Everything You Need to Know About Vibrating Feeder Sourcing in 2025

Introduction: Navigating the Global Market for vibrating feeder

In today’s competitive industrial landscape, sourcing the right vibrating feeder can be a daunting challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Vibrating feeders play a critical role in optimizing material handling processes, ensuring that bulk materials flow smoothly and efficiently. However, with varying types, specifications, and applications available in the market, making an informed purchasing decision is crucial to maximizing operational efficiency and minimizing downtime.

This comprehensive guide delves into the intricacies of the vibrating feeder market, offering insights on different types of feeders, their applications across various industries, and essential factors to consider when vetting suppliers. Additionally, we explore cost considerations, maintenance requirements, and the latest technological advancements that can enhance performance and reliability. By equipping international B2B buyers with actionable insights and practical knowledge, this guide empowers you to navigate the complexities of sourcing vibrating feeders effectively.

Whether you are involved in mining, food processing, pharmaceuticals, or any other sector requiring precise material handling solutions, understanding the nuances of vibrating feeders will enable you to make strategic choices that align with your operational goals. Embrace the potential of this essential equipment and leverage the insights presented in this guide to drive your business forward.

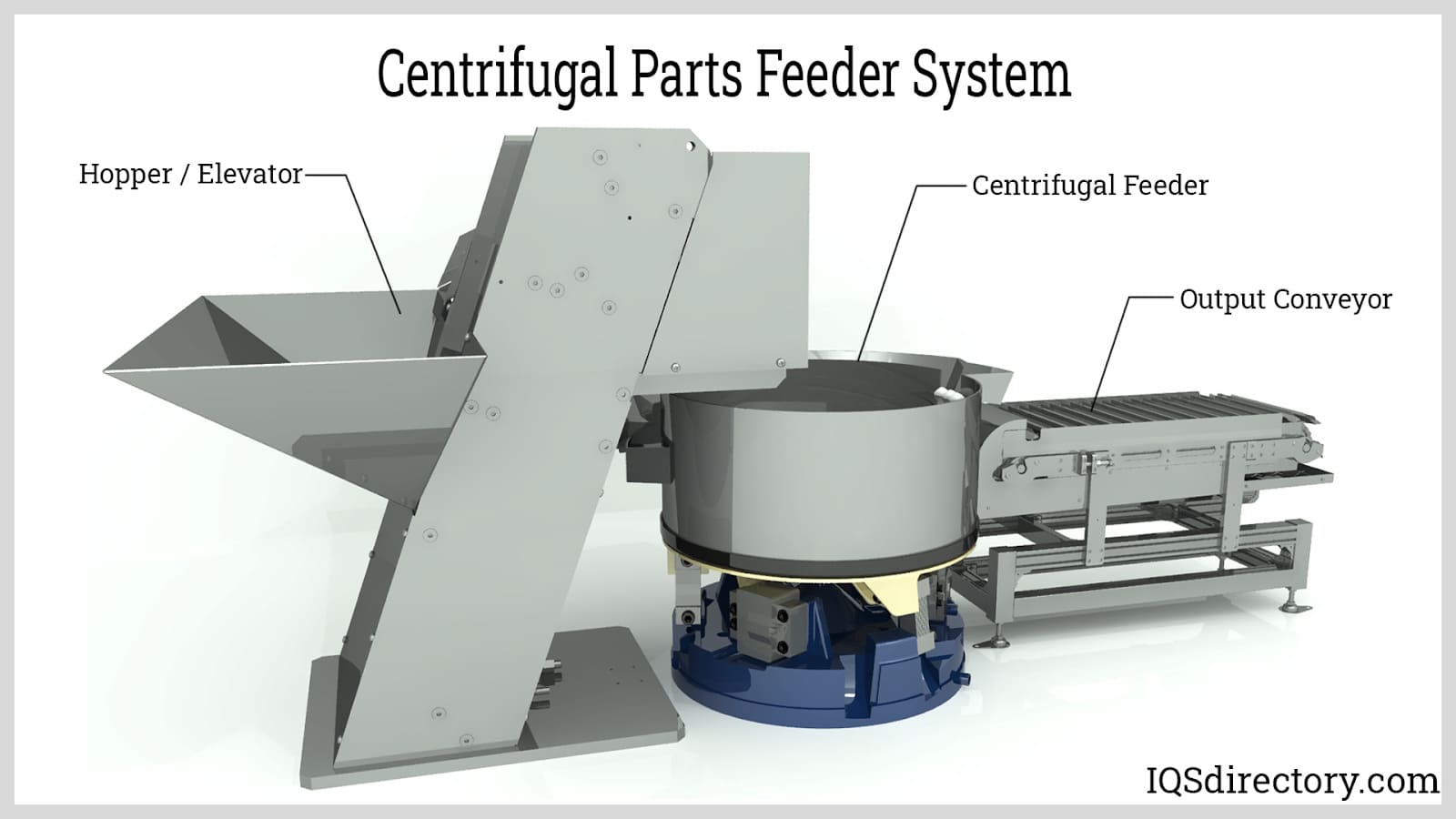

Understanding vibrating feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electromagnetic Feeders | Use electromagnetic vibrations for precise control. | Food processing, pharmaceuticals, and fine powders. | Pros: High precision, low maintenance. Cons: Limited to lighter materials. |

| Electromechanical Feeders | Provide linear motion for uniform material flow. | Aggregate handling, mining, and recycling. | Pros: High capacity, versatile. Cons: More complex than electromagnetic types. |

| Volumetric Feeders | Include a bulk supply hopper and adjustable feed rate controls. | Bulk material feeding in manufacturing and agriculture. | Pros: Simple design, customizable. Cons: Initial setup can be time-consuming. |

| Air-Powered Feeders | Utilize compressed air for operation, suitable for hazardous environments. | Chemical processing, food production, and explosive materials. | Pros: Safe in explosive settings, economical. Cons: Requires air supply infrastructure. |

| Tubular Feeders | Enclosed design prevents dust and contamination. | Handling powders, granules, and other bulk materials. | Pros: Maintains material integrity, reduces contamination. Cons: Limited visibility for monitoring. |

