Eyelet Lace Material: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for eyelet lace material

In the ever-evolving landscape of global textiles, sourcing eyelet lace material presents a unique set of challenges for international B2B buyers. The intricate designs and versatile applications of eyelet lace can enhance various products, from fashion apparel to home décor. However, navigating the complexities of quality assurance, supplier reliability, and cost-effectiveness can be daunting, especially for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, including key players like Germany and Vietnam.

This comprehensive guide aims to demystify the process of sourcing eyelet lace material. It covers a wide array of topics including the different types of eyelet lace, their applications across various industries, effective strategies for supplier vetting, and insights into cost considerations. By providing in-depth analysis and actionable advice, this guide equips B2B buyers with the knowledge they need to make informed purchasing decisions.

Whether you’re looking to enhance your product line or seeking reliable suppliers, understanding the nuances of eyelet lace material will empower you to optimize your sourcing strategy. With this guide, you will be better positioned to navigate the global market, ensuring that your business remains competitive and responsive to consumer demands.

Understanding eyelet lace material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cotton Eyelet Lace | 100% cotton, breathable, soft texture | Apparel, home textiles, crafts | Pros: Natural fabric, comfort; Cons: Prone to wrinkling. |

| Cotton-Blend Eyelet Lace | Combination of cotton and synthetic fibers | Fashion, upholstery, decorative items | Pros: Durable, less prone to wrinkling; Cons: May lack breathability. |

| Embroidered Eyelet Lace | Features intricate embroidery designs | High-end fashion, special occasions | Pros: Unique aesthetic, adds value; Cons: Higher cost. |

| Voile Eyelet Lace | Lightweight, semi-sheer fabric | Summer clothing, curtains, and overlays | Pros: Airy feel, drapes well; Cons: Less durable than heavier fabrics. |

| Lawn Eyelet Lace | Fine, lightweight cotton, smooth finish | Dresses, blouses, children’s clothing | Pros: Soft and comfortable; Cons: Requires careful handling. |

What are the Characteristics of Cotton Eyelet Lace?

Cotton eyelet lace is a popular choice among B2B buyers due to its natural composition, which ensures breathability and comfort. This fabric is typically 100% cotton, making it ideal for apparel and home textiles, such as curtains and table linens. Buyers should consider the softness and ability to absorb moisture, which adds to the fabric’s appeal in warmer climates. However, it is worth noting that cotton eyelet lace can be prone to wrinkling, which may require additional care during production and shipping.

How Does Cotton-Blend Eyelet Lace Compare?

Cotton-blend eyelet lace combines cotton with synthetic fibers, enhancing durability while maintaining some of the natural fabric’s comfort. This type of eyelet lace is commonly used in fashion and upholstery, where durability is critical. The blend reduces wrinkling and increases resistance to wear and tear, making it a practical choice for manufacturers. However, buyers should be aware that the breathability may be compromised compared to 100% cotton options.

What Makes Embroidered Eyelet Lace Unique?

Embroidered eyelet lace stands out due to its intricate designs and patterns, which can significantly enhance the aesthetic value of garments and textiles. This fabric is often utilized in high-end fashion and special occasions, where unique visual appeal is paramount. The detailed embroidery adds a touch of elegance, but it also comes with a higher price point. Buyers should consider the potential for increased retail value when sourcing embroidered eyelet lace.

Why Choose Voile Eyelet Lace for Lightweight Needs?

Voile eyelet lace is characterized by its lightweight and semi-sheer nature, making it an excellent choice for summer clothing and decorative overlays. This fabric drapes beautifully, providing a soft and airy feel that is appealing for garments worn in hot climates. While its delicate nature allows for exquisite design possibilities, buyers should consider that voile may not be as durable as heavier fabrics, requiring careful handling during production.

What are the Advantages of Lawn Eyelet Lace?

Lawn eyelet lace is known for its fine, lightweight cotton and smooth finish, making it a preferred option for dresses and blouses. The softness and comfort of lawn eyelet lace attract buyers focused on children’s clothing and casual wear. However, due to its delicate nature, this fabric requires careful handling and may not withstand heavy use as well as other types of eyelet lace. Buyers should assess their target market’s needs when considering lawn eyelet lace for their product lines.

Key Industrial Applications of eyelet lace material

| Industry/Sector | Specific Application of eyelet lace material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Use in women’s clothing, including dresses and blouses | Enhances aesthetic appeal and adds a premium touch | Quality of lace, design intricacies, and fabric durability |

| Home Textiles | Decorative curtains and table linens | Provides elegance and breathability in home decor | Color options, fabric weight, and maintenance requirements |

| Children’s Apparel | Lightweight dresses and accessories for children | Combines style with comfort, appealing to parents | Safety standards, fabric softness, and washing durability |

| Craft and DIY Projects | Embellishments for handmade items and crafts | Allows for creative expression and unique product offerings | Availability in bulk, variety of designs, and pricing |

| Wedding and Event Decor | Bridal gowns, veils, and decorative elements | Adds a romantic and sophisticated touch to events | Customization options, fabric sourcing, and lead times |

How is Eyelet Lace Material Used in the Fashion and Apparel Industry?

Eyelet lace material is widely utilized in the fashion sector, particularly in women’s clothing such as dresses and blouses. The intricate designs and lightweight nature of eyelet lace provide a delicate aesthetic that appeals to consumers seeking elegance and style. For international buyers, especially from regions like Europe and South America, sourcing high-quality eyelet lace that meets durability standards is crucial. Buyers should consider the lace’s design intricacies and fabric durability to ensure a premium product.

What Role Does Eyelet Lace Material Play in Home Textiles?

