Everything You Need to Know About Woodworking Bolts Sourcing in 2025

Introduction: Navigating the Global Market for woodworking bolts

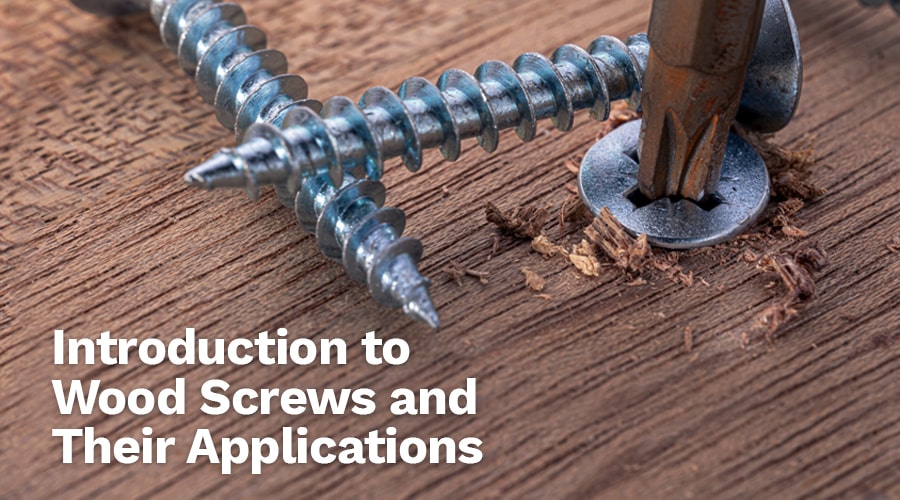

Navigating the global market for woodworking bolts presents unique challenges for international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality woodworking bolts that meet specific project requirements can be daunting, given the diverse materials, sizes, and applications available. This guide aims to equip buyers with the essential knowledge to make informed purchasing decisions, covering the various types of woodworking bolts, their applications, and critical factors for supplier vetting.

Understanding the distinctions between different fasteners, such as T-nuts, dowel screws, and hanger bolts, is crucial for ensuring optimal performance in woodworking projects. Additionally, the guide delves into pricing strategies and cost considerations, offering insights into how to negotiate favorable terms with suppliers. By addressing these key areas, this comprehensive resource empowers businesses to confidently navigate the complexities of the woodworking fastener market.

With a focus on actionable insights tailored to specific regional needs, this guide supports buyers in making strategic decisions that enhance their operations and project outcomes. Whether you’re a manufacturer in Nigeria or a furniture exporter in Saudi Arabia, you’ll find valuable information that streamlines your sourcing process and fosters successful partnerships in the global woodworking industry.

Understanding woodworking bolts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| T-Nuts | Flanged nuts that provide strong anchoring in wood. | Furniture assembly, cabinetry. | Pros: Strong hold, easy to install. Cons: Requires precise drilling. |

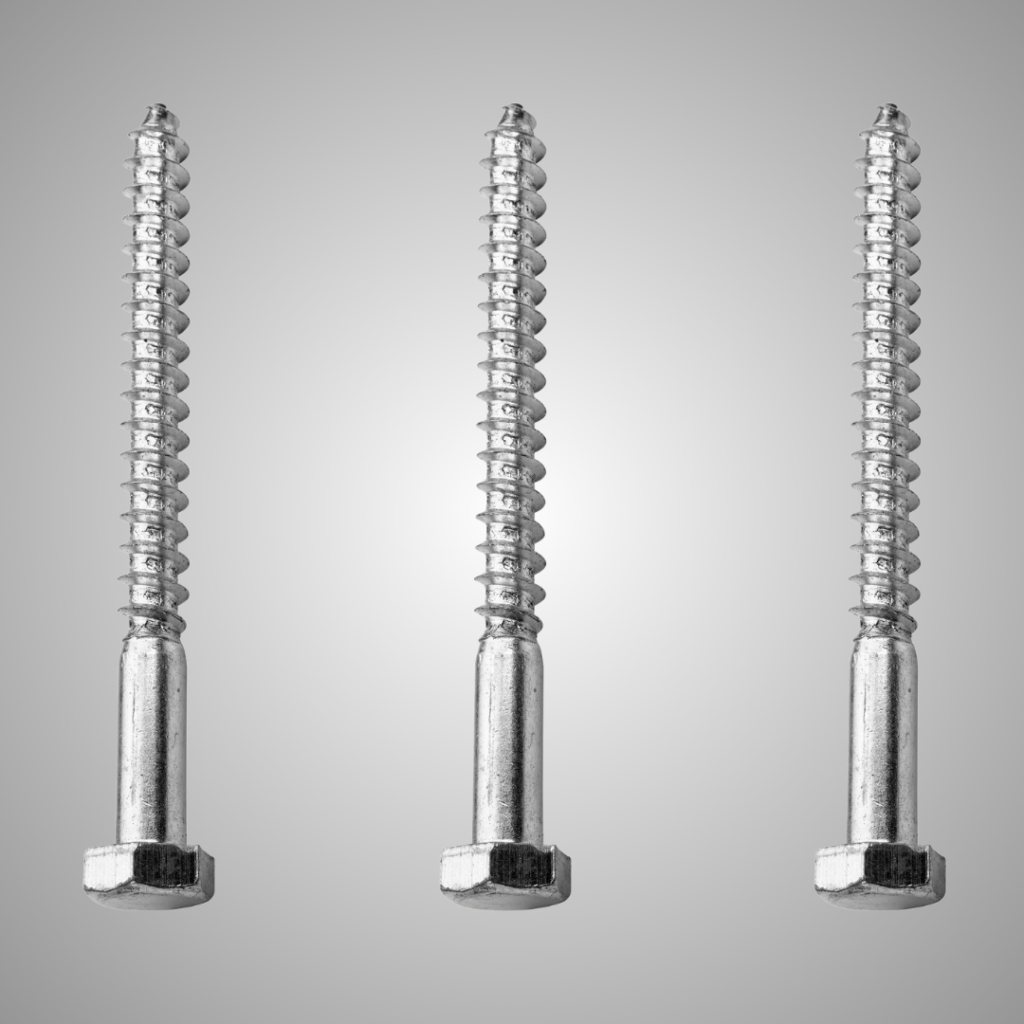

| Hanger Bolts | One end has wood screw threads, the other has machine threads. | Securing furniture legs, mounting fixtures. | Pros: Versatile, great for heavy loads. Cons: May require specific tools for installation. |

