Everything You Need to Know About Vertical Screw Feeder Sourcing in 2025

Introduction: Navigating the Global Market for vertical screw feeder

In the rapidly evolving landscape of bulk material handling, sourcing a reliable vertical screw feeder can present significant challenges for international B2B buyers. The need for efficient, space-saving solutions to elevate various materials is paramount, especially for industries spanning chemical, food processing, and wastewater treatment. This guide serves as a comprehensive resource, delving into the diverse types and applications of vertical screw feeders, while also addressing critical aspects such as supplier vetting, cost considerations, and maintenance requirements.

As businesses in regions like Africa, South America, the Middle East, and Europe strive to optimize their operations, understanding the nuances of vertical screw feeders becomes essential. This guide empowers decision-makers with actionable insights, enabling them to navigate the complexities of sourcing these vital components. By exploring factors such as design specifications, material compatibility, and operational efficiency, buyers can make informed choices that align with their unique needs.

Moreover, we emphasize the importance of selecting reputable suppliers who can offer customized solutions tailored to specific applications. With this knowledge, B2B buyers can enhance their material handling processes, ensuring reliability and cost-effectiveness in their operations. Join us as we uncover the essential elements that will guide you through the global market for vertical screw feeders, paving the way for successful procurement and operational excellence.

Understanding vertical screw feeder Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Vertical Screw Feeder | Basic design, suitable for a variety of bulk materials | Food processing, chemicals, agriculture | Pros: Versatile, cost-effective. Cons: Limited customization options. |

| Shaftless Vertical Screw Feeder | No central shaft, suitable for sticky or viscous materials | Wastewater treatment, food industry | Pros: Reduces material buildup, easy maintenance. Cons: May require more space. |

| Vertical Forced Feeder | Compact, integrates with extruders, precise dosing | Plastics, pharmaceuticals, food | Pros: High accuracy, hygienic design. Cons: Typically higher cost. |

| Customizable Vertical Screw Feeder | Tailored dimensions and materials based on specific needs | Mining, construction, bulk material handling | Pros: Optimized for specific applications. Cons: Longer lead time for custom builds. |

| High-Efficiency Vertical Screw Feeder | Enhanced design for maximum throughput and energy efficiency | Animal feed, wood products, pellets | Pros: Increased capacity, energy savings. Cons: Potentially higher initial investment. |

What are the Characteristics of Standard Vertical Screw Feeders?

Standard vertical screw feeders are designed for general-purpose use, suitable for a wide range of bulk materials such as grains, powders, and small aggregates. Their straightforward construction allows for easy installation and maintenance, making them a popular choice in industries like food processing and agriculture. Buyers should consider their material handling requirements and whether the standard configurations meet their needs, as these feeders may lack customization options.

How Do Shaftless Vertical Screw Feeders Work?

Shaftless vertical screw feeders feature a unique design that eliminates the central shaft, allowing for the efficient movement of sticky or viscous materials without the risk of clogging. This makes them particularly effective in wastewater treatment facilities and food processing applications. When purchasing, buyers should evaluate the space available for installation and the specific characteristics of the materials being handled, as these feeders may require more room compared to standard models.

What are the Benefits of Vertical Forced Feeders?

Vertical forced feeders are compact systems designed for precise dosing and integration with extruders, making them ideal for applications in the plastics and pharmaceutical industries. Their hygienic design simplifies cleaning, which is crucial for maintaining product quality. Buyers should consider the initial investment and the need for high accuracy in their production processes, as these feeders typically come at a higher cost but offer significant operational benefits.

Why Choose Customizable Vertical Screw Feeders?

Customizable vertical screw feeders can be tailored to fit specific applications, accommodating unique dimensions and materials. This flexibility is particularly beneficial in industries like mining and construction, where material characteristics and handling requirements can vary widely. Buyers should weigh the benefits of optimized performance against the longer lead times associated with custom builds, ensuring that their operational needs align with the customization options available.

What Advantages Do High-Efficiency Vertical Screw Feeders Provide?

High-efficiency vertical screw feeders are engineered for maximum throughput while minimizing energy consumption. They are commonly used in applications such as animal feed production and pellet transportation, where high capacity is essential. Buyers should assess the potential for energy savings and increased productivity against the higher upfront costs, as these systems may require a larger initial investment but can lead to significant long-term savings.

Key Industrial Applications of vertical screw feeder

| Industry/Sector | Specific Application of vertical screw feeder | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Elevating flour and other dry ingredients | Ensures consistent flow and minimizes waste | Compliance with food safety standards and hygienic design |

| Wastewater Treatment | Handling dewatered biosolids | Efficient material handling reduces operational costs | Customization for specific waste types and treatment processes |

| Animal Feed Production | Transporting feed pellets | Enhances productivity by streamlining material movement | Durability against abrasion and compatibility with feed types |

| Minerals Processing | Conveying minerals and aggregates | Improves efficiency in material transfer | Material selection based on abrasion and corrosion resistance |

| Plastic and Polymer Industry | Feeding materials to extruders | Provides precise control over material flow | Compatibility with various polymer types and ease of cleaning |

How is a Vertical Screw Feeder Used in Food Processing?

In the food processing industry, vertical screw feeders are instrumental in elevating and transporting flour and other dry ingredients from storage to processing machines. This ensures a consistent flow of materials, which minimizes waste and maintains product quality. For international buyers, especially in regions like Africa and South America, sourcing equipment that complies with stringent food safety standards is crucial. Buyers should consider hygienic design features that facilitate easy cleaning and maintenance, ensuring compliance with local regulations.

What Role Does a Vertical Screw Feeder Play in Wastewater Treatment?

Vertical screw feeders are utilized in wastewater treatment facilities for the efficient handling of dewatered biosolids. Their design allows for the elevation of heavy materials without the need for internal bearings, which can reduce maintenance costs and downtime. Buyers in the Middle East and Europe should focus on customization options that cater to specific waste types and treatment processes, ensuring optimal performance in diverse environmental conditions.

How is a Vertical Screw Feeder Beneficial in Animal Feed Production?

In animal feed production, vertical screw feeders are essential for transporting feed pellets and other bulk materials. They enhance productivity by streamlining the movement of ingredients, ensuring that production lines operate smoothly. For businesses in regions like Saudi Arabia and Vietnam, durability against wear and tear is a key consideration, as is the compatibility of the feeder with various feed types. Buyers should prioritize sourcing options that offer robust construction and adaptability to different material characteristics.

