External Broaching Services: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for external broaching services

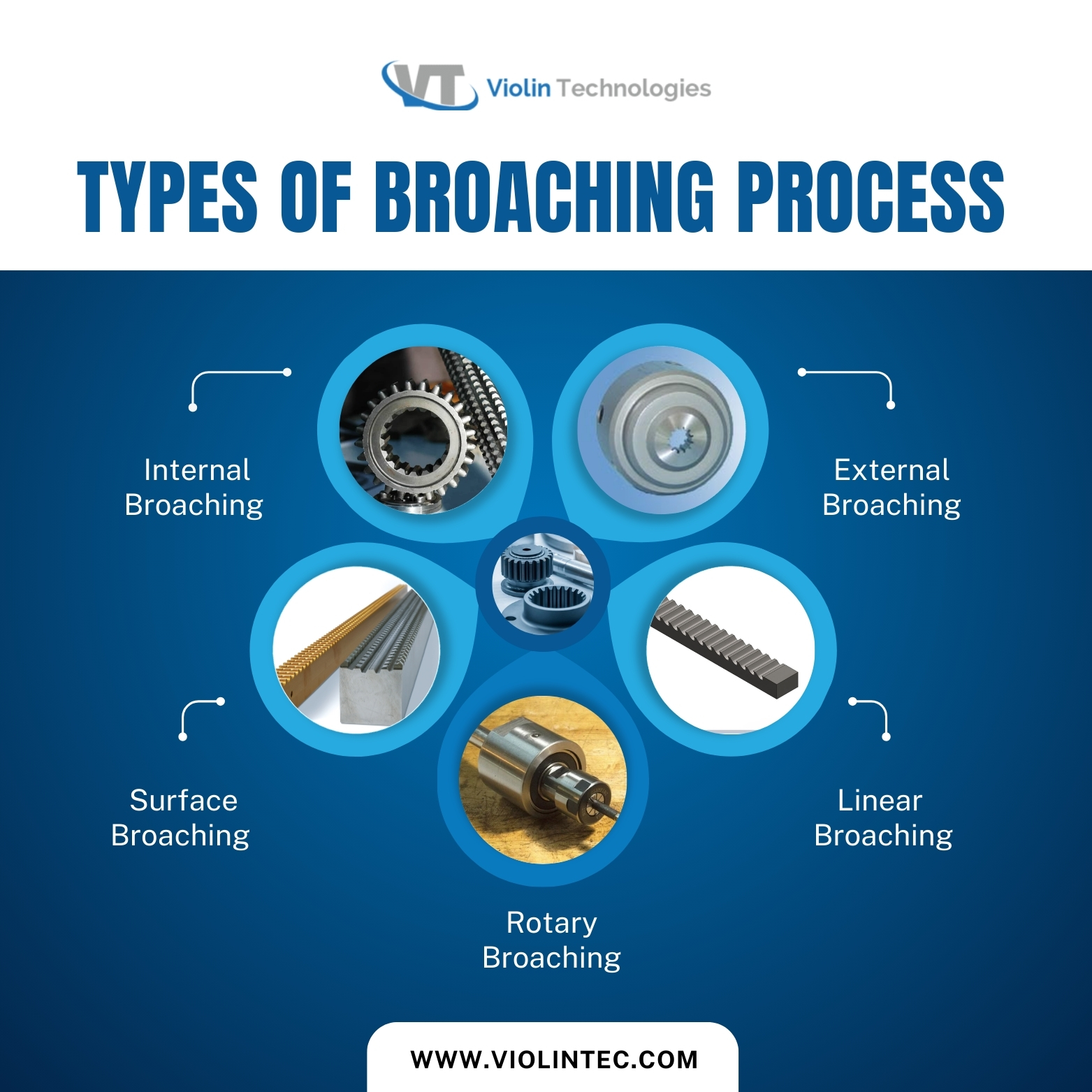

In today’s competitive manufacturing landscape, sourcing external broaching services can be a daunting challenge for B2B buyers. With the demand for precision-engineered components rising across various industries, understanding the nuances of external broaching is essential for ensuring quality and efficiency. This guide serves as a comprehensive resource, detailing the different types of external broaching techniques, their applications in diverse sectors, and practical insights for vetting suppliers. From surface broaching to rotary broaching, we delve into the specifics of each method, highlighting their advantages and ideal use cases.

International buyers, particularly those from Africa, South America, the Middle East, and Europe, face unique challenges in navigating the global market for broaching services. Factors such as supplier reliability, cost-effectiveness, and compliance with regional manufacturing standards are crucial in making informed purchasing decisions. This guide empowers buyers by providing a structured approach to evaluating potential partners, understanding pricing models, and recognizing the critical role that broaching plays in manufacturing efficiency.

By the end of this guide, you will be equipped with the knowledge needed to confidently select external broaching services that align with your production goals, ensuring that your operations run smoothly and effectively in an increasingly interconnected marketplace.

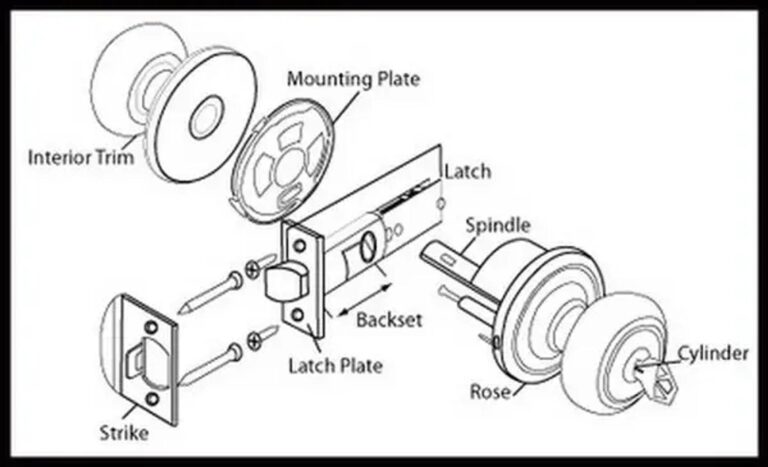

Understanding external broaching services Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface Broaching | Cuts flat or contoured surfaces with high precision | Tool and die manufacturing, automotive parts | Pros: Excellent finish quality; efficient for large surfaces. Cons: May require custom tooling for complex shapes. |

| Keyway Broaching | Specialized for cutting keyways in rotating components | Gears, pulleys, couplings, power transmission systems | Pros: Single-pass accuracy; consistent fit. Cons: Limited to specific applications. |

| Blind Broaching | Creates features that do not pass through the workpiece | Hydraulic components, custom mechanical assemblies | Pros: Exceptional dimensional control; tight tolerances. Cons: Depth limitations may restrict use. |

| Rotary Broaching | Produces non-circular shapes through a wobbling technique | Medical devices, aerospace parts, custom fasteners | Pros: Fast production of intricate features. Cons: Requires precise setup and may not suit all materials. |

| Pot Broaching | Uses multiple broaching tools for complex internal shapes | High-precision manufacturing of splines and gears | Pros: High-volume production; intricate profiles. Cons: Custom tooling can be costly and time-consuming. |

What is Surface Broaching and When Should You Use It?