| Dowel Screws | Fully threaded screws designed for joining wood pieces. | Cabinet making, furniture construction. | Pros: Invisible joint, strong connection. Cons: Limited adjustment post-installation. |

| Threaded Inserts | Metal inserts that allow for repeated assembly/disassembly. | Modular furniture, prototypes. | Pros: Durable, reusable. Cons: Higher initial cost. |

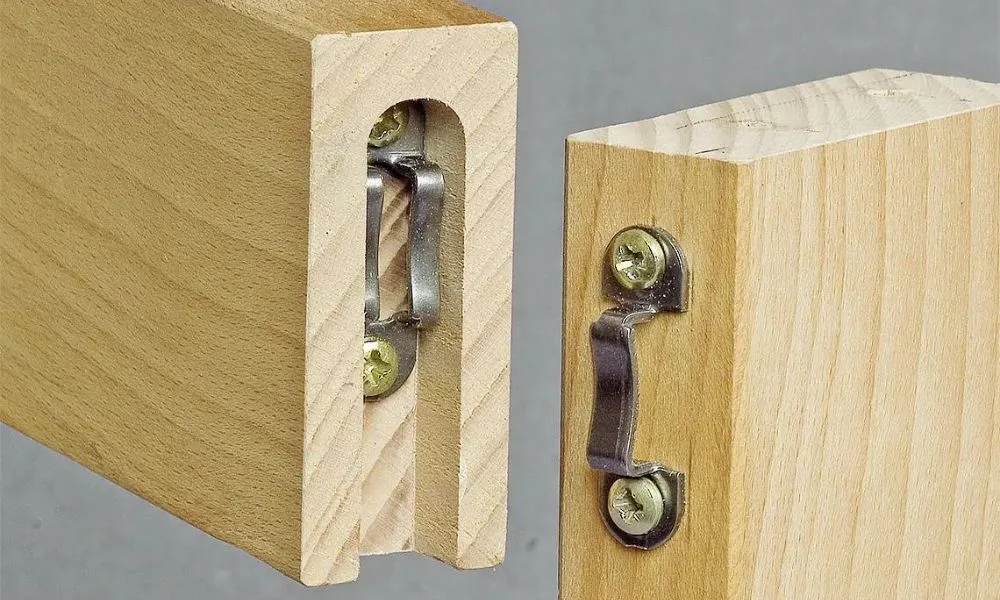

| Knock-Down Hardware | Components designed for easy assembly and disassembly. | Flat-pack furniture, transportable designs. | Pros: Convenient for shipping, cost-effective. Cons: May compromise structural integrity over time. |

What Are T-Nuts and Their Applications in Woodworking?

T-Nuts are an essential component for woodworking projects that require a strong and reliable anchoring method. These flanged nuts are inserted into pre-drilled holes in wood, allowing for secure fastening from the opposite side. They are particularly useful in furniture assembly and cabinetry, where a robust joint is critical. When purchasing T-Nuts, consider the size, material (steel or brass), and compatibility with your project to ensure optimal performance.

How Do Hanger Bolts Enhance Furniture Stability?

Hanger bolts are unique fasteners with one end featuring wood screw threads and the other equipped with machine threads. This design makes them ideal for securing furniture legs or mounting heavy fixtures. Their versatility and strength make them a popular choice in commercial applications, especially where heavy loads are involved. Buyers should focus on the size and load capacity when selecting hanger bolts to match their specific needs.

What Are Dowel Screws and When to Use Them?

Dowel screws are fully threaded fasteners that serve to connect two pieces of wood without visible hardware on the surface. This makes them an excellent choice for cabinetry and fine furniture construction, where aesthetics are paramount. While they provide a strong connection, it’s important to note that dowel screws can limit adjustability once installed. Buyers should assess the thickness of the wood and the required length of the screws before purchasing.

Why Choose Threaded Inserts for Your Wood Projects?

Threaded inserts are metal components that allow for repeated assembly and disassembly of wooden structures. They are particularly beneficial in modular furniture and prototypes, where components may need to be reconfigured frequently. Although they come with a higher initial cost, their durability and reusability make them a smart investment for businesses looking to enhance their product offerings. Consider the material and size of the inserts to ensure compatibility with your designs.

What Is Knock-Down Hardware and Its Benefits?

Knock-Down Hardware refers to a range of fasteners designed for easy assembly and disassembly, ideal for flat-pack furniture and transportable designs. This hardware type is cost-effective and convenient, allowing for quick setup and breakdown of furniture pieces. However, it may compromise structural integrity over time, especially with repeated assembly. Buyers should evaluate the long-term use and potential wear of these components when considering them for their products.

Illustrative image related to woodworking bolts

Key Industrial Applications of woodworking bolts

| Industry/Sector | Specific Application of woodworking bolts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Assembling wooden furniture | Ensures durability and structural integrity | Material quality, corrosion resistance, size options |

| Construction | Structural framing and joinery | Provides strong and reliable connections | Load capacity, weather resistance, compliance with local standards |

| Cabinetry | Cabinet assembly and installation | Enhances aesthetic appeal and functionality | Finish options, thread types, ease of installation |

| Joinery | Creating complex wood joints | Improves joint strength and longevity | Precision engineering, compatibility with wood types |

| DIY Home Improvement | Home renovation projects | Facilitates ease of assembly for non-professionals | Versatility, availability in local markets, packaging options |

How Are Woodworking Bolts Used in Furniture Manufacturing?