In the home textiles industry, eyelet lace is commonly used for decorative curtains and table linens. Its breathable nature and sophisticated appearance make it an ideal choice for enhancing home decor. Buyers from Africa and the Middle East should focus on color options and fabric weight to suit diverse climates and interior styles. Maintenance requirements also play a vital role, as easy-care materials can significantly boost customer satisfaction.

How is Eyelet Lace Material Applied in Children’s Apparel?

Eyelet lace material finds a niche in children’s apparel, particularly in lightweight dresses and accessories. This material blends style with comfort, making it appealing to parents looking for fashionable yet practical clothing for their children. International buyers must ensure that the lace meets safety standards and is soft against the skin, while also considering washing durability to withstand frequent use.

In What Ways is Eyelet Lace Material Used in Craft and DIY Projects?

Craft and DIY enthusiasts often incorporate eyelet lace material into their projects as embellishments for handmade items. This versatility allows for creative expression and the development of unique products. For B2B buyers, especially those in South America and Africa, sourcing eyelet lace in bulk can be advantageous. Variety in designs and competitive pricing are key considerations for businesses aiming to attract a diverse customer base.

How Does Eyelet Lace Material Enhance Wedding and Event Decor?

Eyelet lace material is a popular choice for wedding gowns, veils, and decorative elements in event decor, adding a romantic and sophisticated touch. This application is particularly significant for event planners and bridal boutiques sourcing materials for high-profile events. Buyers should prioritize customization options and reliable fabric sourcing to meet specific design requirements, while also considering lead times to ensure timely delivery.

3 Common User Pain Points for ‘eyelet lace material’ & Their Solutions

Scenario 1: Sourcing Quality Eyelet Lace Material for International Markets

The Problem:

B2B buyers often face challenges in sourcing high-quality eyelet lace material that meets their specific requirements. This can be particularly daunting when dealing with international suppliers, especially for those in regions like Africa and South America where access to premium fabrics may be limited. Buyers may encounter issues such as inconsistent quality, lack of transparency regarding material specifications, or difficulties in understanding the intricacies of fabric types and uses. This can lead to delays in production, increased costs, and ultimately, dissatisfaction from their end customers.

The Solution:

To effectively source quality eyelet lace material, buyers should prioritize working with reputable suppliers who provide detailed product specifications, including the fabric content, width, and intended uses. Utilizing online platforms that specialize in fabric sourcing can facilitate access to a broader range of options. When engaging with suppliers, request samples to assess the quality firsthand. Establishing clear communication channels can also help in discussing specific needs, such as color matching or design intricacies. Moreover, leveraging trade shows and fabric expos can provide direct access to manufacturers and a chance to build relationships, ensuring more reliable sourcing in the future.

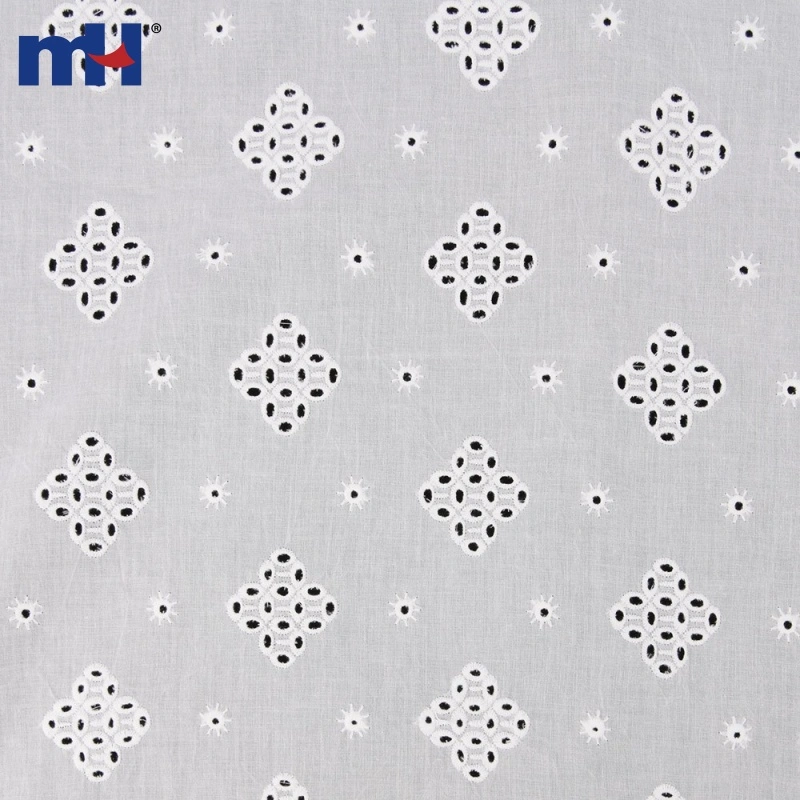

Illustrative image related to eyelet lace material

Scenario 2: Understanding the Different Types of Eyelet Lace Material

The Problem:

Navigating the various types of eyelet lace materials can be overwhelming for B2B buyers, especially when each type offers distinct characteristics and applications. With options ranging from cotton to synthetic blends, and varying weights and textures, buyers may struggle to select the right fabric for their specific projects. This indecision can lead to purchasing materials that do not meet the intended design or functional requirements, resulting in wasted resources and potential delays in production.

The Solution:

To overcome this challenge, buyers should invest time in understanding the different types of eyelet lace materials available in the market. Educational resources such as fabric guides or webinars can provide valuable insights into the properties of each material. It is also beneficial to consult with fabric specialists or suppliers who can offer tailored recommendations based on the intended use, such as garment construction or home decor. Creating a checklist of desired attributes—such as breathability, durability, and aesthetic appeal—can streamline the selection process. Additionally, conducting small-scale trials with different materials can help buyers make informed decisions before committing to larger orders.