Surface broaching is a versatile method used to create flat or contoured surfaces on a workpiece. This technique employs a broach tool equipped with multiple cutting edges, allowing for precise material removal. It is particularly suitable for applications requiring large, flat surfaces, such as in tool and die manufacturing or automotive components. When considering surface broaching, buyers should assess the volume of parts needed, as this method excels in high-volume production scenarios but may require custom tooling for complex geometries.

How Does Keyway Broaching Benefit Your Production Needs?

Keyway broaching is a specialized process designed for creating slots that allow components to lock together effectively. This technique is essential in industries such as automotive and industrial machinery, where precision and fit are critical. Keyway broaching offers the advantage of producing accurate slots in a single pass, ensuring consistency and reliability in component assembly. Buyers should consider their specific requirements for keyways, including dimensions and tolerances, to determine if this broaching type meets their production needs.

Why Choose Blind Broaching for Your Hydraulic Components?

Blind broaching is ideal for producing features that do not extend through the entire workpiece, such as blind holes. This method is particularly beneficial in applications requiring tight tolerances and dimensional control, making it a popular choice for hydraulic components and custom mechanical assemblies. While blind broaching provides exceptional accuracy, buyers should be aware of its depth limitations, which may affect its applicability for certain projects.

What Are the Advantages of Rotary Broaching in Custom Manufacturing?

Rotary broaching, also known as wobble broaching, is used to create non-circular shapes in a workpiece. This technique is favored for its speed and efficiency, making it suitable for high-demand industries like medical device manufacturing and aerospace. Rotary broaching allows for the production of intricate features in a single operation, but it requires careful setup to ensure accuracy. Buyers should evaluate their material types and design complexities to see if rotary broaching aligns with their production goals.

How Does Pot Broaching Facilitate High-Precision Manufacturing?

Pot broaching employs multiple broaching tools to produce complex internal shapes, making it a valuable method for high-precision manufacturing. This technique is particularly well-suited for producing splines and gears in high volumes. While pot broaching can deliver intricate profiles efficiently, it often requires custom tooling, which can lead to higher initial costs. Buyers should weigh the benefits of precision against the investment in tooling when considering pot broaching for their projects.

Key Industrial Applications of external broaching services

| Industry/Sector | Specific Application of external broaching services | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of precision gears and shafts | Enhances performance and reliability of vehicle components | Need for high precision, tight tolerances, and material compatibility. |

| Aerospace | Manufacturing of complex airframe components | Reduces weight while maintaining structural integrity | Compliance with stringent safety and quality standards. |

| Industrial Equipment | Fabrication of hydraulic components | Improves efficiency and longevity of machinery operations | Custom tooling requirements and volume production capacity. |

| Medical Devices | Creation of intricate housings and fittings | Ensures reliability and safety in critical applications | Need for biocompatible materials and high precision. |

| Defense Manufacturing | Production of specialized components for armaments | Supports operational effectiveness and reliability | Adherence to military specifications and durability standards. |

How is External Broaching Used in the Automotive Industry?

In the automotive sector, external broaching services are crucial for producing precision gears and shafts that are essential for vehicle performance. This process ensures that components fit together seamlessly, improving overall reliability and efficiency. Buyers from this industry should prioritize suppliers who can deliver high precision and tight tolerances, as any deviation can lead to significant operational issues. Additionally, compatibility with various material types is necessary to meet the diverse demands of automotive applications.

What Role Does External Broaching Play in Aerospace Manufacturing?

Aerospace manufacturers leverage external broaching services to create complex airframe components that are both lightweight and structurally sound. The precision achieved through broaching is vital for meeting the rigorous safety standards of the industry. International buyers should focus on suppliers who are compliant with aerospace certifications and quality control measures. Understanding the nuances of broaching processes and the specific requirements of aerospace applications can lead to better sourcing decisions.

Why is External Broaching Important for Industrial Equipment?

In the realm of industrial equipment, external broaching is employed for fabricating hydraulic components such as valves and pumps. This service enhances the efficiency and longevity of machinery operations, which is critical for maintaining productivity. Buyers should consider suppliers who can provide custom tooling and demonstrate high-volume production capabilities, ensuring that they can meet fluctuating market demands and maintain operational efficiency.

How Do Medical Devices Benefit from External Broaching Services?

External broaching services are pivotal in the medical device industry for creating intricate housings and fittings that require high precision. The reliability and safety of medical devices depend significantly on the accuracy of these components. Buyers in this sector should seek suppliers with expertise in biocompatible materials and stringent quality control processes to ensure compliance with health regulations. This attention to detail not only safeguards patient safety but also enhances the overall performance of medical devices.

