Fan 24 Cc Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for fan 24 cc

In today’s competitive landscape, sourcing reliable and efficient fan 24 cc solutions poses a significant challenge for international B2B buyers. Whether you’re operating in the manufacturing sector, agriculture, or HVAC industries, understanding the nuances of fan specifications, applications, and supplier capabilities is crucial for making informed purchasing decisions. This comprehensive guide aims to demystify the global market for fan 24 cc, offering insights into various types, applications, and best practices for vetting suppliers.

From hydraulic motors used in agricultural equipment to electric fans designed for industrial ventilation, each application presents unique requirements that impact performance and reliability. This guide will equip buyers from Africa, South America, the Middle East, and Europe—specifically Germany and Brazil—with the knowledge needed to navigate this diverse market landscape confidently.

Additionally, we will explore critical factors such as cost considerations, maintenance requirements, and the importance of compliance with international standards. By leveraging the actionable insights provided in this guide, B2B buyers can streamline their procurement processes, ensuring they secure the best products for their operational needs while minimizing risks and maximizing value. Prepare to elevate your purchasing strategy with a thorough understanding of the fan 24 cc market.

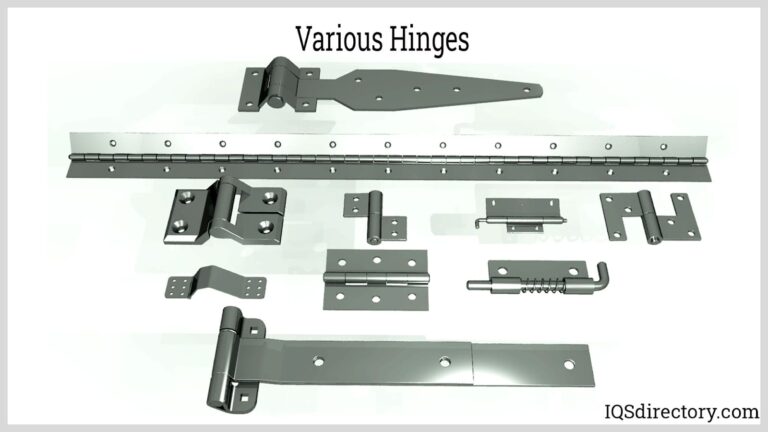

Understanding fan 24 cc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic Fan Motor | 24cc, 2-bolt mount, hydraulic operation | Agricultural machinery, industrial fans | Pros: High torque, efficient for heavy-duty tasks. Cons: Requires hydraulic system integration. |

| Explosion-Proof Electric Fan | 115V/230V electric motor, designed for hazardous environments | Mining, oil & gas, chemical processing | Pros: Safe for flammable environments, high airflow. Cons: Higher initial investment. |

| DC Brushless Fan | 24VDC, compact design, low noise | Electronics cooling, HVAC systems | Pros: Energy efficient, longer lifespan. Cons: May require specific voltage compatibility. |

| Axial Flow Fan | High airflow capacity, direct flow design | Ventilation, HVAC applications | Pros: Effective for large spaces, easy installation. Cons: Less efficient at high static pressures. |

| Portable Industrial Fan | Mobility features, rugged design, various power options | Construction sites, workshops | Pros: Versatile, can be used in multiple locations. Cons: Limited airflow compared to fixed installations. |

What are the Characteristics of Hydraulic Fan Motors?

Hydraulic fan motors are designed for high-torque applications, making them ideal for agricultural machinery and other heavy-duty tasks. With a displacement of 24cc, these motors offer efficient power transfer through hydraulic systems. Buyers should consider the compatibility of their existing hydraulic setup, as well as the motor’s mounting specifications. While they provide significant power and reliability, the need for hydraulic integration may complicate installation for some buyers.

How Do Explosion-Proof Electric Fans Operate in Hazardous Environments?

Explosion-proof electric fans are engineered to function safely in volatile environments, such as mining or chemical processing facilities. Typically operating on 115V or 230V, these fans are built with robust materials to withstand harsh conditions. They provide high airflow rates, crucial for maintaining safe air quality. Buyers must evaluate the initial costs against the safety benefits, especially in industries where compliance with safety regulations is mandatory.

What Advantages Do DC Brushless Fans Offer in B2B Applications?

DC brushless fans are known for their energy efficiency and low noise levels, making them suitable for sensitive electronic cooling and HVAC systems. Operating at 24VDC, these fans have a compact design, which is advantageous in space-constrained environments. When purchasing, businesses should ensure compatibility with their existing systems and consider the long-term savings from reduced energy consumption. The higher upfront cost may be offset by their longevity and lower maintenance needs.

What Makes Axial Flow Fans Suitable for Ventilation?

Axial flow fans are characterized by their ability to move large volumes of air directly. They are commonly used in ventilation systems and HVAC applications, particularly in large spaces requiring effective air circulation. Buyers should consider the installation ease and the fan’s efficiency at varying static pressures, as these factors can impact overall system performance. While they are effective, axial fans may not perform as well in high-resistance environments compared to other fan types.

