Extruded Aluminum Channel Shapes: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for extruded aluminum channel shapes

In today’s competitive global market, sourcing extruded aluminum channel shapes presents a unique challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The diverse applications of these versatile profiles—ranging from structural support in construction to aesthetic enhancements in design—demand a nuanced understanding of specifications, supplier capabilities, and market trends. This guide serves as a comprehensive resource, addressing critical aspects such as types of aluminum channels, their various applications, supplier vetting processes, and cost considerations.

Navigating the complexities of sourcing requires an informed approach, especially when selecting the right materials for projects that require both durability and visual appeal. The insights provided here will empower international buyers to make educated purchasing decisions, ensuring they align with project requirements and budget constraints. By delving into supplier profiles and exploring the nuances of different aluminum alloys and finishes, you can enhance your procurement strategy and establish partnerships that drive success in your projects.

Ultimately, this guide not only aims to streamline your sourcing process but also to equip you with the knowledge necessary to thrive in the evolving landscape of aluminum extrusions. Whether you are a buyer from Brazil or Nigeria, the information contained within will help you confidently navigate the global market for extruded aluminum channel shapes.

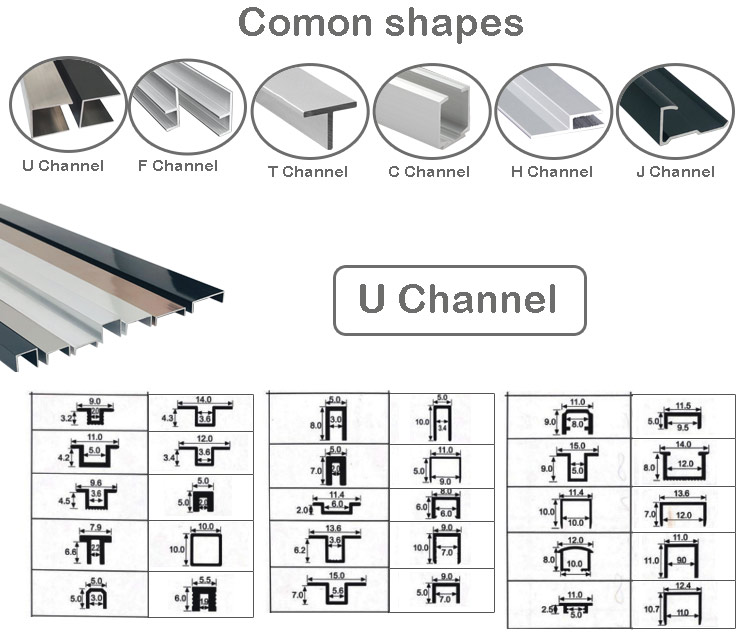

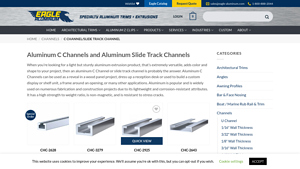

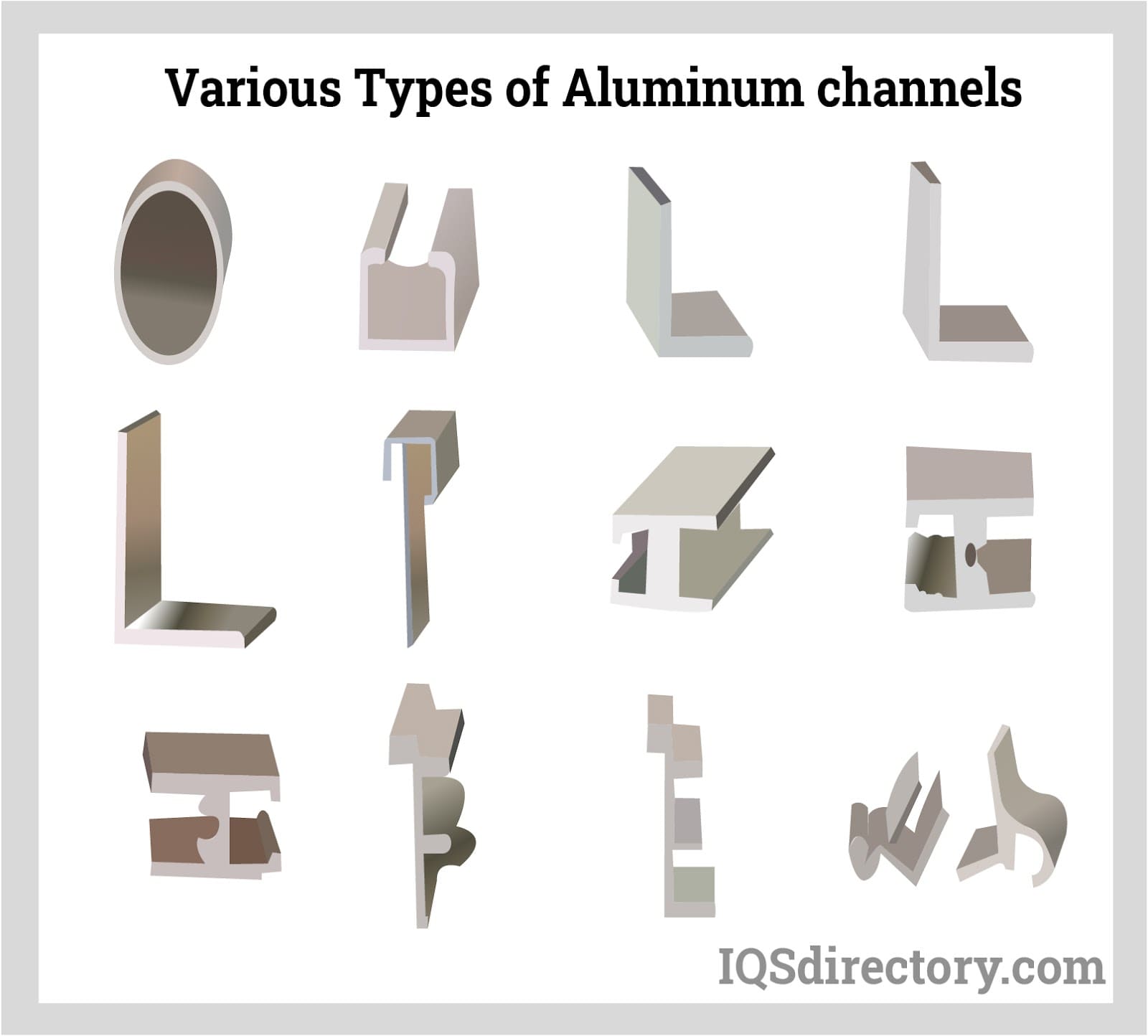

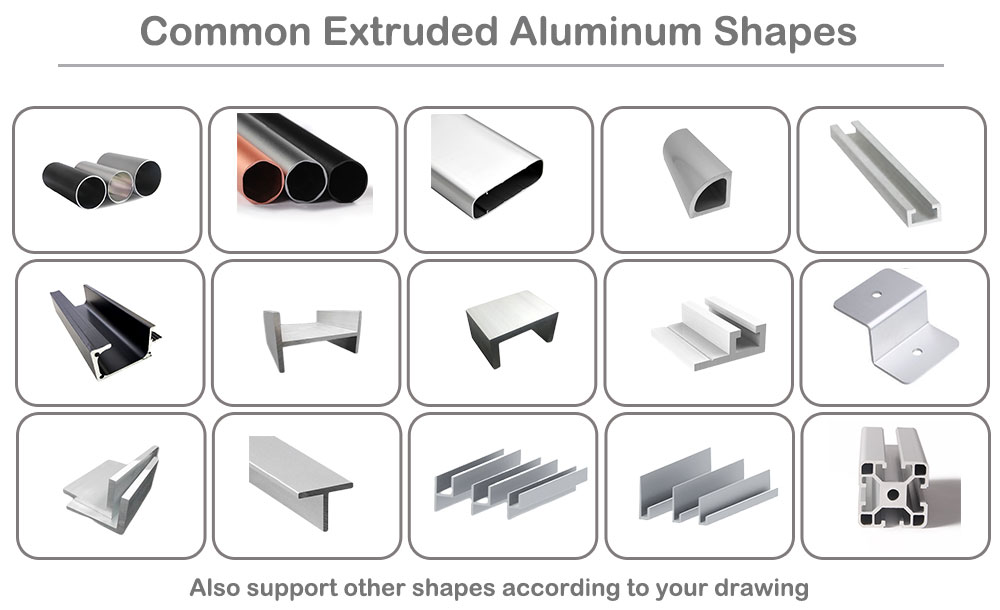

Understanding extruded aluminum channel shapes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum U Channel | U-shaped profile, offers structural support | Door framing, edge protection, shelving | Pros: Lightweight, easy to cut; Cons: May require additional finishing for aesthetics. |

| Aluminum C Channel | C-shaped profile, versatile for various uses | Displays, custom shelving, framing | Pros: High strength-to-weight ratio; Cons: Limited to specific structural applications. |

