Eyelets For Leather Goods: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for eyelets for leather goods

In the competitive landscape of leather goods manufacturing, sourcing high-quality eyelets is a critical challenge that many B2B buyers face. Eyelets not only enhance the aesthetic appeal of products but also ensure durability and functionality, making them essential for various applications, from footwear to handbags. This guide offers an in-depth exploration of eyelets for leather goods, covering various types, materials, and their specific applications.

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe—including key markets such as Brazil and Nigeria—will find actionable insights on how to effectively vet suppliers, assess product quality, and understand pricing structures. By delving into the nuances of eyelet specifications and installation techniques, this guide empowers businesses to make informed purchasing decisions that align with their production needs and market demands.

Additionally, we will address common pitfalls in sourcing and provide strategies for establishing reliable supplier relationships. Whether you are a seasoned buyer or new to the leather goods sector, this comprehensive resource is designed to streamline your procurement process and enhance your product offerings. By equipping you with the knowledge necessary to navigate the global market for eyelets, we aim to foster successful partnerships and drive your business forward.

Understanding eyelets for leather goods Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Eyelets | Smaller diameter, no washer | Footwear, bags, light leather goods | Pros: Cost-effective, easy to install; Cons: Less durable than grommets. |

| Grommets | Larger diameter, includes a washer | Heavy-duty applications, outdoor gear | Pros: Enhanced strength, weather-resistant; Cons: More complex installation. |

| Screw-in Eyelets | Can be easily installed without tools | Custom leather goods, crafts | Pros: Quick installation, reusable; Cons: Limited to lighter applications. |

| Decorative Eyelets | Aesthetic designs, various colors | Fashion accessories, high-end products | Pros: Enhances visual appeal; Cons: May compromise structural integrity. |

| Riveted Eyelets | Permanent installation with rivets | Industrial applications, heavy-duty | Pros: Extremely durable, secure; Cons: Permanent, difficult to replace. |

What Are the Key Characteristics of Standard Eyelets for Leather Goods?

Standard eyelets are typically smaller in diameter and are characterized by their lack of a washer. They are widely used in footwear and bags, making them ideal for lighter leather goods. B2B buyers should consider their cost-effectiveness and ease of installation, which can streamline production. However, it’s essential to note that while they are economical, they may not provide the same durability as other options, particularly in high-stress applications.

