Fiber Sheeting Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for fiber sheeting

The global market for fiber sheeting presents a multitude of opportunities and challenges for B2B buyers. Sourcing high-quality fiber sheeting that meets specific industry needs—be it for automotive, electrical insulation, or construction—can be daunting, particularly for international buyers from diverse regions such as Africa, South America, the Middle East, and Europe. As these markets expand, understanding the nuances of fiber sheeting becomes crucial for making informed purchasing decisions.

This comprehensive guide serves as an essential resource for B2B buyers, detailing various types of fiber sheeting, including vulcanized fiber and carbon fiber options, alongside their unique applications. From exploring the mechanical and electrical properties that enhance performance to assessing the cost implications based on quality and supplier reputation, this guide equips buyers with the knowledge needed to navigate the complexities of sourcing.

By providing insights into supplier vetting processes, buyers can identify reliable manufacturers and distributors, ensuring that their procurement strategies align with industry standards and regulatory requirements. Ultimately, this guide empowers international B2B buyers, particularly those in regions like Nigeria and Saudi Arabia, to make strategic decisions that not only meet their operational needs but also foster sustainable business growth in an increasingly competitive global market.

Understanding fiber sheeting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon Fiber Sheets | High strength-to-weight ratio, excellent rigidity, and thermal resistance. | Aerospace, automotive, sports equipment, and custom tooling. | Pros: Lightweight, strong, and durable. Cons: Higher cost compared to other materials. |

| Vulcanized Fibre Sheets | Chemically pure cellulose, resistant to heat and cold, and machinable. | Electrical insulation, gaskets, automotive parts, and industrial applications. | Pros: Cost-effective, versatile, and easy to machine. Cons: Limited temperature resistance compared to carbon fiber. |

| Glass Fiber Sheets | Made from glass fibers, offering good tensile strength and corrosion resistance. | Marine, construction, automotive, and consumer goods. | Pros: Affordable, lightweight, and resistant to moisture. Cons: Lower strength compared to carbon and vulcanized fiber. |

| Kevlar Fiber Sheets | Exceptional tensile strength and impact resistance, lightweight. | Protective gear, aerospace, automotive, and military applications. | Pros: High durability and resistance to abrasion. Cons: More expensive and less available than other fibers. |

| Honeycomb Composite Sheets | Lightweight structure with high strength and rigidity. | Aerospace, automotive, and architectural applications. | Pros: Excellent strength-to-weight ratio. Cons: Can be more complex to manufacture and install. |

What are the Characteristics and Suitability of Carbon Fiber Sheets for B2B Buyers?

Carbon fiber sheets are renowned for their exceptional strength-to-weight ratio, making them ideal for industries where weight reduction is critical without compromising structural integrity. They exhibit excellent thermal resistance and rigidity, which is essential in high-performance applications such as aerospace and automotive components. When purchasing, buyers should consider the specific ply orientation, thickness, and size, as these factors significantly influence performance and application suitability.

How Do Vulcanized Fibre Sheets Meet Diverse Industrial Needs?

Vulcanized fibre sheets are made from chemically pure cellulose, providing excellent mechanical strength and durability. They are particularly valued in electrical insulation applications due to their good dielectric properties and resistance to heat and cold. This type of fiber sheeting is versatile and can be machined easily, making it suitable for various applications, including automotive parts and gaskets. B2B buyers should evaluate the thickness and grade of the sheets to ensure they meet specific performance requirements.

What Advantages Do Glass Fiber Sheets Offer for Various Applications?

Glass fiber sheets are constructed from woven glass fibers, offering good tensile strength and moisture resistance. They are commonly used in marine and construction applications, where durability and cost-effectiveness are essential. While they are generally more affordable than carbon fiber sheets, buyers should be aware that they do not provide the same level of strength. When sourcing glass fiber sheets, consider the specific environmental conditions they will face, such as exposure to moisture or chemicals.

Why Choose Kevlar Fiber Sheets for Protective Applications?

Kevlar fiber sheets are known for their exceptional tensile strength and impact resistance, making them a preferred choice for protective gear and military applications. Their lightweight nature combined with high durability makes them suitable for various demanding environments. However, Kevlar sheets can be more expensive than other fiber options. Buyers should consider the specific application requirements, including the level of protection needed and the environmental factors the material will encounter.

How Do Honeycomb Composite Sheets Enhance Structural Integrity?

Honeycomb composite sheets are engineered for high strength and low weight, making them ideal for aerospace and architectural applications. Their unique structure provides excellent rigidity while minimizing weight, which is crucial in industries where every gram counts. However, the complexity of manufacturing and installation can be a drawback for some applications. B2B buyers should assess their specific needs and the potential for custom solutions when considering honeycomb composites.

Key Industrial Applications of fiber sheeting

| Industry/Sector | Specific Application of Fiber Sheeting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Structural components in aircraft and drones | Lightweight yet strong materials reduce fuel costs | Compliance with aviation standards and certifications |

| Electrical Engineering | Insulating components for motors and transformers | Enhanced safety and reliability in electrical systems | Material specifications and dielectric strength requirements |

| Automotive | Gaskets and seals in vehicles | Improved durability and reduced maintenance costs | Resistance to heat and chemicals, customization for specific models |

| Construction | Reinforcement in building materials | Increased structural integrity and longevity | Sourcing local suppliers to reduce shipping costs and delays |

| Consumer Goods | Lightweight casings for electronics and appliances | Enhanced product performance and user experience | Aesthetic options and compliance with safety regulations |

How is Fiber Sheeting Utilized in the Aerospace Sector?

In the aerospace industry, fiber sheeting is critical for manufacturing structural components in aircraft and drones. The lightweight yet robust nature of materials like carbon fiber significantly reduces overall weight, leading to lower fuel consumption and operational costs. Buyers in this sector must ensure that the fiber sheeting meets strict aviation standards and certifications, which may vary by region. Compliance with specifications such as FAA regulations is essential for international buyers, particularly from regions like the Middle East and Europe.

