Exhaust System Gaskets: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for exhaust system gaskets

In the ever-evolving landscape of the automotive industry, sourcing high-quality exhaust system gaskets presents a significant challenge for international B2B buyers. These crucial components are essential for ensuring optimal performance and safety in vehicles, yet navigating the complexities of global supply chains can be daunting. This guide is designed to empower buyers from diverse regions, including Africa, South America, the Middle East, and Europe, by providing comprehensive insights into the various types of exhaust system gaskets, their applications, and the nuances of effective supplier vetting.

Throughout this guide, we will explore the different categories of exhaust gaskets—such as flange gaskets, EGR valve gaskets, and catalytic converter gaskets—while delving into their specific applications across various vehicle types. Additionally, we will address key considerations for evaluating suppliers, including quality assurance practices, certifications, and pricing strategies. By equipping buyers with this critical information, the guide aims to facilitate informed purchasing decisions that not only meet operational needs but also align with regional market demands.

As the automotive sector continues to grow, understanding the intricacies of exhaust system gaskets will position international B2B buyers to make strategic choices that enhance their supply chain efficiency and ultimately contribute to their bottom line. Whether you’re in Brazil, Vietnam, or elsewhere, this guide serves as a vital resource for navigating the global market for exhaust system gaskets.

Understanding exhaust system gaskets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Exhaust Flange Gasket | Typically round, designed to seal between flanges | Automotive repair, aftermarket upgrades | Pros: Easy to install, widely available. Cons: Can wear out quickly if not properly torqued. |

| Catalytic Converter Gasket | Specifically designed to fit catalytic converters | Emission control systems, vehicle repairs | Pros: Essential for emissions compliance. Cons: Higher cost due to specialized design. |

| EGR Valve Gasket | Seals exhaust gas recirculation valves | Diesel and gasoline engines | Pros: Improves engine efficiency. Cons: Prone to damage from heat and exhaust gases. |

| Header Gasket | Multi-layer design for high-performance applications | Racing, performance enhancements | Pros: Durable, supports high temperatures. Cons: More expensive than standard gaskets. |

| Donut Gasket | Ring-shaped, used in exhaust pipe connections | Exhaust system repairs | Pros: Provides a flexible seal. Cons: Limited lifespan under extreme conditions. |

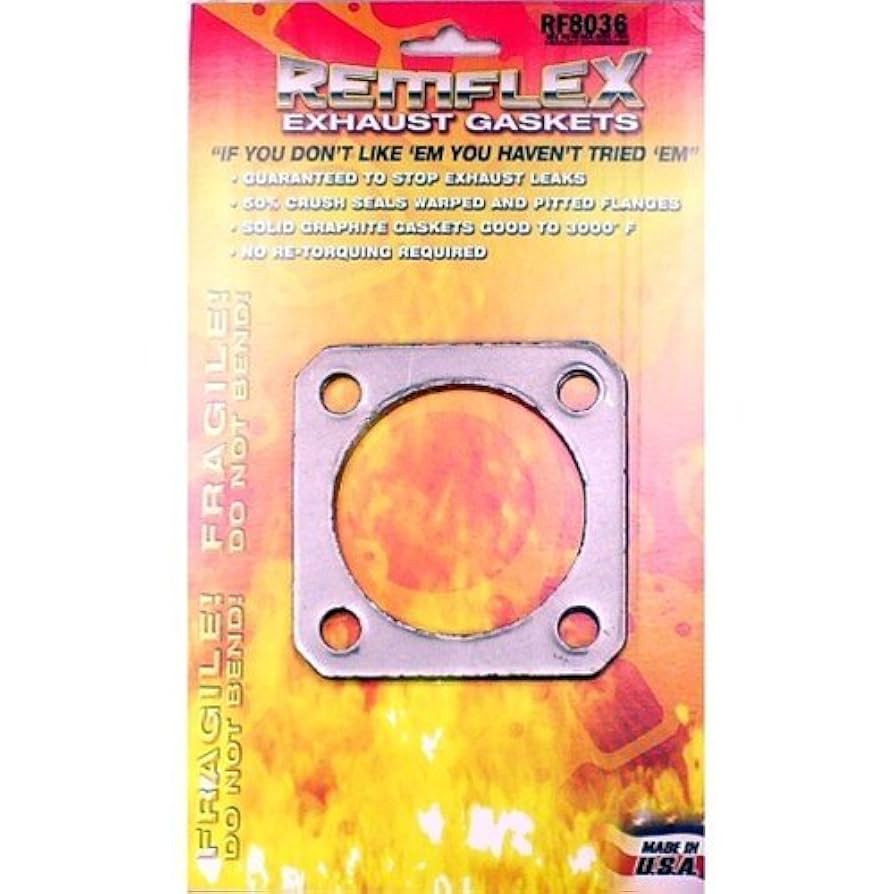

What Are the Characteristics of Exhaust Flange Gaskets?

Exhaust flange gaskets are designed to create a seal between two exhaust flanges, ensuring that exhaust gases do not leak. They are typically made from materials such as graphite or metal, which can withstand high temperatures and pressures. B2B buyers should consider the compatibility of the gasket with their specific vehicle models, as well as the material’s durability. Proper installation is crucial to prevent leaks and ensure optimal performance.

How Do Catalytic Converter Gaskets Function?

Catalytic converter gaskets are specifically engineered to fit around catalytic converters, which are critical for reducing harmful emissions in vehicles. These gaskets must provide a tight seal to prevent exhaust leaks that could lead to increased emissions and potential legal issues. Buyers should assess the gasket’s resistance to heat and corrosion, as well as its compliance with local emissions regulations. The investment in high-quality catalytic converter gaskets can significantly impact overall vehicle performance and compliance.

What Should Buyers Know About EGR Valve Gaskets?

EGR valve gaskets are essential for sealing the connection between the EGR valve and the engine, allowing for the proper recirculation of exhaust gases to improve fuel efficiency. They are often made from materials that can handle high temperatures and corrosive exhaust gases. B2B buyers should prioritize sourcing gaskets that offer excellent durability and heat resistance. Regular inspections and timely replacements can prevent costly engine repairs and enhance overall vehicle efficiency.

Why Are Header Gaskets Important for Performance Vehicles?

Header gaskets are crucial for high-performance applications, as they provide a robust seal between the exhaust headers and the engine block. These gaskets are often multi-layered to handle the extreme conditions found in racing and performance vehicles. Buyers should consider the specific requirements of their engines, including temperature tolerances and pressure ratings, when selecting header gaskets. The initial investment may be higher, but the long-term benefits in performance and durability can justify the cost.

