Eyelets Gold Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for eyelets gold

In today’s competitive landscape, sourcing high-quality eyelets gold can present a significant challenge for international B2B buyers. Whether you’re in the textile industry, manufacturing, or crafting sectors, understanding the nuances of eyelet procurement—from types and applications to supplier vetting and pricing strategies—is crucial for making informed decisions. This guide serves as a comprehensive resource, designed to equip businesses across Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Brazil, with the insights necessary to navigate the global market effectively.

As we delve into the diverse types of eyelets gold available—ranging from standard grommets to specialized handcrafted options—you will gain a clearer understanding of their applications in various industries, including fashion, home décor, and industrial textiles. The guide will also outline essential factors to consider when evaluating suppliers, such as quality assurance, production capabilities, and shipping logistics, ensuring that you can confidently select the best partners for your needs. Additionally, we will explore cost considerations, providing you with strategies to optimize your purchasing power.

By leveraging the information presented in this guide, B2B buyers can enhance their sourcing strategies, mitigate risks, and capitalize on opportunities in the dynamic market for eyelets gold, ultimately leading to more successful business outcomes.

Understanding eyelets gold Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Gold Eyelets | Made from metal with a shiny gold finish; commonly used in fabric applications. | Curtains, bags, apparel | Pros: Durable, aesthetically pleasing. Cons: May require specific tools for installation. |

| Long Barrel Gold Eyelets | Longer barrel for thicker materials; typically used in heavy-duty applications. | Tarps, belts, outdoor gear | Pros: Suitable for heavier fabrics. Cons: Limited to specific use cases. |

| Glass Gold Eyelets | Crafted from solid glass with iridescent finishes; adds a decorative touch. | Jewelry, fashion accessories | Pros: Unique aesthetics, lightweight. Cons: Fragile, not suitable for all applications. |

| Antique Gold Eyelets | Aged finish for a vintage look; often used in crafts and DIY projects. | Home decor, crafts | Pros: Distinctive appearance, versatile. Cons: Not as durable as standard options. |

| Specialty Gold Eyelets | Made from unique materials like wood or stone; often handcrafted. | High-end fashion, artisan goods | Pros: Customizable, exclusive designs. Cons: Higher cost, limited availability. |

What are the Characteristics of Standard Gold Eyelets?

Standard gold eyelets are primarily made from durable metal and feature a shiny gold finish, making them a popular choice for various fabric applications. They are typically used in curtains, bags, and apparel, providing both functionality and aesthetic appeal. When considering bulk purchases, buyers should evaluate the required tools for installation, as these eyelets often necessitate specific setting tools. Their durability is a significant advantage, but the necessity for installation tools may pose a challenge for some businesses.

Illustrative image related to eyelets gold

How Do Long Barrel Gold Eyelets Differ from Other Types?

Long barrel gold eyelets feature an extended barrel designed for thicker materials, making them ideal for heavy-duty applications such as tarps and outdoor gear. This type of eyelet allows for a secure fit in robust fabrics, which is crucial for items exposed to outdoor elements. B2B buyers should consider the specific thickness of the materials they plan to use, as these eyelets are limited to particular use cases. While they offer reliability and strength, the niche application may restrict broader usage.

Why Choose Glass Gold Eyelets for Your Products?

Glass gold eyelets are unique, made from solid glass and often featuring an iridescent finish that adds a decorative touch to products. They are commonly used in jewelry and fashion accessories, appealing to businesses looking to offer distinctive designs. Buyers should be mindful of the fragility of glass eyelets, as they are not suitable for all applications. Their lightweight nature is a plus, but the potential for breakage can be a drawback, especially in high-traffic items.

What Makes Antique Gold Eyelets a Popular Choice?

Antique gold eyelets are characterized by their aged finish, providing a vintage look that is highly sought after in crafts and DIY projects. These eyelets are versatile and can be used in home decor and various craft applications. For B2B buyers, the distinctive appearance can enhance product offerings, but it’s essential to note that antique gold eyelets may not be as durable as standard options. The appeal lies in their aesthetic value, making them a favored choice for artisans and crafters.

How Do Specialty Gold Eyelets Stand Out in the Market?

Specialty gold eyelets are often made from unique materials such as wood or stone and are typically handcrafted, catering to high-end fashion and artisan goods. Their customizable nature allows businesses to offer exclusive designs, appealing to niche markets. However, buyers should consider the higher costs associated with these eyelets and their limited availability. While they provide a unique selling proposition, the investment may be significant for businesses looking to incorporate specialty items into their product lines.

Illustrative image related to eyelets gold

Key Industrial Applications of eyelets gold

| Industry/Sector | Specific Application of eyelets gold | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Reinforcement in garments and accessories | Enhances durability and aesthetic appeal | Quality of materials, customization options, lead times |

| Home Décor & Furnishings | Decorative and functional elements in curtains | Adds elegance and functionality to home textiles | Color matching, size specifications, bulk purchasing rates |

| Industrial Textiles | Fastening solutions for tarps and covers | Provides strong, reliable fastening under stress | Material strength, weather resistance, volume orders |

| Sports Equipment | Eyelets in sportswear for ventilation and style | Improves performance and comfort for athletes | Lightweight materials, resistance to wear, design options |

| Crafting & DIY Projects | Customization in various craft applications | Offers creative solutions for hobbyists and crafters | Variety of sizes, ease of installation, pricing for bulk |

How is ‘eyelets gold’ used in the fashion and apparel industry?

