Expanded Metal Lath: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for expanded metal lath

In the competitive landscape of construction materials, sourcing high-quality expanded metal lath can be a daunting challenge for B2B buyers, especially when navigating diverse international markets. This guide aims to demystify the complexities of procuring expanded metal lath, a versatile and essential component used in various applications, from stucco and plaster to decorative features in architecture. With an emphasis on the unique needs of buyers from regions such as Africa, South America, the Middle East, and Europe—specifically countries like Nigeria and Brazil—this comprehensive resource provides insights into different types of metal lath, their specific applications, and the critical factors to consider when vetting suppliers.

Understanding the diverse offerings available, including dimpled, grooved, and diamond mesh lath, is crucial for making informed purchasing decisions. This guide not only outlines the technical specifications and performance characteristics of each type but also addresses the logistical aspects of sourcing, including cost considerations and compliance with regional building codes. By empowering international buyers with the knowledge to assess quality, negotiate pricing, and ensure timely delivery, this resource serves as a valuable tool in optimizing your construction projects. Whether you are a contractor, distributor, or architect, leveraging the insights provided here will enhance your ability to procure the right materials that meet both functional and aesthetic requirements.

Understanding expanded metal lath Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Diamond Mesh Lath | Galvanized steel, formed to create hundreds of keys per square yard | Stucco, plaster, stone veneer, fireproofing | Pros: Excellent strength, flexibility; Cons: Requires proper installation techniques. |

| Dimpled Self-Furred Metal Lath | Dimpled surface for enhanced plaster adhesion | Ceilings, soffits, interior walls | Pros: Improved bonding; Cons: Slightly higher cost than standard lath. |

| Grooved Self-Furred Metal Lath | Grooved design for better plaster grip | Exterior stucco, interior gypsum plaster | Pros: Effective for heavy applications; Cons: Heavier, which may increase shipping costs. |

| Paper-Backed Metal Lath | Includes a weather-resistant paper backing | Exterior applications, moisture-prone environments | Pros: Added moisture barrier; Cons: More expensive due to added materials. |

| Expanded Metal Lath Without Paper | Lightweight, no backing, suitable for various applications | General construction, ornamental work | Pros: Cost-effective; Cons: Less resistant to moisture without backing. |

What Are the Key Characteristics of Diamond Mesh Lath?

Diamond Mesh Lath is widely recognized for its versatility and strength, making it a popular choice in the construction industry. This lath is made from galvanized steel and features a diamond pattern that creates numerous keys for excellent plaster adhesion. It is particularly suitable for stucco applications, stone veneer, and even as a reinforcing layer for fireproofing. Buyers should consider the installation requirements and ensure that their teams are equipped to handle its specific needs.

How Does Dimpled Self-Furred Metal Lath Enhance Performance?

Dimpled Self-Furred Metal Lath features a unique dimpled surface that significantly improves plaster adhesion. This type is ideal for ceilings, soffits, and interior walls, where a strong bond is crucial. Its design minimizes the risk of plaster cracking or detaching over time. For B2B buyers, the investment in dimpled lath can lead to long-term durability and reduced maintenance costs, although it may come at a slightly higher initial price.

What Advantages Does Grooved Self-Furred Metal Lath Offer?

Grooved Self-Furred Metal Lath is specifically designed to provide superior grip for plaster applications. The grooves enhance the bonding surface, making it particularly effective for heavier applications such as exterior stucco. This lath is heavier than standard options, which may increase shipping costs, but its durability in demanding environments often justifies the expense. Buyers should evaluate their specific project needs to determine if the benefits outweigh the costs.

Why Choose Paper-Backed Metal Lath for Moisture-Prone Areas?

Paper-Backed Metal Lath includes a weather-resistant paper backing that provides an additional layer of protection against moisture. This makes it an excellent choice for exterior applications in climates that experience heavy rainfall or humidity. While it is more expensive than traditional lath options, the added moisture barrier can prevent costly repairs in the long run. B2B buyers in regions prone to moisture should consider this type for enhanced durability.

What Makes Expanded Metal Lath Without Paper a Cost-Effective Option?

Expanded Metal Lath Without Paper is a lightweight and economical solution for various construction needs. It is suitable for general applications and ornamental work where moisture is not a significant concern. While this option is cost-effective, buyers should be aware that it lacks the moisture resistance of paper-backed varieties. This trade-off may be acceptable for projects in dry environments or where budget constraints are a priority.

Key Industrial Applications of expanded metal lath

| Industry/Sector | Specific Application of Expanded Metal Lath | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Stucco and Plaster Base | Provides a strong, flexible base for plaster, enhancing durability and aesthetics. | Ensure compliance with local building codes and standards. |

| Fireproofing | Reinforcement for Fireproofing Materials | Enhances fire resistance and structural integrity in commercial buildings. | Look for products with certified fire ratings and durability. |

| Interior Design | Decorative Wall Panels | Allows for intricate designs and shapes, increasing aesthetic appeal. | Source high-quality, rust-resistant options for longevity. |

| Infrastructure Development | Facade Systems | Supports various facade materials, improving energy efficiency and weather resistance. | Consider local climate conditions for material selection. |

| HVAC and Electrical Installations | Support for Ductwork and Wiring | Provides a stable framework for securing ducts and electrical components. | Ensure compatibility with existing systems and ease of installation. |

How is Expanded Metal Lath Used in Construction for Stucco and Plaster Base?

In construction, expanded metal lath serves as a robust substrate for stucco and plaster applications. Its unique design, featuring a series of “keys,” ensures excellent adhesion of plaster, resulting in a durable finish. This is particularly valuable in regions with extreme weather conditions, as it provides flexibility and strength, preventing cracking and peeling. International buyers should prioritize sourcing lath that meets local building codes and standards to ensure compliance and quality.

What Role Does Expanded Metal Lath Play in Fireproofing Applications?

Expanded metal lath is essential in fireproofing applications, acting as a reinforcing agent for fire-resistant materials. It enhances the structural integrity of fireproofing systems, making it ideal for commercial construction. This application is crucial in regions with stringent fire safety regulations, as it helps meet compliance while providing reliable protection. Buyers should seek products with certified fire ratings and durability to ensure optimal performance in high-risk environments.

How Can Interior Designers Utilize Expanded Metal Lath for Decorative Wall Panels?

Interior designers leverage expanded metal lath to create decorative wall panels, allowing for intricate designs that enhance the aesthetic appeal of spaces. Its flexibility facilitates the creation of both flat and contoured surfaces, making it a versatile choice for various design styles. For international buyers, sourcing high-quality, rust-resistant lath is essential to ensure longevity and maintain visual integrity in diverse climates.