What Are the Benefits and Limitations of Donut Gaskets?

Donut gaskets, named for their ring-like shape, are commonly used in exhaust pipe connections to provide a flexible seal that can accommodate movement and vibration. They are typically made from materials that offer good thermal resistance. For B2B buyers, it’s essential to evaluate the expected lifespan of donut gaskets under various operating conditions, as they may wear out faster than other types. While they are generally cost-effective, ensuring the right fit and material quality is key to maximizing their performance.

Illustrative image related to exhaust system gaskets

Key Industrial Applications of exhaust system gaskets

| Industry/Sector | Specific Application of Exhaust System Gaskets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Sealing connections in exhaust systems for vehicles | Ensures optimal engine performance and emissions control | Quality certifications, compatibility with vehicle models |

| Heavy Machinery | Gaskets for exhaust systems in construction equipment | Reduces noise and emissions, enhancing operator safety | Durability under extreme conditions, material specifications |

| Marine Industry | Exhaust gaskets for marine engines and generators | Prevents leaks, ensuring safety and compliance with regulations | Resistance to corrosion and saltwater, custom sizes available |

| Power Generation | Gaskets in exhaust systems of power plants | Enhances efficiency and compliance with environmental standards | High-temperature resistance, availability of bulk orders |

| Transportation & Logistics | Gaskets for exhaust systems in commercial vehicles | Reduces maintenance costs and improves fuel efficiency | Supply chain reliability, quick turnaround times |

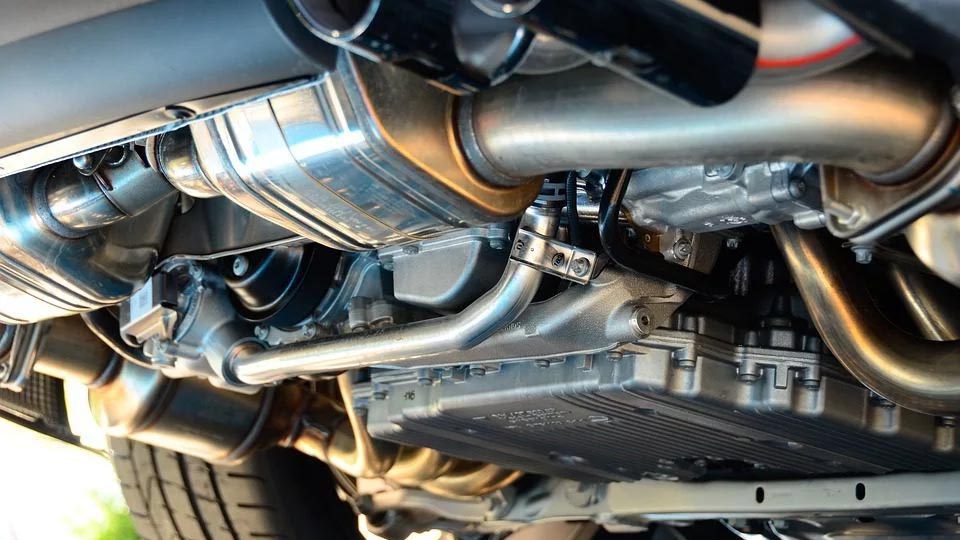

How Are Exhaust System Gaskets Used in Automotive Manufacturing?

In the automotive manufacturing sector, exhaust system gaskets are critical for sealing various components, including the exhaust manifold and catalytic converter. They ensure that exhaust gases are properly channeled away from the engine, optimizing performance and minimizing harmful emissions. Buyers in this industry must consider the specific requirements for different vehicle models and ensure that the gaskets meet quality certifications for safety and reliability.

What Role Do Exhaust System Gaskets Play in Heavy Machinery?

Heavy machinery, such as bulldozers and excavators, relies on exhaust system gaskets to maintain efficient operation. These gaskets help reduce noise and prevent exhaust leaks, which can pose safety hazards to operators and bystanders. When sourcing gaskets for heavy machinery, businesses should prioritize durability and resistance to harsh environments, ensuring that the materials can withstand extreme temperatures and vibrations typical in construction settings.

Why Are Exhaust Gaskets Important in the Marine Industry?

In the marine industry, exhaust gaskets are essential for sealing connections in engines and generators used on boats and ships. These gaskets prevent exhaust leaks, which can lead to toxic fumes entering the vessel and affecting crew safety. Buyers must focus on materials that resist corrosion and saltwater exposure, as well as custom sizes to fit various marine engine configurations, ensuring compliance with maritime regulations.

How Do Exhaust System Gaskets Enhance Power Generation?

In power generation facilities, exhaust gaskets play a vital role in sealing exhaust systems of turbines and generators. They help maintain efficiency by preventing leaks that could lead to energy loss and ensure compliance with environmental regulations. When sourcing gaskets for power plants, companies should look for options that offer high-temperature resistance and durability, as well as the ability to fulfill bulk orders for ongoing maintenance needs.

Illustrative image related to exhaust system gaskets

What Benefits Do Exhaust Gaskets Provide in Transportation and Logistics?

In the transportation and logistics sector, exhaust gaskets are crucial for ensuring the efficiency of commercial vehicles. They help reduce maintenance costs by preventing leaks that could lead to engine damage and improve fuel efficiency through effective exhaust flow. Buyers should consider sourcing gaskets that guarantee supply chain reliability and quick turnaround times to minimize vehicle downtime, which is essential for maintaining operational efficiency.

3 Common User Pain Points for ‘exhaust system gaskets’ & Their Solutions

Scenario 1: Poor Quality Gaskets Leading to Frequent Failures

The Problem: Many B2B buyers, particularly those in automotive repair and manufacturing, encounter issues with the quality of exhaust system gaskets. Subpar gaskets can lead to premature failures, resulting in exhaust leaks, increased noise levels, and even dangerous fumes entering the passenger compartment. This not only compromises safety but also leads to costly repairs and downtime. Buyers often find themselves caught in a cycle of purchasing cheap gaskets that fail to perform, leading to frustration and loss of customer trust.

The Solution: To mitigate this issue, buyers should prioritize sourcing high-quality gaskets from reputable manufacturers known for their durability and performance. It is crucial to evaluate product specifications, including material type (such as multi-layer graphite or stainless steel), thickness, and compatibility with various exhaust systems. Establishing long-term relationships with trusted suppliers can also ensure consistent quality and availability of gaskets. Additionally, implementing a routine inspection schedule can help identify worn-out gaskets before they fail, allowing for proactive replacements and minimizing downtime.