| Rounded Inside Channel | Rounded edges for safety and aesthetics | Architectural features, railings, partitions | Pros: Enhanced safety, appealing design; Cons: May have higher production costs. |

| Rounded Outside Channel | Rounded exterior for a smooth finish | Decorative applications, furniture framing | Pros: Attractive finish, easy to clean; Cons: Less structural rigidity compared to other types. |

| Architectural Channel | Designed for aesthetic appeal, often custom-finished | Retail displays, signage, interior décor | Pros: Customizable finishes, enhances design; Cons: Typically more expensive than structural options. |

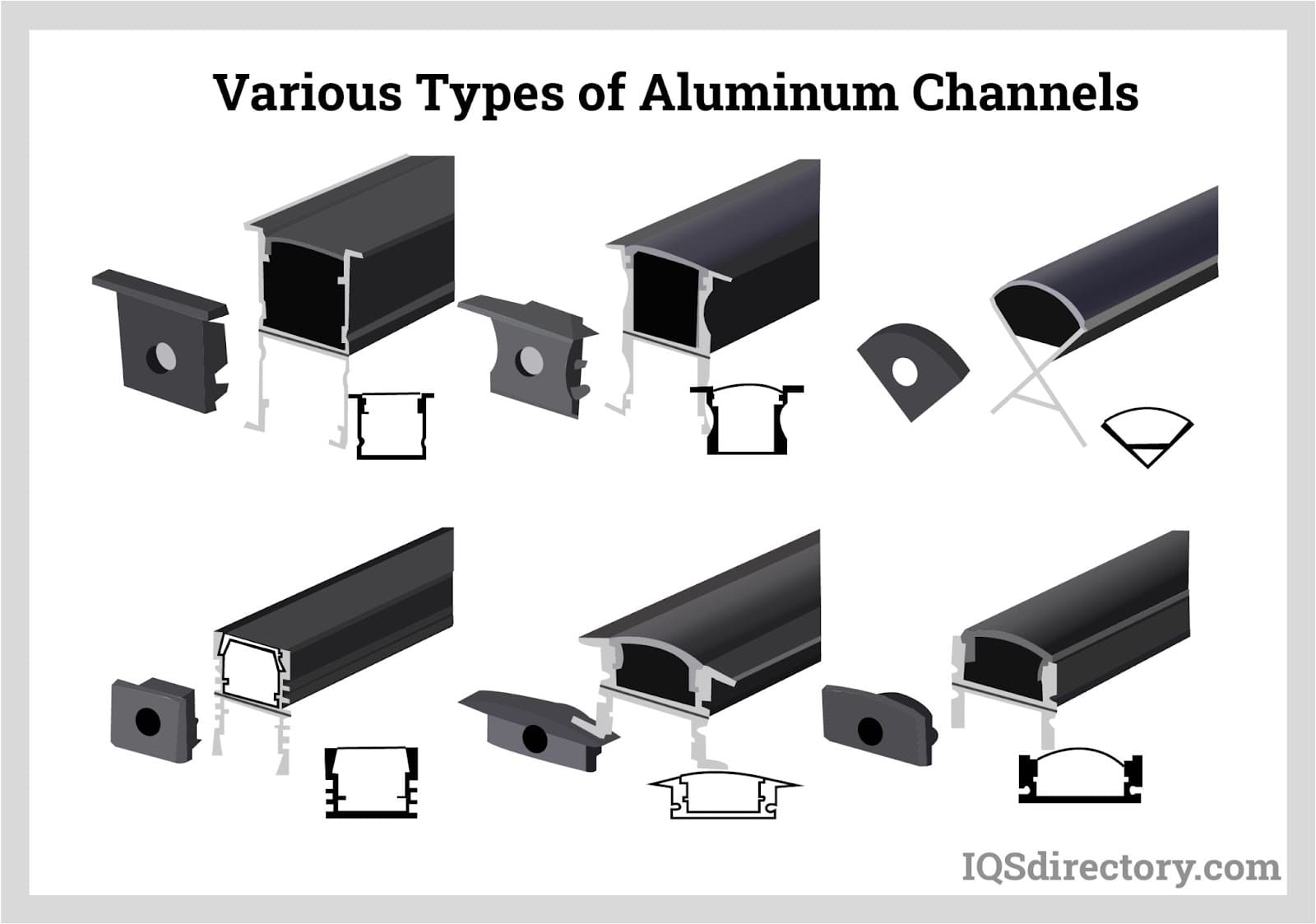

What are the Characteristics of Aluminum U Channels?

Aluminum U Channels are characterized by their U-shaped cross-section, making them ideal for applications that require structural support and durability. These channels are commonly used in door framing, shelving, and edge protection. Their lightweight nature and corrosion resistance make them a favorite among B2B buyers looking for reliable materials that are easy to work with. When purchasing, consider the specific dimensions and weight capacities needed for your project, as these factors can significantly impact performance.

How Do Aluminum C Channels Differ from Other Variations?

Aluminum C Channels feature a C-shaped profile that provides versatility across various applications, including displays and custom shelving. Their design allows for easy integration into different structures, making them suitable for both industrial and commercial projects. Buyers should evaluate the strength-to-weight ratio and specific dimensions required for their applications, as this will determine the channel’s effectiveness in supporting loads without compromising structural integrity.

Why Choose Rounded Inside Channels for Safety?

Rounded Inside Channels have smooth, rounded edges that enhance safety, making them particularly suitable for environments where sharp edges pose a risk. These channels are often used in architectural applications such as railings and partitions. For B2B buyers, the primary consideration should be the balance between aesthetic appeal and safety features, as well as the potential for higher production costs due to their specialized design.