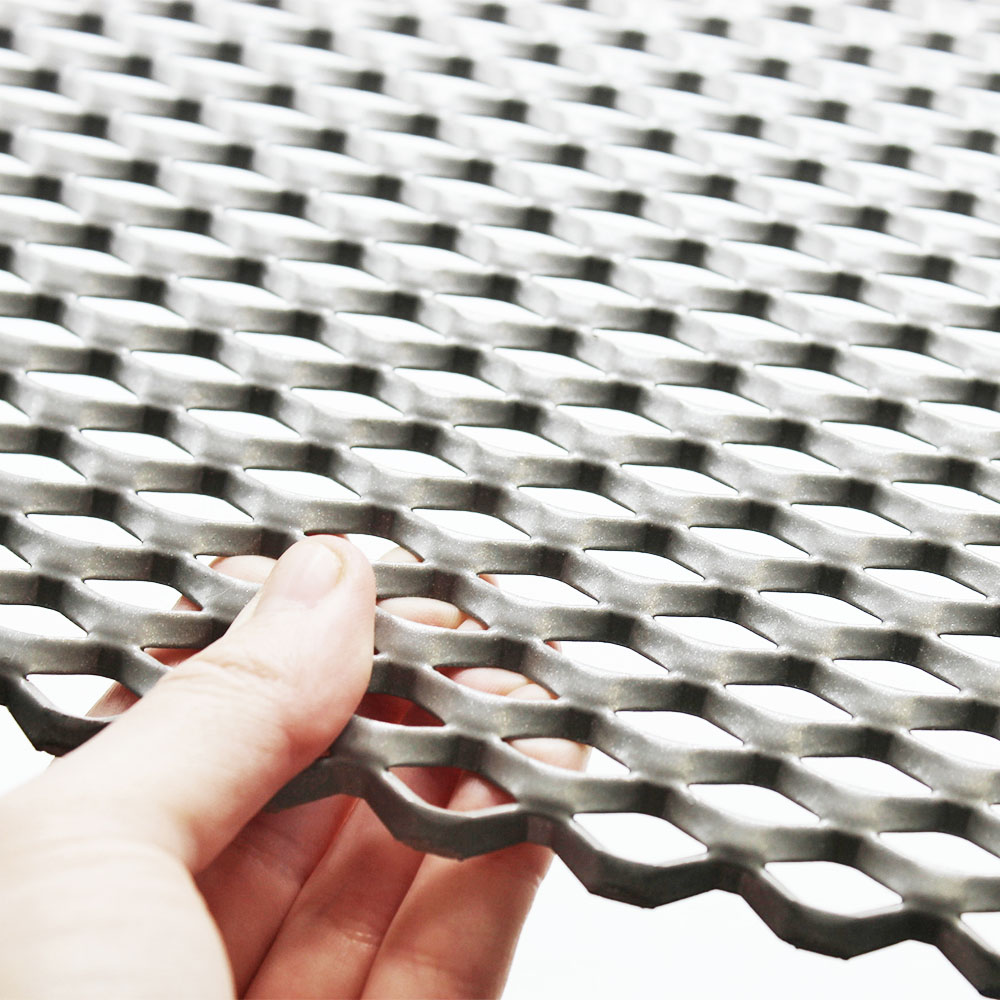

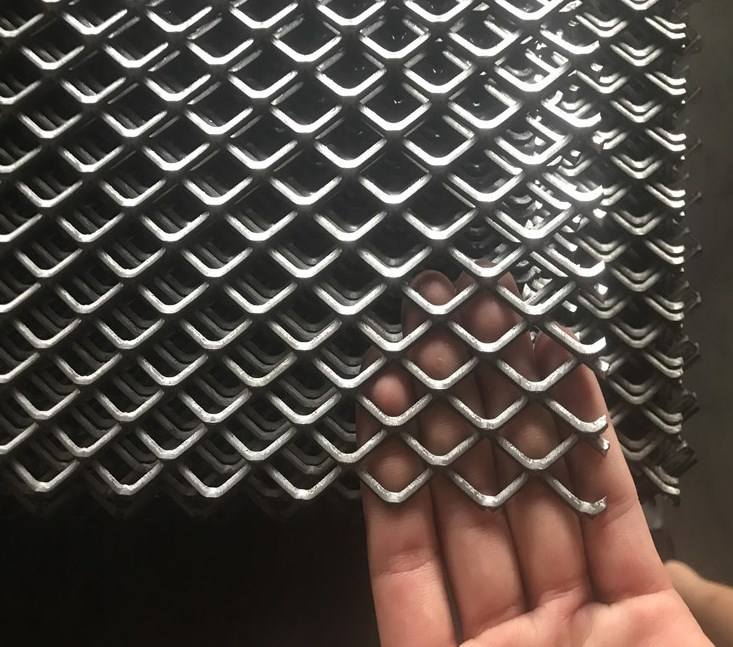

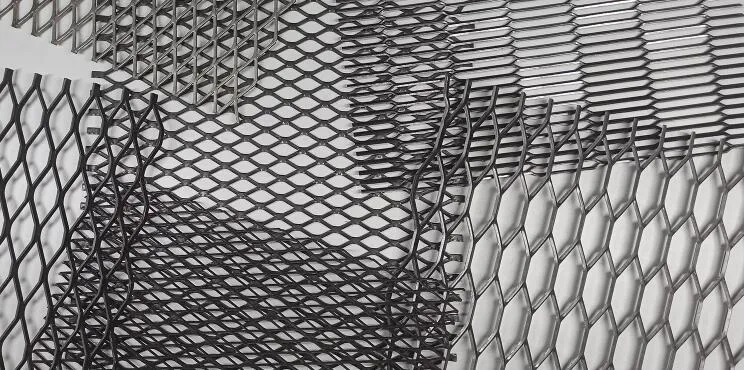

Illustrative image related to expanded metal lath

In What Ways Does Expanded Metal Lath Support Infrastructure Development Facade Systems?

In infrastructure development, expanded metal lath is utilized in facade systems, providing support for various exterior materials. This application improves energy efficiency and weather resistance, which is particularly important in regions facing extreme weather conditions. Buyers should consider local climate factors when selecting lath to ensure compatibility and performance, as well as adherence to local construction standards.

How Does Expanded Metal Lath Aid in HVAC and Electrical Installations?