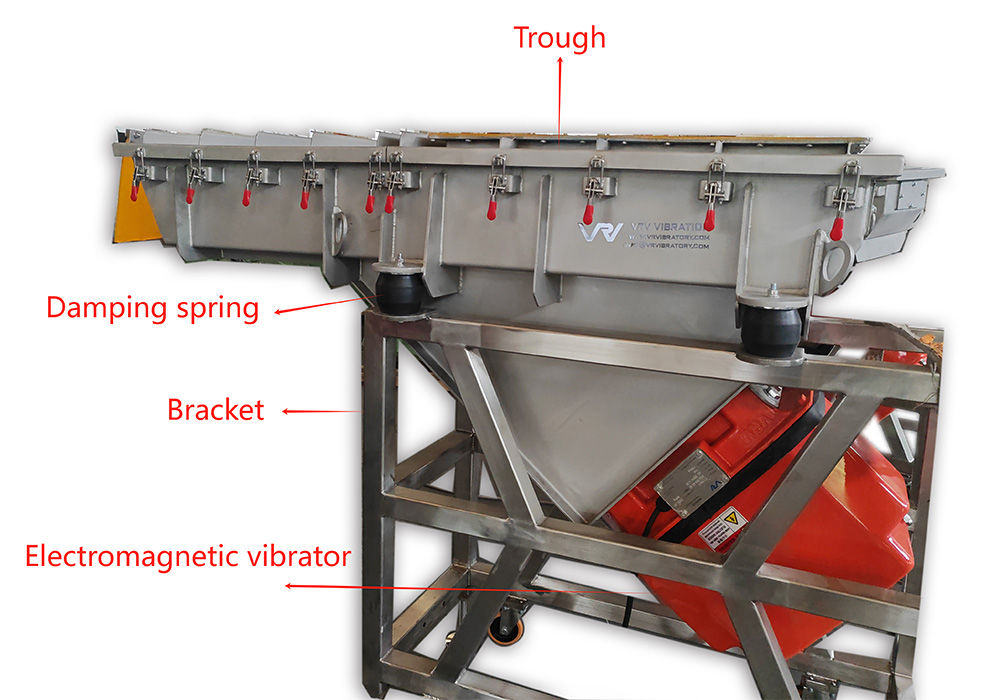

What Are the Characteristics of Electromagnetic Feeders?

Electromagnetic feeders are designed to deliver precise and controlled vibrations to move materials. They are particularly effective for light materials, such as powders and granules, making them suitable for industries like food processing and pharmaceuticals. Buyers should consider the feeder’s ability to handle specific material types and the required precision in feed rates, as well as the low maintenance requirements, which can lead to reduced operational costs.

How Do Electromechanical Feeders Differ from Other Types?

Electromechanical feeders utilize a motor-driven mechanism to create a linear motion that facilitates smooth and uniform material flow. This type is highly versatile, making it ideal for applications in aggregate handling and recycling. When purchasing, buyers should evaluate the feeder’s capacity to handle various materials and the complexity of the drive system, which may require more maintenance than simpler designs. However, the higher capacity can justify the investment for larger operations.

What Makes Volumetric Feeders a Popular Choice?

Volumetric feeders are characterized by their simple design, which includes a supply hopper, a vibrator, and a feeder trough. They allow for adjustable feed rates and can handle a wide range of bulk materials, making them popular in manufacturing and agriculture. Key purchasing considerations include the need for customization to meet specific material requirements and the potential time needed for initial setup. Their reliability and long service life are significant advantages.

Why Choose Air-Powered Feeders in Hazardous Environments?

Air-powered feeders operate using compressed air, making them suitable for environments where electrical equipment may pose a risk, such as in chemical processing or handling explosive materials. The economical operation and safety features are appealing to businesses prioritizing worker safety. Buyers should assess the availability of air supply infrastructure and the specific applications where these feeders will be used to ensure compatibility.

What Are the Advantages of Tubular Feeders?

Tubular feeders feature an enclosed design that effectively prevents dust and contamination, which is crucial in industries dealing with powders and granules. This design ensures that the material integrity is maintained throughout the feeding process. When considering a tubular feeder, buyers should weigh the benefits of reduced contamination against the potential limitations in visibility for monitoring the feeding process. The suitability for various materials makes them a valuable asset in bulk handling operations.

Key Industrial Applications of vibrating feeder

| Industry/Sector | Specific Application of vibrating feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining | Feeding raw materials into crushers and processing plants | Ensures efficient material flow and reduces downtime | Durability, capacity, and compatibility with harsh environments |

| Food Processing | Controlled feeding of ingredients in mixing tanks | Enhances product consistency and reduces waste | Compliance with food safety standards, material quality |

| Pharmaceuticals | Precise dosing of powders and granules | Improves accuracy in formulations | Customization for specific materials and processes |

| Recycling | Feeding materials into shredders and sorting equipment | Increases throughput and operational efficiency | Robust design to handle varying material types |

| Manufacturing | Supplying components to assembly lines | Streamlines production and minimizes manual handling | Flexibility in design to accommodate different components |

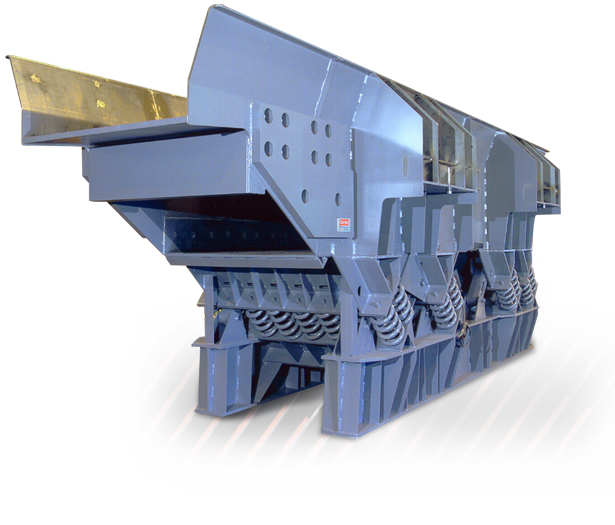

How is Vibrating Feeder Used in the Mining Sector?

