Fiber Sheet: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for fiber sheet

In today’s competitive landscape, sourcing high-quality fiber sheets can pose significant challenges for B2B buyers, particularly those operating in diverse and emerging markets such as Africa, South America, the Middle East, and Europe. The variety of materials, including carbon fiber and Kevlar composites, each with unique properties and applications, complicates the decision-making process. This comprehensive guide aims to demystify the global market for fiber sheets, covering essential topics such as types, applications, supplier vetting processes, and cost considerations.

Navigating the complexities of fiber sheet procurement requires a strategic approach. Buyers must understand the specific needs of their projects, whether for automotive components, aerospace applications, or industrial uses. This guide equips international B2B buyers with actionable insights and expert knowledge, enabling them to make informed purchasing decisions that align with their business objectives.

From evaluating the quality and durability of various fiber sheets to understanding pricing trends and supplier reliability, this resource provides a holistic view of the market. By leveraging this guide, buyers can ensure they select the right materials, optimize their supply chain, and ultimately enhance their product offerings in a competitive global marketplace.

Understanding fiber sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Carbon Fiber Sheets | High strength-to-weight ratio, corrosion resistance, customizable finishes | Aerospace, automotive, sporting goods | Pros: Lightweight, durable, customizable. Cons: Higher cost, requires specialized handling. |

| Kevlar Fiber Sheets | Exceptional impact resistance, lightweight, often hybridized with carbon | Defense, aerospace, industrial applications | Pros: Superior toughness, excellent wear resistance. Cons: Limited availability, higher cost. |

| Fiberglass Sheets | Versatile, cost-effective, good chemical resistance | Construction, marine, automotive | Pros: Affordable, easy to work with. Cons: Heavier than carbon and Kevlar, lower strength. |

| High-Temperature Fiber Sheets | Designed to withstand extreme temperatures, often infused with ceramic | Aerospace, automotive, industrial processes | Pros: High thermal resistance, durable. Cons: Specialized applications, potential higher costs. |

| Colored Fiber Sheets | Variety of colors and finishes, aesthetic appeal | Consumer products, design applications | Pros: Customizable appearance, unique branding. Cons: May have limited structural properties, higher cost. |

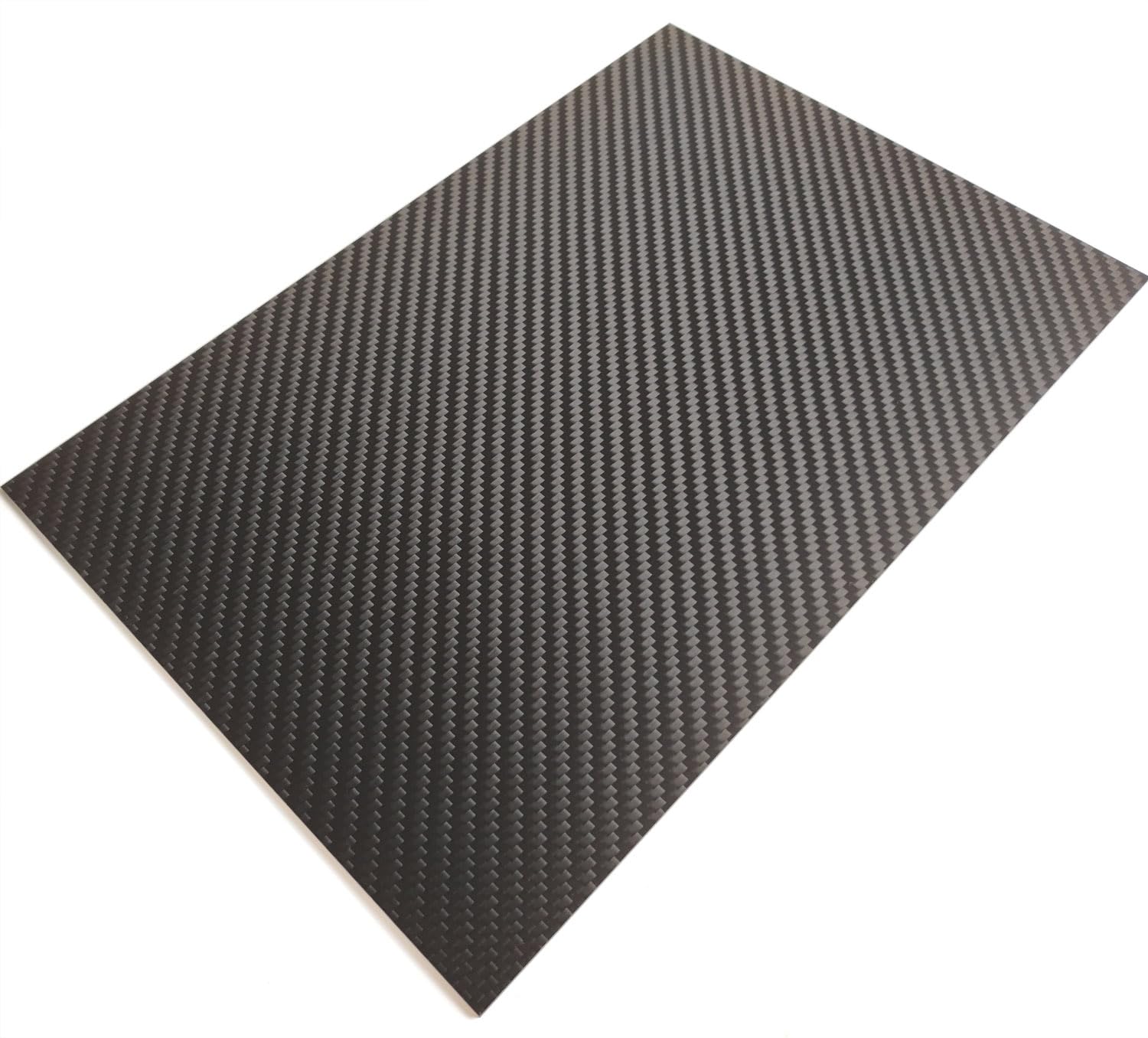

What Are the Key Characteristics of Carbon Fiber Sheets for B2B Buyers?

Carbon fiber sheets are renowned for their high strength-to-weight ratio, making them ideal for applications in aerospace, automotive, and sporting goods. These sheets are available in various thicknesses and finishes, allowing for customization to meet specific project needs. When considering purchasing, B2B buyers should evaluate the cost against performance benefits, as these sheets typically come at a premium price. Additionally, handling carbon fiber requires specialized knowledge to prevent damage during fabrication.

Why Choose Kevlar Fiber Sheets for Specialized Applications?

