are ready, they undergo a forming process, which can vary depending on the desired thickness and application of the sheets. Techniques such as pressing and molding are commonly used. For instance, sheets can be produced by layering fibers and applying heat and pressure to bond them, resulting in a dense and durable product. This stage is crucial as it determines the physical characteristics of the sheets, including thickness, density, and overall strength.

-

Assembly: In cases where multi-layered or composite sheets are required, the assembly stage involves the careful stacking and bonding of different materials. This may include additional layers of resin or other composites to enhance properties like water resistance or electrical insulation. The assembly process must be meticulously controlled to ensure uniformity and integrity throughout the sheet.

-

Finishing: The final stage in the manufacturing process involves finishing treatments that may include cutting, surface treatment, and quality inspections. Finishing processes are essential for ensuring that the sheets are free from defects and meet specific customer requirements. This stage may also involve the application of surface coatings or treatments to enhance performance characteristics such as abrasion resistance or aesthetic appeal.

What Quality Assurance Measures Are Essential for Fibre Plastic Sheets?

Quality assurance (QA) is a critical aspect of the manufacturing process for fibre plastic sheets. It ensures that the products meet international and industry-specific standards, which is particularly important for B2B buyers from diverse regions.

-

International Standards Compliance: Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with such standards demonstrates a commitment to consistent quality, customer satisfaction, and continuous improvement. Additionally, industry-specific certifications such as CE marking (for products sold in the European Economic Area) and API (American Petroleum Institute) certifications for specific applications may also be relevant.

-

Quality Control Checkpoints: Quality control is typically implemented at various stages of the manufacturing process, including:

– Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials before they enter production. Ensuring high-quality inputs is vital for the integrity of the final product.

– In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs to identify any deviations from specified parameters. This proactive approach helps catch potential issues early in the process.

– Final Quality Control (FQC): After production, a thorough examination of the finished sheets is conducted. This includes testing for thickness, weight, and physical properties to ensure compliance with specifications. -

Common Testing Methods: Various testing methods are employed to validate the quality of fibre plastic sheets. These may include tensile strength tests, thermal stability assessments, and electrical insulation tests. Additionally, chemical resistance and moisture absorption tests are crucial for applications in demanding environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure the reliability of fibre plastic sheets.

-

Supplier Audits: Conducting audits of potential suppliers is an effective way to assess their manufacturing processes and quality control measures. An audit can provide insights into the supplier’s adherence to international standards, their quality management systems, and their overall production capabilities.

-

Requesting Quality Reports: B2B buyers should request quality assurance documentation, including inspection reports and test results. These documents should detail the methodologies used during testing and provide evidence of compliance with relevant standards.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These inspections can verify compliance with industry standards and assess the quality of the products before shipment.

What Nuances Should International Buyers Consider in Quality Control?

International buyers must navigate several nuances related to quality control when sourcing fibre plastic sheets from global suppliers.

-

Regional Standards Variability: Different regions may have varying standards and regulations regarding material properties and safety. Buyers should familiarize themselves with the specific requirements in their target markets, such as those in Brazil or Germany, to ensure compliance.

-

Cultural Differences in Quality Perception: The understanding of quality can vary significantly across cultures. Therefore, clear communication about expectations and standards is crucial. Buyers should ensure that suppliers understand the specific requirements related to performance and safety in their markets.

-

Traceability and Documentation: Given the complexities of international trade, maintaining traceability of the materials used in manufacturing is critical. Buyers should ensure that suppliers can provide detailed documentation regarding the sourcing and testing of materials used in fibre plastic sheets.

Conclusion

The manufacturing processes and quality assurance measures for fibre plastic sheets are essential considerations for B2B buyers. By understanding the key stages of production and the importance of rigorous quality control, international buyers can make informed decisions when sourcing these materials. Engaging in thorough supplier evaluations and maintaining open lines of communication can further enhance the procurement process, ensuring that the fibre plastic sheets meet the highest standards of quality and performance.

Illustrative image related to fibre plastic sheet

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fibre plastic sheet’

Introduction

Navigating the procurement of fibre plastic sheets can be complex, especially for international B2B buyers from diverse regions like Africa, South America, the Middle East, and Europe. This guide serves as a practical checklist to streamline your sourcing process, ensuring you make informed decisions that align with your technical requirements, budget, and supplier reliability.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Identify the precise dimensions, thicknesses, colors, and material types required for your application. This clarity will help in effectively communicating your needs to potential suppliers and ensuring that the products meet your operational standards.