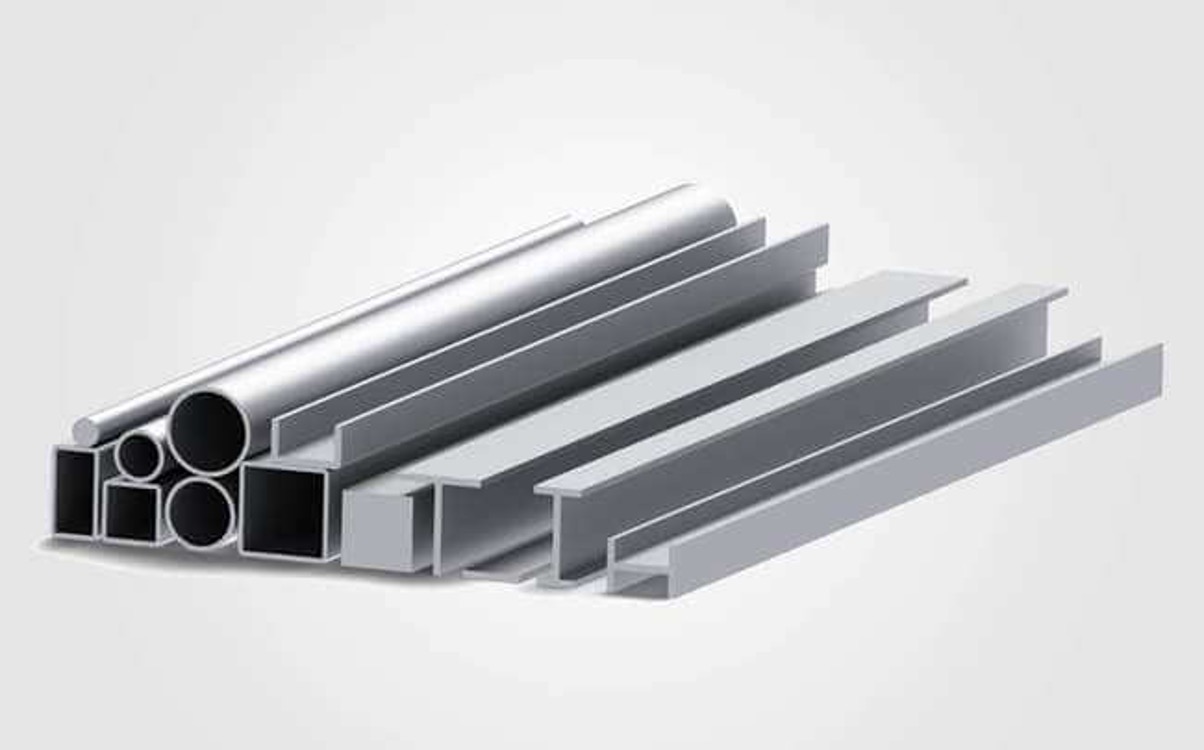

Illustrative image related to extruded aluminum channel shapes

What Are the Advantages of Rounded Outside Channels?

Rounded Outside Channels feature a smooth exterior that not only enhances aesthetic appeal but also makes cleaning easier. These channels are often used in decorative applications, such as furniture framing and architectural features. Buyers should weigh the benefits of an attractive finish against the potential trade-off in structural rigidity compared to standard channels. Understanding the intended application will help in making an informed purchasing decision.

How Do Architectural Channels Enhance Design?

Architectural Channels are designed specifically for aesthetic appeal and are often available in customizable finishes. They are ideal for retail displays, signage, and interior décor, where visual impact is a priority. B2B buyers should consider the additional costs associated with custom finishes and the specific design requirements of their projects. These channels can significantly elevate the overall look of a product or space, making them a worthwhile investment for businesses focused on brand presentation.

Key Industrial Applications of extruded aluminum channel shapes

| Industry/Sector | Specific Application of extruded aluminum channel shapes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Structural framing for buildings and facades | Provides lightweight, durable support; enhances aesthetics | Ensure compliance with local building codes and regulations; consider corrosion resistance based on climate. |

| Manufacturing & Fabrication | Custom shelving and display systems | Maximizes space efficiency and product visibility; offers flexibility in design | Look for customizable options; assess load-bearing capacity based on product specifications. |

| Transportation & Automotive | Components for trailers, buses, and RVs | Reduces overall vehicle weight while maintaining strength; improves fuel efficiency | Verify material quality and weight specifications; consider global shipping logistics for larger orders. |

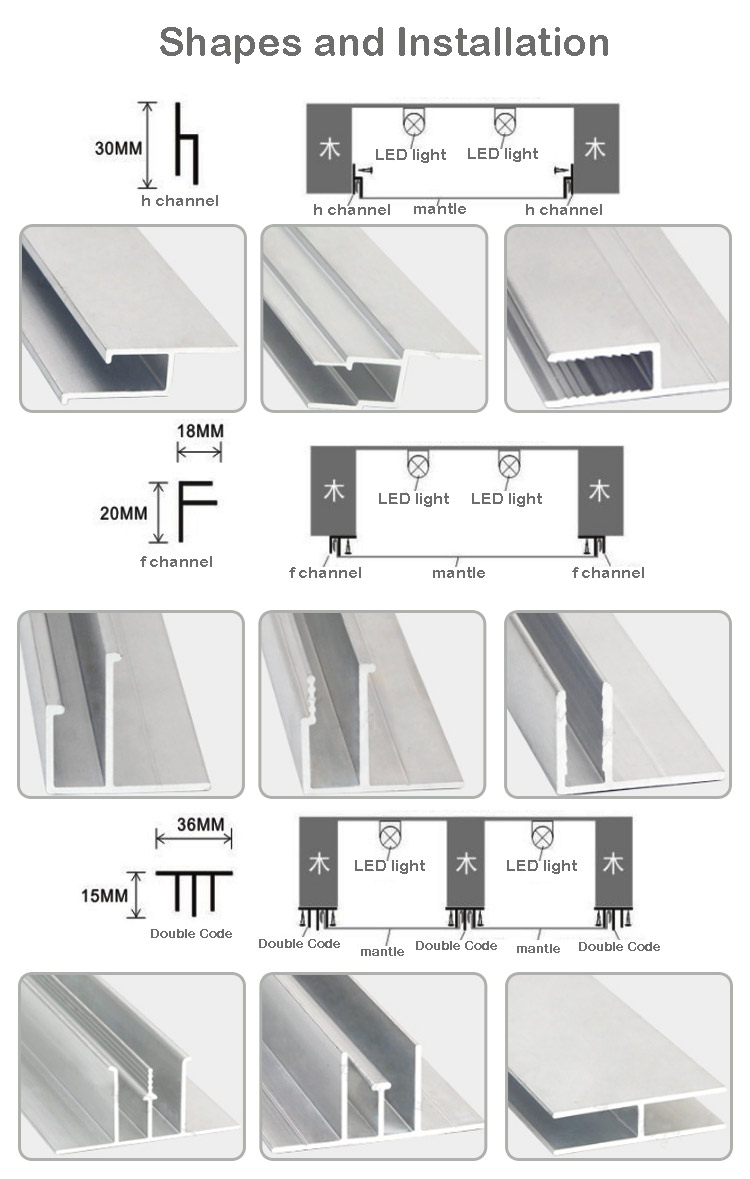

| Electrical & Electronics | Cable management systems and LED lighting fixtures | Organizes wiring for safety and efficiency; enhances aesthetic appeal | Check compatibility with existing systems; evaluate for ease of installation and maintenance. |

| Retail & Exhibitions | Display stands and signage frames | Attracts customer attention; allows for easy modification and updates | Assess for visual appeal and structural integrity; consider transportability and assembly requirements. |

How Are Extruded Aluminum Channel Shapes Used in Construction and Architecture?

Extruded aluminum channels serve a critical role in construction and architecture, particularly in structural framing for buildings and facades. Their lightweight yet sturdy nature allows architects to design innovative structures without compromising on durability. For international buyers, especially from regions like Africa and South America, sourcing channels that comply with local building codes is essential. Corrosion resistance is also a key consideration, as varying climates can impact material longevity.

What Are the Benefits of Using Extruded Aluminum Channels in Manufacturing and Fabrication?

