Everything You Need to Know About What Is A Ribbon Blade Mixer Sourcing in 2025

Introduction: Navigating the Global Market for what is a ribbon blade mixer

In the ever-evolving landscape of industrial manufacturing, sourcing the right equipment can be a daunting challenge, particularly when it comes to selecting a ribbon blade mixer. This essential tool is crucial for achieving uniformity in various powder blending applications, yet many international B2B buyers face hurdles in understanding its diverse functionalities and specifications. This comprehensive guide delves into the intricacies of ribbon blade mixers, exploring their design, operational principles, and wide-ranging applications across industries such as food processing, pharmaceuticals, and chemical production.

Navigating through this guide, you will find valuable insights into the various types of ribbon mixers available, their operational advantages, and key considerations for selecting the right model for your specific needs. We will also cover the critical aspects of supplier vetting, ensuring that you partner with reputable manufacturers who can meet your quality and compliance standards. Additionally, we will provide an overview of cost factors, helping you make informed financial decisions that align with your business objectives.

For B2B buyers from Africa, South America, the Middle East, and Europe—including regions like Germany and Nigeria—this guide serves as a vital resource. By empowering you with the knowledge to evaluate options and make strategic purchasing decisions, we aim to enhance your operational efficiency and drive your business success in the competitive global market.

Understanding what is a ribbon blade mixer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Ribbon Mixer | Features dual helical ribbons for effective mixing; suitable for dry powders. | Food, pharmaceuticals, plastics, and chemicals | Pros: Versatile, efficient, gentle on materials. Cons: Limited for viscous or slurry mixes. |

| Vacuum Ribbon Mixer | Incorporates vacuum capability to remove air during mixing; prevents oxidation. | Pharmaceutical, food processing, and chemicals | Pros: Enhances product quality, suitable for sensitive materials. Cons: Higher initial investment. |

| High-Shear Ribbon Mixer | Combines ribbon mixing with high-shear capabilities for fine emulsions. | Cosmetics, food, and pharmaceuticals | Pros: Effective for emulsifying and dispersing; fast mixing cycles. Cons: More complex maintenance. |

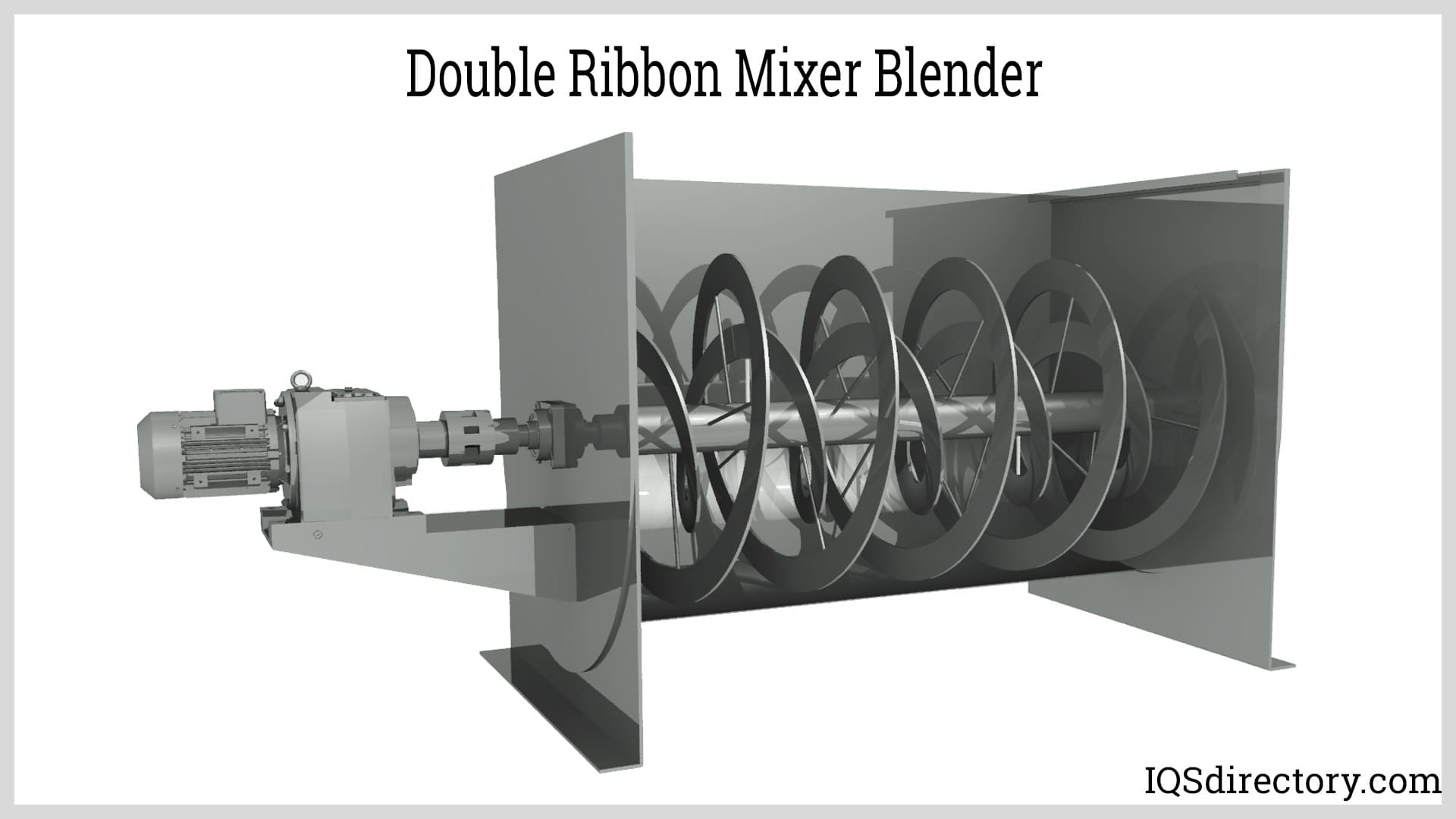

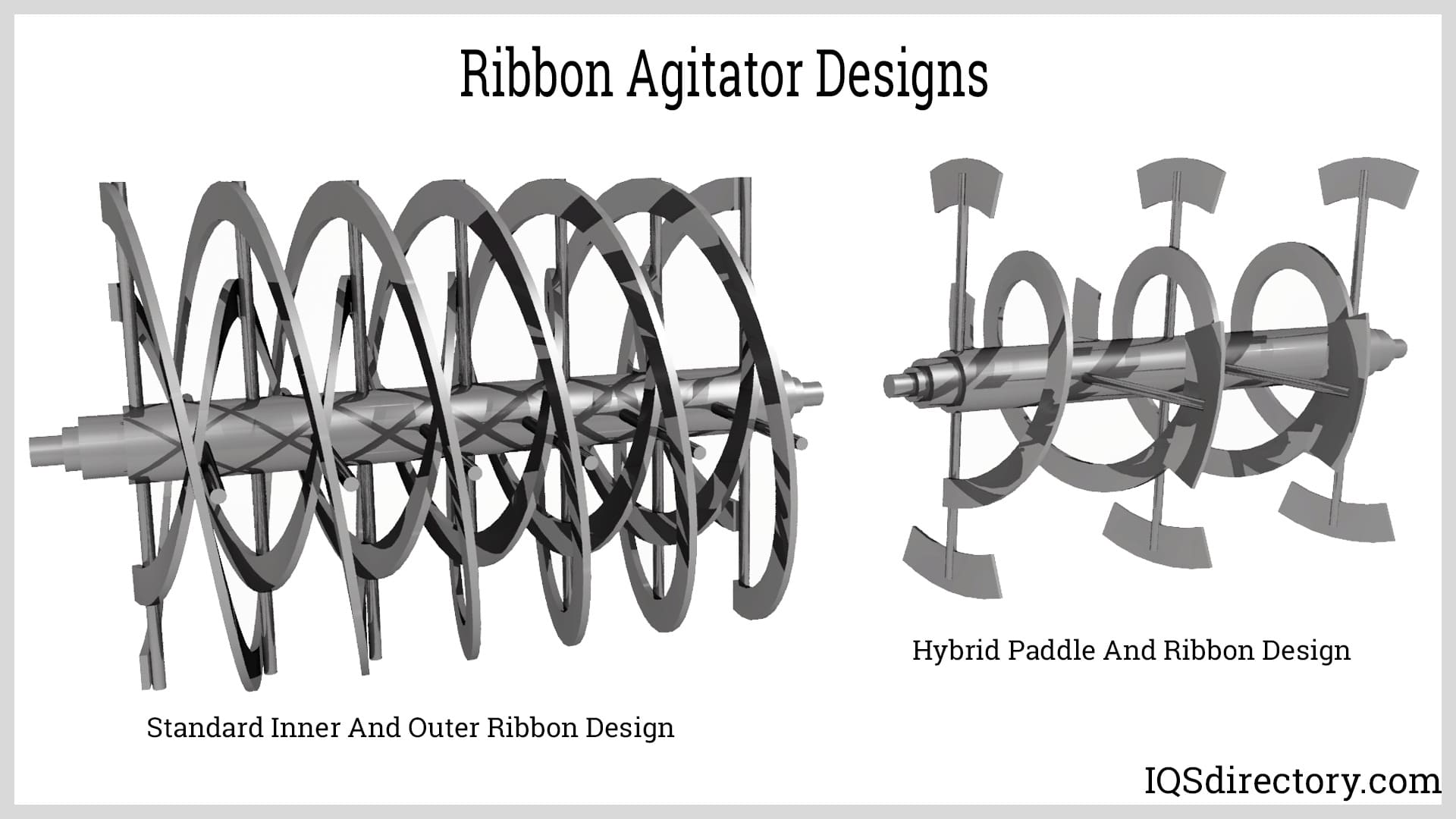

| Double Ribbon Mixer | Features two sets of ribbons for increased mixing efficiency; ideal for large volumes. | Bulk powder processing in various industries | Pros: Improved homogeneity, suitable for large batches. Cons: Requires more space and higher cost. |

| Sanitary Ribbon Mixer | Designed with hygienic standards in mind; often features smooth finishes and easy disassembly. | Food, pharmaceuticals, and biotech | Pros: Easy to clean, minimizes contamination risk. Cons: May be more expensive than standard models. |