What Role Does Fiber Sheeting Play in Electrical Engineering?

Fiber sheeting serves as an essential insulating material in electrical engineering, particularly for motors and transformers. Its excellent electrical properties and high dielectric strength contribute to enhanced safety and reliability in electrical systems, minimizing the risk of short circuits and failures. Buyers should focus on sourcing materials that comply with international electrical standards, ensuring that they can withstand specific environmental conditions, especially in hot and humid regions like Africa and South America.

How is Fiber Sheeting Applied in the Automotive Industry?

In the automotive sector, fiber sheeting is frequently used to manufacture gaskets and seals, which are vital for maintaining vehicle integrity. The material’s durability and resistance to heat and chemicals lead to reduced maintenance costs and prolonged vehicle life. B2B buyers should consider sourcing fiber sheeting that is customizable for specific vehicle models, ensuring compatibility with different automotive designs. Additionally, local sourcing can help mitigate supply chain issues often faced in international trade.

What Are the Benefits of Fiber Sheeting in Construction?

Fiber sheeting is increasingly utilized in construction to reinforce building materials, enhancing structural integrity and longevity. Its lightweight nature allows for easier handling and installation, while its strength ensures that structures can withstand environmental stresses. For international buyers, particularly in developing regions, sourcing fiber sheeting from local suppliers can reduce shipping costs and delays, making projects more efficient. Buyers should also consider the material’s resistance to environmental factors relevant to their specific geographical locations.

How is Fiber Sheeting Transforming Consumer Goods?

In the consumer goods sector, fiber sheeting is commonly used for lightweight casings in electronics and appliances. This application not only improves product performance but also enhances user experience by making products easier to handle. When sourcing fiber sheeting for consumer goods, businesses should prioritize aesthetics, ensuring that the materials can be produced in various finishes and colors to meet market demands. Compliance with safety regulations is also crucial, particularly for products intended for children or sensitive applications.

3 Common User Pain Points for ‘fiber sheeting’ & Their Solutions

Scenario 1: Quality Variability in Fiber Sheeting Products

The Problem: B2B buyers often face challenges with the quality and consistency of fiber sheeting products. For instance, a manufacturer in Nigeria might order a bulk supply of vulcanized fiber sheets only to discover that the tensile strength and electrical insulation properties vary significantly between shipments. This inconsistency can lead to product failures, increased scrap rates, and ultimately, dissatisfied customers. The financial implications of such quality issues can be severe, affecting the buyer’s reputation and bottom line.

The Solution: To mitigate quality variability, buyers should establish rigorous supplier evaluation criteria that include certifications and compliance with industry standards such as ASTM or NEMA. Conducting audits and requesting samples before placing bulk orders can also help ensure the consistency of product quality. Implementing a quality assurance program that includes regular testing of incoming materials will allow manufacturers to catch discrepancies early, ensuring that only products meeting their specifications reach the production line. Additionally, fostering a strong relationship with suppliers can facilitate better communication and transparency regarding manufacturing processes and any potential issues.

Scenario 2: Difficulty in Sourcing Specific Fiber Sheeting Sizes and Types

The Problem: Many businesses struggle to find fiber sheeting in the specific dimensions or types they require for specialized applications. For example, a company in Saudi Arabia producing electrical insulation components may need custom-sized sheets with specific dielectric properties. Off-the-shelf options often do not meet their technical requirements, leading to delays and increased costs in production.

The Solution: To address this challenge, buyers should proactively communicate their specific needs to potential suppliers and inquire about custom manufacturing options. Many manufacturers are equipped to produce fiber sheets tailored to precise specifications, but this may require advance planning and longer lead times. Buyers should develop a detailed specification sheet that outlines thickness, dimensions, and any necessary mechanical properties. Additionally, leveraging industry trade shows and networking events can help buyers connect with specialized suppliers that cater to niche requirements. Building a reliable supply chain that includes multiple sources can also mitigate risks associated with sourcing specific products.

Scenario 3: High Shipping Costs and Logistics Challenges

The Problem: International buyers, particularly from regions such as South America and Africa, often face exorbitant shipping costs and logistical issues when sourcing fiber sheeting. The weight and bulk of these materials can lead to increased freight charges, which in turn affects overall project budgets. Moreover, delays in shipping can disrupt production schedules, leading to missed deadlines and client dissatisfaction.

The Solution: To reduce shipping costs, buyers should consider sourcing fiber sheeting from local or regional suppliers when possible. This can significantly lower freight charges and lead times. If international sourcing is necessary, consolidating shipments or negotiating better rates with freight forwarders can also help manage costs. Employing just-in-time inventory practices can reduce the amount of material held in stock, thus decreasing the financial burden associated with excess inventory. Moreover, utilizing freight optimization software can provide insights into the most cost-effective shipping methods and routes. Engaging with logistics experts who understand the intricacies of international shipping can further streamline the process and mitigate delays.

Strategic Material Selection Guide for fiber sheeting

What Are the Key Properties of Common Fiber Sheeting Materials?

When selecting fiber sheeting materials for industrial applications, it is essential to consider their properties, performance capabilities, and suitability for specific applications. Below, we analyze four common materials: Carbon Fiber, Vulcanized Fiber, Fiberglass, and Aramid Fiber, focusing on their key properties, advantages, disadvantages, and implications for international buyers.

How Does Carbon Fiber Perform in Industrial Applications?

Carbon fiber sheeting is renowned for its exceptional strength-to-weight ratio and rigidity. It can withstand temperatures up to 140°F (60°C) and is resistant to many chemicals, making it suitable for various applications, including aerospace and automotive components.

Pros: Carbon fiber offers high durability and excellent fatigue resistance, making it ideal for applications where weight savings are crucial. It can be machined with standard tools, facilitating ease of fabrication.