In manufacturing and fabrication, extruded aluminum channels are often utilized for creating custom shelving and display systems. This versatility allows businesses to maximize space efficiency while enhancing product visibility. Buyers should look for suppliers that offer customizable options to meet specific design requirements. Additionally, assessing the load-bearing capacity is crucial to ensure that the channels can support the intended weight, particularly for industrial applications.

How Do Extruded Aluminum Channels Contribute to the Transportation and Automotive Sector?

In the transportation and automotive industries, extruded aluminum channels are integral components for trailers, buses, and recreational vehicles (RVs). They help reduce the overall weight of vehicles, which directly contributes to improved fuel efficiency. For B2B buyers, verifying the quality and weight specifications of these channels is vital, especially when sourcing materials for large-scale production. Logistics also play a significant role, as international shipping can affect delivery times and costs.

Why Are Extruded Aluminum Channels Important for Electrical and Electronics Applications?

Extruded aluminum channels are essential for organizing cable management systems and housing LED lighting fixtures in electrical and electronics applications. They provide a safe and efficient way to manage wiring, reducing the risk of electrical hazards while enhancing aesthetic appeal. Buyers should ensure compatibility with existing systems and evaluate ease of installation and maintenance. This is particularly important for international buyers who may face different electrical standards and practices.

Illustrative image related to extruded aluminum channel shapes

How Do Retail and Exhibition Industries Benefit from Extruded Aluminum Channels?

In the retail and exhibition sectors, extruded aluminum channels are commonly used to create display stands and signage frames. Their lightweight and durable properties make them ideal for attracting customer attention while allowing for easy modifications and updates to displays. When sourcing these materials, businesses should assess both visual appeal and structural integrity to ensure that displays can withstand various conditions. Transportability and assembly requirements are also key considerations for international buyers looking to streamline logistics.

3 Common User Pain Points for ‘extruded aluminum channel shapes’ & Their Solutions

Scenario 1: Navigating Limited Customization Options

The Problem: Many B2B buyers face the challenge of sourcing extruded aluminum channel shapes that meet specific design and application needs. Standard products often do not accommodate unique project requirements, such as precise dimensions, specific finishes, or unique shapes necessary for architectural designs. This limitation can lead to project delays, increased costs due to rework, and frustration over incompatible materials.

The Solution: To effectively navigate this pain point, buyers should prioritize suppliers that offer a robust customization program. When sourcing extruded aluminum channels, inquire specifically about options for custom dimensions, finishes, and profiles. For example, many manufacturers allow for custom extrusion profiles tailored to unique specifications, which can be an invaluable asset for projects that require non-standard shapes. Utilize digital tools or CAD software to visualize how the custom extrusions will fit into your project before placing an order. Additionally, establish a collaborative relationship with your supplier; this can facilitate quicker turnaround times and ensure that your specific needs are met without compromising on quality or aesthetics.

Scenario 2: Ensuring Structural Integrity Under Load

The Problem: Buyers often encounter concerns regarding the structural integrity of extruded aluminum channel shapes in load-bearing applications. The lightweight nature of aluminum, while beneficial for many uses, can raise questions about its strength and durability, particularly in environments where heavy loads or high stress are anticipated. This uncertainty can lead to hesitance in making purchasing decisions, especially when the stakes include safety and compliance with industry standards.

The Solution: To address this concern, it’s crucial to thoroughly understand the alloy grades and structural capabilities of the aluminum channels you are considering. Opt for suppliers who provide detailed technical specifications and load capacity charts for their products. For instance, aluminum alloys like 6061 offer superior strength and are often recommended for structural applications. Additionally, consider conducting load tests on samples before full-scale implementation. By verifying that the channels can handle the expected loads, you can mitigate risks and confidently use the materials in your projects. Consulting with an engineering professional during the selection process can also provide insights into the appropriate channel shapes and sizes needed for your specific application, ensuring that your structural requirements are satisfied.

Illustrative image related to extruded aluminum channel shapes

Scenario 3: Overcoming Corrosion and Maintenance Challenges

The Problem: In regions with high humidity or exposure to corrosive environments, extruded aluminum channel shapes can be susceptible to corrosion, which can diminish their aesthetic appeal and structural integrity over time. B2B buyers often struggle with this issue, leading to increased maintenance costs and reduced product lifespan, especially in industries such as construction, transportation, and marine applications.

The Solution: To combat corrosion, it’s essential to select aluminum channels that come with protective finishes, such as anodization or powder coating. These treatments not only enhance the visual appeal of the channels but also provide a robust barrier against environmental factors. When sourcing materials, request detailed information about the finishes available and their resistance to various corrosive elements. Implementing regular maintenance schedules can also prolong the life of aluminum channels; this includes periodic inspections and cleaning to remove any debris or contaminants. Additionally, educating project teams on best practices for handling and installing aluminum channels can prevent damage during the construction phase, further safeguarding against corrosion and ensuring long-term performance. By proactively addressing corrosion concerns, buyers can enhance the durability and reliability of their extruded aluminum channel applications.

Strategic Material Selection Guide for extruded aluminum channel shapes

What Are the Key Properties of Common Materials for Extruded Aluminum Channel Shapes?

When selecting materials for extruded aluminum channel shapes, it is essential to consider various options that can meet specific performance requirements. The most commonly used materials include aluminum alloys, anodized aluminum, painted aluminum, and structural composites. Each material has distinct properties that affect its performance, durability, and suitability for different applications.

Aluminum Alloys: What Are Their Advantages and Limitations?

Aluminum alloys, particularly 6061 and 6063, are widely used for extruded aluminum channels due to their excellent strength-to-weight ratio and good corrosion resistance. These alloys can withstand moderate temperatures and pressures, making them suitable for various applications, including structural support and aesthetic finishes.

Pros: Aluminum alloys are durable, lightweight, and easy to work with, allowing for straightforward fabrication and customization. They are also non-magnetic and resistant to stress cracks, which is beneficial in high-stress environments.

Illustrative image related to extruded aluminum channel shapes

Cons: While generally cost-effective, the price can vary based on alloy specifications and market conditions. Additionally, certain alloys may require additional treatments for enhanced corrosion resistance in harsh environments.

Impact on Application: Aluminum alloys are compatible with various media, including water and chemicals, but may not be suitable for applications involving aggressive acids or bases.

International Considerations: Buyers should be aware of compliance with international standards such as ASTM and DIN. In regions like Africa and South America, sourcing from reputable suppliers who adhere to these standards is crucial for ensuring quality and performance.

Anodized Aluminum: How Does It Enhance Performance?

Anodized aluminum is aluminum that has undergone an electrochemical process to increase its thickness and improve its corrosion resistance. This treatment also enhances the material’s aesthetic appeal, making it suitable for architectural applications.

Pros: The anodization process significantly improves the durability and corrosion resistance of aluminum, making it ideal for outdoor applications. It also allows for a variety of color finishes, adding to its design versatility.

Cons: The anodization process can increase manufacturing complexity and cost. Additionally, while anodized surfaces are durable, they can be more susceptible to scratching compared to untreated aluminum.

Impact on Application: Anodized aluminum is particularly suitable for applications exposed to moisture or corrosive environments, such as coastal areas or industrial settings.

International Considerations: Compliance with environmental regulations regarding anodization processes is essential, especially in Europe and the Middle East, where stricter standards may apply.

Painted Aluminum: What Are the Benefits and Drawbacks?

Painted aluminum involves applying a protective coating to aluminum surfaces, enhancing both aesthetics and corrosion resistance. This option is popular in applications where visual appeal is critical.