Why is a Vertical Screw Feeder Important in Minerals Processing?

In the minerals processing sector, vertical screw feeders facilitate the efficient conveyance of minerals and aggregates from one stage of production to another. This equipment improves operational efficiency by ensuring a steady flow of materials, which is critical in high-volume operations. Buyers from Europe and South America should focus on sourcing feeders made from abrasion-resistant materials to withstand the harsh conditions often found in mineral processing environments.

What Advantages Does a Vertical Screw Feeder Provide in the Plastic and Polymer Industry?

Vertical screw feeders are vital in the plastic and polymer industry for feeding materials into extruders. They provide precise control over material flow, which is essential for maintaining product consistency and quality. Buyers should consider the compatibility of the feeder with various polymer types, as well as its ease of cleaning to comply with industry standards. The ability to customize the feeder to specific operational needs can also enhance overall efficiency, making it a critical investment for manufacturers in this sector.

3 Common User Pain Points for ‘vertical screw feeder’ & Their Solutions

Scenario 1: Frequent Downtime Due to Material Blockages

The Problem: A common issue faced by B2B buyers of vertical screw feeders is unexpected downtime caused by material blockages. This problem can stem from using inappropriate materials or a poorly designed feeding system. For instance, buyers in the food processing or chemical industries may find that materials with varying moisture levels or particle sizes can lead to clogs, halting operations and causing significant financial losses. The frustration mounts when the production line halts, impacting delivery schedules and customer satisfaction.

The Solution: To mitigate the risk of blockages, it is critical to conduct thorough material assessments before selecting a vertical screw feeder. Buyers should work closely with manufacturers to understand the specifications of their materials, including flow characteristics, moisture content, and particle size distribution. Opting for feeders with features such as adjustable feed rates and customized inlet designs can significantly enhance material flow and reduce the likelihood of blockages. Additionally, implementing regular maintenance checks and incorporating sensors for real-time monitoring can help detect potential issues before they escalate, ensuring a smoother operation and increased uptime.

Scenario 2: Inadequate Capacity Leading to Production Bottlenecks

The Problem: Another pressing challenge for B2B buyers is underestimating the required capacity of vertical screw feeders, which can lead to production bottlenecks. Companies often miscalculate the volume of material that needs to be transported vertically, resulting in slow throughput that fails to meet production demands. This is particularly problematic in industries such as agriculture and construction, where timing is critical and delays can have cascading effects on project timelines and budgets.

The Solution: To avoid capacity-related issues, buyers should perform a detailed analysis of their production needs and the specific characteristics of the materials being handled. It’s advisable to consult with suppliers who can provide capacity tables and simulations based on expected throughput. When specifying a vertical screw feeder, consider models that allow for scalability—those that can accommodate future growth without necessitating a complete system overhaul. Also, investing in systems with advanced control features will allow for fine-tuning of operational parameters, ensuring that the feeder operates efficiently and adapts to varying production demands.

Scenario 3: Compliance with Safety and Regulatory Standards

The Problem: Compliance with safety and regulatory standards presents a significant challenge for B2B buyers, especially in industries like food processing, pharmaceuticals, and chemicals. Vertical screw feeders must meet stringent hygiene and safety requirements to prevent contamination and ensure employee safety. Failure to comply can result in costly fines, product recalls, and damage to a company’s reputation.

The Solution: Buyers must prioritize sourcing vertical screw feeders that are designed with compliance in mind. This involves selecting equipment that features a fully enclosed design to minimize dust and contamination risks. Additionally, buyers should seek feeders constructed from materials that meet industry standards, such as FDA-approved stainless steel for food applications. It’s beneficial to work with manufacturers who offer certifications and documentation confirming compliance with relevant regulations. Furthermore, implementing regular audits and maintenance protocols can help maintain compliance over time, ensuring that equipment remains safe and effective throughout its operational life.

In summary, addressing these common pain points involves a proactive approach—thorough planning, proper equipment selection, and ongoing maintenance to ensure that vertical screw feeders perform optimally while adhering to industry standards. By investing in the right solutions, B2B buyers can enhance productivity, reduce downtime, and maintain compliance, ultimately driving business success.

Strategic Material Selection Guide for vertical screw feeder

When selecting materials for vertical screw feeders, it is essential to consider the specific requirements of the application, including the type of bulk materials being handled, environmental conditions, and compliance with industry standards. Below is an analysis of four common materials used in the construction of vertical screw feeders, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

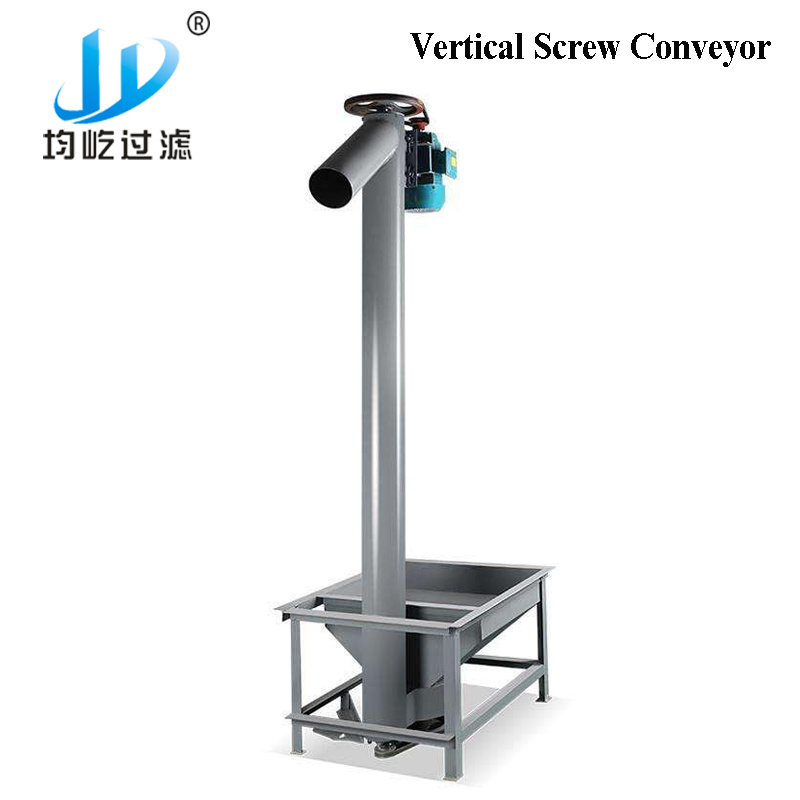

Illustrative image related to vertical screw feeder

What are the Key Properties of Carbon Steel for Vertical Screw Feeders?