Kevlar fiber sheets are distinguished by their exceptional impact resistance and lightweight properties, making them a preferred choice in defense, aerospace, and industrial applications. These sheets can be hybridized with carbon fibers to enhance performance further. Buyers should consider the availability and cost, as Kevlar can be more expensive than other fiber options. Its unique properties make it suitable for environments where durability is critical, but procurement may require navigating niche suppliers.

How Do Fiberglass Sheets Compare in Terms of Cost-Effectiveness?

Fiberglass sheets offer versatility and cost-effectiveness, making them popular in construction, marine, and automotive sectors. They provide good chemical resistance and are easier to work with than other fibers. However, B2B buyers should note that while fiberglass is more affordable, it is heavier and offers lower strength compared to carbon or Kevlar sheets. Understanding the specific application requirements will help buyers determine if fiberglass is the right choice for their projects.

What Are the Benefits of High-Temperature Fiber Sheets?

High-temperature fiber sheets are engineered to withstand extreme thermal conditions, making them suitable for aerospace and industrial processes. These sheets often incorporate ceramic materials to enhance their thermal resistance. For B2B buyers, the key consideration is whether the application requires such specialized materials, as they may come with higher costs and limited availability. However, their durability in harsh environments can justify the investment for specific applications.

How Can Colored Fiber Sheets Enhance Product Appeal?

Colored fiber sheets provide a unique aesthetic appeal, allowing for branding and design flexibility in consumer products. These sheets come in various colors and finishes, catering to industries focused on visual impact. While they offer customization options, buyers should consider the potential trade-offs in structural properties and the higher costs associated with aesthetic variations. Understanding the balance between appearance and performance is crucial for B2B buyers in product design.

Key Industrial Applications of fiber sheet

| Industry/Sector | Specific Application of fiber sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Structural components in aircraft manufacturing | Lightweight yet strong materials enhance fuel efficiency and reduce overall weight. | Certifications for aerospace standards, custom thickness options, and high-quality finishes. |

| Automotive | Body panels and interior components | Improved performance and aesthetics, leading to better customer satisfaction. | Resistance to high temperatures, customization for specific vehicle models, and compliance with safety regulations. |

| Construction | Reinforcement for building materials | Increased durability and reduced weight for construction projects, leading to cost savings. | Availability in large sheets, compatibility with various adhesives, and compliance with local building codes. |

| Sports Equipment | High-performance sporting goods | Enhanced performance and durability, appealing to professional and amateur athletes alike. | Customization options for specific sports, lightweight designs, and availability of color choices for branding. |

| Electronics | Casings and structural supports for devices | Lightweight protection for sensitive components, improving device longevity. | Precision machining capabilities, surface finish options, and compatibility with electronic component standards. |

How is Fiber Sheet Utilized in Aerospace Manufacturing?

In the aerospace sector, fiber sheets are integral for manufacturing structural components such as wing skins and fuselage sections. Their lightweight yet robust characteristics contribute to significant fuel efficiency improvements. Buyers in this industry must consider sourcing from suppliers who can provide materials that meet stringent aerospace certifications, ensuring compliance with international safety standards. Custom thickness and finishes are also essential for specific applications, making it crucial to choose a partner with advanced fabrication capabilities.

What Role Does Fiber Sheet Play in Automotive Applications?

Fiber sheets are increasingly used in the automotive industry for body panels and interior components. They provide a combination of enhanced performance and aesthetics, which can significantly elevate customer satisfaction. Buyers should prioritize sourcing materials that can withstand high temperatures and offer customization options to fit various vehicle models. Additionally, adherence to safety regulations is critical, making it necessary to engage with suppliers that have proven quality assurance processes.

How Does Fiber Sheet Enhance Construction Projects?

In construction, fiber sheets serve as reinforcement for various building materials, offering increased durability while reducing overall weight. This application is particularly beneficial for projects aiming for cost savings and efficiency. International buyers must ensure that the sheets are available in large sizes to accommodate different project scales and that they are compatible with various adhesives. Understanding local building codes is also vital to ensure compliance and safety.

How is Fiber Sheet Employed in Sports Equipment?

The sports equipment industry utilizes fiber sheets to manufacture high-performance goods, from bicycles to protective gear. The lightweight and durable nature of fiber sheets enhances performance, appealing to both professional athletes and enthusiasts. Buyers should look for customization options that cater to specific sports needs, along with lightweight designs that do not compromise safety. Availability in various colors can also aid branding efforts, making it a key consideration for manufacturers.

What Benefits Does Fiber Sheet Provide in Electronics?

In the electronics sector, fiber sheets are used for casings and structural supports for devices, offering lightweight protection for sensitive components. This application not only improves device longevity but also enhances overall performance. Buyers should focus on suppliers that offer precision machining capabilities and a range of surface finish options to meet specific electronic component standards. Ensuring compatibility with various electronic devices is crucial for maintaining functionality and safety.

3 Common User Pain Points for ‘fiber sheet’ & Their Solutions

Scenario 1: Sourcing High-Quality Fiber Sheets Amidst Price Fluctuations

The Problem: B2B buyers often face significant challenges in sourcing high-quality fiber sheets at consistent prices. This is particularly true in regions like Africa and South America, where market volatility can lead to sudden price hikes due to supply chain disruptions or increased demand. Buyers may find themselves uncertain about the quality of the materials they are purchasing, which can affect their projects and ultimately their bottom line.

The Solution: To navigate this issue, buyers should establish relationships with multiple suppliers and conduct thorough research to understand the market trends. Leveraging platforms that aggregate supplier ratings and reviews can help identify reputable sources. Additionally, negotiating long-term contracts with suppliers can stabilize prices and ensure consistent quality. Buyers should also request samples before committing to large orders, allowing them to assess the material’s quality and suitability for their specific applications. Implementing a quality assurance process that includes third-party testing can further mitigate risks associated with sourcing.

Scenario 2: Difficulty in Selecting the Right Thickness and Finish for Applications

The Problem: Choosing the appropriate thickness and finish of fiber sheets can be a daunting task for buyers, especially those unfamiliar with the material’s properties. For instance, in the aerospace and automotive industries, where precision and performance are paramount, selecting the wrong thickness could lead to structural weaknesses. Buyers may also struggle with the decision between matte, gloss, or colored finishes, impacting both aesthetics and functionality.

The Solution: To make informed decisions, buyers should invest time in understanding the specific requirements of their applications. Consulting with technical experts or suppliers who specialize in fiber sheets can provide valuable insights into the appropriate thickness based on load-bearing needs and environmental conditions. Additionally, creating a checklist that outlines the functional and aesthetic needs of the project can help streamline the selection process. Using CAD software for design simulations can also aid in visualizing how different thicknesses and finishes will perform in real-world applications, enabling more confident purchasing decisions.