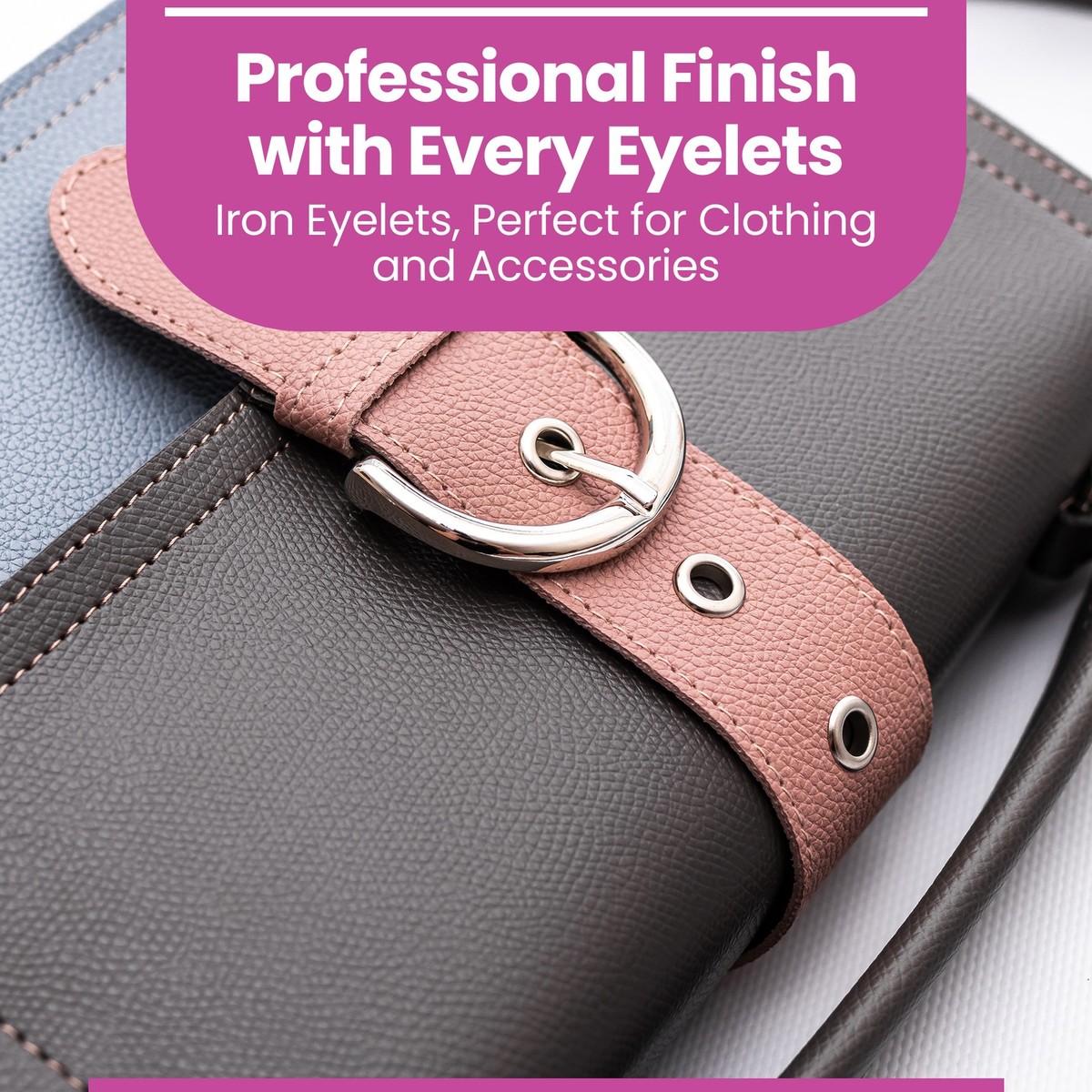

Illustrative image related to eyelets for leather goods

How Do Grommets Compare in Terms of Strength and Application?

Grommets are distinguished by their larger diameter and the inclusion of a washer, which provides additional support. They are suitable for heavy-duty applications such as outdoor gear and industrial products. Their enhanced strength makes them ideal for situations where the leather may be exposed to the elements. B2B buyers should weigh the benefits of durability against the more complex installation process, which may require specialized tools.

What Are the Advantages of Screw-in Eyelets for Custom Applications?

Screw-in eyelets offer a unique advantage as they can be installed without tools, making them a flexible choice for custom leather goods and crafts. Their ease of installation allows for quick adjustments and reusability, which can be appealing for businesses that prioritize adaptability. However, their design limits them to lighter applications, so buyers should assess their intended use carefully.

How Do Decorative Eyelets Enhance Fashion Products?

Decorative eyelets come in various colors and designs, making them perfect for fashion accessories and high-end leather products. Their aesthetic appeal can significantly enhance the visual quality of a product, attracting more customers. However, B2B buyers should be cautious as these eyelets may compromise the structural integrity of the leather goods, especially if used in high-stress areas.

Illustrative image related to eyelets for leather goods

What Makes Riveted Eyelets Ideal for Heavy-Duty Applications?

Riveted eyelets are designed for permanent installation and are known for their extreme durability and security. They are commonly used in industrial applications where strength is paramount. While they provide a long-lasting solution, B2B buyers should consider that their permanence makes them difficult to replace or adjust. This trade-off can be crucial for businesses that may need to modify their products in the future.

Key Industrial Applications of eyelets for leather goods

| Industry/Sector | Specific Application of eyelets for leather goods | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Use in footwear and accessories | Enhances product durability and aesthetic appeal | Sourcing materials that withstand environmental conditions, like humidity and temperature fluctuations. |

| Automotive | Integration in car interiors | Provides secure fastening and enhances design flexibility | Need for high-quality, rust-resistant materials to ensure longevity in various climates. |

| Sporting Goods | Application in bags and equipment | Improves functionality and user experience | Consideration for weight, strength, and resistance to wear and tear. |

| Leather Goods Manufacturing | Reinforcement in handbags and wallets | Increases product lifespan and customer satisfaction | Importance of matching eyelet sizes and materials with specific leather types for optimal performance. |

| Outdoor Gear | Utilization in tents and outdoor equipment | Offers durability and weather resistance | Sourcing eyelets that can withstand extreme conditions, such as UV exposure and moisture. |

How Are Eyelets Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, eyelets are commonly found in footwear and accessories, providing both aesthetic appeal and functional benefits. They allow for the secure threading of laces, enhancing the durability of shoes and bags. For international buyers, particularly in regions like Africa and South America, sourcing high-quality, rust-resistant eyelets is crucial, as they face varying humidity and temperature conditions that can affect product longevity.

What Role Do Eyelets Play in Automotive Applications?

Eyelets are integral to automotive interiors, where they serve as secure fastening points for various materials, including upholstery and trim. Their ability to withstand rigorous use while maintaining a sleek appearance is essential for automotive manufacturers. Buyers from the Middle East and Europe should prioritize sourcing high-quality, corrosion-resistant eyelets to ensure their products can endure the region’s diverse climates without degradation.

How Are Eyelets Beneficial in Sporting Goods?

In the sporting goods industry, eyelets enhance the functionality of bags and equipment by allowing for secure closures and adjustable straps. This not only improves user experience but also boosts the overall durability of the products. For B2B buyers, especially from South America, it’s important to consider the weight and strength of the eyelets to ensure they can withstand rigorous use in various sports environments.

Illustrative image related to eyelets for leather goods

Why Are Eyelets Important in Leather Goods Manufacturing?

In leather goods manufacturing, eyelets reinforce handbags and wallets, providing necessary support for closures and straps. This enhances the product’s lifespan and ensures customer satisfaction. Buyers in Europe should focus on sourcing eyelets that match the specific leather types they work with, as compatibility is key for ensuring optimal performance and aesthetic alignment.

How Do Eyelets Enhance Outdoor Gear Durability?

Eyelets are vital in outdoor gear, particularly in tents and other equipment, where they offer durability and weather resistance. They allow for secure attachment points that can withstand extreme conditions, making them essential for outdoor enthusiasts. International buyers, especially from regions with harsh weather, should seek eyelets designed for high UV exposure and moisture resistance to ensure their products remain functional and durable over time.

