Everything You Need to Know About Vibratory Screener Sourcing in 2025

Introduction: Navigating the Global Market for vibratory screener

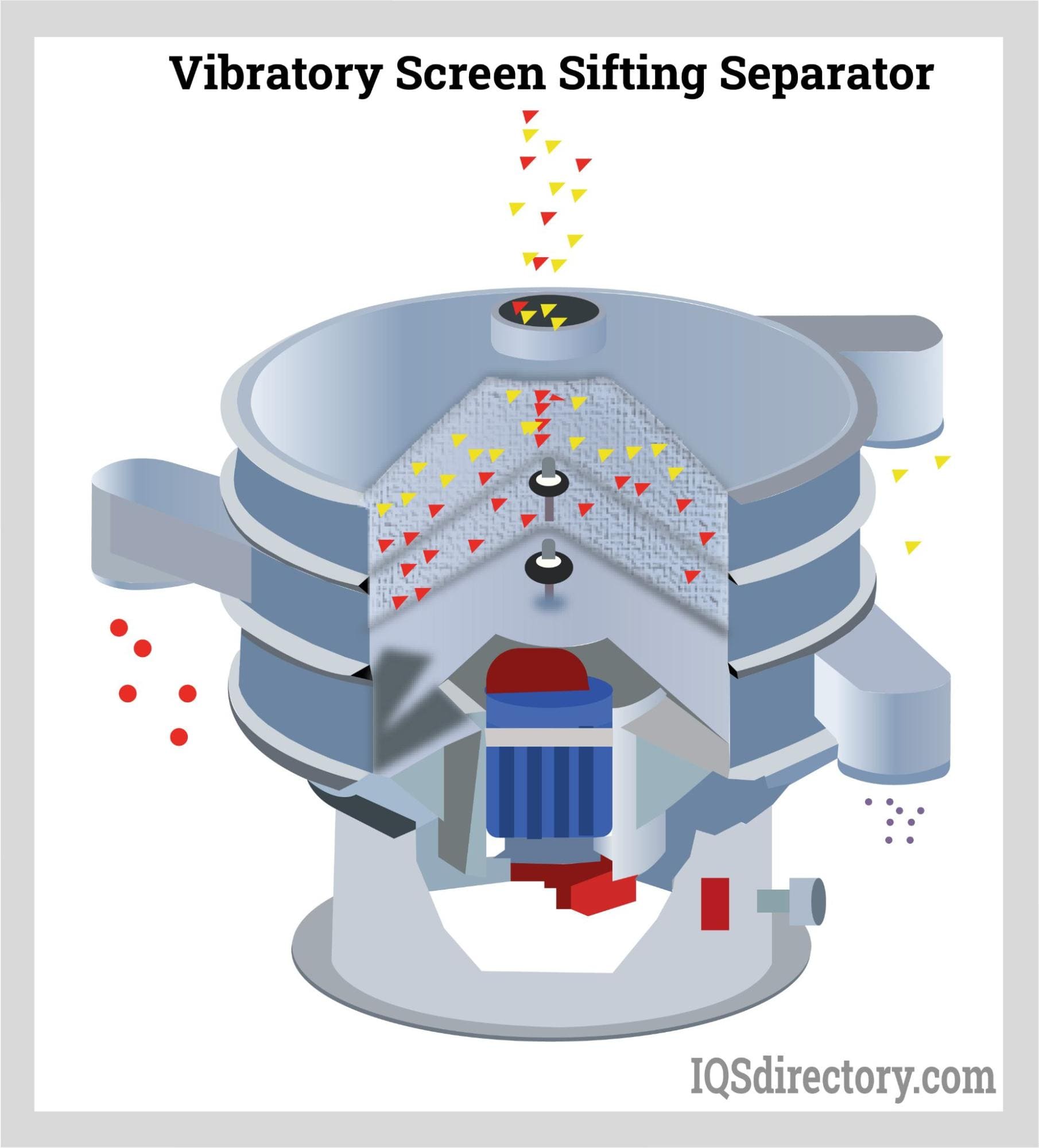

As businesses expand their operations across borders, sourcing the right vibratory screener becomes a critical challenge that can significantly impact productivity and efficiency. Vibratory screeners play a vital role in various industries—from mining and recycling to pharmaceuticals and food processing—ensuring that materials are accurately separated, sized, and classified. However, navigating the complexities of the global market for vibratory screeners can be daunting, especially for international B2B buyers looking to make informed purchasing decisions.

This comprehensive guide aims to demystify the vibratory screener market by exploring various types of screeners, their specific applications, and essential factors to consider during the supplier vetting process. Buyers will gain insights into cost considerations, maintenance requirements, and the benefits of investing in high-quality equipment tailored to their unique operational needs.

With a focus on buyers from Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam, this guide equips decision-makers with the knowledge needed to select the most suitable vibratory screener for their operations. By understanding the nuances of this specialized equipment, businesses can enhance their material handling processes, reduce downtime, and ultimately boost their bottom line.