In the furniture manufacturing sector, woodworking bolts are crucial for assembling various types of wooden furniture, such as tables, chairs, and cabinets. They provide robust connections that enhance durability and structural integrity, ensuring that finished products can withstand regular use. For international buyers, sourcing high-quality bolts that meet specific standards is essential to avoid issues like rusting or breaking. Additionally, understanding the specific dimensions and thread types required for different furniture designs is vital to ensure compatibility and ease of assembly.

What Role Do Woodworking Bolts Play in Construction?

In the construction industry, woodworking bolts are frequently used for structural framing and joinery. They create strong and reliable connections between wooden beams and panels, which is critical for the overall stability of buildings. Buyers in regions like Africa and the Middle East must consider local building codes and load requirements when sourcing bolts. Additionally, weather resistance and the ability to handle various environmental conditions are key factors in ensuring the longevity of the structure.

How Are Woodworking Bolts Essential for Cabinetry?

In cabinetry, woodworking bolts are used extensively in the assembly and installation of cabinets. They not only provide strength but also contribute to the aesthetic appeal of the finished product. For B2B buyers, factors such as finish options and thread types are important to match the cabinetry’s design and functionality. Moreover, sourcing bolts that facilitate easy installation can significantly reduce assembly time and labor costs, making them a preferred choice among manufacturers.

What Benefits Do Woodworking Bolts Offer in Joinery?

Joinery applications benefit greatly from woodworking bolts, which help create complex wood joints that enhance strength and longevity. This is especially important in high-quality woodworking projects where the integrity of the joints is paramount. Buyers should look for precision-engineered bolts that are compatible with various wood types to ensure optimal performance. Understanding the specific requirements for joint types can also aid in sourcing the right bolts, which can improve product quality and reduce returns.

How Do DIY Home Improvement Projects Utilize Woodworking Bolts?

In DIY home improvement projects, woodworking bolts simplify the assembly process for non-professionals. They are commonly used in furniture assembly and home renovations, providing a sturdy yet easy-to-use fastening solution. For international buyers, sourcing versatile bolts that are readily available in local markets can enhance project efficiency. Additionally, packaging options that cater to various project sizes can be a significant consideration for DIY enthusiasts, helping them manage costs while ensuring they have the necessary materials on hand.

Illustrative image related to woodworking bolts

3 Common User Pain Points for ‘woodworking bolts’ & Their Solutions

Scenario 1: Sourcing Quality Woodworking Bolts for Specific Applications

The Problem: Many B2B buyers struggle with sourcing woodworking bolts that meet the specific requirements of their projects. This can lead to delays, increased costs, and ultimately unsatisfactory results. For instance, when a buyer needs bolts that can withstand humidity for outdoor furniture but ends up purchasing standard bolts not designed for such conditions, the entire project can be jeopardized. Additionally, inconsistent quality from suppliers can further complicate sourcing, leading to frustration and potential loss of business.

The Solution: To overcome this challenge, buyers should establish clear specifications for the bolts they require, including material type, corrosion resistance, and load-bearing capacity. Engaging with reputable suppliers that specialize in woodworking fasteners is crucial; they can provide detailed product information and support. Buyers can also request samples to assess quality before committing to larger orders. Leveraging online platforms that showcase reviews and ratings can help in identifying reliable vendors. Finally, forming long-term relationships with suppliers can lead to better pricing and prioritized service, ensuring that buyers can consistently obtain the right bolts for their needs.

Scenario 2: Dealing with Inconsistent Thread Sizes and Compatibility Issues

The Problem: A frequent issue for B2B buyers is the confusion surrounding thread sizes and compatibility between different types of woodworking bolts and their corresponding nuts and inserts. Incompatibility can lead to assembly problems and structural weaknesses, which are particularly critical in industries where safety and durability are paramount, such as furniture manufacturing or construction. This scenario often results in project delays and additional costs due to rework.

The Solution: To mitigate this issue, it is essential for buyers to familiarize themselves with the standardized thread sizes and types used in woodworking bolts, such as UNC (Unified National Coarse) or UNF (Unified National Fine). Buyers should maintain a comprehensive catalog of the bolt sizes and types they commonly use, along with their respective matching nuts and washers. Implementing a quality control process that includes verifying thread compatibility during procurement can prevent mismatches. Additionally, investing in training for the purchasing team on fastener specifications can enhance their knowledge and decision-making capabilities, reducing the likelihood of errors.

Scenario 3: Navigating Cost Fluctuations and Supply Chain Disruptions

The Problem: B2B buyers often face the challenge of fluctuating costs and supply chain disruptions, particularly in regions with unstable logistics networks. This situation can lead to unpredictable pricing for woodworking bolts, making budget management difficult. Moreover, supply chain delays can halt production lines, affecting delivery schedules and customer satisfaction. Buyers need a strategy to manage these risks effectively.

The Solution: One proactive approach is to establish a diversified supplier base to reduce dependency on a single source. This strategy can help mitigate risks associated with supply chain disruptions and price fluctuations. Buyers should consider entering into long-term contracts with suppliers for key components, locking in prices and ensuring availability. Additionally, implementing an inventory management system that includes forecasting and safety stock levels can help buffer against sudden demand spikes or supply shortages. Engaging in regular market analysis to stay informed about price trends and potential disruptions can further empower buyers to make informed purchasing decisions and negotiate better terms with suppliers.

Strategic Material Selection Guide for woodworking bolts

What are the Key Properties of Common Materials Used in Woodworking Bolts?