Carbon steel is a widely used material due to its strength and cost-effectiveness. It typically has a temperature rating of up to 400°F (204°C) and can withstand moderate pressure. However, it is susceptible to corrosion, which can be a significant drawback in humid or corrosive environments.

Pros: Carbon steel is durable and offers excellent tensile strength, making it suitable for handling a variety of bulk materials. It is also relatively inexpensive compared to other materials.

Cons: The primary limitation is its corrosion susceptibility, which may require additional coatings or treatments, increasing maintenance costs. Furthermore, in applications involving moisture or corrosive substances, carbon steel may not be the best choice.

Impact on Application: Carbon steel is suitable for dry and non-corrosive materials, but it may not be ideal for applications involving wet or corrosive media.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards such as ASTM and DIN for carbon steel grades. Coating options may also need to be considered based on local environmental conditions.

How Does Stainless Steel Compare for Vertical Screw Feeders?

Stainless steel is known for its excellent corrosion resistance and is often used in food processing and chemical industries. It can handle temperatures up to 1,500°F (815°C) and is suitable for high-pressure applications.

Pros: The primary advantage of stainless steel is its durability and resistance to corrosion, making it ideal for handling wet or corrosive materials. It also meets stringent hygiene standards, which is crucial in food and pharmaceutical applications.

Cons: The main drawback is its higher cost compared to carbon steel. Additionally, stainless steel can be more challenging to machine and fabricate, leading to increased manufacturing complexity.

Impact on Application: Stainless steel is suitable for a wide range of applications, including those involving corrosive or high-temperature materials.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure compliance with food safety regulations and standards such as FDA and EU regulations. The availability of specific stainless steel grades may vary by region.

What are the Benefits of Using Abrasion-Resistant Steel?

Abrasion-resistant (AR) steel is designed to withstand wear and tear, making it ideal for applications involving abrasive materials. It typically has a hardness rating of 400 to 600 BHN (Brinell Hardness Number) and can handle moderate temperatures and pressures.

Pros: The primary advantage of AR steel is its exceptional durability and resistance to wear, which can significantly extend the lifespan of the feeder in abrasive applications.

Illustrative image related to vertical screw feeder

Cons: AR steel can be more expensive than standard carbon steel and may require specialized welding and fabrication techniques, increasing manufacturing complexity.

Impact on Application: AR steel is particularly suitable for handling abrasive materials like sand, gravel, or minerals, where traditional materials may wear out quickly.

Considerations for International Buyers: Buyers should check for compliance with local standards for AR steel, which may differ by region. In markets like South America, the availability of specific grades may impact project timelines.

Why Choose Plastic Composites for Vertical Screw Feeders?

Plastic composites, such as polyethylene and polypropylene, are increasingly being used for vertical screw feeders, especially in applications where corrosion resistance and weight are critical. These materials can handle temperatures up to 200°F (93°C) and are often used in lightweight applications.

Pros: The main advantages of plastic composites include their lightweight nature and excellent corrosion resistance. They are also easy to clean and maintain, making them suitable for food and pharmaceutical applications.

Cons: The limitations include lower strength compared to metals, which may not be suitable for heavy-duty applications. Additionally, they may be more expensive than traditional materials depending on the application.

Impact on Application: Plastic composites are ideal for handling non-abrasive, lightweight materials and are particularly effective in food processing and chemical industries.

Illustrative image related to vertical screw feeder

Considerations for International Buyers: Buyers should ensure that the selected plastic composites meet local regulatory standards for food safety and chemical compatibility, particularly in regions like Europe and the Middle East.

Summary Table of Material Selection for Vertical Screw Feeders

| Material | Typical Use Case for vertical screw feeder | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General bulk materials | Cost-effective and durable | Corrosion susceptibility | Low |

| Stainless Steel | Food processing, chemical applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Abrasion-Resistant Steel | Abrasive materials | Exceptional durability and wear resistance | Higher cost and specialized fabrication | Med |

| Plastic Composites | Lightweight, non-abrasive materials | Lightweight and easy to maintain | Lower strength compared to metals | Med |

This strategic material selection guide provides insights into the various materials used in vertical screw feeders, helping international B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for vertical screw feeder

What Are the Key Stages in the Manufacturing Process of Vertical Screw Feeders?

The manufacturing process of vertical screw feeders involves several critical stages that ensure the final product meets performance and quality standards. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to vertical screw feeder

Material Preparation: Sourcing and Pre-Processing

The first step in manufacturing vertical screw feeders is sourcing high-quality raw materials. Depending on the application, materials may include carbon steel, stainless steel, or abrasion-resistant alloys. The choice of material directly affects the durability and performance of the feeder.

Once the materials are sourced, they undergo pre-processing, which may involve cutting, machining, or treating to achieve the desired specifications. This ensures that the components will fit together seamlessly in subsequent stages. It’s essential for manufacturers to maintain strict quality control during this phase to prevent defects that could affect the final product.

How Is the Forming Process Executed?

The forming stage involves several techniques, including welding, bending, and machining. For instance, the helical screw, which is crucial for the operation of vertical screw feeders, is often formed using precision machining to create the correct pitch and diameter.

Welding is employed to assemble various components, such as the housing and inlet sections, ensuring that they can withstand the operational stresses. Manufacturers often use advanced welding techniques, such as MIG or TIG welding, to ensure strong, reliable joints.

What Are the Assembly and Finishing Steps in Vertical Screw Feeder Production?

After forming, the assembly process begins. This stage involves fitting together the various components, including the screw, housing, drive units, and any additional features such as kicker paddles or discharge systems.

The assembly is typically done in a clean environment to minimize contamination, especially when the feeders are intended for the food or pharmaceutical industries.