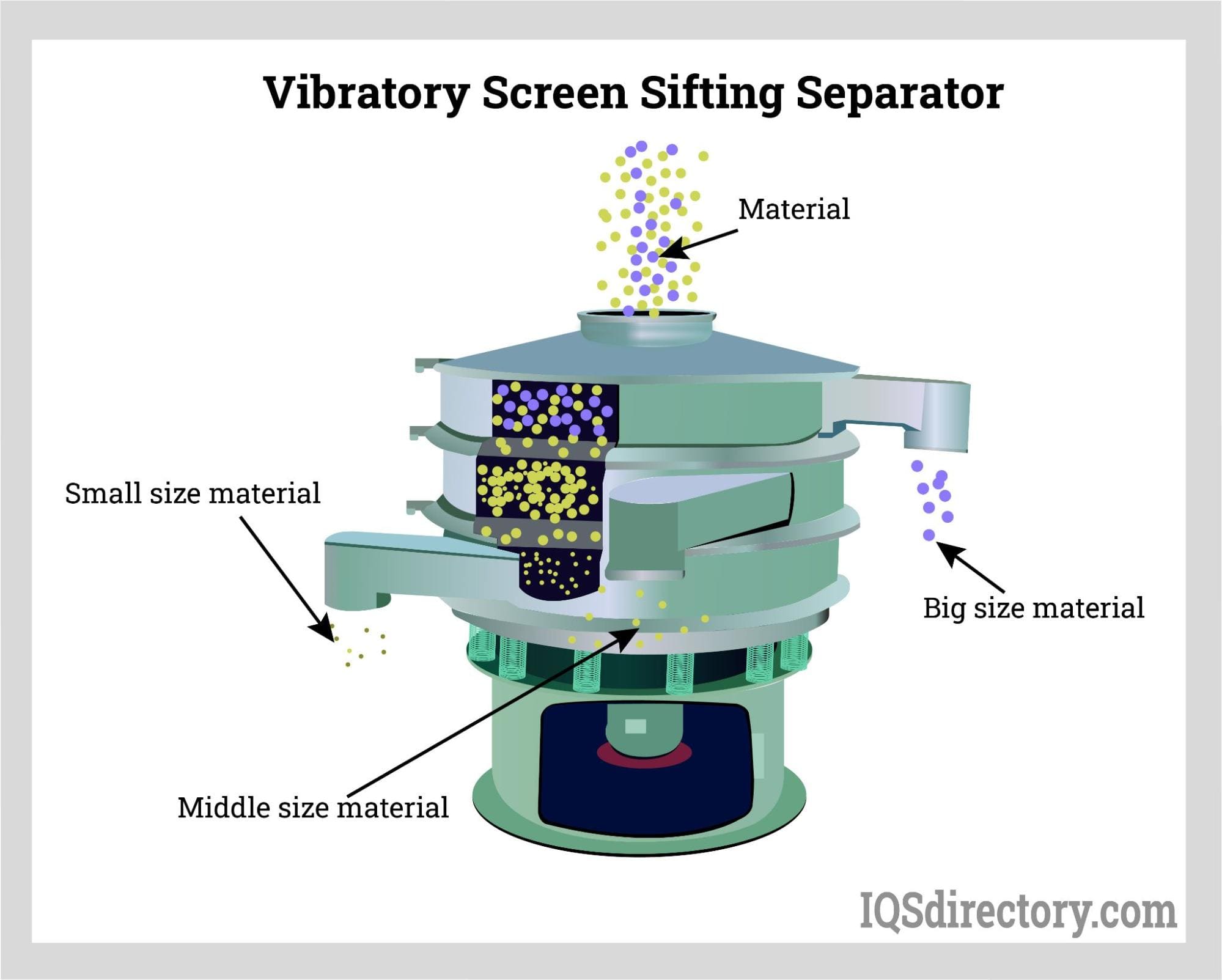

Understanding vibratory screener Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| EMS Electromechanical Screener | Twin motor drives for precise screening; horizontal mounting | Mining, recycling, pharmaceuticals | Pros: High efficiency; customizable; durable. Cons: Higher initial investment. |

| PSC-E Portable Sloped Screener | Lightweight and portable; customizable screening options | Fine bulk material handling in various sectors | Pros: Flexibility and mobility; easy to transport. Cons: May have limited capacity. |

| RSM Volumetric Vibratory Screener | Self-contained with bulk supply hopper; integrated design | Aggregate, food processing, and recycling | Pros: Space-saving; efficient material flow. Cons: Initial setup complexity. |

| SC-E Gravity Flow Screener | Gravity-assisted design; single rotary electric drive | Aggregate sizing, mining, and chemical processing | Pros: Simplicity; lower maintenance. Cons: Limited to applications requiring gravity flow. |

| SF-A Air Powered Screener | Air-powered for hazardous materials; economical control | Chemical, food, and hazardous material handling | Pros: Safe for explosive environments; cost-effective. Cons: Requires air source; lower throughput. |

What Are the Key Characteristics of EMS Electromechanical Screeners?

The EMS Electromechanical Screener is characterized by its twin motor drives, allowing for precise screening and efficient separation of materials. It is designed to handle a wide range of applications, particularly in industries such as mining, recycling, and pharmaceuticals. Buyers should consider the EMS model for high-efficiency operations where accurate particle size is critical. However, the upfront costs can be higher, making it essential to evaluate long-term benefits versus initial investments.

Illustrative image related to vibratory screener

How Does the PSC-E Portable Sloped Screener Stand Out?

The PSC-E Portable Sloped Screener is designed for versatility and ease of transport, featuring a lightweight structure and customizable options. This screener is particularly effective in handling fine bulk materials across various sectors, including construction and food processing. Its portability makes it an ideal choice for businesses that require mobility between different sites. However, potential buyers should assess its capacity limitations to ensure it meets their operational needs.

What Advantages Does the RSM Volumetric Vibratory Screener Offer?

The RSM Volumetric Vibratory Screener integrates a bulk supply hopper with a vibratory pan screener, making it a self-contained solution ideal for industries like aggregate processing and food production. Its design promotes efficient material flow and minimizes space requirements. When considering this model, buyers should weigh its efficiency against the complexity of initial setup, which may require specialized knowledge.

In What Scenarios is the SC-E Gravity Flow Screener Most Effective?

The SC-E Gravity Flow Screener employs a gravity-assisted design that utilizes a single rotary electric drive. This makes it suitable for applications that require simple, low-maintenance solutions, particularly in aggregate sizing and chemical processing. Businesses looking for a straightforward screener that minimizes operational costs will find this model appealing. However, its effectiveness is limited to processes that can utilize gravity flow, which may not suit all materials.

Why Choose the SF-A Air Powered Screener for Hazardous Applications?

The SF-A Air Powered Screener is specifically designed for applications involving hazardous materials, offering an economical solution with safe operation in explosive environments. Its air-powered mechanism allows for precise control of feed rates, making it suitable for industries such as chemicals and food processing. While it provides safety and cost-effectiveness, buyers need to ensure they have a reliable air source and consider potential throughput limitations compared to other models.