When selecting woodworking bolts, the material plays a crucial role in determining the performance, durability, and suitability of the fasteners for specific applications. Below is an analysis of four common materials used for woodworking bolts, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to woodworking bolts

1. Steel

Key Properties: Steel bolts are known for their high tensile strength and durability. They can withstand significant mechanical stress and are often treated for enhanced corrosion resistance, making them suitable for various environments.

Pros & Cons: The primary advantage of steel is its cost-effectiveness and strength, making it ideal for structural applications. However, untreated steel is prone to rust, especially in humid environments, which can limit its use in outdoor applications. Additionally, manufacturing complexity can arise if specialized coatings are required for corrosion protection.

Impact on Application: Steel bolts are compatible with most woodworking applications, but their performance may be compromised in environments with high moisture or exposure to chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM A307 or DIN 933 is essential for ensuring quality. Buyers should also consider local environmental conditions that may affect the longevity of steel bolts.

2. Stainless Steel

Key Properties: Stainless steel bolts offer excellent corrosion resistance due to their chromium content, making them suitable for both indoor and outdoor applications. They maintain their strength at elevated temperatures, providing versatility in various woodworking projects.

Illustrative image related to woodworking bolts

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust, which makes it ideal for applications exposed to moisture. However, stainless steel bolts are generally more expensive than their carbon steel counterparts, and their manufacturing processes can be more complex due to the need for specific alloys.

Impact on Application: Stainless steel is particularly beneficial in coastal regions or environments where exposure to chemicals is a concern, ensuring the longevity of the fasteners.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM A276 or JIS G4303. The higher initial cost may be justified by the extended lifespan of the product, especially in harsh environments.

3. Brass

Key Properties: Brass bolts are known for their aesthetic appeal and good corrosion resistance, particularly in non-corrosive environments. They exhibit moderate strength and are relatively easy to machine.

Pros & Cons: The primary advantage of brass is its resistance to corrosion and attractive finish, making it suitable for decorative woodworking applications. However, brass bolts are not as strong as steel or stainless steel, which limits their use in high-stress applications. Additionally, they can be more expensive than steel options.

Impact on Application: Brass is ideal for applications where appearance matters, such as furniture assembly or decorative fixtures, but it may not be suitable for load-bearing applications.

Considerations for International Buyers: Compliance with standards like ASTM B16 is crucial. Buyers should also consider the cost implications, as brass may not be the most economical choice for structural applications.

4. Aluminum

Key Properties: Aluminum bolts are lightweight and resistant to corrosion, making them suitable for applications where weight is a critical factor. They have moderate strength and good thermal conductivity.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which is beneficial in applications requiring reduced weight. However, aluminum bolts may not provide the same level of strength as steel or stainless steel, making them less suitable for heavy-duty applications.

Illustrative image related to woodworking bolts

Impact on Application: Aluminum is often used in lightweight furniture or cabinetry where ease of handling is essential, but it may not be suitable for high-stress environments.

Considerations for International Buyers: Compliance with standards such as ASTM B211 is important. Buyers should also evaluate the intended application to ensure aluminum bolts meet performance requirements.

Summary Table of Material Selection for Woodworking Bolts

| Material | Typical Use Case for woodworking bolts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural applications | High strength and cost-effective | Prone to rust without treatment | Low |

| Stainless Steel | Outdoor and coastal applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Brass | Decorative applications | Attractive finish and corrosion resistant | Lower strength than steel | Med |

| Aluminum | Lightweight furniture and cabinetry | Lightweight and corrosion resistant | Moderate strength | Med |

This guide provides a comprehensive overview of the materials commonly used in woodworking bolts, enabling international B2B buyers to make informed decisions based on their specific needs and conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for woodworking bolts

What Are the Main Stages in the Manufacturing Process of Woodworking Bolts?

The manufacturing of woodworking bolts involves several crucial stages that ensure both the quality and durability of the final product. Understanding these stages is essential for B2B buyers, particularly those sourcing from diverse regions like Africa, South America, the Middle East, and Europe.

Material Preparation: What Raw Materials Are Used?

The first step in the manufacturing process is material preparation. Woodworking bolts are typically made from high-quality steel, stainless steel, or other metal alloys that provide the necessary strength and corrosion resistance. The choice of material impacts not just the performance of the bolt but also its price point. Suppliers often opt for materials that meet international standards, ensuring that the bolts can withstand varying environmental conditions, which is particularly important for buyers in humid or coastal areas.

After selecting the material, it undergoes processes such as cutting and machining to achieve the desired dimensions. This stage may also involve surface treatment to enhance durability and resistance to wear and tear.

How Are Woodworking Bolts Formed?

The forming stage is where raw materials are shaped into bolts. This can be achieved through several techniques, including:

-

Cold Heading: This method involves deforming the metal at room temperature using dies. Cold heading is preferred for high-volume production as it enhances the mechanical properties of the material and reduces waste.

-

Thread Rolling: After forming the head of the bolt, threads are rolled onto the shaft. This process not only creates the necessary threads but also improves the surface finish, providing better grip and reducing the likelihood of stripping during installation.

-

Machining: Some bolts may require additional machining to achieve specific tolerances or features, such as grooves or special head shapes.

These techniques ensure that woodworking bolts are produced with precise dimensions and high performance, suitable for various woodworking applications.

Illustrative image related to woodworking bolts

What Finishing Processes Are Essential for Quality?

Finishing processes are critical for ensuring that woodworking bolts meet both aesthetic and functional requirements. Common finishing processes include:

-

Coating: Bolts may be coated with materials such as zinc or black oxide to enhance corrosion resistance and provide a more attractive appearance. This is particularly relevant for outdoor applications or environments with high moisture levels.