Once assembled, the feeders undergo finishing processes, including surface treatments such as painting, powder coating, or galvanizing. These treatments enhance corrosion resistance and improve the aesthetic appeal of the product.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a pivotal part of the manufacturing process for vertical screw feeders. International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers consistently meet customer requirements and enhance satisfaction.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) standards for oil and gas applications are crucial. These certifications indicate compliance with safety and performance criteria relevant to specific industries.

Which QC Checkpoints Are Critical During the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure product integrity. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements. Testing may include material composition analysis and mechanical property checks.

-

In-Process Quality Control (IPQC): During the forming and assembly stages, manufacturers conduct regular inspections to identify any deviations from specifications. Techniques may include dimensional checks and visual inspections.

-

Final Quality Control (FQC): Once the vertical screw feeders are fully assembled, they undergo final inspections and testing. This may include operational testing to verify performance under simulated conditions.

What Common Testing Methods Are Employed for Vertical Screw Feeders?

Testing methods for vertical screw feeders vary based on application and industry. Common methods include:

-

Hydraulic Testing: Used to evaluate the integrity of the feeder under pressure, ensuring there are no leaks.

-

Load Testing: This assesses the feeder’s capacity and ensures it can handle the specified load without failure.

-

Vibration Testing: For feeders operating in dynamic environments, this testing helps identify potential issues that may arise from vibration-induced wear.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are several strategies:

Illustrative image related to vertical screw feeder

-

Conduct Audits: Request to perform on-site audits of the manufacturing facility. This allows buyers to assess the QC processes firsthand and ensure compliance with international standards.

-

Review Quality Reports: Ask suppliers for documentation of their QC processes, including results from IQC, IPQC, and FQC. Detailed reports provide insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engage third-party inspection services to evaluate the manufacturing process and final products. This independent verification can provide an additional layer of assurance.

What Are the QC and Certification Nuances for International Buyers?

International buyers, especially those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in QC and certification.

For instance, understanding local regulations and standards is crucial when importing equipment. Some regions may have specific requirements for CE marking or compliance with local safety standards.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Therefore, establishing clear lines of communication and ensuring that both parties understand the specifications and standards required is vital for successful partnerships.

Conclusion: Ensuring Quality in Vertical Screw Feeder Manufacturing

In summary, the manufacturing processes and quality assurance protocols for vertical screw feeders are essential for producing reliable and efficient equipment. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier processes, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. This proactive approach not only enhances supply chain reliability but also builds long-term partnerships with trusted manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vertical screw feeder’

In the competitive landscape of bulk material handling, procuring the right vertical screw feeder is crucial for optimizing your operational efficiency. This guide offers a systematic approach to help international B2B buyers—from regions like Africa, South America, the Middle East, and Europe—navigate the sourcing process effectively.

Illustrative image related to vertical screw feeder

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider factors such as the type of materials to be handled (dry, semi-dry, or viscous), the required capacity (up to 6,000 cubic feet per hour), and the desired elevation height (up to 50 feet). This clarity helps in matching your needs with the right equipment.

Step 2: Research Supplier Expertise and Experience

Investigate potential suppliers to understand their experience and specialization in vertical screw feeders. Look for suppliers who have a track record in your industry, whether it be food processing, minerals, or chemical handling. Assessing their background will give you confidence in their ability to meet your requirements.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to conduct thorough evaluations of potential suppliers. Request detailed company profiles, case studies, and references from previous clients in similar industries or regions. This step ensures that you’re not just relying on marketing materials but are making an informed decision based on real-world performance.

Step 4: Verify Certifications and Compliance Standards

Ensure that the suppliers adhere to international quality standards and certifications. Compliance with standards such as ISO or CEMA indicates that the supplier follows best practices in manufacturing and safety. This verification helps mitigate risks associated with equipment failure and operational disruptions.

Step 5: Assess Customization Capabilities

Inquire about the supplier’s ability to customize vertical screw feeders to your specific needs. Customization options may include variations in materials (carbon steel, stainless steel), sizes, and configurations. Suppliers that offer tailored solutions can better address unique operational challenges and improve efficiency.

Step 6: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that outline all costs, including installation, maintenance, and any additional components. A transparent quotation allows you to compare offers effectively and understand the total cost of ownership. Look for hidden fees and ensure that warranty and service agreements are clearly defined.

Step 7: Consider After-Sales Support and Maintenance Services

Finally, assess the after-sales support and maintenance services offered by the supplier. Reliable support can significantly impact the long-term efficiency of your vertical screw feeder. Check for availability of spare parts, response times for service requests, and the extent of technical support provided.

By following this checklist, B2B buyers can streamline the sourcing process for vertical screw feeders, ensuring they select a solution that meets their operational needs while minimizing risks and costs.

Comprehensive Cost and Pricing Analysis for vertical screw feeder Sourcing

Understanding the cost structure and pricing dynamics of vertical screw feeders is essential for international B2B buyers looking to optimize their procurement strategies. A comprehensive analysis of cost components and price influencers can guide buyers in making informed decisions.

What Are the Key Cost Components for Vertical Screw Feeders?

-

Materials: The choice of materials significantly impacts the overall cost. Common options include carbon steel for standard applications and stainless steel or abrasion-resistant materials for harsher environments. Buyers should consider the specific application requirements to select the most cost-effective material without compromising performance.

-

Labor: Labor costs can vary based on the manufacturing location and complexity of the vertical screw feeder design. Skilled labor is often necessary for assembling custom or high-quality units, which can drive up costs. Understanding the local labor market is crucial when sourcing from different regions.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and general administrative expenses. Overhead can be higher in regions with strict regulatory compliance or advanced manufacturing technologies. Buyers should inquire about how these costs are factored into the pricing.

-

Tooling: Custom designs may require specialized tooling, which can add to the upfront costs. Buyers should assess whether the supplier has the necessary tooling capabilities in-house or if they will need to outsource, impacting lead times and costs.

-

Quality Control (QC): Ensuring product quality through rigorous testing and certification processes can add costs. However, investing in quality control can reduce long-term operational risks, particularly for critical applications in industries like food processing or chemicals.

-

Logistics: Shipping costs can fluctuate based on the geographical location of the supplier, the mode of transportation, and the size/weight of the equipment. Buyers should factor in logistics as a key component of the total cost, especially when importing from regions like Europe or North America to Africa or South America.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the industry standard margins can help buyers identify competitive offers.

How Do Price Influencers Impact the Sourcing of Vertical Screw Feeders?