Scenario 2: Incompatibility with Vehicle Models

The Problem: Another common pain point for B2B buyers is the challenge of finding exhaust gaskets that are compatible with specific vehicle models. With the vast array of vehicles on the market, including various makes and models, it can be time-consuming and frustrating to locate the right gasket. This often leads to stock shortages, backorders, and ultimately delays in service, which can negatively impact customer satisfaction and business operations.

The Solution: To address this issue, buyers should invest in a comprehensive parts catalog or database that provides detailed specifications for exhaust gaskets according to vehicle makes and models. Utilizing advanced inventory management systems can help track which gaskets are frequently requested and identify trends in demand. Additionally, partnering with suppliers that offer customizable gasket solutions can alleviate compatibility issues, allowing buyers to provide tailored options for their clients. Training staff to understand these specifications can further streamline the ordering process and enhance customer service.

Scenario 3: Environmental Regulations and Compliance Issues

The Problem: B2B buyers in regions with strict environmental regulations may face challenges when sourcing exhaust gaskets that meet compliance standards. Non-compliant products can lead to hefty fines, increased scrutiny from regulatory bodies, and damage to a company’s reputation. Moreover, the complexity of varying regulations across different countries adds to the difficulty of ensuring that all products are compliant.

The Solution: To navigate this challenge, buyers should stay informed about the latest environmental regulations and standards relevant to exhaust components in their specific regions. Engaging with suppliers who specialize in eco-friendly materials and are knowledgeable about compliance can greatly enhance the procurement process. Additionally, implementing a thorough vetting process for new products and suppliers can help ensure that all exhaust gaskets meet necessary environmental standards before they are integrated into inventory. Keeping abreast of industry changes through continuous education and training can also empower buyers to make informed decisions that align with regulatory requirements.

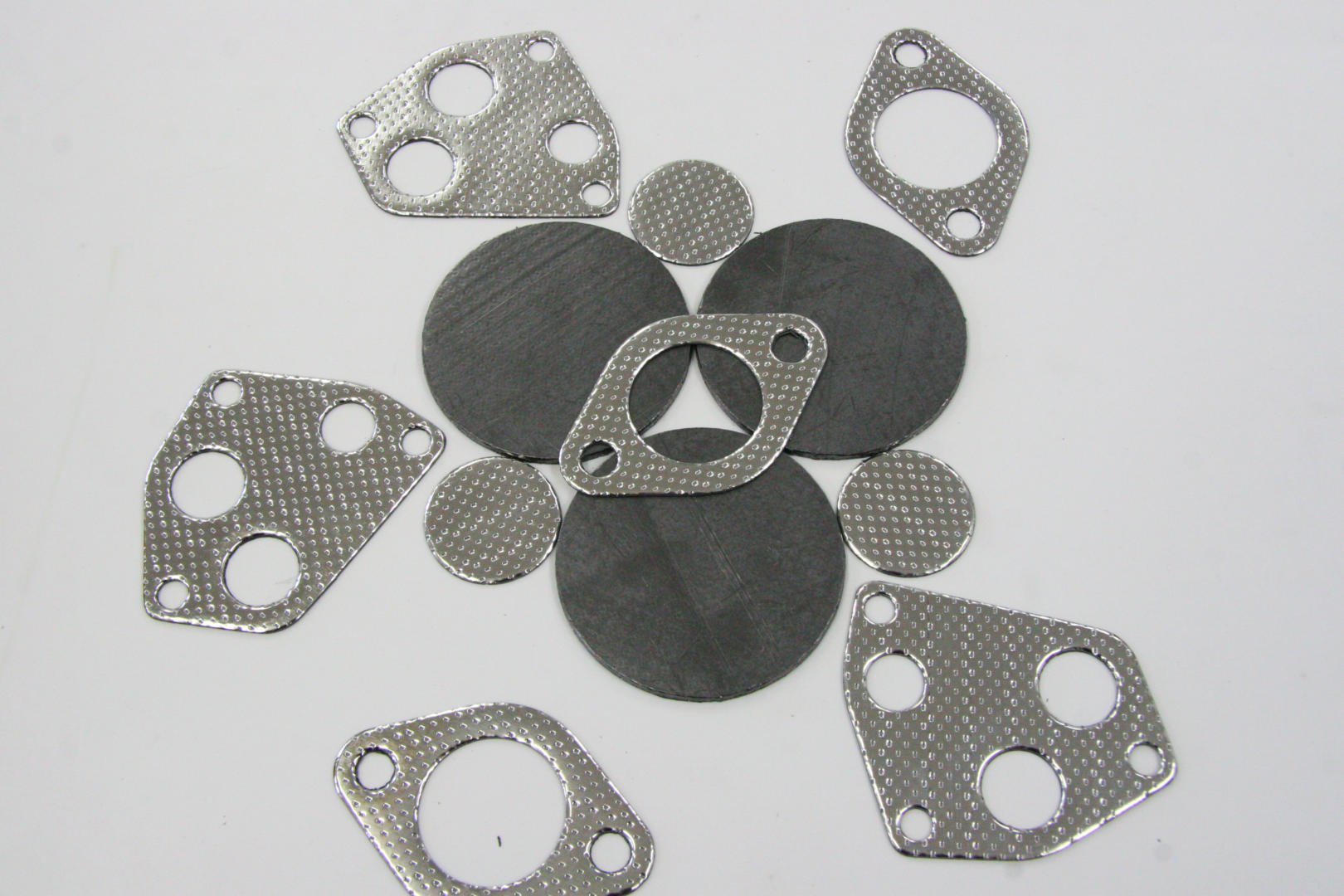

Strategic Material Selection Guide for exhaust system gaskets

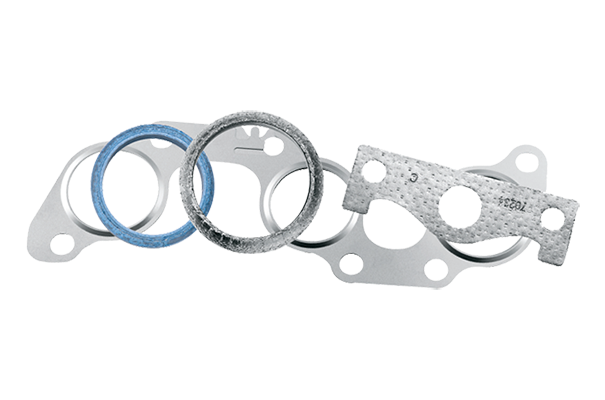

What Are the Key Materials Used in Exhaust System Gaskets?