Key Industrial Applications of vibratory screener

| Industry/Sector | Specific Application of vibratory screener | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Dewatering mined materials | Enhances material recovery and reduces waste | Consider durability, capacity, and suitability for harsh environments. |

| Pharmaceutical & Food Processing | Sanitary screening of powders and granules | Ensures product quality and compliance with health standards | Look for hygienic designs, easy cleaning features, and regulatory certifications. |

| Recycling & Waste Management | Separation of recyclables from waste | Maximizes recycling efficiency and minimizes landfill waste | Evaluate screening efficiency, adaptability to various materials, and maintenance needs. |

| Plastics Manufacturing | Sizing and classifying plastic pellets | Improves product consistency and reduces production costs | Assess compatibility with different pellet sizes and material types. |

| Aggregate & Concrete | Sizing aggregate materials for construction projects | Enhances construction quality and optimizes material use | Focus on screening capacity, versatility, and resistance to wear. |

How Are Vibratory Screeners Used in the Mining Industry?

In the mining sector, vibratory screeners are essential for dewatering mined materials, such as sand and gravel. By removing excess water, these screeners help enhance material recovery and reduce waste, leading to more efficient operations. International buyers should prioritize models that can withstand harsh environments and offer high throughput, ensuring they meet the demands of their specific mining applications.

Why Are Vibratory Screeners Critical in Pharmaceutical & Food Processing?

Vibratory screeners play a pivotal role in the pharmaceutical and food processing industries by ensuring the sanitary screening of powders and granules. This is crucial for maintaining product quality and compliance with stringent health standards. Buyers in these sectors should look for screeners with hygienic designs that facilitate easy cleaning and meet regulatory certifications, particularly when sourcing from global suppliers.

Illustrative image related to vibratory screener

What Role Do Vibratory Screeners Play in Recycling & Waste Management?

In recycling and waste management, vibratory screeners are employed to efficiently separate recyclables from waste materials. This process maximizes recycling efficiency and minimizes the amount of waste sent to landfills. Buyers should evaluate the screening efficiency of the equipment, its adaptability to various materials, and its maintenance requirements to ensure optimal performance in diverse recycling scenarios.

How Are Vibratory Screeners Utilized in Plastics Manufacturing?

In plastics manufacturing, vibratory screeners are utilized for sizing and classifying plastic pellets. This application is vital for improving product consistency and reducing production costs. Buyers should assess the compatibility of the screeners with different pellet sizes and material types to ensure they can meet the specific needs of their production processes.

Why Are Vibratory Screeners Important for Aggregate & Concrete Applications?

Vibratory screeners are crucial in the aggregate and concrete industries for sizing materials used in construction projects. By enhancing construction quality and optimizing material use, these screeners contribute significantly to project success. Buyers should focus on the screening capacity, versatility, and resistance to wear of the equipment to ensure it meets the demands of their construction applications.

3 Common User Pain Points for ‘vibratory screener’ & Their Solutions

Scenario 1: Inconsistent Material Separation Leads to Quality Issues

The Problem: B2B buyers often struggle with inconsistent separation and sizing of materials when using vibratory screeners. For instance, a company in the mining sector might find that their vibratory screener fails to efficiently separate fine particles from larger rocks. This inconsistency can lead to a higher percentage of oversized or undersized materials in the final product, ultimately affecting quality and customer satisfaction. It can also result in increased costs due to reprocessing or scrapping of substandard materials.

The Solution: To address this issue, buyers should focus on selecting a vibratory screener that is specifically designed for their material characteristics and desired particle size distribution. Implementing a machine with adjustable amplitude and frequency settings can significantly enhance the separation process. Buyers should also consider models that allow for real-time adjustments based on material flow and characteristics. Collaborating with manufacturers to conduct in-house testing using the actual materials can provide insights into the optimal settings for their specific application. This proactive approach ensures that the screener operates at peak efficiency, minimizing quality issues.

Scenario 2: Frequent Maintenance Interrupts Production

The Problem: Another common pain point is the frequent maintenance and downtime associated with vibratory screeners. Companies might find that their equipment requires regular repairs due to wear and tear, leading to unexpected production halts. This can be particularly detrimental in high-demand industries, such as food processing or pharmaceuticals, where consistent throughput is critical to meet customer needs and regulatory standards.

The Solution: To mitigate maintenance issues, buyers should invest in high-quality vibratory screeners designed for low wear and tear. Opting for models that incorporate durable components and minimal moving parts can enhance longevity and reduce the frequency of repairs. Additionally, implementing a preventive maintenance schedule that includes regular inspections and part replacements can help identify potential issues before they escalate. Buyers can work with suppliers to ensure they understand the best practices for maintenance and care, thereby prolonging the life of the equipment and minimizing production interruptions.

Scenario 3: Inefficient Integration with Existing Systems

The Problem: Many B2B buyers encounter challenges when integrating vibratory screeners into their existing production lines. For instance, a company looking to upgrade its screening capabilities may find that the new equipment does not seamlessly fit with their existing conveyor systems or other machinery. This can lead to bottlenecks in the production process, reduced efficiency, and increased operational costs.

The Solution: To ensure smooth integration, it is crucial for buyers to thoroughly assess their current production setup and work closely with manufacturers during the selection process. Buyers should request custom design options that allow for modifications to match their specific layout and requirements. Utilizing modular vibratory screeners can also provide the flexibility needed to adapt to existing systems. Moreover, involving engineering teams from both the buyer and the supplier during the installation phase can help troubleshoot any compatibility issues early on. This collaborative approach enables a more efficient production workflow and maximizes the return on investment in new equipment.

Strategic Material Selection Guide for vibratory screener

When selecting materials for vibratory screeners, it’s crucial to consider the specific properties and compatibility of each material with the intended application. Here, we analyze four common materials used in vibratory screeners: stainless steel, carbon steel, polyurethane, and ceramic. Each material offers distinct advantages and limitations that can significantly impact performance, durability, and cost.