-

Volume/MOQ: Bulk purchasing often leads to lower unit prices. Buyers should assess their needs to negotiate the minimum order quantities (MOQ) that align with their operational requirements while maximizing cost efficiency.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses while ensuring the equipment meets operational needs.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but may be necessary for compliance and safety standards. Buyers should weigh the benefits of certification against potential cost increases.

-

Supplier Factors: Supplier reputation, experience, and production capabilities can influence pricing. Established suppliers may charge a premium for their reliability and service, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) governing the sale can help buyers manage costs associated with shipping, insurance, and customs duties. Choosing the right terms can significantly affect the total landed cost of the equipment.

What Are Some Tips for B2B Buyers in Negotiating Vertical Screw Feeder Prices?

-

Negotiate with Clarity: Clearly communicate your needs and expectations to the supplier. This clarity can lead to better negotiations on price, terms, and delivery schedules.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also operational costs over the equipment’s lifespan, including maintenance, energy consumption, and potential downtime. A slightly higher initial investment may result in lower TCO.

-

Be Aware of Regional Pricing Nuances: Different regions may have varying pricing structures based on local demand, labor costs, and material availability. Buyers from Africa, South America, the Middle East, and Europe should conduct market research to understand these dynamics.

-

Seek Multiple Quotes: Obtaining quotes from multiple suppliers can provide leverage in negotiations and help identify competitive pricing.

-

Consider Long-term Partnerships: Building a strong relationship with suppliers can lead to better pricing and service over time, particularly for repeat purchases.

Disclaimer

The prices discussed are indicative and can vary based on market conditions, supplier capabilities, and specific buyer requirements. Always conduct thorough due diligence when sourcing vertical screw feeders.

Alternatives Analysis: Comparing vertical screw feeder With Other Solutions

In the landscape of bulk material handling, selecting the right method for transporting materials vertically can significantly impact operational efficiency, cost-effectiveness, and overall system reliability. Vertical screw feeders are a popular choice; however, it’s essential to evaluate alternative solutions to determine the best fit for specific operational needs. This section compares vertical screw feeders with two viable alternatives: pneumatic conveyors and bucket elevators, providing insights to aid B2B buyers in making informed decisions.

| Comparison Aspect | Vertical Screw Feeder | Pneumatic Conveyor | Bucket Elevator |

|---|---|---|---|

| Performance | Efficient for dry to semi-fluid materials; capacities up to 6,000 cu ft/hr | Suitable for a wide range of materials; high-speed transfer | Effective for bulk materials, especially granules; can handle large volumes |

| Cost | Moderate initial cost; low maintenance expenses | Higher initial investment; operational costs vary based on air supply | Moderate to high initial cost; energy-efficient but requires maintenance |

| Ease of Implementation | Compact design; requires minimal space; straightforward installation | Requires more complex installation; space considerations for ducting | Requires vertical space; installation can be complex depending on height |

| Maintenance | Low maintenance due to fewer moving parts; easy to clean | Moderate maintenance; air filters and blowers require regular checks | Moderate to high; regular inspections needed for belts and pulleys |

| Best Use Case | Ideal for industries like food processing, chemicals, and wastewater treatment | Best for conveying powders, granules, and lightweight materials over long distances | Excellent for handling heavy bulk materials like grains, minerals, and aggregates |

What are the Advantages and Disadvantages of Pneumatic Conveyors?

Pneumatic conveyors utilize air pressure to transport materials through pipelines, making them suitable for various applications. One of their significant advantages is the ability to handle a wide range of materials, including powders and granules, with minimal contamination. Their high-speed transfer capability can enhance overall throughput. However, the initial investment can be substantial, and operational costs may vary depending on the energy needed to maintain airflow. Additionally, their installation can be more complex, requiring careful planning to accommodate ducting and air supply systems.

What are the Pros and Cons of Bucket Elevators?

Bucket elevators are mechanical devices that lift bulk materials vertically using buckets attached to a belt or chain. They excel in transporting heavy materials like grains, minerals, and aggregates efficiently. Their design allows for significant elevation in a compact footprint, making them suitable for facilities with limited vertical space. Despite their effectiveness, bucket elevators can have moderate to high initial costs and require regular maintenance to ensure optimal performance. Inspections of belts and pulleys are necessary to prevent breakdowns, which can lead to operational disruptions.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting a vertical transportation solution, B2B buyers should consider their specific operational requirements, including the type of materials being transported, the desired capacity, and the layout of their facilities. Vertical screw feeders are particularly advantageous for industries dealing with semi-fluid materials where dust and vapor containment is critical. In contrast, pneumatic conveyors may be preferable for operations that require flexibility and speed over longer distances. Bucket elevators are best suited for heavy bulk materials, particularly in environments where space is at a premium. By thoroughly assessing these factors, buyers can make a well-informed choice that aligns with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for vertical screw feeder

What Are the Key Technical Properties of Vertical Screw Feeders?

When selecting a vertical screw feeder for your operations, understanding its critical technical properties is essential. Here are some key specifications that influence performance and suitability for various applications:

-

Material Grade: The construction materials of a vertical screw feeder significantly affect its durability and resistance to corrosion. Common materials include carbon steel, stainless steel, and abrasion-resistant alloys. Choosing the right material is crucial for industries handling corrosive or abrasive materials, as it ensures longevity and reduces maintenance costs.

-

Capacity: This refers to the volume of material that the feeder can handle, typically measured in cubic feet per hour (CFH). Vertical screw feeders can vary in capacity from 400 to 6,000 CFH. Understanding capacity is vital for ensuring that the feeder meets the demands of your production line without bottlenecks.

-

Elevation Height: The maximum height that the feeder can effectively transport materials is a critical specification. Most vertical screw feeders can elevate materials up to 40-50 feet. This specification is essential for planning layout designs in facilities where space is limited and vertical transport is necessary.

-

Screw Diameter: The diameter of the screw influences the amount of material that can be conveyed at one time. Standard diameters range from a few inches to over a foot, depending on the application. Selecting the appropriate screw diameter ensures efficient material flow and minimizes the risk of blockages.

-

RPM (Revolutions Per Minute): This indicates the speed at which the screw rotates. Typical vertical screw feeders operate at speeds between 150 to 250 RPM. Understanding the RPM is critical for controlling the feed rate and ensuring that the material is moved efficiently without causing degradation or damage.