When selecting materials for exhaust system gaskets, it is crucial to consider their performance characteristics, compatibility with various media, and suitability for different applications. Here, we analyze four common materials: graphite, metal, rubber, and composite materials.

How Does Graphite Perform in Exhaust System Gaskets?

Graphite is a popular choice for exhaust gaskets due to its excellent thermal stability and high-temperature resistance, typically rated up to 450°C (842°F). It is also chemically inert, making it resistant to corrosion from exhaust gases. The primary advantage of graphite gaskets is their ability to conform to irregular surfaces, ensuring a tight seal even under varying pressure conditions.

Illustrative image related to exhaust system gaskets

However, graphite gaskets can be brittle and may degrade over time, especially in high-stress applications. They are generally more expensive than rubber options, which may deter cost-sensitive buyers. For international buyers, especially in regions like Africa and South America, it’s essential to ensure compliance with local automotive standards, as graphite gaskets may not be widely available.

What Are the Benefits of Metal Gaskets?

Metal gaskets, often made from stainless steel or aluminum, are known for their durability and high-pressure tolerance. They can withstand extreme temperatures, often exceeding 600°C (1112°F), and are resistant to corrosion and wear. This makes them suitable for high-performance applications, such as racing or heavy-duty vehicles.

While metal gaskets offer excellent longevity, they can be more complex to manufacture, leading to higher costs. Additionally, they may require precise machining to ensure a proper fit, which can complicate the supply chain for international buyers. Compliance with standards such as ASTM or DIN is critical, especially in Europe, where quality regulations are stringent.

How Do Rubber Gaskets Compare in Performance?

Rubber gaskets, typically made from materials like EPDM or silicone, are favored for their flexibility and ease of installation. They are effective at sealing lower pressure applications and offer good resistance to weather and ozone. Rubber gaskets can typically withstand temperatures up to 200°C (392°F), making them suitable for standard automotive applications.

The downside is that rubber gaskets may not perform well under extreme conditions, such as high heat or pressure, leading to a shorter lifespan. They are also less effective in corrosive environments compared to graphite or metal gaskets. For buyers in the Middle East, where high temperatures are common, it is essential to select high-quality rubber compounds that can withstand local conditions.

Illustrative image related to exhaust system gaskets

What Advantages Do Composite Materials Offer?

Composite gaskets, which combine materials like rubber and metal, offer a balanced solution for many applications. They provide the flexibility of rubber while incorporating the strength of metal, making them suitable for a wide range of exhaust systems. Composite gaskets can handle moderate temperatures and pressures, typically around 300°C (572°F).

However, the manufacturing process for composite materials can be complex, leading to higher costs. Additionally, their performance can vary significantly based on the specific materials used in the composite. International buyers should verify the specifications and compliance with local standards, as composite materials can sometimes fall short in extreme conditions.

Summary Table of Material Options for Exhaust System Gaskets

| Material | Typical Use Case for exhaust system gaskets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Graphite | High-temperature applications | Excellent thermal stability | Brittle and may degrade over time | High |

| Metal | High-performance and heavy-duty vehicles | Durable and high-pressure tolerance | Complex manufacturing and higher costs | High |

| Rubber | Standard automotive applications | Flexible and easy to install | Limited performance under extreme conditions | Low |

| Composite | General-purpose applications | Balanced flexibility and strength | Variable performance and higher manufacturing costs | Medium |

This material selection guide provides a comprehensive overview for B2B buyers looking to make informed decisions about exhaust system gaskets. Understanding the properties, advantages, and limitations of each material will facilitate better procurement strategies tailored to specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for exhaust system gaskets

What Are the Typical Manufacturing Processes for Exhaust System Gaskets?

The manufacturing of exhaust system gaskets involves several critical stages, each designed to ensure that the final product meets stringent performance and quality standards. Understanding these processes is essential for B2B buyers looking to source high-quality components for their applications.

How Are Materials Prepared for Exhaust Gasket Production?

The first step in the manufacturing process is material preparation, which involves selecting the appropriate materials based on the specific requirements of the gasket. Common materials include multi-layer graphite, metal, and composite materials, each chosen for their thermal resistance and sealing capabilities.

Once the materials are selected, they undergo a series of treatments to enhance their durability and performance. This may include cutting, shaping, and pre-forming the materials into the desired dimensions. For instance, graphite sheets may be cut into specific shapes while ensuring that the thickness is consistent throughout.

What Forming Techniques Are Used in Gasket Manufacturing?

The next stage is forming, where the prepared materials are shaped into gaskets. This can be achieved through various techniques, including die-cutting, stamping, and molding.

-

Die-Cutting: This method is popular for flat gaskets, where a sharp die cuts the material into the required shape. Precision is paramount here to ensure that the gaskets fit perfectly within the exhaust system.

-

Molding: For more complex shapes or multi-layer gaskets, molding techniques are often employed. This involves placing the material into a mold and applying heat and pressure to form the gasket.

-

Stamping: Stamping is used for metal gaskets, where sheets of metal are pressed into specific forms. This technique is efficient for high-volume production and provides a consistent quality.

How Is the Assembly of Exhaust System Gaskets Managed?

After forming, the next step is assembly, particularly for gaskets that require multiple layers or components. This stage may involve:

-

Layering: In multi-layer gaskets, each layer is assembled in a specific order to ensure optimal sealing performance.

-

Adhesive Application: In some cases, adhesives are used to bond layers together, particularly in composite gaskets.

-

Quality Checking: Throughout the assembly process, quality checkpoints are established to verify that the components meet the specifications required for effective sealing.

What Finishing Processes Are Essential for Exhaust Gaskets?

Finishing processes enhance the gasket’s performance and appearance. These can include:

-

Surface Treatment: Gaskets may undergo surface treatments to improve their resistance to corrosion and wear.

-

Trimming: Excess material is trimmed away to ensure that the gaskets fit precisely within the exhaust system.

-

Final Inspection: A thorough inspection is performed to ensure that all specifications are met before the gaskets are packaged for distribution.

What Quality Assurance Standards Are Applicable to Exhaust Gaskets?

Quality assurance is critical in the production of exhaust system gaskets, particularly for international B2B buyers who require reliability and consistency.

Which International Standards Should Buyers Be Aware Of?