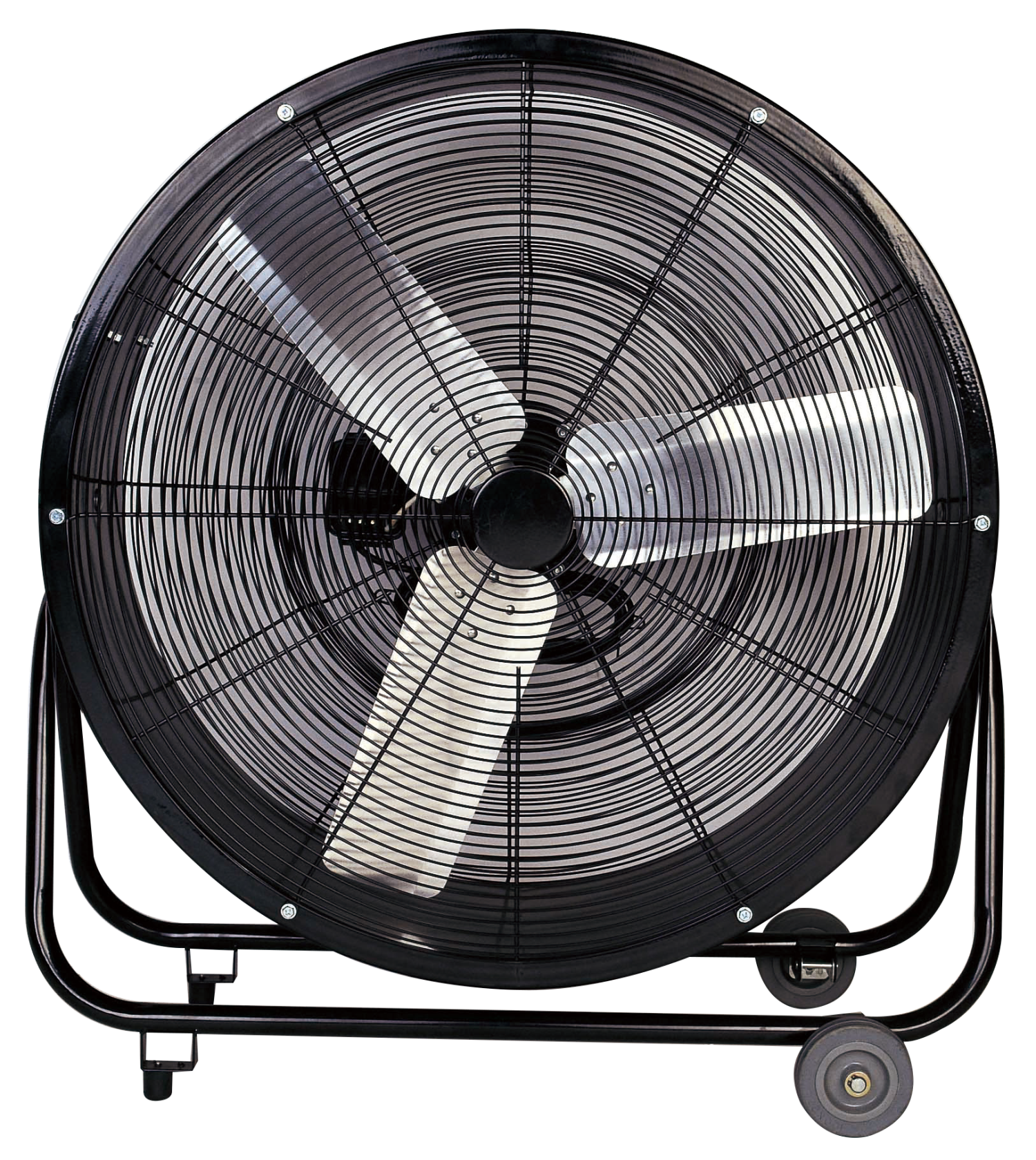

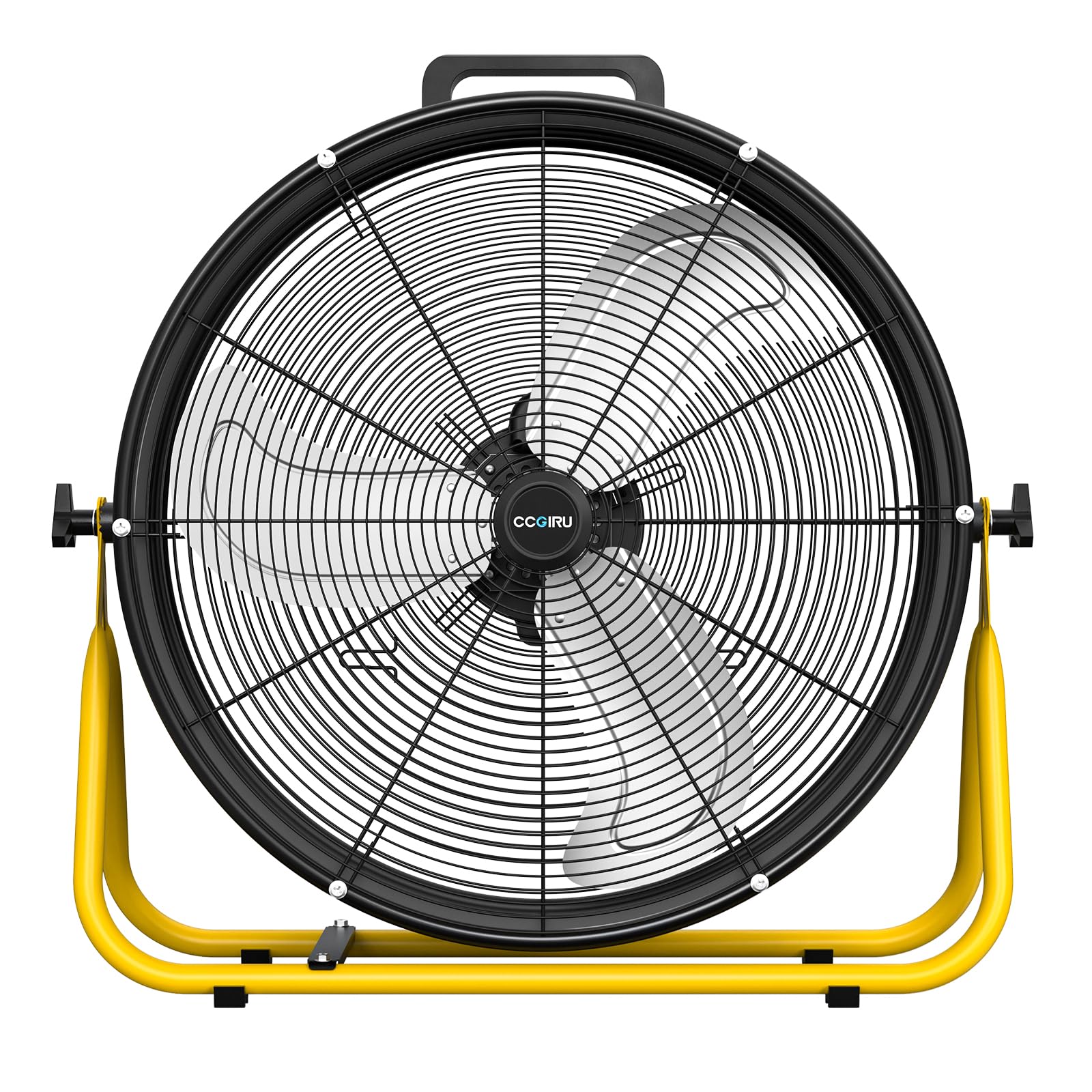

Why Are Portable Industrial Fans Essential for Construction Sites?