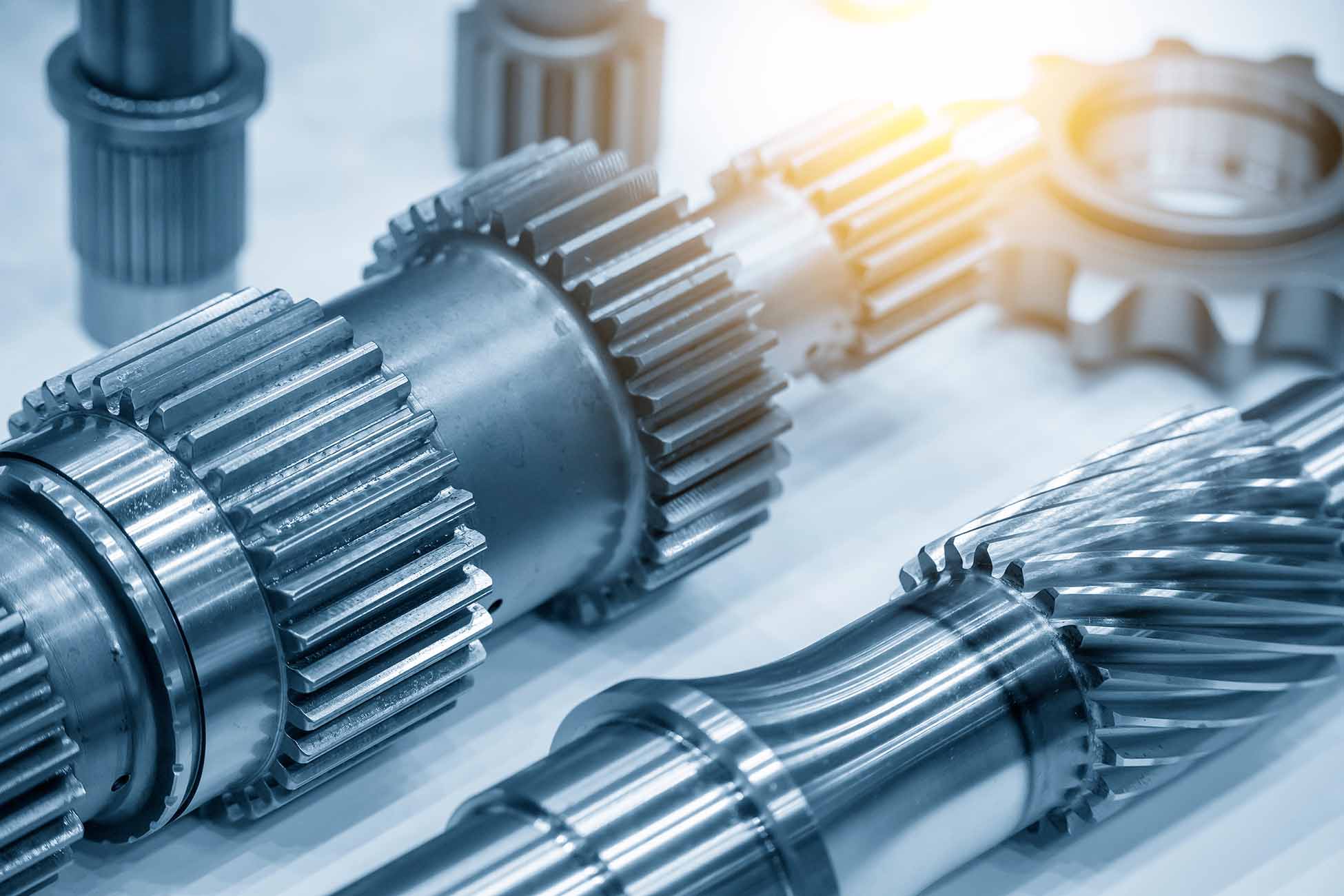

Illustrative image related to external broaching services

In What Ways Does External Broaching Support Defense Manufacturing?

In defense manufacturing, external broaching is utilized for producing specialized components that are integral to armaments and military equipment. The operational effectiveness of these components relies heavily on their precision and durability. Buyers should prioritize sourcing from suppliers who adhere to military specifications and can demonstrate a robust quality assurance framework. Understanding the specific requirements of defense applications can facilitate better partnerships and ensure the reliability of critical components.

3 Common User Pain Points for ‘external broaching services’ & Their Solutions

Scenario 1: Unexpected Production Delays Impacting Timelines

The Problem: In the fast-paced world of manufacturing, timely delivery is crucial. A B2B buyer sourcing external broaching services may find themselves facing unexpected production delays due to machine breakdowns, tool failures, or unanticipated demand surges. These delays can have a ripple effect, disrupting the entire supply chain, leading to missed deadlines, and potentially damaging client relationships.

The Solution: To mitigate production delays, buyers should establish a robust partnership with a reliable broaching service provider that emphasizes preventive maintenance and rapid response capabilities. When evaluating potential partners, inquire about their equipment maintenance schedules and their inventory of spare parts. A provider with a large inventory of machines and tooling, as well as a dedicated team for maintenance and quick repairs, can significantly reduce downtime. Additionally, consider engaging in a service-level agreement (SLA) that outlines specific performance metrics, including turnaround times and penalties for missed deadlines. This proactive approach ensures that your production schedules remain intact, even in the face of unforeseen challenges.

Scenario 2: Difficulty in Achieving Precision and Quality Standards

The Problem: Buyers often struggle with achieving the desired precision and quality in their broached components, particularly in industries with stringent tolerances, such as aerospace and automotive. Issues such as tool wear, incorrect broaching parameters, or material inconsistencies can lead to parts that do not meet specifications, resulting in costly rework and scrap.

The Solution: To ensure high precision and quality in broaching services, it is essential to collaborate closely with your service provider to define clear specifications and tolerances upfront. Provide detailed drawings and, if possible, prototypes to help the broaching service understand your requirements fully. Furthermore, inquire about their quality control processes, including in-process inspections and final verification methods. A reputable broaching service will utilize advanced measurement technologies, such as coordinate measuring machines (CMM), to ensure that each part meets the specified tolerances. Additionally, ask for samples of previous work or client testimonials that can attest to their precision capabilities. By establishing clear communication and quality expectations, you can significantly enhance the accuracy of the components produced.

Scenario 3: Uncertainty in Cost and Budget Management

The Problem: B2B buyers often face uncertainty regarding the costs associated with external broaching services, which can lead to budget overruns and financial strain. Hidden costs related to tooling, setup, and unforeseen rework can make it difficult to predict total expenditure accurately, causing friction in project management and financial planning.

The Solution: To address cost uncertainties, buyers should engage in thorough discussions with potential broaching service providers about pricing structures, including any additional fees for tooling, setup, or rush orders. Request a detailed quote that breaks down each component of the pricing model. Additionally, consider sourcing multiple quotes to compare pricing and services offered. This competitive analysis not only helps in identifying the best value but also provides leverage in negotiations. Furthermore, establishing a fixed-price contract for larger projects can mitigate the risk of unexpected expenses. By being proactive and transparent in budget discussions, you can ensure that financial expectations are aligned and avoid surprises down the line.

Strategic Material Selection Guide for external broaching services

What Are the Key Properties of Common Materials Used in External Broaching Services?

External broaching services can accommodate a range of materials, each with distinct properties that influence their performance in various applications. Understanding these properties is crucial for B2B buyers aiming to select the right material for their specific needs.

How Does Steel Perform in External Broaching Applications?

Steel is one of the most commonly used materials in external broaching due to its excellent mechanical properties. It offers high strength, durability, and resistance to wear, making it suitable for applications requiring high pressure and temperature ratings. Steel can be alloyed with various elements to enhance its properties, such as chromium for corrosion resistance or carbon for increased hardness.

Pros: Steel is durable and cost-effective, making it an ideal choice for high-volume production. Its versatility allows it to be used in a wide range of applications, from automotive components to industrial machinery.

Cons: While steel is strong, it can be susceptible to corrosion if not properly treated or coated. Additionally, the manufacturing complexity can increase with certain steel grades, which may require specialized broaching tools.

Impact on Application: Steel is compatible with various media types, including oils and gases, making it suitable for hydraulic and pneumatic systems. However, its performance can be compromised in highly corrosive environments unless treated.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or DIN. Preference for certain steel grades may vary based on regional availability and application requirements.

What Are the Benefits of Using Aluminum in Broaching?

Aluminum is another popular choice for external broaching, particularly in lightweight applications. It is known for its excellent corrosion resistance, low density, and good thermal conductivity. These properties make aluminum suitable for industries such as aerospace and automotive.

Pros: The lightweight nature of aluminum reduces overall product weight, which is advantageous in applications where weight savings are critical. Its corrosion resistance extends the life of the end product, making it suitable for outdoor or harsh environments.

Cons: Aluminum is generally less durable than steel, which can limit its use in high-stress applications. Additionally, it may be more expensive than some steel options, depending on the alloy used.

Impact on Application: Aluminum is compatible with various media, including water and certain chemicals, but it may not perform well in high-temperature applications.