Scenario 3: Challenges with Custom Fabrication and Machining of Fiber Sheets

The Problem: Many B2B buyers encounter difficulties when it comes to the custom fabrication and machining of fiber sheets. Often, the complexity of their designs requires precise cuts and shapes that standard products cannot fulfill. Buyers may be frustrated by the lack of flexibility from suppliers who cannot accommodate custom requests, leading to delays and increased costs in their projects.

The Solution: To overcome these challenges, buyers should seek suppliers that offer extensive customization capabilities. It is advisable to inquire about the supplier’s machining and fabrication capabilities upfront, including tolerances and turnaround times. Building a collaborative relationship with a supplier that can understand and refine your design requirements is crucial. Utilizing 3D modeling software can help in communicating precise specifications to the supplier, ensuring that the final product meets your expectations. Additionally, considering a supplier that has in-house engineering support can facilitate the design and prototyping phases, reducing the overall time to market and enhancing project efficiency.

By proactively addressing these common pain points, B2B buyers can enhance their procurement processes for fiber sheets, ensuring quality, performance, and cost-effectiveness in their projects.

Strategic Material Selection Guide for fiber sheet

What Are the Key Properties of Common Fiber Sheet Materials?

When selecting fiber sheets for various applications, understanding the properties of the materials involved is crucial. Below is an analysis of four common materials used in fiber sheets: carbon fiber, fiberglass, aramid fiber, and natural fibers. Each material has distinct characteristics that can significantly impact performance and suitability for specific applications.

Carbon Fiber: High Strength and Lightweight

Carbon fiber sheets are renowned for their exceptional strength-to-weight ratio, making them ideal for applications requiring lightweight yet durable materials. They typically exhibit high stiffness, low thermal expansion, and excellent fatigue resistance. Carbon fiber can withstand temperatures up to 140°F (60°C) and is resistant to many chemicals, although it can be susceptible to UV degradation.

Pros: Carbon fiber sheets are lightweight and have high tensile strength, making them suitable for aerospace, automotive, and sporting goods applications. Their manufacturing process can be complex, often leading to higher costs.

Cons: The primary limitations include their susceptibility to UV damage and relatively high cost compared to other materials. Additionally, the complexity of the manufacturing process can lead to longer lead times.

Impact on Application: Carbon fiber sheets are compatible with various media, including fuels and oils, making them suitable for automotive and aerospace applications.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East must consider compliance with international standards such as ASTM and ISO, especially in industries like aerospace and automotive.

Fiberglass: Versatile and Cost-Effective

Fiberglass sheets are made from glass fibers and resin, offering a balance between performance and cost. They are known for their corrosion resistance and can withstand temperatures up to 200°F (93°C). Fiberglass is also lightweight and has good tensile strength, though not as high as carbon fiber.

Pros: Fiberglass is generally more affordable than carbon fiber and can be produced in various thicknesses and finishes. It is also resistant to moisture and many chemicals.

Cons: While durable, fiberglass sheets are less strong than carbon fiber and can be heavier, which may limit their use in weight-sensitive applications. Additionally, they may not perform as well under high-temperature conditions.

Impact on Application: Fiberglass is commonly used in construction, marine, and automotive applications where corrosion resistance is crucial.

Considerations for International Buyers: Buyers should ensure that fiberglass products meet local regulations regarding fire safety and environmental impact, especially in construction projects.

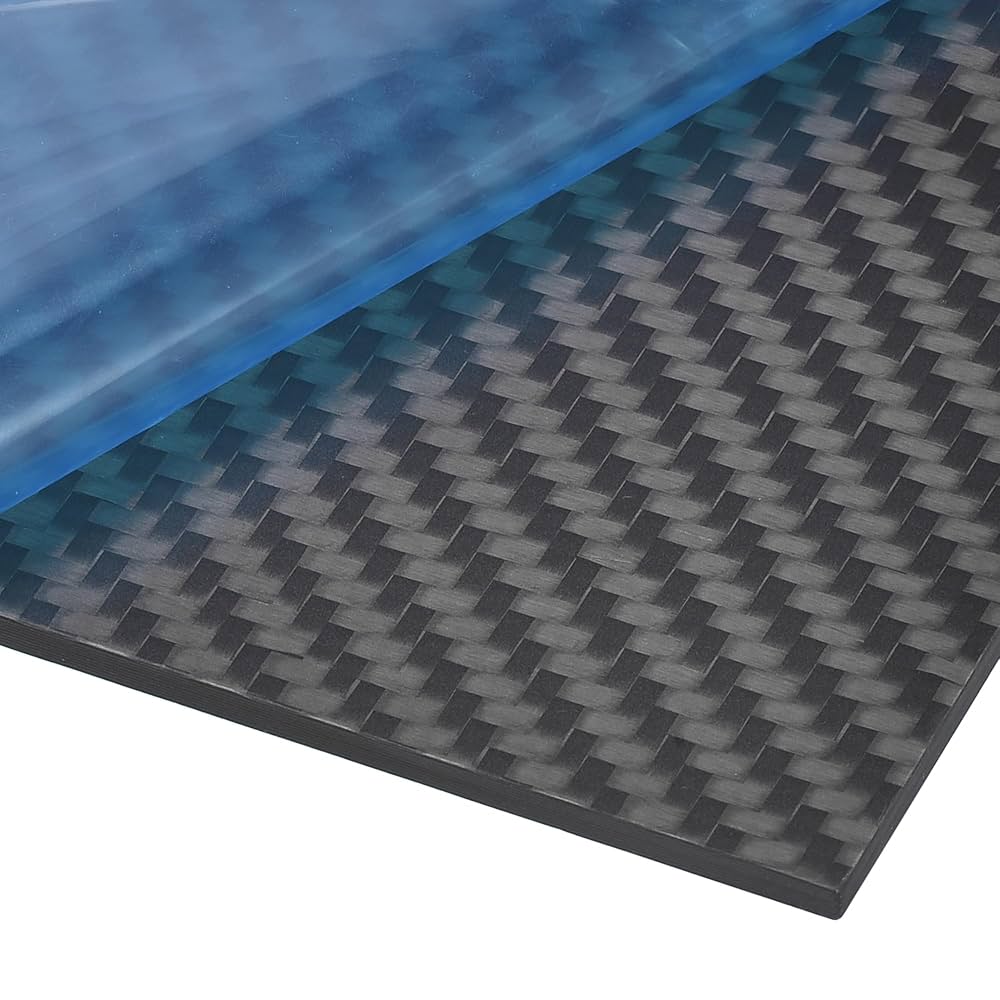

Illustrative image related to fiber sheet

Aramid Fiber: Tough and Impact-Resistant

Aramid fibers, such as Kevlar, are known for their high impact resistance and strength. They can endure temperatures up to 400°F (204°C) and are often used in applications requiring high durability, such as ballistic protection and industrial components.