Portable industrial fans are designed for mobility and rugged use, making them ideal for construction sites and workshops. They come with various power options, allowing them to adapt to different work environments. While they offer versatility and ease of transport, their airflow capacity might be lower than that of fixed installations. Businesses should assess their airflow requirements and consider the trade-offs between portability and performance when selecting a fan for industrial use.

Key Industrial Applications of fan 24 cc

| Industry/Sector | Specific Application of fan 24 cc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Cooling systems in greenhouses and farms | Enhances crop yields by maintaining optimal temperatures | Durability, energy efficiency, and local climate adaptability |

| Manufacturing | Ventilation in industrial processing plants | Improves air quality and worker safety | Compliance with safety standards and energy consumption |

| Automotive | Cooling in vehicle assembly lines | Ensures efficient production and reduces downtime | Compatibility with existing systems and maintenance support |

| HVAC | Air circulation in large commercial buildings | Increases energy efficiency and occupant comfort | Size, noise level, and integration with existing HVAC systems |

| Mining | Dust control in mining operations | Enhances safety by reducing airborne particles | Explosion-proof features and reliability in harsh conditions |

How is ‘fan 24 cc’ Used in Agriculture?

In agriculture, the fan 24 cc is instrumental in cooling systems within greenhouses and farms. By ensuring a consistent airflow, it helps maintain optimal temperatures for crops, which is critical for maximizing yields. International buyers, particularly from regions with varying climates, should consider the fan’s durability and energy efficiency to ensure it can withstand local environmental conditions while minimizing operational costs.

Illustrative image related to fan 24 cc

What Role Does ‘fan 24 cc’ Play in Manufacturing?

In manufacturing, fan 24 cc units are commonly used for ventilation in industrial processing plants. They significantly improve air quality, which is essential for worker safety and productivity. Buyers in this sector should prioritize sourcing fans that comply with safety standards and offer low energy consumption, as this can lead to substantial cost savings and a healthier work environment.

How Does ‘fan 24 cc’ Contribute to Automotive Production?

In the automotive industry, fan 24 cc is utilized for cooling in vehicle assembly lines. This application is vital to ensure that machinery operates efficiently and to minimize production downtime. When sourcing these fans, businesses must ensure compatibility with existing systems and consider the availability of maintenance support to avoid production interruptions.

Why is ‘fan 24 cc’ Important for HVAC Systems?

Within HVAC systems, the fan 24 cc plays a crucial role in air circulation for large commercial buildings. This application not only enhances energy efficiency but also improves occupant comfort by maintaining a stable indoor climate. Buyers should focus on the fan’s size, noise level, and ease of integration with existing HVAC systems to ensure optimal performance.

How is ‘fan 24 cc’ Used in Mining Operations?

In mining operations, the fan 24 cc is essential for dust control, which is crucial for maintaining safety standards. By effectively reducing airborne particles, it helps create a safer working environment for miners. Buyers in this industry must consider the fan’s explosion-proof features and reliability, particularly in harsh operating conditions, to ensure long-term operational success.

Illustrative image related to fan 24 cc

3 Common User Pain Points for ‘fan 24 cc’ & Their Solutions

Scenario 1: Sourcing Quality Components for Efficient Operations

The Problem: B2B buyers often struggle with sourcing high-quality ‘fan 24 cc’ components that meet specific operational requirements. In many cases, buyers face challenges related to inconsistent product quality, leading to potential breakdowns and inefficiencies in their systems. This can be particularly problematic in industries like agriculture or manufacturing, where reliable airflow is critical for maintaining optimal conditions. Buyers may also find it difficult to navigate the complexities of international shipping, varying quality standards, and differing regulatory requirements across regions, especially when sourcing from diverse geographical locations like Africa or Europe.

The Solution: To ensure the procurement of high-quality ‘fan 24 cc’ components, buyers should implement a multi-tiered sourcing strategy. First, they should establish relationships with reputable suppliers who provide detailed product specifications, certifications, and quality assurance processes. Conducting a thorough supplier evaluation that includes checking customer reviews and industry certifications can also be beneficial. Additionally, considering local suppliers can mitigate shipping issues and streamline the supply chain, thus reducing lead times. Buyers should specify their operational needs clearly, including airflow requirements, voltage specifications, and environmental conditions, to avoid miscommunication and ensure that the components meet their applications. Utilizing platforms that aggregate supplier information can also facilitate informed decision-making.

Scenario 2: Managing Maintenance and Downtime Effectively

The Problem: Another common pain point for B2B buyers is the unanticipated downtime caused by malfunctioning ‘fan 24 cc’ units. This not only affects productivity but can also lead to significant financial losses and strained relationships with clients. Many companies lack a proactive maintenance plan, resulting in reliance on reactive strategies that often lead to extended downtimes. Furthermore, understanding the specific maintenance needs for ‘fan 24 cc’ units can be complex, particularly when equipment varies across different manufacturers.

The Solution: Implementing a comprehensive maintenance program tailored to the specific requirements of ‘fan 24 cc’ units is crucial. Buyers should invest in training for their maintenance teams, focusing on regular inspection routines, cleaning, and lubrication practices that can extend the lifespan of the fans. Establishing a predictive maintenance schedule based on usage patterns and environmental factors will enable companies to anticipate and mitigate potential failures before they occur. Additionally, having a reliable inventory of spare parts readily available can significantly reduce downtime. Buyers should also consider leveraging IoT technologies for real-time monitoring of fan performance, allowing for immediate action if performance metrics fall below acceptable levels.