In the mining industry, vibrating feeders are essential for feeding raw materials into crushers and processing plants. They ensure a consistent and controlled flow of materials, which minimizes downtime and enhances productivity. Buyers in this sector should consider the durability and capacity of the feeders, as they must operate in harsh environments with heavy loads. Additionally, compatibility with existing equipment and ease of maintenance are critical factors for successful integration.

What Role Does Vibrating Feeder Play in Food Processing?

Vibrating feeders are widely used in food processing to control the feeding of ingredients into mixing tanks. This application improves product consistency and reduces waste by ensuring accurate material flow. For international buyers, especially in regions with strict food safety regulations, it is vital to source feeders that comply with FDA and USDA standards. Material quality, sanitation features, and ease of cleaning are also key considerations to maintain food safety.

How is Vibrating Feeder Important in the Pharmaceutical Industry?

In the pharmaceutical sector, vibrating feeders are employed for the precise dosing of powders and granules into manufacturing processes. This application is crucial for ensuring accuracy in formulations, which directly impacts product efficacy and safety. Buyers must look for feeders that can be customized to handle specific materials and processes, as well as those that provide precise control over feed rates. Compliance with industry regulations is also paramount to ensure quality and safety.

What Benefits Do Vibrating Feeders Provide in Recycling?

Vibrating feeders are instrumental in the recycling industry, where they feed materials into shredders and sorting equipment. This application increases throughput and operational efficiency, allowing businesses to process a higher volume of materials. Buyers should focus on robust designs that can handle varying material types and sizes, as well as features that enhance reliability and reduce maintenance costs. Additionally, understanding the specific requirements for different recycling materials can help in selecting the right feeder.

Illustrative image related to vibrating feeder

How Do Vibrating Feeders Enhance Manufacturing Operations?

In manufacturing, vibrating feeders supply components to assembly lines, significantly streamlining production processes. They reduce the need for manual handling, thus improving efficiency and safety in the workplace. When sourcing vibrating feeders for manufacturing applications, buyers should consider the flexibility of design to accommodate different component sizes and shapes. Ensuring compatibility with existing production lines and evaluating the total cost of ownership, including maintenance and operational costs, are also critical factors for decision-making.

3 Common User Pain Points for ‘vibrating feeder’ & Their Solutions

Scenario 1: Inconsistent Material Flow Leading to Production Delays

The Problem: One of the most pressing challenges B2B buyers face with vibrating feeders is inconsistent material flow, which can significantly disrupt production schedules. This inconsistency may arise from improper feeder settings, variations in material characteristics, or mechanical issues. For instance, if a feeder is not calibrated correctly, it may underfeed or overfeed materials, leading to bottlenecks or excess inventory. Such disruptions can cause delays in downstream processes, ultimately affecting the bottom line.

The Solution: To tackle this issue, it is crucial to focus on proper calibration and regular maintenance of the vibrating feeder. First, invest in a reliable controller that allows for precise adjustments of the feed rate. Features such as variable frequency drives (VFD) can help maintain consistent material flow by adjusting the vibration intensity based on real-time feedback from the production line. Additionally, conducting routine checks on the feeder’s components—like the springs and vibratory motor—can prevent mechanical failures that lead to inconsistent performance. Finally, training your operators to understand the material properties and how they affect flow can enhance the overall efficiency of the feeding system.

Scenario 2: Material Bridging and Blockages in Feeders

The Problem: Another common pain point is material bridging or blockages within the hopper. This issue is particularly prevalent when dealing with cohesive or granular materials that tend to clump together. When bridging occurs, it can halt production as operators must manually intervene to clear the blockage, resulting in downtime and wasted labor hours. This situation is often exacerbated in regions with varying humidity levels, which can affect material consistency.

The Solution: To mitigate bridging, consider employing a vibrating feeder equipped with an electromagnetic or pneumatic vibrator that can provide sufficient energy to keep materials flowing freely. Additionally, modifying the hopper design to include features like a conical shape or incorporating anti-bridging devices, such as flow aids or agitators, can significantly reduce the risk of material blockages. Furthermore, conducting a thorough analysis of the material’s flow properties can help in selecting the right feeder configuration, ensuring that the setup is tailored to the specific challenges posed by the materials being handled.

Illustrative image related to vibrating feeder

Scenario 3: High Maintenance Costs and Downtime

The Problem: Many businesses experience high maintenance costs associated with traditional mechanical feeders, which often require regular part replacements and extensive downtime for repairs. This situation not only drains financial resources but also affects productivity, as the equipment may be offline for longer periods than anticipated. Buyers are often concerned about the long-term viability and reliability of their feeding solutions, especially in harsh operating environments common in industries such as mining and construction.

The Solution: To address high maintenance costs, consider investing in modern vibratory feeders that feature fewer moving parts and robust designs. Electromechanical feeders, for example, are known for their durability and low maintenance requirements, as they lack gears, belts, and other components that are prone to wear and tear. When sourcing a vibrating feeder, prioritize models that offer dust-proof and waterproof construction, as these features can extend the lifespan of the equipment in challenging environments. Additionally, establish a preventive maintenance schedule that includes regular inspections and performance assessments to identify potential issues before they escalate, ensuring optimal operational efficiency and minimal downtime.

Strategic Material Selection Guide for vibrating feeder

What Are the Key Materials for Vibrating Feeders and Their Properties?

Vibrating feeders are essential components in many industrial applications, and the selection of the right material can significantly impact performance, durability, and cost. Below, we analyze four common materials used in the construction of vibrating feeders, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Mild Steel Perform in Vibrating Feeders?

Mild steel is one of the most commonly used materials for vibrating feeders due to its balance of strength and cost-effectiveness.

Key Properties: Mild steel offers good tensile strength and is readily available. It typically has a temperature rating up to 400°F (204°C) and can withstand moderate pressure. However, it lacks inherent corrosion resistance.