Expanded metal lath plays a crucial role in HVAC and electrical installations by providing a stable framework for securing ductwork and electrical components. This application enhances the organization and safety of installations, ensuring that systems are well-supported and accessible. For international buyers, it is important to ensure compatibility with existing systems and ease of installation, which can significantly reduce labor costs and improve project timelines.

3 Common User Pain Points for ‘expanded metal lath’ & Their Solutions

Scenario 1: Navigating the Complexity of Product Specifications

The Problem:

B2B buyers often face confusion when trying to navigate the various specifications and types of expanded metal lath available on the market. With numerous options like galvanized steel, various gauge thicknesses, and different coatings, it can be overwhelming to determine the right product for specific applications. This confusion can lead to incorrect purchases, project delays, and increased costs, particularly in regions where construction standards may vary.

The Solution:

To alleviate this issue, buyers should start by clearly defining their project requirements, including the intended application (e.g., stucco, plaster, or fireproofing). Researching industry standards, such as ASTM specifications, can provide valuable insights into the most suitable types of metal lath for specific conditions. Additionally, engaging with manufacturers or suppliers who offer detailed technical data sheets can help clarify differences in product performance. For instance, opting for G90 galvanized steel lath for outdoor applications can provide enhanced rust resistance, ensuring longevity. Establishing relationships with trusted distributors who can provide guidance on specifications can also streamline the purchasing process.

Scenario 2: Ensuring Quality and Consistency in Materials

The Problem:

Quality control is a significant concern for buyers of expanded metal lath, especially when sourcing from multiple suppliers or international markets. Variability in material quality can lead to structural weaknesses, installation issues, and costly rework. This is particularly relevant in regions where local suppliers may not adhere to international quality standards, leading to unpredictable results on-site.

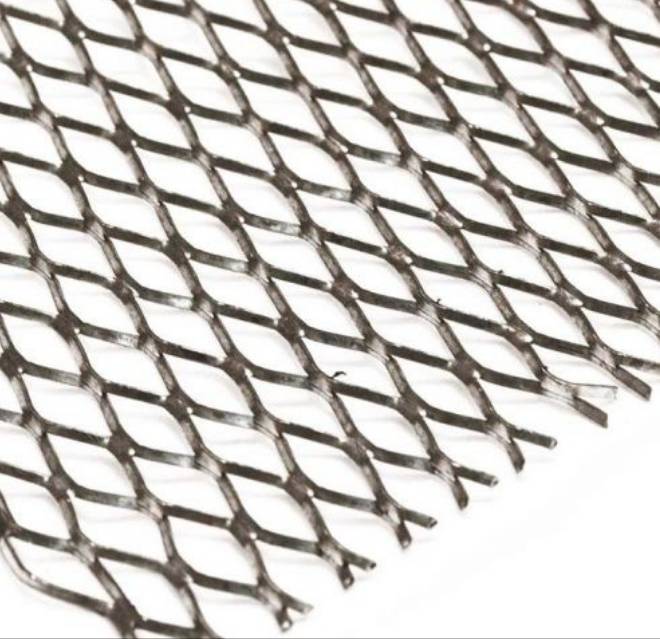

Illustrative image related to expanded metal lath

The Solution:

To ensure high-quality materials, buyers should prioritize sourcing from reputable manufacturers who provide certification of compliance with industry standards. Requesting third-party test results or certifications, such as ICC-ES reports, can verify that the metal lath meets the necessary performance criteria. Additionally, establishing a quality assurance process that includes inspecting samples before bulk orders can mitigate risks. Consider implementing a standardized checklist for evaluating the quality of expanded metal lath, including assessing the gauge, coating, and overall integrity of the product. This proactive approach not only guarantees consistent quality but also enhances trust with contractors and clients.

Scenario 3: Overcoming Installation Challenges

The Problem:

Installation of expanded metal lath can present challenges, particularly for teams unfamiliar with the nuances of the product. Issues such as improper alignment, inadequate fastening, or failure to account for expansion can lead to defects in the final finish, affecting both aesthetics and functionality. These challenges can be exacerbated in regions with specific climate considerations, such as high humidity or temperature fluctuations.

The Solution:

To overcome installation challenges, it is crucial to invest in training for installation teams. Conducting workshops or utilizing manufacturer-provided installation guides can enhance understanding of best practices, including proper fastening techniques and spacing requirements. It is also beneficial to choose products designed for ease of installation, such as soft-weave expanded metal lath that remains flat and pliable during application. Implementing a phased installation approach can help identify and rectify issues early in the process, ensuring that the final outcome meets quality expectations. Collaborating closely with suppliers to access their technical support can also provide invaluable on-site assistance, leading to smoother project execution and better results.

Strategic Material Selection Guide for expanded metal lath

What Are the Key Materials Used for Expanded Metal Lath?

In the construction industry, expanded metal lath is a versatile product used for various applications, including stucco, plaster, and reinforcement. The selection of material significantly impacts the performance, durability, and overall effectiveness of the lath. Here, we analyze four common materials used for expanded metal lath, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Galvanized Steel

Key Properties:

Galvanized steel is coated with a layer of zinc to enhance corrosion resistance. This material typically withstands temperatures up to 400°F and offers good tensile strength, making it suitable for various applications.

Pros & Cons:

The primary advantage of galvanized steel is its durability and resistance to rust, which is essential for outdoor applications. However, it can be more expensive than non-galvanized options. Manufacturing processes are relatively straightforward, but the additional coating can add complexity.

Impact on Application:

Galvanized steel is ideal for stucco and plaster applications, providing a robust substrate that can handle moisture and temperature fluctuations. It is compatible with various media, including cement-based products.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure compliance with local building codes and standards, such as ASTM A653 for galvanized steel. Understanding the environmental conditions, such as humidity and temperature, is crucial for selecting the appropriate gauge and coating.

2. Stainless Steel

Key Properties:

Stainless steel offers superior corrosion resistance, especially in harsh environments. It can withstand high temperatures and has excellent tensile strength.

Pros & Cons:

The main advantage of stainless steel is its longevity and resistance to corrosion, making it suitable for coastal and industrial applications. However, it is significantly more expensive than galvanized steel and may require specialized tools for installation.

Impact on Application:

Stainless steel expanded metal lath is ideal for high-end projects where aesthetics and durability are critical. It is compatible with various finishes and can be used in both interior and exterior applications.

Considerations for International Buyers:

In regions with stringent building regulations, such as Europe, compliance with standards like EN 10088 for stainless steel is essential. Buyers should also consider the cost implications and whether the investment aligns with project budgets.

3. Aluminum

Key Properties:

Aluminum is lightweight and resistant to corrosion, making it a popular choice for various construction applications. It typically has a lower tensile strength than steel but compensates with its lightweight nature.