What Are the Key Properties of Stainless Steel for Vibratory Screeners?

Stainless steel is renowned for its corrosion resistance, high strength, and ability to withstand elevated temperatures. It typically has a temperature rating of up to 1,500°F (815°C) and excellent resistance to oxidation and rust. This makes it ideal for applications in food processing, pharmaceuticals, and chemical industries where hygiene and material integrity are paramount.

Pros: Stainless steel is durable and easy to clean, making it suitable for environments requiring strict sanitary standards. Its longevity reduces the need for frequent replacements, thus lowering long-term costs.

Cons: The primary drawback is its higher initial cost compared to other materials. Additionally, while it is resistant to corrosion, it can still suffer from pitting in highly acidic or alkaline environments.

Illustrative image related to vibratory screener

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive materials, making it a versatile choice for various industries.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel grades. In regions like Africa and South America, where local standards may differ, verifying material specifications is essential.

How Does Carbon Steel Perform in Vibratory Screeners?

Carbon steel is a cost-effective option widely used in industrial applications. It has a lower temperature rating than stainless steel, typically around 1,200°F (650°C), and is less resistant to corrosion.

Illustrative image related to vibratory screener

Pros: The main advantage of carbon steel is its affordability and strength. It is suitable for heavy-duty applications where high impact resistance is needed.

Cons: Carbon steel is prone to rust and corrosion, especially in humid environments, which can lead to increased maintenance costs and shorter lifespan.

Impact on Application: While effective for screening non-corrosive materials, its limitations in harsh environments may restrict its use in certain applications.

Illustrative image related to vibratory screener

Considerations for International Buyers: Compliance with standards such as ASTM A36 is crucial. Buyers in the Middle East, where humidity can be high, should consider protective coatings or treatments to enhance durability.

What Are the Benefits of Using Polyurethane in Vibratory Screeners?

Polyurethane is a flexible material known for its excellent wear resistance and ability to handle abrasive materials. It can withstand temperatures up to 200°F (93°C) and is often used in applications where noise reduction is a priority.

Pros: Its lightweight nature and flexibility allow for easier installation and reduced energy consumption. Polyurethane also provides effective vibration damping, which can enhance the lifespan of the screener.

Cons: However, its lower temperature resistance and potential for degradation in UV exposure can limit its use in certain environments.

Impact on Application: Polyurethane is ideal for screening fine powders and aggregates, where its wear resistance can significantly improve operational efficiency.

Considerations for International Buyers: Buyers should check for compliance with relevant safety and environmental regulations, especially in regions with stringent industrial standards.

How Do Ceramics Enhance Vibratory Screener Performance?

Ceramics are used in specialized applications requiring exceptional hardness and wear resistance, particularly in the mining and mineral processing industries. They can withstand high temperatures and corrosive environments.

Pros: The primary advantage of ceramics is their durability and ability to handle extreme conditions without degrading. They are ideal for abrasive materials.

Cons: The main limitation is their brittleness, which can lead to cracking under impact. Additionally, ceramics can be more expensive and complex to manufacture.

Impact on Application: Ceramics are particularly suited for applications involving highly abrasive materials, where their hardness can prevent wear on other components.

Illustrative image related to vibratory screener

Considerations for International Buyers: Compliance with international standards such as ISO 12677 for ceramics is essential. Buyers should also consider local sourcing options to reduce transportation costs.

Summary Table of Material Selection for Vibratory Screeners

| Material | Typical Use Case for vibratory screener | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Corrosion resistance and durability | Higher initial cost | High |

| Carbon Steel | Heavy-duty industrial applications | Cost-effective and strong | Prone to rust and corrosion | Low |

| Polyurethane | Fine powders, aggregates | Lightweight and wear-resistant | Lower temperature resistance | Medium |

| Ceramics | Mining, mineral processing | Exceptional hardness | Brittle and expensive | High |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding vibratory screeners, considering both performance and regional compliance factors.

In-depth Look: Manufacturing Processes and Quality Assurance for vibratory screener

What Are the Main Stages in the Manufacturing Process of Vibratory Screeners?

The manufacturing process of vibratory screeners involves several critical stages, ensuring that the final product meets performance and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Processed?

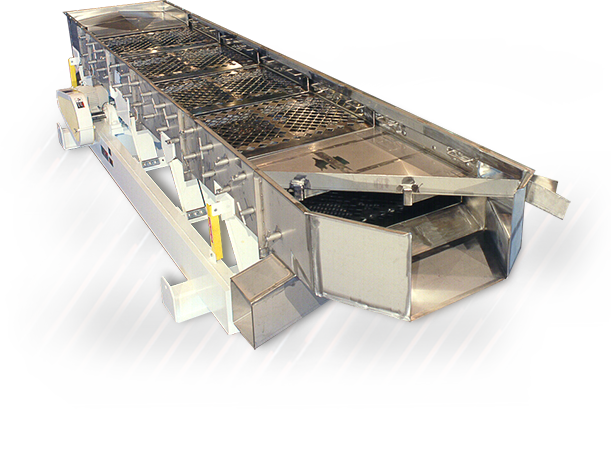

The first step in manufacturing vibratory screeners involves selecting high-quality materials that can withstand the rigors of continuous operation. Common materials include stainless steel for components that come in contact with materials, and heavy-duty mild steel for structural elements. The material preparation stage includes cutting, bending, and machining processes to create precise parts according to specifications. This is crucial as the material characteristics directly affect the durability and performance of the screener.

How Are Vibratory Screeners Formed and Assembled?

Once the materials are prepared, the forming stage begins, where the parts are shaped into their final form. This can involve processes like welding and stamping to create frames, screens, and other components. During assembly, various parts are brought together, including motors, screens, and support structures. Precision in this stage is essential, as any misalignment can lead to operational inefficiencies or increased wear and tear.

What Finishing Techniques Are Commonly Applied to Vibratory Screeners?