Pros & Cons: The primary advantage of mild steel is its low cost and ease of fabrication, making it suitable for a wide range of applications. However, its susceptibility to rusting and corrosion limits its use in environments exposed to moisture or chemicals.

Impact on Application: Mild steel is ideal for handling bulk materials in dry environments. However, for applications involving corrosive materials, its use may lead to premature failure.

Considerations for International Buyers: Buyers from regions with high humidity or corrosive environments should consider the need for protective coatings or alternative materials. Compliance with local standards such as ASTM or DIN is crucial for ensuring quality and safety.

Illustrative image related to vibrating feeder

Why Choose Stainless Steel for Vibrating Feeders?

Stainless steel is favored in applications where hygiene and corrosion resistance are paramount.

Key Properties: Stainless steel has excellent corrosion resistance, high-temperature tolerance (up to 1,500°F or 815°C), and is easy to clean. Its durability makes it suitable for harsh environments.

Pros & Cons: The main advantage is its longevity and ability to maintain structural integrity in corrosive settings. However, stainless steel is significantly more expensive than mild steel, and its fabrication can be more complex.

Impact on Application: Stainless steel is particularly suitable for food processing, pharmaceuticals, and chemical industries where cleanliness is essential.

Illustrative image related to vibrating feeder

Considerations for International Buyers: Buyers should ensure compliance with FDA and USDA standards when selecting stainless steel for food-related applications. Understanding the grade of stainless steel (e.g., 304 vs. 316) is also important for specific applications.

What Role Does Aluminum Play in Vibrating Feeders?

Aluminum is a lightweight alternative that offers unique benefits for specific applications.

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can operate effectively at temperatures up to 1,200°F (649°C). It is also non-magnetic, which can be advantageous in certain applications.

Pros & Cons: The primary advantage of aluminum is its low weight, which can reduce the overall load on supporting structures. However, it is less durable than steel and can be more expensive, especially for thicker sections.

Impact on Application: Aluminum is ideal for applications requiring portability or where weight is a critical factor, such as in mobile or temporary setups.

Illustrative image related to vibrating feeder

Considerations for International Buyers: Buyers should verify the aluminum alloy specifications to ensure compatibility with their specific applications. Compliance with international standards like JIS may also be necessary.

When Is Polyurethane the Best Choice for Vibrating Feeders?

Polyurethane is increasingly used in vibrating feeders, especially in specialized applications.

Key Properties: Polyurethane is known for its excellent abrasion resistance, flexibility, and ability to withstand a wide temperature range (-40°F to 200°F or -40°C to 93°C). It is also resistant to many chemicals.

Pros & Cons: The main advantage is its ability to reduce noise and wear on both the feeder and the materials being handled. However, it can be more expensive than metals and may not be suitable for high-temperature applications.

Impact on Application: Polyurethane is particularly effective in applications involving abrasive materials, where it can extend the lifespan of the feeder.

Considerations for International Buyers: Buyers should consider the specific chemical compatibility of polyurethane with the materials being handled. Compliance with local industrial standards is also essential.

Summary Table of Material Selection for Vibrating Feeders

| Material | Typical Use Case for vibrating feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Mild Steel | General bulk material handling | Low cost and easy fabrication | Susceptible to corrosion | Low |

| Stainless Steel | Food and pharmaceutical industries | Excellent corrosion resistance | Higher cost and complex fabrication | High |

| Aluminum | Portable applications | Lightweight and non-magnetic | Less durable and more expensive | Medium |

| Polyurethane | Abrasive material handling | High abrasion resistance | Not suitable for high temperatures | Medium |

This strategic material selection guide serves as a valuable resource for international B2B buyers, helping them make informed decisions based on their specific applications and regional requirements.

Illustrative image related to vibrating feeder

In-depth Look: Manufacturing Processes and Quality Assurance for vibrating feeder

What Are the Main Stages of the Manufacturing Process for Vibrating Feeders?

The manufacturing process for vibrating feeders consists of several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential to ensure that the final product meets the rigorous demands of various industries.

Material Preparation

This initial stage involves sourcing high-quality raw materials, typically mild or stainless steel, depending on the application requirements. The materials are subjected to quality checks to verify their properties, including tensile strength and corrosion resistance. For specific industries, such as food processing, materials may need to comply with FDA or USDA specifications.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques, including cutting, bending, and welding. Advanced CNC (Computer Numerical Control) machines are often used to achieve precision in shaping components like troughs and hoppers. Techniques such as laser cutting can enhance accuracy and reduce material waste. Additionally, the use of electromagnetic or electromechanical systems in forming ensures that the feeders can produce the necessary vibrations for material movement.

Assembly Process

After forming, the components are assembled into the final product. This stage often involves the integration of vibration mechanisms, control systems, and safety features. For instance, the assembly might include installing an electromagnetic vibrator, which plays a crucial role in material flow regulation. Quality checks during assembly ensure that each component fits correctly and operates as intended.

Illustrative image related to vibrating feeder

Finishing Touches

The final stage involves surface treatments, which may include painting, powder coating, or galvanizing to enhance durability and prevent corrosion. The application of seals and protective covers is also common to ensure that the equipment can operate in various environments, including dusty or hazardous conditions. Finishing processes are critical for achieving compliance with international standards, thus enhancing the product’s marketability.

How Is Quality Assurance Implemented in Vibrating Feeder Manufacturing?

Quality assurance (QA) is a vital component of the vibrating feeder manufacturing process, ensuring that products meet specific standards before reaching the market. The QA process typically adheres to various international standards such as ISO 9001, as well as industry-specific certifications like CE and API.

International Standards and Certifications

ISO 9001 is a globally recognized standard that outlines criteria for a quality management system (QMS). Manufacturers often pursue this certification to demonstrate their commitment to quality, which can significantly enhance their credibility in international markets. Additionally, CE marking is essential for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

Key Quality Control Checkpoints

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that products meet the required specifications. These checkpoints typically include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the assembly and manufacturing stages, periodic inspections are conducted to identify any defects or deviations from standards.