Several international standards govern the quality of automotive components, including:

-

ISO 9001: This standard focuses on quality management systems and is essential for ensuring that manufacturers maintain consistent quality throughout their processes.

-

CE Marking: Required for products sold in the European Economic Area, CE marking indicates that the product meets EU safety, health, and environmental protection standards.

-

API Standards: The American Petroleum Institute sets standards that may apply to exhaust system components, particularly in terms of performance and safety.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) processes are integrated at various stages of the manufacturing process to ensure that each gasket meets the required specifications:

-

Incoming Quality Control (IQC): This initial checkpoint examines raw materials for compliance with specifications before they enter the production process.

-

In-Process Quality Control (IPQC): During manufacturing, various tests and inspections are conducted to monitor the quality of the products. This can include dimensional checks and visual inspections.

-

Final Quality Control (FQC): Once the gaskets are assembled and finished, a final inspection is conducted to confirm that they meet all necessary standards and specifications before shipment.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is paramount to ensuring product reliability. Here are some actionable strategies:

What Audit Processes Should Buyers Consider?

Conducting audits is a crucial step in assessing a supplier’s quality management system. Buyers should request:

Illustrative image related to exhaust system gaskets

-

Supplier Audits: Regular audits can reveal compliance with international standards and the effectiveness of the supplier’s quality assurance processes.

-

Quality Reports: Suppliers should provide documentation detailing their quality control measures, including inspection reports and test results.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection agencies can add an additional layer of assurance. These agencies can provide independent verification of the supplier’s processes and products, ensuring that they meet the required standards.

What Nuances Should International Buyers Consider Regarding Quality Control?

When sourcing exhaust system gaskets from different regions, buyers should be aware of specific nuances:

-

Cultural Differences: Understanding the business practices and quality expectations in regions such as Africa, South America, the Middle East, and Europe can help buyers navigate potential challenges.

-

Regulatory Compliance: Different regions may have varying regulations regarding automotive components, making it essential for buyers to ensure that their suppliers comply with local laws and standards.

-

Communication: Clear communication regarding quality expectations and specifications is vital to prevent misunderstandings that could affect product quality.

By understanding the manufacturing processes and quality assurance measures in place for exhaust system gaskets, B2B buyers can make informed decisions that will enhance their operations and ensure product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘exhaust system gaskets’

Introduction

This guide serves as a practical checklist for B2B buyers looking to source exhaust system gaskets effectively. Whether you’re an automotive manufacturer, repair shop, or distributor, understanding the procurement process is crucial for ensuring quality and compatibility. Following these steps will help you navigate the complexities of sourcing gaskets tailored to your specific needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications required for the exhaust system gaskets. This includes dimensions, material types (such as graphite or metal), and specific performance characteristics like temperature tolerance and pressure ratings. Knowing these details will streamline your search and ensure compatibility with existing systems.

- Key Considerations:

- Vehicle make and model compatibility.

- Specific applications (e.g., racing, general use).

- Environmental factors (e.g., temperature and exposure to chemicals).

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in exhaust system gaskets. Look for manufacturers with a solid reputation in the industry, as well as those who offer a diverse range of products. A well-established supplier is more likely to provide quality assurance and reliable service.

- Where to Look:

- Industry-specific trade shows and exhibitions.

- Online marketplaces and B2B platforms.

- Recommendations from industry peers.

Step 3: Evaluate Supplier Certifications

Before making a decision, verify that potential suppliers hold relevant certifications and comply with international quality standards. Certifications such as ISO 9001 can indicate a commitment to quality management processes, which is essential for ensuring the reliability of the gaskets.

- Important Certifications:

- ISO 9001: Quality Management Systems.

- TS16949: Automotive Quality Standards.

- Local certifications relevant to your region.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the exhaust gaskets for testing. This step is crucial for assessing the quality and performance of the gaskets in real-world conditions. Testing samples will help you identify any compatibility issues or deficiencies before committing to a larger order.

- What to Test:

- Fit and seal integrity.

- Resistance to environmental factors.

- Performance under operational conditions.

Step 5: Compare Pricing and Payment Terms

Gather quotes from your shortlisted suppliers and compare pricing structures. Consider not just the cost of the gaskets but also shipping fees, payment terms, and potential discounts for bulk purchases. A comprehensive cost analysis will help you make an informed financial decision.

Illustrative image related to exhaust system gaskets

- Considerations:

- Total landed cost, including shipping and customs duties.

- Payment options (e.g., upfront, net 30).

- Volume discounts for larger orders.

Step 6: Review Supplier Logistics and Support

Assess the logistics capabilities of your potential suppliers, including their shipping options and delivery timelines. Additionally, inquire about after-sales support, warranty policies, and return processes. Reliable logistics and support can significantly impact your operational efficiency.

- Key Questions:

- What are the average lead times for orders?

- How does the supplier handle defective products?

- Is technical support available post-purchase?

Step 7: Finalize Your Purchase Agreement

After evaluating all factors, finalize the purchase agreement with your chosen supplier. Ensure that all terms are clearly outlined, including product specifications, pricing, delivery schedules, and warranty conditions. A well-drafted agreement will protect your interests and clarify expectations.

- Important Elements:

- Clear specifications and quantities.

- Agreed timelines for delivery.

- Conditions for returns and exchanges.

Following this checklist will position you to make informed decisions when sourcing exhaust system gaskets, ensuring that you select high-quality products tailored to your business’s needs.

Comprehensive Cost and Pricing Analysis for exhaust system gaskets Sourcing

What Are the Key Cost Components in Sourcing Exhaust System Gaskets?

When sourcing exhaust system gaskets, it’s essential to understand the various cost components that contribute to the overall pricing structure. These include:

-

Materials: The choice of materials significantly influences costs. Gaskets may be made from rubber, metal, or composite materials, with variations in durability and heat resistance affecting the price. For instance, multi-layer graphite gaskets typically command a premium due to their superior sealing properties.

-

Labor: Labor costs encompass both manufacturing and assembly. Skilled labor is often required for complex gasket designs, which can increase the overall cost. Regions with higher labor costs, such as parts of Europe, may see higher prices compared to manufacturers in Asia or South America.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and indirect labor. Efficient manufacturing processes can help minimize overhead, thereby reducing costs.

-

Tooling: Custom tooling for specialized gasket designs can be a significant upfront investment. This cost can be amortized over larger production runs, making it more feasible for high-volume orders.