Scenario 3: Ensuring Consistency in Fabric Delivery and Quality

The Problem:

Inconsistent delivery and quality of eyelet lace material can significantly disrupt production schedules for B2B buyers. This issue often arises when dealing with multiple suppliers or when suppliers face manufacturing challenges. Delays in receiving materials or variations in fabric quality can lead to increased lead times, production bottlenecks, and potential financial losses. Buyers may find themselves at the mercy of supply chain fluctuations, which is particularly detrimental in fast-paced industries like fashion and home textiles.

The Solution:

To mitigate the risk of inconsistency, buyers should establish long-term partnerships with a limited number of trusted suppliers. This fosters a reliable supply chain and allows for better negotiation of terms regarding quality and delivery schedules. Implementing a robust inventory management system can also help in forecasting needs and maintaining buffer stock to accommodate unexpected delays. Regular quality audits and performance reviews of suppliers can ensure that they adhere to agreed standards. Additionally, setting up contingency plans, such as identifying alternate suppliers or materials, can further safeguard against potential disruptions in the supply chain.

Strategic Material Selection Guide for eyelet lace material

When selecting eyelet lace materials for various applications, it is essential to consider the unique properties, advantages, and limitations of each material type. This guide analyzes four common materials used in eyelet lace production: cotton, polyester, cotton-blend, and nylon. Each material has distinct characteristics that can influence product performance, manufacturing complexity, and end-use suitability.

What Are the Key Properties of Cotton Eyelet Lace Material?

Cotton is a natural fiber known for its breathability, softness, and comfort. It exhibits excellent moisture absorption, making it suitable for warm climates. Cotton eyelet lace is often used in apparel and home textiles due to its aesthetic appeal and versatility. However, it has a lower durability compared to synthetic fibers and may require more care in washing and maintenance.

Pros: Cotton is biodegradable, hypoallergenic, and offers a classic look. It is also relatively easy to dye, allowing for vibrant colors and patterns.

Cons: Cotton eyelet lace can shrink and wrinkle easily, and its durability is lower than synthetic options. Additionally, it may be more expensive than some synthetic materials.

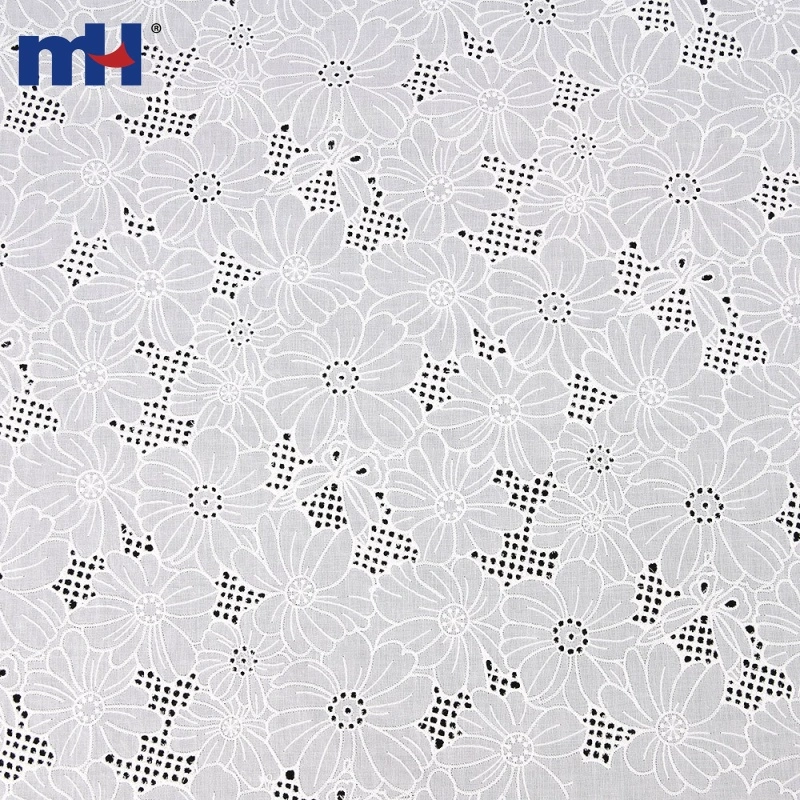

Illustrative image related to eyelet lace material

How Does Polyester Eyelet Lace Material Compare?

Polyester is a synthetic fiber that is highly durable and resistant to shrinking, stretching, and wrinkling. It is less absorbent than cotton, which can be beneficial in applications where moisture resistance is required. Polyester eyelet lace is often used in fashion and home décor due to its ability to maintain shape and color over time.

Pros: Polyester is cost-effective, lightweight, and easy to care for. It also has excellent color retention and is less prone to fading.

Cons: The material is less breathable than cotton, which may not be suitable for all applications, particularly in hot climates. Additionally, polyester is not biodegradable, raising environmental concerns.

What Are the Benefits of Cotton-Blend Eyelet Lace Material?

Cotton-blend eyelet lace combines the advantages of both cotton and synthetic fibers, typically polyester. This blend aims to enhance durability while maintaining the softness and breathability of cotton. It is commonly used in garments and home textiles, offering a balance between comfort and resilience.

Illustrative image related to eyelet lace material

Pros: Cotton-blend materials are often more affordable than pure cotton while still providing a soft feel. They also exhibit improved durability and lower maintenance needs compared to 100% cotton.

Cons: While cotton-blends offer a compromise, they may not possess the full benefits of either fiber. The specific properties can vary based on the blend ratio, making it essential for buyers to verify material specifications.

What Role Does Nylon Play in Eyelet Lace Material Selection?

Nylon is another synthetic option that offers exceptional strength and elasticity. It is resistant to abrasion and has a smooth texture, making it ideal for applications requiring flexibility and durability. Nylon eyelet lace is often used in activewear and specialty garments.