-

Final Quality Control (FQC): This final inspection ensures that the finished product meets all specifications and is functioning correctly before it is shipped to the customer.

What Common Testing Methods Are Used to Ensure Vibrating Feeders Meet Quality Standards?

Testing methods are crucial for verifying the performance and reliability of vibrating feeders. Common testing techniques include:

-

Functional Testing: This involves running the feeder under its operational conditions to ensure it performs as expected. This can include testing feed rates, vibration patterns, and material flow.

-

Load Testing: Conducted to verify the feeder’s capacity to handle specified loads without failure.

-

Vibration Analysis: This assesses the performance of the vibratory mechanisms, ensuring they operate within designated parameters.

-

Durability Testing: Simulates long-term use to identify potential points of failure.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several strategies buyers can employ:

Audits and Inspections

Conducting on-site audits of the manufacturing facilities can provide valuable insights into the supplier’s quality control processes. During these audits, buyers can assess the cleanliness of the production area, the condition of machinery, and the adherence to safety standards.

Requesting Quality Reports

Buyers should ask suppliers for detailed quality reports, including IQC, IPQC, and FQC findings. These documents can provide a comprehensive overview of the supplier’s quality management practices and any issues encountered during production.

Third-Party Inspections

Engaging third-party inspection services can add an additional layer of assurance. These independent entities can evaluate the supplier’s processes and products, providing unbiased reports that can aid in decision-making.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances that can differ significantly from one region to another. Understanding these nuances is essential for ensuring compliance and product reliability.

Regional Compliance Standards

Different regions may have specific compliance requirements. For instance, the European market is stringent about CE marking, while other regions might prioritize different certifications. Buyers should familiarize themselves with the relevant standards in their target markets.

Cultural Differences in Quality Perception

Quality expectations can vary culturally. For example, European buyers might prioritize precision and reliability, while buyers in emerging markets might be more price-sensitive. Understanding these differences can help suppliers tailor their offerings to meet diverse buyer needs.

Illustrative image related to vibrating feeder

Logistics and Supply Chain Considerations

Quality assurance does not end at production; it extends to logistics and transportation. Buyers should inquire about how suppliers manage quality during shipping, including packaging and handling procedures, to ensure that products arrive in optimal condition.

In conclusion, the manufacturing processes and quality assurance practices for vibrating feeders are crucial elements for B2B buyers to consider. By understanding these processes and verifying supplier quality, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vibrating feeder’

When sourcing a vibrating feeder, it’s crucial to follow a structured approach to ensure you select the right equipment that meets your operational needs and budget. This guide provides actionable steps that B2B buyers can take to navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the vibrating feeder based on your material handling needs. Consider factors such as the type of materials to be handled, required feed rates, and any environmental conditions (e.g., moisture, temperature).

– Material Compatibility: Ensure the feeder is compatible with the materials in terms of size, weight, and abrasiveness.

– Capacity Requirements: Determine the desired throughput to select a model that meets your production demands.

Step 2: Establish Your Budget

Develop a comprehensive budget that includes not only the initial purchase price but also installation, maintenance, and operational costs.

– Price Range: Be aware that prices can vary significantly based on features and specifications, ranging from a few hundred to tens of thousands of dollars.

– Total Cost of Ownership: Consider long-term costs associated with energy consumption, spare parts, and potential downtime.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and deliver quality equipment.

– Company Reputation: Research their history, customer reviews, and case studies related to similar industries.

– Certifications and Compliance: Verify that the supplier meets industry standards, including ISO certifications, and complies with relevant safety regulations.

Step 4: Request Detailed Quotations

Once you have identified potential suppliers, request detailed quotations that break down the costs associated with the vibrating feeders.

– Inclusions and Exclusions: Ensure the quote specifies what is included in the price, such as installation and training, and clarify any excluded services.

– Customization Options: Inquire about customization capabilities to ensure the feeder can be tailored to your specific needs.

Illustrative image related to vibrating feeder

Step 5: Assess After-Sales Support and Warranty

Evaluate the level of after-sales support offered by the supplier, including training, maintenance services, and warranty terms.

– Service Agreements: Check if they provide service agreements for routine maintenance and emergency repairs.

– Warranty Coverage: Understand the warranty terms, including duration and what components are covered, to protect your investment.

Step 6: Conduct Site Visits or Demos

If possible, arrange site visits or product demonstrations to see the vibrating feeder in action.

– Real-World Performance: Observing the equipment can provide insights into its operational efficiency and compatibility with your processes.

– Operator Feedback: Engage with current users to get firsthand feedback on performance, reliability, and ease of use.

Step 7: Finalize Your Decision

After thorough evaluation, compare all collected data and make a decision based on your defined criteria.

– Risk Assessment: Consider potential risks associated with each option, including supplier reliability and equipment performance.

– Long-Term Partnership: Choose a supplier that aligns with your company’s values and can support future growth and changes in your operational needs.

Following this checklist will enable you to make an informed decision when procuring a vibrating feeder, ensuring it meets both your operational requirements and budget constraints.

Comprehensive Cost and Pricing Analysis for vibrating feeder Sourcing

What Are the Key Cost Components in Vibrating Feeder Manufacturing?

When sourcing vibrating feeders, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

-

Materials: The choice of materials significantly impacts the cost. Common materials include mild steel for standard applications and stainless steel for environments requiring corrosion resistance. Bulk purchases may lower material costs due to economies of scale.

-

Labor: Labor costs vary by region and the complexity of the feeder design. Skilled labor is necessary for custom designs, which can increase costs. In regions like Europe and the Middle East, labor costs may be higher compared to South America or Africa.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Custom tooling for specialized feeders can be expensive. However, standard tooling may reduce initial costs, making it crucial to evaluate whether customization is necessary for your application.

-

Quality Control (QC): Ensuring the reliability and safety of vibrating feeders involves rigorous QC processes. Certifications such as ISO or FDA compliance can add to the costs but may be essential depending on the industry.