-

Heat Treatment: This process involves heating and cooling the bolts to alter their physical properties, enhancing strength and ductility. Heat-treated bolts can withstand greater loads, making them ideal for heavy-duty applications.

-

Surface Treatment: Techniques like shot peening or polishing can be applied to improve surface quality, reducing friction and wear during use.

These finishing processes ensure that the bolts not only perform well but also have a longer lifespan, which is a crucial consideration for B2B buyers looking for cost-effective solutions.

What Quality Assurance Measures Are Critical for Woodworking Bolts?

Quality assurance (QA) is vital in the manufacturing process of woodworking bolts, ensuring that products meet both international standards and specific customer requirements.

Which International Standards Are Relevant for Woodworking Bolt Quality?

International standards such as ISO 9001 are essential for manufacturers aiming to demonstrate their commitment to quality management systems. Compliance with these standards indicates that a company has established processes for continual improvement, customer satisfaction, and product quality.

Illustrative image related to woodworking bolts

In addition to ISO 9001, specific industry standards may apply, such as CE marking for products sold in Europe, which ensures compliance with safety, health, and environmental protection standards. API standards might also be relevant for bolts used in specific applications, particularly in the oil and gas sectors.

What Are the Key Quality Control Checkpoints?

Quality control in woodworking bolt manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet specified standards before they enter the production process. It includes checking material certifications and conducting random sampling tests.

-

In-Process Quality Control (IPQC): During production, ongoing inspections help identify any deviations from quality standards. This includes monitoring the forming and finishing processes to ensure compliance with tolerances and specifications.

-

Final Quality Control (FQC): Once the bolts are manufactured, a final inspection is conducted before packaging. This may involve dimensional checks, visual inspections, and functional testing to ensure that the bolts meet all quality requirements.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of their suppliers:

-

Audits: Conducting supplier audits can provide insight into the manufacturing processes and quality assurance practices. This allows buyers to assess compliance with international standards and identify areas for improvement.

-

Reports: Requesting detailed quality control reports can help buyers understand the supplier’s QA practices. These reports should include information on test results, inspection frequencies, and corrective actions taken for non-conformances.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. This is especially important for buyers in regions with stringent import regulations or those looking to mitigate risks associated with sourcing from international suppliers.

What Nuances Should International B2B Buyers Consider?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality assurance is crucial. Different regions may have varying standards and regulations that affect product quality and compliance.

-

Cultural Differences: Buyers should be aware of cultural differences that may influence business practices and communication styles. Establishing clear expectations upfront can help mitigate misunderstandings.

-

Import Regulations: Understanding the import regulations in the buyer’s country is vital. Compliance with local standards can affect the ability to sell or use the products once they arrive.

-

Supplier Relationships: Building strong relationships with suppliers can facilitate better communication regarding quality control issues and lead to more favorable terms in future transactions.

By understanding the manufacturing processes and quality assurance measures for woodworking bolts, B2B buyers can make informed decisions that align with their quality expectations and business needs. This knowledge not only enhances procurement strategies but also contributes to the long-term success of woodworking projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘woodworking bolts’

In the competitive world of woodworking, sourcing the right bolts is essential for ensuring the quality and durability of your projects. This guide aims to provide B2B buyers with a comprehensive checklist to streamline the procurement process for woodworking bolts, ensuring that you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before diving into supplier options, clearly outline the technical requirements for the bolts you need. Consider factors such as material (e.g., stainless steel, carbon steel), size, thread type, and finish. This clarity will not only help you communicate effectively with suppliers but also ensure you acquire products that meet your project specifications.

Illustrative image related to woodworking bolts

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in woodworking bolts. Utilize online directories, industry forums, and trade shows to compile a list. Focus on suppliers with a strong reputation for quality and reliability, as well as those who have experience servicing businesses in your target regions, such as Africa, South America, or the Middle East.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is critical to ensuring product quality and compliance with international standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management, or other relevant industry certifications. This step helps mitigate risks associated with sourcing inferior products that could compromise your projects.

Step 4: Request Product Samples

Before making a large order, request samples of the woodworking bolts you intend to purchase. This allows you to assess the quality, fit, and functionality of the bolts in real-world applications. Pay attention to the material properties, corrosion resistance, and any specific features that are critical for your projects.

Step 5: Review Pricing and Payment Terms

Compare pricing across multiple suppliers, but remember that the lowest price does not always equate to the best value. Evaluate the total cost of ownership, which includes shipping, duties, and any potential tariffs for international purchases. Additionally, clarify payment terms and conditions to ensure they align with your cash flow requirements.

Step 6: Check Delivery Times and Logistics

Understanding the supplier’s delivery times is essential for planning your project timelines. Inquire about their logistics capabilities, especially if you require international shipping. Ensure that the supplier can meet your delivery deadlines consistently, as delays can significantly impact your production schedules.

Illustrative image related to woodworking bolts

Step 7: Establish a Communication Plan

Effective communication with your supplier is vital for a successful partnership. Establish a clear communication plan that outlines how often you expect updates on your orders, how to handle potential issues, and who to contact for different concerns. Good communication fosters a strong relationship and can lead to better service and support in the long run.

By following this checklist, B2B buyers can streamline their sourcing process for woodworking bolts, ensuring that they make informed decisions that enhance their operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for woodworking bolts Sourcing

What Are the Key Cost Components in Woodworking Bolts Manufacturing?

When sourcing woodworking bolts, understanding the cost structure is critical for B2B buyers. The total cost of woodworking bolts encompasses several components:

-

Materials: The choice of materials (e.g., stainless steel, carbon steel, or brass) significantly influences the base cost. Higher quality materials often lead to increased durability and performance, which can justify a higher price point.

-

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. Skilled labor may be required for precision machining or quality control, impacting overall costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can help reduce these costs, providing competitive pricing for buyers.