Pros: Nylon is lightweight, resistant to mold and mildew, and has excellent tensile strength. It can withstand harsh conditions, making it suitable for outdoor applications.

Cons: Like polyester, nylon is less breathable than natural fibers, which could limit comfort in certain applications. Its production process can also be more environmentally taxing.

Summary Table of Eyelet Lace Materials

| Material | Typical Use Case for eyelet lace material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Apparel, home textiles | Breathable and comfortable | Lower durability, higher care | Medium |

| Polyester | Fashion, home décor | Cost-effective and durable | Less breathable, non-biodegradable | Low |

| Cotton-Blend | Garments, home textiles | Soft feel with improved durability | Variable properties based on blend | Medium |

| Nylon | Activewear, specialty garments | High strength and elasticity | Less breathable, environmental concerns | Medium |

This guide provides a comprehensive overview of the strategic selection of eyelet lace materials, catering to the needs of international B2B buyers. Understanding the properties and implications of each material can significantly impact product development and market success.

In-depth Look: Manufacturing Processes and Quality Assurance for eyelet lace material

What Are the Main Stages in the Manufacturing Process of Eyelet Lace Material?

The manufacturing process of eyelet lace material involves several key stages, each critical to ensuring the quality and aesthetic appeal of the final product. Here’s a breakdown of the main stages:

Material Preparation

The first stage in the manufacturing of eyelet lace material begins with the selection and preparation of raw materials. Cotton is the most commonly used fabric due to its softness, breathability, and ability to hold intricate designs. Suppliers often source high-quality cotton from reputable regions, ensuring consistency in texture and color. The cotton fibers are then treated to remove impurities, followed by dyeing, if necessary, to achieve the desired color palette. This stage is crucial, as the quality of the raw material directly impacts the final product’s durability and appearance.

Forming Techniques

Once the materials are prepared, the next step is forming the eyelet lace. This is primarily done through various embroidery techniques, including machine embroidery and laser cutting. In machine embroidery, specialized sewing machines create intricate patterns and cutouts in the fabric, allowing for precision and repeatability. Laser cutting has gained popularity for its ability to produce complex designs with clean edges, reducing the risk of fraying. The choice of technique depends on the design intricacy, fabric type, and production volume.

Illustrative image related to eyelet lace material

Assembly and Finishing

After forming, the eyelet lace pieces are assembled, particularly if they are part of a larger fabric or product. This may involve sewing together different lace sections or attaching the lace to other materials, such as lining fabrics. The finishing stage includes processes like washing, ironing, and applying any necessary coatings or treatments to enhance the fabric’s properties, such as water resistance or UV protection. This stage is vital for ensuring that the lace retains its shape and quality through various applications, from fashion to home textiles.

How Is Quality Assurance Implemented in Eyelet Lace Production?

Quality assurance (QA) is integral to the manufacturing process of eyelet lace materials, ensuring that products meet the required standards and specifications. Here are some critical aspects of QA in this sector:

What Are the Relevant International Standards for Eyelet Lace Quality?

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on quality management systems, and CE marking for products sold within the European Economic Area. These standards help ensure that products are safe, reliable, and of good quality. Additionally, industry-specific standards like the American Petroleum Institute (API) may apply for specialized lace used in industrial applications. Compliance with these standards is crucial for manufacturers targeting international markets, as it enhances credibility and marketability.

What QC Checkpoints Should Be Established During Production?

Quality control (QC) checkpoints should be established throughout the manufacturing process to identify and address issues early on. Typical checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): This stage monitors the manufacturing process itself, checking for consistency in stitching, pattern accuracy, and any defects that may arise during production.

- Final Quality Control (FQC): Before shipping, a thorough inspection is conducted to ensure the final product meets all specifications, including dimensions, colorfastness, and finish quality.

What Common Testing Methods Are Used to Ensure Eyelet Lace Quality?

Several testing methods are employed to verify the quality of eyelet lace materials. Common tests include:

- Physical Testing: This includes checking the fabric’s tensile strength, tear resistance, and durability. Samples may be subjected to stress tests to simulate real-world usage.

- Colorfastness Testing: This assesses how well the fabric retains its color when exposed to light, washing, and rubbing. It is crucial for maintaining the aesthetic quality of the lace.

- Dimensional Stability Testing: This examines how well the fabric maintains its shape and size after washing or exposure to moisture.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in international markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Here are several strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing environment, equipment, and QC processes firsthand. This can provide insights into the supplier’s commitment to quality.

- Quality Reports: Requesting detailed quality reports that outline inspection results, testing methods, and compliance with international standards can help buyers make informed decisions.

- Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. These services often provide comprehensive reports that detail compliance with relevant standards.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from different regions must navigate various quality control nuances when sourcing eyelet lace materials. Here are some considerations:

- Cultural Differences: Understanding the cultural context of suppliers can impact communication and expectations regarding quality. Buyers should be clear about their requirements and standards from the outset.

- Regulatory Requirements: Different regions may have specific regulations regarding textile products. Buyers should familiarize themselves with local laws and ensure their suppliers are compliant.

- Shipping and Logistics: Quality can be compromised during shipping. Buyers should consider how materials are packed and transported to minimize damage and ensure that quality is maintained upon arrival.

By understanding the manufacturing processes and quality assurance practices specific to eyelet lace materials, B2B buyers can make more informed decisions and develop stronger partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘eyelet lace material’

In the competitive landscape of textiles, sourcing eyelet lace material effectively is crucial for businesses looking to enhance their product offerings. This guide provides a structured checklist to streamline your procurement process, ensuring quality, compliance, and value for your investment.

1. Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s vital to establish clear technical specifications for the eyelet lace material you need. This includes details such as material type (e.g., 100% cotton, cotton-blend), weight, width, and design patterns. Clearly defined specifications help avoid misunderstandings with suppliers and ensure that the materials meet your production requirements.

2. Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers. Utilize online platforms, industry directories, and trade shows to gather a list of manufacturers specializing in eyelet lace material. Pay attention to their reputation, experience, and product range, as these factors will influence the quality and reliability of your sourcing.

- Check reviews and testimonials from previous clients.

- Look for suppliers with a strong track record in your target regions, such as Africa or Europe.

3. Step 3: Evaluate Supplier Certifications

Before moving forward, verify that your potential suppliers possess the necessary certifications. Certifications such as ISO, Oeko-Tex, or GOTS can be indicators of quality standards and ethical practices. This step is essential not only for compliance but also for ensuring that the materials are safe and sustainable.

Illustrative image related to eyelet lace material

- Request documentation and evidence of compliance.

- Confirm that their production processes align with international standards.

4. Step 4: Request Samples for Quality Assessment

Once you have shortlisted suppliers, request samples of the eyelet lace materials. Evaluating samples allows you to assess the quality, texture, and overall appearance of the fabric. This step is crucial to ensure that the materials meet your aesthetic and functional requirements.

- Inspect the samples for consistency in color, stitching, and design.

- Test the durability and feel of the fabric to ensure it aligns with your product standards.

5. Step 5: Negotiate Pricing and Terms

After selecting a supplier based on quality, the next step is to negotiate pricing and terms. Discuss bulk pricing, payment terms, lead times, and shipping options. Clear negotiations can lead to better pricing and favorable conditions, which can significantly affect your bottom line.

- Be prepared to compare offers from multiple suppliers to ensure you get the best deal.

- Consider the total cost of ownership, including shipping and potential tariffs.

6. Step 6: Establish a Communication Plan

Effective communication is key to a successful sourcing relationship. Establish a clear communication plan with your supplier, detailing how you will exchange information regarding orders, changes, and issues. Regular updates can prevent misunderstandings and ensure that both parties are aligned.

Illustrative image related to eyelet lace material

- Decide on preferred communication channels (email, phone, etc.).

- Set regular check-ins to discuss ongoing orders and future needs.

7. Step 7: Monitor and Evaluate Supplier Performance

Once you begin sourcing from a supplier, it’s important to continuously monitor and evaluate their performance. Track metrics such as quality consistency, delivery times, and responsiveness to inquiries. Regular evaluations help maintain a strong supplier relationship and allow you to make informed decisions about future sourcing.

- Keep a record of performance metrics for periodic review.

- Provide constructive feedback to help improve supplier performance.

By following this checklist, B2B buyers can navigate the complexities of sourcing eyelet lace material with confidence, ensuring they secure high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for eyelet lace material Sourcing

When sourcing eyelet lace materials, understanding the comprehensive cost structure and pricing nuances is crucial for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. Here, we break down the key cost components, pricing influencers, and provide actionable buyer tips.

What Are the Key Cost Components in Eyelet Lace Material Sourcing?

The cost structure of eyelet lace materials typically comprises several components:

-

Materials: The primary cost driver is the fabric itself, which can vary significantly based on the type (e.g., cotton, polyester blends) and quality. For instance, premium cotton eyelet fabrics can range from $29 to $49 per yard, depending on design intricacies and fabric weight.

-

Labor: Labor costs include the wages for skilled workers involved in the embroidery and manufacturing processes. In regions with lower labor costs, buyers may find more competitive pricing, but this can also impact quality.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Efficient factories may offer lower overhead costs, which can be passed on to buyers.

-

Tooling: Custom designs may require specialized tools or machinery, adding to initial costs. For bulk orders, these costs can be amortized over the total volume, making them less significant per unit.

-

Quality Control (QC): Ensuring that the eyelet lace meets specified standards incurs costs associated with inspections and testing. Higher quality assurance can raise initial costs but reduce returns and dissatisfaction.

-

Logistics: Shipping costs can vary based on origin, destination, and mode of transport. Incoterms play a vital role in determining who bears these costs, influencing the overall price.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. The expected profit margin can vary by supplier and market conditions.

How Do Pricing Influencers Affect Eyelet Lace Material Costs?

Several factors influence the pricing of eyelet lace materials:

-

Volume/MOQ: Higher purchase volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk orders, making it advantageous for buyers to plan their inventory accordingly.

-

Specifications and Customization: Custom designs or specific fabric characteristics (e.g., eco-friendly materials) can increase costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Material Quality and Certifications: Fabrics with certifications (e.g., organic cotton) may command higher prices due to perceived value. Buyers should weigh the benefits against their budget.

-

Supplier Factors: Different suppliers have varying cost structures based on their location, production capabilities, and reputation. It’s essential to evaluate suppliers based on their reliability and quality.

-

Incoterms: Understanding Incoterms is crucial for calculating total costs, as they define who is responsible for shipping and insurance. This can significantly affect the final price.

What Are the Best Negotiation and Cost-Efficiency Strategies for Buyers?

For international B2B buyers, particularly in diverse markets, implementing effective negotiation strategies can lead to significant savings:

-

Engage in Long-Term Partnerships: Building a long-term relationship with suppliers can lead to better pricing and terms. Suppliers may be more inclined to offer discounts or favorable payment terms to loyal customers.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, maintenance, and logistics in your TCO analysis to make informed decisions.

-

Leverage Competitive Quotes: Obtain quotes from multiple suppliers to understand market rates. This can empower buyers during negotiations and help secure the best deal.

-

Stay Informed on Market Trends: Awareness of global market trends, including material shortages or price fluctuations, can enhance negotiation power. Buyers should keep abreast of industry news to anticipate changes.