Pros & Cons:

The primary advantage of aluminum is its ease of handling and installation due to its lightweight. However, it may not be suitable for high-stress applications and can be more expensive than traditional steel options.

Impact on Application:

Aluminum expanded metal lath is often used in non-load-bearing applications, such as interior partitions and decorative elements. Its compatibility with various coatings allows for versatile design options.

Considerations for International Buyers:

Buyers in the Middle East and Africa should be aware of the local availability of aluminum products and their compliance with standards like ASTM B221. Understanding the local market can help in negotiating better prices.

4. Fiberglass Reinforced Plastic (FRP)

Key Properties:

FRP is a composite material that combines fiberglass with a resin matrix, providing excellent corrosion resistance and strength-to-weight ratio.

Pros & Cons:

The key advantage of FRP is its resistance to chemicals and moisture, making it ideal for specialized applications. However, it can be less durable than metals in high-stress environments and may have higher upfront costs.

Impact on Application:

FRP expanded metal lath is suitable for environments where traditional metals may corrode, such as chemical plants or coastal areas. Its compatibility with various finishes allows for flexibility in design.

Considerations for International Buyers:

International buyers should check compliance with standards like ASTM D638 for plastics. Understanding local market conditions and the availability of FRP products is crucial for effective procurement.

Summary Table

| Material | Typical Use Case for expanded metal lath | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Galvanized Steel | Stucco and plaster applications | Durable and corrosion-resistant | Higher cost than non-galvanized options | Medium |

| Stainless Steel | High-end projects | Superior corrosion resistance | Significantly more expensive | High |

| Aluminum | Interior partitions and decorative work | Lightweight and easy to handle | Not suitable for high-stress applications | Medium |

| Fiberglass Reinforced Plastic | Chemical plants and coastal areas | Excellent chemical resistance | Less durable under stress | High |

This guide provides a comprehensive overview of the strategic material selection for expanded metal lath, aiding international B2B buyers in making informed decisions tailored to their specific needs and regional conditions.

Illustrative image related to expanded metal lath

In-depth Look: Manufacturing Processes and Quality Assurance for expanded metal lath

What Are the Main Stages of Manufacturing Expanded Metal Lath?

The manufacturing process of expanded metal lath involves several critical stages that ensure the final product meets the rigorous standards expected by international B2B buyers. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Expanded Metal Lath Production?

The process begins with the selection of high-quality steel, typically hot-dipped galvanized to enhance corrosion resistance. Steel sheets are sourced according to industry specifications, ensuring they meet the required thickness and strength. The sheets undergo an inspection for any defects before moving to the next stage, where they are cut to predetermined dimensions suitable for expansion.

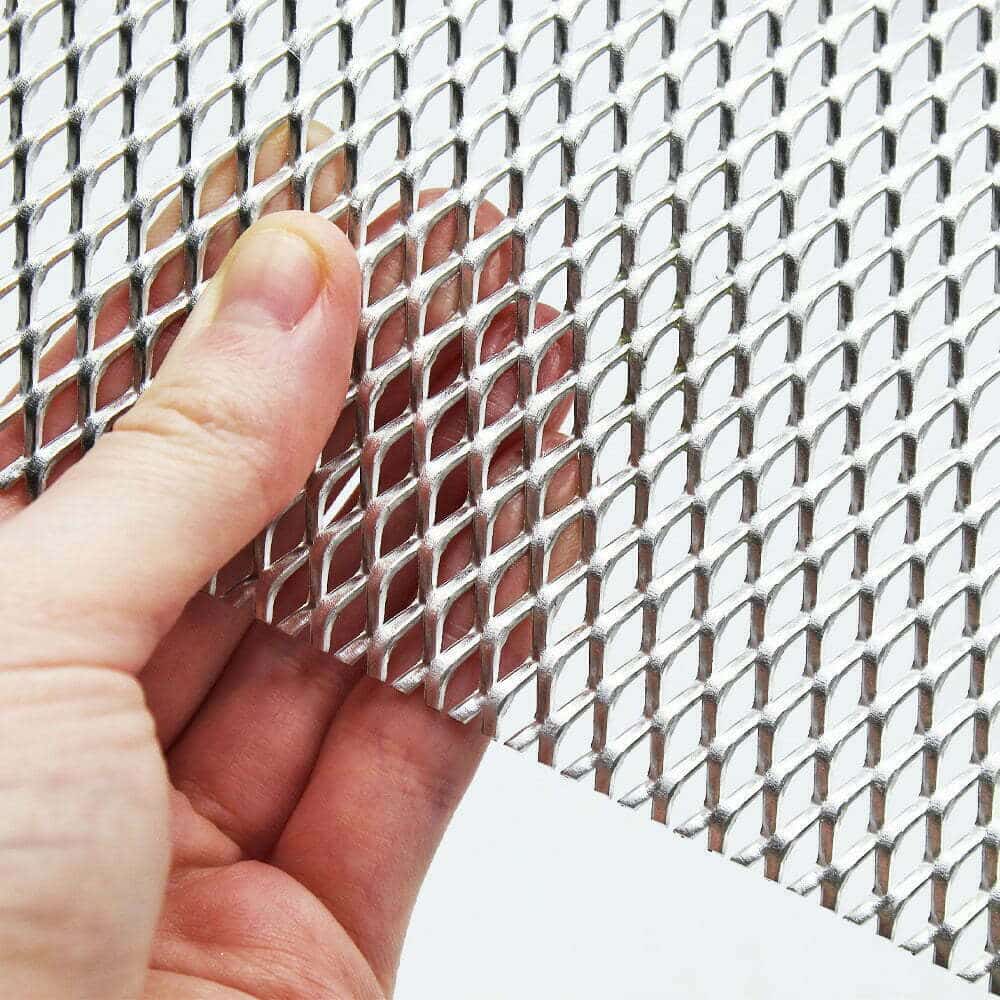

What Techniques Are Used in Forming Expanded Metal Lath?

In the forming stage, the prepared steel sheets are slit and expanded using specialized machinery. This process creates a diamond-shaped mesh, which results in hundreds of “keys” per square yard, allowing for superior adhesion in plaster and stucco applications. The expansion process not only provides structural integrity but also ensures flexibility and lightweight characteristics essential for various construction applications.

Illustrative image related to expanded metal lath

How Is the Assembly Process Structured?