Pros: Aramid fiber sheets offer excellent toughness and are resistant to abrasion and impact, making them suitable for protective gear and industrial applications.

Cons: The cost of aramid fiber is generally high, and its manufacturing process can be complex. Additionally, aramid fibers can absorb moisture, which may affect their performance in certain environments.

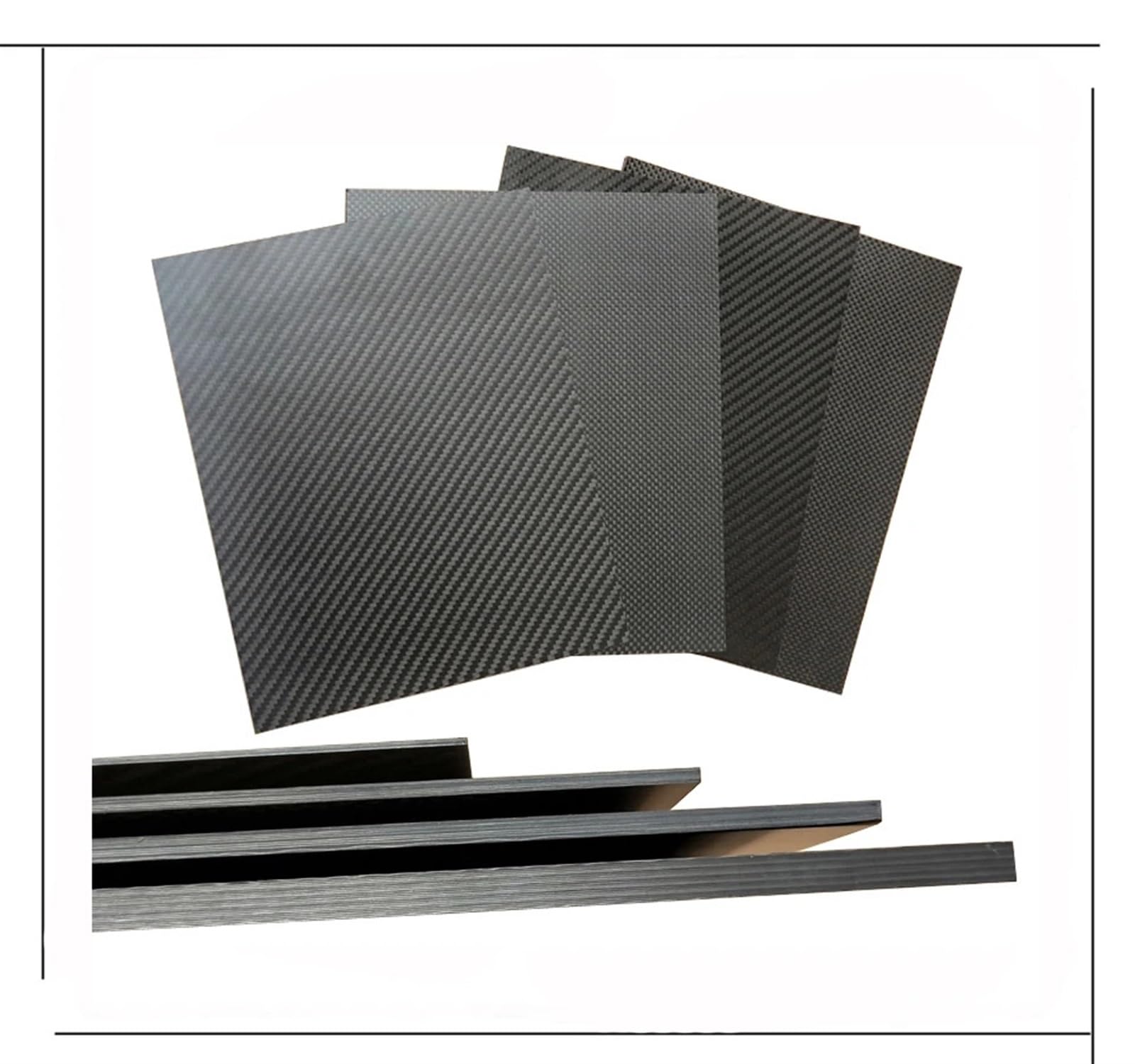

Illustrative image related to fiber sheet

Impact on Application: Aramid fiber sheets are particularly effective in applications requiring high strength and impact resistance, such as personal protective equipment and aerospace components.

Considerations for International Buyers: Compliance with safety standards is critical for aramid fiber products, especially in industries like defense and aerospace. Buyers should verify certifications and standards applicable in their regions.

Natural Fibers: Sustainable and Lightweight

Natural fiber sheets, such as those made from hemp or jute, are increasingly popular due to their sustainability and biodegradability. They typically have lower strength compared to synthetic fibers but offer good thermal insulation and are lightweight.

Pros: Natural fibers are environmentally friendly and cost-effective. They can be produced with lower energy inputs compared to synthetic fibers.

Cons: The primary limitation is their lower mechanical strength and durability compared to synthetic options. They may also be more susceptible to moisture and pests.

Impact on Application: Natural fiber sheets are suitable for applications in construction and automotive interiors, where sustainability is a priority.

Considerations for International Buyers: Buyers should consider local regulations regarding the use of natural fibers, especially in construction, where fire safety and durability standards may apply.

Summary Table of Fiber Sheet Materials

| Material | Typical Use Case for fiber sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Fiber | Aerospace, automotive, sporting goods | High strength-to-weight ratio | High cost, UV sensitivity | High |

| Fiberglass | Construction, marine, automotive | Cost-effective, corrosion-resistant | Lower strength than carbon fiber | Medium |

| Aramid Fiber | Protective gear, aerospace components | High impact resistance | High cost, moisture absorption | High |

| Natural Fibers | Sustainable construction, automotive interiors | Environmentally friendly | Lower strength, moisture sensitivity | Low |

This guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding fiber sheet materials, ensuring compliance with regional standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for fiber sheet

What Are the Main Stages of Fiber Sheet Manufacturing?

The manufacturing process for fiber sheets, particularly carbon fiber sheets, involves several critical stages: material preparation, forming, assembly, and finishing.

Material Preparation

This initial stage is crucial for ensuring the quality of the final product. It involves selecting the right type of fiber and resin, which typically includes multiple layers of woven carbon fibers combined with an epoxy matrix. The fibers are cut to size and arranged according to the desired ply orientation, which can significantly influence the material’s strength and flexibility. Proper material preparation also includes the conditioning of fibers to remove moisture and contaminants that could compromise adhesion.