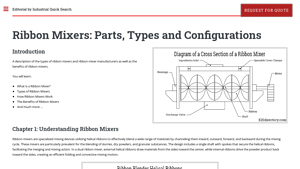

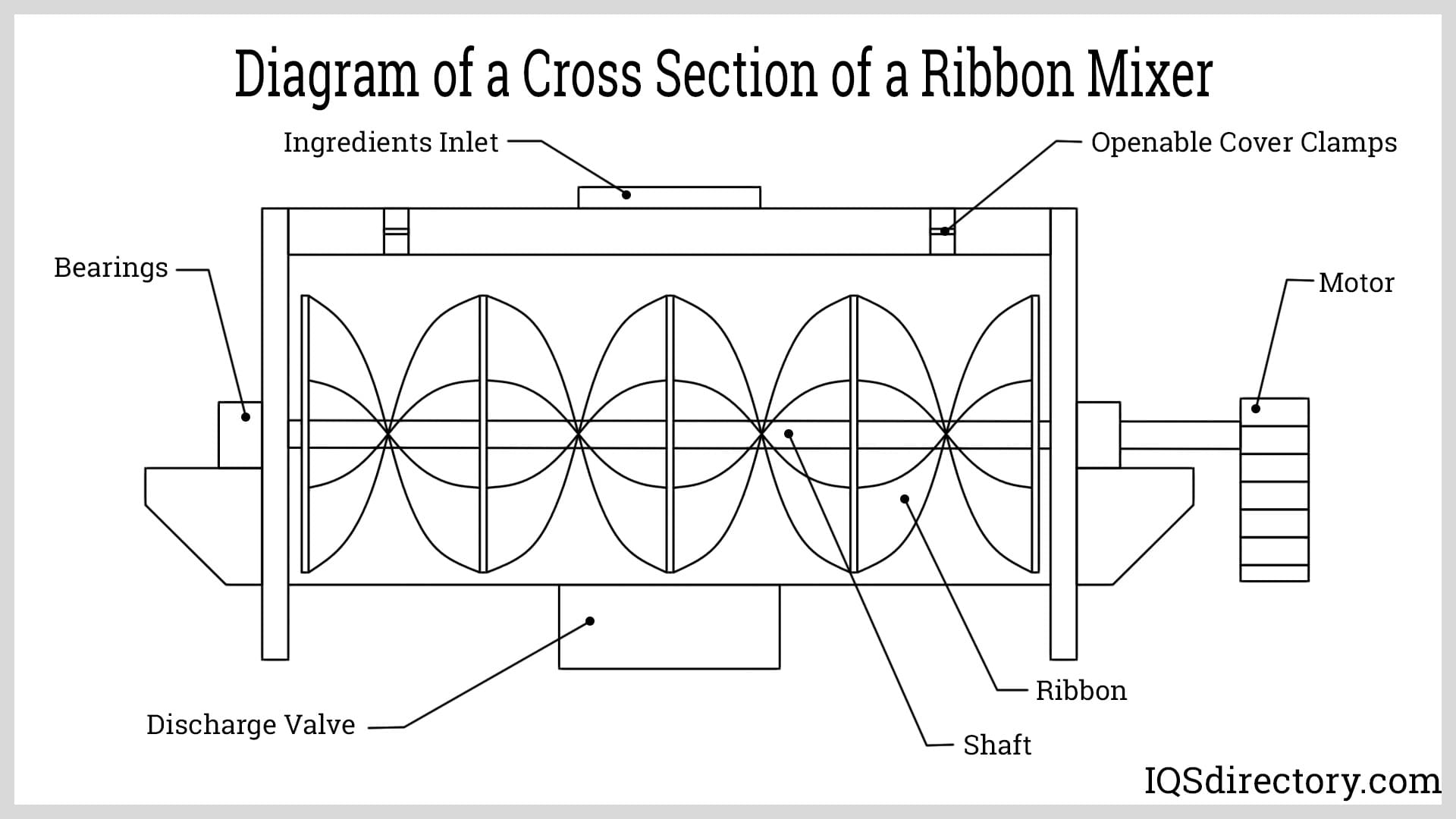

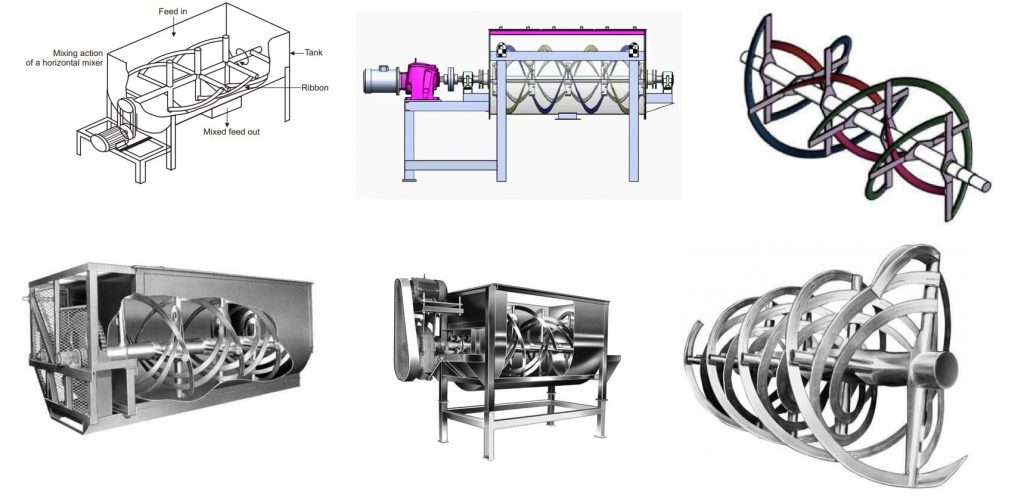

What Are the Key Characteristics of a Standard Ribbon Mixer?

The standard ribbon mixer is the most commonly used type, featuring two helical ribbons that move materials inward and outward. This design facilitates efficient blending of dry powders and granules, making it suitable for various industries, including food, pharmaceuticals, and plastics. When considering this option, buyers should assess the required capacity and bulk density of their materials, as these factors significantly influence the mixer’s performance and efficiency.

How Does a Vacuum Ribbon Mixer Enhance Product Quality?

The vacuum ribbon mixer is engineered to eliminate air from the mixing environment, which is essential for preventing oxidation in sensitive materials. This capability is particularly beneficial in the pharmaceutical and food processing sectors, where product integrity is paramount. Buyers should consider the initial investment versus the long-term benefits of enhanced product quality and reduced spoilage, especially for high-value ingredients.

What Advantages Does a High-Shear Ribbon Mixer Offer?

High-shear ribbon mixers combine the gentle mixing action of standard ribbon mixers with high-shear capabilities, making them ideal for creating fine emulsions and dispersions. These mixers are commonly used in cosmetics and food applications where texture and consistency are critical. While they offer fast mixing cycles, buyers should be aware of the more complex maintenance requirements and ensure they have the necessary support for upkeep.