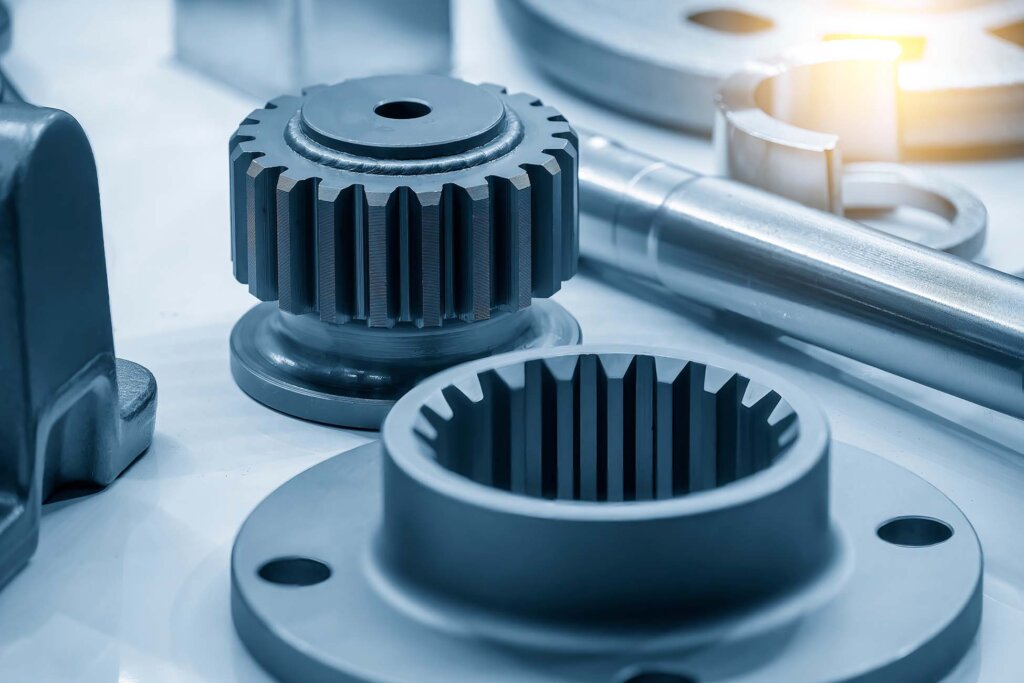

Illustrative image related to external broaching services

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of specific aluminum standards, such as EN or JIS, and consider the availability of specific alloys in their regions.

Why Is Brass a Viable Option for External Broaching?

Brass is often used in external broaching due to its excellent machinability and corrosion resistance. It is commonly found in plumbing and electrical applications where non-ferrous materials are preferred.

Pros: Brass offers good strength and is highly resistant to corrosion, making it ideal for applications exposed to moisture. Its machinability allows for complex shapes to be broached efficiently.

Cons: Brass can be more expensive than steel and aluminum. It is also less robust under high-stress conditions, which may limit its application scope.

Impact on Application: Brass is highly compatible with water and various chemicals, making it suitable for plumbing fittings and electrical components.

Illustrative image related to external broaching services

Considerations for International Buyers: Buyers should check for compliance with local standards, such as ASTM B16 for brass fittings, and consider the implications of using brass in specific environments, especially in regions with stringent regulations.

Summary Table of Material Selection for External Broaching Services

| Material | Typical Use Case for external broaching services | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive components, industrial machinery | High strength and durability | Susceptible to corrosion without treatment | Medium |

| Aluminum | Aerospace parts, lightweight automotive applications | Lightweight and corrosion-resistant | Less durable under high stress | High |

| Brass | Plumbing fittings, electrical components | Excellent machinability and corrosion resistance | Higher cost and lower strength | Medium |

This strategic material selection guide provides a comprehensive overview of the key materials used in external broaching services, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for external broaching services

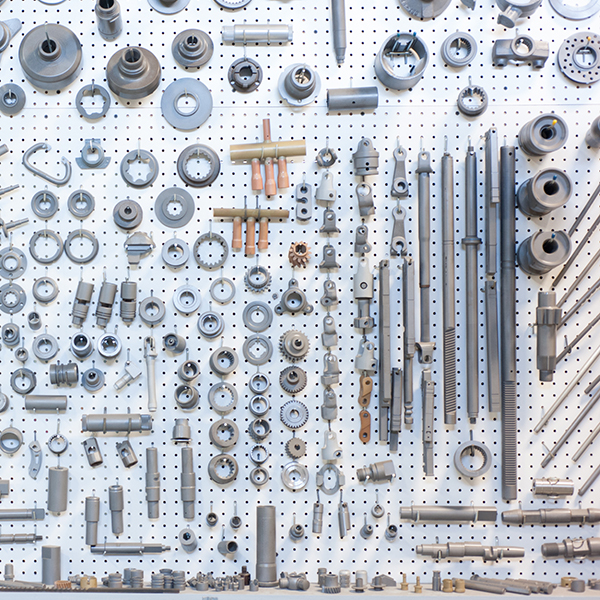

What Are the Main Stages of the Manufacturing Process for External Broaching Services?

The manufacturing process for external broaching services involves several critical stages that ensure precision and quality in the final product. Understanding these stages can help B2B buyers make informed decisions when selecting a broaching service provider.

How Does Material Preparation Impact the Broaching Process?

Material preparation is the first step in the external broaching process. It involves selecting the right material based on the desired mechanical properties and end-use application. Common materials include various metals, plastics, and composites. Once selected, the materials undergo cutting and shaping to the appropriate dimensions, which may involve processes such as sawing or CNC machining. Proper preparation is vital, as the quality of the material directly affects the broaching outcome, influencing precision, surface finish, and overall performance.