-

Logistics: Shipping costs can vary dramatically based on the destination and chosen Incoterms. For international buyers, understanding freight costs and customs duties is crucial to total expenditure.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. This can vary widely based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect Vibrating Feeder Costs?

Several factors can influence the pricing of vibrating feeders.

-

Volume/MOQ: Bulk orders often come with significant discounts. Understanding the minimum order quantities (MOQs) can help buyers negotiate better pricing.

-

Specifications/Customization: Custom feeders tailored for specific applications generally incur higher costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materials: The type of material used can influence not just the initial cost but also long-term performance and maintenance. Opting for higher-quality materials may lead to lower total costs over the product’s lifespan.

-

Quality/Certifications: Products meeting strict quality standards or certifications tend to be priced higher but offer greater reliability and safety, which is especially important in industries like food processing and pharmaceuticals.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers can significantly affect pricing. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: Understanding shipping terms can impact costs. Options like FOB (Free On Board) or CIF (Cost Insurance and Freight) can affect overall expenditure based on the responsibilities for shipping and insurance.

What Are Effective Buyer Tips for Sourcing Vibrating Feeders?

B2B buyers should adopt strategic approaches to ensure cost-effectiveness when sourcing vibrating feeders.

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for larger orders. Leverage competitive quotes to negotiate better terms.

-

Cost-Efficiency: Assess the total cost of ownership (TCO) rather than just the initial purchase price. Consider long-term operational costs such as maintenance, energy consumption, and potential downtime.

-

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, currency fluctuations can impact pricing. It’s wise to factor in exchange rates when negotiating. Additionally, be aware of local tariffs and duties that may apply.

-

Supplier Evaluation: Research suppliers thoroughly. Look for those with positive reviews and a history of reliability in your region. Building relationships with reputable suppliers can lead to more favorable terms in the long run.

Conclusion

When sourcing vibrating feeders, understanding the cost components and pricing influencers is essential for making informed decisions. By employing effective negotiation strategies and considering the total cost of ownership, international buyers can optimize their purchasing process and secure the best value for their investment.

Alternatives Analysis: Comparing vibrating feeder With Other Solutions

Understanding Alternatives to Vibrating Feeders

In industrial applications, the choice of feeding systems can significantly affect production efficiency and operational costs. Vibrating feeders, known for their reliability and precision in material handling, are one option among several available technologies. This section explores alternative solutions to vibrating feeders, providing B2B buyers with insights to inform their purchasing decisions.

Comparison of Vibrating Feeders and Alternative Solutions

| Comparison Aspect | Vibrating Feeder | Screw Feeder | Belt Feeder |

|---|---|---|---|

| Performance | High precision, adjustable flow rates | Continuous flow with variable speed | Suitable for large volumes, less precision |

| Cost | Moderate to high ($687 – $21,000) | Moderate ($1,500 – $10,000) | Low to moderate ($1,000 – $5,000) |

| Ease of Implementation | Requires minimal setup, adaptable design | Moderate complexity, needs alignment | Simple installation, easy to integrate |

| Maintenance | Low maintenance, fewer moving parts | Moderate maintenance, some wear parts | Higher maintenance due to belt wear |

| Best Use Case | Fine and bulk materials in controlled environments | Bulk materials requiring consistent flow | Large quantities of materials, such as aggregates |

Detailed Breakdown of Alternatives

Screw Feeders

Screw feeders are designed to move bulk materials through a rotating screw mechanism. They are particularly effective for conveying powders and granular materials in a continuous manner. The advantage of screw feeders lies in their ability to handle various material types and provide a consistent flow rate. However, they can be more complex to install and require careful alignment to prevent wear on the screw and housing.

Belt Feeders

Belt feeders utilize a moving belt to transport materials from one point to another. They are ideal for high-capacity applications, such as transporting aggregates or bulk materials in mining operations. Their simplicity in design allows for easy installation and integration into existing systems. However, belt feeders may lack the precision of vibrating feeders and can incur higher maintenance costs due to belt wear and the need for periodic replacements.

Conclusion: Choosing the Right Feeding Solution

When selecting a feeding system, B2B buyers should consider several factors, including the type of material being handled, required flow rates, installation space, and budget constraints. Vibrating feeders offer precision and low maintenance, making them suitable for applications requiring careful material handling. In contrast, screw and belt feeders may be more appropriate for specific bulk material needs or high-capacity operations. By assessing these alternatives against their operational requirements, buyers can make informed decisions that enhance productivity and reduce costs in their manufacturing processes.

Essential Technical Properties and Trade Terminology for vibrating feeder

What Are the Key Technical Properties of Vibrating Feeders?

When selecting a vibrating feeder for industrial applications, understanding the following technical properties is crucial for ensuring optimal performance and longevity.

1. Material Grade

The grade of material used in the construction of vibrating feeders, such as mild steel or stainless steel, significantly impacts durability and corrosion resistance. For industries dealing with food or pharmaceuticals, stainless steel is often preferred due to its hygienic properties and compliance with FDA standards. Choosing the right material can reduce maintenance costs and downtime, making it essential for B2B buyers to consider their specific industry requirements.

Illustrative image related to vibrating feeder

2. Feed Rate

Feed rate, typically measured in tons per hour, indicates how much material the feeder can handle within a given timeframe. This specification is vital for determining whether a feeder can meet production demands without bottlenecks. Understanding the required feed rate helps businesses plan their operations efficiently, ensuring that production schedules are adhered to and operational costs are minimized.

3. Vibration Frequency

Vibration frequency, often expressed in vibrations per minute (vpm), influences the flow characteristics of the material being fed. Different materials require different vibration frequencies for optimal flow; for example, finer powders may need higher frequencies to prevent arching or clogging. This specification is critical for B2B decision-makers to ensure that the feeder suits the specific material being handled.

4. Trough Design

The trough design—flat, V-shaped, or tubular—affects material handling and flow. For instance, a V-shaped trough can be more effective for bulkier materials, while a flat trough is suitable for lighter products. Selecting the appropriate trough design enhances material flow and minimizes spillage, which is essential for maintaining efficiency and reducing waste in production environments.