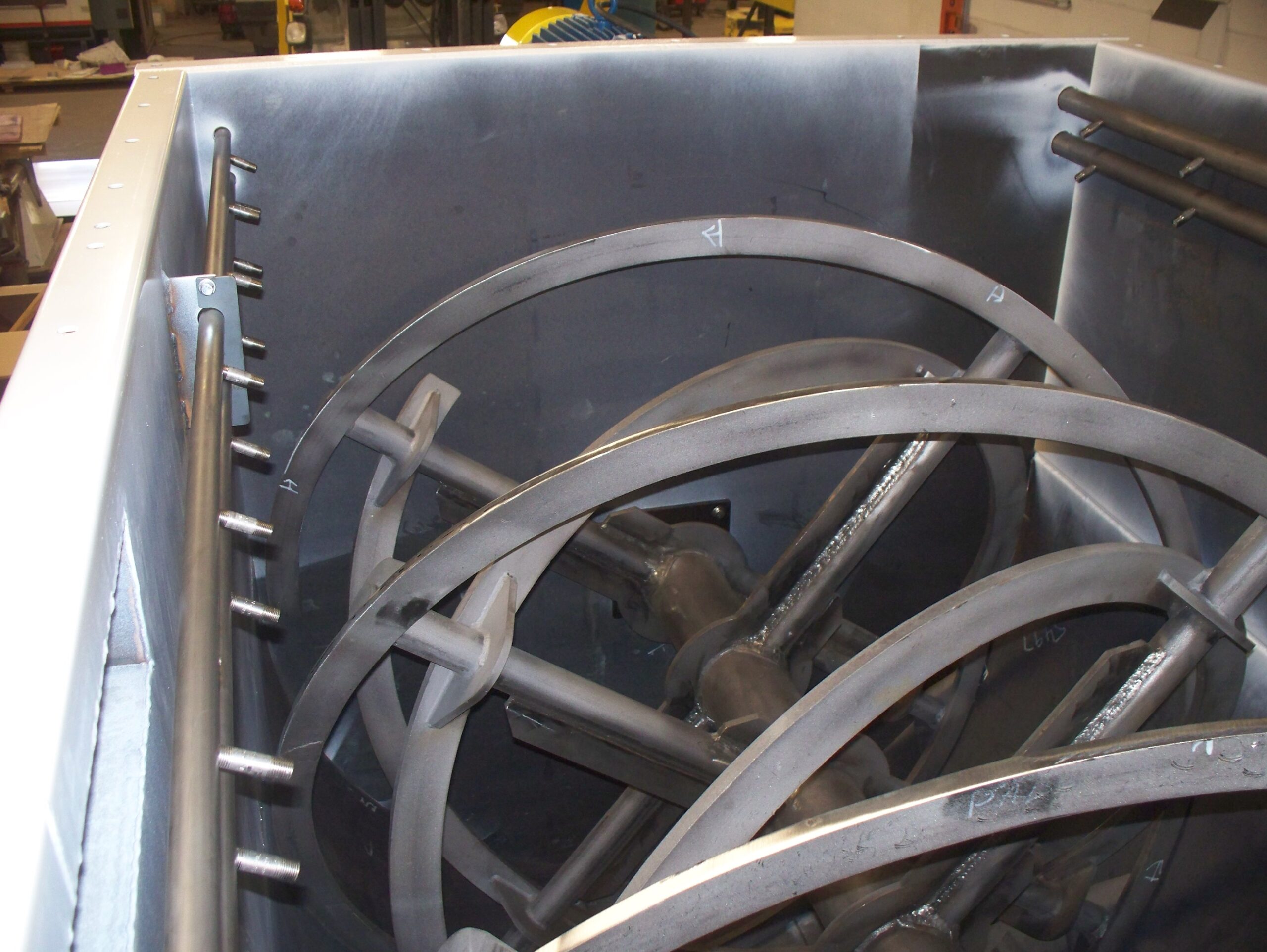

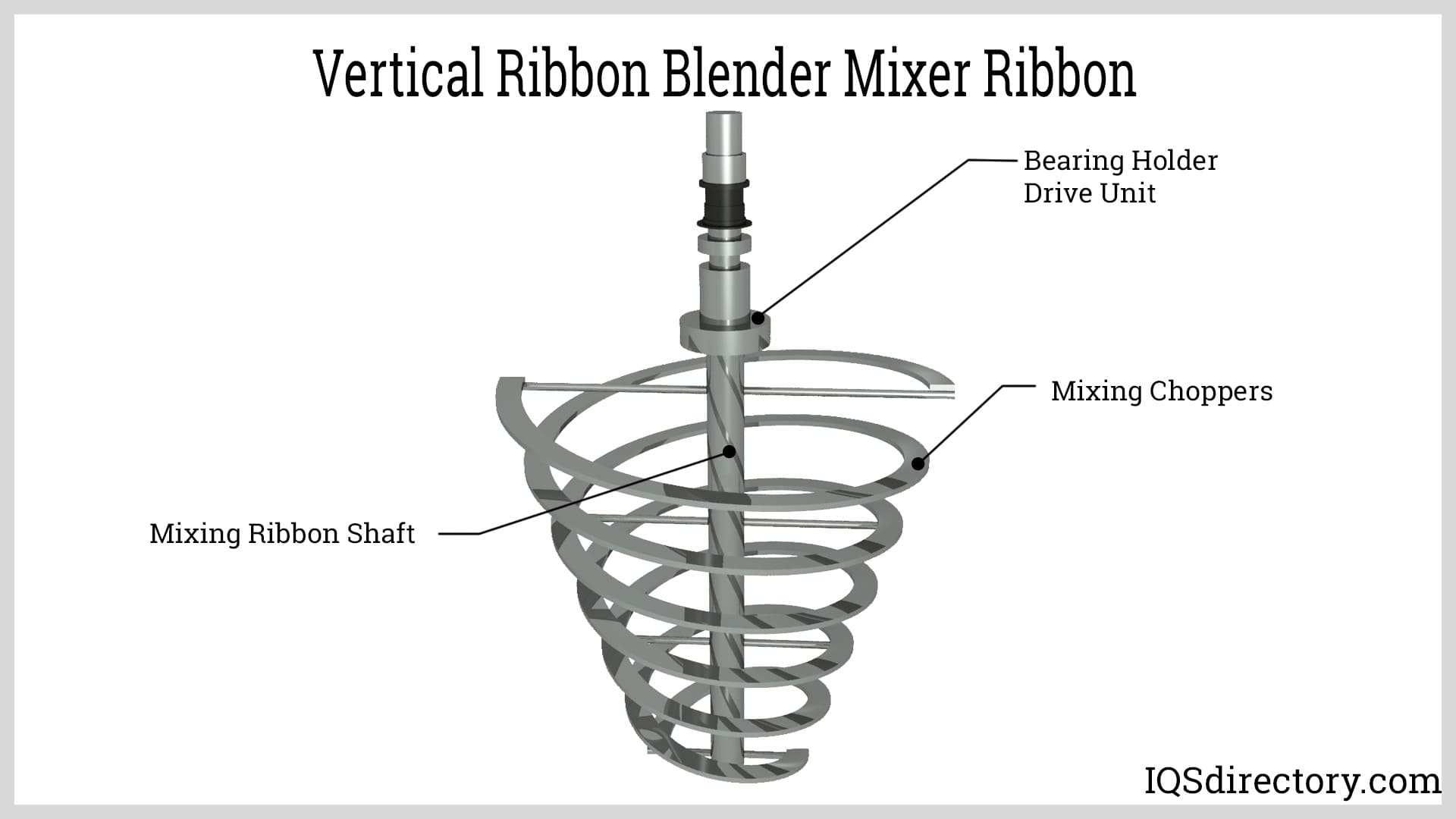

Illustrative image related to what is a ribbon blade mixer

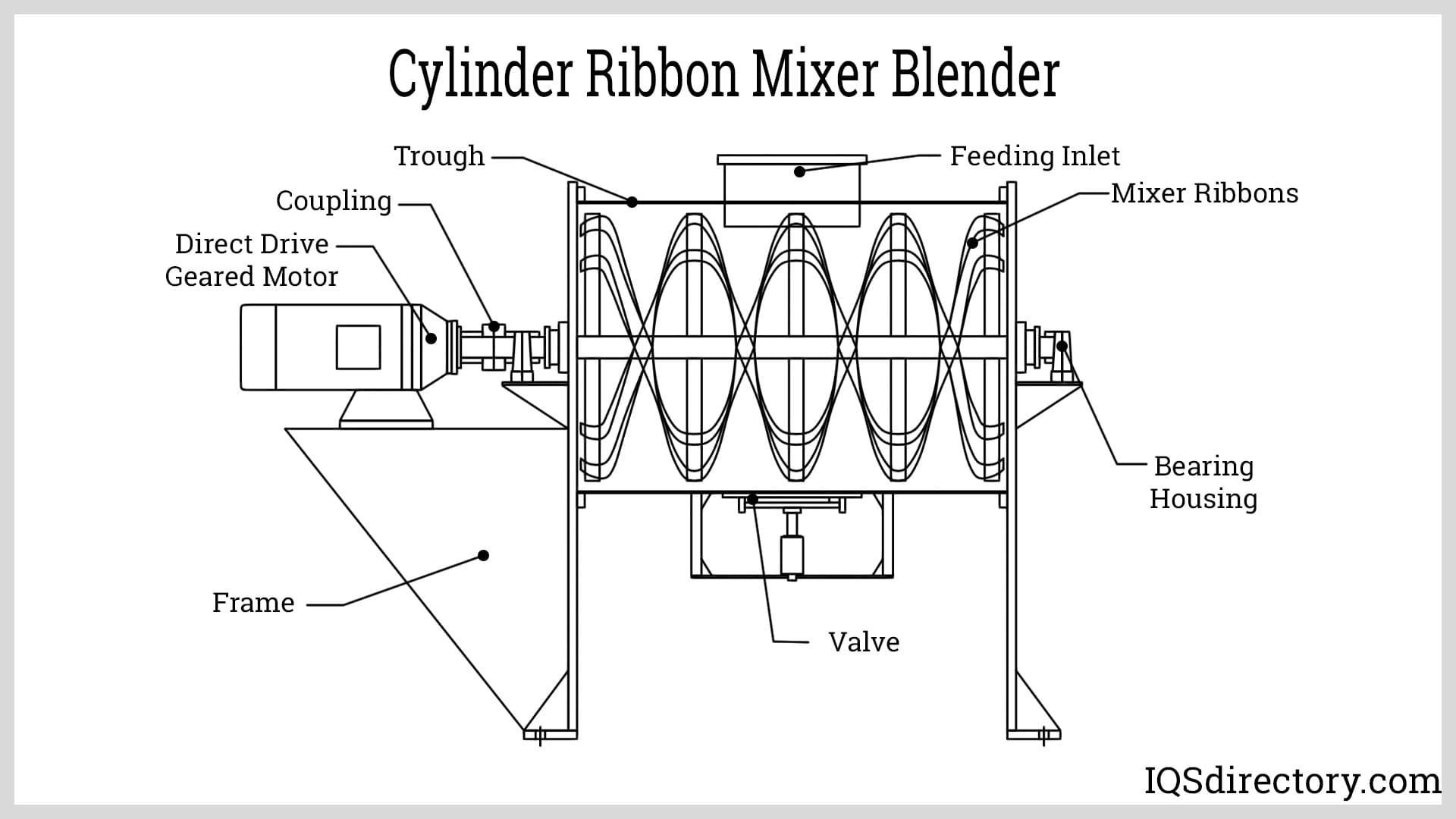

In What Scenarios Is a Double Ribbon Mixer Most Effective?