The finishing stage involves surface treatments such as painting, powder coating, or galvanizing, which enhance corrosion resistance and improve aesthetics. Additionally, this stage may include the installation of vibration isolation mounts and dust covers, which are vital for maintaining the performance and safety of the equipment. Attention to detail in the finishing process ensures that the vibratory screener is not only functional but also reliable under various operational conditions.

What Quality Assurance Practices Are Essential for Vibratory Screeners?

Quality assurance (QA) is a critical aspect of the vibratory screener manufacturing process, ensuring that each unit meets international standards and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 play a significant role in the manufacturing and quality assurance processes. ISO 9001 outlines the requirements for a quality management system (QMS) that organizations must adhere to for consistency in quality. Additionally, certifications such as CE mark for European markets and API specifications for specific industries ensure compliance with safety and operational standards.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early, minimizing waste and rework.

- Final Quality Control (FQC): The finished product undergoes comprehensive testing to verify performance, durability, and compliance with specifications.

Common testing methods include vibration analysis, load testing, and dimensional inspections to ensure that the screener functions as intended.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially in international markets, verifying a supplier’s QC practices is essential for ensuring product reliability and compliance.

What Are Effective Strategies for Conducting Supplier Audits?

Conducting supplier audits can provide insights into the manufacturing and quality assurance processes. Buyers should evaluate the supplier’s adherence to international standards and their internal QC protocols. This may involve on-site visits, reviewing documentation, and assessing the outcomes of past quality audits.

How Can Third-Party Inspections Enhance Buyer Confidence?

Utilizing third-party inspection services can further enhance buyer confidence. Independent inspectors can evaluate the production process and verify that the supplier meets specified quality standards. This is particularly beneficial for buyers in regions such as Africa and South America, where local regulations and standards may vary significantly.

What Unique Quality Control Considerations Exist for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control. Understanding local regulations, industry standards, and cultural differences is crucial. For instance, buyers from Nigeria may have different expectations regarding product durability compared to buyers in Europe. It is essential to communicate specific requirements clearly and ensure that the supplier is capable of meeting those expectations.

How Can Buyers Ensure Consistent Quality Across Different Markets?

To ensure consistent quality across different markets, buyers should establish clear specifications and standards that suppliers must adhere to, regardless of location. This includes regular communication, monitoring production processes, and setting up a feedback mechanism for continuous improvement. By fostering a collaborative relationship with suppliers, buyers can enhance quality assurance and ensure that vibratory screeners meet their operational needs.

In summary, understanding the manufacturing processes and quality assurance practices for vibratory screeners is crucial for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality assurance measures, buyers can ensure they select reliable and high-performing equipment for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vibratory screener’

To assist B2B buyers in the procurement of vibratory screeners, this practical sourcing guide provides a structured checklist. This guide aims to streamline the purchasing process by ensuring that key considerations are met, leading to informed decision-making and successful outcomes.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your operational requirements. This includes the type of materials you will be screening, the desired particle size, and the throughput capacity needed. Specific parameters such as screen size, mesh type, and vibration frequency are critical to ensure optimal performance and compatibility with existing processes.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers that specialize in vibratory screeners. Focus on manufacturers with a strong reputation in your industry, especially those familiar with the unique challenges of your region. Look for suppliers that provide detailed product information, including specifications and application case studies.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their experience with the specific type of vibratory screener you need, and inquire about their after-sales support and warranty policies to ensure reliability.

Illustrative image related to vibratory screener

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers meet relevant industry standards and certifications. This may include ISO certifications, safety standards, and environmental compliance. Verification of these certifications not only ensures quality but also reduces the risk of operational disruptions caused by non-compliant equipment.

Step 5: Assess Customization Options

Different applications may require customized features in vibratory screeners. Inquire about the flexibility of suppliers to tailor their equipment to meet your specific needs, such as unique dimensions, specialized materials, or enhanced safety features. Customization can significantly improve the efficiency of your screening processes.

Step 6: Request Demonstrations or Trials

Whenever possible, arrange for demonstrations or trials of the vibratory screeners you are considering. Observing the equipment in action will give you insights into its performance, ease of use, and maintenance requirements. Additionally, this step allows you to evaluate how well the screener integrates with your existing systems.

Step 7: Negotiate Terms and Conditions

Once you’ve narrowed down your options, engage in discussions about pricing, delivery times, and payment terms. Ensure that all aspects of the contract are clear, including warranties, support services, and any additional costs associated with installation or maintenance. A well-negotiated agreement can lead to a more favorable long-term partnership.

By following these steps, B2B buyers can make informed decisions when sourcing vibratory screeners, ensuring that they select the right equipment to enhance their operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for vibratory screener Sourcing

What Are the Key Cost Components in Vibratory Screener Manufacturing?

When sourcing vibratory screeners, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. High-quality, durable materials, like stainless steel, may increase initial expenses but can lead to lower maintenance costs and longer lifespans. Conversely, lower-cost materials might reduce upfront costs but can compromise performance and durability.

-

Labor: Labor costs vary by region and the complexity of the screener design. Skilled labor is crucial for manufacturing high-quality equipment, and labor costs can be higher in regions with stringent labor laws or higher living standards.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and indirect labor. Efficient manufacturing processes can help reduce these overheads, leading to more competitive pricing.

-

Tooling: Custom tooling for specialized designs can add significant costs. Buyers should consider whether standard models meet their needs or if custom designs are necessary, as this can heavily influence pricing.

-

Quality Control (QC): Implementing robust QC processes can add to production costs but is essential for ensuring product reliability and compliance with industry standards. Certifications such as ISO can further influence pricing.

-

Logistics: Shipping costs depend on the weight and size of the vibratory screeners, as well as the shipping distance and method. International buyers should consider tariffs and customs duties that may apply, particularly when importing from regions with different regulations.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the market average for margins in your specific industry can help in evaluating supplier quotes.

How Do Price Influencers Impact Vibratory Screener Costs?

Several factors can influence the pricing of vibratory screeners, including:

-

Volume/MOQ: Larger orders often qualify for discounts due to economies of scale. Establishing a minimum order quantity (MOQ) can help buyers leverage better pricing.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should clearly define their needs and consider whether standard models can suffice to control costs.