Conclusion

Navigating the complexities of eyelet lace material sourcing requires a thorough understanding of the cost structure, pricing influencers, and effective negotiation strategies. By leveraging these insights, B2B buyers can make informed decisions that align with their budgetary constraints and quality expectations. Keep in mind that indicative prices can fluctuate based on market conditions, so always confirm current rates with suppliers before finalizing orders.

Illustrative image related to eyelet lace material

Alternatives Analysis: Comparing eyelet lace material With Other Solutions

Understanding Alternatives to Eyelet Lace Material for B2B Buyers

In the textile industry, eyelet lace material is renowned for its aesthetic appeal and versatility. However, B2B buyers often seek alternatives that may better fit their specific needs, whether related to cost, functionality, or application. This analysis compares eyelet lace material with two viable alternatives: embroidered cotton fabric and synthetic lace. Each alternative presents unique advantages and drawbacks, which are critical for making an informed purchasing decision.

Comparison Table

| Comparison Aspect | Eyelet Lace Material | Embroidered Cotton Fabric | Synthetic Lace |

|---|---|---|---|

| Performance | Excellent breathability; ideal for garments and home decor | High durability; versatile for apparel | Good elasticity; suitable for various applications |

| Cost | Moderate to high ($29-$49/yard) | Moderate ($15-$39/yard) | Low to moderate ($10-$30/yard) |

| Ease of Implementation | Requires careful handling during production | Easy to cut and sew; minimal fraying | Simple to work with; machine-friendly |

| Maintenance | Requires gentle washing; can fade | Machine washable; retains color well | Easy to clean; resistant to staining |

| Best Use Case | Fashion apparel, curtains, and table linens | Everyday clothing, crafts, and home textiles | Cost-effective fashion items, costume design |

Detailed Breakdown of Alternatives

What are the Pros and Cons of Embroidered Cotton Fabric?

Embroidered cotton fabric offers a combination of durability and versatility, making it an attractive option for various applications, including clothing and home textiles. Its moderate price point allows businesses to manage costs effectively, especially for bulk orders. The fabric is machine washable, which simplifies maintenance, and it retains color well, ensuring longevity in design. However, it may lack the intricate designs and delicate appearance that eyelet lace provides, potentially making it less suitable for high-end fashion.

How Does Synthetic Lace Compare to Eyelet Lace Material?

Synthetic lace is an economical choice that provides an appealing alternative to eyelet lace material. It is typically less expensive and offers good elasticity, making it suitable for a range of applications from fashion to costume design. The ease of handling and machine-friendliness of synthetic lace can significantly reduce production time and costs. However, it may not offer the same level of breathability or aesthetic appeal as natural fibers, which can be a critical consideration for luxury or high-quality products.

Conclusion: How Should B2B Buyers Choose the Right Textile Solution?

When selecting the appropriate textile solution, B2B buyers should consider their specific needs, including budget constraints, intended application, and desired aesthetic. Eyelet lace material shines in high-end applications where design intricacy is paramount, while embroidered cotton fabric offers a durable and versatile alternative for everyday use. Synthetic lace stands out for its cost-effectiveness and ease of use, making it suitable for mass production. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for eyelet lace material

What Are the Key Technical Properties of Eyelet Lace Material?

When sourcing eyelet lace material, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications that buyers should consider:

-

Material Composition

Eyelet lace is commonly made from cotton, polyester, or blends of these materials. Cotton eyelet lace is valued for its softness, breathability, and natural aesthetic, making it suitable for garments and home textiles. Polyester, on the other hand, offers durability and wrinkle resistance. Knowing the material composition helps buyers assess the suitability of the lace for specific applications, such as fashion versus home décor. -

Width

The width of eyelet lace typically ranges from 40 to 60 inches. This measurement is crucial for buyers to determine how much fabric they need for their projects. A wider lace may reduce the amount of material required, thereby optimizing costs. Buyers should also consider the width in relation to the design and application, as it can impact the final product’s appearance. -

Weight

The weight of the fabric is an important indicator of its thickness and sturdiness. Lighter weights (around 3-4 oz/yard) are often used for delicate garments, while heavier weights (5-7 oz/yard) are preferred for more structured pieces. Understanding the weight allows buyers to align their choices with the intended use, ensuring that the fabric meets functional and aesthetic requirements. -

Thread Count

Thread count refers to the number of threads per square inch of fabric. A higher thread count typically indicates a denser and more durable fabric. For eyelet lace, a thread count of 80-100 is common. Buyers should recognize that while a higher thread count can enhance quality, it may also impact the price. This knowledge aids in negotiating costs with suppliers. -

Embellishments and Patterns

Eyelet lace can feature various patterns and embellishments, such as floral designs or geometric shapes. These aesthetic elements are important for buyers looking to create unique products. Understanding the types of embellishments available can help in selecting lace that aligns with brand identity and market trends. -

Color Fastness

Color fastness refers to the fabric’s ability to retain its color when exposed to light, washing, and other environmental factors. High color fastness is crucial for ensuring that the finished product maintains its aesthetic appeal over time. Buyers should inquire about color fastness ratings to avoid quality issues in their final products.

What Are Common Trade Terms Associated with Eyelet Lace Material?