-

Quality Control (QC): Implementing stringent QC processes ensures that gaskets meet required specifications, which can add to costs. However, investing in quality often results in fewer returns and warranty claims.

-

Logistics: Transportation costs vary significantly based on distance, mode of transport, and current fuel prices. Import duties and tariffs can also influence the total cost for international buyers.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. This margin can vary based on the supplier’s market position and the competitiveness of their pricing.

How Do Price Influencers Affect Exhaust System Gasket Costs?

Several factors can influence the pricing of exhaust system gaskets, particularly in international markets:

Illustrative image related to exhaust system gaskets

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower unit costs. Suppliers may offer discounts for larger orders, making it advantageous for buyers to consolidate purchases.

-

Specifications and Customization: Customized gaskets designed for specific applications may incur higher costs due to the additional engineering and material considerations involved. Buyers should clearly communicate their specifications to avoid unexpected costs.

-

Quality and Certifications: Gaskets that meet specific industry standards or certifications (e.g., ISO, OEM specifications) may come at a premium. However, investing in higher-quality gaskets can reduce maintenance costs in the long run.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can all influence pricing. Established suppliers with a track record of quality may charge more, but they can also offer reliability and consistency.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can impact the final cost. Understanding these terms is crucial for international buyers to accurately calculate total costs, including shipping and duties.

What Are Effective Buyer Tips for Cost-Efficient Sourcing?

To maximize value when sourcing exhaust system gaskets, buyers should consider the following strategies:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers may be willing to offer discounts or more favorable terms to secure a deal.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with the gaskets, including installation, maintenance, and potential downtime.

-

Understand Pricing Nuances for International Buyers: Buyers in regions like Africa, South America, the Middle East, and Europe should be aware of local market dynamics and how they affect pricing. Currency fluctuations and geopolitical factors can also impact costs.

-

Stay Informed on Market Trends: Regularly monitoring market trends can provide insights into pricing shifts and help buyers time their purchases effectively.

Conclusion

Understanding the comprehensive cost and pricing structure for exhaust system gaskets is crucial for international B2B buyers. By considering material choices, labor, overhead, and logistics, alongside effective negotiation and strategic purchasing, companies can optimize their sourcing strategy to achieve cost efficiency and reliability.

Alternatives Analysis: Comparing exhaust system gaskets With Other Solutions

Exploring Alternatives to Exhaust System Gaskets

When it comes to maintaining the integrity of an exhaust system, exhaust gaskets play a crucial role in preventing leaks and ensuring optimal performance. However, various alternative solutions can also achieve similar goals. Understanding these alternatives is essential for B2B buyers looking to make informed decisions for their operations.

Illustrative image related to exhaust system gaskets

| Comparison Aspect | Exhaust System Gaskets | Alternative 1: Metal Flanges | Alternative 2: High-Temperature Sealants |

|---|---|---|---|

| Performance | High sealing capability, preventing leaks and toxic emissions. | Excellent leak prevention but may require additional sealing materials. | Provides a strong seal but may degrade over time under extreme conditions. |

| Cost | Generally affordable with a wide range of options. | Higher initial investment due to material costs and machining. | Low cost for materials but may incur higher labor costs for application. |

| Ease of Implementation | Easy to install with standard tools; typically a direct replacement. | Installation may require precise machining and alignment. | Requires skill for effective application; not as straightforward as gaskets. |

| Maintenance | Regular inspections needed; easy to replace. | Durable but may require periodic checks for alignment and tightness. | May require reapplication over time, especially in high-stress areas. |

| Best Use Case | Ideal for standard exhaust systems in vehicles. | Best suited for custom or high-performance exhaust systems. | Effective for temporary fixes or in situations where gaskets cannot be used. |

What Are the Advantages and Disadvantages of Metal Flanges?

Metal flanges are a robust alternative to traditional exhaust gaskets. They offer excellent sealing capabilities and can withstand higher temperatures and pressures, making them suitable for performance applications. However, they can be more expensive due to the need for precise machining and may require additional sealing materials to ensure a leak-free installation. Furthermore, the installation process can be more complex, necessitating specialized tools and expertise.

How Do High-Temperature Sealants Compare to Exhaust System Gaskets?

High-temperature sealants are another alternative that provides a strong seal in exhaust applications. These materials can fill gaps and create a bond that withstands extreme temperatures. While they can be cost-effective, their performance may diminish over time, especially in high-stress environments. Applying sealants requires a certain level of skill, as improper application can lead to leaks or failure. They are often viewed as a temporary solution or a stopgap measure rather than a long-term fix.

Making the Right Choice for Your Exhaust System Needs

For B2B buyers, selecting the right exhaust system solution hinges on understanding specific operational needs and constraints. If you prioritize ease of installation and regular maintenance, exhaust gaskets remain a dependable choice. For custom or high-performance applications, metal flanges may offer superior durability, albeit at a higher cost and complexity. Lastly, if budget constraints are critical, high-temperature sealants can provide an alternative, though they may not deliver the longevity of gaskets or flanges. By carefully evaluating these alternatives, buyers can ensure optimal performance and reliability for their exhaust systems.

Essential Technical Properties and Trade Terminology for exhaust system gaskets

What Are the Key Technical Properties of Exhaust System Gaskets?

Understanding the critical specifications of exhaust system gaskets is essential for B2B buyers looking to ensure product reliability and performance. Here are some key properties to consider:

Illustrative image related to exhaust system gaskets

1. Material Grade

Exhaust gaskets are typically made from materials like multi-layer steel (MLS), graphite, or fiber-reinforced composites. The choice of material directly impacts durability, thermal resistance, and sealing performance. For instance, MLS gaskets offer excellent strength and are designed for high-performance applications, while graphite gaskets are favored for their thermal stability and flexibility.

2. Tolerance

Tolerance refers to the permissible limit of variation in a gasket’s dimensions. Accurate tolerances ensure a precise fit between components, which is crucial for preventing leaks. In B2B transactions, specifying the correct tolerance can help avoid costly rework or system failures, enhancing overall operational efficiency.

3. Thickness

Gasket thickness can affect compression and sealing capabilities. Thicker gaskets might compensate for irregularities in mating surfaces but can also lead to excessive compression under load. Understanding the right thickness for specific applications is vital for maintaining optimal performance and preventing premature wear.

4. Temperature Resistance

Exhaust gaskets are exposed to high temperatures and aggressive exhaust gases. A gasket’s temperature resistance rating indicates its ability to withstand thermal cycling without degrading. This property is crucial for applications in demanding environments, as it directly influences the longevity and reliability of the exhaust system.