The double ribbon mixer features two sets of ribbons, significantly improving mixing efficiency for larger volumes. This type is particularly suited for bulk powder processing across various industries. When purchasing a double ribbon mixer, buyers should consider the space requirements and the increased cost, as the benefits of enhanced homogeneity and reduced mixing times often justify the investment.

Why Choose a Sanitary Ribbon Mixer for Sensitive Applications?

Sanitary ribbon mixers are specifically designed to meet stringent hygiene standards, featuring smooth finishes and easy disassembly for cleaning. These mixers are essential in industries such as food, pharmaceuticals, and biotech, where contamination risks must be minimized. Buyers should evaluate their specific cleaning requirements and the potential for cross-contamination when selecting a sanitary ribbon mixer, as the investment in hygiene can lead to better compliance and product safety.

Key Industrial Applications of what is a ribbon blade mixer

| Industry/Sector | Specific Application of what is a ribbon blade mixer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Mixing dry ingredients for snacks and seasonings | Ensures uniformity and consistent flavor profiles | Consider sanitary design, material quality, and ease of cleaning. |

| Pharmaceuticals | Blending active pharmaceutical ingredients (APIs) | Guarantees accurate dosing and product efficacy | Evaluate compliance with health regulations and material standards. |

| Chemicals | Mixing powdered chemicals for coatings | Achieves homogeneity in chemical formulations | Focus on durability against abrasive materials and mixing efficiency. |

| Plastics & Polymers | Compounding polymer blends | Enhances material properties and reduces production waste | Assess compatibility with various polymer types and batch size requirements. |

| Agriculture & Fertilizers | Blending fertilizers with additives | Improves nutrient distribution and effectiveness | Look for customization options to cater to specific fertilizer formulations. |

How is a Ribbon Blade Mixer Used in the Food & Beverage Industry?

In the food and beverage sector, ribbon blade mixers are essential for blending dry ingredients, such as spices and seasonings, ensuring a homogeneous mixture. This uniformity is crucial for maintaining consistent flavor profiles in products like snack foods and ready-to-eat meals. Buyers must prioritize mixers that comply with sanitary standards, as food safety regulations are stringent. Additionally, ease of cleaning and maintenance is vital to prevent cross-contamination between batches, particularly in regions like Europe and Africa where food safety is a top concern.

What Role Does a Ribbon Blade Mixer Play in Pharmaceuticals?

Ribbon blade mixers are employed in the pharmaceutical industry to blend active pharmaceutical ingredients (APIs) with excipients, ensuring accurate dosing and effective medication formulations. The mixing process must maintain the integrity of sensitive compounds, which requires careful design considerations such as low shear mixing capabilities. For international buyers, particularly from regions with strict health regulations, sourcing mixers that comply with Good Manufacturing Practices (GMP) and other regulatory standards is essential to ensure product safety and efficacy.

How Do Ribbon Blade Mixers Benefit the Chemical Sector?

In the chemicals industry, ribbon blade mixers are used to blend powdered chemicals for applications like coatings and adhesives. The ability to achieve a homogenous mixture is critical for product performance and consistency. Buyers should consider mixers that offer durability, particularly when handling abrasive materials, as this can significantly impact maintenance costs. Additionally, the mixer’s ability to accommodate varying batch sizes is a key factor, especially in markets like South America where production scales can differ widely.

Why Are Ribbon Blade Mixers Important in Plastics & Polymers?

In the plastics and polymers industry, ribbon blade mixers facilitate the compounding of various polymer blends, enhancing material properties and reducing waste during production. The gentle mixing action preserves the integrity of sensitive materials while ensuring uniform distribution of additives. Buyers must assess compatibility with different types of polymers and the required batch sizes, as these factors can vary significantly based on regional production practices, especially in emerging markets in Africa and the Middle East.

What Applications Exist for Ribbon Blade Mixers in Agriculture & Fertilizers?

Ribbon blade mixers are utilized in the agriculture sector to blend fertilizers with various additives, improving nutrient distribution and overall effectiveness. This application is particularly important in regions where soil quality varies, requiring tailored fertilizer formulations. Buyers should focus on sourcing mixers that allow for customization to meet specific agricultural needs, as well as those that can handle the unique properties of different fertilizer types. Moreover, understanding local regulations regarding fertilizer composition is crucial for compliance and market success.

3 Common User Pain Points for ‘what is a ribbon blade mixer’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Mix Quality

The Problem: Many B2B buyers struggle with achieving uniform mixing of materials in their ribbon blade mixers, particularly when dealing with various densities and particle sizes. In industries like food production or pharmaceuticals, inconsistencies can lead to product defects, regulatory non-compliance, or customer dissatisfaction. This challenge is compounded when the mixer is not properly calibrated to handle the specific characteristics of the ingredients being mixed, resulting in uneven distribution and potentially wasted materials.

The Solution: To ensure consistent mix quality, buyers should conduct a thorough analysis of their materials before sourcing a ribbon blade mixer. This includes understanding the bulk density, particle size, and flow characteristics of each component. When specifying a mixer, consider options such as adjustable ribbon speeds and variable frequency drives (VFDs) that allow for fine-tuning the mixing process. Regular maintenance checks, including recalibrating the mixer and cleaning the internal surfaces, will help sustain performance. Additionally, implementing a sampling protocol during the mixing process can provide real-time feedback on mix quality, allowing for immediate adjustments if inconsistencies arise.

Scenario 2: Managing Product Build-up and Contamination Risks

The Problem: Another common pain point for B2B buyers is the build-up of materials on the internal surfaces of ribbon blade mixers, which can lead to contamination and prolonged cleaning times. This is particularly concerning in industries like food processing and pharmaceuticals, where hygiene is paramount. The challenge is often exacerbated by the mixer’s design, which may not facilitate easy cleaning or access to hard-to-reach areas.

The Solution: To mitigate build-up and contamination risks, buyers should prioritize ribbon mixers with features designed for easy cleaning. Look for models that include removable or hinged agitators, which allow for better access to the mixing chamber. Opt for mixers with a smooth internal surface finish, such as mirror-polished or 150-grit finishes, to minimize material adhesion. Additionally, incorporating a cleaning-in-place (CIP) system can significantly reduce downtime and labor costs associated with manual cleaning. Regular training for operators on proper cleaning protocols will also enhance hygiene standards and operational efficiency.

Scenario 3: Insufficient Capacity for Diverse Mixing Applications

The Problem: B2B buyers often face challenges related to the capacity of their ribbon blade mixers, especially when their production needs fluctuate or when mixing different types of materials. A mixer that is not adequately sized or designed for specific applications can result in inefficient mixing cycles, longer processing times, and potential overloads that compromise the equipment’s lifespan.

Illustrative image related to what is a ribbon blade mixer

The Solution: Buyers should carefully assess their production requirements and select a ribbon blade mixer that can accommodate both current and anticipated future needs. This involves understanding not only the required volume capacity but also the nature of the materials being mixed. When sourcing a mixer, consider models that offer adjustable mixing volumes or modular designs that can be easily upgraded. Additionally, consulting with a manufacturer or a mixing expert can provide insights into selecting the right mixer configuration for specific applications. Implementing a monitoring system to track mixer performance can also help identify bottlenecks and optimize production workflows, ensuring that the mixer remains efficient as demands change.

Strategic Material Selection Guide for what is a ribbon blade mixer

What Materials Are Commonly Used in Ribbon Blade Mixers?

When selecting materials for ribbon blade mixers, it’s essential to consider the specific properties and performance requirements of the application. Here, we analyze four common materials used in the construction of ribbon blade mixers: carbon steel, stainless steel, plastic, and ceramic. Each material offers unique advantages and disadvantages that can significantly impact the performance and longevity of the mixer.

How Does Carbon Steel Perform in Ribbon Blade Mixers?

Key Properties: Carbon steel is known for its strength and durability. It can withstand high pressure and is suitable for mixing dry powders. However, it has limited corrosion resistance, which can be a drawback in humid or reactive environments.

Illustrative image related to what is a ribbon blade mixer

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-conscious projects. However, its susceptibility to rust and corrosion can lead to increased maintenance costs and reduced lifespan, particularly in industries like food processing or pharmaceuticals where hygiene is critical.

Impact on Application: Carbon steel is best suited for applications involving non-corrosive materials. It is not recommended for mixing materials that may cause rust or require stringent sanitary conditions.

Considerations for International Buyers: Buyers from regions with high humidity or corrosive environments, such as coastal areas in Africa or South America, should consider the limitations of carbon steel. Compliance with local regulations regarding food safety and material standards is also crucial.

Why Choose Stainless Steel for Ribbon Blade Mixers?

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand a wide range of temperatures and pressures. Its smooth surface finish makes it ideal for sanitary applications.