Illustrative image related to external broaching services

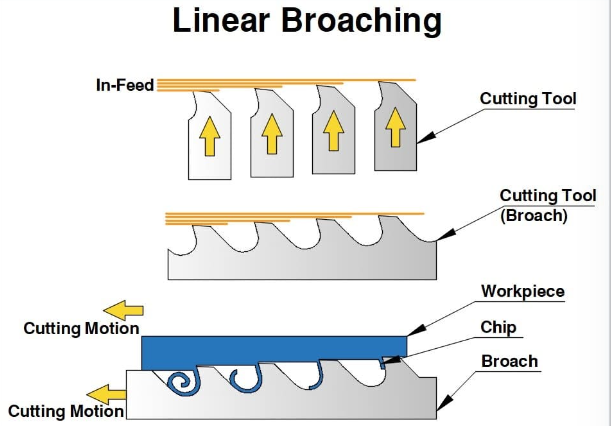

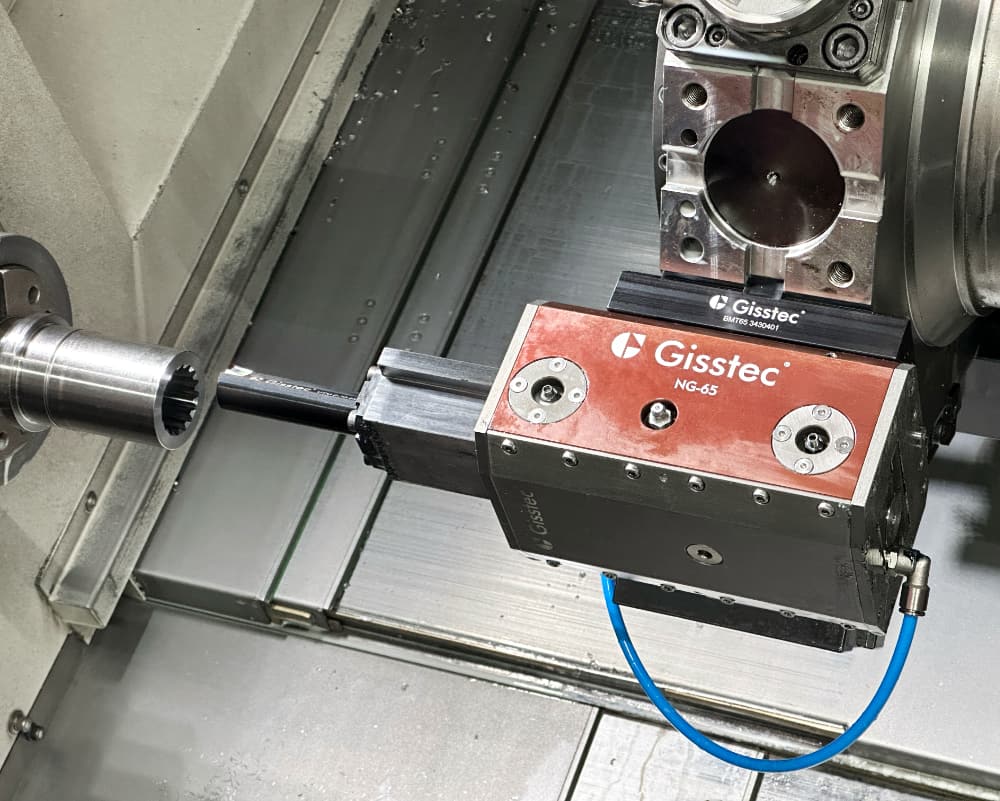

What Techniques Are Employed During the Forming Stage of Broaching?

The forming stage is where the actual broaching takes place. This involves utilizing a broach, a specialized tool with a series of progressively larger teeth, which cuts the material to create external features such as keyways, splines, and slots. The broach is either pulled or pushed through the workpiece, allowing each tooth to remove a precise amount of material. The choice of broaching technique—whether flat, surface, or rotary broaching—depends on the shape and complexity of the desired feature. Proper alignment and tool maintenance are crucial during this stage to ensure consistent results.

What Role Does Assembly Play in the Broaching Process?

While external broaching primarily focuses on the machining of components, assembly can be a vital part of the process, particularly for complex products requiring multiple broached parts. This stage may involve fitting the broached components with other machined parts, ensuring they meet specified tolerances and function correctly within the final assembly. Effective communication between the broaching service provider and the buyer is essential to align assembly processes with the overall manufacturing plan.

How Is Finishing Achieved in External Broaching Services?

Finishing is the final stage in the broaching process, where the components undergo additional treatments to enhance their surface quality and functional characteristics. Techniques may include polishing, grinding, or applying coatings to improve wear resistance and reduce friction. The finishing stage is critical for components that operate in high-stress environments, such as automotive or aerospace applications, where precision and durability are paramount. By focusing on finishing, manufacturers ensure that their broached parts meet both aesthetic and functional requirements.

What Quality Assurance Measures Are Implemented in External Broaching Services?

Quality assurance is a cornerstone of the external broaching service industry, ensuring that components meet international standards and customer specifications. For B2B buyers, understanding these quality control measures is essential for selecting reliable suppliers.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are crucial in the broaching industry. This standard focuses on quality management systems, ensuring that companies continuously improve their processes and maintain high product quality. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) certifications for the oil and gas sector may also be relevant, depending on the application of the broached components. Buyers should seek suppliers who possess these certifications, as they reflect a commitment to quality and compliance with regulatory requirements.

What Are the Key Quality Control Checkpoints in the Broaching Process?

Quality control in external broaching services typically involves several checkpoints throughout the manufacturing process. Incoming Quality Control (IQC) checks the quality of raw materials before production begins. In-Process Quality Control (IPQC) involves monitoring the broaching process to ensure that dimensions and tolerances are maintained during machining. Finally, Final Quality Control (FQC) occurs after the components are completed, where they undergo rigorous testing to verify that they meet the specified standards. Each of these checkpoints plays a vital role in maintaining quality throughout the production cycle.

How Are Common Testing Methods Utilized to Ensure Quality?

Common testing methods in broaching include dimensional checks, surface finish evaluations, and material property assessments. Techniques such as coordinate measuring machines (CMM) are often employed to verify dimensions accurately. Surface roughness testers can assess the quality of the finish, while tensile and hardness tests ensure that the material properties meet specified requirements. Implementing these testing methods helps manufacturers identify any defects early, reducing the risk of non-compliance with customer specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. One effective approach is to conduct regular audits of the supplier’s facilities and quality management systems. This can involve reviewing documentation, observing production processes, and assessing compliance with international standards. Additionally, suppliers should provide detailed quality reports that outline their quality control measures, including test results and process validations.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital. Different regions may have varying regulatory requirements and standards, necessitating that buyers familiarize themselves with local compliance issues. Additionally, cultural differences in business practices may impact supplier relationships. Buyers should prioritize communication and transparency to ensure that their expectations regarding quality and delivery are clearly understood and met.

Illustrative image related to external broaching services

Conclusion

By comprehensively understanding the manufacturing processes and quality assurance measures associated with external broaching services, B2B buyers can make informed decisions when selecting suppliers. Focusing on material preparation, forming techniques, assembly, and finishing, along with robust quality control protocols, ensures that the broached components meet the highest standards of precision and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘external broaching services’

Introduction

Sourcing external broaching services requires careful consideration to ensure that you select a provider that meets your specific manufacturing needs. This checklist serves as a practical guide to help B2B buyers navigate the complexities of procuring broaching services, particularly in diverse markets like Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your selection process and make informed decisions.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, it is essential to have a clear understanding of your technical requirements. Specify the types of external broaching you need—such as surface, keyway, or rotary broaching—and detail the materials you will be working with. This clarity will help suppliers assess their capability to meet your demands effectively.

- Material Types: Identify whether you require broaching for metals, plastics, or composites.

- Tolerances and Finishes: Establish the precision and surface finish you expect to ensure compatibility with your overall project.

Step 2: Research Potential Suppliers

Take the time to research various broaching service providers. Look for companies with a strong track record in your industry and positive reviews from previous clients. A well-established supplier is more likely to have the experience and resources necessary to handle your project efficiently.

Illustrative image related to external broaching services

- Industry Experience: Focus on suppliers that have worked with businesses similar to yours.

- Geographic Location: Consider the logistical implications of supplier location, especially for international shipping.