Navigating the world of B2B trade often involves specific jargon. Familiarity with these terms can facilitate smoother transactions and negotiations:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of eyelet lace, buyers may work with OEMs to create custom lace designs that fit their unique specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for buyers, as it can impact inventory management and cash flow. Buyers should negotiate MOQs that align with their production needs and market demand. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. Providing detailed specifications in an RFQ can help ensure accurate and competitive pricing for eyelet lace material. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for clarifying shipping responsibilities, costs, and risks associated with eyelet lace procurement. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. This is particularly important in the fashion industry, where timely delivery can significantly impact market competitiveness. Buyers should factor lead time into their planning to ensure they meet their production schedules. -

Sustainability Certifications

Certifications such as OEKO-TEX or GOTS (Global Organic Textile Standard) indicate that the fabric meets specific environmental and social standards. Buyers increasingly seek these certifications to align with consumer demand for sustainable products, making them a key consideration in sourcing decisions.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing eyelet lace material, ultimately leading to better product quality and enhanced market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the eyelet lace material Sector

What Are the Current Market Dynamics and Key Trends in the Eyelet Lace Material Sector?

The eyelet lace material sector is experiencing significant growth driven by various global factors. Increasing demand for lightweight and breathable fabrics in apparel, particularly in warmer climates, is propelling the market. In regions such as Africa and South America, where the fashion industry is rapidly evolving, eyelet lace is gaining traction for its aesthetic appeal and versatility in clothing, home textiles, and accessories. European markets, including Germany and Italy, are also showing a renewed interest in traditional lace designs, blending them with modern styles to cater to contemporary tastes.

Illustrative image related to eyelet lace material

Emerging B2B technology trends are reshaping sourcing strategies in the eyelet lace market. The rise of e-commerce platforms and digital marketplaces enables international buyers to access a broader range of suppliers and products. Additionally, advancements in textile technology are facilitating the production of innovative eyelet lace materials, including eco-friendly options that appeal to environmentally conscious consumers. As buyers increasingly seek customization, suppliers that offer bespoke designs and quick turnaround times are becoming more competitive.

Furthermore, geopolitical factors and supply chain disruptions have highlighted the importance of diversification in sourcing strategies. B2B buyers are encouraged to consider suppliers from various regions, including Southeast Asia and Eastern Europe, to mitigate risks associated with single-source dependencies. This trend towards diversified sourcing not only enhances resilience but also allows buyers to tap into different cultural aesthetics and craftsmanship.

How Important Is Sustainability and Ethical Sourcing in the Eyelet Lace Material Sector?

Sustainability and ethical sourcing have become paramount in the eyelet lace material sector. The environmental impact of textile production, particularly in terms of water usage, chemical waste, and carbon emissions, is prompting B2B buyers to prioritize sustainable practices. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX are increasingly sought after, as they assure buyers of environmentally friendly processes and materials.

Moreover, ethical supply chains are essential for enhancing brand reputation and consumer trust. Buyers are more inclined to partner with suppliers who demonstrate transparency in their sourcing practices, including fair labor conditions and responsible sourcing of raw materials. This shift is particularly important in markets like Europe, where consumers are increasingly aware of the social implications of their purchases.

To cater to this demand, many manufacturers are investing in sustainable production techniques, such as using organic cotton for eyelet lace materials or adopting water-saving dyeing processes. B2B buyers are encouraged to assess potential suppliers’ commitment to sustainability by reviewing their practices and certifications. By aligning with suppliers focused on sustainability, buyers can not only reduce their environmental footprint but also attract a growing segment of eco-conscious consumers.

Illustrative image related to eyelet lace material

What Is the Brief Evolution and History of Eyelet Lace Material in B2B Context?

The history of eyelet lace material dates back to the 19th century, with its origins rooted in traditional embroidery techniques. Initially, eyelet lace was hand-stitched, making it a luxury item primarily used in high-fashion garments. Over time, industrial advancements led to machine-made eyelet lace, increasing production efficiency and accessibility.

The evolution of this material has seen it transition from a niche luxury product to a staple in both fashion and home textiles. Today, eyelet lace is embraced in various applications, from casual wear to elegant evening attire, and is increasingly featured in children’s clothing, reflecting its versatility. As global trends shift towards personalization and sustainability, the eyelet lace sector continues to innovate, blending traditional craftsmanship with modern production techniques to meet the diverse needs of B2B buyers around the world.

Frequently Asked Questions (FAQs) for B2B Buyers of eyelet lace material

-

How do I solve quality concerns when sourcing eyelet lace material?

To address quality concerns, start by conducting thorough supplier vetting. Look for manufacturers with certifications such as ISO 9001, which indicates adherence to quality management standards. Request samples of the eyelet lace before placing bulk orders to assess fabric quality, embroidery precision, and color consistency. Additionally, consider visiting the supplier’s production facility or using third-party quality assurance services to verify that their practices align with your quality expectations. -

What is the best type of eyelet lace material for fashion apparel?

The best eyelet lace for fashion apparel often depends on the intended use. Cotton eyelet is favored for its breathability and softness, making it ideal for summer dresses and blouses. For more structured garments, consider poly-cotton blends that offer durability while maintaining comfort. Always evaluate the fabric’s weight, width, and embroidery design to ensure it aligns with your design vision and end-use. -

How do I determine the minimum order quantity (MOQ) for eyelet lace materials?

Minimum order quantities (MOQs) can vary widely among suppliers, often depending on production capabilities and material costs. To determine the MOQ, directly communicate with potential suppliers and inquire about their policies. Some manufacturers may offer flexibility on MOQs for first-time buyers or larger ongoing orders. It’s advisable to balance your needs with the supplier’s production requirements to establish a mutually beneficial agreement. -

What are the common payment terms for international eyelet lace material purchases?

Payment terms can differ significantly based on supplier policies and buyer relationships. Commonly, suppliers may request a deposit (20-30%) upfront, with the balance due before shipment. For larger orders or long-term partnerships, you might negotiate more favorable terms such as net 30 or 60 days. Always ensure that payment methods are secure, and consider using letters of credit for added protection in international transactions. -

How can I customize eyelet lace materials for my brand?