In the fashion and apparel sector, gold eyelets are prominently used for reinforcing holes in garments, bags, and accessories. This not only enhances the durability of the fabric but also adds a touch of elegance, appealing to consumers looking for premium products. B2B buyers in this industry should consider the quality of materials used, as well as customization options for unique designs. Additionally, understanding lead times is crucial for aligning production schedules with market demands.

What role do gold eyelets play in home décor and furnishings?

In home décor, gold eyelets serve as both decorative and functional elements in items like curtains and drapes. They provide a polished finish that elevates the aesthetic of home textiles while ensuring that the fabric can withstand regular use. Buyers from various regions, including Europe and the Middle East, should focus on color matching to existing décor, as well as size specifications to fit different fabric types. Bulk purchasing rates can also lead to cost efficiencies for large-scale projects.

How are gold eyelets utilized in industrial textiles?

Gold eyelets are essential in the industrial textiles sector, particularly for fastening solutions in tarps and covers. Their robust design ensures reliable fastening, even under significant stress, making them ideal for outdoor applications. B2B buyers must prioritize material strength and weather resistance, especially in regions with extreme climates. Additionally, sourcing in volume can provide better pricing, which is essential for budget-conscious businesses.

Illustrative image related to eyelets gold

What benefits do gold eyelets offer in sports equipment?

In the sports equipment industry, gold eyelets are used in sportswear for ventilation and style. They help improve breathability while adding a fashionable element, enhancing both performance and comfort for athletes. Buyers should consider lightweight materials that resist wear and tear, as well as various design options to cater to different sports and preferences. This is particularly important for international buyers looking to differentiate their product offerings in competitive markets.

How do crafters benefit from using gold eyelets?

In crafting and DIY projects, gold eyelets are popular for customization in various applications, from scrapbooking to jewelry making. They provide creative solutions that allow hobbyists to enhance their projects with unique designs and finishes. B2B buyers in this sector should look for a variety of sizes and ease of installation to cater to diverse crafting needs. Pricing for bulk purchases can also be a significant factor, enabling cost-effective sourcing for materials.

3 Common User Pain Points for ‘eyelets gold’ & Their Solutions

Scenario 1: Sourcing Quality Gold Eyelets for Production Needs

The Problem: B2B buyers often struggle to find reliable suppliers of high-quality gold eyelets that meet their specific production requirements. This issue is compounded by variations in quality, sizes, and styles available in the market. Buyers may receive subpar products that lead to increased production costs, delays, and ultimately, customer dissatisfaction. This can be particularly challenging for businesses that rely on eyelets for fashion items, home decor, or industrial applications, where consistency and quality are paramount.

The Solution: To address this challenge, buyers should establish a clear set of criteria for sourcing gold eyelets, including material quality, size specifications, and durability requirements. Conducting thorough supplier research is essential; leverage platforms like Alibaba, ThomasNet, or industry-specific trade shows to identify potential suppliers. Request samples before placing bulk orders to assess quality directly. Additionally, consider partnering with suppliers who offer custom manufacturing options, allowing you to specify exact dimensions and finishes, ensuring that the eyelets meet your production needs perfectly.

Scenario 2: Managing Inventory and Stock Levels of Gold Eyelets

The Problem: Maintaining optimal inventory levels of gold eyelets can be a significant pain point for B2B buyers, especially in industries with fluctuating demand. Overstocking can lead to increased holding costs and wasted resources, while understocking can result in production halts and missed sales opportunities. This delicate balance is often exacerbated by suppliers’ varying lead times and shipping reliability, creating uncertainty in supply chain management.