Illustrative image related to fan 24 cc

Scenario 3: Navigating Compatibility Issues in System Integration

The Problem: B2B buyers often encounter compatibility issues when integrating ‘fan 24 cc’ units into existing systems. This can be particularly challenging in older facilities where outdated technology may not support modern fan specifications. The lack of standardization in design and functionality among different manufacturers can lead to confusion during installation, resulting in operational inefficiencies and increased costs.

The Solution: To effectively navigate compatibility issues, buyers should conduct a thorough assessment of their current systems before purchasing ‘fan 24 cc’ units. This includes evaluating existing electrical systems, ductwork, and control mechanisms to ensure that the new units can be seamlessly integrated. Collaborating with engineers during the design phase can help identify potential integration challenges early on. Buyers should also consider manufacturers that offer customizable solutions, allowing them to tailor the fan specifications to fit their systems. Additionally, investing in comprehensive installation and integration services from experienced professionals can prevent common pitfalls and enhance overall system performance. By prioritizing compatibility during the selection process, buyers can ensure that their investments in ‘fan 24 cc’ units yield optimal results without significant additional costs.

Strategic Material Selection Guide for fan 24 cc

What Are the Key Materials for Manufacturing a 24cc Fan?

When selecting materials for a 24cc fan, it’s essential to consider the specific requirements of the application, including performance characteristics, environmental conditions, and compliance with international standards. Here, we analyze four common materials used in the construction of 24cc fans, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Aluminum Perform in Fan Applications?

Aluminum is a lightweight and corrosion-resistant material commonly used in fan construction. Its key properties include a temperature rating of up to 150°C and excellent thermal conductivity, making it suitable for high-performance applications.

Pros: Aluminum’s lightweight nature enhances energy efficiency, while its corrosion resistance makes it ideal for humid or coastal environments. Additionally, it is relatively easy to machine, facilitating complex designs.

Illustrative image related to fan 24 cc

Cons: While durable, aluminum can be less robust than other metals under high-stress conditions. Its cost can also be higher than some alternatives, which may affect budget-sensitive projects.

Impact on Application: Aluminum is compatible with various media, including air and light liquids, making it versatile for different fan applications.

Considerations for International Buyers: Buyers in regions like Europe and South America should ensure compliance with standards such as EN 573 for aluminum and consider local sourcing to mitigate transportation costs.

What Role Does Steel Play in Fan Construction?

Steel, particularly stainless steel, is known for its strength and durability. It typically has a temperature rating of up to 300°C and excellent corrosion resistance, especially when treated.

Pros: Steel’s high strength-to-weight ratio makes it suitable for heavy-duty applications. It also offers good resistance to wear and tear, extending the lifespan of the fan.

Cons: Steel can be heavier than aluminum, which may lead to increased energy consumption. Additionally, it is more susceptible to rust if not properly coated or treated.

Illustrative image related to fan 24 cc

Impact on Application: Steel is ideal for environments where the fan may be exposed to harsh conditions or chemicals, such as in industrial settings.

Considerations for International Buyers: Buyers should be aware of compliance with ASTM A240 for stainless steel and ensure that the material meets local regulations regarding emissions and safety.

Why Is Plastic a Viable Option for Fan Components?

Plastics, particularly high-performance polymers like polycarbonate and polypropylene, are increasingly used in fan applications due to their lightweight and corrosion-resistant properties. They can typically withstand temperatures up to 80-120°C, depending on the type.

Pros: Plastics are cost-effective and can be molded into complex shapes, allowing for innovative designs. They also exhibit good resistance to chemicals and UV light.

Illustrative image related to fan 24 cc

Cons: While lightweight, plastics may not provide the same structural integrity as metals, making them less suitable for high-stress applications. Their temperature tolerance is also lower than metals, which can limit their use in high-heat environments.

Impact on Application: Plastic fans are often used in residential or light commercial applications where weight and cost are critical factors.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with relevant standards, such as ISO 9001 for quality management, and consider the environmental impact of plastic waste.

How Does Composite Material Enhance Fan Performance?

Composite materials, often a combination of fibers and resins, offer unique properties such as high strength-to-weight ratios and excellent corrosion resistance. They can typically withstand temperatures up to 150°C.

Pros: Composites are lightweight and can be engineered to meet specific performance requirements, making them suitable for advanced applications. They also offer superior resistance to environmental degradation.

Cons: The manufacturing process for composites can be complex and costly, which may deter budget-conscious buyers. Additionally, they may require specialized knowledge for repair or recycling.

Impact on Application: Composites are particularly effective in aerospace and automotive applications, where weight savings are critical.

Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM D3039 for composite materials and consider the availability of skilled labor for maintenance and repair.

Illustrative image related to fan 24 cc

Summary of Material Selection for 24cc Fans

| Material | Typical Use Case for fan 24 cc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Residential and light commercial | Lightweight and corrosion-resistant | Less robust under high stress | Medium |

| Steel | Industrial applications | High strength and durability | Heavier, susceptible to rust | Medium to High |

| Plastic | Residential applications | Cost-effective and versatile | Lower structural integrity | Low |

| Composite | Aerospace and automotive | High strength-to-weight ratio | Complex and costly manufacturing | High |

This guide provides a comprehensive overview of material options for 24cc fans, assisting international B2B buyers in making informed decisions that align with their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fan 24 cc

What Are the Main Stages of Manufacturing Processes for Fan 24 cc?

The manufacturing process for the fan 24 cc involves several critical stages that ensure the final product meets industry standards and customer specifications. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

Material Preparation: What Materials Are Used?

The initial stage of manufacturing begins with material preparation. For fan 24 cc, high-quality materials such as metals (typically aluminum or steel) and durable plastics are commonly used. These materials are selected for their strength, weight, and resistance to environmental factors. Suppliers must ensure that these materials conform to relevant international standards to prevent defects during the manufacturing process.

Forming: How Are Fan Components Shaped?

After material preparation, the next step is forming. This stage involves various techniques such as machining, casting, and stamping, depending on the component being produced. For example, the fan blades may be stamped or molded, while motor housings could be machined for precision. Advanced techniques like CNC machining are often employed to ensure tight tolerances and optimal performance characteristics.

Illustrative image related to fan 24 cc

Assembly: What Are the Key Processes?