3 Common User Pain Points for ‘eyelets for leather goods’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Eyelet Size for Leather Projects

The Problem: B2B buyers often struggle with selecting the appropriate size of eyelets for their leather goods. This challenge can stem from varying leather thicknesses and the specific use-case requirements of the product. For instance, manufacturers creating bags may require larger eyelets for added strength, while those making footwear may need smaller sizes for a refined look. Incorrect sizing can lead to production delays, increased costs, and ultimately, unsatisfactory product quality.

The Solution: To address this issue, buyers should invest in a comprehensive sizing chart provided by their suppliers. When sourcing eyelets, it’s crucial to consider the thickness of the leather being used and the intended application. For example, a standard leather thickness of 2-3 mm typically requires a specific eyelet size that offers a snug fit without compromising the material. Buyers should also consider purchasing a sample kit of various sizes to test on their actual materials before making a bulk order. This proactive approach not only minimizes the risk of errors but also ensures that the right eyelet is used for the right application, ultimately enhancing product durability and customer satisfaction.

Scenario 2: Inconsistent Quality of Eyelets from Different Suppliers

The Problem: Quality inconsistency is a significant pain point for B2B buyers who source eyelets from various suppliers. Variations in materials and manufacturing processes can lead to eyelets that are prone to rust, breakage, or improper fitting. Such inconsistencies can damage the reputation of a brand, especially if products fail during use, leading to costly returns and repairs.

The Solution: To mitigate quality concerns, buyers should establish long-term relationships with trusted suppliers who provide transparency regarding their manufacturing processes and materials. Requesting certifications or quality assurance documents can help verify that the eyelets meet industry standards. Additionally, implementing a quality control process upon receipt of shipments can help identify defective products before they reach production. For businesses operating in regions with high humidity or exposure to the elements, opting for solid brass or nickel-plated eyelets can enhance durability and performance. By prioritizing quality and reliability in their sourcing strategy, buyers can ensure a consistent product offering and maintain their brand integrity.

Scenario 3: Challenges in Eyelet Installation Leading to Production Delays

The Problem: Installing eyelets can be a complicated process, particularly for manufacturers without the right tools or experience. Incorrect installation can lead to damaged leather or improperly set eyelets, resulting in significant production delays and increased labor costs. This challenge is especially pronounced for businesses scaling up production or those new to working with leather goods.

The Solution: To streamline the installation process, buyers should invest in high-quality eyelet setter tools that are compatible with the specific sizes of eyelets they are using. Comprehensive training for staff on proper installation techniques can also minimize errors. Suppliers often provide guides or instructional videos on using their tools effectively, which can be invaluable. Additionally, conducting a trial run with a small batch of materials can help identify potential issues before full-scale production begins. By equipping their teams with the right tools and knowledge, businesses can enhance efficiency, reduce waste, and ultimately improve their bottom line.

Strategic Material Selection Guide for eyelets for leather goods

When selecting materials for eyelets in leather goods, it is crucial to understand the properties, advantages, and limitations of various materials. This knowledge aids B2B buyers in making informed decisions that align with their production needs and market demands.

What Are the Key Properties of Brass Eyelets for Leather Goods?

Brass is a popular choice for eyelets due to its excellent corrosion resistance and aesthetic appeal. It can withstand moderate temperatures and pressures, making it suitable for various applications, including bags and shoes. Brass eyelets are also known for their durability, as they do not rust, which is particularly advantageous in humid environments.

Pros: Brass eyelets are durable, visually appealing, and resistant to corrosion. They are relatively easy to manufacture and can be produced in various sizes and finishes.

Cons: The main drawback of brass is its higher cost compared to other materials. Additionally, while brass is resistant to corrosion, it can tarnish over time, which may affect the visual quality of the end product.

How Do Steel Eyelets Compare in Performance and Cost?

Steel eyelets are known for their strength and affordability. They can handle significant stress and are often used in heavy-duty applications. Steel is also readily available, which can reduce lead times for manufacturers.

Pros: Steel eyelets are cost-effective and provide excellent strength, making them suitable for applications requiring high durability.

Cons: The primary disadvantage of steel is its susceptibility to rust, especially in environments with moisture. This limitation can restrict its use in outdoor applications unless properly coated or treated.

Illustrative image related to eyelets for leather goods

What Advantages Do Aluminum Eyelets Offer for Lightweight Applications?

Aluminum eyelets are lightweight and resistant to corrosion, making them ideal for applications where weight is a concern, such as in lightweight bags or outdoor gear. They can be anodized to enhance their corrosion resistance and aesthetic appeal.

Pros: Aluminum is lightweight, corrosion-resistant, and can be produced in various colors through anodizing, which adds to its visual appeal.

Cons: However, aluminum eyelets may not offer the same strength as brass or steel, which can limit their use in heavy-duty applications. Additionally, they can be more expensive than steel.

What Are the Considerations for Plastic Eyelets in Leather Goods?

Plastic eyelets are gaining popularity due to their versatility and low cost. They are lightweight and can be produced in various colors, making them suitable for fashion-oriented products.