Cons: The primary drawback is its high cost, which can be prohibitive for some applications. Additionally, carbon fiber can be more challenging to source in specific regions, leading to longer lead times.

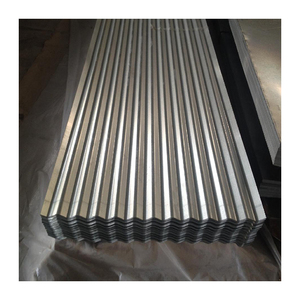

Illustrative image related to fiber sheeting

Impact on Application: Carbon fiber is compatible with various media, including corrosive substances, but care must be taken in environments with high humidity, as it may absorb moisture.

Considerations for International Buyers: Compliance with international standards such as ASTM and JIS is crucial. Buyers from regions like Africa and the Middle East should ensure that suppliers can meet local regulations regarding material safety and performance.

What Are the Advantages of Vulcanized Fiber in Industrial Use?

Vulcanized fiber is a cellulose-based product known for its high mechanical strength and excellent electrical insulation properties. It is lightweight, half the weight of aluminum, and can operate effectively in temperatures ranging from -40°F to 200°F (-40°C to 93°C).

Pros: Its durability and resistance to heat and cold make it suitable for various applications, including electrical insulation and gaskets. It is also cost-effective, especially in bulk purchases.

Cons: While it is versatile, vulcanized fiber is not as strong as carbon fiber and may not be suitable for high-stress applications. It can also be affected by moisture if not properly treated.

Impact on Application: Vulcanized fiber is ideal for electrical applications due to its excellent dielectric properties, making it suitable for components like switchgear and motor insulation.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM D-710 and NEMA grades. The availability of vulcanized fiber in local markets can vary, so sourcing from reliable suppliers is essential.

How Does Fiberglass Compare in Terms of Performance and Cost?

Fiberglass sheeting is composed of glass fibers and resin, providing a balance of strength, weight, and cost. It can withstand temperatures up to 300°F (150°C) and offers good corrosion resistance, making it suitable for various industrial applications.