Illustrative image related to extruded aluminum channel shapes

Pros: The paint provides a protective layer that can resist corrosion and wear, while also offering a wide range of color options. Painted aluminum is relatively cost-effective compared to anodized finishes.

Cons: The durability of the paint can vary based on the quality of the application and the environment. In harsh conditions, the paint may chip or fade, requiring maintenance or reapplication.

Impact on Application: Painted aluminum is suitable for applications where aesthetic considerations are paramount, such as signage and decorative elements, but may not be ideal for environments with extreme weather conditions.

International Considerations: Buyers should ensure that the paint used meets local environmental regulations, particularly in Europe, where VOC emissions are closely monitored.

Structural Composites: When Are They a Suitable Choice?

Structural composites, though less common than aluminum, are sometimes used in specialized applications requiring lightweight yet strong materials. These composites can offer unique properties, such as enhanced thermal insulation.

Pros: Composites are lightweight and can be engineered for specific performance characteristics, making them suitable for unique applications. They also offer excellent resistance to corrosion and environmental degradation.

Cons: The manufacturing process for composites can be more complex and costly than aluminum. Additionally, they may not have the same strength-to-weight ratio as high-grade aluminum alloys.

Impact on Application: Composites are often used in applications where thermal insulation is critical, such as in certain construction projects.

International Considerations: Compliance with international standards for composite materials is essential, particularly in regions with stringent building codes.

Summary Table of Material Selection for Extruded Aluminum Channel Shapes

| Material | Typical Use Case for extruded aluminum channel shapes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Structural support, aesthetic finishes | Excellent strength-to-weight ratio | Variable cost based on alloy | Medium |

| Anodized Aluminum | Architectural applications, outdoor use | Enhanced corrosion resistance | Higher manufacturing complexity | High |

| Painted Aluminum | Decorative elements, signage | Wide range of color options | Durability can vary with environment | Low |

| Structural Composites | Specialized applications requiring insulation | Lightweight and customizable | Higher manufacturing complexity | High |

This guide provides a comprehensive overview of material options for extruded aluminum channel shapes, emphasizing the importance of selecting the right material based on application requirements and international compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for extruded aluminum channel shapes

What Are the Key Stages in the Manufacturing Process of Extruded Aluminum Channel Shapes?

The manufacturing of extruded aluminum channel shapes involves several critical stages that ensure the final product meets the specifications and quality standards required by various industries. Here’s a breakdown of the primary stages involved:

-

Material Preparation: The process begins with the selection of aluminum alloys suitable for extrusion. Common choices include 6061 and 6063 alloys, which are chosen based on their strength, corrosion resistance, and suitability for the intended application. The raw aluminum is typically supplied in the form of billets, which are cut to length and heated to a specific temperature to facilitate easier extrusion.

-

Forming: In this stage, the heated aluminum billets are placed in an extrusion press. The press uses a die to shape the aluminum into the desired channel profile. The force applied during extrusion is significant, often exceeding thousands of tons, which ensures that the aluminum flows smoothly through the die. This process can produce a wide variety of shapes, including U-channels, C-channels, and specialized designs tailored to customer needs.

-

Cooling and Aging: Once extruded, the aluminum profiles are rapidly cooled, typically through air or water quenching. This step is crucial for achieving the desired mechanical properties of the aluminum. Following cooling, the profiles may undergo an aging process, which enhances their strength and stability.

-

Finishing: The final stage includes various finishing processes such as cutting to length, surface treatments, and anodizing. Anodizing not only improves corrosion resistance but can also enhance the aesthetic appeal of the aluminum channels. Other finishes may include powder coating or mill finishes, depending on customer specifications.

-

Assembly (if applicable): For applications requiring assembly, extruded aluminum channels can be integrated with other components, such as brackets or connectors. This stage may involve welding, riveting, or using fasteners to create a robust assembly.

How Is Quality Assurance Implemented in the Production of Extruded Aluminum Channels?

Quality assurance is vital to ensure that extruded aluminum channel shapes meet both international standards and specific customer requirements. Here’s how quality assurance is typically structured:

-

Adherence to International Standards: Manufacturers often comply with international standards such as ISO 9001, which outlines a framework for quality management systems. This certification ensures that a company consistently provides products that meet customer and regulatory requirements. Additionally, industry-specific standards like CE marking for construction products in Europe or API standards for applications in the oil and gas sector may also be applicable.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control checkpoints are established:

– Incoming Quality Control (IQC): This step involves inspecting raw materials upon delivery to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are performed to monitor parameters such as temperature, pressure, and the dimensions of the extruded profiles.

– Final Quality Control (FQC): After production, a comprehensive inspection is conducted to verify that the finished products meet all specified tolerances and quality standards. -

Common Testing Methods: Various testing methods are employed to ensure product quality. These may include:

– Dimensional Inspections: Using calipers and gauges to measure the dimensions of the extrusions.

– Mechanical Testing: Assessing properties such as tensile strength, hardness, and impact resistance through standardized tests.

– Surface Quality Tests: Evaluating surface finishes for defects, corrosion resistance, and adherence to specified coatings.

How Can B2B Buyers Verify the Quality Control Practices of Suppliers?

For B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is crucial. Here are some strategies to ensure that suppliers maintain high-quality standards:

Illustrative image related to extruded aluminum channel shapes

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes, quality control systems, and compliance with international standards. This firsthand observation can provide insights into the supplier’s operational capabilities and commitment to quality.

-

Requesting Quality Reports: Buyers should request documentation of quality control processes and results, including IQC, IPQC, and FQC reports. These documents should detail the testing methods used, results obtained, and any corrective actions taken in case of non-conformance.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These independent entities can conduct audits and inspections throughout the manufacturing process, providing unbiased verification of the supplier’s quality standards.

-

Certifications and Compliance: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001 or specific industry certifications (e.g., CE, API). These certifications indicate adherence to recognized quality management practices.

What Nuances Should International B2B Buyers Consider Regarding Quality Assurance?

International buyers must navigate various nuances in quality assurance, particularly when sourcing from regions with differing regulatory frameworks and manufacturing standards. Here are some considerations:

-

Understanding Local Standards: Each region may have its own set of regulations and standards governing manufacturing practices. Buyers should familiarize themselves with these standards to ensure compliance and quality.

-

Cultural Differences: Cultural factors can influence business practices, including quality assurance. It’s essential for buyers to establish clear communication and expectations regarding quality standards to avoid misunderstandings.

-

Logistical Challenges: Sourcing materials internationally may present logistical challenges that can affect product quality. Buyers should consider the entire supply chain and its impact on the final product, from raw material sourcing to shipping and handling.

-

Building Long-Term Relationships: Establishing long-term relationships with reliable suppliers can lead to improved quality assurance over time. Regular communication and feedback help ensure that suppliers remain aligned with the buyer’s quality expectations.

By thoroughly understanding the manufacturing processes and quality assurance protocols for extruded aluminum channel shapes, B2B buyers can make informed decisions that enhance their procurement strategies and ensure the delivery of high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘extruded aluminum channel shapes’

In the competitive landscape of B2B procurement, sourcing extruded aluminum channel shapes requires careful consideration and strategic planning. This guide provides a structured approach to help international buyers effectively navigate the procurement process, ensuring they make informed decisions that align with their project requirements.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the specifications for the extruded aluminum channels you need. Consider dimensions, leg types (e.g., C or U channels), and any specific performance attributes, such as weight capacity and corrosion resistance. By establishing these criteria upfront, you can streamline your supplier search and ensure that the products meet your project needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in extruded aluminum channels. Look for manufacturers with a strong reputation in the industry, particularly those that have experience serving your region (Africa, South America, the Middle East, or Europe). Utilize online resources, trade shows, and industry publications to compile a list of potential partners.