Pros: Plastic eyelets are inexpensive, lightweight, and resistant to corrosion. They can also be molded into various shapes and colors, allowing for creative designs.

Illustrative image related to eyelets for leather goods

Cons: The main limitation of plastic is its lower strength compared to metal options, which may not be suitable for all applications. Additionally, plastic can degrade under UV exposure, which is a consideration for outdoor products.

Summary of Material Selection for Eyelets

| Material | Typical Use Case for eyelets for leather goods | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-end leather goods, bags, shoes | Corrosion-resistant and durable | Higher cost, can tarnish | High |

| Steel | Heavy-duty applications, industrial leather goods | Cost-effective and strong | Susceptible to rust | Low |

| Aluminum | Lightweight bags, outdoor gear | Lightweight and corrosion-resistant | Lower strength than metals | Medium |

| Plastic | Fashion accessories, lightweight products | Inexpensive and versatile | Lower strength, UV degradation | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties and applications of various eyelet materials. Understanding these factors will help in making informed choices that align with market demands and production capabilities.

In-depth Look: Manufacturing Processes and Quality Assurance for eyelets for leather goods

What Are the Main Stages in the Manufacturing Process of Eyelets for Leather Goods?

The manufacturing process for eyelets involves several critical stages that ensure the final product meets the required specifications for quality and functionality. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in manufacturing eyelets is the selection of appropriate raw materials, typically metals like brass, steel, or aluminum. Each material has its unique properties; for example, brass offers corrosion resistance, making it suitable for outdoor leather goods. The raw materials undergo a thorough inspection to ensure they meet quality standards before proceeding to the next stage.

-

Forming: In this stage, the prepared materials are shaped into eyelet forms using methods such as stamping or extrusion. Stamping involves pressing the metal sheets into molds to create the desired eyelet shape, while extrusion pushes the metal through a die to form long shapes that can be cut to size. This step is crucial, as precision in forming directly affects the performance and durability of the eyelets.

-

Assembly: Once the eyelets are formed, they are assembled with components such as washers, which provide additional support. This assembly is often done manually or through automated machinery, depending on the production scale. Ensuring that the parts fit together correctly is vital for the overall strength and functionality of the eyelet.

-

Finishing: The final stage involves applying surface treatments, such as plating or coating, to enhance durability and aesthetics. Common techniques include nickel plating for a silver finish or powder coating for color variety. This stage may also include polishing to eliminate sharp edges and enhance the eyelet’s appearance.

How Is Quality Assurance Implemented in Eyelet Manufacturing?

Quality assurance (QA) is an integral aspect of the manufacturing process for eyelets, ensuring that each product meets both international and industry-specific standards.

-

International Standards: Compliance with standards such as ISO 9001 is crucial for manufacturers. This standard focuses on effective quality management systems and continuous improvement. Additionally, industry-specific certifications, such as CE marking for products sold in Europe, ensure that the eyelets meet safety and environmental requirements.

-

Quality Control Checkpoints: Effective QA involves multiple checkpoints throughout the production process:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter production. Any non-conforming materials are rejected.

– In-Process Quality Control (IPQC): During manufacturing, random samples are taken to ensure adherence to specifications. This includes checking dimensions, strength, and surface finishes.

– Final Quality Control (FQC): After finishing, a final inspection is conducted to ensure that the eyelets meet all quality standards before they are packaged and shipped. -

Common Testing Methods: Various tests are employed to verify the quality of eyelets, including tensile strength tests, corrosion resistance tests, and dimensional checks. These tests ensure that the eyelets can withstand the stresses they will encounter in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, ensuring supplier quality is paramount. Here are several methods to verify QC practices:

-

Supplier Audits: Conducting audits of potential suppliers allows buyers to assess their manufacturing processes, quality control measures, and compliance with international standards. This hands-on approach can help identify any gaps in quality management.

-

Review of Quality Reports: Suppliers should provide documentation outlining their quality control processes, including test results and compliance certifications. Reviewing these reports allows buyers to gauge the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing processes and quality control. These services can conduct pre-shipment inspections to verify that the products meet the agreed-upon specifications.

What Are the Nuances of Quality Control Certification for International Buyers?

Navigating the complexities of quality control certification can be challenging for international buyers. Here are some key considerations:

-

Understanding Local Regulations: Buyers must be aware of the regulations and standards applicable in their regions. For instance, products imported into the European Union must meet CE marking requirements, while those in the United States may need to comply with ASTM standards.

-

Cultural Differences in Quality Standards: Different regions may have varying perceptions of quality and standards. It is essential for buyers to communicate their specific requirements clearly to ensure alignment with the supplier’s quality practices.

-

Building Relationships with Suppliers: Establishing strong relationships with suppliers can facilitate better communication about quality expectations and certifications. This relationship can also lead to more favorable terms and enhanced collaboration on product development.

Conclusion

Understanding the manufacturing processes and quality assurance practices for eyelets in leather goods is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, manufacturers can ensure that their products meet high-quality standards. Additionally, implementing robust quality control measures and verifying supplier practices are essential steps for international buyers to ensure they receive reliable and durable eyelets for their leather goods. By navigating these aspects effectively, businesses can foster strong partnerships and ensure customer satisfaction in their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘eyelets for leather goods’

This guide serves as a practical checklist for B2B buyers looking to source eyelets for leather goods effectively. Eyelets play a crucial role in enhancing the durability and functionality of leather products, making it vital to choose the right materials and suppliers. By following this step-by-step checklist, you can ensure that your procurement process is streamlined, efficient, and aligned with your business needs.