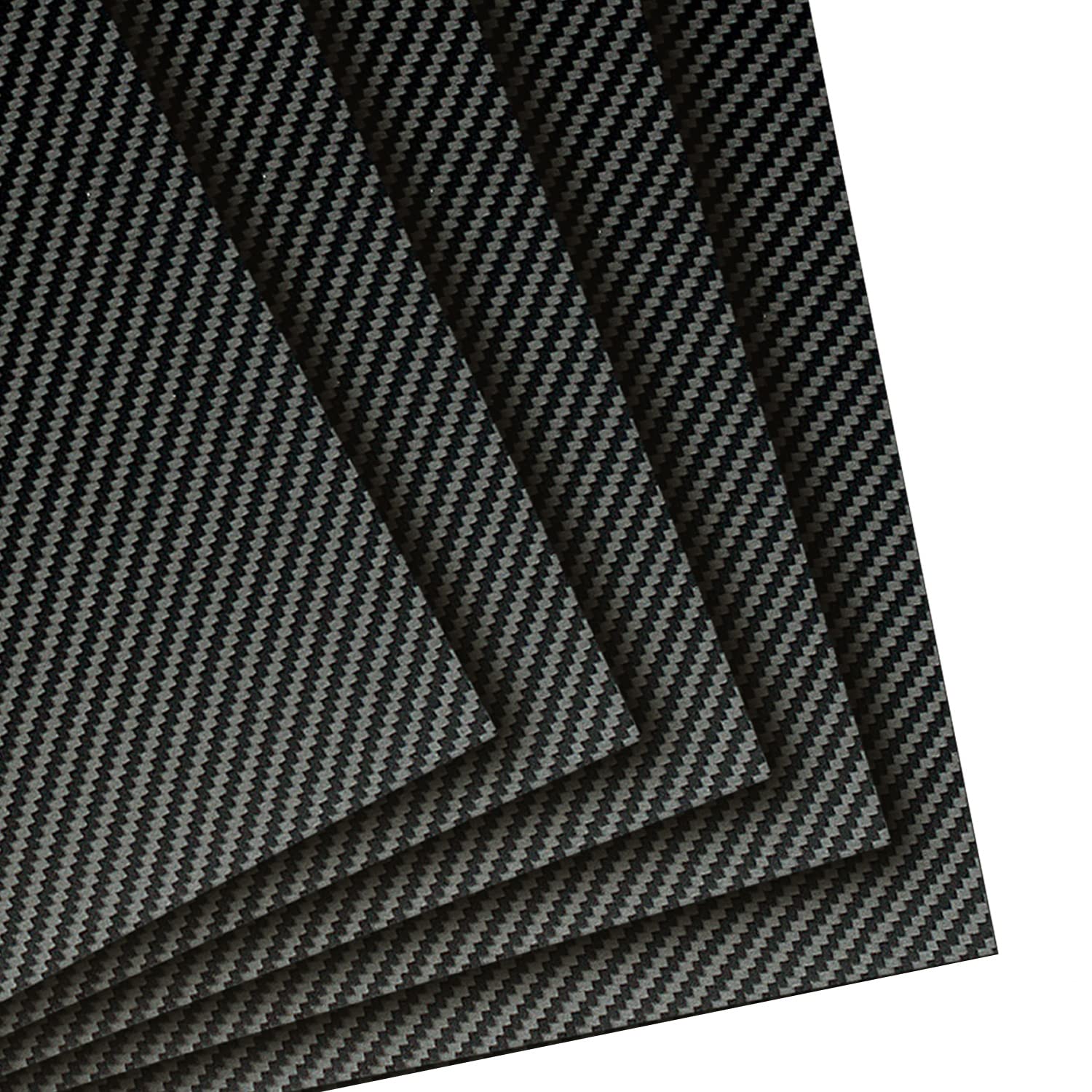

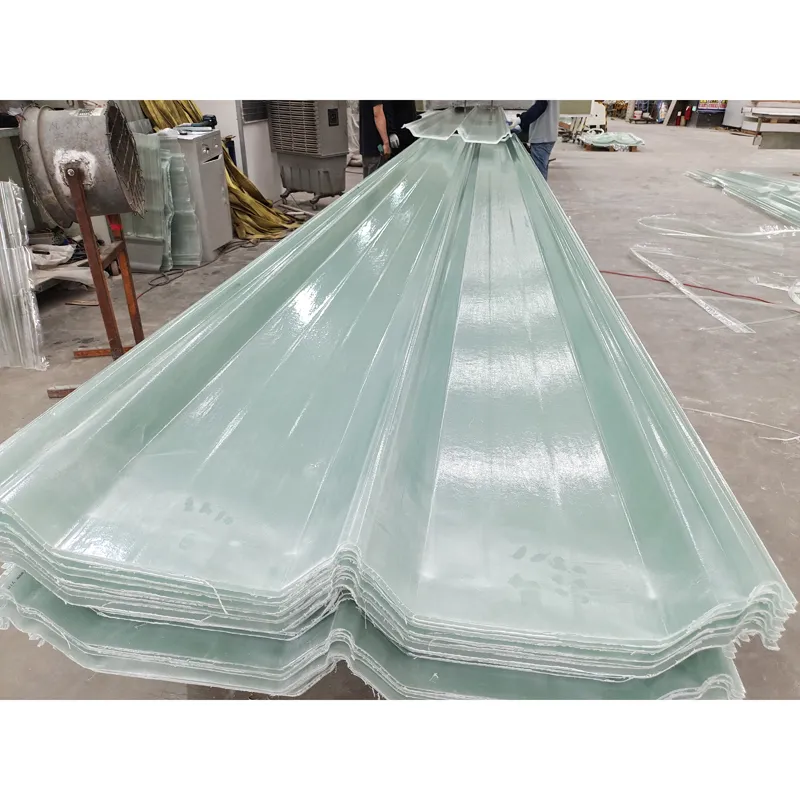

Illustrative image related to fiber sheeting

Pros: Fiberglass is relatively inexpensive compared to carbon fiber and offers good mechanical properties. It is also resistant to many chemicals, making it versatile for diverse applications.

Cons: The primary limitation of fiberglass is its brittleness; it can crack under impact or stress. Additionally, it requires specialized tools for machining, which may increase production costs.

Impact on Application: Fiberglass is compatible with various media, including water and chemicals, making it suitable for piping and storage applications.

Considerations for International Buyers: Compliance with standards like ASTM D-578 is important. Buyers should also consider the availability of fiberglass products in their region, especially in remote areas.

What Makes Aramid Fiber a Unique Choice for Fiber Sheeting?

Aramid fiber, commonly known as Kevlar, is known for its high tensile strength and resistance to abrasion. It operates effectively in temperatures up to 400°F (204°C) and is often used in applications requiring high impact resistance.

Pros: Aramid fiber is lightweight yet incredibly strong, making it ideal for protective gear and applications in the automotive and aerospace sectors. It also has excellent chemical resistance.

Cons: The cost of aramid fiber can be high, and its processing can be more complex than other materials. Additionally, it may not perform as well in high-temperature applications compared to carbon fiber.

Impact on Application: Aramid fiber is particularly effective in environments where impact resistance is critical, such as in protective equipment and military applications.

Considerations for International Buyers: Buyers should ensure compliance with military specifications if applicable. Understanding local regulations regarding the use of aramid fibers is also essential, especially in defense-related applications.

Summary Table of Fiber Sheeting Materials

| Material | Typical Use Case for fiber sheeting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Fiber | Aerospace components | High strength-to-weight ratio | High cost | High |

| Vulcanized Fiber | Electrical insulation | Excellent dielectric properties | Less strength than carbon fiber | Low |

| Fiberglass | Piping and storage | Cost-effective and versatile | Brittle under stress | Medium |

| Aramid Fiber | Protective gear | High impact resistance | Complex processing and high cost | High |

This guide serves as a comprehensive resource for B2B buyers looking to make informed decisions regarding fiber sheeting materials, ensuring they select the right product for their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for fiber sheeting

What Are the Main Stages in the Manufacturing Process of Fiber Sheeting?

The manufacturing of fiber sheeting typically involves several key stages: material preparation, forming, assembly, and finishing.

Illustrative image related to fiber sheeting

Material Preparation

The process begins with the selection and preparation of raw materials, which may include cellulose fibers, carbon fibers, or synthetic resins. For example, vulcanized fiber sheets are made from pure cellulose, which is processed to enhance its mechanical and thermal properties. This stage may involve cutting the raw materials into specific sizes and ensuring they meet quality standards before moving forward.

Forming

Once the materials are prepared, the next step is forming. This can be done through various techniques such as pressing, molding, or lamination. In the case of carbon fiber sheets, layers of fabric are laid out in a specific orientation (e.g., woven 0/90 degrees) and then bonded together under heat and pressure to create a solid sheet. This stage is critical as it defines the structural integrity and performance characteristics of the final product.

Assembly

After forming, the sheets may undergo an assembly phase where they are cut, shaped, or combined with other materials. This could include adding insulation layers or incorporating additional components to meet specific application needs. Automation in this stage can enhance efficiency and reduce waste, which is particularly important for B2B buyers looking for cost-effective solutions.

Finishing

The final stage involves finishing processes such as surface treatment, coating, or cutting to the final specifications. This is crucial for ensuring that the fiber sheeting meets aesthetic and functional requirements. For instance, carbon fiber sheets may receive a glossy finish to improve appearance and protect against environmental factors.

How Is Quality Assurance Implemented in Fiber Sheeting Production?