-

Sealing and Dust Control: Many vertical screw feeders are designed with a totally enclosed housing, which is important for preventing dust and vapor leaks. This feature is particularly crucial in industries where hygiene and environmental safety are paramount, such as food processing and pharmaceuticals.

What Are Common Trade Terms Associated with Vertical Screw Feeders?

Familiarizing yourself with trade terminology can streamline procurement processes and enhance communication with suppliers. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of vertical screw feeders, understanding OEM specifications ensures compatibility with existing systems and adherence to quality standards.

-

MOQ (Minimum Order Quantity): This refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, as it can affect your purchasing strategy, especially for custom or specialized feeders.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers to request pricing and other details for specific products or services. Issuing an RFQ for vertical screw feeders can help you gather competitive offers and make informed decisions based on cost and specifications.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial when negotiating shipping and delivery terms for vertical screw feeders, as they clarify who bears the costs and risks at various stages of transport.

-

Lead Time: This refers to the amount of time from placing an order to receiving the product. Knowing the lead time for vertical screw feeders is important for planning production schedules and ensuring that operations run smoothly without delays.

-

Customization: This term refers to the ability to modify a standard product to meet specific requirements. Understanding customization options for vertical screw feeders allows buyers to tailor equipment to their unique operational needs, enhancing efficiency and effectiveness.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions when investing in vertical screw feeders, ensuring they meet their operational requirements and industry standards.

Navigating Market Dynamics and Sourcing Trends in the vertical screw feeder Sector

What Are the Global Drivers and Key Trends in the Vertical Screw Feeder Market?

The vertical screw feeder market is experiencing significant growth, fueled by the rising demand for efficient bulk material handling solutions across various industries, including food processing, chemicals, and waste management. The increasing need for automation and the adoption of Industry 4.0 technologies are reshaping the sourcing landscape. B2B buyers are increasingly seeking advanced systems that offer precision control, reduced energy consumption, and enhanced material handling capabilities.

Emerging trends include the integration of IoT technologies, which enable real-time monitoring and predictive maintenance, thereby reducing downtime and operational costs. Additionally, the shift toward customizable solutions is evident, as manufacturers offer vertical screw feeders tailored to specific application requirements, such as varying material types and operational environments. Buyers from regions like Africa and South America are increasingly prioritizing systems that can handle diverse materials efficiently, while those in Europe and the Middle East often seek robust solutions that comply with stringent regulatory standards.

Illustrative image related to vertical screw feeder

How Are Sustainability and Ethical Sourcing Impacting Vertical Screw Feeder Supply Chains?

Sustainability is becoming a central focus in the vertical screw feeder sector, driven by both regulatory pressures and growing consumer awareness. B2B buyers are increasingly evaluating the environmental impact of their supply chains, leading to a demand for ethically sourced materials and sustainable manufacturing practices. The use of recyclable or biodegradable materials in vertical screw feeder construction is gaining traction, as companies strive to minimize their carbon footprints.

Moreover, certifications such as ISO 14001 for environmental management systems are becoming essential for suppliers aiming to establish credibility with international buyers. Companies that prioritize sustainability not only enhance their brand reputation but also tap into new market opportunities, particularly in regions where environmental regulations are stringent. B2B buyers are encouraged to partner with manufacturers who demonstrate a commitment to sustainability, ensuring that their sourcing decisions align with global environmental goals.

What Is the Historical Context of Vertical Screw Feeders in B2B Applications?

The evolution of vertical screw feeders can be traced back to the mid-20th century when bulk material handling began to gain prominence in industrial applications. Initially, these systems were simple mechanical devices designed to transport materials vertically with limited capacity. Over the decades, advancements in materials science and engineering have led to the development of more sophisticated designs, including the introduction of shaftless and dust-tight configurations.

Today, vertical screw feeders are recognized for their versatility and efficiency, capable of handling a wide range of materials from dry powders to semi-fluid substances. This evolution reflects a broader trend in the B2B landscape, where companies increasingly seek reliable, high-performance solutions that enhance operational efficiency and reduce costs. As industries continue to innovate, vertical screw feeders will likely evolve further, adapting to meet the changing demands of the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of vertical screw feeder

-

How do I solve issues with material clogging in vertical screw feeders?

Material clogging can be addressed by ensuring proper design and configuration of the vertical screw feeder. Consider using a shaftless design, which minimizes friction and allows for a smoother flow of bulk materials. Additionally, regular maintenance checks and adjustments to the feed rate can help mitigate clogging. Ensuring that the materials being transported are compatible with the feeder’s design and capacity is also crucial. If persistent issues arise, consulting with the manufacturer for tailored solutions based on your specific materials may be beneficial. -

What is the best vertical screw feeder for handling bulk powders?

The ideal vertical screw feeder for handling bulk powders should feature a totally enclosed design to prevent dust emissions and maintain product integrity. Look for models that offer adjustable feed rates and are capable of managing varying material characteristics, such as flowability and particle size. A feeder with a dust-tight construction and options for stainless steel or abrasion-resistant materials is recommended, especially for industries like food processing or chemicals. Consulting with suppliers about specific application requirements can help identify the best fit for your operations. -

How can I customize a vertical screw feeder for my unique application?

Customization of vertical screw feeders typically involves adjustments in dimensions, materials of construction, and design features to suit specific applications. Most manufacturers provide options for varying the diameter, height, and capacity of the feeder, as well as the type of inlet and discharge configurations. It’s important to engage with suppliers early in the design process to discuss your specific needs, including material characteristics and throughput requirements, to ensure the final product meets your operational standards. -

What are the minimum order quantities (MOQ) when sourcing vertical screw feeders?

Minimum order quantities for vertical screw feeders can vary significantly depending on the manufacturer and the complexity of the design. Generally, larger suppliers may have higher MOQs due to production costs, while smaller or specialized manufacturers may be more flexible. It’s advisable to discuss your needs directly with potential suppliers to negotiate MOQs that align with your operational scale and budget. Additionally, consider the implications of MOQ on inventory management and long-term operational costs. -

What payment terms should I expect when purchasing vertical screw feeders internationally?