While expanded metal lath is typically a singular product, some manufacturers may choose to assemble additional features, such as paper backing or specific coatings to enhance performance in different environments. This may include applying a weather-resistant barrier or additional galvanization for specific applications. Each assembly step is closely monitored to ensure compliance with specifications.

What Are the Finishing Touches for Expanded Metal Lath?

The finishing stage includes surface treatments such as galvanization, which adds a protective layer to prevent rust and corrosion. The lath may also undergo quality checks for flatness and dimensional accuracy. Finally, products are packaged in bundles or pallets for distribution, ensuring they remain intact during transport.

What Quality Assurance Standards Are Relevant to Expanded Metal Lath Manufacturing?

Quality assurance in the manufacturing of expanded metal lath is paramount, especially for B2B buyers who require reliable and durable products. Various international standards apply, including ISO 9001, which outlines a framework for quality management systems. Adhering to these standards ensures that manufacturers consistently produce high-quality products.

How Do International and Industry-Specific Standards Impact Manufacturing Quality?

In addition to ISO 9001, industry-specific standards such as CE marking in Europe and ASTM specifications in the United States are crucial for expanded metal lath. These standards dictate specific performance criteria for materials, including tensile strength, corrosion resistance, and dimensional tolerances. Compliance with such standards not only enhances product reliability but also facilitates easier entry into international markets.

What Are the Key Quality Control Checkpoints in Expanded Metal Lath Production?

Quality control (QC) processes are integral to ensuring that expanded metal lath meets both customer and regulatory expectations. Key checkpoints throughout the manufacturing process include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and compliance with specifications before they enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, operators conduct regular checks to monitor the quality of the product in real-time. This includes assessing the expansion process for uniformity and structural integrity.

-

Final Quality Control (FQC): Once production is complete, the finished products undergo comprehensive testing, including dimensional checks, surface inspection, and adherence to specific standards.

What Common Testing Methods Are Used to Ensure Product Quality?

Manufacturers employ various testing methods to validate the performance and durability of expanded metal lath. These may include:

- Tensile Testing: Measures the strength and flexibility of the lath.

- Corrosion Resistance Testing: Assesses how well the galvanized coating withstands environmental factors.

- Dimensional Accuracy Checks: Ensures that the product meets specified dimensions and tolerances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC practices is essential. Here are several actionable steps:

-

Supplier Audits: Conduct on-site audits to assess the manufacturing processes, quality control systems, and adherence to standards. This can provide insights into the operational integrity of the supplier.

-

Requesting Quality Reports: Buyers should request detailed QC reports that outline testing results, compliance with industry standards, and any certifications held by the manufacturer.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s products and processes. This adds an additional layer of assurance for buyers.

What Are the Nuances of Quality Control Certification for International Buyers?

When sourcing expanded metal lath globally, buyers must be aware of the certification nuances that may vary by region. For instance, while CE marking is essential for products sold in Europe, other regions may have different compliance requirements. Understanding these distinctions can help buyers navigate the complexities of international trade and ensure they are procuring compliant products.

In conclusion, the manufacturing processes and quality assurance practices for expanded metal lath are critical elements that B2B buyers must consider. By understanding the stages of production, relevant standards, and effective verification methods, buyers can make informed decisions and select suppliers that align with their quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘expanded metal lath’

Expanded metal lath is a versatile material essential for various construction applications, including stucco and plaster systems. This guide provides a step-by-step checklist to help B2B buyers navigate the sourcing process effectively, ensuring they procure high-quality products that meet their project specifications.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the expanded metal lath you need. Consider factors such as weight (e.g., 2.5 lbs vs. 3.4 lbs per square yard), dimensions, and the type of coating (galvanized, G90, etc.). These specifications will guide your selection process and help you communicate effectively with suppliers.

Step 2: Identify Your Application Requirements

Different projects may require specific types of expanded metal lath. For instance, determine whether your application is for interior plaster, exterior stucco, or ornamental work. Understanding the application will help you choose the right product, as some lath types are better suited for specific environments and finishes.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. Request company profiles, product certifications, and references from previous clients in similar industries or regions. Look for suppliers with a proven track record in the market and those who can demonstrate compliance with international standards.

- Check for Certifications: Ensure the supplier’s products meet relevant industry standards, such as ASTM specifications or ICC-ES evaluation reports.

- Assess Manufacturing Capabilities: Inquire about their manufacturing processes and quality control measures to guarantee product consistency and reliability.

Step 4: Request Samples and Product Data

Once you have shortlisted potential suppliers, request samples of the expanded metal lath. This will allow you to assess the quality, texture, and performance characteristics firsthand. Additionally, ask for technical data sheets to understand the product specifications and installation guidelines better.

Step 5: Compare Pricing and Terms

Gather quotations from multiple suppliers and compare not only the pricing but also the terms of sale. Look for bulk purchase discounts, shipping costs, and payment terms. Understanding the total cost of ownership will help you make a more informed decision.

- Consider Shipping Logistics: If you are sourcing internationally, evaluate shipping times and costs, as these can impact your project timeline.

- Negotiate Payment Terms: Explore flexible payment options that could enhance your cash flow management.

Step 6: Verify Delivery Capabilities

Confirm that the supplier can meet your delivery timelines and quantities. Delays in the supply chain can severely impact project schedules, so it’s essential to ensure your chosen supplier has a reliable logistics network in place.

Illustrative image related to expanded metal lath

Step 7: Establish a Communication Plan

Maintain open lines of communication with your supplier throughout the procurement process. Establish a clear point of contact and set expectations regarding updates on production and shipping. This proactive approach can help mitigate potential issues and foster a strong supplier relationship.

By following this checklist, B2B buyers can effectively navigate the procurement process for expanded metal lath, ensuring they select the right products that meet their technical and project requirements.

Comprehensive Cost and Pricing Analysis for expanded metal lath Sourcing

What Are the Key Cost Components in Expanded Metal Lath Sourcing?

Sourcing expanded metal lath involves several cost components that can significantly impact the overall expenditure. The primary cost elements include:

Illustrative image related to expanded metal lath

-

Materials: The base material for expanded metal lath is typically galvanized steel, which is cost-effective and provides excellent durability. Prices can fluctuate based on the type of steel used (e.g., G60 vs. G90), availability, and market demand.

-

Labor: Labor costs encompass the workforce required for manufacturing, handling, and installation. Skilled labor, particularly for custom installations, can add to the cost. In regions with a labor shortage, such as parts of Africa and South America, these costs can be higher.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, equipment depreciation, and utilities. A manufacturer’s production efficiency can influence these costs, impacting the final price of the lath.