-

Tooling: The initial investment in tooling for specialized bolt designs can be substantial. Custom tooling can increase upfront costs but may lead to lower long-term production costs if the demand is sufficient.

-

Quality Control (QC): Rigorous quality control processes ensure that each bolt meets the required specifications. While this adds to the cost, it is essential for maintaining reliability and safety in woodworking applications.

-

Logistics: Shipping costs, including freight and customs duties, can significantly affect the final price, particularly for international buyers. Efficient logistics planning can mitigate some of these expenses.

-

Margin: Suppliers typically add a markup to cover operational costs and profit margins. Understanding the market dynamics can help buyers negotiate better prices.

What Influences Pricing for Woodworking Bolts?

Several factors can influence the pricing of woodworking bolts, making it essential for buyers to consider these elements during negotiations:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts. Suppliers may offer tiered pricing, where larger quantities lead to lower per-unit costs.

-

Specifications and Customization: Custom-designed bolts tailored to specific applications may incur additional costs. Buyers should balance the need for customization against the potential price increases.

-

Material Choices: The grade and type of material selected can significantly impact pricing. Stainless steel bolts, for instance, will generally be more expensive than carbon steel options due to their corrosion resistance.

-

Quality Certifications: Bolts that meet international quality standards or certifications (like ISO or ASTM) may come at a premium. However, these certifications can enhance the reliability and safety of woodworking projects.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can also affect pricing. Established suppliers may charge higher prices due to their reliability and quality assurance processes.

-

Incoterms: Understanding the shipping terms agreed upon can affect total costs. Buyers should clarify who bears the shipping and customs responsibilities to avoid unexpected expenses.

How Can Buyers Negotiate Better Prices for Woodworking Bolts?

B2B buyers can employ several strategies to optimize cost-efficiency when sourcing woodworking bolts:

-

Conduct Market Research: Understanding market prices and trends can empower buyers during negotiations. Gathering quotes from multiple suppliers can provide leverage.

-

Emphasize Long-Term Relationships: Building a strong relationship with suppliers can lead to better pricing and terms. Regular orders can encourage suppliers to offer discounts or improved payment terms.

-

Focus on Total Cost of Ownership (TCO): Consider not only the purchase price but also factors like durability and performance, which can influence the long-term value of the bolts.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing strategies. Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions and supplier dynamics.

Important Note on Pricing

Prices for woodworking bolts can fluctuate based on market conditions, supply chain issues, and geopolitical factors. It is advisable for buyers to request indicative quotes and be prepared for potential variations in pricing during negotiations.

Alternatives Analysis: Comparing woodworking bolts With Other Solutions

Understanding Alternatives to Woodworking Bolts: Key Comparisons for B2B Buyers

In the woodworking industry, selecting the right fastening solution is crucial for ensuring durability, performance, and cost-effectiveness. While woodworking bolts are a popular choice, various alternatives exist, each with unique advantages and disadvantages. This analysis will compare woodworking bolts against dowel screws and pocket hole joinery, two viable options for fastening wood pieces.

Comparison Table

| Comparison Aspect | Woodworking Bolts | Dowel Screws | Pocket Hole Joinery |

|---|---|---|---|

| Performance | High load-bearing capacity | Moderate load-bearing capacity | Strong, hidden joints |

| Cost | Moderate | Low to moderate | Moderate to high |

| Ease of Implementation | Requires drilling and threading | Easy to install with pre-drilled holes | Requires special jigs and tools |

| Maintenance | Low maintenance | Low maintenance | Low maintenance |

| Best Use Case | Heavy-duty applications | Furniture assembly and repairs | Cabinet construction and face frames |

What are the Advantages and Disadvantages of Dowel Screws?

Dowel screws are a popular alternative due to their simplicity and effectiveness in joining wood pieces. These screws feature a double-ended design that allows for easy insertion into pre-drilled holes, making them user-friendly, especially for quick furniture assembly. Their cost-effectiveness is another significant advantage, as they are generally less expensive than woodworking bolts. However, while they provide decent load-bearing capacity, they may not be suitable for high-stress applications where stronger mechanical connections are necessary.

How Does Pocket Hole Joinery Compare to Woodworking Bolts?

Pocket hole joinery is another alternative that offers a unique method for connecting wooden parts. This technique involves drilling angled holes into one piece of wood, allowing for screws to be driven into the adjoining piece at an angle, creating a strong joint. One of the primary benefits of pocket hole joinery is the aesthetic advantage it offers; the screws are hidden, resulting in a cleaner finish. However, it requires specific jigs and tools, which can increase initial setup costs and complexity. While it provides a strong joint, the requirement for specialized equipment may deter some buyers.

Conclusion: Choosing the Right Fastening Solution for Your Needs

When selecting the best fastening solution, B2B buyers should consider the specific demands of their projects. Woodworking bolts are ideal for applications that require robust load-bearing capabilities, making them suitable for heavy-duty furniture and structural components. Conversely, dowel screws offer an economical and straightforward solution for lighter applications, while pocket hole joinery provides an aesthetically pleasing option for cabinetry and visible joints. By weighing the performance, cost, ease of implementation, and intended use case, buyers can make informed decisions that align with their operational needs and project goals.

Essential Technical Properties and Trade Terminology for woodworking bolts

What Are the Key Technical Properties of Woodworking Bolts?