Forming

During the forming stage, the prepared materials are laid into molds. Techniques such as vacuum bagging and autoclave curing are commonly used to consolidate the layers and remove air pockets. Vacuum bagging allows for uniform pressure distribution across the sheet, promoting optimal resin flow and minimizing voids. In contrast, autoclave curing involves applying heat and pressure, ensuring complete polymerization of the resin, which enhances the mechanical properties of the fiber sheet.

Assembly

Once formed, the fiber sheets may undergo additional assembly processes depending on the application. This could involve cutting sheets to specific dimensions or layering them with other materials, such as aluminum or other composites, to create hybrid structures. Customization options, such as adding adhesive layers or integrating electronic components, can also occur at this stage.

Finishing

The final stage of manufacturing includes finishing processes that can enhance the aesthetic and functional properties of the fiber sheets. This may involve sanding, surface coating, or applying protective finishes to improve durability and resistance to environmental factors. Quality control checks at this stage ensure that the sheets meet the specified thickness, weight, and surface finish standards.

How Is Quality Assurance Implemented in Fiber Sheet Manufacturing?

Quality assurance (QA) in fiber sheet manufacturing is essential to ensure that products meet international standards and customer specifications. The process typically adheres to standards such as ISO 9001, which establishes guidelines for quality management systems, and industry-specific certifications like CE for European markets or API for the oil and gas industry.

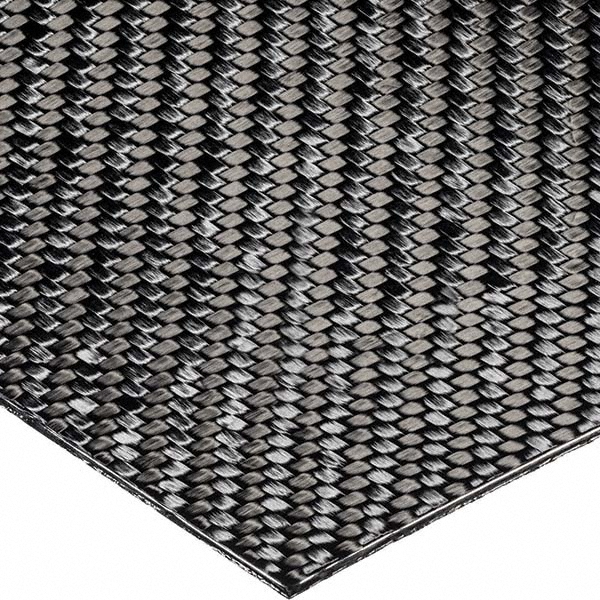

Illustrative image related to fiber sheet

International and Industry-Specific Standards

ISO 9001 certification is a hallmark of quality management that demonstrates a company’s commitment to continuous improvement and customer satisfaction. For B2B buyers, verifying a supplier’s certification can provide assurance of their manufacturing capabilities. Additionally, compliance with industry-specific standards ensures that the products are suitable for their intended applications, particularly in sectors like aerospace, automotive, and construction.

What Are the Key Quality Control Checkpoints in Fiber Sheet Production?

Quality control (QC) is integrated into several checkpoints throughout the manufacturing process, ensuring that each stage meets the required specifications.

Incoming Quality Control (IQC)

IQC involves inspecting raw materials before they enter the production line. This step ensures that the fibers and resins meet quality standards and are free from defects. Samples may be tested for tensile strength, fiber density, and other relevant properties.

In-Process Quality Control (IPQC)

During production, IPQC monitors critical parameters such as temperature, pressure, and curing time. Regular inspections and tests throughout the forming and curing stages help identify any deviations from the established processes, allowing for immediate corrective actions.

Final Quality Control (FQC)

FQC is conducted once the fiber sheets are completed. This stage involves a comprehensive evaluation of the finished products, including dimensional checks, surface inspections, and mechanical testing. Common testing methods include tensile strength tests, flexural tests, and impact resistance evaluations. Ensuring that the final product meets all specifications is crucial for customer satisfaction.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is vital for mitigating risks associated with procurement.

Audits and Reports

Buyers should request regular quality audit reports from their suppliers, which should detail QC processes, results of inspections, and any corrective measures taken. Conducting on-site audits can also be beneficial, as it allows buyers to assess the manufacturing environment and quality practices firsthand.

Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control measures. These organizations can conduct random inspections and testing, offering additional assurance that the products meet international standards.

What Are the Quality Control and Certification Nuances for International Buyers?

Navigating the complexities of quality control and certification can be particularly challenging for B2B buyers in diverse regions. Each market may have different regulatory requirements and certifications that suppliers must meet.

Understanding Regional Standards

Buyers should familiarize themselves with the specific standards applicable in their regions. For instance, while ISO 9001 is widely recognized, CE marking is crucial for products sold within the European Union. In contrast, buyers in the Middle East may need to consider local certifications that align with regional compliance requirements.

Supply Chain Transparency

Establishing a transparent supply chain can help buyers understand the manufacturing processes and quality control measures in place. This transparency is essential for building trust and ensuring consistent product quality.

By understanding the manufacturing processes and quality assurance practices associated with fiber sheets, international B2B buyers can make informed decisions, ensuring that they source high-quality materials suited to their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fiber sheet’

To effectively source fiber sheets, a structured approach is essential to ensure that you meet your project requirements while also optimizing costs. This guide provides a step-by-step checklist to streamline your procurement process, ensuring that you make informed decisions.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step in the procurement process. Determine the required thickness, size, and type of fiber sheet, whether carbon fiber, fiberglass, or a composite material. This will guide your search and help you communicate effectively with potential suppliers.

Step 2: Identify Your Application Needs

Understanding how the fiber sheet will be used is crucial. Different applications may require specific properties such as temperature resistance, tensile strength, or flexibility. For instance, aerospace applications might need high-strength, lightweight materials, while automotive uses might prioritize durability.

Step 3: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in fiber sheets. Look for companies that have a proven track record and positive customer reviews. Use industry-specific directories, trade shows, and online marketplaces to compile a list of potential vendors.

- Check for Certifications: Ensure that suppliers have relevant certifications (e.g., ISO 9001) that indicate adherence to quality management standards.

- Evaluate Product Range: Assess if they offer a diverse range of products that can cater to your specific requirements.

Step 4: Request Samples for Evaluation

Before making a large order, request samples of the fiber sheets you are considering. Testing these samples will allow you to evaluate their quality, weight, and finish. This step is essential for ensuring that the materials meet your specifications and performance criteria.