5. Dust and Moisture Resistance

Vibrating feeders often come with options for dust-proof or waterproof construction. This property is particularly important in industries like food processing and chemicals, where contamination from dust or moisture can compromise product quality. Ensuring that the feeder has the right sealing and protective features can safeguard the integrity of the materials being handled.

Illustrative image related to vibrating feeder

6. Control Systems

Modern vibrating feeders come with advanced control systems that allow for precise adjustment of feed rates and vibration intensity. Features like timers and rheostats enable operators to customize the feeder’s performance to match production needs. Understanding these systems can lead to improved operational efficiency and adaptability in dynamic production environments.

What Are Common Trade Terms Related to Vibrating Feeders?

Navigating the purchasing process for vibrating feeders requires familiarity with specific trade terminology. Here are some essential terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vibrating feeders, it’s important to know whether the supplier is an OEM, as this can impact warranty, support, and the availability of replacement parts.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers, especially those with budget constraints or limited storage capacities, as it affects purchasing decisions and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to invite suppliers to submit price proposals for specific products or services. B2B buyers should prepare detailed RFQs for vibrating feeders to ensure they receive accurate and comparable quotes from multiple suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, risk transfer, and cost allocation, which is critical for effective logistics planning.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Knowing the lead time for vibrating feeders helps buyers plan their production schedules and manage inventory effectively.

6. Technical Specifications

Technical specifications encompass all measurable properties of a product, such as dimensions, performance metrics, and compliance standards. Buyers should request detailed technical specifications to ensure that the vibrating feeder meets their operational requirements.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions, ultimately enhancing operational efficiency and product quality.

Illustrative image related to vibrating feeder

Navigating Market Dynamics and Sourcing Trends in the vibrating feeder Sector

What Are the Key Market Dynamics and Trends Influencing Vibrating Feeder Sourcing?

The vibrating feeder sector is experiencing significant transformations driven by globalization and technological advancements. As industries worldwide, particularly in Africa, South America, the Middle East, and Europe, seek efficient material handling solutions, the demand for vibrating feeders is on the rise. Key drivers include the growing emphasis on automation and process optimization, which help businesses reduce operational costs and improve throughput. The integration of IoT technology into vibrating feeder systems is also emerging, enabling real-time monitoring and predictive maintenance, which enhances reliability and minimizes downtime.

Furthermore, the market is witnessing a shift towards customization, with manufacturers offering tailored solutions to meet specific application requirements across various sectors, including mining, food processing, and pharmaceuticals. As international buyers become increasingly sophisticated, they seek suppliers that can provide not only standard products but also bespoke designs that align with their unique operational needs.

How Is Sustainability Shaping B2B Practices in the Vibrating Feeder Industry?

Sustainability has become a cornerstone of sourcing strategies in the vibrating feeder sector. As environmental concerns rise, companies are prioritizing suppliers that adopt eco-friendly practices and materials. This shift is not only about compliance with regulations but also about enhancing brand reputation and customer loyalty. Suppliers that incorporate sustainable materials in their vibrating feeders—such as recyclable steel or energy-efficient components—are gaining traction among B2B buyers.

Ethical sourcing practices are equally important. Buyers are increasingly scrutinizing supply chains to ensure responsible sourcing of materials, minimizing environmental impact, and promoting fair labor practices. Certifications such as ISO 14001 for environmental management or other “green” labels can serve as indicators of a supplier’s commitment to sustainability. By choosing suppliers with robust sustainability credentials, international buyers can align their procurement strategies with global sustainability goals, thereby enhancing their market competitiveness.

What Is the Historical Context of Vibrating Feeders and Their Evolution?

The vibrating feeder technology has evolved significantly since its inception in the early 20th century. Originally designed for simple bulk material handling, advancements in design and technology have transformed these systems into sophisticated machinery capable of precise material flow control. The introduction of electromagnetic vibrators and modern control systems has enhanced the efficiency and reliability of vibrating feeders, allowing them to cater to a wide range of applications across diverse industries.

Over the years, the focus has shifted from merely functionality to include aspects such as energy efficiency, noise reduction, and automated controls. This evolution reflects broader industry trends towards automation and smart manufacturing, making vibrating feeders an integral part of modern production processes. Understanding this historical context enables B2B buyers to appreciate the technological advancements that influence current product offerings and sourcing decisions.

Illustrative image related to vibrating feeder

Frequently Asked Questions (FAQs) for B2B Buyers of vibrating feeder

-

How do I choose the right vibrating feeder for my application?

Selecting the right vibrating feeder involves understanding your material’s characteristics, including size, weight, and flow properties. Assess the feeder’s design options, such as trough shape and material construction (e.g., stainless steel for food applications). Additionally, consider the feeder’s capacity, vibration frequency, and control mechanisms to ensure it meets your production needs. Consulting with suppliers can provide insights into custom designs that fit your specific requirements. -

What factors affect the pricing of vibrating feeders?

The cost of vibrating feeders is influenced by several factors, including the materials used in construction, the complexity of the design, and the feeder’s capacity. Additional features like dust-tight sealing, variable speed controls, and compliance with industry standards (e.g., FDA, USDA) can also impact the price. It’s essential to discuss your specific needs with suppliers to obtain accurate quotes that reflect your requirements. -

What are the common applications for vibrating feeders in various industries?

Vibrating feeders are utilized across diverse industries, including mining, pharmaceuticals, food processing, and manufacturing. They are essential for the controlled flow of bulk materials to mixers, heat treating furnaces, or packaging systems. Applications range from feeding raw materials like grains and powders to dispensing finished products. Understanding your industry’s specific needs will help in selecting the most suitable feeder. -

What should I consider when vetting suppliers for vibrating feeders?

When evaluating suppliers, assess their experience in the industry, the range of products they offer, and their ability to provide customization. Check for certifications that indicate compliance with international quality standards. Additionally, request references or case studies to understand their past performance and customer satisfaction. Engaging with suppliers who have a strong support system can also be beneficial for ongoing maintenance and troubleshooting. -

Can vibrating feeders be customized to meet specific needs?