Illustrative image related to what is a ribbon blade mixer

Pros & Cons: The key advantage of stainless steel is its durability and resistance to corrosion, which is vital for industries like food and pharmaceuticals. However, it comes at a higher cost compared to carbon steel, and its manufacturing can be more complex.

Impact on Application: Stainless steel is suitable for mixing a variety of materials, including those sensitive to contamination. Its ability to maintain hygiene makes it ideal for applications involving food, pharmaceuticals, and chemicals.

Considerations for International Buyers: Buyers in Europe, particularly Germany, often prefer stainless steel due to stringent hygiene standards. Compliance with DIN standards is essential, and buyers should verify the grade of stainless steel used to ensure it meets their specific application requirements.

What Role Does Plastic Play in Ribbon Blade Mixers?

Key Properties: Plastic materials, such as polyethylene and polypropylene, are lightweight and resistant to corrosion. They are suitable for lower-temperature applications and can handle a variety of non-abrasive materials.

Pros & Cons: The main advantage of plastic is its low cost and ease of fabrication. However, plastics may not be suitable for high-temperature applications and can wear down more quickly than metals.

Impact on Application: Plastic is ideal for mixing lightweight powders and granules, especially in industries like agriculture and non-food consumer products. However, it is not suitable for abrasive materials or those requiring high durability.

Considerations for International Buyers: Buyers in regions with less stringent regulations, such as parts of Africa and South America, may find plastic mixers appealing due to their cost-effectiveness. However, they should ensure that the plastic meets relevant safety and environmental standards.

How Do Ceramic Materials Enhance Ribbon Blade Mixers?

Key Properties: Ceramic materials are highly resistant to wear and can withstand high temperatures and corrosive substances. They are often used as liners in mixers to protect against abrasion.

Pros & Cons: The primary advantage of ceramics is their durability and ability to maintain integrity in harsh conditions. However, they can be brittle and are often more expensive than other materials.

Impact on Application: Ceramics are suitable for mixing abrasive materials, such as powders in the ceramics and minerals industries. Their resistance to wear makes them ideal for long-term use in demanding applications.

Considerations for International Buyers: Buyers in the Middle East, where abrasive materials are common, should consider ceramic options for enhanced durability. Compliance with local standards regarding material safety and performance is essential.

Summary Table of Material Selection for Ribbon Blade Mixers

| Material | Typical Use Case for what is a ribbon blade mixer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Non-corrosive materials | Cost-effective | Limited corrosion resistance | Low |

| Stainless Steel | Food, pharmaceuticals, and chemicals | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Lightweight powders and granules | Lightweight and low cost | Not suitable for high temperatures | Medium |

| Ceramic | Abrasive materials in ceramics and minerals | Highly durable and wear-resistant | Brittle and higher cost | High |

This detailed analysis and summary table provide B2B buyers with critical insights into the material selection process for ribbon blade mixers, facilitating informed decision-making tailored to their specific industrial needs.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a ribbon blade mixer

What are the Typical Manufacturing Processes for Ribbon Blade Mixers?

The manufacturing of ribbon blade mixers involves several distinct stages, each critical to ensuring the final product meets the necessary performance and quality standards. Understanding these stages helps B2B buyers appreciate the complexity of the machinery and the importance of supplier selection.

Illustrative image related to what is a ribbon blade mixer

How is Material Prepared for Ribbon Blade Mixer Production?

The first stage in manufacturing ribbon blade mixers is material preparation. This typically involves sourcing high-quality stainless steel or other durable materials that can withstand the rigors of industrial use. Suppliers often utilize materials with specific grades, such as AISI 304 or AISI 316 stainless steel, known for their corrosion resistance and strength.

During this stage, materials are subjected to quality checks to confirm they meet industry standards. This may include chemical composition testing and mechanical property assessments. Buyers should inquire about the supplier’s material sourcing and testing processes to ensure they are using the best materials available.

What Forming Techniques are Used in Ribbon Blade Mixer Manufacturing?

Once the materials are prepared, the next stage is forming. This process typically involves cutting, bending, and welding the metal sheets into the desired shapes for the mixer components, including the housing and ribbon blades. Advanced techniques such as CNC machining and laser cutting are commonly employed to ensure precision and reduce waste.

For the ribbon blades, forming involves creating helical shapes that will facilitate effective mixing. The design must account for the specific application and material characteristics to ensure optimal performance. Buyers should consider requesting samples or CAD designs to verify the accuracy of the supplier’s manufacturing capabilities.

How is the Assembly of Ribbon Blade Mixers Conducted?

Following the forming stage, assembly is performed. This stage involves fitting together the various components, including the ribbons, housing, motor mounts, and discharge ports. Quality during assembly is critical; therefore, manufacturers often implement jigs and fixtures to maintain consistency.

Illustrative image related to what is a ribbon blade mixer

During assembly, manufacturers may also integrate features such as variable frequency drives (VFDs) for better control over the mixer’s operation. Buyers should ask about the assembly processes and any quality control measures in place, such as the use of torque wrenches to ensure proper tightening of components.

What Finishing Techniques are Applied to Ribbon Blade Mixers?

The finishing stage is where the ribbon blade mixers are polished and treated to enhance their durability and aesthetic appeal. This can involve processes like sandblasting, bead blasting, or mirror polishing, depending on the application requirements.

For industries requiring stringent sanitary standards, finishing must ensure that surfaces are smooth and free of contaminants. In such cases, a 150-grit finish or higher may be necessary. B2B buyers should ensure that suppliers can provide evidence of their finishing processes and the resultant surface quality, especially for applications in food, pharmaceuticals, or cosmetics.

What Quality Assurance Measures Are Essential for Ribbon Blade Mixers?

Quality assurance (QA) is vital in the manufacturing of ribbon blade mixers. This ensures that the equipment not only performs as intended but also meets international and industry-specific standards.

Which International Standards Should B2B Buyers Consider?

Most reputable manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards indicates a commitment to quality and continuous improvement. Additionally, industry-specific certifications such as CE marking for European markets or API for oil and gas applications may be relevant, depending on the end-use of the mixer.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral throughout the manufacturing process. These typically include:

- Incoming Quality Control (IQC): This stage verifies that all incoming materials meet specified standards before they are used in production.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted during manufacturing to catch any deviations in real-time.

- Final Quality Control (FQC): Once assembly is complete, the final product undergoes comprehensive testing to ensure it meets all operational specifications.

Testing methods may include performance testing under load, dimensional checks, and stress testing for durability. B2B buyers should inquire about the specific QC protocols that suppliers employ.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider several verification methods:

- Audits: Regular audits of the supplier’s manufacturing and quality control processes can provide insights into their operational integrity.

- Quality Reports: Requesting detailed quality reports that outline test results and compliance with standards can help verify a supplier’s claims.

- Third-Party Inspections: Engaging third-party inspection services can offer unbiased assessments of the manufacturing processes and product quality.

What Are the Nuances of Quality Control for International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, it’s crucial to understand the specific regulatory requirements in their markets. This may involve additional certifications or compliance documentation.

Moreover, cultural differences in business practices and standards can affect quality expectations. Buyers should engage in open communication with suppliers to clarify any concerns and ensure that all quality assurance measures align with their operational requirements.

Conclusion

Understanding the manufacturing processes and quality assurance measures for ribbon blade mixers is essential for B2B buyers looking to make informed purchasing decisions. By focusing on material preparation, forming techniques, assembly, and finishing, alongside rigorous quality control standards, buyers can ensure that they select suppliers who deliver reliable and effective mixing solutions tailored to their specific industry needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a ribbon blade mixer’

To assist international B2B buyers in procuring a ribbon blade mixer, this guide outlines essential steps to ensure a successful purchase. Ribbon blade mixers are vital for efficient powder blending in various industries, making it crucial to approach sourcing with clarity and precision.

Step 1: Define Your Technical Specifications

Clearly articulate the specifications required for your ribbon blade mixer. This includes understanding the volume capacity, material types, and desired mixing speed. Knowing these details helps you select a mixer that meets your operational needs and prevents costly adjustments later.

- Volume Capacity: Determine the maximum batch size you intend to mix, factoring in the bulk densities of your materials.

- Material Compatibility: Consider the materials you will be mixing, as different applications may require specific construction materials to avoid contamination.

Step 2: Assess Application Requirements

Identify the specific applications for which the mixer will be used. Ribbon blade mixers can handle a variety of materials, including powders, granules, and even liquids under certain conditions. Understanding your unique requirements will guide you in selecting the right mixer configuration.

Illustrative image related to what is a ribbon blade mixer

- Type of Materials: Will you be mixing fragile materials or abrasive powders? This affects the design and durability of the mixer.

- Mixing Process: Determine if you need features like heating/cooling jackets or variable frequency drives for enhanced control.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from businesses in similar industries or regions. This step helps ensure that the supplier has a proven track record.

- Supplier Experience: Look for suppliers with extensive experience in manufacturing ribbon mixers.

- Customer Feedback: Seek testimonials or reviews from previous clients to gauge satisfaction levels and service quality.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers you consider comply with relevant industry standards and possess necessary certifications. This is particularly important in industries like food and pharmaceuticals, where safety and hygiene are paramount.

- Quality Standards: Check for certifications such as ISO 9001, which indicates a commitment to quality management.

- Safety Compliance: Confirm adherence to local and international safety regulations relevant to your industry.