Once individual components are formed, assembly takes place. This involves fitting together the motor, blades, and housing, often with the aid of automated systems for efficiency and accuracy. During this stage, components are secured using screws, rivets, or welding, ensuring that the fan operates safely and effectively. Proper assembly is crucial, as it directly affects the fan’s performance and durability.

Finishing: What Techniques Are Used?

The finishing stage enhances the fan’s aesthetic appeal and protective qualities. This may include surface treatments like painting, powder coating, or anodizing, which help prevent corrosion and wear. Additionally, quality assurance checks are conducted during this stage to ensure that the finish meets specified standards, which is vital for both functionality and appearance.

What Quality Assurance Standards Are Relevant for Fan 24 cc?

Quality assurance (QA) is integral to the manufacturing process, ensuring that products meet both regulatory and customer expectations. For fan 24 cc, adherence to international and industry-specific standards is essential.

Which International Standards Should B2B Buyers Look For?

ISO 9001 is a globally recognized standard for quality management systems. Compliance with ISO 9001 demonstrates that a manufacturer has established a systematic approach to managing quality, which is vital for B2B buyers. Additionally, industry-specific certifications such as CE marking in Europe or API standards for specific applications can provide further assurance of product quality and safety.

How Are QC Checkpoints Established?

Quality control (QC) checkpoints are typically integrated into the manufacturing process at various stages:

Illustrative image related to fan 24 cc

- Incoming Quality Control (IQC): This is the first checkpoint where raw materials are inspected upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): During production, ongoing checks are performed to monitor the quality of components being manufactured. This may involve measurements, visual inspections, and functional tests.

- Final Quality Control (FQC): Once assembly is complete, the final product undergoes thorough testing to verify its performance and safety. This may include airflow tests, electrical safety tests, and noise level assessments.

What Testing Methods Are Commonly Used in Fan Manufacturing?

Various testing methods are employed to ensure that the fan 24 cc meets performance and safety standards. These methods provide critical data on the fan’s operation and durability.

Which Testing Methods Should B2B Buyers Be Aware Of?

-

Performance Testing: This assesses the fan’s airflow capacity (CFM), static pressure, and efficiency. Buyers should request performance curves that detail how the fan operates under different conditions.

-

Electrical Testing: For electric fans, insulation resistance, power consumption, and thermal performance are measured to ensure safe operation.

-

Noise Level Testing: The sound produced by the fan during operation is measured to ensure compliance with noise regulations, especially for applications in residential or commercial settings.

-

Durability Testing: Fans may undergo accelerated life testing to simulate long-term use and assess their reliability over time.

How Can B2B Buyers Verify Supplier Quality Control?

When engaging with suppliers, B2B buyers must take proactive steps to verify their quality control processes. This ensures that they are sourcing from reliable manufacturers who prioritize quality.

What Are Effective Strategies for Supplier QC Verification?

-

Supplier Audits: Conducting regular audits of suppliers helps verify compliance with quality standards and practices. This includes assessing their manufacturing facilities, processes, and documentation.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the results of various tests and inspections conducted during production. This transparency is vital for establishing trust.

-

Utilizing Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes. These agencies can conduct random inspections and testing to validate the quality of products before shipment.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification.

Illustrative image related to fan 24 cc

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying standards and regulations. For instance, European buyers should be particularly attentive to CE marking, which indicates conformity with health, safety, and environmental protection standards. Similarly, buyers in the Middle East may require compliance with local standards that could differ from international norms.

What Should Buyers Consider Regarding Supply Chain Transparency?

Supply chain transparency is crucial for international buyers. Understanding where and how components are sourced, and how they adhere to quality standards can significantly affect the final product’s quality. Buyers should engage in open discussions with suppliers about their sourcing practices, material certifications, and compliance with international standards.

In conclusion, the manufacturing processes and quality assurance measures for fan 24 cc are multifaceted and require diligent oversight. By understanding these aspects, B2B buyers can make informed decisions, ensuring they partner with manufacturers who prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fan 24 cc’

The following guide provides a structured approach for B2B buyers looking to source ‘fan 24 cc’ products effectively. This checklist will help ensure that you make informed decisions and secure high-quality products that meet your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it is essential to establish clear technical specifications for the ‘fan 24 cc’ you require. This includes determining the desired airflow capacity, voltage, size, and any specific features such as explosion-proof capabilities or hydraulic compatibility. Having a detailed specification helps streamline discussions with suppliers and ensures that you receive products that meet your operational requirements.

Illustrative image related to fan 24 cc

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to identify potential suppliers that specialize in ‘fan 24 cc’ products. Utilize online platforms, trade shows, and industry networks to compile a list of manufacturers and distributors. Pay attention to their geographical reach, as sourcing from suppliers in your target regions (Africa, South America, the Middle East, and Europe) can reduce shipping costs and lead times.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it is crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Check for customer reviews and testimonials to gauge their reliability and product quality. Additionally, ensure that the suppliers have the necessary certifications and compliance with international standards.

Step 4: Request Samples and Assess Quality

Once you have shortlisted potential suppliers, request samples of the ‘fan 24 cc’ products to evaluate their quality firsthand. Inspect the materials, craftsmanship, and overall performance of the samples. This step is vital to ensure that the products meet your specifications and will perform reliably in your application.

Step 5: Negotiate Terms and Conditions

Engage in negotiations with your chosen supplier to establish favorable terms and conditions. Discuss pricing, payment terms, delivery schedules, and warranty policies. Be clear about your expectations regarding lead times and after-sales support. A well-structured agreement can help prevent misunderstandings and ensure a smooth procurement process.

Illustrative image related to fan 24 cc

Step 6: Finalize Purchase Order

After agreeing on terms, finalize your purchase order with the supplier. Ensure that all specifications, quantities, and delivery expectations are clearly documented in the order. This step is crucial for maintaining clarity and accountability throughout the transaction.

Step 7: Monitor Delivery and Quality Assurance

As the order progresses, maintain communication with the supplier to monitor the delivery process. Upon receipt of the ‘fan 24 cc’ products, conduct a thorough quality assurance check to ensure that they meet the agreed specifications. Address any discrepancies promptly to uphold your operational standards.