Quality assurance (QA) is vital in ensuring that fiber sheeting products meet international standards and customer expectations. Various quality control checkpoints and methodologies are utilized throughout the manufacturing process.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers have processes in place to maintain high-quality output. Additionally, industry-specific certifications like CE marking for products sold in Europe or API specifications for oil and gas applications may also apply. These certifications not only enhance product credibility but also facilitate market access.

What Are the Key Quality Control Checkpoints?

Quality control in fiber sheeting manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. Materials are tested against specifications to ensure they are suitable for manufacturing.

-

In-Process Quality Control (IPQC): During the manufacturing process, samples may be taken at various stages to ensure that the production is proceeding according to established parameters. This could involve monitoring temperature and pressure during the forming stage.

-

Final Quality Control (FQC): Once manufacturing is complete, finished products undergo thorough inspections to verify that they meet all quality and performance standards. This may include visual inspections, dimensional checks, and functional testing.

What Testing Methods Are Commonly Used in Quality Assurance?

To ensure that fiber sheeting products meet the required specifications, various testing methods are employed:

-

Mechanical Testing: This includes tensile strength tests, tear resistance tests, and impact resistance assessments to evaluate the physical properties of the sheets.

-

Thermal Testing: Given the importance of thermal resistance in applications, thermal conductivity and heat resistance tests are conducted to ensure that products can withstand specified temperatures.

-

Electrical Testing: For applications requiring electrical insulation, dielectric strength and arc resistance tests are essential to verify the material’s performance in electrical environments.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to ensure that their suppliers adhere to quality control measures:

-

Conduct Audits: Regular audits of the manufacturing facilities can provide insights into the quality management systems in place. Buyers should look for adherence to ISO standards and other relevant certifications.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from IQC, IPQC, and FQC. This transparency can help buyers assess the reliability of the products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and the products themselves. This is particularly important for international buyers who may not have the ability to conduct on-site audits.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance. These may include:

-

Regulatory Compliance: Different countries may have varying regulations regarding product safety and quality standards. Buyers must ensure that their suppliers comply with local regulations in their target markets.

-

Logistics and Supply Chain Considerations: The complexity of international logistics can affect product quality. Buyers should consider how products are stored and transported, as improper handling can lead to damage or degradation.

-

Cultural and Communication Barriers: Effective communication with suppliers regarding quality expectations and standards is crucial. Language barriers or cultural differences can lead to misunderstandings that affect product quality.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions and establish reliable partnerships with suppliers of fiber sheeting. This knowledge not only helps in selecting the right products but also in ensuring that those products meet the necessary quality standards for their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fiber sheeting’

Introduction

Sourcing fiber sheeting for industrial applications requires a meticulous approach to ensure that the materials meet your technical and operational needs. This step-by-step checklist is designed to guide B2B buyers through the critical phases of procurement, helping you make informed decisions that align with your business objectives.

Illustrative image related to fiber sheeting

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital before starting the sourcing process. Identify the specific type of fiber sheeting required, considering factors such as thickness, size, material composition (e.g., vulcanized fiber or carbon fiber), and any additional performance characteristics like heat resistance or electrical insulation. This clarity will streamline communication with suppliers and prevent misunderstandings later.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers specializing in fiber sheeting. Utilize industry directories, trade shows, and online marketplaces to find reputable companies. Pay attention to their market presence and customer reviews, as these factors can provide insights into their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your shortlisted suppliers hold relevant certifications. Look for quality standards such as ISO certifications, compliance with ASTM specifications, and industry-specific certifications. These credentials indicate that the supplier adheres to high manufacturing and quality assurance practices, which is crucial for ensuring the integrity of your fiber sheeting.

Step 4: Request Product Samples

Request samples of the fiber sheeting from potential suppliers to assess quality and suitability for your applications. Evaluate the samples based on your defined specifications, checking for consistency in thickness, finish, and overall durability. This step is essential to avoid potential issues with product performance once the materials are in use.

Step 5: Review Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures. Pay attention to not only the unit price but also shipping costs, bulk order discounts, and payment terms. Understanding the total cost of ownership, including any hidden fees, will help you make a financially sound decision.

Step 6: Assess Supplier Capabilities

Examine the production capabilities of your shortlisted suppliers. Ensure they can meet your order volume and delivery timelines consistently. Inquire about their production processes, lead times, and ability to handle custom orders if your project requires specific modifications.

Step 7: Finalize the Agreement

Once you have selected a supplier, finalize the agreement by discussing delivery schedules, payment terms, and warranty policies. Ensure all specifications, including quality standards and service levels, are documented in the contract to protect your interests. This clarity will facilitate a smoother transaction and foster a positive long-term relationship with the supplier.

By following this checklist, B2B buyers can navigate the complexities of sourcing fiber sheeting effectively, ensuring that their procurement decisions are well-informed and aligned with their operational needs.

Comprehensive Cost and Pricing Analysis for fiber sheeting Sourcing

What Are the Key Cost Components for Fiber Sheeting?

When sourcing fiber sheeting, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

Illustrative image related to fiber sheeting

-

Materials: The type of fiber used—such as carbon fiber, vulcanized fiber, or other composites—greatly influences pricing. Higher quality materials typically command a higher price, affecting the overall cost of the sheets.

-

Labor: Labor costs vary by region and can significantly impact the price of manufacturing. In countries with higher labor costs, such as those in Europe, the overall pricing might be higher compared to regions with lower labor costs.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these costs, benefiting the buyer.

-

Tooling: Custom tooling for specific sheet designs or sizes can add to initial costs. However, investing in the right tooling can lead to cost savings in the long term through enhanced production efficiency.

-

Quality Control: Ensuring that products meet specific standards often incurs additional costs. Buyers should consider the importance of certifications and quality assurance in their sourcing decisions.

-

Logistics: Transportation costs can vary widely based on the supplier’s location and the chosen shipping method. Incoterms will dictate who bears the shipping costs and risks, which is crucial for budgeting.

-

Margin: Finally, suppliers will include a profit margin in their pricing. Understanding typical margins within the industry can provide leverage in negotiations.