Step 5: Request Detailed Quotations

Obtain detailed quotations from shortlisted suppliers. These should include not only the price but also the specifications, delivery timelines, and warranty terms. A comprehensive quote allows for better comparison and decision-making.

- Breakdown of Costs: Ensure the quotation itemizes costs for each component, including shipping and installation.

- Warranty and Support: Review warranty terms to understand the support available post-purchase.

Step 6: Conduct Site Visits or Virtual Tours

If possible, arrange site visits to the supplier’s facility or request virtual tours. Observing the manufacturing process can provide insights into the quality control measures in place and the overall operational capabilities of the supplier.

- Manufacturing Standards: Check the cleanliness and organization of the production area to assess quality.

- Equipment and Technology: Ensure that the supplier uses up-to-date technology and practices in their manufacturing processes.

Step 7: Finalize Contract Terms

Once you have selected a supplier, ensure that all terms are clearly defined in the contract. This includes payment terms, delivery schedules, and after-sales support. A well-drafted contract protects both parties and clarifies expectations.

- Legal Considerations: Consult with legal advisors to review contract terms, especially regarding liability and dispute resolution.

- Performance Metrics: Consider including performance metrics to evaluate the mixer’s efficiency once operational.

By following these steps, B2B buyers can confidently navigate the procurement process for a ribbon blade mixer, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for what is a ribbon blade mixer Sourcing

When sourcing a ribbon blade mixer, understanding the cost structure is essential for making informed purchasing decisions. The costs associated with these mixers can be broken down into several key components.

Illustrative image related to what is a ribbon blade mixer

What Are the Key Cost Components for Ribbon Blade Mixers?

-

Materials: The primary materials for ribbon blade mixers include high-quality stainless steel, which ensures durability and resistance to corrosion. The choice of materials significantly affects the cost, with higher-grade stainless steel or specialized alloys costing more. Additionally, components like the helical ribbons and internal liners may require specific materials based on the application, further influencing the overall price.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembly, and quality control processes. Skilled labor is often required for precise fabrication and assembly, particularly for custom or complex designs. Labor costs can vary by region, impacting the final price depending on the supplier’s location.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Overhead can vary significantly based on the operational efficiency of the manufacturing plant and the economies of scale achieved by the supplier.

-

Tooling: Custom tooling for specific mixer designs or configurations can add to initial costs. While standard designs may have lower tooling costs due to existing molds, custom projects will require more investment upfront.

-

Quality Control (QC): Ensuring the mixer meets industry standards and client specifications involves rigorous quality control processes. Costs associated with testing, inspection, and certification can contribute to the overall price, particularly for mixers intended for regulated industries like food and pharmaceuticals.

-

Logistics: Shipping and handling costs depend on the mixer’s size and weight, as well as the distance to the buyer’s location. Incoterms also play a crucial role, as they determine who bears the cost of transportation and insurance. International shipping can introduce additional costs, including tariffs and duties.

-

Margin: Finally, suppliers will apply a profit margin to cover their operational costs and ensure profitability. This margin can vary based on market demand, competitive landscape, and the supplier’s positioning in the market.

What Influences the Price of Ribbon Blade Mixers?

Several factors can influence the pricing of ribbon blade mixers:

-

Volume/MOQ: Higher order quantities typically lead to reduced per-unit costs due to economies of scale. Buyers should consider negotiating minimum order quantities (MOQ) that align with their needs.

-

Specifications and Customization: Custom features, such as specific dimensions or additional functionalities, can significantly increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and whether the mixer meets specific quality certifications (e.g., FDA, ISO) will affect the price. High-quality and certified mixers generally command a premium.

-

Supplier Factors: The supplier’s reputation, experience, and location can impact pricing. Established suppliers with a strong track record may charge more, but they often provide greater reliability and support.

-

Incoterms: Understanding the Incoterms is vital for cost management. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift cost burdens between the buyer and seller, affecting the total landed cost.

What Are Essential Tips for Buyers When Sourcing Ribbon Blade Mixers?

-

Negotiation: Leverage your position as a buyer to negotiate terms, especially for larger orders. Discuss bulk pricing and payment terms to optimize costs.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes not just the purchase price but also maintenance, operational costs, and expected lifespan.

-

Understand Pricing Nuances for International Procurement: Different regions may have varying pricing structures due to local manufacturing costs, import taxes, and currency fluctuations. Buyers in Africa, South America, the Middle East, and Europe should consider these factors when budgeting for their mixers.

-

Disclaimer for Indicative Prices: Always be aware that prices can fluctuate based on market conditions, supplier changes, and material costs. Request up-to-date quotes and be prepared for potential price variations during the procurement process.

In summary, understanding the comprehensive cost structure and pricing influencers associated with ribbon blade mixers is crucial for international B2B buyers. Careful consideration of the outlined components and strategic negotiation can lead to more favorable procurement outcomes.

Alternatives Analysis: Comparing what is a ribbon blade mixer With Other Solutions

Understanding Alternatives to Ribbon Blade Mixers

In the industrial mixing landscape, ribbon blade mixers serve as a versatile and efficient solution for blending powders and granules. However, several alternative mixing technologies can also achieve similar outcomes, each with its unique set of advantages and limitations. This section explores these alternatives, enabling international B2B buyers to make informed decisions based on their specific operational needs.

Comparison Table

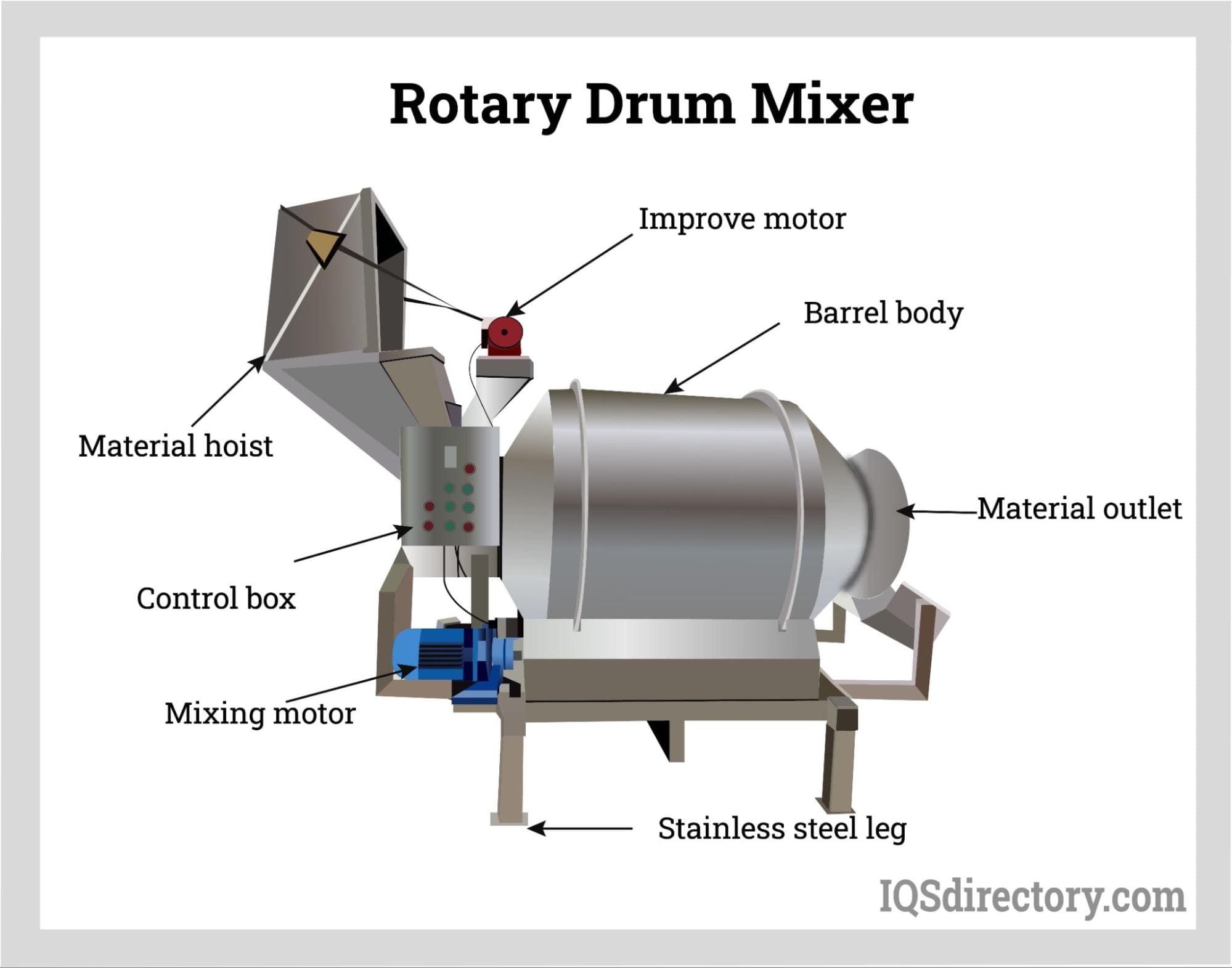

| Comparison Aspect | What Is A Ribbon Blade Mixer | Drum Mixer | High Shear Mixer |

|---|---|---|---|

| Performance | Excellent for dry powders; gentle mixing action preserves material integrity | Good for free-flowing materials; less effective for viscous mixes | High efficiency for emulsifying and dispersing; ideal for liquids and pastes |

| Cost | Moderate initial investment; low operating costs due to low power consumption | Generally lower initial cost; operating costs vary based on maintenance | Higher initial investment; operational costs can be high due to energy use |

| Ease of Implementation | Requires specific installation space and setup; moderately complex | Simple setup; can be integrated easily into existing processes | More complex installation; may require specialized operators |

| Maintenance | Low maintenance with proper design; occasional wear on ribbons | Moderate maintenance; regular inspection needed for flights | High maintenance; frequent checks needed due to wear on rotor-stator |

| Best Use Case | Ideal for blending dry powders, granules, and light bulk solids | Best for bulk materials and light mixing; suitable for aggregates | Optimal for emulsifying, homogenizing, and grinding; effective for liquid mixtures |

Detailed Breakdown of Alternatives

Drum Mixer

Drum mixers utilize a simple rotational mechanism to blend materials. They are particularly effective for free-flowing powders and can handle larger batch sizes. The main advantage of drum mixers is their lower initial cost and ease of integration into existing processes. However, they are less effective for viscous materials and may not provide the consistent homogeneity required for specialized applications. Their performance can be limited by the properties of the materials being mixed, making them less versatile than ribbon blade mixers.