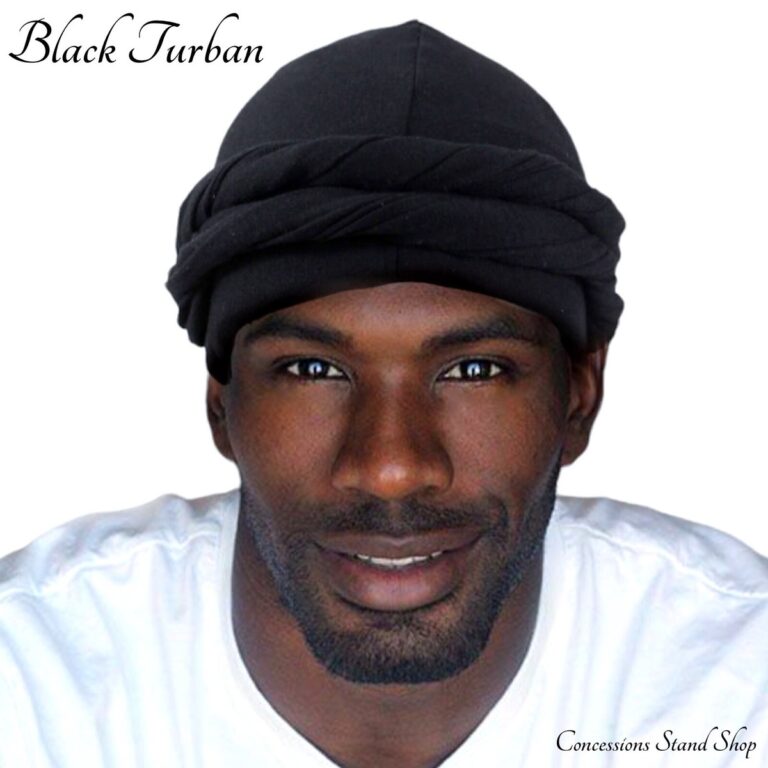

Illustrative image related to eyelets gold

The Solution: Implementing an effective inventory management system is crucial. Buyers should utilize inventory tracking software that integrates with their existing systems to monitor stock levels in real-time. Establish reorder points based on historical sales data and lead times, allowing for proactive purchasing decisions. Collaborating closely with suppliers to understand their production and shipping schedules can also aid in anticipating needs and managing stock levels. Additionally, consider building a buffer stock for critical items like gold eyelets to mitigate the risk of supply chain disruptions.

Scenario 3: Ensuring Compatibility of Gold Eyelets with Various Materials

The Problem: Another common issue faced by B2B buyers is ensuring that gold eyelets are compatible with the diverse range of materials used in their products. Different fabrics and materials require specific types of eyelets to ensure proper function and aesthetic appeal. Using incompatible eyelets can lead to damage, unsatisfactory product performance, and increased returns, impacting overall customer satisfaction and brand reputation.

The Solution: To overcome this challenge, buyers should conduct thorough material compatibility testing. Prior to finalizing purchases, evaluate the eyelets with the intended materials to ensure a secure and aesthetically pleasing fit. Additionally, create a detailed specification guide that outlines the recommended eyelet types for various materials. This guide can serve as a reference for your production team and help in training new staff on best practices. Collaborating with suppliers who provide detailed product specifications and usage guidelines can also assist in making informed decisions about which eyelets to use for specific applications.

Strategic Material Selection Guide for eyelets gold

What are the Key Properties of Common Materials Used for Eyelets Gold?

When selecting materials for eyelets gold, understanding the properties of each option is crucial for ensuring optimal performance in various applications. The most commonly used materials include brass, aluminum, stainless steel, and plastic. Each material offers unique benefits and drawbacks that can significantly impact the final product’s quality and suitability for specific uses.

How Does Brass Perform as a Material for Eyelets Gold?

Brass is a popular choice for eyelets due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for applications that may involve exposure to harsh environments. The alloy typically contains copper and zinc, which enhances its mechanical properties.

Pros: Brass eyelets are known for their aesthetic appeal and strength. They are relatively easy to manufacture and can be plated for additional finishes, including gold.

Cons: However, brass can be more expensive than other materials, and its susceptibility to tarnishing may require regular maintenance, especially in humid climates.

Impact on Application: Brass eyelets are ideal for high-end fashion items, outdoor gear, and industrial applications where durability is essential.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential, particularly in regions like Europe and the Middle East, where quality assurance is paramount.

What Advantages Does Aluminum Offer for Eyelets Gold?

Aluminum is another widely used material for eyelets, valued for its lightweight nature and resistance to corrosion. It is often anodized to enhance its surface properties, which can also provide a gold finish.

Pros: The lightweight characteristic of aluminum makes it an excellent choice for applications where weight is a concern, such as in the aerospace and automotive industries. It is also cost-effective compared to brass.

Cons: However, aluminum may not provide the same level of strength as brass and can be more prone to deformation under high stress.

Impact on Application: Aluminum eyelets are suitable for lightweight fabrics, sportswear, and applications where ease of handling is critical.

Considerations for International Buyers: Buyers should ensure that aluminum eyelets meet local standards, especially in markets like South America, where regulatory compliance can vary significantly.

Why Choose Stainless Steel for Eyelets Gold?

Stainless steel is renowned for its exceptional strength and resistance to corrosion, making it a premium choice for eyelets in demanding applications. Its ability to withstand extreme temperatures and pressures adds to its appeal.

Pros: Stainless steel eyelets are incredibly durable and require minimal maintenance. They are suitable for both indoor and outdoor applications, including marine environments.

Cons: The primary drawback is the higher cost compared to other materials like aluminum and plastic, which may deter some buyers.

Impact on Application: Ideal for industrial applications, stainless steel eyelets are often used in heavy-duty fabrics, tarps, and outdoor gear.

Considerations for International Buyers: Buyers should look for certifications that verify the quality of stainless steel, particularly in regions with stringent quality control measures.

What Role Does Plastic Play in Eyelets Gold?

Plastic eyelets are a cost-effective alternative to metal options, often used in applications where weight and cost are critical factors. They are available in various colors and finishes, including gold.

Pros: Plastic eyelets are lightweight, resistant to corrosion, and can be produced in large quantities at a low cost. They are also flexible, making them suitable for various fabric types.

Cons: However, plastic may not offer the same strength and durability as metal options, limiting its use in heavy-duty applications.

Impact on Application: Ideal for crafts, children’s clothing, and lightweight fabrics, plastic eyelets are popular in the DIY market.

Considerations for International Buyers: Buyers should verify that plastic eyelets comply with safety standards, especially in regions where regulations on materials used in children’s products are strict.