By following this checklist, B2B buyers can effectively navigate the sourcing process for ‘fan 24 cc’ products, ensuring they make informed decisions and secure the best possible outcomes for their businesses.

Comprehensive Cost and Pricing Analysis for fan 24 cc Sourcing

When sourcing a 24cc fan for industrial applications, understanding the cost structure is essential for effective budgeting and decision-making. This analysis breaks down the primary cost components involved in the procurement process, identifies the factors influencing pricing, and offers strategic tips for international B2B buyers.

What Are the Key Cost Components in 24cc Fan Sourcing?

-

Materials: The cost of raw materials significantly affects the overall pricing of a 24cc fan. Common materials include high-grade metals for the motor casing and blades, plastic composites, and electrical components. Sourcing quality materials can enhance performance and durability but may increase costs.

-

Labor: Labor costs encompass wages for the workforce involved in manufacturing the fans. This includes assembly line workers, technicians, and quality control personnel. Labor costs can vary by region, so understanding local wage standards is crucial, especially for buyers from diverse markets.

-

Manufacturing Overhead: Overhead includes indirect costs such as utilities, facility maintenance, and equipment depreciation. These costs are typically allocated to the product based on production volume, impacting the final price.

-

Tooling: Tooling costs involve the creation and maintenance of molds and dies used in fan production. Custom tooling for specific designs can lead to higher initial costs but may be justified by the production of tailored solutions that meet buyer specifications.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the fans meet industry standards and buyer specifications. While this can increase costs, it ultimately leads to higher customer satisfaction and reduced returns.

-

Logistics: Transportation costs for shipping the fans from the manufacturer to the buyer can vary widely based on the distance and chosen shipping method. Factors such as fuel prices and customs duties also play a role in the overall logistics cost.

-

Margin: Suppliers typically add a markup to cover their costs and generate profit. This margin can fluctuate based on market demand, competition, and supplier reputation.

What Influences the Pricing of 24cc Fans?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to volume discounts. Buyers should negotiate MOQs that align with their purchasing capabilities while maximizing cost efficiency.

-

Specifications and Customization: Custom features, such as specific voltage requirements or enhanced durability for harsh environments, can significantly influence pricing. Buyers should clearly communicate their needs to suppliers to avoid unexpected costs.

-

Materials and Quality Certifications: Higher-quality materials or specialized certifications (like ISO or CE) can increase costs. Buyers should weigh the benefits of certification against the potential for increased expenses.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers with a track record of quality may charge more but can offer greater assurance of product reliability.

-

Incoterms: The chosen Incoterms (International Commercial Terms) impact the distribution of costs and responsibilities between buyers and suppliers. Understanding these terms can help buyers negotiate better shipping arrangements and manage risks.

What Are the Best Practices for B2B Buyers in International Markets?

-

Negotiation Strategies: Engage suppliers in discussions about pricing, especially regarding bulk orders. Establishing a long-term relationship can also lead to more favorable terms.

-

Cost-Efficiency Analysis: Evaluate the total cost of ownership (TCO), which includes initial costs, maintenance, and operational efficiency. A lower initial price may not always equate to better value if the product has higher operational costs.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, trade tariffs, and local regulations that may affect costs. Staying informed can help mitigate risks associated with international purchasing.

-

Supplier Diversification: Consider sourcing from multiple suppliers to reduce dependency and increase competitive pricing. This strategy can also provide alternatives in case of supply chain disruptions.

Conclusion

Navigating the complexities of sourcing a 24cc fan requires a clear understanding of the cost structure and the various pricing influencers. By leveraging strategic negotiation, understanding the total cost of ownership, and considering supplier dynamics, international B2B buyers can make informed purchasing decisions that align with their business objectives. Always remember that indicative prices can fluctuate based on market conditions, so maintaining an agile approach is essential for optimizing procurement strategies.

Alternatives Analysis: Comparing fan 24 cc With Other Solutions

Exploring Alternative Solutions to Fan 24 cc

When considering the optimal solution for cooling and ventilation needs, it is essential to evaluate various options in the market. The ‘Fan 24 cc’ serves specific applications, but alternative technologies and methods may better suit different contexts. This analysis presents a comparative overview of the Fan 24 cc against two viable alternatives: the Black Max Explosion-Proof Fan and the Mechatronics DC Brushless Fan.

Illustrative image related to fan 24 cc

Comparison Table

| Comparison Aspect | Fan 24 cc | Black Max Explosion-Proof Fan | Mechatronics DC Brushless Fan |

|---|---|---|---|

| Performance | Moderate airflow, suitable for standard applications | High airflow (10,800 CFM), explosion-proof | High efficiency, 205 CFM, quiet operation |

| Cost | Approx. $1,576 | Approx. $4,868 | Approx. £19.04 (bulk discounts available) |

| Ease of Implementation | Requires some installation effort | Complex installation due to safety features | Simple installation, lightweight design |

| Maintenance | Moderate; routine checks needed | High; specialized service required | Low; designed for longevity with minimal upkeep |

| Best Use Case | General industrial applications | Hazardous environments like paint or sandblasting | Electronic cooling and thermal management |

Detailed Breakdown of Alternatives

1. Black Max Explosion-Proof Fan

The Black Max fan is engineered for high-performance cooling in hazardous environments. With a maximum airflow of 10,800 CFM, it excels in applications where safety is paramount, such as in chemical plants or during sandblasting. However, its complexity in installation and higher price point may be a deterrent for some buyers. Additionally, maintenance can be intensive, requiring specialized knowledge to ensure safe operation, making it less appealing for general use.

2. Mechatronics DC Brushless Fan

The Mechatronics fan is a compact and efficient option, particularly suitable for electronic cooling applications. Its quiet operation and low power consumption make it ideal for environments where noise reduction is crucial. With an airflow of 205 CFM, it may not match the raw power of the Black Max or the Fan 24 cc, but it offers a balance of performance and longevity with minimal maintenance requirements. Its affordability and ease of installation make it attractive for smaller-scale operations or where space is limited.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right cooling solution requires careful consideration of your specific operational needs, budget constraints, and the environment in which the fan will be used. For businesses operating in hazardous conditions, the Black Max fan may be the best choice despite its higher cost and maintenance demands. Conversely, if you need a lightweight and efficient option for electronic cooling, the Mechatronics fan is likely to be more suitable. The Fan 24 cc remains a reliable option for general applications, offering a balance of performance and cost. Ultimately, aligning the choice with your operational requirements and resource availability will ensure optimal performance and value.