Payment terms for international purchases of vertical screw feeders typically include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers require a deposit upfront, followed by the balance upon shipment or delivery. It’s crucial to clarify these terms before finalizing any agreements and to ensure that they align with your cash flow management practices. Additionally, consider discussing currency exchange risks and potential additional costs, such as customs duties or taxes, when planning your budget. -

What quality assurance measures should I look for when sourcing vertical screw feeders?

When sourcing vertical screw feeders, it’s essential to inquire about the manufacturer’s quality assurance protocols. Look for certifications like ISO 9001, which indicate adherence to international quality management standards. Additionally, ask about testing procedures for materials and components, as well as warranty and service agreements. Engaging in thorough supplier vetting, including visiting facilities or requesting references, can also provide insight into their commitment to quality and reliability. -

How do I evaluate potential suppliers for vertical screw feeders?

Evaluating potential suppliers involves assessing their experience, industry reputation, and product offerings. Start by researching their history and customer reviews, focusing on their expertise in the specific application you require. Requesting product samples or case studies can provide insight into their capabilities. Additionally, consider their responsiveness to inquiries and their willingness to customize solutions. Certifications and compliance with international standards are also critical indicators of a reliable supplier. -

What are the logistics considerations for importing vertical screw feeders?

When importing vertical screw feeders, logistics considerations include shipping methods, customs clearance, and delivery timelines. Determine whether air or sea freight is more suitable based on cost and urgency. It’s also vital to understand the documentation required for customs clearance, including invoices, packing lists, and certificates of origin. Engaging a freight forwarder can facilitate smoother logistics, ensuring compliance with regulations and timely delivery to your facility. Additionally, factor in potential delays due to customs inspections, especially in regions with stringent import regulations.

Top 7 Vertical Screw Feeder Manufacturers & Suppliers List

1. Conveyors Inc – Vertical Screw Conveyors

Domain: conveyorsinc.net

Registered: 1998 (27 years)