Summary Table of Material Selection for Eyelets Gold

| Material | Typical Use Case for eyelets gold | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-end fashion, outdoor gear | Excellent corrosion resistance | Susceptible to tarnishing | High |

| Aluminum | Lightweight fabrics, sportswear | Lightweight and cost-effective | Lower strength than brass | Medium |

| Stainless Steel | Heavy-duty fabrics, industrial gear | Exceptional strength and durability | Higher cost | High |

| Plastic | Crafts, children’s clothing | Lightweight and low-cost | Limited strength | Low |

This guide aims to empower international B2B buyers with the knowledge needed to make informed decisions regarding the selection of materials for eyelets gold, ensuring that their applications meet both performance and regulatory standards.

In-depth Look: Manufacturing Processes and Quality Assurance for eyelets gold

What Are the Main Stages in the Manufacturing Process of Gold Eyelets?

The manufacturing process of gold eyelets involves several critical stages, each designed to ensure the final product meets the high standards demanded by B2B buyers. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality materials, typically metal alloys that include a significant gold content for aesthetic appeal and corrosion resistance. Manufacturers often use brass or aluminum as base materials, which are then coated with gold through processes such as electroplating or physical vapor deposition (PVD). Quality checks on raw materials are crucial to ensure they meet specifications for durability and appearance.

-

Forming: During this stage, the prepared materials are shaped into eyelet forms. Techniques such as stamping or die-cutting are commonly employed, allowing for precision in hole diameter and barrel length. This stage may also include the creation of the flared edges that help secure the eyelet in place. Advanced machinery, such as CNC (Computer Numerical Control) machines, is often used to enhance precision and repeatability in forming operations.

-

Assembly: After forming, eyelet components are assembled. This may involve attaching washers or additional reinforcement elements that enhance the eyelet’s strength. In some cases, automated systems are used for assembly to improve efficiency and reduce labor costs.

-

Finishing: The finishing stage is where eyelets receive their final touches. This may include polishing, additional coating, or treatment to enhance their visual appeal and durability. The finishing process often involves strict quality control to ensure that the eyelets are free from defects and meet the specifications of international standards.

How Is Quality Assurance Implemented in the Eyelet Manufacturing Process?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for gold eyelets, ensuring that products are safe, reliable, and meet the expectations of B2B buyers across various regions.

-

International Standards and Certifications: Manufacturers typically adhere to international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards is essential for companies looking to export their products, particularly to markets in Africa, South America, the Middle East, and Europe. Other relevant certifications may include CE marking for compliance with European health, safety, and environmental protection standards.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production process. Suppliers must provide documentation that verifies the quality and compliance of the materials.

– In-Process Quality Control (IPQC): During manufacturing, IPQC involves ongoing inspections at various stages to ensure that the production process adheres to established standards. This might include monitoring machinery calibration and inspecting formed components for dimensional accuracy.

– Final Quality Control (FQC): Once the eyelets are finished, a final inspection is conducted to check for defects, finish quality, and packaging standards. This ensures that only products meeting quality specifications are shipped to buyers. -

Common Testing Methods: Various testing methods are employed to verify the quality and performance of gold eyelets. These include tensile strength tests to assess durability, corrosion resistance tests to determine the longevity of the gold coating, and visual inspections for aesthetic quality. Additionally, manufacturers may conduct functional testing to ensure eyelets perform as expected in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers play a crucial role in ensuring they source high-quality products by conducting thorough due diligence on their suppliers. Here are several ways to verify quality control measures:

-

Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality control practices. Audits can be performed by the buyer’s internal team or through third-party services that specialize in supplier assessments.

-

Quality Control Reports: Requesting detailed quality control reports can help buyers understand how a manufacturer maintains quality throughout the production process. These reports should detail the results of IQC, IPQC, and FQC, along with any corrective actions taken for non-conformities.

-

Third-Party Inspections: Engaging third-party inspection services is a common practice among international buyers. These services can verify that the products meet specified standards before shipment, providing an additional layer of assurance.

-

Certifications and Compliance Documentation: Buyers should request copies of certifications and compliance documentation from suppliers. This may include ISO certification, CE marking, and any other relevant industry-specific certifications that demonstrate a commitment to quality.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers operating in diverse markets, particularly in Africa, South America, the Middle East, and Europe, must navigate various quality control nuances that can affect sourcing decisions.

-

Cultural and Regulatory Differences: Understanding the cultural and regulatory environment in the supplier’s country is essential. Different regions may have varying standards for quality and safety, which can impact product compliance and market acceptance.

-

Logistical Considerations: Shipping and logistics can introduce additional quality control challenges. For example, products may be exposed to environmental factors during transport that could affect their quality. Buyers should ensure that suppliers have robust packaging and shipping protocols to mitigate these risks.

-

Market-Specific Requirements: Certain markets may have unique requirements for eyelets based on local industry standards. For instance, the textile and fashion industries in Europe may have stricter compliance requirements compared to those in other regions. Buyers must be aware of these specifics to ensure that the products they import meet local regulations.

-

Building Relationships with Suppliers: Establishing strong relationships with suppliers can enhance communication regarding quality control issues. Regular interaction can lead to better transparency and quicker resolution of any quality concerns that may arise.