Yes, many manufacturers offer customization options for vibrating feeders. This includes modifications in size, shape, and material to suit specific applications. You can also request features like adjustable feed rates, specialized trough designs, and integration with existing systems. Discuss your requirements with potential suppliers to ensure they can deliver a solution tailored to your operational demands. -

What are the minimum order quantities (MOQs) for vibrating feeders?

Minimum order quantities can vary significantly between suppliers and are often influenced by factors such as the feeder type and customization level. Some manufacturers may have a low MOQ for standard models, while custom feeders could require larger orders. It’s advisable to discuss your needs directly with suppliers to negotiate MOQs that align with your purchasing strategy. -

What payment terms are typically offered by suppliers of vibrating feeders?

Payment terms can vary widely among suppliers, often depending on the order size and the buyer’s creditworthiness. Common terms include partial payment upfront, with the balance due upon delivery or after installation. Some suppliers may also offer financing options or payment plans for larger purchases. Always clarify payment terms before finalizing contracts to ensure they meet your financial capabilities. -

How do I ensure quality assurance (QA) for my vibrating feeder order?

To ensure quality assurance, request detailed specifications and performance testing reports from suppliers. Consider manufacturers that adhere to recognized international standards, such as ISO certifications. It’s also beneficial to inquire about their QA processes, including inspections during production and before shipment. Establishing clear communication with the supplier regarding your quality expectations will help mitigate issues before they arise.

Top 7 Vibrating Feeder Manufacturers & Suppliers List

1. Eriez – Vibratory Feeders and Conveyors

Domain: eriez.com

Registered: 1995 (30 years)

Introduction: Vibratory Feeders and Conveyors from Eriez provide effective and efficient conveying, screening, and feeding of materials in various applications. Key product details include: 1. Electromagnetic Vibratory Feeders: Offer precise flow rate control for accurate material handling of bulk products, from granulated sugar to rock products. 2. Mechanical Vibratory Feeders: Utilize eccentric motors to gene…

2. Hoffman Manufacturing – Vibratory Feeders

Domain: hoffmanmfg.com

Registered: 1998 (27 years)

Introduction: Category: Vibratory Feeders

Products:

1. Syntron Electromagnetic Bin Vibrators – Price range: $380.00 – $21,000.00

2. Volumetric Feeder Machines – Price: $6,601.00

3. Syntron® Vibrating Feeders for Light Industry – Price range: $687.00 – $4,499.00

4. DC-420 Controller – Original price: $2,450.00, Current price: $2,233.00

5. Syntron® Light-Duty BF Series Feeders – Price range: $1,547.00 – $1,652.00…

3. Cleveland Vibrator – Vibratory Feeders

Domain: clevelandvibrator.com

Registered: 2000 (25 years)

Introduction: Cleveland Vibrator Company offers a range of vibratory feeders including: CF-A Air Powered Vibratory Feeder, EMF Electromechanical Vibratory Feeder, RFM Volumetric Vibratory Feeder, CT-A Air Powered Vibratory Tube Feeder, and EMF-T Vibratory Tube Feeder. Key features include: CF-A Series can handle feed rates up to 50 tons per hour in hazardous environments; EMF models provide smooth, uniform, adj…

4. IQS Directory – Vibratory Feeders

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Vibratory feeders are transportation mechanisms designed to supply components or materials into assembly processes using controlled vibratory forces, gravity, and guiding systems. They feature accumulation tracks of varying widths, lengths, and depths tailored to specific application requirements. Key functions include the movement, transfer, and conveyance of bulk materials with vibrations ensuri…

5. Schenck Process – Vibratory Feeder

Domain: qlar.com

Registered: 2006 (19 years)

Introduction: The vibratory feeder is designed for continuous, gentle volumetric or gravimetric feeding of granules, chips, flakes, or fibers. It is part of the LIW Feeder MET and SolidsFlow product lines offered by Schenck Process. The feeders utilize vibrating drives to gently feed a wide variety of materials and can achieve accuracies up to ±0.5%.

6. Hoosier Feeder – Vibratory Feeders

Domain: hoosierfeeder.com

Registered: 2012 (13 years)

Introduction: Vibratory Feeders are high-quality and efficient parts orienting solutions designed for various applications including counting, feeding, separating, laning, and orienting. They are available in cosmetic-grade and pharmaceutical-grade options, suitable for food processing, manufacturing, packaging, and more. The company offers custom parts handling solutions tailored to specific applications, ensu…

7. Action Vibratory Equipment – Vibratory Feeders

Domain: actionconveyors.com

Registered: 1999 (26 years)

Introduction: Vibratory Feeders from Action Vibratory Equipment are engineered for efficient conveying and metering of bulk materials. Key features include:

– Customizable troughs in carbon steel, stainless steel, or abrasion-resistant materials.

– Vibration isolation springs to minimize dynamic load transfer.

– Structural steel supports designed for specific elevation requirements.

– In-feed configurations…

Strategic Sourcing Conclusion and Outlook for vibrating feeder

How Can Strategic Sourcing Enhance Your Vibrating Feeder Procurement?

In conclusion, strategic sourcing for vibrating feeders is essential for optimizing operational efficiency and cost-effectiveness. By understanding the diverse options available—from electromagnetic to volumetric feeders—businesses can tailor their procurement strategies to meet specific application needs. This approach not only ensures the selection of high-quality equipment but also fosters long-term supplier relationships that can lead to better pricing, support, and innovation.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, the emphasis should be on aligning supplier capabilities with operational requirements. Establishing a collaborative dialogue with manufacturers can unlock customized solutions that enhance productivity while minimizing downtime.

Looking ahead, the demand for efficient bulk material handling solutions will only grow. Now is the time to take proactive steps in sourcing vibrating feeders that not only meet today’s challenges but are also adaptable for future needs. Engage with reputable suppliers, request tailored quotes, and explore innovative technologies that can drive your business forward. Your commitment to strategic sourcing will yield significant returns in the years to come.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.