Illustrative image related to eyelets for leather goods

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define the technical specifications of the eyelets you require. This includes determining the size, material (such as brass, steel, or nickel-plated options), and specific designs that fit your leather goods.

– Why it matters: Proper specifications prevent misunderstandings with suppliers and ensure you receive the correct products.

– Look for: Detailed descriptions of the eyelet types, including dimensions and weight capacities.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in eyelets for leather goods. Utilize industry directories, trade shows, and online platforms to compile a list of candidates.

– Why it matters: A diverse supplier pool increases your chances of finding a reliable partner that meets your needs.

– Look for: Suppliers with a strong reputation in the leather goods sector and positive customer reviews.

Step 3: Evaluate Supplier Certifications

Verify the certifications and quality standards of potential suppliers. This may include ISO certifications or compliance with local regulations in your target markets.

– Why it matters: Certifications indicate that the supplier adheres to industry standards, ensuring product quality and safety.

– Look for: Documentation proving compliance and a history of successful audits.

Step 4: Request Samples

Before finalizing an order, request samples of the eyelets from shortlisted suppliers. This allows you to assess the quality and suitability of the products for your specific applications.

– Why it matters: Sampling helps you avoid costly mistakes by ensuring the eyelets meet your functional and aesthetic requirements.

– Look for: Consistency in size, finish, and overall quality in the samples provided.

Illustrative image related to eyelets for leather goods

Step 5: Assess Pricing and Terms

Compare pricing structures and payment terms from different suppliers. Consider bulk pricing options and any additional costs such as shipping or customs fees.

– Why it matters: Understanding the total cost helps you stay within budget and manage cash flow effectively.

– Look for: Transparent pricing models and flexible payment terms that suit your financial capabilities.

Step 6: Verify Production Capacity and Lead Times

Inquire about the supplier’s production capacity and lead times for fulfilling your orders. This is essential for planning your production schedules and meeting customer demands.

– Why it matters: Timely delivery is crucial in maintaining your business’s reputation and operational efficiency.

– Look for: Suppliers who can meet your volume needs without compromising quality or deadlines.

Step 7: Establish Communication Channels

Ensure that there are clear communication channels with your chosen supplier. This includes setting up regular check-ins and defining points of contact for any issues that may arise.

– Why it matters: Effective communication fosters a strong supplier relationship and enables quick resolution of any concerns.

– Look for: Suppliers who are responsive and provide dedicated account management.

By following this checklist, B2B buyers can streamline the process of sourcing eyelets for leather goods, ensuring that they select the best suppliers and products for their needs.

Comprehensive Cost and Pricing Analysis for eyelets for leather goods Sourcing

Understanding the cost structure and pricing dynamics of eyelets for leather goods is crucial for international B2B buyers. This analysis will break down the cost components, discuss price influencers, and provide strategic tips for negotiation and procurement.

What Are the Key Cost Components in Eyelets for Leather Goods?

When sourcing eyelets, several cost components come into play:

-

Materials: The primary material for eyelets and grommets is typically solid brass, steel, or aluminum. The choice of material significantly impacts the cost, with brass often being more expensive due to its durability and resistance to corrosion. Custom finishes, such as nickel plating, also add to material costs.

-

Labor: Labor costs are incurred in the manufacturing process, including the assembly of eyelets and grommets. Labor rates can vary widely based on geographic location and manufacturing practices, impacting overall pricing.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, equipment maintenance, and administrative expenses. Efficient production processes can help mitigate these costs.

-

Tooling: Custom tooling for specific eyelet designs or sizes can be a significant upfront investment. Buyers should consider these costs when evaluating suppliers, especially if they require unique specifications.

-

Quality Control (QC): Ensuring that products meet quality standards involves additional costs related to testing and inspections. Certifications for quality can also influence pricing.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping method, and customs duties must be considered in the total cost.

-

Margin: Suppliers will typically add a profit margin to their costs, which can vary based on market demand and competition.

How Do Price Influencers Affect Eyelet Sourcing?

Several factors can influence the pricing of eyelets for leather goods:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs. Buyers should negotiate MOQs that align with their production needs to optimize pricing.

-

Specifications and Customization: Custom designs or specific size requirements can increase costs. Buyers should weigh the benefits of customization against the potential for higher expenses.

-

Quality and Certifications: Higher-quality materials and certifications (such as ISO) typically command higher prices. Buyers must assess whether the added quality justifies the cost for their intended applications.

-

Supplier Factors: Different suppliers may offer varying prices based on their operational efficiencies, geographic location, and market positioning. Building relationships with multiple suppliers can provide leverage in negotiations.

-

Incoterms: Understanding the terms of trade can significantly affect costs. Incoterms define the responsibilities of buyers and sellers in international transactions, impacting logistics and risk management.

What Are the Best Practices for B2B Buyers in Eyelet Sourcing?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, effective sourcing strategies are essential:

-

Negotiation: Engage suppliers in discussions to clarify pricing structures and explore discounts for bulk orders. Transparency about your needs can foster better deals.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, potential tariffs, and long-term durability. Cheaper eyelets may incur higher replacement costs.