By understanding these aspects of manufacturing and quality assurance for gold eyelets, B2B buyers can make informed sourcing decisions that align with their quality standards and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘eyelets gold’

When sourcing gold eyelets, it’s essential for B2B buyers to follow a structured approach to ensure quality and reliability. This guide serves as a practical checklist to streamline your procurement process, helping you make informed decisions that align with your business needs.

Illustrative image related to eyelets gold

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the gold eyelets you need. Consider factors such as size, material, and application. This step is critical as it ensures that the eyelets will meet your specific project demands, such as durability for outdoor use or aesthetic qualities for fashion items.

- Size and Dimensions: Specify the hole diameter and length of the barrel to fit your fabric or project.

- Material Quality: Determine if you need solid brass, plated, or other materials based on the end-use.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers who specialize in gold eyelets. A well-informed choice can significantly impact the quality and reliability of your sourcing. Look for suppliers with a strong reputation in your target markets, especially in regions like Africa, South America, the Middle East, and Europe.

- Supplier Ratings and Reviews: Check online platforms for feedback from previous customers.

- Industry Experience: Preference should be given to suppliers with a proven track record in your specific industry.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify the certifications and compliance of potential suppliers. This step is crucial to ensure that the products meet international standards and regulations, which can vary by region.

- Quality Certifications: Look for ISO certifications or other relevant quality assurance certifications.

- Ethical Sourcing Practices: Ensure the supplier adheres to ethical sourcing guidelines, particularly important in regions where labor practices may be scrutinized.

Step 4: Request Samples

Always request samples of the eyelets before placing a bulk order. This allows you to evaluate the quality and ensure they meet your specifications. Testing samples can prevent costly mistakes and ensure product compatibility with your materials.

- Material Testing: Check for durability, finish, and ease of installation.

- Fit and Functionality: Ensure the eyelets perform as expected in your intended applications.

Step 5: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier and confirmed the product quality, it’s time to negotiate pricing and terms. Effective negotiation can lead to better pricing, favorable payment terms, and shipping conditions.

- Volume Discounts: Inquire about discounts for bulk orders, which can significantly reduce costs.

- Payment Terms: Understand the payment options available, including upfront deposits or letters of credit.

Step 6: Establish a Communication Protocol

Set up a clear communication protocol with your chosen supplier. Good communication is key to successful procurement and can help in resolving any issues that may arise during the order process.

- Regular Updates: Agree on how often you will receive updates on your order status.

- Point of Contact: Designate a specific person for communication on both sides to streamline discussions.

Step 7: Plan for Logistics and Delivery

Finally, ensure that logistics and delivery are well-planned. Discuss shipping methods, timelines, and costs with your supplier to avoid delays.

- Shipping Options: Consider various shipping methods and select one that balances speed and cost.

- Customs and Duties: Be aware of any customs regulations or duties that may apply to your shipment, especially for international orders.

By following these steps, B2B buyers can effectively source gold eyelets that meet their technical specifications, ensuring quality and reliability for their projects.

Comprehensive Cost and Pricing Analysis for eyelets gold Sourcing

When sourcing gold eyelets, understanding the cost structure and pricing dynamics is crucial for B2B buyers. The costs can significantly influence your purchasing decisions and overall profitability, especially in international markets like Africa, South America, the Middle East, and Europe.

What are the Key Cost Components in Gold Eyelet Sourcing?

-

Materials: The primary cost driver in eyelet production is the raw materials used. Gold eyelets typically consist of metal alloys that can vary in purity and quality, which directly impacts the pricing. Sourcing high-quality materials may incur higher costs, but it also ensures durability and aesthetic appeal.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process. Skilled labor is required for the production of high-quality eyelets, especially when customization is involved. Regions with lower labor costs may offer competitive pricing, but this can affect the quality.

-

Manufacturing Overhead: This includes expenses related to the factory, utilities, and equipment maintenance. Overhead costs can vary significantly by location, impacting the final price of the eyelets. Manufacturers in regions with advanced technology may have lower overheads due to efficiency, translating to better prices for buyers.

-

Tooling: The initial cost of tooling can be substantial, particularly for customized or specialized eyelets. This cost is often amortized over large production runs, which means higher volume orders can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring quality through rigorous testing and inspection processes adds to the overall cost. Buyers should consider whether the supplier has adequate QC measures in place, as this can prevent costly returns and enhance product reliability.

-

Logistics: Shipping and handling costs can vary based on the destination, mode of transport, and volume of the order. International buyers should account for customs duties and taxes, which can significantly affect the total landed cost.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the supplier’s pricing strategy can give insight into how flexible they may be during negotiations.

What Influences the Pricing of Gold Eyelets?

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract volume discounts, reducing the per-unit cost. Buyers should assess their demand forecasts to optimize order sizes.

-

Specifications and Customization: Eyelets can be tailored in terms of size, finish, and design. Customization typically incurs additional costs, so buyers should weigh the benefits against the price increase.

-

Material Quality and Certifications: Eyelets made from higher-grade materials or those that meet specific industry certifications may command higher prices. Buyers should consider the long-term benefits of investing in quality.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to perceived value and trustworthiness.

-

Incoterms: Understanding the Incoterms used in the transaction is essential. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect pricing structures and the responsibilities of both buyer and seller.

What are the Best Buyer Tips for Cost-Efficiency?