Step 3: Evaluate Supplier Certifications

Certifications are essential indicators of a supplier’s quality assurance practices. Verify that suppliers hold relevant certifications, such as ISO 9001, which indicates adherence to international quality management standards. Additionally, check for compliance with regional standards that may affect your project, ensuring that the materials you procure meet local regulations.

Step 4: Request Samples

Before making a large order, request samples of the extruded aluminum channels. This step allows you to assess the quality, finish, and suitability of the products for your specific application. Evaluate the samples for durability and aesthetic appeal, ensuring they align with your project’s requirements.

Step 5: Review Pricing and Payment Terms

Once you have identified potential suppliers, obtain detailed quotations that include pricing, lead times, and payment terms. Compare these factors across different suppliers to identify the best value. Be cautious of prices that seem too low, as they may indicate compromised quality.

Step 6: Check for Customization Options

Many projects require specific modifications to standard extruded aluminum channels. Inquire whether the suppliers offer customization services, such as cutting, drilling, or finishing options. Understanding the flexibility of suppliers in this regard can significantly impact your project’s success and efficiency.

Step 7: Establish Clear Communication Channels

Finally, ensure that you establish effective communication with your chosen supplier. Discuss timelines, project milestones, and any potential challenges upfront. Clear communication fosters a productive relationship and helps to mitigate misunderstandings, ultimately leading to smoother procurement and delivery processes.

By following this practical sourcing checklist, B2B buyers can confidently navigate the procurement of extruded aluminum channel shapes, ensuring that their projects are completed on time and within budget.

Comprehensive Cost and Pricing Analysis for extruded aluminum channel shapes Sourcing

What are the Key Cost Components in Sourcing Extruded Aluminum Channel Shapes?

When sourcing extruded aluminum channel shapes, understanding the cost structure is crucial for B2B buyers. The primary components include:

-

Materials: The cost of aluminum itself is influenced by market fluctuations, alloy type, and specifications. Common alloys used are 6061 and 6063, which vary in strength and application suitability. Prices can change based on global supply and demand dynamics.

-

Labor: Labor costs encompass the workforce involved in the extrusion process, including skilled labor for setup, operation, and finishing. This varies by region, with countries in Africa and South America often facing different wage structures compared to those in Europe.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and indirect labor. Efficient manufacturing processes can help reduce overhead, impacting the overall pricing.

-

Tooling: Custom tooling for specific shapes or dimensions can significantly increase initial costs. However, once amortized over larger production runs, these costs can decrease per unit.

-

Quality Control (QC): Ensuring that extrusions meet industry standards and certifications adds to costs. Buyers should consider suppliers with robust QC processes to minimize defects and associated costs later in the supply chain.

-

Logistics: Transportation costs can vary widely based on distance, shipping methods, and Incoterms. International buyers should be aware of additional costs such as tariffs and customs duties.

-

Margin: Suppliers typically apply a margin to cover their costs and generate profit. This can vary based on market conditions and competition.

How Do Price Influencers Impact Extruded Aluminum Channel Shapes?

Several factors influence the pricing of extruded aluminum channel shapes, which B2B buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating MOQ can be beneficial, especially for long-term contracts.

-

Specifications and Customization: Custom dimensions or finishes (e.g., anodized or brushed) can increase costs. Buyers should weigh the necessity of customization against budget constraints.

-

Material Quality and Certifications: Higher-quality materials or those that meet specific industry certifications (such as ISO or ASTM) typically command higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may charge a premium for their track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms is vital for cost management. Different Incoterms (e.g., FOB, CIF) can significantly impact the final cost due to variations in responsibility for shipping and insurance.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, adopting strategic approaches can enhance cost-efficiency:

-

Negotiation: Engaging suppliers in negotiation can yield favorable terms. Understanding the supplier’s cost structure can provide leverage in discussions.

-

Total Cost of Ownership (TCO): Buyers should consider not only the purchase price but also the TCO, which includes shipping, handling, and potential maintenance costs. A lower initial price may lead to higher long-term costs if quality is compromised.

-

Pricing Nuances for International Buyers: Currency fluctuations can affect pricing, so locking in exchange rates or negotiating in stable currencies can mitigate risks. Additionally, understanding local market conditions and regulations can aid in making informed decisions.

-

Research and Comparison: Conduct thorough market research and compare multiple suppliers to ensure competitive pricing. Utilize resources like industry trade shows or online platforms to gather information.

In summary, a comprehensive understanding of the cost structure, price influencers, and strategic negotiation tactics can significantly benefit B2B buyers in sourcing extruded aluminum channel shapes. By taking these factors into account, buyers can make informed decisions that align with their project requirements and budget constraints.

Alternatives Analysis: Comparing extruded aluminum channel shapes With Other Solutions

Exploring Alternatives to Extruded Aluminum Channel Shapes

In the realm of construction and design, extruded aluminum channel shapes are recognized for their versatility and strength. However, various alternatives can also meet the demands of similar applications. Understanding these alternatives allows B2B buyers to make informed decisions based on performance, cost, and specific project requirements.

| Comparison Aspect | Extruded Aluminum Channel Shapes | Steel Channels | PVC Channels |

|---|---|---|---|

| Performance | High strength-to-weight ratio, corrosion-resistant | Excellent load-bearing capacity, durable | Lightweight, less structural strength |

| Cost | Moderate to high | Generally lower initial cost but higher long-term maintenance | Low initial cost, less durable over time |

| Ease of Implementation | Easy to cut, drill, and customize | Requires specialized tools for cutting and welding | Simple to install, often requires adhesives |

| Maintenance | Low maintenance, resistant to corrosion | Moderate maintenance, can rust if not treated | Low maintenance, but can become brittle over time |

| Best Use Case | Architectural and structural applications | Heavy-duty applications, industrial uses | Lightweight applications, non-structural uses |

Analyzing Alternatives: Steel Channels

Steel channels are a traditional alternative to aluminum channels, particularly in heavy-duty applications. They offer superior load-bearing capabilities and are widely used in construction for structural framing. However, while they tend to have a lower initial cost, the maintenance can be more demanding due to the risk of rusting and corrosion unless properly coated. This makes steel channels more suitable for industrial environments or projects where strength is prioritized over aesthetics.

Evaluating Alternatives: PVC Channels

PVC channels provide a lightweight and cost-effective solution, particularly in non-structural applications. They are easy to install and can be used for various purposes, such as cable management and decorative framing. The main advantage of PVC is its resistance to moisture and chemicals, making it ideal for environments where corrosion is a concern. However, its structural integrity is limited compared to aluminum or steel channels, which can be a significant drawback for applications requiring robust support.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right channel solution, B2B buyers must consider the specific requirements of their projects. For applications demanding high strength and durability, extruded aluminum or steel channels are preferable. In contrast, for cost-sensitive or lightweight needs, PVC channels may suffice. Evaluating factors such as performance, cost, ease of implementation, and maintenance will guide buyers toward the best choice for their unique circumstances. By carefully weighing these alternatives, businesses can ensure they select the optimal solution that aligns with their operational goals and project specifications.

Illustrative image related to extruded aluminum channel shapes

Essential Technical Properties and Trade Terminology for extruded aluminum channel shapes

What Are the Key Technical Properties of Extruded Aluminum Channel Shapes?