How Do Price Influencers Impact Fiber Sheeting Costs?

Several factors can influence the pricing of fiber sheeting, especially in an international context.

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing significantly. Suppliers often provide better pricing for larger orders, so buyers should assess their needs and consider bulk purchasing.

-

Specifications and Customization: Custom specifications such as thickness, size, and ply orientation can lead to variations in pricing. Buyers should clearly define their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Higher-quality materials and relevant certifications (e.g., ASTM, NEMA) can increase costs but are often essential for specific applications. Buyers should weigh the importance of these factors against their budget.

-

Supplier Factors: Supplier reputation, reliability, and location can influence both cost and service quality. Establishing a good relationship with suppliers can lead to better pricing and terms.

-

Incoterms: Understanding Incoterms is critical for international transactions. They define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, impacting the total cost.

What Tips Can Help Buyers Negotiate Better Prices for Fiber Sheeting?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, can employ several strategies to enhance their purchasing power:

-

Negotiation: Don’t hesitate to negotiate terms and prices. Suppliers often have some flexibility, especially for large orders or long-term contracts.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, shipping, and disposal costs. This holistic view can lead to better long-term decisions.

-

Pricing Nuances: Be aware of pricing fluctuations due to market conditions, exchange rates, and geopolitical factors, especially when sourcing from different regions.

-

Local Suppliers: Exploring local suppliers can sometimes reduce logistics costs and lead to faster turnaround times.

-

Bulk Orders: Consider placing larger orders to take advantage of discounts associated with volume purchasing.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and seek quotations from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing fiber sheeting With Other Solutions

Exploring Viable Alternatives to Fiber Sheeting

When considering fiber sheeting as a solution for various industrial applications, it’s essential to evaluate its performance against other materials available in the market. This analysis will provide international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, with actionable insights into alternative materials that may better suit their specific needs.

Illustrative image related to fiber sheeting

| Comparison Aspect | Fiber Sheeting | Carbon Fiber Sheets | Vulcanized Fiber Sheets |

|---|---|---|---|

| Performance | High tensile strength, lightweight, and resistant to chemicals and moisture | Superior strength-to-weight ratio, highly rigid, and excellent fatigue resistance | Good mechanical strength, excellent electrical properties, and durable against heat and cold |

| Cost | Moderate pricing, varies by thickness and size | Higher cost per sheet due to advanced manufacturing | Generally lower cost, especially in bulk, price decreases with quantity |

| Ease of Implementation | Relatively easy to cut and shape | Requires specialized tools for cutting; limited flexibility | Easily machinable with standard tools; available in various formats |

| Maintenance | Low maintenance; durable against environmental factors | Minimal maintenance; prone to damage from impacts | Low maintenance; resistant to wear and tear |

| Best Use Case | General insulation, protective coverings, and structural components | Aerospace, automotive, and high-performance applications | Electrical insulation, gaskets, and mechanical components |

What Are the Advantages and Disadvantages of Carbon Fiber Sheets?

Carbon fiber sheets are known for their exceptional strength and rigidity, making them ideal for applications where weight and performance are critical, such as in aerospace and high-end automotive industries. However, their higher cost can be a significant drawback for budget-conscious buyers. Additionally, while they offer excellent fatigue resistance, cutting and shaping carbon fiber sheets often require specialized tools, which may complicate implementation for some businesses.

How Does Vulcanized Fiber Compare in Performance and Cost?

Vulcanized fiber sheets present a cost-effective alternative, particularly for applications requiring good electrical insulation and mechanical strength. They are lightweight and can be easily machined using standard tools, making them versatile for various industries. However, they may not provide the same level of rigidity and strength as fiber sheeting or carbon fiber, which could limit their use in high-stress applications. Their pricing structure is advantageous for bulk purchases, allowing companies to reduce costs significantly.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the most suitable material, B2B buyers should consider their specific application requirements, including performance needs, budget constraints, and ease of implementation. Fiber sheeting may be the best option for general-purpose use, while carbon fiber sheets are ideal for high-performance applications that justify the investment. Conversely, vulcanized fiber sheets offer a practical solution for projects that require decent mechanical strength and electrical insulation at a lower price point. Evaluating these factors will help buyers make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for fiber sheeting

What Are the Key Technical Properties of Fiber Sheeting?

Understanding the technical properties of fiber sheeting is crucial for B2B buyers seeking durable and reliable materials for various applications. Here are some essential specifications to consider:

1. Material Grade

Material grade indicates the quality and characteristics of the fiber sheet. Common grades include vulcanized fiber, carbon fiber, and fiberglass. Each grade has unique properties, such as strength, weight, and thermal resistance, influencing its suitability for different applications. Buyers must choose the right grade to ensure compatibility with their product requirements.

2. Thickness

The thickness of fiber sheeting significantly impacts its strength, flexibility, and application suitability. Common thicknesses range from 0.010 inches for lightweight applications to over 0.045 inches for heavy-duty uses. A thicker sheet typically provides greater durability but may also increase weight, which can affect shipping and handling costs.

3. Ply Orientation

Ply orientation refers to the direction of the fibers in the sheet, usually expressed in degrees (e.g., 0/90). This specification determines the mechanical strength and flexibility of the fiber sheet. For instance, a woven 0/90 orientation offers balanced strength in both directions, making it ideal for structural applications. Understanding ply orientation helps buyers predict how the material will perform under stress.

4. Electrical Properties

Fiber sheeting can possess specific electrical properties, such as dielectric strength and conductivity. Materials like vulcanized fiber are often used for electrical insulation due to their high dielectric strength, making them suitable for applications in motors and electrical equipment. Buyers should assess these properties to ensure compliance with safety standards.

5. Temperature Resistance

Different fiber sheets have varying degrees of temperature resistance, essential for applications exposed to extreme conditions. For example, carbon fiber sheets can withstand temperatures up to 140°F without losing structural integrity. Knowing the temperature limits is vital for buyers to prevent material failure in high-heat environments.