Step 3: Evaluate Supplier Capabilities

Assess the technical capabilities of potential suppliers. This includes reviewing their machinery, technology, and production capacity. A capable supplier should have modern equipment and the ability to handle both large and small production runs.

- Technology Assessment: Inquire about the types of broaching machines used and their maintenance history.

- Production Volume: Ensure that the supplier can accommodate your order size without compromising quality.

Step 4: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes. Ensure that the quotes include all costs associated with the broaching services, such as tooling, setup, and delivery. Comparing these quotes will help you identify the best value for your investment.

- Cost Breakdown: Look for transparency in pricing to avoid unexpected expenses.

- Volume Discounts: Ask if they offer discounts for larger orders or long-term contracts.

Step 5: Verify Supplier Certifications

It’s crucial to ensure that your chosen supplier adheres to industry standards and possesses the necessary certifications. This not only guarantees the quality of the services provided but also enhances your supply chain’s credibility.

- Quality Management Systems: Check for certifications like ISO 9001 or industry-specific standards.

- Compliance with Regulations: Ensure they meet any relevant safety and environmental regulations applicable in your region.

Step 6: Conduct Site Visits or Virtual Tours

If feasible, arrange for a site visit or a virtual tour of the supplier’s facilities. This allows you to inspect their operations firsthand and assess their commitment to quality and efficiency. Observing the production environment can provide valuable insights into their practices.

Illustrative image related to external broaching services

- Operational Standards: Look for cleanliness, organization, and adherence to safety protocols.

- Employee Expertise: Engage with staff to gauge their knowledge and skills related to broaching services.

Step 7: Establish Communication Protocols

Effective communication is vital for a successful partnership. Clearly outline your expectations regarding project updates, timelines, and points of contact. Establishing a communication plan will facilitate smoother collaboration and help address any issues promptly.

- Regular Updates: Agree on the frequency and format of progress reports.

- Response Times: Set expectations for how quickly the supplier should respond to inquiries or concerns.

By following this checklist, you can enhance your sourcing process for external broaching services and ensure a successful partnership with your chosen supplier.

Comprehensive Cost and Pricing Analysis for external broaching services Sourcing

What Are the Key Cost Components for External Broaching Services?

When sourcing external broaching services, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type and quality of materials directly influence the cost of broaching services. Common materials such as aluminum, steel, and plastics vary in price, impacting overall service costs. Specialty materials may incur additional costs due to their unique processing requirements.

-

Labor: Skilled labor is essential in broaching operations. Labor costs can vary based on the complexity of the broaching task, the skill level required, and regional wage differences. In regions with a higher cost of living, labor expenses may be significantly elevated.

-

Manufacturing Overhead: This includes costs associated with the facilities, utilities, and equipment used in broaching services. Overhead costs are often spread across multiple jobs, making it essential for buyers to consider how these costs can affect pricing.

-

Tooling: Custom tooling, especially for specialized broaching tasks, can add to the initial setup costs. Some suppliers may offer tooling as part of their service, while others may charge separately, depending on the complexity of the job.

-

Quality Control (QC): Ensuring that broached components meet specified tolerances and quality standards requires robust QC processes. The cost of quality assurance can vary based on the level of certification (ISO, etc.) and testing required.

-

Logistics: Transportation costs for raw materials and finished products can impact overall pricing, especially for international shipments. Factors like distance, mode of transport, and shipping terms (Incoterms) will significantly influence logistics costs.

-

Margin: Suppliers typically incorporate a profit margin into their pricing structure. This margin can vary based on market competition, the supplier’s reputation, and their operational efficiencies.

What Influences the Pricing of External Broaching Services?

Several factors influence the pricing of external broaching services that buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from economies of scale, leading to reduced per-unit costs. However, buyers should be aware of any MOQ requirements, as these can affect initial order costs.

-

Specifications and Customization: Custom specifications may lead to increased costs due to the need for specialized tooling or adjustments in the manufacturing process. Clear communication of requirements is essential to avoid unexpected expenses.

-

Material Selection: The choice of material not only impacts the initial cost but also affects machining difficulty and the durability of the final product. Buyers should evaluate long-term needs against upfront costs.

-

Quality Certifications: Components requiring specific quality certifications can incur higher costs. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: The experience, reputation, and capabilities of the supplier can influence pricing. Established suppliers may charge a premium for their reliability and quality assurance.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is vital for international buyers, as these terms dictate who bears the shipping costs and risks.

What Tips Can Help Buyers Achieve Cost-Efficiency in External Broaching?

B2B buyers looking to optimize costs should consider the following strategies:

-

Negotiate Pricing: Engage suppliers in negotiations to explore potential discounts, especially for bulk orders. Building a relationship can lead to better pricing over time.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial pricing but also the long-term costs associated with maintenance, quality, and logistics. A lower initial price might not always equate to a better deal.

-

Understand Pricing Nuances for International Sourcing: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and import duties that may impact the overall cost of broaching services.

-

Request Detailed Quotes: Ensure that quotes break down costs clearly, allowing for better comparison across suppliers. This transparency can highlight areas where cost savings might be found.

Disclaimer on Pricing

Prices for external broaching services can vary significantly based on the aforementioned factors. It is advisable for buyers to request customized quotes from multiple suppliers to gain a comprehensive understanding of current market rates and to ensure the best value for their specific requirements.

Illustrative image related to external broaching services

Alternatives Analysis: Comparing external broaching services With Other Solutions

Understanding Alternatives to External Broaching Services

When evaluating manufacturing processes, it’s crucial to consider various solutions that can meet your specific production needs. External broaching services are known for their precision and efficiency in creating complex shapes and features. However, other viable alternatives exist that may better align with your operational requirements, budget constraints, or production volume. This analysis will compare external broaching services against two alternatives: CNC Machining and Stamping.

| Comparison Aspect | External Broaching Services | CNC Machining | Stamping |

|---|---|---|---|

| Performance | High precision for complex shapes | Excellent for intricate designs | Fast for high-volume production |

| Cost | Moderate to high, depending on complexity | Generally lower for simple parts | Cost-effective for large runs |

| Ease of Implementation | Requires specialized equipment | Widely available, easier setup | Requires tooling setup, can be complex |

| Maintenance | Regular tool maintenance needed | Minimal for CNC machines | Tooling maintenance required |

| Best Use Case | Low to medium volume, complex geometries | High precision, versatile applications | High volume, simple to moderate geometries |

In-Depth Analysis of Alternatives

CNC Machining: Is It Right for Your Project?

CNC machining is a versatile manufacturing process that utilizes computer-controlled machines to create complex parts from various materials. It excels in producing intricate designs and can accommodate a range of tolerances. One of the significant advantages of CNC machining is its ability to handle both simple and complex geometries without the need for specialized tooling for each new design. However, for high-volume production, CNC machining may not be as cost-effective as broaching due to longer cycle times. It’s best suited for projects requiring high precision and flexibility.