High Shear Mixer

High shear mixers excel in applications requiring the emulsification or dispersion of liquid ingredients. They operate using a rotor-stator mechanism that generates high shear forces, making them highly efficient for mixing and homogenizing. While they deliver superior results for liquid mixtures and pastes, their initial investment is higher, and they require more energy to operate. Additionally, the maintenance demands are significant due to the wear on components, which can increase long-term operational costs. High shear mixers are best suited for industries such as pharmaceuticals, cosmetics, and food processing where liquid formulations are prevalent.

Conclusion: Choosing the Right Mixing Solution

Selecting the appropriate mixing technology depends on a variety of factors including the nature of the materials, production volume, and budget constraints. Ribbon blade mixers are ideal for dry powders and granular materials, offering gentle yet effective blending with low maintenance. Drum mixers may appeal to businesses looking for cost-effective solutions for bulk materials, while high shear mixers are essential for applications demanding precise emulsification and dispersion. B2B buyers should assess their specific needs, including material characteristics and production requirements, to determine the most suitable mixing technology for their operations.

Essential Technical Properties and Trade Terminology for what is a ribbon blade mixer

What Are the Key Technical Properties of a Ribbon Blade Mixer?

When considering the purchase of a ribbon blade mixer, understanding its essential technical properties is crucial for making informed decisions. Here are some of the key specifications to keep in mind:

1. Material Grade

The material used for the construction of a ribbon blade mixer is vital for durability and hygiene. Common materials include stainless steel, which is favored in food and pharmaceutical industries for its resistance to corrosion and ease of cleaning. Choosing the appropriate material grade ensures compliance with industry standards and extends the lifespan of the equipment.

2. Mixing Capacity

Mixing capacity refers to the volume of material that the mixer can handle effectively. For optimal performance, it’s important to select a mixer that can operate at 50-70% of its total capacity. This range allows for adequate contact between the ribbons and materials, promoting efficient mixing. Understanding your specific volume needs will help in selecting the right equipment.

3. Tolerance Levels

Tolerance levels indicate the precision of the mixer’s components, particularly the gap between the ribbons and the mixer walls. Tight tolerances prevent material buildup and ensure uniform mixing. In applications where product integrity is critical, such as in the cosmetics or nutraceutical industries, investing in high-tolerance machinery can significantly impact product quality.

4. Drive Mechanism

The drive mechanism can vary between ribbon mixers, with options such as belt drives or direct drive gear motors. A direct drive system is generally preferred for its reduced maintenance needs and higher efficiency. Understanding the differences helps buyers choose a mixer that fits their operational requirements and reduces long-term costs.

5. Speed and RPM

The operational speed of ribbon mixers typically remains below 300 feet/minute. This low speed allows for gentle mixing, preserving the integrity of fragile materials. Evaluating the speed requirements based on the materials being processed is essential to prevent damage and ensure optimal mixing results.

6. Discharge Mechanism

The discharge mechanism, often a centrally located port, is crucial for ensuring complete product removal. Various valve options, like plug valves, can facilitate efficient discharge while minimizing material buildup. A well-designed discharge system can enhance productivity and reduce downtime during cleaning and maintenance.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon is essential for effective communication in B2B transactions. Here are some common terms you may encounter:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of ribbon mixers, knowing whether a supplier is an OEM can help gauge the quality and reliability of the equipment.

Illustrative image related to what is a ribbon blade mixer

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. Understanding the MOQ can help buyers plan their procurement strategies and manage inventory effectively, especially when dealing with specialized mixers.

3. RFQ (Request for Quotation)

An RFQ is a formal process used to solicit price quotes from suppliers. Issuing an RFQ for ribbon mixers allows buyers to compare costs and features, ensuring they select the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping contracts. Familiarity with these terms helps in understanding shipping costs, risk management, and delivery timelines, which are crucial for international purchases.

5. VFD (Variable Frequency Drive)

A VFD is a type of drive that controls the speed and torque of an electric motor by varying the frequency and voltage supplied. Incorporating a VFD in a ribbon mixer can improve energy efficiency and reduce wear on components, making it a valuable feature for long-term operations.

6. Batch Mixing

Batch mixing refers to the process of mixing a specific quantity of materials in one go. Understanding batch sizes and mixing cycles is essential for planning production schedules and ensuring consistent product quality.

Understanding these technical specifications and trade terms can empower B2B buyers to make informed decisions when selecting a ribbon blade mixer, ultimately leading to improved operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the what is a ribbon blade mixer Sector

What Are the Key Market Drivers for Ribbon Blade Mixers?

The ribbon blade mixer market is experiencing robust growth driven by several global factors. The increasing demand for efficient and versatile mixing solutions across industries—such as food and beverage, pharmaceuticals, and chemicals—plays a pivotal role. Notably, manufacturers are seeking equipment that can handle diverse materials, from powders to granules, while ensuring consistent quality in production. Emerging technologies such as Industry 4.0, which emphasizes automation and data exchange in manufacturing processes, are also influencing sourcing decisions. This trend is particularly relevant for international buyers in Africa, South America, the Middle East, and Europe, where the adoption of smart manufacturing technologies is gradually gaining momentum.

Illustrative image related to what is a ribbon blade mixer

Furthermore, the rising emphasis on process optimization and energy efficiency is shaping sourcing trends. Buyers are increasingly inclined towards ribbon mixers that incorporate features like variable frequency drives (VFDs) for better energy management, leading to significant cost savings. The need for fast mixing cycles without compromising product integrity is also driving innovation in design and materials used in ribbon mixers. As a result, the market is witnessing a shift towards custom solutions tailored to specific industry requirements, enhancing the competitive landscape for suppliers.

How Is Sustainability Influencing Sourcing in the Ribbon Blade Mixer Sector?

Sustainability has become a critical consideration in the sourcing of ribbon blade mixers, as companies across various sectors strive to minimize their environmental impact. The manufacturing processes for these mixers are increasingly focused on reducing waste, utilizing energy-efficient technologies, and selecting materials that are recyclable or sustainably sourced. For B2B buyers, this means that investing in equipment that adheres to sustainable practices is not just an ethical choice but also a strategic one that aligns with global sustainability goals.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are becoming more vigilant about the sourcing practices of their suppliers, seeking transparency and accountability in the materials used. Certifications such as ISO 14001 for environmental management and compliance with REACH regulations are becoming critical in the decision-making process. By prioritizing suppliers that demonstrate a commitment to sustainability, companies can enhance their brand reputation and meet the growing consumer demand for environmentally responsible products.

What Is the Historical Context of Ribbon Blade Mixers in B2B Markets?

The ribbon blade mixer has evolved significantly since its inception, emerging as a cornerstone in powder blending technology. Initially developed in the mid-20th century, these mixers were designed to address the growing need for efficient blending in various industries, including food processing and pharmaceuticals. Over the years, advancements in engineering and materials science have led to the development of more sophisticated designs that enhance mixing efficiency and reduce maintenance needs.

Illustrative image related to what is a ribbon blade mixer

The introduction of variable speed drives and automation technologies has further transformed the ribbon mixer landscape, enabling greater control over mixing processes and improved product quality. This evolution reflects the broader trends in manufacturing towards automation and efficiency, making ribbon blade mixers indispensable tools for modern production lines. For B2B buyers, understanding this historical context can inform their purchasing decisions, highlighting the importance of investing in advanced mixing technologies that meet contemporary industry demands.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a ribbon blade mixer

-

1. How do I choose the right ribbon blade mixer for my application?

Selecting the appropriate ribbon blade mixer involves considering several factors, including the material properties (bulk density, particle size), desired mixing time, and batch size. Assess the mixer’s capacity and ensure it matches your production needs. Additionally, evaluate the design features, such as the gap tolerances between ribbons and the internal surface finish, to ensure compatibility with your materials. Consulting with manufacturers can provide insights into the best configurations for specific applications, such as food processing, pharmaceuticals, or chemical blending. -

2. What are the key benefits of using a ribbon blade mixer?

Ribbon blade mixers are favored for their versatility and efficiency in blending dry materials. They offer a gentle mixing action, preserving the integrity of fragile particles while achieving uniformity in a short time frame, often within 20 minutes. The design allows for easy discharge of mixed products, reducing waste and downtime. Additionally, they can be customized for various applications, including coating and liquid absorption, making them suitable for diverse industries, such as food, pharmaceuticals, and chemicals. -