Understanding the essential technical properties of extruded aluminum channel shapes is crucial for making informed purchasing decisions. Here are some critical specifications that B2B buyers should consider:

1. Material Grade

Aluminum extrusions typically come in various alloy grades, with 6061 and 6063 being the most common. Grade 6061 is known for its high strength and versatility, making it suitable for structural applications. In contrast, 6063 is favored for architectural applications due to its excellent finish and workability. Selecting the right material grade is vital for ensuring that the extrusions meet the strength, corrosion resistance, and aesthetic requirements of your project.

2. Tolerance

Tolerance refers to the permissible limit or limits of variation in a physical dimension. In the context of aluminum extrusions, it is crucial to ensure that the channels meet specified dimensions to fit within existing designs or systems. Tight tolerances are essential for applications where precision is critical, such as in structural components or custom assemblies. Understanding tolerances can help prevent costly rework and delays in your projects.

3. Finish Options

Aluminum channels can be finished in various ways, including anodizing, mill finish, and powder coating. Anodizing enhances corrosion resistance and provides a decorative finish, while powder coating offers a wide range of colors and textures. The finish you choose can significantly impact the durability and aesthetic appeal of the final product, influencing customer satisfaction and the longevity of installations.

4. Weight-to-Strength Ratio

Aluminum is renowned for its favorable weight-to-strength ratio, which means that it provides substantial strength while remaining lightweight. This property is especially beneficial in applications where reducing weight is critical, such as in transportation and construction. A lightweight material can lead to lower shipping costs and easier handling during installation, making it a preferred choice for many industries.

Illustrative image related to extruded aluminum channel shapes

5. Corrosion Resistance

Aluminum naturally forms a protective oxide layer that makes it highly resistant to corrosion. This property is particularly important for applications exposed to harsh environments, such as marine or industrial settings. Understanding the corrosion resistance of aluminum channels ensures that your investments will last longer and require less maintenance, which is a key consideration for B2B buyers looking to minimize long-term costs.

What Are Common Trade Terms in the Extruded Aluminum Industry?

Familiarizing yourself with industry jargon can enhance communication with suppliers and streamline the purchasing process. Here are some common trade terms relevant to extruded aluminum channels:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of aluminum extrusions, understanding OEM specifications can help ensure that the products meet the unique requirements of your application or industry.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is essential for planning purchases, especially for smaller companies or projects with limited budgets. It allows buyers to gauge the feasibility of sourcing specific extrusions without overcommitting financially.

Illustrative image related to extruded aluminum channel shapes

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Submitting an RFQ can help buyers compare costs, lead times, and other terms, facilitating better decision-making when selecting suppliers for aluminum extrusions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms can help buyers clarify shipping responsibilities, costs, and risks associated with transporting aluminum channels across borders.

By grasping these key technical properties and industry terms, B2B buyers can navigate the market for extruded aluminum channel shapes more effectively, ensuring they make informed decisions that align with their project needs and business objectives.

Navigating Market Dynamics and Sourcing Trends in the extruded aluminum channel shapes Sector

What are the Current Market Trends Impacting Extruded Aluminum Channel Shapes?

The global market for extruded aluminum channel shapes is experiencing dynamic changes driven by various factors, including technological advancements, increasing demand for lightweight materials, and the growing emphasis on sustainability. The versatility of aluminum channels, which find applications in construction, automotive, and consumer goods, is a key driver for their adoption. For B2B buyers in regions like Africa, South America, the Middle East, and Europe, understanding these market dynamics is crucial for informed sourcing decisions.

Illustrative image related to extruded aluminum channel shapes

Emerging technologies such as automation in manufacturing and advanced extrusion techniques are enhancing the efficiency and precision of aluminum production. This not only reduces lead times but also enables the customization of channel shapes to meet specific project requirements. Additionally, the rise of e-commerce platforms is facilitating easier access to a wider range of suppliers, allowing buyers to compare products and prices seamlessly.

A notable trend in the market is the shift towards sustainable practices. Buyers are increasingly prioritizing suppliers that offer environmentally friendly materials and manufacturing processes. This shift is evident in the growing demand for recycled aluminum and certifications that reflect a commitment to sustainability. For international buyers, aligning with suppliers who adhere to these principles can enhance brand reputation and meet regulatory requirements in their respective markets.

How is Sustainability Shaping the Sourcing of Extruded Aluminum Channel Shapes?

The environmental impact of aluminum production is a significant concern in today’s B2B landscape. Traditional aluminum extraction and processing are energy-intensive, leading to high carbon emissions. As a result, the importance of ethical supply chains and sustainable sourcing has become paramount. Buyers are encouraged to seek suppliers that prioritize recycled materials, as recycled aluminum requires only a fraction of the energy needed for primary production.

In addition to reducing environmental footprints, sourcing from companies that hold green certifications—such as ISO 14001—can provide buyers with a competitive edge. These certifications demonstrate a commitment to sustainable practices, which can resonate well with environmentally conscious consumers and businesses alike. Furthermore, suppliers that utilize eco-friendly anodizing processes and water-based finishes can significantly lower the ecological impact of their products.

Ethical sourcing not only contributes to environmental sustainability but also fosters positive social impacts. Engaging with suppliers who adhere to fair labor practices and support local communities can enhance a company’s corporate social responsibility (CSR) profile. For buyers in emerging markets, this can also translate into stronger relationships with local stakeholders and improved market positioning.

How Have Extruded Aluminum Channel Shapes Evolved Over Time?

The evolution of extruded aluminum channel shapes is closely tied to advancements in manufacturing technology and changing market needs. Historically, aluminum extrusion was a labor-intensive process limited to basic shapes and sizes. However, the introduction of modern extrusion techniques in the mid-20th century revolutionized the industry, allowing for the creation of more complex and customized profiles.

As industries such as construction and transportation grew, the demand for lightweight, durable materials surged. This led to innovations in aluminum alloys and finishes, enhancing the performance characteristics of channel shapes. Today, extruded aluminum channels are not only valued for their strength and versatility but also for their aesthetic appeal, with options for various finishes and colors to meet design requirements.

The ongoing trend towards sustainability is shaping the future of aluminum extrusion, with an increased focus on recycling and eco-friendly practices. As the industry continues to adapt to these changes, the evolution of extruded aluminum channel shapes will likely prioritize both functionality and environmental responsibility, ensuring they remain a staple in B2B sourcing strategies across diverse sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of extruded aluminum channel shapes

-

How do I select the right extruded aluminum channel shape for my project?

When choosing the appropriate extruded aluminum channel shape, consider the specific application requirements, such as load-bearing capacity, aesthetic needs, and environmental conditions. For structural applications, a thicker gauge C or U channel may be necessary, while architectural projects might benefit from lighter, decorative profiles. Additionally, evaluate the dimensions, alloy types (like 6061 or 6063), and finishes (anodized, mill, etc.) that align with your project goals. Consulting with suppliers can provide insights into the best options based on your unique specifications. -

What are the common applications for extruded aluminum channel shapes?

Extruded aluminum channel shapes are widely used in various industries due to their versatility. Common applications include framing for doors and windows, edge protection, wire management, and supporting shelving or displays. They are also utilized in architectural features, shower enclosures, and structural components for vehicles and machinery. Understanding the specific requirements of your industry will help you identify the most suitable channel shape for your needs. -

How can I ensure the quality of extruded aluminum channels when sourcing internationally?

To ensure quality when sourcing extruded aluminum channels internationally, vet potential suppliers thoroughly. Check for certifications such as ISO or ASTM, which indicate adherence to industry standards. Request samples to assess the material quality and dimensional accuracy. Additionally, consider suppliers with a proven track record of reliability and customer service. Engaging in direct communication and establishing a clear quality assurance process can further mitigate risks. -

What are the typical minimum order quantities (MOQs) for extruded aluminum channels?