-

Pricing Nuances for International Buyers: Be aware of exchange rates and potential fluctuations that could affect pricing. Additionally, consider the impact of local regulations and tariffs on overall costs.

-

Supplier Evaluation: Conduct thorough research on suppliers’ reputations, production capacities, and historical performance. This due diligence can help mitigate risks associated with quality and delivery timelines.

Conclusion

Sourcing eyelets for leather goods involves a complex interplay of costs and pricing influences. By understanding these factors and employing strategic negotiation tactics, international B2B buyers can make informed decisions that optimize their supply chain and enhance their product offerings. As prices can fluctuate, always obtain indicative quotes and ensure clarity on all terms before finalizing agreements.

Alternatives Analysis: Comparing eyelets for leather goods With Other Solutions

Introduction: Understanding Alternatives to Eyelets for Leather Goods

When selecting hardware for leather goods, eyelets are a popular choice due to their versatility and strength. However, it is essential for B2B buyers to explore alternative solutions that may better suit specific applications or budget constraints. This analysis compares eyelets with grommets and rivets, providing insights into their respective benefits and drawbacks to facilitate informed decision-making.

Comparison Table

| Comparison Aspect | Eyelets For Leather Goods | Grommets | Rivets |

|---|---|---|---|

| Performance | Good for lightweight materials; offers moderate strength | Superior strength; supports heavier loads | High durability; prevents shearing |

| Cost | Generally low cost | Higher cost due to additional washers | Moderate cost; varies with size |

| Ease of Implementation | Simple to install with a setter | Requires specific setting tools; slightly more complex | Requires drilling; installation can be labor-intensive |

| Maintenance | Minimal maintenance required | Low maintenance; rust-resistant options available | Very low maintenance; highly durable |

| Best Use Case | Ideal for lightweight bags and shoes | Perfect for outdoor gear and heavy-duty applications | Best for structural applications or heavy leather items |

Detailed Breakdown of Alternatives

Grommets

Grommets are similar to eyelets but are designed with a washer that provides added support, making them ideal for applications requiring greater strength. They are particularly effective in outdoor settings, as many grommets are made from rust-resistant materials such as solid brass. While they tend to be more expensive than eyelets, their durability and performance in high-stress applications justify the cost. Installation requires specific tools and a bit more skill, making them less straightforward than eyelets.

Rivets

Rivets serve as a robust fastening solution for leather goods, often used in heavy-duty applications like belts, bags, and even armor. They are highly durable and provide excellent shear strength, preventing the materials from separating under stress. While the initial cost can be moderate, the installation process is more labor-intensive, often requiring drilling and specialized tools. Rivets are ideal for applications that demand long-lasting integrity, but they may not be suitable for lighter materials where flexibility is needed.

Conclusion: How to Choose the Right Solution for Your Leather Goods

Selecting the appropriate fastening solution for leather goods hinges on the specific requirements of the project. Eyelets are a reliable choice for lightweight applications, while grommets excel in durability and outdoor use. Rivets offer unmatched strength for heavy-duty needs but come with a more complex installation process. B2B buyers should assess their project’s performance requirements, cost considerations, and ease of implementation before making a decision. By understanding the strengths and limitations of each alternative, businesses can optimize their product offerings and better meet customer demands.

Essential Technical Properties and Trade Terminology for eyelets for leather goods

What Are the Key Technical Properties of Eyelets for Leather Goods?

Understanding the technical specifications of eyelets is crucial for B2B buyers, especially when sourcing materials for leather goods. Here are the essential properties to consider:

-

Material Composition

– Eyelets are typically made from materials such as solid brass, steel, or aluminum. Solid brass is favored for its corrosion resistance, making it ideal for outdoor leather products. Steel eyelets, while sturdy, may rust if exposed to moisture. The choice of material affects durability, appearance, and cost, which are critical factors for manufacturers in various regions. -

Diameter and Size Tolerance

– Eyelets come in various diameters, usually ranging from 1/8 inch to 1 inch. Size tolerance refers to the acceptable range of variation in the diameter and thickness of the eyelet. Precise tolerances ensure that eyelets fit snugly in the leather, preventing slippage or damage. Inconsistent sizes can lead to production delays and quality issues, which are detrimental in a competitive market. -

Plating and Finish

– The finish of an eyelet (e.g., nickel-plated, brass-plated) not only impacts aesthetics but also influences resistance to rust and wear. Nickel plating offers a shiny, corrosion-resistant surface, while brass plating provides a classic look. Buyers should choose finishes based on the end product’s intended use and environmental exposure, balancing cost and performance. -

Pull-Out Strength

– This property refers to the amount of force required to pull the eyelet out of the leather. Higher pull-out strength indicates better performance, particularly for products subjected to stress, like bags and shoes. Manufacturers need to select eyelets with adequate pull-out strength to ensure the longevity of their leather goods. -

Installation Method

– Eyelets can be installed using various tools, with the most common being manual setters or hydraulic presses. The installation method affects the eyelet’s integrity and the leather’s condition. Understanding the installation process is crucial for ensuring that the eyelets are set correctly, minimizing the risk of damage during production.