3. What customization options are available for ribbon blade mixers?

Many manufacturers provide customization options for ribbon blade mixers to meet specific processing requirements. Customizations can include variations in size, capacity, internal surface finishes, and the inclusion of features like heating/cooling jackets or specialized discharge valves. It’s essential to communicate your unique needs to potential suppliers, ensuring the mixer design aligns with your production processes and quality standards. -

4. What should I consider regarding the minimum order quantity (MOQ) for ribbon blade mixers?

Minimum order quantities can vary significantly among suppliers, influenced by factors such as production capacity and customization requirements. When sourcing ribbon blade mixers, inquire about the MOQ and assess whether it aligns with your production scale. If you are a smaller operation, some manufacturers may offer flexible options or allow for smaller batch orders, especially for standard models, to accommodate your needs without excessive inventory costs. -

5. How can I vet suppliers for ribbon blade mixers?

When vetting suppliers, consider their industry experience, customer reviews, and certifications. Request case studies or references from similar industries to gauge their expertise and reliability. Additionally, assess their manufacturing processes, quality control measures, and after-sales support. Engaging in direct communication can provide insight into their responsiveness and willingness to meet your specific needs. -

6. What payment terms are typically offered for international orders of ribbon blade mixers?

Payment terms for international orders can vary widely, but common practices include upfront deposits (usually 30-50%) with the balance payable upon delivery or after installation. Some suppliers may offer financing options or letters of credit, particularly for larger orders. It’s crucial to clarify payment terms during negotiations and ensure they align with your budget and cash flow management. -

7. What quality assurance measures should I expect from ribbon blade mixer manufacturers?

Reputable manufacturers should have comprehensive quality assurance protocols in place. Expect to see certifications for quality management systems, such as ISO 9001, which indicate adherence to international standards. Additionally, inquire about in-process inspections, final testing procedures, and warranty offerings. A supplier’s commitment to quality should reflect in their willingness to provide documentation of tests and certifications for the equipment. -

8. How do logistics and shipping impact the procurement of ribbon blade mixers?

Logistics play a critical role in the procurement process, especially for international buyers. Consider factors such as shipping costs, lead times, and customs regulations that may affect delivery schedules. Collaborate with suppliers to understand their shipping capabilities and whether they provide support in navigating customs documentation. Effective logistics planning can minimize delays and ensure that your ribbon blade mixer arrives in optimal condition for immediate use.

Top 8 What Is A Ribbon Blade Mixer Manufacturers & Suppliers List

1. IQS Directory – Ribbon Mixers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Ribbon mixers are specialized mixing devices utilizing helical ribbons to blend a wide range of materials, particularly slurries, dry powders, and granular substances. They feature a U-shaped drum that houses the helical ribbons, allowing for efficient mixing and practical aspects such as easy loading and cleaning. Types of ribbon mixers include single ribbon blenders, double ribbon blenders, and …

2. Mixers.com – Ribbon Blenders

Domain: mixers.com

Registered: 1999 (26 years)

Introduction: Ribbon blenders are designed for fast, straightforward, and reliable mixing of solid-solid and liquid-solid applications. They can achieve complete mixing in 15 minutes or less, with minimal risk of overmixing or unmixing. A well-designed ribbon blender can last 20-30 years or more. Key considerations include proper sizing based on desired batch volume and bulk density, using a variable frequency …

3. Topspack – Ribbon Mixer Machine

Domain: topspack.com

Registered: 2009 (16 years)

Introduction: Ribbon Mixer Machine for Food, Pharma, Agricultural, Chemical Industries. Efficient and cost-effective for combining powders, powders with liquids, granules, and dry solids. Features a whirling agitator and horizontal U-shaped design. Models available: TDPM 40 (40L), TDPM100-300 (100L, 200L, 300L), TDPM500-1000 (500L, 1000L), TDPM1500 (1500L), TDPM2000 (2000L), TDPM3000 (3000L, customizable up to …

4. Karvil – Ribbon Mixer

Domain: karvil.com

Registered: 2020 (5 years)

Introduction: Ribbon Mixer (also known as ribbon blender) is an industrial mixing machine used in food processing, pharmaceuticals, chemicals, and more. It consists of a U-shaped horizontal trough with a central shaft and inner and outer helical ribbons. The ribbons move materials in opposite directions for thorough mixing. The operation includes loading materials via a screw conveyor, creating convective and s…

5. Munson Machinery – Blenders and Mixing Solutions

Domain: munsonmachinery.com

Registered: 1996 (29 years)

Introduction: Features for Ribbon Blenders, Paddle Blenders, and Plow Blenders include:

– Capacities from 1 to 1,150 cu ft (0.028 to 32.56 m3)

– Designs range from heavy duty to extreme heavy duty

– Extensive selection of drives, seals, agitators, and discharge gate designs

– Low or high pressure ASME-code jackets for steam, hot water, oil, or coolant

– Tight-tolerance construction minimizes residual mater…

6. EvenMix – Ribbon Blenders

Domain: evenmix.com

Registered: 2007 (18 years)

Introduction: EvenMix® Ribbon Blenders are industrial mixers designed with a ribbon agitator featuring inner and outer blades that rotate materials inside the mixer. They are effective for mixing fine materials such as powders and fine gravel, but not suitable for sticky products like two-part adhesives. Available designs include vertical ribbon blenders for animal feed and horizontal ribbon blenders with a U-s…

7. Pharma Guideline – Ribbon Blenders

Domain: pharmaguideline.com

Registered: 2011 (14 years)

Introduction: Ribbon blenders are used for mechanically mixing and powdering solids through a shuffle action. They consist of an agitator ribbon embedded in a semicylindrical trough centered on a central shaft, with two counteracting ribbons facilitating the mixing process. There are three types of ribbon blenders: U-shaped troughs, shells, and spiral agitators. They are powered by motors ranging from 10HP to 1…

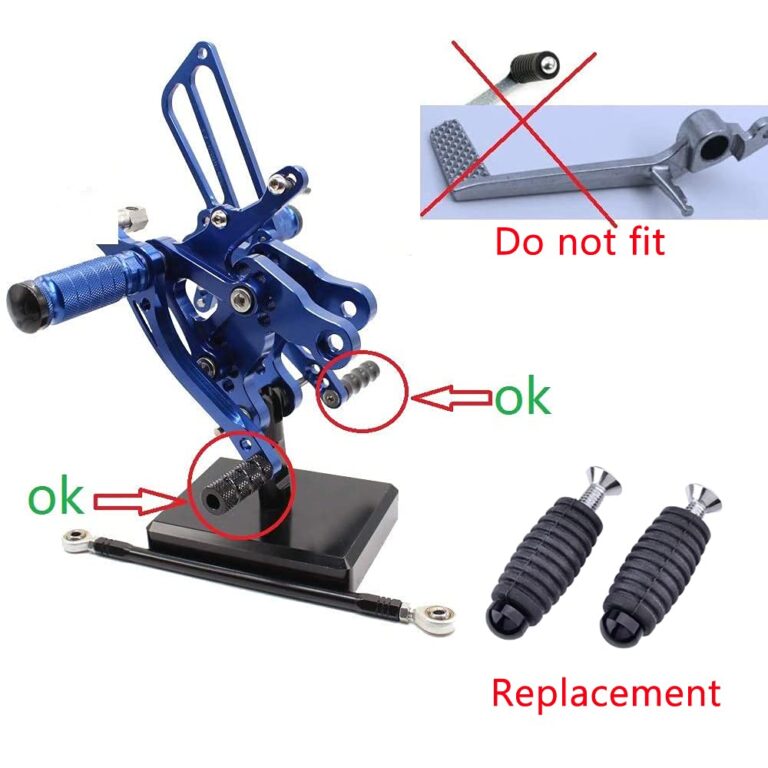

8. S&L Powder – Vertical Ribbon Mixer

Domain: powder-mixer.com

Registered: 2023 (2 years)

Introduction: Product Name: Vertical Ribbon Mixer

Manufacturer: S&L Powder

Type: Industrial blending machine for mixing solids, powders, and pastes

Other Names: Vertical mixer, ribbon blade mixer, ribbon blender

Mixing Capability: Suitable for materials with various characteristics (density, particle size, shape, proportions) with good mixing effect for ratios up to 1:100-10000.

Design: Consists of a vertical m…

Strategic Sourcing Conclusion and Outlook for what is a ribbon blade mixer

In conclusion, understanding the intricacies of ribbon blade mixers is paramount for international B2B buyers across diverse industries. These mixers offer a unique blend of efficiency, versatility, and gentle handling of materials, making them ideal for applications ranging from food processing to pharmaceuticals and beyond. Strategic sourcing of ribbon mixers not only enhances production capabilities but also supports the optimization of operational costs through reduced maintenance and increased mixing efficacy.

As you evaluate potential suppliers, consider the specific requirements of your operations, such as material characteristics and production volumes. Look for manufacturers that can provide tailored solutions, including customizable designs, high-quality materials, and advanced features like variable frequency drives and specialized surface finishes.

The global market for ribbon blade mixers continues to evolve, presenting opportunities for businesses in Africa, South America, the Middle East, and Europe to leverage cutting-edge technology for enhanced productivity. By investing in high-quality mixing equipment, you can position your company for sustainable growth and competitive advantage. Engage with suppliers that understand your regional challenges and can offer innovative solutions tailored to your needs. Your next step could redefine your production process—explore your options today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to what is a ribbon blade mixer

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.