- Consider application requirements: Different applications may require specific features such as electrical insulation properties or resistance to chemicals.

- Document standards and certifications: Ensure your specifications align with industry standards relevant to your region or sector.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of fibre plastic sheets. Utilize industry directories, trade shows, and online marketplaces to gather a list of potential partners. A well-researched shortlist increases the likelihood of finding reliable suppliers who can meet your needs.

- Look for suppliers with experience: Focus on those who have a proven track record in your industry to ensure they understand your unique requirements.

- Check online reviews and testimonials: Insights from other buyers can provide valuable information about a supplier’s reliability and product quality.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, it’s crucial to assess their capabilities. Review their production processes, quality control measures, and capacity to handle your order volume. This evaluation helps in ensuring that the supplier can meet your delivery timelines and quality expectations.

- Request samples: Obtain product samples to assess the quality and suitability of the fibre plastic sheets for your specific application.

- Investigate manufacturing practices: Ensure the supplier adheres to best practices in manufacturing and quality assurance.

Step 4: Verify Supplier Certifications

Confirm that your chosen suppliers possess the necessary certifications and compliance with relevant industry standards. Certifications can serve as a benchmark for quality and reliability, ensuring that the products meet international standards.

- Look for ISO certifications: These indicate adherence to quality management systems and consistent product quality.

- Check for compliance with local regulations: Ensure the products meet any specific regulatory requirements in your target markets.

Step 5: Negotiate Terms and Pricing

Engage in negotiations with your shortlisted suppliers to secure favorable terms and pricing. This step is vital for ensuring that you receive the best value for your investment while establishing a mutually beneficial relationship.

- Discuss bulk pricing options: Larger orders may qualify for discounts, so be sure to inquire about volume pricing.

- Clarify payment terms: Understand payment options, including upfront payments, credit terms, and any penalties for late payments.

Step 6: Establish a Communication Plan

Effective communication is key to successful procurement. Establish a clear communication plan with your supplier, detailing points of contact, preferred communication channels, and frequency of updates. This plan will help in managing expectations and addressing any potential issues promptly.

- Set regular check-ins: Schedule periodic updates to monitor order progress and address any concerns that may arise.

- Utilize project management tools: Consider using digital platforms for tracking order status and facilitating communication.

Step 7: Plan for Logistics and Delivery

Finally, ensure you have a logistics plan in place for the delivery of your fibre plastic sheets. Coordinate with your supplier regarding shipping methods, timelines, and any customs requirements. This foresight can prevent delays and ensure that your materials arrive when needed.

- Choose the right shipping method: Evaluate options based on cost, speed, and reliability.

- Understand customs regulations: Familiarize yourself with import regulations in your country to avoid potential complications during delivery.

By following this structured checklist, B2B buyers can navigate the procurement process for fibre plastic sheets with greater confidence and efficiency.

Comprehensive Cost and Pricing Analysis for fibre plastic sheet Sourcing

What Are the Key Cost Components in Sourcing Fibre Plastic Sheets?

When sourcing fibre plastic sheets, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts the overall cost. High-quality cellulose-based materials are essential for durability and performance. Sourcing from reputable suppliers can help ensure material integrity but may come at a premium.

-

Labor: Labor costs encompass the workforce involved in manufacturing, quality control, and logistics. In regions with higher wage standards, such as Europe, these costs can be substantial. Conversely, sourcing from countries with lower labor costs may reduce overall expenses but could affect quality.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient production processes can mitigate these costs, making it essential to evaluate a supplier’s operational efficiency.

-

Tooling: Custom tooling for specialized fibre plastic sheets may incur additional costs. Suppliers often pass these expenses onto buyers, especially for low-volume orders. Understanding tooling costs is vital for budget planning.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. Suppliers that invest in robust QC measures may charge higher prices, but this can lead to long-term savings by reducing defects and returns.

-

Logistics: Transportation and warehousing costs vary based on the supplier’s location and the buyer’s destination. International buyers must consider shipping costs, customs duties, and potential delays that could affect the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary widely based on market competition and supplier relationships.

How Do Price Influencers Affect Fibre Plastic Sheet Costs?

Several factors influence the pricing of fibre plastic sheets:

-

Volume/MOQ: Bulk orders usually result in lower unit prices. Establishing a minimum order quantity (MOQ) with suppliers can lead to significant cost savings.