Illustrative image related to fiber sheet

Step 5: Review Pricing and Payment Terms

Compare pricing among different suppliers but remember that the cheapest option may not always provide the best value. Evaluate payment terms, shipping costs, and any potential discounts for bulk orders. Clear understanding of the total cost will help you budget effectively.

Step 6: Negotiate Terms and Conditions

Once you have selected a preferred supplier, negotiate the terms of the contract. Discuss delivery timelines, return policies, and warranty terms. Establishing clear agreements will prevent misunderstandings and ensure that both parties have aligned expectations.

Step 7: Establish a Quality Assurance Process

After placing your order, implement a quality assurance process to monitor the delivery and performance of the fiber sheets. This can include inspections upon receipt and testing during initial usage. A proactive approach to quality management will help mitigate issues and ensure compliance with project requirements.

By following this checklist, B2B buyers can navigate the complexities of sourcing fiber sheets effectively, ensuring that they select the right materials for their projects while maintaining quality and cost efficiency.

Comprehensive Cost and Pricing Analysis for fiber sheet Sourcing

Understanding the cost structure and pricing dynamics of fiber sheet sourcing is crucial for international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. A comprehensive analysis can help optimize procurement strategies and ensure cost-effectiveness.

What Are the Key Cost Components in Fiber Sheet Pricing?

When evaluating the pricing of fiber sheets, several cost components come into play:

-

Materials: The choice of raw materials significantly influences the final price. For instance, carbon fiber sheets typically use high-grade carbon fibers and epoxy resins, which can vary in cost based on quality and source. Premium materials will command higher prices.

-

Labor: Labor costs encompass the wages of skilled workers involved in the manufacturing process. This includes both direct labor for production and indirect labor for support functions such as maintenance and administration.

-

Manufacturing Overhead: This includes utilities, rent, and other indirect costs associated with running the manufacturing facility. Efficient production processes and advanced machinery can help mitigate these expenses.

-

Tooling: Custom tooling for specific designs or dimensions can add to the cost. Buyers should consider whether standard sizes suffice or if customizations are essential for their projects.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and adherence to standards. This adds to the cost but is vital for maintaining quality, especially in high-stakes applications like aerospace or automotive industries.

-

Logistics: Shipping and handling costs vary based on distance, shipping method, and packaging requirements. International buyers should account for potential tariffs, duties, and insurance.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding market dynamics can help buyers negotiate better terms.

How Do Volume and Specifications Affect Fiber Sheet Pricing?

The pricing of fiber sheets is often influenced by several factors:

-

Volume/MOQ: Suppliers may offer discounts for bulk purchases. Understanding minimum order quantities (MOQs) can help buyers leverage better pricing, particularly for large projects.

-

Specifications/Customization: Custom specifications, such as unique sizes, thicknesses, or finishes, can increase costs. Buyers should assess whether these custom features are necessary or if standard options are sufficient.

-

Materials and Quality Certifications: Certifications (e.g., ISO, ASTM) can affect pricing, with certified materials generally being more expensive. Buyers should ensure that the materials meet their specific industry standards.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers with a history of quality may command higher prices but offer better assurance of product performance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for international buyers. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact overall costs.

What Negotiation Strategies Can Buyers Use to Optimize Costs?

To maximize cost efficiency when sourcing fiber sheets, buyers should consider the following strategies:

-

Negotiate Bulk Pricing: Engage suppliers in discussions about bulk purchase discounts. Highlighting commitment to future orders can incentivize better pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider long-term costs associated with quality, maintenance, and performance. Investing in higher-quality sheets may lead to lower TCO over time.

-

Understand Pricing Nuances for International Procurement: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing variances due to local demand, supply chain issues, and economic factors. This knowledge can enhance negotiation leverage.

-

Request Detailed Quotes: Ensure suppliers provide comprehensive quotes that outline all cost components. This transparency will help in comparing offers effectively.

Conclusion

Navigating the complexities of fiber sheet sourcing requires a keen understanding of cost structures and pricing influences. By leveraging insights on cost components, volume impacts, and effective negotiation strategies, international B2B buyers can make informed decisions that enhance procurement efficiency and drive value in their projects. Always remember that prices can vary widely based on specifications and market conditions; therefore, it’s prudent to seek multiple quotes and perform due diligence before finalizing purchases.

Alternatives Analysis: Comparing fiber sheet With Other Solutions

Understanding Alternatives to Fiber Sheets in B2B Applications

In the realm of advanced materials, fiber sheets are widely recognized for their exceptional strength-to-weight ratio and versatility. However, B2B buyers must consider various alternative solutions that may better suit specific project requirements or budget constraints. Below, we compare fiber sheets with two viable alternatives: aluminum sheets and fiberglass panels. Each option presents unique benefits and challenges, making it essential for buyers to evaluate them carefully.

Comparison Table

| Comparison Aspect | Fiber Sheet | Aluminum Sheet | Fiberglass Panel |

|---|---|---|---|

| Performance | High strength, lightweight | Good strength, moderate weight | Moderate strength, lightweight |

| Cost | Moderate to high | Moderate | Low to moderate |

| Ease of Implementation | Requires specialized tools | Easy to cut and shape | Requires careful handling |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance |

| Best Use Case | Aerospace, automotive, robotics | Construction, automotive | Marine applications, insulation |

Detailed Breakdown of Alternatives

Aluminum Sheets

Aluminum sheets are a popular alternative due to their favorable strength-to-weight ratio, corrosion resistance, and ease of machining. They are widely used in construction and automotive industries. One of the key advantages of aluminum is its cost-effectiveness compared to fiber sheets, making it an attractive option for projects with budget constraints. Furthermore, aluminum sheets can be easily cut and shaped with common tools, facilitating straightforward implementation.

However, aluminum does not match the specific performance characteristics of fiber sheets, particularly in applications requiring high rigidity and low weight. Additionally, while aluminum is durable, it is heavier than fiber sheets, which can be a disadvantage in applications where weight savings are critical.

Fiberglass Panels

Fiberglass panels are another alternative that offers a lightweight solution with good insulation properties. They are particularly effective in marine applications and for creating lightweight structures. The cost of fiberglass panels is generally lower than that of fiber sheets, making them a suitable choice for projects that prioritize budget over performance.

Illustrative image related to fiber sheet

The main drawback of fiberglass is its moderate strength compared to fiber sheets, which may limit its use in high-stress applications. Additionally, fiberglass can require more maintenance than fiber sheets, particularly in environments exposed to moisture or harsh chemicals. Careful handling during installation is also necessary to prevent damage.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between fiber sheets and their alternatives, B2B buyers should assess their specific project requirements, including performance needs, budget constraints, and implementation capabilities. Fiber sheets excel in high-performance applications where weight and strength are paramount, while aluminum sheets offer a cost-effective and easily workable alternative for general use. Fiberglass panels may serve well in budget-sensitive projects requiring insulation but may not provide the same structural integrity as fiber sheets. By understanding the distinct advantages and limitations of each material, buyers can make informed decisions that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for fiber sheet

What Are the Key Technical Properties of Fiber Sheets?