Stamping: A Cost-Effective Alternative for High Volumes

Stamping is a manufacturing process that shapes material, typically metal, using dies and presses. This method is incredibly efficient for high-volume production runs, allowing for rapid production cycles and lower per-unit costs. Stamping is ideal for producing simple to moderately complex shapes and can be highly automated. However, the initial tooling costs can be significant, and the process is less effective for intricate geometries that require high precision. Stamping is best used in industries like automotive manufacturing where large quantities of similar parts are required.

Choosing the Right Solution for Your Manufacturing Needs

Selecting the appropriate manufacturing solution depends on various factors, including the complexity of the part, production volume, and budget considerations. For low to medium volume runs requiring high precision and intricate designs, external broaching services may be the best fit. Conversely, if your needs lean towards high volume with simpler geometries, stamping could be the most cost-effective option. CNC machining offers a flexible middle ground, suitable for projects needing versatility and precision. Understanding these alternatives will empower B2B buyers to make informed decisions that align with their operational goals and resource availability.

Essential Technical Properties and Trade Terminology for external broaching services

What Are the Key Technical Properties in External Broaching Services?

When considering external broaching services, understanding critical specifications is essential for ensuring quality and performance in manufacturing processes. Here are some key technical properties to consider:

-

Material Grade

The material grade refers to the specific type of material used for the workpiece, which can include metals, plastics, or composites. Different grades offer varying levels of strength, ductility, and machinability. For B2B buyers, selecting the correct material grade is crucial for ensuring that the final product meets performance requirements and industry standards, such as aerospace or automotive specifications. -

Tolerance

Tolerance indicates the permissible limit of variation in a part’s dimensions. It is critical in broaching because even minor deviations can lead to significant issues in assembly and function. For instance, tighter tolerances are necessary for components in high-performance machinery. Understanding tolerance levels helps buyers specify their requirements accurately, ensuring that the finished parts will fit and function as intended. -

Surface Finish

The surface finish is a measure of the texture of the part’s surface, typically expressed in microinches or micrometers. A finer surface finish is often required for aesthetic purposes or to enhance performance characteristics, such as reducing friction in moving parts. B2B buyers should specify the desired surface finish to avoid issues related to wear and tear or aesthetic appeal in their final products. -

Broaching Speed

This refers to the rate at which the broach tool moves through the workpiece, impacting both production efficiency and the quality of the finish. Faster speeds can increase throughput but may compromise the precision of the broaching process. Buyers should understand the relationship between speed and quality to make informed decisions that align with their production timelines and quality expectations. -

Quantity and Production Volume

The volume of parts required can influence the broaching method chosen, as certain techniques are more suited for high-volume production. B2B buyers should communicate their expected quantities clearly, as this can affect cost, lead time, and the choice of tooling and machinery used in the process.

What Are Common Trade Terms in External Broaching Services?

Understanding industry jargon is vital for effective communication between buyers and service providers. Here are some common terms in the broaching industry:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of broaching services, OEMs often require precision broaching for components that meet strict specifications. Understanding this term helps buyers identify potential partners who can meet OEM standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to produce or sell. This is crucial for buyers, especially when considering cost-efficiency and production capabilities. Knowing the MOQ can help companies plan their budgets and production schedules effectively. -

RFQ (Request for Quote)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. For broaching services, an RFQ typically outlines the specifications, quantities, and timelines. This term is important for initiating the procurement process and ensuring that potential suppliers understand the buyer’s requirements. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Understanding these terms is vital for B2B buyers engaged in cross-border transactions, as they dictate who is responsible for shipping, insurance, and tariffs. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the finished product. In broaching services, lead time can vary significantly based on the complexity of the parts and the production volume. Buyers must factor lead time into their project timelines to avoid delays in production and delivery.

By grasping these essential technical properties and industry terms, B2B buyers can make more informed decisions when engaging with external broaching service providers, ensuring that they receive high-quality products that meet their specific manufacturing needs.

Navigating Market Dynamics and Sourcing Trends in the external broaching services Sector

What Are the Current Market Trends Influencing External Broaching Services?

The external broaching services sector is experiencing significant transformation driven by technological advancements and changing buyer preferences. Key trends include the increasing automation of broaching processes, which enhances efficiency and precision while reducing operational costs. This shift is particularly relevant for international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where competitive pricing and quality are paramount. Additionally, the demand for customized solutions is on the rise. Businesses are seeking external broaching services that can cater to specific project requirements, often resulting in shorter lead times and more tailored product offerings.

Another notable trend is the growing interest in digital technologies such as IoT and AI, which are being integrated into broaching operations. These technologies facilitate predictive maintenance and real-time monitoring, thus minimizing downtime and ensuring consistent quality. Furthermore, as global supply chains become increasingly complex, buyers are focusing on sourcing partners that demonstrate resilience and flexibility in their operations. This trend is especially crucial for international buyers who must navigate varying regulations and standards across different markets.

How Is Sustainability and Ethical Sourcing Shaping the External Broaching Services Industry?

Sustainability has emerged as a critical factor in the sourcing of external broaching services. B2B buyers are now more conscious of the environmental impact of their suppliers, leading to a heightened demand for companies that prioritize eco-friendly practices. This includes the use of recyclable materials, energy-efficient manufacturing processes, and reducing waste through lean production methodologies. Buyers should look for suppliers that possess certifications such as ISO 14001, which indicates a commitment to effective environmental management systems.

Ethical sourcing is also becoming a priority, as businesses seek partners that maintain transparent supply chains and uphold labor rights. This demand is particularly relevant for international buyers who are increasingly scrutinizing their suppliers’ ethical practices, especially in regions where labor laws may be less stringent. By choosing suppliers committed to ethical practices, companies not only enhance their brand reputation but also mitigate risks associated with compliance and supply chain disruptions.

What Historical Developments Have Shaped the External Broaching Services Landscape?

The evolution of external broaching services can be traced back over a century, with the technique originally developed for cutting keyways in firearms. Over time, broaching has evolved into a sophisticated machining process that plays a vital role in various industries, including automotive, aerospace, and industrial equipment manufacturing. The introduction of automated broaching machines in the mid-20th century revolutionized the industry, allowing for greater precision and efficiency in production.

As manufacturing demands have intensified, the broaching process has adapted to meet new challenges. Today, advancements in tool design and material science have led to the development of specialized broaches capable of producing intricate shapes and features. This historical context is essential for B2B buyers, as understanding the evolution of broaching services can inform their sourcing decisions and highlight the importance of partnering with suppliers that have a proven track record and technological expertise.

Conclusion: Strategic Insights for B2B Buyers

In summary, international B2B buyers seeking external broaching services must navigate a dynamic market characterized by technological advancements, sustainability considerations, and historical context. By focusing on suppliers that offer innovative solutions, demonstrate a commitment to ethical practices, and possess a deep understanding of the broaching process, businesses can ensure they are well-positioned to meet their manufacturing needs efficiently and responsibly.