Illustrative image related to exhaust system gaskets

5. Compression Set

Compression set measures how well a gasket maintains its original shape after being compressed over time. A low compression set indicates that the gasket will retain its sealing properties longer, which is especially important in high-stress applications. Buyers should prioritize gaskets with low compression set ratings to ensure long-term effectiveness.

6. Chemical Resistance

Exhaust gaskets must withstand exposure to various chemicals, including oil and fuel. Chemical resistance is a critical property that determines how well a gasket can perform in different environments. Gaskets with high chemical resistance minimize the risk of degradation and ensure a longer service life.

What Are Common Trade Terms in the Exhaust Gasket Industry?

Familiarizing yourself with industry jargon can enhance communication and negotiation effectiveness. Here are some essential trade terms:

Illustrative image related to exhaust system gaskets

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. These parts are designed to meet specific standards and are typically more reliable than aftermarket alternatives. For B2B buyers, sourcing OEM gaskets ensures compatibility and compliance with manufacturer specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for inventory management, especially for international buyers who may face shipping constraints. It’s essential to negotiate favorable MOQs to maintain cost efficiency.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers use RFQs to compare offers and assess supplier capabilities. A well-prepared RFQ can streamline procurement and foster better supplier relationships.

Illustrative image related to exhaust system gaskets

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. They clarify who bears the cost and risk at each stage of transportation. Familiarity with Incoterms is essential for international transactions to avoid misunderstandings and ensure smooth logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. Understanding lead times helps B2B buyers plan their inventory and production schedules effectively, ensuring that they maintain operational continuity.

6. Warranty Period

The warranty period is the duration during which a supplier guarantees the performance of a gasket. A longer warranty period often indicates higher confidence in product quality. Buyers should consider warranty terms as part of their procurement strategy to mitigate risks associated with product failure.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their supply chain efficiency and product performance.

Navigating Market Dynamics and Sourcing Trends in the exhaust system gaskets Sector

What Are the Current Market Dynamics and Key Trends Influencing the Exhaust System Gaskets Sector?

The exhaust system gaskets market is currently experiencing significant growth due to the increasing demand for automotive parts driven by the global rise in vehicle production and maintenance. Key trends include the adoption of advanced materials such as multi-layer graphite and metal composites, which offer superior durability and thermal resistance. Additionally, the growing emphasis on performance enhancement in vehicles is leading to a surge in demand for performance-oriented gaskets, particularly among aftermarket suppliers catering to modified vehicles.

Illustrative image related to exhaust system gaskets

International B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly leveraging digital platforms for sourcing. E-commerce solutions enable buyers to access a broader range of products and suppliers, facilitating easier comparisons of pricing and quality. Furthermore, the implementation of Industry 4.0 technologies, such as AI and IoT, is reshaping supply chain management, improving inventory forecasting, and enhancing the efficiency of logistics. This is particularly relevant for buyers in emerging markets where supply chain optimization can significantly reduce costs.

The rise of electric and hybrid vehicles is also influencing market dynamics, as manufacturers adapt their product lines to include gaskets suitable for these new technologies. As the automotive industry shifts towards sustainability, there is an increasing need for suppliers to align their offerings with the evolving regulatory frameworks aimed at reducing emissions and improving fuel efficiency.

How Is Sustainability and Ethical Sourcing Impacting the Exhaust System Gaskets Market?

Sustainability has become a cornerstone of modern business practices, particularly in the automotive sector. The environmental impact of exhaust system gaskets is significant, as traditional materials can contribute to pollution and waste. This has led to a growing demand for eco-friendly alternatives. B2B buyers are increasingly prioritizing suppliers who use sustainable materials, such as biodegradable composites and recycled metals, which not only reduce the carbon footprint but also enhance brand reputation.

Ethical sourcing is also gaining traction, with buyers seeking transparency in their supply chains. This includes ensuring that raw materials are sourced responsibly, without contributing to environmental degradation or human rights violations. Certifications such as ISO 14001 (Environmental Management) and the use of verified recycled materials are becoming essential for suppliers aiming to attract international buyers.

The push for greener alternatives is further driven by consumer demand for environmentally responsible products. As a result, companies that invest in sustainable practices are likely to gain a competitive edge, appealing to a broader audience and fostering customer loyalty.

What Is the Historical Context of the Exhaust System Gaskets Market?

The evolution of exhaust system gaskets can be traced back to the early days of the automotive industry, where simple materials like cork and rubber were used to seal exhaust systems. Over the decades, advancements in material science have transformed gasket technology. The introduction of multi-layer gaskets in the late 20th century provided enhanced sealing capabilities and longevity, which significantly reduced the occurrence of leaks and exhaust-related issues.

As the automotive industry has progressed, so too have the demands placed on gaskets. Today’s gaskets are designed to withstand higher temperatures and pressures, reflecting the performance needs of modern vehicles. This evolution continues to shape the market, with ongoing research and development focused on creating innovative materials that meet the stringent requirements of both manufacturers and consumers in a competitive global landscape.

By understanding these dynamics, B2B buyers can navigate the complexities of sourcing exhaust system gaskets, making informed decisions that align with current market trends and sustainability initiatives.

Frequently Asked Questions (FAQs) for B2B Buyers of exhaust system gaskets

-

How do I solve exhaust leaks caused by faulty gaskets?

To address exhaust leaks stemming from damaged gaskets, first identify the source of the leak, usually indicated by increased noise or visible damage. Inspect gaskets for cracks, pinches, or wear. Replace the defective gaskets with high-quality, compatible options from reputable suppliers. Ensure proper installation by following manufacturer specifications to maintain a leak-free seal. Regular inspections and timely replacements can prevent further complications in the exhaust system, enhancing vehicle performance and safety. -

What is the best type of exhaust gasket for high-performance applications?

For high-performance applications, multi-layer steel (MLS) gaskets are typically the best choice due to their durability and ability to withstand high pressures and temperatures. MLS gaskets offer excellent sealing properties, making them ideal for racing or modified vehicles. Additionally, consider gaskets made from advanced materials like graphite or composite materials, which can provide enhanced thermal resistance and flexibility, ensuring a tight seal even under extreme conditions. -

What factors should I consider when vetting a supplier for exhaust system gaskets?