What Are Common Trade Terms Related to Eyelets for Leather Goods?

Navigating the trade landscape involves understanding specific terminology that can impact purchasing decisions:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, partnering with OEMs can ensure consistent quality and availability of eyelets tailored to specific product lines. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory effectively and avoid overstocking, especially in markets with fluctuating demand. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. This process allows buyers to compare offers, negotiate prices, and ensure they receive the best possible terms for their eyelet orders. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, risks, and costs associated with sourcing eyelets globally. -

Lead Time

– Lead time refers to the period between placing an order and receiving the products. Knowing the lead time is crucial for planning production schedules and ensuring timely delivery of leather goods to the market. -

Batch Testing

– This term involves testing a sample from a production batch to ensure quality standards are met. For eyelets, batch testing can verify strength, size, and material integrity, helping to prevent defects in the final product. Understanding batch testing processes can reassure buyers about the quality of their purchases.

By grasping these properties and terms, B2B buyers can make informed decisions, ensuring the selection of high-quality eyelets that meet the demands of their leather goods production.

Illustrative image related to eyelets for leather goods

Navigating Market Dynamics and Sourcing Trends in the eyelets for leather goods Sector

What Are the Key Market Dynamics and Trends Influencing Eyelets for Leather Goods?

The market for eyelets in the leather goods sector is experiencing dynamic growth driven by several factors. Increasing demand for leather products—ranging from fashion accessories to industrial applications—is propelling the need for durable and aesthetically pleasing hardware. Global trends indicate a shift towards customization, where businesses are seeking unique eyelet designs and materials that align with their brand identity. Additionally, digital transformation is influencing sourcing strategies; more buyers are leveraging e-commerce platforms to access a wider range of suppliers and products, often opting for bulk purchasing to reduce costs.

Emerging technologies such as 3D printing are also making waves in the eyelet production process. This innovation allows for rapid prototyping and customization, catering to the specific requirements of buyers from diverse markets, including Africa and South America. Furthermore, as manufacturers strive for efficiency, automation in production is becoming increasingly common. The rise of data analytics is enabling companies to better understand market demands, helping them forecast trends and manage inventory more effectively.

How Is Sustainability Shaping the Eyelets for Leather Goods Market?

Sustainability is becoming a critical component of sourcing strategies for eyelets in leather goods. The environmental impact of traditional manufacturing processes, including water pollution and resource depletion, has heightened the demand for ethical sourcing and sustainable materials. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to environmentally friendly practices, such as using recycled materials or adopting eco-conscious manufacturing processes.

Illustrative image related to eyelets for leather goods

Certifications such as the Global Organic Textile Standard (GOTS) and the Responsible Down Standard (RDS) are gaining importance, as they assure buyers of the ethical sourcing of materials. Suppliers that offer ‘green’ alternatives, such as biodegradable or recyclable eyelets, are becoming more appealing to businesses aiming to enhance their sustainability credentials. For international buyers, especially those from Europe, the Middle East, and South America, aligning with suppliers that adhere to sustainability standards can also enhance their brand image, making them more competitive in a market that values corporate responsibility.

What Is the Historical Context of Eyelets in Leather Goods?

The use of eyelets in leather goods dates back centuries, initially serving functional purposes in clothing and armor. Over time, these small yet vital components evolved to enhance not only the durability of leather products but also their aesthetic appeal. The transition from handmade to machine-produced eyelets in the late 19th century marked a significant evolution, allowing for mass production and greater accessibility.

As consumer preferences shifted towards personalization and quality, the design and material used in eyelets have become more sophisticated. Today, solid brass and stainless steel are commonly used for their durability and resistance to corrosion, which is especially important for products exposed to various environmental conditions. This historical evolution highlights the ongoing relationship between functionality and design, which continues to shape the eyelets for leather goods sector.

In summary, understanding these market dynamics, sustainability trends, and historical context can empower B2B buyers to make informed decisions when sourcing eyelets for their leather goods, ensuring they align with both market demands and ethical practices.

Frequently Asked Questions (FAQs) for B2B Buyers of eyelets for leather goods

-

1. How do I choose the right eyelets or grommets for my leather goods?

When selecting eyelets or grommets, consider factors such as the thickness of the leather, the intended use of the product, and the aesthetic appeal. Eyelets are generally suited for lighter applications, while grommets provide additional strength and durability, particularly in heavier materials. Assess the size and material options—solid brass is rust-resistant and ideal for outdoor use, while steel may rust over time. Always verify that the diameter of the eyelet or grommet matches your project requirements. -

2. What is the minimum order quantity (MOQ) for eyelets and grommets?

The MOQ can vary significantly among suppliers, typically ranging from 100 to several thousand pieces. It is essential to clarify this with your supplier before placing an order, as some may offer lower MOQs for specific product lines or custom designs. Understanding the MOQ will help you plan your production schedule and budget accordingly, ensuring you have enough inventory to meet your business demands without overcommitting financially. -

3. How can I ensure the quality of eyelets and grommets from suppliers?

To ensure quality, conduct thorough research on potential suppliers. Look for certifications, customer reviews, and industry experience. Request samples before placing bulk orders to evaluate the material quality and manufacturing standards. Additionally, inquire about their quality assurance processes and if they perform regular inspections. Establishing a clear communication channel can also help address any concerns promptly. -