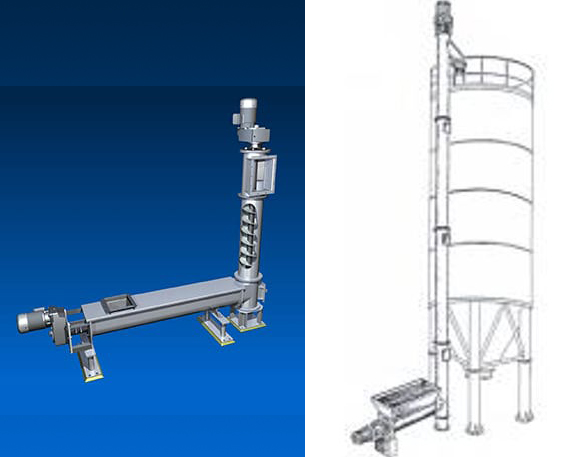

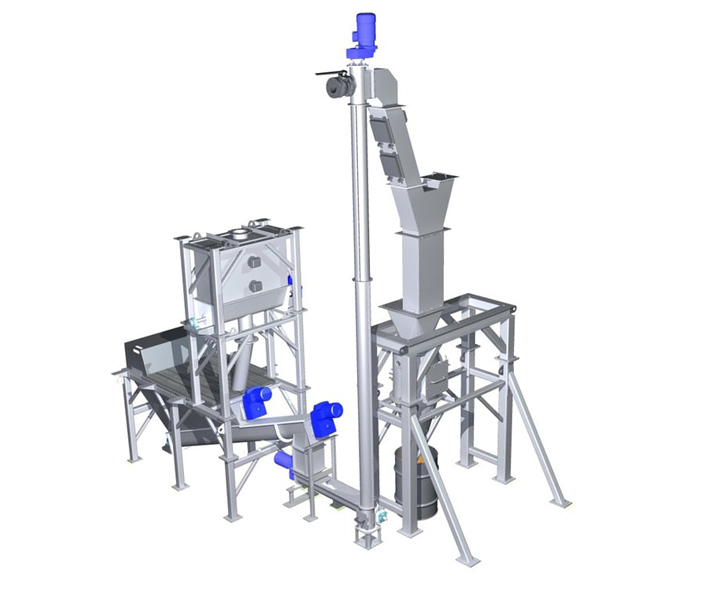

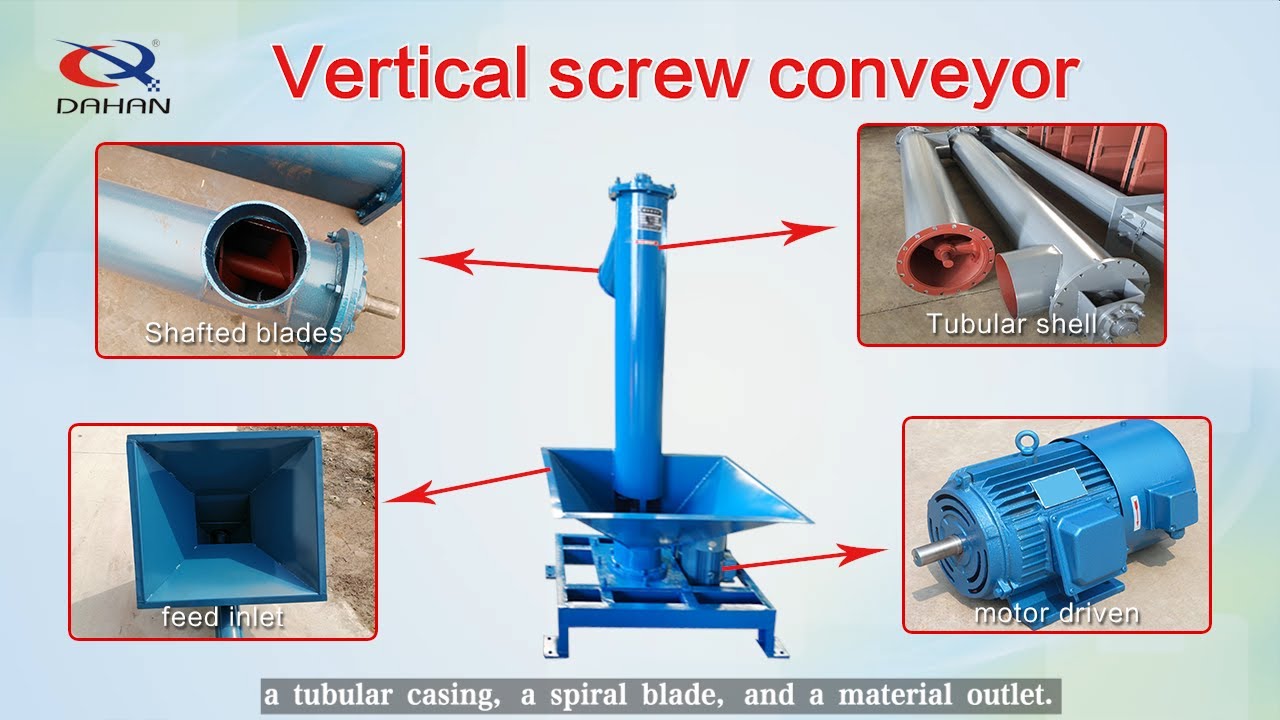

Introduction: Vertical Screw Conveyors are designed to move bulk materials vertically and are specialized screw feeders suitable for applications with a small footprint. They consist of a conveyor screw rotating in a tubular housing with an inlet at the lower end and an outlet at the upper end. Drives are typically located at the top, and the top bearing must handle both radial and thrust loads. Feeding methods…

2. WAMGROUP – VE Vertical Screw Lift Systems

Domain: wamgroup.com

Registered: 1998 (27 years)

Introduction: VE Vertical Screw Lift Systems are designed for transferring powders or granular materials from a lower to a higher level. They are characterized by high volumetric efficiency, excellent mechanical features, and a compact design, making them the smallest footprint of all vertical conveying systems. They are easier to maintain and have the lowest number of spare parts. These systems can discharge b…

3. Orthman – Vertical Screw Conveyors

Domain: orthmanconveying.com

Registered: 2021 (4 years)

Introduction: Vertical Screw Conveyors from Orthman Conveying Systems provide a cost-effective solution for elevating materials with minimal space requirements. Key features include:

– System includes a horizontal feed screw synchronized with the vertical screw for efficient material handling.

– Independent drives for both feed and vertical screws for precise control.

– Available in multiple materials: carbon,…

4. Conveyor Engineering – Vertical Screw Conveyors

Domain: conveyoreng.com

Registered: 1996 (29 years)

Introduction: Vertical Screw Conveyors offer efficient material conveyance, occupy a small footprint, and have high reliability due to few moving parts. They can elevate products up to 45 feet and are available in various materials including stainless steel, corrosion-resistant alloys, carbon steel, and abrasion-resistant materials. Shaftless options are available for sticky materials. Custom solutions are offe…

5. Cozzini – Giraffe™ Vertical Screw Conveyor

Domain: cozzini.com

Registered: 1996 (29 years)

Introduction: Giraffe™ Vertical Screw Conveyor is designed for gentle, non-smearing vertical movement of products. It can be directly fed from Cozzini grinders or through a hopper feed unit. Features include two swivel and two rigid casters for easy maneuverability, a space-saving compact design, and a stainless steel body with a fine sanitary finish. It is USDA accepted and CE approved, built in conformity wit…

6. Brabender – Vertical Forced Feeder

Domain: anton-paar.com

Registered: 1995 (30 years)

Introduction: Brabender Vertical Forced Feeder is a compact screw feeder designed for feeding bulk materials to extruders in the Brabender product line. It is particularly suitable for laboratory operations and dosing smaller product quantities. Key features include:

– Compact size with integrated control electronics

– Hygienic design for easy cleaning

– Suitable for various industries including chemical, food,…

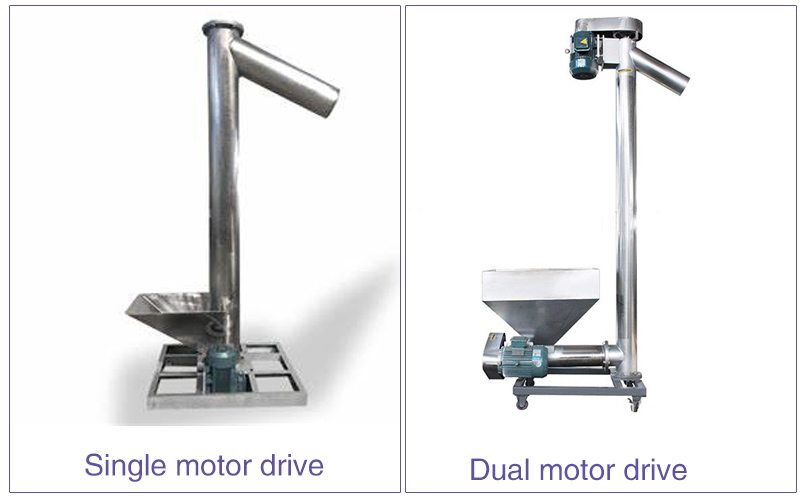

7. Dahan – Vertical Screw Conveyor

Domain: dahanmachine.com

Registered: 2018 (7 years)

Introduction: Vertical Screw Conveyor

– Types: Stainless steel, Carbon steel, Mobile, Flexible

– Purpose: Vertical conveying and lifting/loading of powder materials

– Price Range: $500.00-$5,000.00/Set

– Features: Space-saving, Dust-proof, Easy to maintain

– Diameter: 114mm-800mm

– Conveying Height: ≤6 meters

– Capacity: 7-300m3/h

– Speed: 200-315rpm

– Motor Power: 2.2-18.5 kw

– Application: Discharging bulk ma…

Strategic Sourcing Conclusion and Outlook for vertical screw feeder

In the evolving landscape of bulk material handling, vertical screw feeders emerge as a pivotal solution for industries across Africa, South America, the Middle East, and Europe. Their compact design and versatility allow for efficient elevation of a wide range of materials, addressing the unique operational challenges faced by businesses in diverse sectors, including food processing, chemicals, and wastewater treatment.

Strategic sourcing of vertical screw feeders not only enhances productivity but also reduces operational costs. By leveraging the latest technology and customizable features, companies can optimize their material handling processes to ensure maximum efficiency and reliability. This is particularly crucial for international buyers who must navigate varying regional requirements and standards.

As we look to the future, the demand for innovative and sustainable material handling solutions will continue to grow. International B2B buyers are encouraged to engage with reputable suppliers who can provide tailored solutions that meet specific operational needs. Investing in high-quality vertical screw feeders can significantly impact productivity and operational success. Embrace this opportunity to enhance your supply chain and position your business for success in a competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.