When considering fiber sheets for various applications, understanding their technical properties is crucial for B2B buyers. Here are some essential specifications to keep in mind:

-

Material Grade

Material grade refers to the quality and type of fiber used in the sheet. Common materials include carbon fiber, fiberglass, and aramid fibers. Each material offers distinct benefits, such as carbon fiber’s high strength-to-weight ratio or fiberglass’s cost-effectiveness. Selecting the appropriate material grade affects the sheet’s durability, performance, and suitability for specific applications. -

Sheet Thickness

The thickness of fiber sheets typically ranges from 0.5 mm to several millimeters, with thicker sheets providing increased strength and rigidity. The choice of thickness is critical, as it impacts the weight, flexibility, and overall performance of the final product. For instance, thinner sheets may be ideal for lightweight applications, while thicker variants are better suited for structural uses. -

Ply Orientation

Ply orientation describes the arrangement of the fiber layers within the sheet, commonly specified as 0/90, ±45, or unidirectional. The orientation significantly influences the mechanical properties, including tensile strength and stiffness. Understanding ply orientation allows buyers to match the product’s performance characteristics with their specific application requirements. -

Tolerance

Tolerance indicates the allowable deviation from specified dimensions in the manufacturing process. For fiber sheets, tight tolerances are essential for applications requiring precise fitting and alignment, such as in aerospace or automotive sectors. Ensuring accurate tolerances can prevent costly rework and enhance the overall quality of the end product. -

Weight

The weight of fiber sheets is a significant consideration, particularly in industries where minimizing weight is paramount, such as aerospace and automotive. Lightweight materials contribute to fuel efficiency and lower operational costs, making them attractive to manufacturers. Buyers should assess weight specifications in conjunction with other properties to achieve the desired balance of performance and cost.

What Are Common Trade Terms in the Fiber Sheet Industry?

Understanding industry jargon is vital for effective communication and negotiation in the fiber sheet market. Here are some essential terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the fiber sheet industry, OEMs often require custom sheets tailored to their specifications, making it essential for suppliers to understand their specific needs and standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers who are looking to manage inventory costs effectively. Understanding the MOQ helps businesses plan their purchases and optimize supply chain operations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For fiber sheets, an RFQ typically includes details on material grade, dimensions, and required tolerances. This process helps buyers compare offers and select the best supplier based on price and quality. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is critical for B2B buyers to understand shipping costs, risk management, and delivery obligations, ensuring clarity in contracts and agreements. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the fiber sheet industry, lead times can vary based on the complexity of the order and the manufacturer’s capabilities. Understanding lead times is essential for supply chain management and ensuring timely project execution.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that they select the right fiber sheets for their specific applications and needs.

Navigating Market Dynamics and Sourcing Trends in the fiber sheet Sector

What Are the Current Market Dynamics and Key Trends Affecting the Fiber Sheet Sector?

The fiber sheet market is experiencing robust growth driven by advancements in technology, increasing demand for lightweight and high-strength materials, and a shift towards sustainability. Key sectors such as aerospace, automotive, construction, and consumer goods are particularly prominent in driving demand. The rise of electric vehicles and renewable energy technologies necessitates the use of advanced materials like carbon fiber sheets, which are favored for their strength-to-weight ratio and durability.

Emerging trends include the integration of digital technologies into the supply chain, enhancing transparency and efficiency. For instance, blockchain technology is being utilized to track the provenance of materials, ensuring quality and compliance with international standards. Additionally, customization is gaining traction, with suppliers offering tailored solutions to meet specific project requirements, appealing to industries that require precision-engineered components.

International buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of the competitive landscape. The market is characterized by several established players and new entrants vying for market share, which can create both opportunities and challenges in sourcing. Buyers should evaluate suppliers not only based on price but also on their technological capabilities, quality certifications, and delivery reliability to ensure they are making informed decisions.

How Is Sustainability Shaping Sourcing Strategies in the Fiber Sheet Sector?

Sustainability has become a crucial factor in the sourcing of fiber sheets, as buyers increasingly prioritize environmentally responsible practices. The production of fiber sheets can have significant environmental impacts, from resource extraction to manufacturing processes. Therefore, B2B buyers must consider suppliers who adhere to sustainable practices, including the use of recycled materials and eco-friendly production methods.

Ethical supply chains are also paramount. Buyers should seek out manufacturers who can provide evidence of responsible sourcing and fair labor practices. Certifications such as ISO 14001 for environmental management and Sourcing Certification for sustainable materials can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the growing consumer demand for green products is pushing companies to innovate. Suppliers are increasingly offering ‘green’ materials, such as bio-based resins and composites, which meet the performance needs of various applications while minimizing environmental impact. By aligning procurement strategies with sustainability goals, B2B buyers can enhance their brand reputation and meet the expectations of environmentally conscious customers.

How Has the Fiber Sheet Sector Evolved Over Time?

The fiber sheet sector has undergone significant evolution since the introduction of composite materials. Initially utilized in specialized applications, advancements in manufacturing processes and material science have broadened their use across various industries. The development of high-performance carbon fiber sheets in the late 20th century marked a turning point, as these materials began to replace traditional metals in aerospace and automotive sectors due to their lightweight and strength characteristics.

In recent years, the advent of advanced manufacturing techniques, such as automated fiber placement and 3D printing, has further revolutionized the production of fiber sheets, allowing for greater customization and efficiency. As industries continue to innovate, the fiber sheet market is poised for ongoing growth, driven by emerging applications and the increasing importance of sustainability in manufacturing practices.

Illustrative image related to fiber sheet

By understanding these dynamics, international B2B buyers can navigate the complexities of the fiber sheet market, making strategic sourcing decisions that align with both their operational needs and sustainability objectives.