Illustrative image related to fan 24 cc

Essential Technical Properties and Trade Terminology for fan 24 cc

What Are the Key Technical Properties of a 24cc Fan?

When evaluating a 24cc fan for B2B applications, understanding its technical specifications is crucial. Here are several key properties that influence performance and compatibility:

-

Displacement Volume (cc)

The displacement volume, measured in cubic centimeters (cc), indicates the capacity of the fan motor. For a 24cc fan, this means it is designed to handle airflow and pressure suitable for various applications, such as HVAC systems or industrial machinery. This specification is vital as it directly impacts the fan’s efficiency and suitability for specific tasks. -

Motor Type

The type of motor, whether hydraulic or electric, affects the fan’s performance and operational costs. Hydraulic motors, like the Parker motors often used in agricultural machinery, offer high torque and efficiency in demanding environments. In contrast, electric motors are generally easier to integrate into systems where electrical power is available. Understanding the motor type helps buyers assess maintenance needs and energy consumption. -

Mounting Configuration

The mounting configuration, such as a two-bolt or four-bolt design, determines how the fan can be installed within a system. This is important for ensuring compatibility with existing infrastructure. A proper fit minimizes vibration and noise, enhancing operational reliability, which is critical for B2B applications where downtime can lead to significant losses. -

Pressure and Flow Rate

Key performance metrics include airflow (CFM – Cubic Feet per Minute) and static pressure (in H2O or Pascal). These figures indicate how much air the fan can move and the resistance it can overcome, which is essential for applications requiring consistent air delivery under varying conditions. Buyers should match these specifications with their operational requirements to ensure optimal performance. -

Operating Temperature Range

The operational temperature range indicates the environmental conditions in which the fan can function effectively. Fans designed for extreme temperatures may require special materials or coatings to prevent degradation. This specification is critical for industries such as agriculture or manufacturing, where temperature fluctuations can be significant. -

Noise Level (dB)

The noise level, measured in decibels (dB), is a crucial consideration for applications where sound levels must be kept to a minimum, such as in residential or office environments. A fan with a lower dB rating will provide a quieter operation, which can enhance user comfort and compliance with local regulations.

What Are Common Trade Terminology Terms for 24cc Fans?

Understanding industry jargon can facilitate smoother negotiations and procurement processes. Here are some essential trade terms relevant to 24cc fans:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Knowing the OEM for a fan ensures compatibility with existing systems and helps in sourcing replacement parts. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs and ensure they can meet their operational needs without excess expenditure. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price offers from suppliers for specific products. This process helps businesses gauge market pricing and supplier capabilities before making purchasing decisions. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international buyers to understand their liabilities and ensure smooth transactions. -

Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times is essential for inventory planning and project timelines, especially in industries with tight schedules. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the performance and reliability of the product. Knowing the warranty terms helps buyers assess the risk involved in their purchase and the potential costs of future repairs or replacements.

By grasping these technical properties and industry terms, international B2B buyers can make informed decisions when sourcing 24cc fans, ensuring they select products that meet their operational requirements while navigating the complexities of global trade.

Illustrative image related to fan 24 cc

Navigating Market Dynamics and Sourcing Trends in the fan 24 cc Sector

What Are the Key Trends Influencing the Global Fan 24 cc Market?

The global fan 24 cc market is witnessing significant growth driven by an increasing demand for efficient cooling solutions across various industries, including HVAC, automotive, and agriculture. Emerging technologies such as IoT (Internet of Things) are enabling smarter fan systems that enhance energy efficiency and performance. As industries in Africa, South America, the Middle East, and Europe look to optimize their operations, the integration of smart technologies in fan systems is becoming increasingly essential.

Moreover, the rise in urbanization and industrialization, especially in developing regions, is fueling the demand for reliable ventilation solutions. In Europe, countries like Germany are focusing on high-efficiency models that comply with stringent energy regulations. Similarly, Brazil is experiencing a surge in demand for hydraulic fan motors, particularly in agricultural machinery, highlighting regional variations in sourcing needs.

Another notable trend is the shift towards e-commerce and digital platforms for B2B transactions, allowing international buyers to access a wider range of suppliers and products. This trend is particularly prominent in the Middle East, where businesses are leveraging online marketplaces to streamline their procurement processes. As market dynamics evolve, international buyers should remain vigilant about technological advancements and regional preferences to make informed sourcing decisions.

How Is Sustainability and Ethical Sourcing Reshaping the Fan 24 cc Sector?

Sustainability is becoming a crucial factor in the sourcing of fan 24 cc products, as companies increasingly recognize the environmental impact of their operations. The manufacturing processes for fans often involve substantial energy consumption and material waste, prompting buyers to seek suppliers committed to reducing their carbon footprint.

Ethical sourcing practices, including the use of sustainable materials and responsible supply chains, are gaining traction. Buyers are encouraged to inquire about certifications that demonstrate a supplier’s commitment to sustainability, such as ISO 14001 for environmental management or LEED certification for energy-efficient buildings. Additionally, the adoption of recyclable materials in fan production is becoming a selling point, appealing to environmentally conscious buyers.

In regions such as Africa and South America, where environmental challenges are pronounced, the emphasis on sustainable sourcing is not just a trend but a necessity. Companies that prioritize ethical practices not only enhance their brand reputation but also ensure compliance with increasingly stringent regulations on environmental standards. For international buyers, aligning with suppliers who uphold sustainability can lead to long-term partnerships and improved market positioning.

What Is the Historical Context of the Fan 24 cc Industry?

The fan 24 cc industry has evolved significantly over the past few decades, transitioning from traditional mechanical systems to advanced, electronically controlled technologies. Initially, fans were primarily used for basic ventilation; however, as industries grew, the demand for more specialized applications emerged. The advent of hydraulic and electric motors revolutionized the sector, allowing for greater efficiency and versatility.