6. Weight

The weight of fiber sheets can impact shipping costs and the final product’s portability. Lighter materials, such as carbon fiber, provide an advantage in applications where weight reduction is critical, such as in aerospace and automotive industries. Buyers must balance weight against strength and durability requirements.

What Are Common Trade Terms Used in Fiber Sheeting?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

Illustrative image related to fiber sheeting

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to source high-quality components that fit specific manufacturing needs.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is vital for buyers to understand as it impacts inventory management and budgeting. Negotiating MOQs can help secure favorable pricing while ensuring adequate supply.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and availability information for specific products or services. For B2B buyers, crafting a clear RFQ can streamline the procurement process and facilitate better pricing negotiations.

Illustrative image related to fiber sheeting

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade transactions, covering aspects like shipping, insurance, and risk transfer. Familiarity with these terms helps buyers understand their obligations and manage costs effectively.

5. NEMA Grade

NEMA (National Electrical Manufacturers Association) grades classify materials based on their electrical insulation properties. Understanding these grades is essential for buyers in the electrical and electronics sectors to ensure compliance with safety standards.

6. ASTM Specification

ASTM (American Society for Testing and Materials) specifications set the standards for the quality and performance of materials. Knowledge of relevant ASTM specifications allows buyers to assess the suitability of fiber sheeting for their intended applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right fiber sheeting for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the fiber sheeting Sector

What Are the Current Market Dynamics and Key Trends in the Fiber Sheeting Sector?

The fiber sheeting sector is currently experiencing a transformative phase influenced by global drivers such as technological advancements, increasing demand for lightweight and high-strength materials, and a growing focus on sustainability. Key markets in Africa, South America, the Middle East, and Europe are witnessing a surge in applications for fiber sheeting across various industries, including automotive, aerospace, construction, and electrical insulation. Notably, the rise of electric vehicles and renewable energy solutions has significantly driven the demand for durable and lightweight materials like carbon fiber and vulcanized fiber.

Emerging B2B technologies, such as advanced manufacturing techniques and digital supply chain management, are reshaping sourcing strategies. Buyers are increasingly leveraging data analytics to optimize inventory management, predict market trends, and enhance supplier relationships. Furthermore, the adoption of e-commerce platforms for B2B transactions is streamlining procurement processes, enabling buyers from regions like Nigeria and Saudi Arabia to access a wider range of products and suppliers efficiently.

How Is Sustainability Influencing Sourcing Trends in Fiber Sheeting?

Sustainability is becoming a cornerstone of sourcing strategies in the fiber sheeting sector. As global awareness of environmental issues increases, buyers are prioritizing materials that are not only high-performing but also eco-friendly. The environmental impact of manufacturing processes, particularly in terms of energy consumption and waste generation, is under scrutiny. This shift is prompting companies to seek suppliers who adhere to sustainable practices and offer certifications that validate their environmental claims.

Illustrative image related to fiber sheeting

Ethical sourcing is also gaining traction, with companies emphasizing transparency in their supply chains. Buyers are looking for partners who can provide information about raw material origins, production methods, and labor practices. Certifications such as ISO 14001 for environmental management systems and the Forest Stewardship Council (FSC) for sustainable forestry are becoming critical in the selection process. Emphasizing these certifications can enhance brand reputation and appeal to environmentally conscious customers.

What Is the Historical Evolution of Fiber Sheeting in B2B Markets?

The history of fiber sheeting dates back to the early 20th century when the need for lightweight, durable materials became evident in various industries. Early applications were primarily in electrical insulation and automotive components, where materials like vulcanized fiber were favored for their mechanical strength and electrical resistance. Over the decades, advancements in manufacturing technologies and material science led to the introduction of composite materials, notably carbon fiber, which revolutionized the sector by offering superior strength-to-weight ratios.

As industries evolved, so did the applications for fiber sheeting. Today, it is integral in high-performance sectors, including aerospace and renewable energy, reflecting a continuous demand for innovation and quality. The ongoing evolution of this sector is shaped by the interplay between technological advancements, market needs, and an increasing emphasis on sustainable practices, setting the stage for future growth and development in the fiber sheeting market.

Frequently Asked Questions (FAQs) for B2B Buyers of fiber sheeting

-

How do I choose the right type of fiber sheeting for my project?

Choosing the right fiber sheeting depends on the specific application and performance requirements. Consider factors such as mechanical strength, thermal resistance, electrical insulation properties, and weight. For instance, vulcanized fiber is excellent for electrical insulation, while carbon fiber sheets are preferred for applications requiring high strength-to-weight ratios. Additionally, assess the size and thickness needed for your project, and evaluate whether customization is necessary to meet your specifications. -

What are the most common applications for fiber sheeting in various industries?

Fiber sheeting is widely utilized across multiple industries. In the automotive sector, it serves as insulation and structural components. In electrical applications, it acts as an insulator for motors and switches. The aerospace industry values carbon fiber sheeting for its lightweight yet strong characteristics. Additionally, construction and manufacturing sectors use fiber sheeting for gaskets, washers, and reinforcement materials. Understanding your industry’s specific needs will help you select the appropriate type of fiber sheeting. -

What minimum order quantities (MOQ) should I expect when sourcing fiber sheeting?

Minimum order quantities for fiber sheeting vary by supplier and material type. Generally, MOQs can range from a few sheets to several hundred pounds, depending on the manufacturer’s production capabilities and the material’s nature. It is advisable to communicate your needs upfront to the supplier, as some may offer flexibility for first-time buyers or smaller businesses. Always clarify MOQ during negotiations to avoid unexpected costs. -

What payment terms are typically offered by suppliers of fiber sheeting?