When selecting woodworking bolts, understanding their technical properties is crucial for ensuring quality and performance in various applications. Here are some essential specifications to consider:

-

Material Grade

Woodworking bolts are typically made from various materials, including steel, stainless steel, and brass. The grade of the material affects the bolt’s strength, corrosion resistance, and overall durability. For instance, Grade 8 steel bolts are often preferred for heavy-duty applications due to their high tensile strength, while stainless steel bolts are ideal for outdoor use due to their resistance to rust and corrosion. -

Thread Type and Pitch

The thread type (coarse or fine) and pitch (the distance between threads) significantly impact the bolt’s holding power and compatibility with nuts and inserts. Coarse threads are easier to install and remove, making them suitable for softwoods, while fine threads provide better tension and are ideal for hardwoods or denser materials. Understanding these aspects helps ensure the right fit and performance in woodworking projects. -

Diameter and Length

The diameter and length of the bolt determine its load-bearing capacity and application suitability. Common diameters range from #8 to 1/2 inch, with lengths varying from 1 inch to over 6 inches. Selecting the correct size ensures that the bolt can withstand the forces applied during use without failing, which is critical in structural applications. -

Finish and Coating

The finish on woodworking bolts—such as zinc plating, black oxide, or powder coating—affects both aesthetics and functionality. Coatings can enhance corrosion resistance, which is particularly important in humid or outdoor environments. For B2B buyers, specifying the appropriate finish can prolong the lifespan of the product and reduce maintenance costs. -

Tolerance Levels

Tolerance refers to the allowable deviation in dimensions from the specified size. For woodworking bolts, precise tolerances are essential to ensure compatibility with other components and to avoid issues during assembly. Understanding tolerance levels helps in selecting bolts that will perform reliably under various conditions.

What Are Common Trade Terminology and Concepts Related to Woodworking Bolts?

Navigating the B2B landscape involves understanding specific terminology that facilitates effective communication and decision-making. Here are several key terms to familiarize yourself with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of woodworking bolts, OEM suppliers are crucial for businesses looking for customized or specialized fasteners for specific applications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products a supplier is willing to sell. Understanding MOQs is vital for B2B buyers to manage inventory and budget effectively. For woodworking bolts, MOQs can vary significantly based on the supplier and the type of bolts ordered. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. This is particularly useful for B2B buyers to compare costs, lead times, and payment conditions for woodworking bolts, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps B2B buyers understand shipping, insurance, and liability aspects when importing woodworking bolts from overseas suppliers. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is critical for planning production schedules, especially in the woodworking industry, where delays can impact project timelines. -

Certification Standards

Certifications, such as ISO or ASTM standards, indicate that the bolts meet specific quality and safety criteria. For international buyers, ensuring that woodworking bolts comply with relevant certifications can mitigate risks and ensure product reliability.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their procurement processes and optimize their woodworking projects.

Navigating Market Dynamics and Sourcing Trends in the woodworking bolts Sector

What Are the Key Trends Influencing the Woodworking Bolts Market?

The woodworking bolts market is witnessing significant changes driven by globalization, technological advancements, and evolving consumer preferences. Key trends include the increasing demand for specialized fasteners that cater to specific applications, such as dowel screws and hanger bolts, which are essential for furniture assembly and construction. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers that offer customized solutions and a diverse range of products to meet local market needs.

Emerging technologies such as automation and e-commerce platforms are transforming sourcing strategies. Buyers now prioritize suppliers that provide comprehensive online catalogs and digital tools for easy comparison and ordering. The rise of Industry 4.0 is also influencing manufacturing processes, leading to enhanced precision in bolt production and reduced lead times. Additionally, sustainability concerns are prompting buyers to source from companies that emphasize eco-friendly practices in production and packaging.

As market dynamics evolve, understanding regional nuances is essential. For instance, buyers in Nigeria and Saudi Arabia may prioritize different product features based on local construction standards and climate conditions. Establishing strong supplier relationships and leveraging digital sourcing tools will be key for international buyers to navigate these complexities effectively.

How Important Is Sustainability and Ethical Sourcing in the Woodworking Bolts Sector?

Sustainability and ethical sourcing have become paramount in the woodworking bolts sector, reflecting broader trends in global supply chains. The environmental impact of fastener production, particularly in terms of resource extraction and manufacturing emissions, necessitates a focus on sustainable practices. B2B buyers are increasingly evaluating suppliers based on their commitment to reducing carbon footprints and implementing eco-friendly manufacturing processes.

Moreover, ethical supply chains are critical for building brand reputation and customer loyalty. Buyers are encouraged to seek suppliers that hold certifications such as FSC (Forest Stewardship Council) or ISO 14001, which indicate responsible sourcing and environmental management. The use of recycled materials in bolt production is also gaining traction, as it aligns with the circular economy model and meets the growing demand for sustainable products.

Illustrative image related to woodworking bolts

Investing in sustainable sourcing not only mitigates environmental impact but also ensures compliance with international regulations and standards. This approach can lead to long-term cost savings and improved operational efficiency for businesses, making it a strategic priority for international buyers in the woodworking bolts market.

What Is the Brief Evolution of Woodworking Bolts in the B2B Context?

The evolution of woodworking bolts has been closely tied to advancements in woodworking technology and changing consumer demands. Historically, woodworking fasteners were limited to basic screws and nails, primarily used in simple furniture construction. However, as woodworking techniques evolved, so did the complexity of the fasteners required.

The introduction of specialized bolts, such as dowel screws and hanger bolts, addressed the need for stronger and more reliable connections in furniture and cabinetry. The rise of engineered wood products also spurred innovations in bolt design, leading to improved performance and ease of use. Today, B2B buyers benefit from a wide variety of options tailored to different woodworking applications, supported by technological advancements in manufacturing and sourcing processes. This ongoing evolution highlights the importance of staying informed about product developments and market trends for competitive advantage in the woodworking industry.

Frequently Asked Questions (FAQs) for B2B Buyers of woodworking bolts

-

How do I choose the right woodworking bolts for my project?