4. What customization options are available for eyelets and grommets?

Many suppliers offer customization options, including size, color, material, and branding. Custom eyelets can enhance your product’s uniqueness and appeal to your target market. When seeking customization, discuss your specific requirements with the supplier, including any design files or specifications needed. Be sure to confirm any additional costs and lead times associated with customized orders. -

5. What are the payment terms typically offered by suppliers of eyelets and grommets?

Payment terms can vary by supplier and often include options such as upfront payment, net 30, or letters of credit. International buyers should be aware of currency exchange rates and any additional fees associated with cross-border transactions. Discussing payment terms upfront can help establish a clear understanding and avoid potential disputes later in the process. Always ensure that payment methods are secure to protect your investment. -

6. How can I manage logistics when importing eyelets and grommets?

Managing logistics involves planning for shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with the regulations in your region. Ensure that your supplier provides accurate shipping documentation to facilitate smooth customs processing. It is also wise to account for potential delays in delivery due to customs inspections or logistical challenges, especially when sourcing from international suppliers. -

7. What should I know about the differences between eyelets and grommets?

Eyelets and grommets serve similar purposes but differ in construction and application. Eyelets are typically smaller and used for lighter materials, while grommets have a washer that provides added support and durability, making them suitable for heavier applications. Understanding these differences will help you select the appropriate product for your specific leather goods project, ensuring functionality and longevity. -

8. How do I handle discrepancies in my order of eyelets and grommets?

In case of discrepancies, promptly contact your supplier to discuss the issue. Document any discrepancies with photos and detailed descriptions to support your claim. Most reputable suppliers will have policies in place for returns or exchanges. It’s vital to address discrepancies quickly to minimize disruptions in your production process. Establishing a good relationship with your supplier can also facilitate smoother resolutions in such cases.

Top 5 Eyelets For Leather Goods Manufacturers & Suppliers List

1. Weaver Leather Supply – Eyelets and Grommets

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Eyelets and grommets for leather, sewing, bags and more. Large selection of bulk grommet sets for manufacturing, screw together eyelets, and eyelets available in solid brass, steel, and metal. Sort by color, size, and material. Key features include: 81 products available, colors include Black, Antique Brass, Brass, Gold, Gunmetal, Nickel, Rainbow; sizes range from 1/4″ to 1″ and various metric siz…

2. Leathersmith Designs – Eyelets and Grommets

Domain: leathersmithdesigns.com

Registered: 2000 (25 years)

Introduction: Eyelets and grommets are used to strengthen holes in thinner and softer leathers for laces, strings, ropes, or hooks. Grommets have a washer underneath for added strength, while eyelets are typically smaller and often referred to as shoe eyelets. The grommets are made of solid brass, preventing rust, and are suitable for outdoor applications. Silver-colored metal grommets are brass-based with nick…

3. Tandy Leather – Eyelets 100 Pack

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: Eyelets 100 Pack from Tandy Leather, Inc. – Includes 100 eyelets for leather crafting and projects.

4. Reddit – Grommets vs. Eyelets in Leathercraft

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the differences between grommets and eyelets, with a focus on their applications in leathercraft. Key points include: 1. Eyelets are generally smaller, while grommets are larger and often come in two-piece sets. 2. Users recommend ensuring the quality of the materials, with brass being less prone to splitting compared to aluminum. 3. Proper setting techniques are emp…

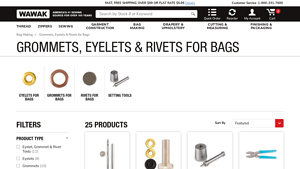

5. WAWAK – Grommets, Eyelets & Rivets

Domain: wawak.com

Registered: 2002 (23 years)

Introduction: Grommets, Eyelets & Rivets for Bags at WAWAK. Fast, free shipping over $99 or flat rate $5.95. Customer service contact: 1-800-331-7600. Various types available including eyelets, grommets, and rivets. Tools and fabric glues for installation are also offered.

Strategic Sourcing Conclusion and Outlook for eyelets for leather goods

What Are the Key Takeaways for Sourcing Eyelets for Leather Goods?

In conclusion, strategic sourcing of eyelets for leather goods is crucial for manufacturers seeking quality, durability, and aesthetic appeal in their products. The diversity in materials—ranging from solid brass to nickel-plated options—allows businesses to select products that align with their specific needs and branding. Notably, understanding the differences between eyelets and grommets can enhance product design, ensuring optimal functionality in various applications.

How Can International Buyers Leverage Strategic Sourcing?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize reliable suppliers that offer a comprehensive selection of eyelets and grommets. By fostering strong relationships with manufacturers, businesses can gain access to bulk purchasing options, competitive pricing, and tailored solutions that meet unique market demands.

What Is the Future Outlook for Eyelet Sourcing?

Looking ahead, the demand for high-quality eyelets in leather goods is expected to rise, driven by trends in fashion and custom leather products. Embracing strategic sourcing will empower international buyers to stay ahead of the competition and innovate within their product lines. Now is the time to explore partnerships that will not only enhance product quality but also support sustainable practices. Engage with suppliers today to secure your position in this evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to eyelets for leather goods

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.