-

Specifications and Customization: Custom sizes, thicknesses, or colors can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or ASTM) can raise costs but may be necessary for compliance and performance. Evaluating the necessity of certifications based on end-use applications is crucial.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities play a significant role in pricing. Established suppliers with a track record of quality may command higher prices, but they often offer better service and reliability.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects logistics costs and responsibilities. Understanding these terms helps buyers avoid unexpected expenses and liabilities.

What Buyer Tips Can Help Optimize Costs When Sourcing Fibre Plastic Sheets?

B2B buyers should consider the following strategies for cost-efficient sourcing:

-

Negotiate Effectively: Engage in transparent negotiations with suppliers. Emphasize long-term relationships and potential future orders to secure better pricing.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices to consider maintenance, longevity, and potential replacements. A higher upfront cost may lead to lower TCO if the product lasts longer and requires less frequent replacement.

-

Research Pricing Nuances for International Markets: Buyers from regions like Africa, South America, and the Middle East should be aware of currency fluctuations, import duties, and local market conditions that can affect pricing. Building relationships with local suppliers may offer competitive advantages.

-

Stay Informed About Market Trends: Regularly monitor market trends and material prices. Being aware of fluctuations can help buyers time their purchases effectively and negotiate better deals.

-

Request Samples: Before placing large orders, request samples to evaluate quality. This practice ensures that the product meets specifications and helps avoid costly mistakes.

In conclusion, understanding the cost structure, price influencers, and implementing strategic sourcing techniques can significantly impact the procurement of fibre plastic sheets, leading to better decision-making and cost savings for international buyers.

Alternatives Analysis: Comparing fibre plastic sheet With Other Solutions

Understanding the Importance of Alternative Solutions in B2B Procurement

In the competitive landscape of industrial materials, B2B buyers are often faced with various options to meet their operational needs. Evaluating alternatives to fibre plastic sheets can lead to better decision-making, potentially enhancing performance, reducing costs, or improving ease of implementation. This analysis compares fibre plastic sheets against other viable alternatives such as polycarbonate sheets and metal sheets, focusing on key factors that influence procurement decisions.

Comparison Table

| Comparison Aspect | Fibre Plastic Sheet | Polycarbonate Sheets | Metal Sheets |

|---|---|---|---|

| Performance | Excellent insulation, lightweight, durable | High impact resistance, good insulation | Strong structural support, high durability |

| Cost | Moderate initial cost, lower in bulk | Higher initial investment, varies by type | Generally higher cost, especially for specialized alloys |

| Ease of Implementation | Easy to cut and shape, requires minimal tools | Requires specialized tools for cutting and shaping | Requires heavy machinery for cutting and installation |

| Maintenance | Low maintenance, resistant to chemicals | Low maintenance, UV protection available | Moderate maintenance, can corrode if not treated |

| Best Use Case | Electrical insulation, gaskets, seals | Greenhouses, safety glazing, signage | Structural applications, roofing, cladding |

Detailed Breakdown of Alternatives

Polycarbonate Sheets

Polycarbonate sheets are known for their high impact resistance and excellent insulation properties. They are typically used in applications requiring transparency, such as safety glazing and greenhouses. While they provide superior durability against physical impacts, polycarbonate sheets come with a higher initial investment compared to fibre plastic sheets. Additionally, they require specialized tools for cutting and installation, which may increase overall project costs. However, their UV protection capabilities make them ideal for outdoor applications.

Metal Sheets

Metal sheets, particularly those made from aluminum or steel, offer unparalleled strength and structural support. They are often used in construction and heavy-duty applications where load-bearing is crucial. The primary disadvantage of metal sheets is their higher cost and the complexity of installation, which may require heavy machinery and skilled labor. Furthermore, metal sheets can be prone to corrosion unless treated appropriately. Despite these drawbacks, their longevity and performance in demanding environments make them a reliable choice for many industrial applications.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between fibre plastic sheets and their alternatives, it is essential for B2B buyers to consider the specific requirements of their applications. Factors such as performance, cost, ease of implementation, and maintenance should guide the decision-making process. For instance, if insulation and chemical resistance are priorities, fibre plastic sheets may be the best fit. Conversely, for applications requiring structural integrity and durability, metal sheets might be more suitable. Understanding the unique advantages and limitations of each option will empower buyers to make informed choices that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for fibre plastic sheet

Fibre plastic sheets, often referred to as vulcanized fibre or fibre sheets, are widely used in various industrial applications due to their unique properties and versatility. Understanding their technical specifications and trade terminology is crucial for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. This knowledge not only aids in informed purchasing decisions but also enhances communication with suppliers and manufacturers.