-

Quality and Certifications: Higher quality and certified equipment usually comes with a premium price. Buyers should assess the necessity of certifications based on their operational requirements and regulatory compliance.

-

Supplier Factors: Supplier reputation, experience, and location can affect pricing. Established suppliers with a history of reliability may charge more but offer better support and product assurance.

-

Incoterms: The chosen Incoterm can influence total costs significantly. Understanding the implications of terms like FOB (Free on Board) versus CIF (Cost, Insurance, and Freight) is crucial for budgeting.

What Negotiation Tips Can Help B2B Buyers Reduce Costs?

Effective negotiation strategies can lead to more favorable pricing and terms for vibratory screeners:

Illustrative image related to vibratory screener

-

Research Market Rates: Buyers should familiarize themselves with industry pricing trends to negotiate effectively. Knowledge of competitor pricing can provide leverage in discussions.

-

Focus on Total Cost of Ownership (TCO): Emphasizing the long-term benefits of quality and durability can justify higher upfront costs. Presenting a TCO analysis to suppliers can encourage them to offer better terms.

-

Be Open to Alternative Solutions: Flexibility in specifications or delivery schedules can open up avenues for discounts. Suppliers may be more willing to negotiate if they can optimize their production schedule.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers allows buyers to compare options and negotiate better terms. It can also create competition that can drive down prices.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following nuances:

-

Currency Fluctuations: Exchange rates can affect pricing when dealing with international suppliers. Buyers should account for potential fluctuations when budgeting.

-

Import Regulations: Understanding local import regulations and tariffs is crucial to avoid unexpected costs. Engaging with customs brokers can facilitate smoother transactions.

-

Cultural Differences: Negotiation styles and business practices can vary by region. Being culturally sensitive can foster better relationships and lead to more favorable outcomes.

Conclusion

While sourcing vibratory screeners, it’s imperative for B2B buyers to comprehensively analyze costs, understand pricing influencers, and apply effective negotiation strategies. By being informed and strategic, buyers can secure equipment that meets their needs without exceeding their budgets.

Alternatives Analysis: Comparing vibratory screener With Other Solutions

When evaluating material separation and screening solutions in a B2B context, it’s essential to consider various options that align with specific operational needs. Vibratory screeners are a popular choice, but alternatives such as static screeners and air classifiers may also meet certain requirements. This analysis will provide a comparative overview of these technologies to assist international buyers in making informed decisions.

| Comparison Aspect | Vibratory Screener | Static Screener | Air Classifier |

|---|---|---|---|

| Performance | High efficiency with adjustable screening | Moderate efficiency, limited by gravity | High precision in particle separation |

| Cost | Moderate to high initial investment | Lower upfront costs | Higher initial investment due to complexity |

| Ease of Implementation | Requires specific mounting and setup | Simple installation, minimal setup needed | Complex setup, requires skilled labor |

| Maintenance | Low maintenance due to robust design | Moderate maintenance, more wear parts | Low maintenance, but sensitive to dust |

| Best Use Case | Bulk material processing across industries | Ideal for coarse materials and aggregates | Excellent for fine particle separation |

What Are the Advantages and Disadvantages of Static Screeners Compared to Vibratory Screeners?

Static screeners utilize gravity to separate materials and are generally less complex than vibratory systems. Their design is straightforward, allowing for quick installation and minimal operational adjustments. However, they may not achieve the same level of efficiency as vibratory screeners, especially in applications requiring precise particle size separation. Static screeners are best suited for coarse materials where high throughput is necessary, but their performance diminishes with finer materials.

How Do Air Classifiers Compare to Vibratory Screeners?

Air classifiers use a combination of air flow and centrifugal forces to separate particles based on size and density. This technology excels in applications requiring high precision, making it ideal for fine powders and lightweight materials. However, the complexity of air classifiers often leads to higher initial costs and requires skilled labor for installation and operation. While they offer low maintenance, they may not be suitable for all industries, particularly those dealing with bulk materials where vibratory screeners shine.

Conclusion: How Should B2B Buyers Choose the Right Screening Solution?

Selecting the appropriate screening technology depends on the specific requirements of the application. Buyers should consider factors such as the type of materials being processed, desired efficiency, budget constraints, and available maintenance resources. For bulk processing of various materials, vibratory screeners offer flexibility and efficiency. In contrast, static screeners may be optimal for simpler operations involving coarse materials, while air classifiers excel in precision applications. By analyzing these aspects, B2B buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for vibratory screener

What Are the Key Technical Properties of a Vibratory Screener?

Understanding the essential technical properties of vibratory screeners is crucial for B2B buyers, particularly when selecting equipment that meets specific operational needs. Here are several critical specifications to consider:

-

Material Grade

Vibratory screeners are typically constructed from high-grade materials such as stainless steel or carbon steel. The choice of material affects durability, corrosion resistance, and hygiene—particularly important in food and pharmaceutical applications. For buyers, selecting the appropriate material grade ensures that the screener can withstand the operational environment and maintain product integrity. -

Screen Size and Mesh Opening

The screen size and mesh opening define the particle size that can be effectively separated. Common sizes range from fine mesh (20 microns) to coarse openings (4 inches). Understanding these dimensions is vital for buyers as it determines the screener’s suitability for specific applications, whether for separating fine powders or larger aggregates. -

Vibration Frequency and Amplitude

The vibration frequency (measured in RPM) and amplitude (the distance of the screen’s movement) impact material flow and separation efficiency. For example, higher frequencies may be suitable for fine materials, while lower frequencies may be more effective for heavier, bulk materials. Buyers should consider these parameters to optimize performance based on the materials they are processing. -

Capacity and Throughput

Capacity refers to the volume of material a screener can handle over a specified time, typically measured in tons per hour. This specification is crucial for B2B buyers as it directly correlates to production efficiency. Selecting a screener with the right capacity ensures that operational demands are met without compromising throughput. -

Power Source

Vibratory screeners can be powered by electric motors or pneumatic systems. The choice between these options often depends on the operational environment, such as whether the screener will be used in hazardous areas. Buyers should assess power requirements to ensure compatibility with existing systems and to optimize safety and efficiency. -

Maintenance Requirements

Understanding the maintenance needs of a vibratory screener can help buyers minimize downtime and operational costs. Features such as easy access to wear parts and low maintenance design can significantly enhance operational efficiency. Buyers should inquire about maintenance intervals and part availability to ensure long-term performance.