When vetting suppliers, consider their reputation, product quality, and industry experience. Look for certifications that demonstrate compliance with international standards, such as ISO or TS certifications. Evaluate their ability to provide customized solutions tailored to your specific needs, including material options and dimensions. Additionally, inquire about their lead times, minimum order quantities (MOQs), and after-sales support to ensure a reliable partnership that meets your business requirements. -

How can I ensure the quality of exhaust gaskets during international trade?

To ensure the quality of exhaust gaskets in international trade, request samples before placing large orders. Implement a quality assurance process that includes third-party inspections at the supplier’s facility. Specify quality standards in your purchase agreement and ensure that the supplier understands and agrees to them. Establish clear communication channels to address any issues promptly and consider using escrow services for payments to protect your investment until quality is confirmed. -

What are the typical minimum order quantities (MOQs) for exhaust system gaskets?

Minimum order quantities for exhaust system gaskets can vary widely depending on the supplier and the type of gasket. Generally, MOQs range from 100 to 1,000 units, especially for customized gaskets. Suppliers may offer lower MOQs for standard sizes or pre-made gaskets. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms that align with your inventory management strategy. -

What payment terms are commonly accepted for international B2B transactions?

Common payment terms for international B2B transactions include letters of credit, wire transfers, and payment upon delivery. Some suppliers may offer net payment terms, such as net 30 or net 60 days, depending on your relationship and order size. Always clarify payment terms in advance to avoid misunderstandings. Consider using secure payment platforms to mitigate risks associated with international transactions. -

How can I customize exhaust gaskets for specific applications?

Customization of exhaust gaskets typically involves specifying dimensions, materials, and design features based on your application’s requirements. Collaborate closely with your supplier to provide detailed specifications, including the intended use, operating conditions, and any unique sealing needs. Suppliers experienced in custom manufacturing will often have the capability to create prototypes for testing before full-scale production, ensuring the gaskets meet your exact requirements. -

What logistics considerations should I keep in mind when sourcing exhaust gaskets internationally?

When sourcing exhaust gaskets internationally, consider shipping methods, customs regulations, and potential tariffs that could impact delivery times and costs. Evaluate the supplier’s logistics capabilities and their experience in exporting to your region. Additionally, ensure that you have a clear understanding of the estimated delivery times and any tracking options available. Building a robust logistics plan will help mitigate delays and ensure timely receipt of your products.

Top 7 Exhaust System Gaskets Manufacturers & Suppliers List

1. Ace Race Parts – Automotive Flanges & Gaskets

Domain: aceraceparts.com

Registered: 2014 (11 years)

Introduction: This company, Ace Race Parts – Automotive Flanges & Gaskets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Remflex – Exhaust Header Gaskets

Domain: catalog.remflex.com

Registered: 2004 (21 years)

Introduction: Remflex Exhaust Header / Manifold Gaskets include a variety of gasket sets for different vehicle makes and models. Key product details include:

– PN 6046: V8 – Mopar V8, fits 5.7L BBK Performance Headers Model #4028, 2 Piece Set, MSRP $57.99.

– PN 6008: Mopar Slant 6 (170, 198, 225), includes Riser Gasket, 2 Piece Set, MSRP $57.29.

– PN 3006: Ford V8 – 351 (’70-’74) Cleveland, 2bbl Carb, 2/Set,…

3. Fel-Pro – Exhaust System Gaskets

Domain: felpro.com

Registered: 1998 (27 years)

Introduction: Fel-Pro® offers exhaust system solutions for effectively resealing exhaust system joints and surfaces, including: Manifold gaskets, Pipe flange gaskets, Flange bolt & spring kits, Converter / Connector / Crossover gaskets, EGR gaskets. These gaskets are designed to withstand heat and motion, compensate for corrosion, pitting, and warping, and are tailored for the repair environment. A technical no…

4. S&S – Replacement Exhaust Gasket

Domain: sscycle.com

Registered: 1996 (29 years)

Introduction: S&S Replacement Exhaust Gasket, most 1984-Up models

Item #: 106-5029

Price: $7.95

Description: S&S exhaust gaskets are a perfect match for performance exhaust systems. Tapered wire mesh construction provides a larger contact area to ensure a perfect seal, preventing gasket crush into the exhaust port, which can obstruct exhaust gas flow.

Fits: 1984-2000 Evo models, 1999-2017 Twin Cam models, 2017-…

5. Cometic Gasket – Hi-Performance Gaskets

Domain: cometic.com

Registered: 1996 (29 years)

Introduction: This company, Cometic Gasket – Hi-Performance Gaskets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. MAPerformance – Exhaust Gaskets and Components

Domain: maperformance.com

Registered: 2004 (21 years)

Introduction: Exhaust Gaskets and components available at MAPerformance. Vendor restrictions prevent sales in Australia, the UK, California, and outside the United States. Customer service contact available for inquiries. Products include various brands such as BLOX Racing, Cobb Tuning, ETS, FactionFab, Fel-Pro, GrimmSpeed, HKS, Honda OEM, IAG Performance, Killer B Motorsports, MAPerformance, OEM Ford, OEM Mits…

7. A’PEXi – Replacement Exhaust Gaskets

Domain: apexi-usa.com

Registered: 1998 (27 years)

Introduction: A’PEXi Replacement Exhaust Gaskets – Available in Three Bolt and Two Bolt options – Price starts from $5.00 – Free shipping on orders over $60.00 (USA lower 48 states) – Compatible with various vehicle models including Honda, Acura, Lexus, Mazda, Mitsubishi, Nissan, Subaru, and Toyota.

Strategic Sourcing Conclusion and Outlook for exhaust system gaskets

How Can Strategic Sourcing Enhance Your Supply Chain for Exhaust System Gaskets?

In the competitive landscape of automotive parts procurement, strategic sourcing for exhaust system gaskets is crucial for optimizing performance and cost-efficiency. By partnering with reliable suppliers who offer high-quality materials—such as multi-layer graphite and stainless steel—businesses can significantly reduce the risk of leaks and enhance the longevity of their exhaust systems. This not only ensures compliance with environmental standards but also fosters customer satisfaction through improved vehicle performance.

Moreover, staying abreast of market trends and emerging technologies can provide a competitive edge. As automotive manufacturers increasingly focus on sustainability, sourcing eco-friendly gasket solutions can position your business as a leader in responsible sourcing.

Looking forward, international B2B buyers from Africa, South America, the Middle East, and Europe should leverage local market insights to identify suppliers that align with their specific needs. Establishing strong relationships with manufacturers will not only streamline operations but also enhance adaptability to evolving market demands. Embrace strategic sourcing today to secure a robust supply chain for your exhaust system gaskets and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.