What are the Key Technical Properties of Fibre Plastic Sheets?

1. Material Grade

Material grade refers to the quality of the fibre plastic sheet, which can significantly affect its performance in specific applications. Higher grades typically offer better durability, chemical resistance, and electrical insulation properties. For B2B buyers, selecting the appropriate material grade is essential for ensuring product reliability and longevity in demanding environments.

2. Thickness

Thickness is a critical specification that influences the strength and application suitability of fibre plastic sheets. Common thicknesses range from 0.010 inches to 0.078 inches. Thicker sheets generally provide greater strength and resistance to wear and tear, making them suitable for heavy-duty applications. Buyers must consider the specific requirements of their projects to choose the right thickness.

3. Dimensions

Fibre plastic sheets come in various standard dimensions, such as 40 x 52 inches or 26 x 40 inches. Knowing the available sizes is important for optimizing material usage and minimizing waste. B2B buyers should ensure that the dimensions align with their operational needs to reduce cutting and handling costs.

Illustrative image related to fibre plastic sheet

4. Weight per Sheet

The weight of each sheet varies depending on its thickness and dimensions. Understanding the weight is essential for logistical planning, as it affects shipping costs and handling procedures. Buyers should assess their transportation capabilities and storage solutions when considering heavier sheets.

5. Electrical Insulation Properties

Fibre plastic sheets are often chosen for their excellent electrical insulation properties. This characteristic makes them ideal for applications in electrical and electronic components. B2B purchasers in sectors like manufacturing and construction must evaluate the electrical insulation requirements of their projects to ensure compliance and safety.

6. Chemical Resistance

The ability of fibre plastic sheets to resist various chemicals is another important property. This resistance is vital for applications in environments where exposure to oils, solvents, and other corrosive substances is common. Buyers should assess the specific chemical environments their products will encounter and select sheets accordingly.

What Are Common Trade Terms Associated with Fibre Plastic Sheets?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is vital for B2B buyers, as it ensures compatibility and quality in the components they source for their operations.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budget-conscious buyers, as it influences purchasing decisions and inventory management. Buyers should negotiate MOQs to align with their operational needs while ensuring cost-effectiveness.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing and terms for specific products. This process is essential for B2B buyers to compare offers and negotiate favorable terms, ensuring they receive the best value for their purchases.

4. Incoterms

Incoterms, or International Commercial Terms, define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to navigate shipping, insurance, and liability issues effectively, especially in cross-border transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving it. This term is critical for project planning and inventory management, as longer lead times can impact production schedules. B2B buyers should factor lead time into their procurement strategies to ensure timely project execution.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding fibre plastic sheets, enhancing their operational efficiency and fostering stronger supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the fibre plastic sheet Sector

What Are the Key Market Dynamics and Trends Influencing the Fibre Plastic Sheet Sector?

The global market for fibre plastic sheets is driven by several interrelated factors, including technological advancements, increasing industrial applications, and a growing demand for lightweight, durable materials. Key trends include the rise of automation in manufacturing processes, which enhances precision and reduces costs. As industries such as automotive, aerospace, and construction seek lightweight yet robust materials, fibre plastic sheets have gained traction for their superior strength-to-weight ratio and versatility.

Regional dynamics play a crucial role in shaping market opportunities. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding local market conditions is vital. In emerging markets like Brazil and various African nations, there is a burgeoning demand for sustainable building materials, which drives interest in fibre plastic sheets. Conversely, in established markets such as Germany, the focus is on high-performance materials that meet stringent regulatory standards, leading to a preference for certified products.

Illustrative image related to fibre plastic sheet

Additionally, the shift towards digital sourcing platforms is transforming procurement practices. Buyers are increasingly leveraging e-commerce and digital marketplaces to access a wider range of suppliers, compare prices, and evaluate product specifications efficiently. This trend is particularly beneficial for international buyers seeking to navigate complex supply chains and optimize their sourcing strategies.

How Is Sustainability Shaping the Fibre Plastic Sheet Supply Chain?

Sustainability has emerged as a key consideration in the sourcing of fibre plastic sheets. The environmental impact of production processes, particularly concerning resource consumption and waste generation, has prompted B2B buyers to seek out manufacturers who prioritize sustainable practices. Ethical sourcing is becoming increasingly important, with companies expected to demonstrate transparency in their supply chains and adhere to environmentally responsible practices.

Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are gaining prominence in the fibre plastic sheet sector. These certifications not only assure buyers of the product’s environmental credentials but also enhance brand reputation and consumer trust. Additionally, manufacturers are exploring bio-based and recycled materials to produce fibre plastic sheets, aligning with the growing demand for ‘green’ products.

As international buyers assess suppliers, they should prioritize those who can provide documentation of sustainable practices and certifications. This focus on ethical sourcing not only mitigates risks associated with environmental regulations but also positions companies as leaders in sustainability within their respective markets.

Illustrative image related to fibre plastic sheet

How Has the Fibre Plastic Sheet Sector Evolved Over Time?

The evolution of the fibre plastic sheet sector can be traced back to its origins in the early 20th century, when advancements in material science led to the development of synthetic polymers. Initially utilized in niche applications, these materials have since expanded into mainstream use across various industries. The introduction of vulcanized fibre, a product known for its durability and electrical insulation properties, marked a significant milestone in the sector’s growth.

Over the decades, innovations in production techniques and material formulations have enhanced the performance characteristics of fibre plastic sheets. The rise of digital technologies and automation has further revolutionized manufacturing processes, allowing for greater customization and efficiency. Today, the sector is characterized by a diverse range of products tailored to meet specific industrial requirements, reflecting a shift towards more specialized and application-driven solutions.

As international B2B buyers navigate this evolving landscape, staying informed about technological advancements and market trends will be crucial for making informed sourcing decisions and maintaining a competitive edge.

Frequently Asked Questions (FAQs) for B2B Buyers of fibre plastic sheet

-

How do I choose the right fibre plastic sheet for my application?

Choosing the right fibre plastic sheet involves understanding the specific requirements of your application. Consider factors such as thickness, color, dimensions, and the environment in which the sheet will be used. For instance, if the sheet will be exposed to chemicals or high temperatures, ensure it meets the necessary resistance standards. Additionally, consult with suppliers to discuss your needs and request samples to evaluate performance before making a bulk purchase. -

What are the key benefits of using fibre plastic sheets in industrial applications?

Fibre plastic sheets offer several advantages, including high durability, excellent insulation properties, and resistance to chemicals and moisture. They are lightweight yet strong, making them suitable for various applications such as electrical insulation, automotive parts, and construction. Their versatility allows for customization in size and thickness, catering to diverse industry needs. Furthermore, these sheets are often more cost-effective than metal alternatives, reducing overall project costs. -

What are the minimum order quantities (MOQs) for fibre plastic sheets?

Minimum order quantities for fibre plastic sheets can vary significantly by supplier and product type. Generally, MOQs may range from a few sheets to several hundred, depending on the manufacturer’s production capabilities and inventory levels. It’s advisable to negotiate MOQs with potential suppliers, especially if you are a smaller buyer or require a specific custom size. This flexibility can help you manage costs effectively while ensuring you have the materials needed for your projects. -

How can I verify the credibility of a fibre plastic sheet supplier?

To verify a supplier’s credibility, conduct thorough research on their background and reputation. Check for industry certifications, such as ISO standards, and read customer reviews or testimonials. Additionally, ask for references from past clients and inquire about their experience with the supplier. Visiting the supplier’s facilities, if possible, can also provide insights into their manufacturing processes and quality control measures, ensuring that you partner with a reliable source. -

What payment terms should I expect when sourcing fibre plastic sheets internationally?

Payment terms can vary widely between suppliers and regions. Common terms include advance payment, letters of credit, or payment upon delivery. It’s crucial to discuss and negotiate terms upfront to ensure clarity. Consider using secure payment methods that offer buyer protection. Additionally, understand any currency fluctuations that may impact pricing, especially in international transactions, and factor these into your budgeting process. -

What are the common shipping and logistics considerations for importing fibre plastic sheets?

When importing fibre plastic sheets, consider shipping methods, lead times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments but requires more time. Ensure your supplier provides all necessary documentation for customs clearance, such as invoices and packing lists. Additionally, work with a logistics partner familiar with international trade to navigate potential challenges, ensuring timely delivery to your location. -

How can I customize fibre plastic sheets to meet my specific needs?

Customization of fibre plastic sheets can include adjustments in thickness, dimensions, color, and even specific material properties such as flame resistance or moisture barriers. When discussing customization with suppliers, provide detailed specifications and any relevant standards your product must meet. Some manufacturers may offer prototype samples to test before placing a larger order. This approach ensures that the final product aligns with your requirements and enhances operational efficiency. -

What quality assurance measures should I expect from fibre plastic sheet suppliers?