-

Negotiate Wisely: Leverage your knowledge of market prices and suppliers’ costs to negotiate better deals. Building a long-term relationship with suppliers can also lead to more favorable terms over time.

-

Consider Total Cost of Ownership (TCO): Look beyond initial purchase prices. Evaluate factors such as durability, maintenance, and potential replacement costs to understand the true cost of ownership.

-

Be Aware of Pricing Nuances: International buyers should account for fluctuations in currency exchange rates and potential tariffs. These can impact the overall cost and should be factored into budgeting.

-

Seek Multiple Quotes: Always obtain quotes from multiple suppliers to ensure competitive pricing. This not only aids in cost comparison but can also provide leverage in negotiations.

Disclaimer on Indicative Prices

Prices for gold eyelets can vary widely based on the factors discussed above. The figures mentioned in various sources are indicative and subject to change based on market conditions and supplier pricing strategies. Always verify current pricing with suppliers to ensure accuracy in your budgeting and planning.

By understanding these elements, international B2B buyers can make informed decisions when sourcing gold eyelets, optimizing costs while ensuring quality and reliability.

Alternatives Analysis: Comparing eyelets gold With Other Solutions

Introduction to Alternatives in Eyelet Solutions

In the realm of fastening solutions for fabric and other materials, gold eyelets are a popular choice due to their aesthetic appeal and functionality. However, various alternatives are available that may better suit different needs based on performance, cost, and specific application requirements. This section evaluates gold eyelets against other viable solutions, helping B2B buyers make informed decisions based on their unique project demands.

Comparison Table

| Comparison Aspect | Eyelets Gold | Grommets | Snap Fasteners |

|---|---|---|---|

| Performance | Durable and visually appealing | Highly durable, strong hold | Quick fastening, reusable |

| Cost | Moderate ($1.99 – $22.00 per pack) | Low ($0.10 – $0.50 each) | Moderate ($0.50 – $1.50 each) |

| Ease of Implementation | Requires special tools (hammer) | Easy to install with tools | Very easy, no special tools |

| Maintenance | Minimal maintenance needed | Low maintenance | Low maintenance |

| Best Use Case | Decorative applications (curtains, belts) | Heavy-duty projects (tarps, tents) | Clothing and accessories |

Detailed Breakdown of Alternatives

Grommets

Grommets are a widely used alternative to eyelets, particularly in heavy-duty applications. They provide a strong hold and are ideal for projects requiring reinforced openings, such as tarps and banners. The installation of grommets is straightforward and typically involves a simple setting tool. While they can be less visually appealing than gold eyelets, their low cost makes them a practical choice for bulk applications. However, they may not offer the same decorative aspect, which could be a downside for projects that prioritize aesthetics.

Snap Fasteners

Snap fasteners are another alternative that offers quick and convenient fastening solutions, particularly in clothing and accessory applications. They are easy to install without the need for special tools, making them accessible for manufacturers and crafters alike. Snap fasteners can be reused multiple times, which adds to their cost-effectiveness over time. However, they may not provide the same level of durability as gold eyelets or grommets, especially in applications requiring heavy stress or tension.

Conclusion: Choosing the Right Solution for Your Needs

When considering fastening solutions, B2B buyers must evaluate their specific project requirements, including the intended use, cost constraints, and desired aesthetics. Gold eyelets offer a unique blend of durability and style, making them suitable for decorative applications, while grommets excel in heavy-duty settings. Snap fasteners provide an easy, reusable option for everyday use. By analyzing the performance, cost, and ease of implementation of these alternatives, buyers can select the most appropriate solution to enhance their product offerings and meet customer expectations effectively.

Essential Technical Properties and Trade Terminology for eyelets gold

When considering the procurement of eyelets gold, understanding the essential technical properties and industry terminology is crucial for making informed purchasing decisions. This guide outlines critical specifications and common jargon that can help B2B buyers navigate their options effectively.

What are the Key Technical Properties of Eyelets Gold?

-

Material Grade

– Eyelets are typically made from materials like brass, aluminum, or stainless steel, with gold plating to enhance aesthetics and corrosion resistance. The material grade affects durability, weight, and cost. Buyers should consider the environment where the eyelets will be used, as specific materials may perform better under certain conditions. -

Hole Diameter

– The hole diameter is a critical specification that dictates the size of the eyelet and the type of fabric it can accommodate. Common sizes include 3/16″ (approximately 4.76 mm) and 5/16″ (approximately 7.94 mm). Selecting the appropriate diameter ensures a secure fit and functionality in applications such as garment construction or industrial uses. -

Barrel Length

– The barrel length refers to the length of the cylindrical portion of the eyelet that fits through the fabric. A longer barrel can provide better grip and stability, especially in thicker materials. This property is essential for applications requiring high durability, such as outdoor gear or heavy-duty fabrics. -

Finish Type

– Eyelets come in various finishes, including matte, glossy, and iridescent. The finish not only impacts the visual appeal but also the functionality, as certain finishes can enhance resistance to wear and tear. Buyers should consider the intended aesthetic and application when selecting the finish. -

Quantity per Package

– Eyelets are often sold in bulk packages, with quantities varying significantly. A standard package might contain anywhere from 24 to 1000 pieces. Understanding the quantity is essential for budgeting and ensuring that enough eyelets are available for production runs.