Frequently Asked Questions (FAQs) for B2B Buyers of external broaching services

-

1. How do I choose the right external broaching service provider for my needs?

Choosing the right external broaching service provider involves assessing their capabilities, experience, and quality assurance measures. Look for suppliers with a strong track record in your specific industry and product type. Request case studies or references from previous clients to gauge their expertise. Additionally, verify their equipment and technology to ensure they can meet your precision and volume requirements. It’s also beneficial to check for certifications like ISO to ensure adherence to quality standards. -

2. What are the typical minimum order quantities (MOQs) for external broaching services?

Minimum order quantities for external broaching services can vary significantly based on the supplier’s capabilities and your project requirements. Generally, MOQs may range from a few hundred to several thousand parts. It’s essential to communicate your specific needs to potential suppliers, as many are willing to accommodate smaller runs for prototyping or testing purposes. Always clarify MOQs upfront to avoid unexpected costs or delays. -

3. How can I ensure the quality of the broached parts I receive?

To ensure quality, it is crucial to partner with a broaching service provider that implements stringent quality control measures. Inquire about their inspection processes, such as dimensional checks and surface finish evaluations, and whether they utilize advanced measuring equipment. Request documentation of their quality management system, including certifications like ISO 9001. Regular communication during production can also help address any concerns before parts are shipped. -

4. What types of materials can be broached, and how do they affect the process?

External broaching can accommodate a variety of materials, including metals, plastics, and composites. The choice of material significantly impacts the broaching process, affecting tool selection, cutting speeds, and coolant requirements. For instance, harder materials may require specialized broaches and slower cutting speeds to prevent tool wear. Discuss your material specifications with potential suppliers to ensure they have the necessary tools and expertise for your project. -

5. What payment terms should I expect when sourcing external broaching services internationally?

Payment terms for international broaching services can vary widely based on the supplier and the nature of the transaction. Common arrangements include upfront deposits, payment upon delivery, or net terms (e.g., net 30 or net 60 days). It’s advisable to negotiate terms that align with your cash flow and project timelines. Ensure that the terms are clearly outlined in your contract to avoid misunderstandings later in the process. -

6. How does international shipping work for broached components?

International shipping for broached components typically involves coordination between the supplier, freight forwarders, and customs authorities. Suppliers should provide packaging that protects parts during transit, and you may need to arrange for shipping insurance. Be aware of customs duties and import regulations in your country, as these can affect delivery times and costs. Establish a clear timeline with your supplier to ensure timely delivery of your components. -

7. What customization options are available for external broaching services?

Many broaching service providers offer customization options to meet specific design requirements. This may include custom tooling, unique shapes, or specific surface finishes. When discussing your project, provide detailed specifications and drawings to facilitate accurate quotations and tooling designs. Some suppliers may also offer prototyping services to test designs before full production, allowing for adjustments based on performance and fit. -

8. How can I effectively vet a potential broaching service supplier?

To effectively vet a potential broaching service supplier, conduct thorough research on their reputation and track record. Look for customer reviews, industry certifications, and case studies that demonstrate their capabilities. It’s beneficial to request site visits or virtual tours of their facilities to assess their equipment and production processes. Additionally, engaging in direct communication can help gauge their responsiveness and willingness to collaborate on your project needs.

Top 6 External Broaching Services Manufacturers & Suppliers List

1. Miller Broach – Custom Broaching Solutions

Domain: millerbroach.com

Registered: 2002 (23 years)

Introduction: Broaching Services, In-House Production Services, Custom Carbide Tooling, Broaching Tools, Broaching Tool Design, Pot Broaches, Round Broaches, Flat Broaches, Cut-Off Tooling, Fixture Design and Build, Machine Re-Tool, Broach Holder Services, New Broach Tooling, Broach Sharpening & Reconditioning, Production Broaching, Grinding & CNC Grinding, New/Used/Rebuilt – Broach Machines, CNC Sawing, CNC Ma…

2. Broaching Job Shops – Precision Broaching Services

Domain: broachingjobshops.com

Registered: 2006 (19 years)

Introduction: Broaching is a metalworking process that creates precision holes, slots, and contours in materials such as metal, plastic, and composites. Key types of broaching services include: 1. Blind Broaching: Creates closed-end features with exceptional dimensional control, ideal for hydraulic components and automotive engine parts. 2. Internal Broaching: Produces internal features like keyways and splines…

3. IQS Directory – Broaching Services

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Broaching services and machinery, including keyway broaches, blind splines, surface cuts, pot broaching, surface broaching, and turnkey broaching cells. Precision broaching for internal, external, surface, and form broaching on various materials. Industries served include aerospace, automotive, commercial, and military. Additional services include CNC operations, hobbing, shaping, tooling, machini…

4. Sturdy Broaching – Precision Broaching Services

Domain: sturdybroaching.com

Registered: 2006 (19 years)

Introduction: Broaching Services: Production broaching in prototype or production quantities. Surface Broaching: Capable of broaching most external configurations with closer tolerances and better surface finishes than milling or shaping. Keyway Broaching: Keyway broaches available for widths from 3/32″ to 5/8″. Internal Broaching: Large inventory of internal broaches including square, hex, octagon, involute sp…

5. V W Broaching – Comprehensive Broaching Services

Domain: vwbroaching.com

Registered: 1996 (29 years)

Introduction: V W Broaching Service offers a variety of broaching services including blind broaching, external broaching, high speed broaching, horizontal broaching, internal shapes broaching (such as double D, double hex, hex involute splines, square, straight sided spline, triple square, and keyway broaching), pot broaching, and specialty broaching (including continuous chain, multiple pass, spiral, straddle,…

6. Precision Gears – Custom Keyway & Broaching Services

Domain: precisiongears.com

Registered: 1998 (27 years)

Introduction: Custom Keyway and Broaching Services offered by Precision Gears, Inc. include:

1. **Shaping Services**:

– Width: 1/16” to 3/8”

– Depth: 0.032” to 0.1875”

– Length: up to 6”

2. **Broaching Services**:

– Width: 0.063” up to 1”

– Depth: 0.031” to 0.5”

– Length: up to 5”

– Large variety of broach bars in stock for internal spline needs.

3. **Materials Used**:

– Metals: alloy…

Strategic Sourcing Conclusion and Outlook for external broaching services

In the evolving landscape of global manufacturing, the strategic sourcing of external broaching services presents a significant opportunity for businesses across diverse sectors. By leveraging precision broaching techniques, companies can ensure the production of high-quality components that meet stringent specifications, thereby enhancing their operational efficiency and product reliability. Understanding the various broaching methods—such as surface, internal, and rotary broaching—enables buyers to select the most suitable solutions tailored to their specific manufacturing needs.

As international buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize their supply chains, investing in reliable broaching partners is crucial. The ability to access advanced broaching technologies and expertise can lead to substantial cost savings, improved lead times, and superior product quality.

Looking forward, the demand for precise, efficient manufacturing solutions will continue to rise. Buyers are encouraged to explore partnerships with established broaching service providers who can offer innovative approaches and custom tooling options. Engage with industry leaders today to secure a competitive edge in your manufacturing processes and drive sustainable growth for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.