Customization of eyelet lace can include alterations in color, embroidery patterns, and fabric composition. To initiate the customization process, provide detailed specifications to your supplier, including design files and color samples. Many manufacturers are equipped to handle custom orders but may require minimum quantities. Collaborate closely with the supplier to ensure that your vision aligns with their capabilities and production timelines. -

What logistics considerations should I keep in mind when importing eyelet lace materials?

When importing eyelet lace, consider shipping methods, lead times, and customs regulations. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency and budget. Familiarize yourself with the customs requirements of your country, including import duties and taxes. Partnering with a reliable freight forwarder can streamline the logistics process and help navigate potential challenges. -

How do I ensure timely delivery of my eyelet lace orders?

To ensure timely delivery, establish clear communication with your supplier regarding production timelines and shipping schedules. Confirm lead times before placing your order, and include clauses in your purchase agreement regarding penalties for delays. Regularly check in with the supplier during production and prepare contingency plans for unexpected delays, such as alternative sourcing options or expedited shipping methods. -

What are the best practices for supplier vetting in the eyelet lace market?

Effective supplier vetting is critical in the eyelet lace market. Start by researching potential suppliers through online platforms and trade directories. Request references and check reviews from previous clients to assess reliability. Evaluate their production capacity, quality control processes, and adherence to ethical standards. Conducting factory visits or utilizing third-party audits can provide deeper insights into their operations and capabilities.

Top 9 Eyelet Lace Material Manufacturers & Suppliers List

1. Fabrics & Fabrics – Cotton Eyelet Fabrics

Domain: fabrics-fabrics.com

Registered: 2012 (13 years)

Introduction: Cotton Eyelet Fabrics available at Fabrics & Fabrics NYC. High-quality fabrics for sophisticated and stylish fashioners. Free U.S. shipping on orders of $200 or more. Customer service available via WhatsApp. Various cotton fabric types including Cotton Eyelet, Cotton Printed & Patterned, Cotton Embroidered, Cotton Corduroy, Cotton Lawn, Cotton Poplin, Cotton Pique, Cotton Sateen, Cotton Shirting, …

2. Britex Fabrics – Eyelet Trims

Domain: britexfabrics.com

Registered: 1998 (27 years)

Introduction: Eyelet trims available in various widths and colors. Key products include:

1. 2 1/4″ Black Double Gathers Scalloped Cotton Eyelet Trim (Made in Italy) – $9.95 / Yard

2. 1 1/2″ Wine Gathered Scalloped Cotton Eyelet Trim (Made in France) – $4.95 / Yard

3. 2 1/4″ Floral Garland Ecru Cotton Eyelet Trim (Made in France) – $10.95 / Yard

4. 2 1/4″ Garden Maze Ivory Cotton Trim (Made in Switzerland) -…

3. B&J Fabrics – Cotton Eyelet Fabrics

Domain: bandjfabrics.com

Registered: 1999 (26 years)

Introduction: This company, B&J Fabrics – Cotton Eyelet Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Fabric Wholesale Direct – Eyelet Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Eyelet Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Mood Fabrics – Eyelet Lace Trim

6. Etsy – Eyelet Fabric Selection

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Eyelet Fabric Selection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Cheep Trims – Eyelet Lace Collection

Domain: cheeptrims.com

Registered: 2000 (25 years)

Introduction: Eyelet lace is a small patterned cut-out with embroidered stitches throughout the body of the trim or fabric. It is extremely versatile, used in apparel, embellishments, home decor, and more. The selection includes flat, ruffled, classic, and unique designs, with all ruffled eyelet laces produced in-house. Product categories include Beading – Faggotting (26 products), Flat (77 products), Galloon (…

8. Pinterest – Eyelet Lace Fabric

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Eyelet Lace Fabric, Length: 14 yards, Width: 2.8″ (7 cm), Base Fabric: Cotton, Embroidery Thread: Cotton, Color: White or Ivory.

9. Anbella Designs – Cotton Eyelet Lace

Domain: anbelladesigns.com

Registered: 2017 (8 years)

Introduction: Cotton Eyelet Lace – High-end European cotton eyelet lace, perfect for tops, skirts, and dresses for summer. Made from 100% cotton thread, adds a classic touch. Available in various trims and widths: 1.8cm, 2.5cm, 2.7cm, and more. Prices range from 0.33 € to 26.90 € excl. VAT. Rated 5.00 out of 5 by customers. Various options include insertion lace, edging, and colorful variations.

Strategic Sourcing Conclusion and Outlook for eyelet lace material

Why is Strategic Sourcing Important for Eyelet Lace Material?

In the competitive landscape of textile sourcing, particularly for eyelet lace materials, strategic sourcing has emerged as a crucial factor for B2B buyers. Engaging with reliable suppliers ensures access to high-quality fabrics, such as 100% cotton eyelet options that are available in diverse colors and patterns. Establishing long-term partnerships can lead to better pricing, consistent supply, and innovative designs that align with market trends.

Illustrative image related to eyelet lace material

How Can International Buyers Navigate the Eyelet Lace Market?

International buyers from Africa, South America, the Middle East, and Europe should prioritize understanding regional preferences and demand dynamics. By leveraging market research and data analytics, businesses can tailor their sourcing strategies to meet the specific needs of their target demographics. Additionally, fostering relationships with manufacturers in key regions can streamline logistics and reduce lead times, enhancing overall operational efficiency.

What is the Future Outlook for Eyelet Lace Materials?

Looking ahead, the demand for eyelet lace materials is expected to rise as fashion trends continue to embrace intricate designs and sustainable fabrics. B2B buyers are encouraged to stay agile and responsive to market shifts, adopting practices that promote sustainability and innovation. By investing in strategic sourcing now, businesses can position themselves favorably in an evolving textile landscape. Connect with trusted suppliers today to seize opportunities in this vibrant market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.