What Common Trade Terms Should B2B Buyers Know?

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce components or products that are used in another company’s end product. For eyelets, knowing the OEM can ensure that you are sourcing from reputable manufacturers known for quality. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers as it can affect inventory costs and cash flow. Suppliers often set MOQs based on production costs and logistics considerations. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This is an essential step in the procurement process, allowing buyers to compare prices and terms before making a decision. -

Incoterms (International Commercial Terms)

– Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and rights in international transactions. -

Lead Time

– Lead time refers to the time taken from placing an order to delivery. Understanding lead times is critical for planning production schedules and ensuring timely availability of materials. -

Certification Standards

– Many industries require products to meet specific certification standards, such as ISO or ASTM. Knowing these standards can help buyers ensure that the eyelets they purchase meet safety and quality requirements.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed purchasing decisions regarding eyelets gold, ensuring they meet their business needs effectively.

Navigating Market Dynamics and Sourcing Trends in the eyelets gold Sector

What Are the Current Trends Impacting the Eyelets Gold Market?

The global eyelets gold market is experiencing significant shifts driven by various factors. Firstly, the rise of e-commerce platforms has made sourcing more accessible for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. Buyers can now explore a wider range of products and suppliers, allowing them to compare prices and quality more effectively. Additionally, there is an increasing demand for customizable and unique eyelet designs, which reflects broader consumer trends towards personalization in fashion and craft applications.

Technological advancements are also influencing sourcing trends. The integration of digital tools, such as supply chain management software and AI-driven analytics, helps businesses optimize inventory management and forecast demand more accurately. As a result, buyers can streamline their procurement processes, reduce lead times, and enhance overall operational efficiency. Furthermore, the market is witnessing a shift towards bulk purchasing, driven by the need for cost savings and improved supplier relationships.

Emerging markets, particularly in Africa and South America, are becoming vital players in the eyelets gold sector. These regions are characterized by a burgeoning craft and fashion industry, fostering a growing local demand for high-quality eyelet products. As these markets expand, international buyers should consider establishing partnerships with local suppliers to tap into this potential and create a more resilient supply chain.

How Is Sustainability and Ethical Sourcing Shaping the Eyelets Gold Industry?

Sustainability and ethical sourcing are paramount in the eyelets gold sector, as environmental concerns continue to take center stage. The production of eyelets, particularly those made from precious metals, can have significant environmental impacts if not managed responsibly. As a result, B2B buyers are increasingly prioritizing suppliers that adhere to sustainable practices and demonstrate transparency in their supply chains.

The importance of ethical sourcing cannot be overstated. Buyers are now seeking suppliers who can provide certifications that verify their commitment to responsible sourcing. Certifications such as Fair Trade, Responsible Jewelry Council, and ISO 14001 can serve as crucial indicators of a supplier’s dedication to minimizing environmental impact and ensuring fair labor practices. By prioritizing suppliers with these certifications, international buyers can enhance their brand reputation and appeal to a growing consumer base that values ethical consumption.

Additionally, there is a rising trend towards the use of eco-friendly materials in the production of eyelets. Suppliers are increasingly exploring alternatives, such as recycled metals or biodegradable materials, to meet the demands of environmentally conscious businesses. This shift not only supports the planet but also aligns with global initiatives aimed at reducing waste and promoting circular economies.

What Is the Historical Context of Eyelets Gold in the B2B Landscape?

The history of eyelets, particularly in the context of the gold sector, dates back centuries, with their use evolving significantly over time. Initially, eyelets were primarily functional components in clothing and textiles, serving to reinforce holes and prevent fraying. However, as fashion and design trends evolved, eyelets became decorative elements, adding both functionality and aesthetic appeal to garments and accessories.

With the industrial revolution, the mass production of eyelets became feasible, allowing for widespread use in various applications, from clothing to home décor. This evolution paved the way for the modern eyelets gold market, where buyers now seek a blend of quality, design, and ethical considerations. As the market continues to grow, understanding this historical context helps B2B buyers appreciate the value and significance of eyelets gold in today’s diverse applications.

Illustrative image related to eyelets gold

Frequently Asked Questions (FAQs) for B2B Buyers of eyelets gold

-

How do I choose the right supplier for gold eyelets?

Selecting a reliable supplier for gold eyelets requires careful consideration of several factors. First, verify their reputation through online reviews and industry references. Ensure they have experience in international trade, particularly in your region, to navigate any regulatory hurdles. Request samples to evaluate product quality and consistency. Additionally, assess their production capabilities and lead times, as timely delivery is critical in B2B transactions. Finally, establish clear communication channels to facilitate smooth negotiations and ongoing collaboration. -

What are the minimum order quantities (MOQs) for gold eyelets?

Minimum order quantities for gold eyelets can vary significantly based on the supplier and the type of eyelet required. Generally, MOQs range from 100 to 1,000 units, depending on the customization and manufacturing processes involved. It’s advisable to discuss specific requirements with potential suppliers to understand their MOQ policies. For bulk orders, negotiating lower MOQs or tiered pricing can be beneficial, especially for long-term partnerships. Always factor in your production needs to avoid overstocking or supply shortages. -

What payment terms should I expect when sourcing gold eyelets?