-

Tooling: Specialized tooling for creating various lath profiles adds to initial costs. Custom designs may require unique tooling, which can be a significant upfront investment.

-

Quality Control (QC): Ensuring that products meet industry standards, such as ASTM specifications, involves additional QC costs. Compliance with certifications can enhance product reliability but may also increase the price.

-

Logistics: Transportation costs can vary widely based on the shipping method, distance, and logistics provider. International buyers should consider additional costs for customs clearance and import duties.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary significantly based on supplier reputation, product quality, and market competition.

What Influences the Pricing of Expanded Metal Lath?

Several factors influence the pricing of expanded metal lath, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases usually attract discounts. Buyers should negotiate MOQs to reduce per-unit costs, which is particularly beneficial for large projects.

-

Specifications and Customization: Custom sizes, gauges, and coatings can increase costs. Buyers should evaluate whether standard products meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications typically command higher prices. Buyers should assess the long-term benefits of investing in certified products, particularly in demanding applications.

-

Supplier Factors: Supplier reputation, reliability, and service quality can affect pricing. Established suppliers may charge a premium but often offer better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can influence the total landed cost of goods, affecting overall pricing strategies.

How Can Buyers Negotiate for Cost-Efficiency in Expanded Metal Lath Procurement?

To achieve cost-efficiency in sourcing expanded metal lath, buyers should adopt the following strategies:

-

Leverage Volume Discounts: Consider consolidating orders to meet higher volume thresholds for better pricing. Group purchasing with other contractors can also be beneficial.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase costs, consider long-term factors such as maintenance, installation, and durability. Investing in higher-quality lath may reduce repair or replacement costs over time.

-

Research and Compare Suppliers: Conduct thorough market research to identify multiple suppliers and compare their offerings. Utilize online platforms and trade shows to gather quotes and assess product quality.

-

Negotiate Terms: Engage suppliers in discussions about payment terms, delivery schedules, and potential discounts for early payments. Building a good rapport can often lead to better pricing.

-

Understand Regional Pricing Nuances: Pricing can vary significantly by region due to local market conditions, tariffs, and logistics. Buyers should be aware of these factors when sourcing from international suppliers, especially in markets like Nigeria and Brazil, where economic conditions can be volatile.

Conclusion

While the pricing of expanded metal lath can vary due to multiple factors, understanding the cost components and influencers can help buyers make informed decisions. By negotiating effectively and considering the total cost of ownership, international B2B buyers can optimize their sourcing strategies and achieve better pricing outcomes. Please note that prices are indicative and may vary based on market conditions and specific supplier agreements.

Alternatives Analysis: Comparing expanded metal lath With Other Solutions

Introduction: Exploring Alternatives to Expanded Metal Lath

In the construction and building materials industry, selecting the right substrate for plaster and stucco applications is crucial for achieving durability, strength, and aesthetic appeal. Expanded metal lath has long been a popular choice due to its unique properties. However, other solutions are available that may better suit specific project needs. This analysis provides a comparison between expanded metal lath and viable alternatives, helping B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Expanded Metal Lath | Fiberglass Mesh Lath | Steel Wire Lath |

|---|---|---|---|

| Performance | High strength and flexibility; excellent bonding | Good tensile strength; less flexible | Strong but can rust if not properly coated |

| Cost | Moderate initial investment | Lower cost, especially in large volumes | Generally lower cost, but varies by gauge |

| Ease of Implementation | Requires skilled labor for installation | Easier to handle; can be cut with scissors | Requires specialized tools for installation |

| Maintenance | Low maintenance; resistant to corrosion | Requires careful handling to avoid tears | Moderate; rust can be an issue without treatment |

| Best Use Case | Ideal for stucco, plaster, and fireproofing | Suitable for lightweight applications and repairs | Good for heavy-duty applications like masonry |

Detailed Breakdown of Alternatives

Fiberglass Mesh Lath

Fiberglass mesh lath is a lightweight alternative that offers good tensile strength and is often used for exterior insulation and finish systems (EIFS). It is easier to handle and cut compared to metal lath, making it suitable for DIY projects or lighter applications. However, fiberglass mesh can be less flexible, which may lead to cracking in certain situations. Additionally, while it generally costs less upfront, its longevity and durability may not match that of expanded metal lath, especially in high-stress environments.

Steel Wire Lath

Steel wire lath is another common alternative, primarily used in heavy-duty masonry applications. It provides a robust framework for plaster and stucco and is often more cost-effective than expanded metal lath. However, it has a higher risk of rusting if not properly coated, which can compromise its structural integrity over time. Installation of steel wire lath may require specialized tools and skilled labor, making it less accessible for some projects. Despite these downsides, it can be an excellent choice for projects requiring extra strength.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between expanded metal lath and its alternatives, B2B buyers should consider the specific requirements of their projects. Expanded metal lath offers unmatched strength and versatility, making it ideal for a wide range of applications, particularly in environments where durability is critical. However, if cost, ease of handling, or specific application requirements are a priority, alternatives like fiberglass mesh or steel wire lath may be more suitable. Evaluating the project scope, budget, and installation capabilities will help ensure the chosen solution aligns with both immediate needs and long-term performance expectations.

Essential Technical Properties and Trade Terminology for expanded metal lath

What Are the Key Technical Properties of Expanded Metal Lath?

Understanding the technical properties of expanded metal lath is crucial for B2B buyers involved in construction and renovation projects. Here are some essential specifications that influence material selection and performance:

-

Material Grade

Expanded metal lath is typically made from galvanized steel, with common grades including G60 and G90. The grade indicates the thickness and protective zinc coating, which affects corrosion resistance. For projects in humid or coastal regions, selecting a higher grade (like G90) ensures durability and longevity. -

Weight per Square Yard

The weight of expanded metal lath, usually ranging from 2.5 lbs to 3.4 lbs per square yard, is a critical property that determines its strength and application suitability. Lighter lath is easier to handle and install but may not support heavier materials as effectively as heavier lath, making it essential to match the weight to the project’s requirements. -

Sheet Size and Coverage

Common sheet dimensions, such as 27″ x 97″, dictate how much area can be covered in a single installation. Larger sheets can reduce labor costs by minimizing the number of seams, while smaller sheets may offer greater flexibility for specific applications. Buyers should consider the layout of their projects when selecting sheet sizes. -

Furring Points

The presence and spacing of furring points (often 4 inches apart) are vital for ensuring a secure attachment to the substrate. Properly placed furring points enhance the stability of the lath and improve the overall performance of the plaster or stucco applied over it. Understanding this specification can help buyers select the right product for their specific installation needs. -

Coating Options

Beyond galvanization, expanded metal lath can feature additional coatings for enhanced weather resistance, such as asphalt paper backing. This adds a layer of protection against moisture and weathering, making it suitable for exterior applications. Buyers should evaluate the environmental conditions of their project locations when deciding on coatings. -

Compliance Standards

Familiarity with industry standards, such as ASTM C847 and ICC-ES Evaluation Reports, is crucial for ensuring product quality and compliance. These standards guide material performance, installation practices, and safety, offering buyers peace of mind that their selected products meet regulatory requirements.