In recent years, the introduction of smart technology and automation has further transformed the landscape, enabling predictive maintenance and enhanced performance monitoring. As the global focus on sustainability increases, the industry is also adapting to incorporate eco-friendly practices and materials. This evolution reflects a broader trend within the B2B sector, where innovation and sustainability are at the forefront of competitive advantage.

Understanding the historical context of the fan 24 cc market is essential for international buyers, as it informs current trends and future directions, enabling them to make strategic sourcing decisions that align with both market demands and their corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of fan 24 cc

-

How do I ensure the quality of a 24 cc fan before purchasing?

To ensure the quality of a 24 cc fan, request detailed product specifications and certifications from potential suppliers. Look for third-party testing reports that verify compliance with international standards such as ISO or CE. Additionally, consider asking for samples to evaluate performance firsthand, and check for customer testimonials or case studies that highlight the product’s reliability in similar applications. -

What is the best type of 24 cc fan for agricultural applications?

For agricultural applications, hydraulic fans with a 24 cc motor, such as those from reputable manufacturers, are ideal due to their robust design and efficient performance. Look for features like corrosion resistance and high airflow rates. Additionally, ensure that the fan is compatible with your specific machinery to optimize performance and maintain operational efficiency. -

What are the typical lead times for ordering 24 cc fans internationally?

Lead times for ordering 24 cc fans can vary significantly depending on the manufacturer and order size. Generally, expect 4 to 12 weeks for production and shipping. Factors such as customization, shipping methods, and local regulations can also impact delivery times. Always confirm lead times with your supplier and consider placing orders well in advance of peak seasons to avoid delays. -

What should I consider when vetting suppliers for 24 cc fans?

When vetting suppliers for 24 cc fans, assess their industry experience, production capacity, and customer reviews. Verify their certifications and compliance with international quality standards. It’s also beneficial to request references from other businesses in your sector. Engaging with suppliers through trade shows or direct communications can provide insights into their reliability and customer service capabilities. -

Are there customization options available for 24 cc fans?

Yes, many manufacturers offer customization options for 24 cc fans, including modifications to size, airflow, and motor specifications. Discuss your specific requirements with potential suppliers, such as unique mounting configurations or material selections. Customization can enhance performance and ensure the fan meets your operational needs effectively. -

What are the minimum order quantities (MOQ) for 24 cc fans?

Minimum order quantities (MOQ) for 24 cc fans vary by manufacturer and can range from a single unit to several hundred. Larger orders often lead to discounted pricing, but smaller orders may incur higher per-unit costs. It’s advisable to clarify MOQ with suppliers upfront and explore options for bulk purchasing if you anticipate future needs. -

What payment terms are commonly offered by suppliers of 24 cc fans?

Payment terms for suppliers of 24 cc fans can vary widely, but common practices include a deposit upfront (typically 30-50%) with the balance due upon delivery. Some suppliers may offer net payment terms (e.g., Net 30 or Net 60 days) for established customers. Ensure to negotiate favorable terms that align with your cash flow while considering the supplier’s policies. -

What logistics considerations should I be aware of when importing 24 cc fans?

When importing 24 cc fans, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with your destination country to ensure compliance with import regulations. Additionally, factor in lead times for customs clearance and delivery, and maintain communication with your supplier to track the shipment status effectively.

Top 4 Fan 24 Cc Manufacturers & Suppliers List

1. Sport 24 – Live Sports Channels

Domain: sport24live.com

Registered: 2018 (7 years)

Introduction: Sport 24 and Sport 24 Extra are live sports channels for the international airline and cruise line markets, broadcasting popular sports 24 hours a day, year-round. They offer live coverage of events such as the Premier League, UEFA European Qualifiers, MotoGP, Ligue 1, National Rugby League, Formula 1, Women’s Rugby World Cup, and DP World Tour. Upcoming events include the DP World Tour Day 1 on S…

2. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

3. Industrial Fans Direct – Triangle Whole House Fan 24 Inch

Domain: industrialfansdirect.com

Registered: 2005 (20 years)

Introduction: {“product_name”: “Triangle Whole House Fan 24 Inch 2 Speed 800 sq. ft. Max Belt Drive CC2422”, “fan_size”: “24 inch”, “speed_options”: “2 speed”, “coverage_area”: “800 sq. ft.”, “drive_type”: “belt drive”}

4. Mechatronics – MD1238X24B-FSR-CC-L15 Fan

Domain: digikey.co.uk

Registered: 2004 (21 years)

Introduction: MD1238X24B-FSR-CC-L15 Mechatronics Fan Group | Fans, Blowers, Thermal Management | DigiKey

Strategic Sourcing Conclusion and Outlook for fan 24 cc

What Are the Key Takeaways for Sourcing Fan 24 cc Products?

As international B2B buyers consider the procurement of Fan 24 cc products, it is essential to recognize the importance of strategic sourcing. Understanding the specifications, such as the hydraulic motor capabilities and the compatibility with various applications, can significantly enhance decision-making processes. Buyers should focus on suppliers that offer robust support and reliable lead times, particularly those with established reputations in the markets of Africa, South America, the Middle East, and Europe.

How Can Strategic Sourcing Enhance Your Supply Chain?

Strategic sourcing not only ensures that you obtain high-quality products but also fosters long-term partnerships with manufacturers and distributors. By leveraging insights into market trends and supplier capabilities, buyers can achieve cost efficiencies and mitigate risks associated with supply chain disruptions. This proactive approach is especially critical in regions where logistics and regulatory challenges may arise.

What’s Next for International B2B Buyers?

Looking ahead, the demand for Fan 24 cc products is anticipated to grow, driven by advancements in technology and increased application across various industries. B2B buyers are encouraged to engage with suppliers who demonstrate innovation and adaptability. Investing in these relationships will not only secure a competitive advantage but also contribute to sustainable growth. Now is the time to explore potential partnerships and enhance your sourcing strategies to meet the evolving needs of your business.

Illustrative image related to fan 24 cc

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.