Minimum order quantities for extruded aluminum channels can vary significantly based on the supplier and the specific product. Generally, MOQs can range from 100 to 1,000 units, depending on the complexity and customization of the channels. For custom extrusions, MOQs might be higher due to the initial setup costs involved in production. It’s advisable to discuss your needs with suppliers directly to negotiate suitable terms that accommodate your project scale. -

What payment terms should I expect when purchasing extruded aluminum channels internationally?

Payment terms can vary based on the supplier’s policies and the buyer’s relationship with them. Common terms include upfront payments, partial payments upon order confirmation, and the balance upon delivery. For international transactions, letters of credit or secure payment platforms may be required to ensure security for both parties. Always clarify payment terms in advance to avoid misunderstandings and ensure a smooth transaction process. -

How do I handle logistics and shipping when sourcing extruded aluminum channels?

When sourcing extruded aluminum channels, logistics and shipping arrangements are critical. Work with suppliers who have experience in international shipping and understand the customs regulations of your country. Determine whether you prefer door-to-door delivery or if you can manage freight forwarding. Additionally, consider shipping costs, transit times, and insurance options to protect your investment during transport. Clear communication with your supplier about logistics can help streamline the process. -

Can I customize the dimensions and finishes of extruded aluminum channels?

Yes, many suppliers offer customization options for extruded aluminum channels, allowing you to specify dimensions, shapes, and finishes. Custom extrusions can be tailored to meet specific project requirements, whether for structural strength or aesthetic appeal. When requesting customizations, provide detailed specifications and collaborate with the supplier’s design team to ensure that your vision aligns with manufacturing capabilities. -

What should I do if I encounter issues with the quality or delivery of my order?

If you face issues with the quality or delivery of your extruded aluminum channel order, promptly communicate with your supplier to address the problem. Document any discrepancies or defects with photographs and detailed descriptions. Most reputable suppliers will have a return or replacement policy in place. If resolution proves difficult, consider escalating the matter through formal channels or seeking mediation to ensure that your concerns are addressed effectively.

Top 9 Extruded Aluminum Channel Shapes Manufacturers & Suppliers List

1. Orange Aluminum – Extruded Aluminum Channels

Domain: orangealuminum.com

Registered: 2006 (19 years)

Introduction: Extruded aluminum channels, also known as track, U-channel or C-channel, are versatile profiles used for door framing, edge protection, and wire management. They are lightweight, corrosion-resistant, easy to cut, drill, and customize, providing a clean, professional finish for various projects. Ideal for guiding sliding panels, supporting shelving, LED strip lighting, and organizing cables in resi…

2. Extrude-A-Trim – Aluminum Extrusions & Architectural Channels

Domain: extrude-a-trim.com

Registered: 1998 (27 years)

Introduction: Aluminum Channel, Aluminum Extrusions, Architectural Channel (Rounded Outside, Rounded Inside), Structural Channel, C Channel, U Channel, Sliding Track Systems, Shower Enclosure, Corner Moulding, Divider, Drawer & Finger Pull, Finger Pull, Drawer Pull, EX Sign Shapes, Glass Railing System, Hollow Tube (Rectangular, Round, Square), Structural Square Hollow Tube (Rounded Corners), Telescopic Tube, J…

3. Eagle Aluminum – Aluminum C Channels & Slide Track Channels

Domain: eagle-aluminum.com

Registered: 2010 (15 years)

Introduction: Aluminum C Channels and Aluminum Slide Track Channels are lightweight, sturdy aluminum extrusion products that are versatile and suitable for various applications, including wood panel projects, reception desks, custom displays, and shelf units. Key attributes include:

– Lightweight and corrosion-resistant

– High strength-to-weight ratio

– Non-magnetic

– Resistant to stress cracks

Available …

4. SAF – Channel Aluminum Extrusions

Domain: saf.com

Registered: 1992 (33 years)

Introduction: Channel Aluminum Extrusions are available in various finishes including Mill Finish, Clear Anodized, Bronze Anodized, Black Anodized, Gold Anodized, and Painted Aluminum. The product is made from 6063 alloy aluminum, known for its sharp, 90-degree angle corners. Common uses include architectural trim, framing, store fixtures, displays, glass and mirror projects, and woodworking. The workability of…

5. Industrial Metal Supply – 6061 & 6063 Aluminum Channel

Domain: industrialmetalsupply.com

Registered: 1999 (26 years)

Introduction: 6061 and 6063 Aluminum Channel (U Channel) – 6061 Structural Channel H = Height, 6063 Architectural Channel H = Height, W = Width, L = Length, T = Thickness. 6061 Aluminum Channel: Manufactured with inside radius corners for structural applications requiring strength, widely used in fabrication projects needing lightweight and corrosion resistance. Available lengths: 8′, 16′, 25′, height options f…

6. Wellste – Extruded Aluminum Shapes

Domain: wellste.com

Registered: 2016 (9 years)

Introduction: {“Product Type”:”Extruded Aluminum Shapes”,”Material”:”Aluminum Alloy 6063/6061/6463/6000 Series”,”Temper”:”T4/T5/T6″,”Shapes”:”T/J/Y/Z/F/G/Bar/Angle/Oval/Round/Square/Triangular/Hexagonal”,”Applications”:”Industry, Electronic, Construction, Aircraft, Marine, etc.”,”Surface Treatments”:”Anodizing, Mill finish, Electroplating, Polishing, Sand blasted, Powder coating, Silver plating, Brushed, Painte…

7. Testrite Aluminum – Extruded Aluminum Shapes

Domain: testritealuminum.com

Registered: 2022 (3 years)

Introduction: Extruded Aluminum Shapes including Round Aluminum Tubing, Square Tubing, Rectangular Tubing, Oval Tubing, Aluminum Rods, Aluminum Bars, Aluminum L Angles, Aluminum Slatwall, Aluminum Trays, Aluminum U, Aluminum Slotted Tracks, SEG & Graphic Frames, Tubing Locks, Parts & Accessories. Specific products include: 29/32″ ID Aluminum U Channel for Double Sided Slatwall, 1/2″ ID Aluminum U Channel Single…

8. Metal Supermarkets – Aluminum Channel

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Aluminum Channel is a non-ferrous metal product shaped for industrial and structural purposes, available in grades 6061 and 6063. Typical applications for 6061 include screw machine parts, truck bodies, running boards, and platforms, while 6063 is used for construction tubes, lawn furniture, and luggage racks. Aluminum channels are produced through extrusion, offering a high strength-to-weight rat…

9. Outwater – Extruded Aluminum U Channels

Domain: outwater.com

Registered: 1995 (30 years)

Introduction: This company, Outwater – Extruded Aluminum U Channels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for extruded aluminum channel shapes

As the demand for extruded aluminum channel shapes continues to grow across diverse industries, strategic sourcing has become a crucial component for international B2B buyers. By prioritizing quality, customization, and supplier reliability, businesses can enhance operational efficiency and maintain competitive advantages. The versatility of aluminum channels—ranging from structural support to aesthetic enhancements—makes them an ideal choice for various applications, including construction, cabinetry, and display systems.

Investing in robust supply chain partnerships will not only ensure access to high-quality products but also facilitate innovations in design and functionality. Buyers from regions such as Africa, South America, the Middle East, and Europe should leverage local and international suppliers that offer customized solutions to meet specific project requirements.

Looking ahead, the market for extruded aluminum channel shapes is poised for expansion, driven by advancements in manufacturing technology and increasing sustainability initiatives. Now is the time for B2B buyers to reassess their sourcing strategies, ensuring they align with emerging trends and customer demands. Engage with trusted suppliers to explore tailored solutions that will elevate your projects and drive business growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.