Frequently Asked Questions (FAQs) for B2B Buyers of fiber sheet

-

1. How do I choose the right fiber sheet for my application?

Selecting the appropriate fiber sheet involves considering factors such as thickness, material composition, and ply orientation. For applications requiring high strength and low weight, carbon fiber sheets are ideal. Evaluate the specific requirements of your project, including environmental conditions and load-bearing needs. Additionally, consult with suppliers who can provide technical specifications and recommendations based on your intended use. -

2. What is the best thickness of fiber sheet for structural applications?

The optimal thickness of fiber sheet for structural applications typically ranges from 2mm to 6mm, depending on the load requirements and the specific application. Thicker sheets offer greater strength but can add weight. It’s essential to balance strength with weight considerations, particularly in industries like aerospace or automotive. Always consult with your supplier to ensure the chosen thickness meets your project’s engineering specifications. -

3. What customization options are available for fiber sheets?

Customization options for fiber sheets can include variations in thickness, size, color, and finish. Suppliers often provide services like CNC machining, cutting to specific dimensions, and applying different surface finishes such as matte, glossy, or textured. When discussing your needs with suppliers, be clear about your application requirements to get tailored solutions that enhance your product’s functionality and aesthetic appeal. -

4. What are the minimum order quantities (MOQ) for fiber sheets?

Minimum order quantities for fiber sheets can vary significantly based on the supplier and the type of material. Many suppliers set MOQs to ensure cost-effectiveness in production and shipping. Typically, for standard products, MOQs may range from 10 to 50 sheets, while custom orders might require higher quantities. When sourcing, inquire about MOQs upfront to align with your budget and project needs. -

5. How do I vet suppliers for international fiber sheet purchases?

To vet suppliers for international purchases, start by researching their reputation through reviews and testimonials from previous clients. Verify their certifications, such as ISO standards, which indicate adherence to quality management practices. Request samples to assess product quality and engage in direct communication to gauge their responsiveness and willingness to collaborate on your specific requirements. Engaging with local trade associations can also provide insights into reliable suppliers. -

6. What payment terms should I expect when sourcing fiber sheets internationally?

Payment terms for international fiber sheet purchases can vary widely. Common practices include upfront payments, net 30 or net 60 terms, and letters of credit for larger transactions. Always clarify payment terms before finalizing orders to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers to mitigate risks associated with international transactions. -

7. How is quality assurance managed in fiber sheet production?

Quality assurance in fiber sheet production typically involves rigorous testing and inspection at multiple stages of the manufacturing process. Suppliers should adhere to established quality standards, conducting tests for tensile strength, durability, and surface finish. Request documentation of quality control measures, including certifications, test results, and compliance with international standards. This ensures that the products you receive meet your specific quality requirements. -

8. What logistics considerations should I keep in mind when importing fiber sheets?

When importing fiber sheets, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable shipping partner experienced in handling composite materials to ensure safe delivery. Understand your destination country’s import regulations to avoid delays and additional costs. Additionally, factor in lead times for production and shipping to align with your project timelines, ensuring a smooth procurement process.

Top 7 Fiber Sheet Manufacturers & Suppliers List

1. DragonPlate – 1/8 Economy Carbon Fiber Sheets

Domain: dragonplate.com

Registered: 2003 (22 years)

Introduction: {‘product_name’: ‘1/8″ Economy Carbon Fiber Sheets’, ‘product_type’: ‘Carbon Fiber Sheets’, ‘brand’: ‘DragonPlate’, ‘sheet_thickness’: ‘1/8″‘, ‘ply_orientation’: ‘Woven 0/90’, ‘available_sizes’: [{‘sku’: ‘FEPL04_*90*0606’, ‘size’: ‘6″ x 6″‘, ‘price’: ‘$31.64’}, {‘sku’: ‘FEPL04_*90*1212’, ‘size’: ’12” x 12″‘, ‘price’: ‘$96.58’}, {‘sku’: ‘FEPL04_*90*1224’, ‘size’: ’12” x 24″‘, ‘price’: ‘$173.15’}, {…

2. ESPE Mfg. Co. – Fibre Sheets

Domain: electrical-insulation.espemfg.com

Registered: 2000 (25 years)

Introduction: This company, ESPE Mfg. Co. – Fibre Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Topoloc FRT – Fiberglass Roofing Sheets

Domain: topolocfrt.com

Registered: 2017 (8 years)

Introduction: Fiberglass roofing sheets are a fiber-reinforced composite material (FRP/GRP) made from high-performance film, high-quality polyester, and reinforced glass fiber. They are lightweight yet strong, with a corrugated profile for added strength. Key characteristics include:

– Strong impact resistance: 250-300 times that of ordinary glass, 30 times that of acrylic, and 2-20 times that of tempered glass…

4. Easy Composites – High Strength Carbon Fiber Sheet

Domain: easycomposites.us

Registered: 2024 (1 years)

Introduction: This company, Easy Composites – High Strength Carbon Fiber Sheet, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. IQS Directory – Fiberglass Sheets

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Fiberglass sheets are composed of fine, small-diameter glass fibers reinforced with plastic, known for their outstanding tensile strength and resistance to corrosion, fire, and chemicals. They have a strength-to-weight ratio due to the fibers absorbing loads while the plastic distributes weight. Thickness ranges from 1.5 mm to 75 mm. Key components include silica sand, soda ash, and limestone, wit…

6. Livspace – Fiber Glass Sheet

Domain: livspace.com

Registered: 2007 (18 years)

Introduction: Fiber Glass Sheet: A lightweight, strong material made from woven glass fibers and plastic resin, offering exceptional strength-to-weight ratio. Uses include fiber glass conduit for corrosion resistance in chemical environments, composite roofing with a lifespan of 20 years, earthquake-resistant bricks, transparent screens for windows, and rust-proof roofing. Types include fiber glass roof, fiber …

7. ScienceDirect – Continuous Fiber Sheets

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Continuous fiber sheets (CFS) are materials used in construction to enhance the tensile strength and structural integrity of reinforced concrete. They must be attached with specified position, direction, and number of plies to ensure proper bonding and thorough resin impregnation, especially at overlap splice sections. It is critical to prepare a working diagram that matches the actual structure, …

Strategic Sourcing Conclusion and Outlook for fiber sheet

In navigating the landscape of fiber sheet sourcing, international B2B buyers must prioritize strategic partnerships that align with their unique project needs. The versatility of fiber sheets, particularly carbon fiber, offers significant advantages such as lightweight strength, durability, and customization options. By leveraging these properties, businesses can enhance product performance while reducing overall costs.

Establishing strong relationships with suppliers not only ensures access to high-quality materials but also facilitates innovation. Buyers should consider factors such as material specifications, production capabilities, and supplier certifications to make informed decisions. Engaging with manufacturers who offer extensive customization options can lead to tailored solutions that meet specific operational requirements.

Looking ahead, the demand for fiber sheets is poised to grow, driven by advancements in technology and material science. As markets in Africa, South America, the Middle East, and Europe expand, it is crucial for buyers to stay ahead by exploring emerging trends and sustainable sourcing practices. By investing in strategic sourcing now, businesses can position themselves for success in the competitive global marketplace. Embrace the opportunity to elevate your projects—connect with trusted suppliers today to unlock the full potential of fiber sheets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.