What Are Common Trade Terms in the Expanded Metal Lath Industry?

In the world of expanded metal lath, understanding trade terminology can streamline communication and transactions. Here are key terms that B2B buyers should know:

Illustrative image related to expanded metal lath

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or products that are used in another company’s end products. In the context of expanded metal lath, an OEM may manufacture lath for construction firms or distributors. Buyers should consider OEMs for reliability and quality assurance in their supply chain. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, particularly for large-scale projects that require significant material quantities. -

RFQ (Request for Quotation)

An RFQ is a formal request to suppliers for pricing and terms for specific products or services. Issuing an RFQ for expanded metal lath allows buyers to compare options, negotiate prices, and secure favorable terms, thus optimizing procurement. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding Incoterms helps buyers clarify delivery obligations and manage costs effectively, especially when sourcing lath from global suppliers. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. In construction, timely delivery of expanded metal lath is critical to project schedules. Buyers should confirm lead times with suppliers to avoid delays in their construction timelines. -

SDS (Safety Data Sheet)

An SDS provides detailed information about the properties of a particular substance, including handling, storage, and safety precautions. Familiarity with SDS for expanded metal lath ensures compliance with safety regulations and promotes safe handling practices on job sites.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, optimize their procurement processes, and ensure the success of their construction projects.

Navigating Market Dynamics and Sourcing Trends in the expanded metal lath Sector

What Are the Key Market Dynamics and Trends Influencing the Expanded Metal Lath Sector?

The global market for expanded metal lath is undergoing significant transformation, driven by various factors that international B2B buyers must navigate. One of the primary drivers is the growing demand for lightweight yet durable construction materials in regions such as Africa, South America, the Middle East, and Europe. As urbanization accelerates and infrastructure projects proliferate, the need for reliable materials like expanded metal lath is surging. Emerging technologies are also reshaping sourcing practices, with digital platforms facilitating easier access to suppliers and product information. This shift towards e-commerce is particularly relevant for buyers in developing regions, where traditional supply chains may be less established.

Moreover, sustainability is becoming a central theme in the procurement process. Buyers are increasingly prioritizing suppliers who can demonstrate eco-friendly practices, including the use of recycled materials and energy-efficient production methods. The rise of smart construction technologies, such as Building Information Modeling (BIM), is enhancing the planning and execution of projects, allowing for more efficient use of materials, including expanded metal lath. As a result, international buyers must be proactive in understanding these evolving dynamics to make informed purchasing decisions.

How Is Sustainability and Ethical Sourcing Reshaping the Expanded Metal Lath Market?

The environmental impact of construction materials is a pressing concern for many international B2B buyers. Expanded metal lath, traditionally made from galvanized steel, poses sustainability challenges, including high energy consumption during production and the carbon footprint associated with steel manufacturing. However, the industry is witnessing a shift towards more sustainable practices. Suppliers are increasingly adopting ethical sourcing strategies and utilizing green certifications to appeal to environmentally conscious buyers.

Buyers should seek out manufacturers who prioritize sustainability by using recycled steel or implementing energy-efficient technologies in their production processes. Certifications like ISO 14001 for environmental management systems or LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainable practices. Furthermore, understanding the entire supply chain—from raw material extraction to final product delivery—can help buyers ensure that their sourcing choices align with ethical standards and environmental responsibility.

What Is the Historical Context of Expanded Metal Lath in the Construction Industry?

Expanded metal lath has evolved significantly since its inception in the late 19th century. Initially developed as a cost-effective solution for plastering, it quickly gained popularity due to its versatility and strength. The introduction of galvanized steel in the mid-20th century further enhanced its durability, making it a preferred choice for various applications, including stucco and fireproofing.

As construction practices evolved, so did the manufacturing processes for expanded metal lath. The industry has embraced technological advancements, resulting in products that meet stringent building codes and offer improved performance. Today, expanded metal lath remains a staple in the construction sector, valued for its reliability and adaptability to modern architectural designs. This historical context underscores the material’s enduring relevance and highlights the importance of staying informed about its advancements in sourcing and application.

Frequently Asked Questions (FAQs) for B2B Buyers of expanded metal lath

-

How do I choose the right type of expanded metal lath for my project?

Choosing the right type of expanded metal lath depends on the specific application and the environment where it will be used. For stucco applications, consider whether you need a one-coat or three-coat system. One-coat systems typically use lighter gauges, while three-coat systems require heavier, more robust lath. Additionally, assess environmental factors such as moisture exposure and potential rusting; opting for galvanized steel can enhance durability. Always consult with your supplier for recommendations based on your project requirements. -

What is the best gauge of expanded metal lath for stucco applications?

The best gauge of expanded metal lath for stucco applications generally falls between 20-gauge and 17-gauge. A 20-gauge lath is often recommended for one-coat stucco systems due to its lightweight nature, while a 17-gauge lath is preferred for three-coat systems, providing additional strength and support. Always evaluate your specific project needs, including the type of finish and local environmental conditions, to determine the most suitable option. -

What are the typical minimum order quantities (MOQs) for expanded metal lath?

Minimum order quantities for expanded metal lath can vary significantly based on the supplier and region. Typically, MOQs may range from 100 to 500 square yards, depending on the product specifications and the manufacturer’s capabilities. It’s advisable to communicate directly with potential suppliers to understand their MOQs and see if they can accommodate smaller orders, especially for smaller projects or initial testing. -

How do I vet suppliers of expanded metal lath for international purchases?

When vetting suppliers for international purchases of expanded metal lath, consider their manufacturing certifications, quality control processes, and customer reviews. Look for suppliers with ISO certifications or those recognized by local regulatory bodies. Request samples to assess product quality and inquire about their experience in exporting to your region. Additionally, establish clear communication to ensure they understand your specific requirements and can provide timely support. -

What are the payment terms typically offered by suppliers for expanded metal lath?