Payment terms in B2B transactions can vary widely among suppliers. Common arrangements include upfront payments, net 30, or net 60 terms, where the buyer pays within a specified period after receiving the goods. Some suppliers may offer discounts for early payment or bulk orders. It’s essential to negotiate terms that align with your cash flow and financial strategy. Additionally, consider using secure payment methods like letters of credit or escrow services to protect your investment during international transactions. -

How can I ensure the quality of gold eyelets I purchase?

To ensure the quality of gold eyelets, request detailed product specifications, including material composition, size, and finish. Engage in quality assurance measures such as third-party inspections before shipment, especially for bulk orders. Establish a clear return policy in case the products do not meet your standards. Additionally, consider visiting the supplier’s facility if feasible, as firsthand observation can provide valuable insights into their manufacturing practices and quality control processes. -

What are the key logistics considerations for importing gold eyelets?

When importing gold eyelets, logistics play a crucial role in your supply chain. Consider shipping methods (air vs. sea), which affect transit times and costs. Understand customs regulations in your country and ensure all necessary documentation is in order to avoid delays. Work with a reliable freight forwarder who can navigate international shipping complexities. Additionally, factor in local warehousing solutions to streamline distribution once the products arrive. -

Can I customize gold eyelets according to my specifications?

Many suppliers offer customization options for gold eyelets, including size, color, and material. When discussing customization, provide detailed specifications to ensure the final product meets your expectations. Be aware that customized orders may come with higher MOQs and longer lead times. It’s advisable to request prototypes or samples before placing a large order to confirm that the customization aligns with your requirements. -

What is the typical lead time for gold eyelets orders?

Lead times for gold eyelet orders can vary based on factors such as order size, customization, and supplier location. Typically, standard orders may take 2-4 weeks for production, while customized orders can extend to 6-8 weeks or longer. Always confirm lead times during the negotiation process and consider including penalties for delays in your agreement. Planning ahead can help mitigate the impact of longer lead times on your production schedules. -

What are the best practices for maintaining a good relationship with my eyelet supplier?

Maintaining a strong relationship with your eyelet supplier is key to ensuring smooth operations. Regular communication is essential; keep them informed about your needs and any potential changes in demand. Provide feedback on product quality and service, as this fosters improvement and responsiveness. Consider establishing long-term contracts to secure favorable terms and reliability. Additionally, building personal rapport can enhance trust and collaboration, making it easier to navigate challenges together.

Top 4 Eyelets Gold Manufacturers & Suppliers List

1. Sew-Ology – Eyelets

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {‘name’: ‘Eyelets’, ‘brand’: ‘Sew-Ology’, ‘SKU’: ‘112896’, ‘original_price’: ‘$1.99’, ‘color’: ‘Antique Gold’, ‘size_options’: [‘5/16″‘, ‘5/32″‘, ’15/32″‘], ‘package_contents’: ’24 sets of eyelets’, ‘warning’: ‘CHOKING HAZARD: Small Parts. Not for children under 3 yrs.’, ‘description’: “Protect the fabrics on all of your crafty projects with Eyelets. Simply insert the eyelet into the hole cut of y…

2. KAMsnaps – Grommets (Eyelets)

Domain: kamsnaps.com

Registered: 2008 (17 years)

Introduction: Grommets (Eyelets) are no-sew fasteners that reinforce holes in fabric or other materials. They are commonly used in shoes, corsets, and hoodies for laces. Grommets can also serve as decorative elements. Available sizes and colors include: 4mm, 5.1mm, 7mm, 10mm, 12mm, and 17mm in various finishes such as Silver, Gunmetal, Antique Brass, Gold, Rose Gold, and Rainbow. Each size is offered in sets of…

3. Eyelet Outlet – Gold 4mm Eyelets

Domain: eyeletoutlet.com

Registered: 2002 (23 years)

Introduction: {“item_number”:”122A”,”price”:”$22.00″,”quantity”:”1000″,”hole_diameter”:”4mm”,”outside_diameter”:”8mm”,”length_of_barrel”:”6mm”,”color”:”Gold”}

4. Buddha Jewelry – Gold Iridescent Glass Eyelets

Strategic Sourcing Conclusion and Outlook for eyelets gold

In the rapidly evolving market for gold eyelets, strategic sourcing emerges as a critical component for international B2B buyers seeking to capitalize on this niche. As demand grows across diverse sectors—from fashion and textiles to industrial applications—understanding supplier capabilities and product specifications is paramount. Buyers should prioritize partnerships with manufacturers who offer a variety of eyelet types, sizes, and materials, ensuring they meet both aesthetic and functional requirements. The ability to source high-quality eyelets can significantly enhance product offerings, leading to greater customer satisfaction and loyalty.

Moreover, leveraging data analytics and market insights can help businesses identify emerging trends and cost-effective sourcing options. For buyers in Africa, South America, the Middle East, and Europe, fostering relationships with reliable suppliers can lead to improved supply chain efficiency and reduced lead times.

As we look ahead, the potential for innovation in eyelet design and functionality is vast. Engaging with suppliers who are committed to sustainability and quality will not only differentiate your product line but also align with the growing consumer demand for responsible sourcing. Now is the time to explore new partnerships and elevate your sourcing strategy to stay competitive in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.