What Are Common Trade Terms Related to Vibratory Screeners?

Familiarity with industry jargon can streamline communications and negotiations. Here are several common terms relevant to vibratory screeners:

Illustrative image related to vibratory screener

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For buyers, understanding OEM products can help in sourcing replacement parts or entire systems that are compatible with existing machinery. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of an item that a supplier is willing to sell. This is significant for B2B buyers as it can impact inventory management and initial investment. Knowing the MOQ helps businesses plan their purchases effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specific products or services. For buyers, submitting an RFQ is a critical step in the procurement process, ensuring that they receive competitive pricing and detailed specifications. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international trade. They cover aspects such as shipping costs, insurance, and risk transfer. B2B buyers must understand Incoterms to clarify obligations and avoid disputes during the shipping process. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This is crucial for B2B buyers who need to align equipment delivery with production schedules. Understanding lead times allows for better planning and resource allocation. -

After-Sales Support

This encompasses services provided by the manufacturer after the purchase, including installation, maintenance, and training. For buyers, robust after-sales support is essential for ensuring optimal operation and longevity of the equipment.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding the acquisition of vibratory screeners that meet their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the vibratory screener Sector

What Are the Current Market Dynamics and Key Trends Influencing Vibratory Screener Sourcing?

The vibratory screener market is witnessing significant growth driven by various global factors. Industries such as mining, recycling, pharmaceuticals, and food processing are increasingly adopting advanced vibratory screening technologies to enhance productivity and efficiency. This is particularly relevant for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where demand for efficient material handling solutions is rising.

Emerging trends include the integration of automation and IoT technologies in vibratory screeners, allowing for real-time monitoring and optimization of material processing. Buyers are also gravitating towards equipment that offers flexibility in design and application, catering to diverse materials and operational requirements. Additionally, the demand for high-capacity screening solutions is escalating, especially in developing markets where industrial growth is robust.

Sourcing trends reflect a shift towards suppliers who can offer customized solutions and strong after-sales support. Buyers are now more inclined to collaborate with manufacturers that provide comprehensive service packages, including installation, maintenance, and training, which enhances the overall value proposition. Moreover, sustainability considerations are becoming paramount, prompting buyers to seek screeners that are energy-efficient and designed with environmentally friendly materials.

How Can Sustainability and Ethical Sourcing Impact the Vibratory Screener Sector?

Sustainability and ethical sourcing are increasingly integral to the vibratory screener sector, shaping purchasing decisions among B2B buyers. The environmental impact of industrial operations has prompted many companies to adopt greener practices, leading to a demand for vibratory screeners made from sustainable materials. Suppliers offering eco-friendly certifications or materials, such as recycled metals and low-emission components, are becoming more attractive to buyers who prioritize environmental stewardship.

Illustrative image related to vibratory screener

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices to ensure compliance with labor laws and environmental regulations. This trend is particularly relevant in regions like Africa and South America, where regulatory frameworks are evolving. Companies that adhere to ethical sourcing standards not only enhance their reputation but also mitigate risks associated with supply chain disruptions.

Investing in sustainable and ethically sourced vibratory screeners can lead to long-term cost savings through reduced energy consumption and maintenance requirements. B2B buyers should consider these factors as part of their sourcing strategy to align with global sustainability goals and consumer expectations.

How Has the Vibratory Screener Market Evolved Over Time?

The vibratory screener market has undergone significant transformations since its inception. Initially designed for basic material separation tasks, vibratory screeners have evolved into sophisticated machines equipped with advanced technologies that enhance their efficiency and versatility. The introduction of automation and variable frequency drives has allowed for greater control over screening processes, improving the precision of material separation.

In recent decades, the focus has shifted towards developing high-performance screeners that cater to specific industries, such as food processing and pharmaceuticals, where hygiene and material integrity are paramount. This evolution has been driven by the increasing complexity of materials being processed and the need for compliance with stringent industry regulations.

Today, vibratory screeners are not only integral to traditional sectors but are also pivotal in emerging markets, reflecting the growing demand for efficient material handling solutions across diverse applications. This historical context is crucial for B2B buyers to understand the technological advancements and market dynamics that influence their sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of vibratory screener

-

How do I solve issues related to material clogging in vibratory screeners?

To address material clogging, consider using screeners with adjustable vibration settings. This allows you to fine-tune the amplitude and frequency to match your material’s characteristics. Additionally, incorporating a dual motor system can enhance the linear vibration, which is effective in reducing material build-up. Regular maintenance, such as cleaning and inspecting screen decks for wear, will also help prevent clogging and ensure optimal performance. -

What is the best vibratory screener for processing fine powders?

For processing fine powders, the EMS Electromechanical Vibratory Screener is ideal due to its precise control over vibration parameters, enabling efficient separation of particles as small as 20 microns. Its design promotes optimal material throughput and can be customized for different applications. For ultra-hygienic environments, consider the Dynamic Screener™, which features easy-to-clean components that meet sanitary standards, ensuring product quality and safety. -

What customization options are available for vibratory screeners?

Vibratory screeners can be highly customized to meet specific operational needs. Options include varying screen sizes, different discharge configurations (e.g., circular or tapered chutes), and specific materials for construction based on the product being processed. Custom features such as dust-tight covers, variable frequency drives for adjustable feed rates, and specialized mounting solutions can also be added to enhance performance and fit into existing systems. -

What are the typical minimum order quantities (MOQ) for vibratory screeners?