Reputable suppliers typically implement stringent quality assurance measures to ensure product consistency and reliability. Look for suppliers that conduct regular inspections and testing of their products, including checks for thickness, strength, and resistance to environmental factors. Inquire about their quality control processes, certifications, and any warranties offered on the products. This commitment to quality not only assures you of the product’s performance but also reduces the risk of defects and operational disruptions.

Top 6 Fibre Plastic Sheet Manufacturers & Suppliers List

1. Espemfg – Vulcanized Fibre Sheets

Domain: electrical-insulation.espemfg.com

Registered: 2000 (25 years)

Introduction: Fibre Sheets are made from Vulcanized Fibre, a hard, durable, chemically pure cellulose product without resin or bonding agents. Available in various forms including rolls, coils, sheets, tubes, and rods. Common applications include washers, insulating plates, switch and appliance insulation, electric motor insulation, gaskets, and automobile parts. Key properties include high mechanical strength,…

2. Ensinger – Thin Gauge Engineering Plastics

Domain: pennfibre.com

Registered: 1996 (29 years)

Introduction: Ensinger offers a broad line of Thin Gauge Engineering and High Performance plastics suitable for various applications. Key product categories include: 1. High Performance Materials (> 300°F): – Polyetheretherketone (PEEK): TECAPEEK, TECAPEEK GF30 – Polyphenylene Sulfide (PPS): TECATRON PPS, TECATRON GF40 – Polyetherimide (Ultem®): TECAPEI, TECAPEI GF30 – Sulfones: TECASON S – Polysulfone: TECASON…

3. New Process Fibre Company – High-Quality Plastic Sheets and Rolls

Domain: newprocess.com

Registered: 1996 (29 years)

Introduction: New Process Fibre Company, Inc. produces high-quality plastic sheets and rolls using various materials including PTFE (Teflon™), PEEK, and PEI (Ultem®). The plastic sheets are made through an extrusion process, resulting in products that can be customized in lengths from 0.75 in. to 38 in. and thicknesses ranging from 0.008 in. to 0.250 in. Key benefits include customization at scale, lightweight …

4. Atlas Fibre – Thermoset Composite Sheets

Domain: atlasfibre.com

Registered: 1996 (29 years)

Introduction: Thermoset composite sheets available in various materials including Glass Epoxy, Glass Melamine, Paper Phenolic, Linen Phenolic, and Canvas Phenolic. Sheet thickness ranges from 0.005″ to over 8″. Standard sheet sizes are 36×48″, 48×48″, and 48×96″, with extra large sheets up to 48×120″ available by request. Compliance with NEMA and MIL-I standards. Options for thermoplastic sheets also available….

5. McMaster – Fiber Sheets Selection

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Fiber Sheets Selection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Professional Plastics – Fish Paper Insulation

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: Fish paper is a type of electrical insulation material made from cellulose fibers. It is known for its excellent dielectric properties, high strength, and resistance to moisture and chemicals. Fish paper is commonly used in electrical applications, including transformers, capacitors, and other electrical devices. It is available in various thicknesses and sizes to meet specific application require…

Strategic Sourcing Conclusion and Outlook for fibre plastic sheet

How Can Strategic Sourcing Enhance Your Procurement of Fibre Plastic Sheets?

In today’s competitive landscape, strategic sourcing of fibre plastic sheets offers significant advantages for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. By leveraging a comprehensive understanding of market dynamics, suppliers can optimize their procurement processes to achieve cost efficiencies while ensuring high-quality materials. This is particularly crucial given the diverse applications of fibre plastic sheets across various industries, from electrical insulation to manufacturing.

Understanding the pricing tiers based on volume purchases allows businesses to negotiate better terms and foster long-term relationships with suppliers. Additionally, sourcing from reliable manufacturers ensures compliance with regional standards and minimizes supply chain disruptions.

As markets evolve and sustainability becomes increasingly important, aligning sourcing strategies with environmentally responsible practices will not only improve brand reputation but also appeal to a growing segment of eco-conscious consumers.

International buyers are encouraged to proactively engage with suppliers, explore innovative product offerings, and stay informed about industry trends. Embracing strategic sourcing not only enhances operational efficiency but also positions businesses for sustainable growth in the rapidly changing global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to fibre plastic sheet

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.