Payment terms for expanded metal lath can vary widely among suppliers. Common arrangements include net 30 or net 60 days, where payment is due within 30 or 60 days after delivery. Some suppliers may require a deposit upfront, particularly for large orders or custom products. Always clarify payment terms before finalizing a deal, and consider using secure payment methods to protect your investment. -

How can I ensure quality assurance when sourcing expanded metal lath internationally?

To ensure quality assurance when sourcing expanded metal lath, request detailed product specifications and certifications from your supplier. Consider third-party inspections or audits to verify compliance with international standards. Establish a clear quality control process, including material testing and compliance with ASTM standards. Additionally, maintain open communication with your supplier to address any concerns promptly throughout the manufacturing and shipping process. -

What logistics considerations should I keep in mind when importing expanded metal lath?

Logistics considerations for importing expanded metal lath include shipping methods, customs regulations, and lead times. Determine whether ocean freight or air freight is more cost-effective based on your timeline and budget. Familiarize yourself with local customs requirements and ensure all necessary documentation is prepared to avoid delays. Additionally, consider the supplier’s shipping capabilities and their experience with international logistics to ensure smooth delivery. -

Can expanded metal lath be customized for specific applications?

Yes, many suppliers offer customization options for expanded metal lath to meet specific application needs. Customizations can include variations in gauge, size, coating, and even the pattern of the lath. When requesting custom products, provide detailed specifications and discuss any unique requirements with your supplier. This ensures that the final product aligns with your project objectives and enhances overall performance.

Top 8 Expanded Metal Lath Manufacturers & Suppliers List

1. CEMCO – Expanded Metal Lath Products

Domain: cemcosteel.com

Registered: 1996 (29 years)

Introduction: Expanded Metal Lath products include: Dimpled Self-Furred Metal Lath, Grooved Self-Furred Metal Lath, Diamond Metal Lath (Expanded) with ‘D’ Paper, Paper-Backed Grooved Self-Furred Metal Lath, Paper-Backed Dimpled Self-Furred Metal Lath, and Diamond Metal Lath (Expanded) Without Paper. CEMCO is a manufacturer of steel framing and metal lath systems, established in 1974, known for quality materials…

2. ClarkDietrich – Metal Lath

Domain: clarkdietrich.com

Registered: 2011 (14 years)

Introduction: Metal lath provides a lightweight and easily attachable base for plaster application. Made from expanded steel, it is applied flat across the stud plane and attached with staples, nails, or wafer head lath screws. The openings in the lath enable plaster to key around the metal for a secure bond and a flat, smooth surface. Available configurations include self-furring (dimpled and continuous groove…

3. Mainline Materials – Expanded Metal Lath

Domain: mainlinematerials.com

Registered: 2019 (6 years)

Introduction: Expanded Metal Lath is a versatile building material used for various applications, including plastering and stucco. It is made from sheets of metal that are slit and stretched to create a mesh-like structure. This product offers excellent bonding capabilities for plaster and stucco, ensuring durability and strength in construction. Available in different sizes and gauges, it is suitable for both …

4. McNICHOLS – Expanded Metal & Grating

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: Expanded Metal & Expanded Grating in-stock at McNICHOLS. Product Types: Flattened, Standard (Raised), Grating, Catwalk Grating, Designer Expanded. Primary Materials: Aluminum, Carbon Steel, Galvanized Steel, Stainless Steel. Series Names: LANCET™ 11618-F, LANCET™ 31651-F, LANCET™ 31618-F, LANCET™ 31618-S. Styles include various gauges and thicknesses ranging from 1/16″ to 2″. Percent Open Area opt…

5. Expanded Metal Company – 95S Stainless Steel Mesh

Domain: expandedmetalcompany.com

Registered: 2014 (11 years)

Introduction: {“Product Name”: “95S – Large, Expanded Metal, Raised, Stainless Steel Mesh”, “SKU”: “P00095-406-2500X0700-000-00”, “Material”: “Stainless Steel”, “Mesh Type”: “Raised”, “Pitch LWP”: “30.48”, “Pitch SWP”: “10.5”, “Strand Thickness”: “0.46”, “Strand Width”: “1.5”, “Shape”: “Diamond”, “Area”: “71”, “Sheet Size Long Way”: “2500”, “Sheet Size Short Way”: “700”, “Price”: “£50.45”, “Discounted Price”: “…

6. The Mesh Company – Metal Lath Solutions

Domain: themeshcompany.com

Registered: 2007 (18 years)

Introduction: Metal Lath: A versatile building material used as a base for plaster or stucco applications, made by expanding, perforating, or pressing metal sheets to create a network of small openings. Types include: Expanded Metal Lath (diamond-shaped pattern), Ribbed Metal Lath (additional ribs for strength), and Self-Furring Lath (built-in dimples for better plaster bond). Made from galvanized steel for rus…

7. Sunshine Supply – 2.5 Galvanized Metal Lath

Domain: sunshinesupply.com

Registered: 1997 (28 years)

Introduction: Metal Lath, 2.5 Galvanized, 18 Square Feet per Sheet, Dimensions: 27 x 96 inches.

8. Bailey Metal Products – Galvanized Diamond Mesh Lath

Domain: bmp-group.com

Registered: 1998 (27 years)

Introduction: Bailey Metal Products offers a range of metal lath products including: 1. Galvanized Diamond Mesh Lath 1.75 – A general all-purpose mesh lath ideal for ceramic and concrete base reinforcement in interior and exterior construction, available in sheet sizes of 27″ x 96″ and 27″ x 84″. 2. Galvanized Diamond Mesh Lath 2.5 – Suitable for exterior adhered concrete masonry veneer applications, also avail…

Strategic Sourcing Conclusion and Outlook for expanded metal lath

As the construction industry continues to evolve, the strategic sourcing of expanded metal lath emerges as a critical factor for success in projects across diverse markets, including Africa, South America, the Middle East, and Europe. Buyers should prioritize high-quality materials, such as those made from mill-certified hot-dipped galvanized steel, ensuring durability and compliance with international standards. Understanding the various applications—from stucco and plastering to ornamental work—can greatly influence project outcomes and cost-efficiency.

Illustrative image related to expanded metal lath

International buyers are encouraged to establish relationships with reputable suppliers who offer a range of products, including dimpled, grooved, and paper-backed options tailored to specific project needs. Leveraging these relationships can provide competitive pricing and timely deliveries, essential for maintaining project schedules.

Looking ahead, the demand for versatile and robust construction materials like expanded metal lath is set to rise. By investing in strategic sourcing practices, businesses can enhance their operational efficiency and responsiveness to market trends. We invite B2B buyers to explore innovative solutions and reliable partnerships that will drive their projects forward in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.