Minimum order quantities can vary significantly based on the manufacturer and the complexity of the screener. Typically, MOQs range from one unit for standard models to larger quantities for customized designs. It is advisable to discuss your specific needs with suppliers to negotiate terms that align with your project requirements, especially if you are sourcing for a large-scale operation. -

What payment terms should I expect when sourcing vibratory screeners internationally?

Payment terms for international purchases often include options like upfront deposits (commonly 30-50%), with the balance due upon shipping or delivery. Some suppliers may offer credit terms or financing options depending on the buyer’s creditworthiness and relationship history. Ensure to clarify these terms upfront to avoid misunderstandings, and consider using secure payment methods to protect your transaction. -

How can I vet suppliers of vibratory screeners effectively?

When vetting suppliers, consider their industry reputation, years of experience, and customer testimonials. Request references and check their compliance with international quality standards, such as ISO certifications. Additionally, assess their ability to provide technical support and after-sales services. Visiting their facilities or requesting virtual tours can provide insights into their manufacturing processes and quality control measures. -

What logistics considerations should I keep in mind when importing vibratory screeners?

Logistics for importing vibratory screeners involve understanding shipping methods, customs regulations, and potential tariffs. Ensure that your supplier provides necessary documentation for customs clearance, such as commercial invoices and packing lists. It’s also wise to partner with a reliable freight forwarder who is familiar with the regulations in your country, especially in regions like Africa or South America where customs processes can vary widely. -

What quality assurance processes should be in place for vibratory screeners?

Quality assurance processes should include thorough testing of screeners before shipment, such as performance testing in conditions that simulate actual use. Request documentation of these tests, including results and compliance with industry standards. A reputable supplier should also offer warranties and support for maintenance, ensuring that you receive a reliable product that meets your operational needs and minimizes downtime.

Top 7 Vibratory Screener Manufacturers & Suppliers List

1. Cleveland Vibrator – Vibratory Screeners

Domain: clevelandvibrator.com

Registered: 2000 (25 years)

Introduction: Cleveland Vibrator offers a range of vibratory screeners designed for efficient material separation and sizing. Key models include: 1. EMS Electromechanical Vibratory Screener: Features twin motor drives for precise screening and high efficiency. 2. PSC-E Portable Sloped Screener: Lightweight and customizable for fine bulk materials. 3. RSM Volumetric Vibratory Screener: Self-contained with a bulk…

2. VibraScreener – Dynamic Screener™ & Ranger Separator™

Domain: vibrascreener.com

Registered: 2014 (11 years)

Introduction: VibraScreener offers a range of industrial vibratory sieves and sieving equipment, including: 1. Dynamic Screener™ – Ultra-hygienic design for sanitary screening applications. 2. Ranger Separator™ – High performance round industrial vibratory separator designed to improve product quality. 3. Bison Separator™ – High performance industrial vibrating screen machine for efficient and cost-effective sc…

3. Kason – VIBROSCREEN Circular Vibratory Screeners

Domain: kason.com

Registered: 1996 (29 years)

Introduction: VIBROSCREEN Circular Vibratory Screeners & Separators from Kason Corporation are designed for sifting, classifying, scalping, and dewatering bulk solids and slurries. They are available in various sizes and configurations, capable of processing different capacities for batch or continuous operations. Key features include:

– Precision circular vibratory screeners that ensure products are free from…

4. Eriez – Vibratory Screeners

Domain: eriez.com

Registered: 1995 (30 years)

Introduction: Eriez Vibratory Screeners provide dependable material separation solutions at an affordable price. They are available in a wide range of models for specific applications, including processing slurries, waste water, minerals, chemicals, and dry or dewatering applications. Key features include:

– Electromagnetic and mechanical designs

– Sizes ranging from 6″ to over 4 feet wide

– Adjustable material…

5. Witte – Linear Vibrating Screens

Domain: witte.com

Registered: 1996 (29 years)

Introduction: Witte Linear Vibrating Screens are designed to gently separate and size dry, bulk solids and free-flowing materials using wire mesh or perforated screens. They are suitable for high or low-capacity operations, handling materials from microns to multiple inches. Key features include single, double, or triple separation models, total enclosure with removable covers, a fixed angle linear vibratory dr…

6. Wohl Associates – Vibratory Screens & Classifiers

Domain: wohlassociates.com

Registered: 1997 (28 years)

Introduction: Used Screens & Classifiers include vibratory screens and continuous rotary screens. Available products include: 24 Inch Sweco Stainless Vibratory Screener (Stock #: 7495D, Capacity/Model: LS24S44), 40 Inch Sweco Stainless Vibratory Screener Classifier Sifter (Stock #: 7495E, Capacity/Model: XS40S666), 48 In. Diameter Single Deck Vibratory Screener, Portable (Stock #: 8967D, Capacity/Model: 48 inch…

7. Chery Industrial – Greatbear Skid Steer Vibratory Screen

Domain: cheryindustrial.com

Registered: 2020 (5 years)

Introduction: Greatbear Skid Steer Vibratory Screen

Strategic Sourcing Conclusion and Outlook for vibratory screener

As international B2B buyers navigate the complexities of sourcing vibratory screeners, several key insights emerge. First, understanding the diverse applications and benefits of vibratory screeners is essential for maximizing efficiency in material handling. Whether used in mining, recycling, or food processing, these machines offer tailored solutions that enhance productivity and product quality.

Strategic sourcing not only involves selecting the right equipment but also ensuring compatibility with existing production processes. Buyers should prioritize suppliers who provide comprehensive support, including in-house testing and customization options, to meet specific operational needs. This approach not only reduces downtime but also fosters long-term partnerships that can yield significant cost savings.

Illustrative image related to vibratory screener

Looking ahead, the demand for advanced vibratory screening solutions is poised to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As industries evolve and the need for sustainable practices increases, investing in high-quality, efficient vibratory screeners will be crucial. We encourage buyers to engage with reputable manufacturers and leverage their expertise to optimize sourcing strategies that align with future market trends. By doing so, you position your business for success in an increasingly competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.