Payment terms can vary significantly among suppliers, but common practices include net 30, net 60, or even payment in advance for first-time orders. Some suppliers may offer discounts for bulk purchases or early payments. It is essential to establish clear payment terms before placing an order, ensuring that both parties understand the expectations and conditions. Always review the supplier’s credit policies and consider trade insurance if necessary. -

How can I ensure the quality of the fiber sheeting I purchase?

To ensure quality, request certifications and compliance documentation from your supplier, such as ISO certifications or ASTM standards relevant to the material. Additionally, consider ordering samples before committing to a larger purchase, allowing you to test the material’s performance in your application. Establishing a quality assurance process with your supplier can also help maintain consistent quality in future orders. -

What logistics considerations should I keep in mind when importing fiber sheeting?

When importing fiber sheeting, consider shipping methods, lead times, and customs regulations in your country. Air freight may be faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure that your supplier provides the necessary documentation for customs clearance. Additionally, understand any tariffs or duties that may apply to your import, as these can impact overall costs. -

Can I customize fiber sheeting to meet my specific needs?

Many suppliers offer customization options for fiber sheeting, including specific sizes, thicknesses, and surface finishes. When inquiring about custom orders, provide detailed specifications to ensure the supplier can meet your requirements. Customization may impact pricing and lead times, so discuss these factors early in the negotiation process to avoid delays in production. -

What should I look for when vetting suppliers of fiber sheeting?

When vetting suppliers, assess their industry experience, reputation, and customer reviews. Verify their production capabilities and compliance with international quality standards. It’s also beneficial to request references from other businesses that have sourced similar materials. Engaging with suppliers who have experience in your region can enhance communication and logistics, ensuring a smoother procurement process.

Top 5 Fiber Sheeting Manufacturers & Suppliers List

1. Dragonplate – EconomyPlate™ Solid Carbon Fiber Sheet

Domain: dragonplate.com

Registered: 2003 (22 years)

Introduction: [{‘sku’: ‘FEPL06_*90*0606’, ‘name’: ‘EconomyPlate™ Solid Carbon Fiber Sheet’, ‘sheet_size’: ’06” x 06″‘, ‘sheet_thickness’: ‘3/16″‘, ‘ply_orientation’: ‘Woven 0/90’, ‘price’: ‘$36.60’}, {‘sku’: ‘FEPL06_*90*1212’, ‘name’: ‘EconomyPlate™ Solid Carbon Fiber Sheet’, ‘sheet_size’: ’12” x 12″‘, ‘sheet_thickness’: ‘3/16″‘, ‘ply_orientation’: ‘Woven 0/90’, ‘price’: ‘$116.41’}, {‘sku’: ‘FEPL06_*90*1224’, ‘…

2. ESPE Mfg. Co., Inc. – Fibre Sheets

Domain: electrical-insulation.espemfg.com

Registered: 2000 (25 years)

Introduction: {‘product_name’: ‘Fibre Sheets’, ‘manufacturer’: ‘ESPE Mfg. Co., Inc.’, ‘material’: ‘Vulcanized Fibre’, ‘grade’: ‘Commercial Grade’, ‘properties’: [‘High Mechanical Strength’, ‘Excellent Resistance to Heat and Cold’, ‘Light Weight’, ‘Excellent Electrical Properties’, ‘Good Arc Resistance’, ‘Excellent Tear Resistance’, ‘Can be Machined with Standard Tools’], ‘applications’: [‘Washers’, ‘Insulating …

3. Easy Composites – Rigid Carbon Fiber Sheets

Domain: easycomposites.us

Registered: 2024 (1 years)

Introduction: Rigid Carbon Fiber Sheets / Plates – Easy Composites US

Key Product Details:

– Appearance: 2×2 Twill (Glossy)

– Fibre Orientation: 0, 90; Quasi Isotropic

– Length Options (mm): 250, 285, 450, 480, 500, 580, 980, 1000

– Thickness Options (mm): 0.25, 0.25 to 3.00, 3

– Thickness Tolerance (+/- mm): 0.1mm

– Type: Double Sided, Single Sided

– Weight (kg/m2): 3.36

– Width Options (mm): 140, 140 to 980,…

4. Allied Lutherie – Fiber Sheets

Domain: alliedlutherie.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Fiber Sheets”, “regular_price”: “$13.50”, “variants”: [{“type”: “White Fiber”, “dimensions”: “36” x 6″ x .020″”, “price”: “$13.50”}, {“type”: “Black Fiber”, “dimensions”: “36” x 6″ x .020″”, “price”: “$13.50”}, {“type”: “White Fiber Thin”, “dimensions”: “36” x 6″ x .010″”, “price”: “$12.50”}, {“type”: “Black Fiber Thin”, “dimensions”: “36” x 6″ x .010″”, “price”: “$12.50”}, {“typ…

5. Reddit – Cement Boards

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Cement boards are made up of multiple layers of cement and open weave fiberglass fabric for reinforcement.

Strategic Sourcing Conclusion and Outlook for fiber sheeting

In today’s competitive landscape, effective strategic sourcing of fiber sheeting is paramount for businesses aiming to optimize their operations and reduce costs. Key takeaways from this guide emphasize the importance of understanding the unique specifications of fiber sheeting, such as thickness, ply orientation, and material properties. By aligning these specifications with your business needs, you can ensure that the sourced products not only meet quality standards but also enhance performance in various applications—from automotive to electrical insulation.

Moreover, leveraging supplier relationships and diversifying your sourcing strategies can yield significant advantages. Engaging with manufacturers who provide high-quality, reliable products can lead to better pricing models and improved supply chain resilience, particularly crucial for buyers in emerging markets like Nigeria and Saudi Arabia.

Looking ahead, as the demand for advanced materials continues to grow, international B2B buyers must stay proactive in evaluating market trends and technological advancements. This is your opportunity to gain a competitive edge—consider initiating conversations with suppliers today to explore innovative fiber sheeting solutions that can drive your business forward. Embrace the future of sourcing and secure your position in a rapidly evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.