Selecting the appropriate woodworking bolts involves considering the material, size, and type of joint you are working with. For hardwood applications, look for bolts made from high-strength steel or stainless steel to ensure durability. Additionally, assess the length and diameter based on the thickness of the materials being joined. It is also crucial to consider the type of head (e.g., hex, round) based on the tools available for installation. Consulting with suppliers about specific project requirements can provide further guidance. -

What are the advantages of using threaded inserts and T-nuts in woodworking?

Threaded inserts and T-nuts provide a reliable method for securing bolts in wood, particularly in applications requiring repeated assembly and disassembly. These fasteners allow for a stronger joint and distribute load more evenly, reducing the risk of splitting. They are especially useful in furniture assembly or modular designs. When sourcing these fasteners, ensure they are compatible with the thickness of the material and the bolt size to maintain structural integrity. -

What are common minimum order quantities (MOQs) for woodworking bolts?

Minimum order quantities for woodworking bolts can vary significantly depending on the supplier and the type of fasteners. Generally, MOQs range from 100 to 1,000 pieces for standard sizes. Custom orders or specialized bolts may have higher MOQs. It is advisable to discuss your specific needs with suppliers early in the sourcing process to negotiate favorable terms and avoid excess inventory. -

What payment terms should I expect when sourcing woodworking bolts internationally?

Payment terms in international transactions often include options such as advance payment, letter of credit, or net 30/60/90 days. Many suppliers may require a deposit upfront, especially for custom orders. It’s important to clarify these terms before placing an order to ensure cash flow management aligns with your business operations. Also, consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers. -

How can I vet suppliers for woodworking bolts to ensure quality?

Vetting suppliers is crucial to ensure the quality and reliability of woodworking bolts. Start by checking their certifications (e.g., ISO 9001) and customer reviews. Request samples to assess the quality firsthand and inquire about their manufacturing processes and quality control measures. Additionally, visiting the manufacturing facility, if feasible, can provide insights into their operational standards and capacity to meet your demands. -

What logistics considerations should I keep in mind when importing woodworking bolts?

When importing woodworking bolts, consider factors such as shipping methods, customs duties, and lead times. Choose a reliable freight forwarder who understands international trade regulations and can assist with documentation. Ensure that you are aware of any import restrictions or tariffs in your country. Additionally, factor in storage solutions upon arrival to prevent damage or delays in distribution. -

How can I customize woodworking bolts to meet specific project needs?

Customization options for woodworking bolts often include variations in size, material, finish, and thread type. Many suppliers offer bespoke solutions tailored to your specifications. To initiate customization, provide detailed drawings or specifications to the supplier. Discuss lead times and potential costs associated with custom orders to ensure they fit within your project timeline and budget. -

What quality assurance measures should I implement when sourcing woodworking bolts?

Implementing quality assurance measures involves establishing clear specifications for the bolts you require and communicating these to your suppliers. Regular inspections during the manufacturing process and upon receipt of goods are essential. Consider third-party inspections for larger orders to ensure compliance with your quality standards. Keeping open communication with suppliers about quality expectations can help mitigate issues before they arise.

Top 4 Woodworking Bolts Manufacturers & Suppliers List

1. KNAPP® – KLICK Dovetail Connector

Domain: knappconnectors.com

Registered: 2016 (9 years)

Introduction: KNAPP® offers a range of concealed woodworking fasteners designed for architectural millwork and shop fittings. Key products include:

1. **KLICK Dovetail Connector** – Snap-in connector for trims and moldings, designed for a clean finish without visible hardware. Price range: $28.99 – $127.99.

2. **sKLICK Dovetail Connector** – Concealed connector for trims and moldings, allows for on-site adju…

2. Reddit – Carriage and Galvanized Bolts

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Stainless steel or galvanized carriage or hex head bolts; galvanized bolts are cheaper; carriage bolts protrude less on one side; Timberlocks may also be considered.

3. Newport Fasteners – Wood Screws

Domain: newportfasteners.com

Registered: 2018 (7 years)

Introduction: Wood Screws Deep Thread Phillips Flat Head Nibs Type 17 Point Steel Black Oxide SKU: DPF17B As low as $232.99; Wood Screws Phillips Flat Head Brass SKU: SWSBFP As low as $17.99; Wood Screws Slotted Flat Head Brass SKU: SWSBFS As low as $16.99; Wood Screws Slotted Oval Head Brass SKU: SWSBOS As low as $43.99; Wood Screws Phillips Round Head Brass SKU: SWSBRP As low as $16.99; Wood Screws Slotted Ro…

4. Quickscrews – Particle Board Screws

Domain: quickscrews.com

Registered: 1997 (28 years)

Introduction: Particle Board screws are the primary fasteners used in woodworking, designed to connect wood pieces and attach hardware. Key features include:

– Drive Types: Phillips Drive, Square Drive, and Combo Drive (Square/Phillips). The Combo Drive is preferred for its resistance to stripping.

– Head Shapes: Pan or Round Washer, Flat, and Oval. Each serves different purposes, such as affixing thin object…

Strategic Sourcing Conclusion and Outlook for woodworking bolts

In today’s competitive woodworking industry, strategic sourcing of bolts is essential for ensuring quality and reliability in your projects. By selecting the right suppliers and understanding the various types of woodworking bolts available—such as T-nuts, dowel screws, and hanger bolts—international buyers can enhance their operational efficiency and product offerings. It’s crucial to consider factors such as material quality, compatibility with specific woodworking applications, and pricing strategies to optimize procurement processes.

Investing time in establishing strong supplier relationships not only secures better pricing but also fosters innovation through collaboration. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for high-quality woodworking fasteners is expected to rise. Buyers are encouraged to leverage this trend by sourcing from reputable manufacturers who can meet their specific needs and adhere to international standards.

Looking ahead, the woodworking industry presents significant opportunities for growth and expansion. By aligning procurement strategies with market demands, buyers can position themselves for success. Engage with suppliers today to explore how strategic sourcing can elevate your woodworking projects and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.