Everything You Need to Know About Valve Coil Sourcing in 2025

Introduction: Navigating the Global Market for valve coil

In the complex landscape of industrial operations, sourcing high-quality valve coils can pose significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As industries demand precision and reliability, understanding the nuances of valve coil specifications, such as voltage options and connection types, becomes essential. This guide aims to streamline the purchasing process for valve coils, addressing key factors such as types, applications, supplier vetting, and cost considerations.

By delving into the various categories of valve coils—from solenoid coils to specialized replacement options—this comprehensive resource equips international buyers with the knowledge needed to make informed decisions. Whether your operations rely on hydraulic systems or pneumatic applications, understanding the performance and compatibility of different coil types is crucial for operational efficiency.

Furthermore, this guide emphasizes the importance of vetting suppliers to ensure quality and reliability, especially in a global market where standards can vary widely. By navigating through the complexities of sourcing valve coils, B2B buyers can enhance their procurement strategies, reduce downtime, and ultimately drive their business success. Empowered with actionable insights, you will be well-positioned to select the right valve coils that meet your unique operational needs and challenges.

Understanding valve coil Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solenoid Coils | Electromagnetic operation, available in various voltages (e.g., 12V, 24V, 120V) | Industrial automation, irrigation systems | Pros: High reliability; Cons: Sensitive to voltage fluctuations. |

| E-Coils | Aluminum body, often includes Zener diodes for surge protection | Hydraulic systems, automotive applications | Pros: Lightweight and durable; Cons: Limited to specific applications. |

| DIN Connector Coils | Standardized 3-prong DIN connection for easy installation | Manufacturing, HVAC systems | Pros: Quick installation; Cons: Compatibility issues with non-DIN systems. |

| High-Voltage Coils | Designed for high-voltage applications (e.g., 220V) | Power generation, large machinery | Pros: Efficient for heavy-duty use; Cons: Higher cost and safety concerns. |

| Low-Voltage Coils | Typically operate at lower voltages (e.g., 12V, 24V) for safety | Residential applications, small machinery | Pros: Safer to handle; Cons: Limited power output. |

What Are Solenoid Coils and Their Key Characteristics?

Solenoid coils are essential components in many industrial applications, functioning through electromagnetic principles to control fluid flow. They are available in various voltage ratings, including 12V, 24V, and 120V, which makes them adaptable for different operational environments. B2B buyers should consider the reliability of solenoid coils, particularly in automation and irrigation systems, where consistent performance is critical. However, these coils can be sensitive to voltage fluctuations, which may necessitate additional surge protection measures.

How Do E-Coils Differ from Other Types?

E-coils are characterized by their aluminum body and often come equipped with Zener diodes, enhancing their durability and protecting against voltage surges. This makes them particularly suitable for hydraulic systems and automotive applications, where high-performance and reliability are paramount. When considering E-coils, B2B buyers should evaluate their specific application needs, as these coils may be limited to certain uses due to their design. Their lightweight nature is advantageous for installations where weight is a concern.

What Are the Benefits of DIN Connector Coils?

DIN connector coils feature a standardized 3-prong connection, making them easy to install and replace. This standardization is particularly beneficial in manufacturing and HVAC systems, where quick maintenance is essential to minimize downtime. While DIN connector coils provide a straightforward installation process, buyers must ensure compatibility with existing systems, as non-DIN setups may pose challenges. The ease of installation can significantly reduce labor costs, making these coils an attractive option for many B2B buyers.

Why Choose High-Voltage Coils for Heavy-Duty Applications?

High-voltage coils are specifically designed for demanding applications, such as power generation and large machinery. Operating at voltages like 220V, these coils can efficiently manage the requirements of heavy-duty equipment. B2B purchasers should weigh the benefits of efficiency against the higher costs and safety concerns associated with high-voltage systems. While they offer excellent performance in robust environments, adequate safety measures must be in place to mitigate risks.

How Do Low-Voltage Coils Enhance Safety in Operations?

Low-voltage coils are typically used in residential applications and smaller machinery, operating at voltages like 12V and 24V. Their lower voltage levels make them safer to handle, which is a significant advantage in environments where safety is a priority. However, buyers should be aware that low-voltage coils may have limited power output, which could restrict their use in more demanding applications. Evaluating the specific needs of an operation will help determine if low-voltage coils are the right choice for a business.

Key Industrial Applications of valve coil

| Industry/Sector | Specific Application of valve coil | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Automated irrigation systems | Improved water management and crop yield | Compatibility with existing systems, voltage options |

| Oil & Gas | Control of drilling fluid systems | Enhanced safety and operational efficiency | Durability under harsh conditions, certification standards |

| Manufacturing | Automation in assembly lines | Increased productivity and reduced labor costs | Customization options, reliable performance ratings |

| HVAC Systems | Temperature control in heating and cooling systems | Energy efficiency and improved comfort levels | Voltage specifications, environmental ratings |

| Water Treatment | Flow regulation in filtration systems | Enhanced water quality and regulatory compliance | Material compatibility, operational reliability |

How is valve coil used in Agriculture for Automated Irrigation Systems?

In the agriculture sector, valve coils are integral to automated irrigation systems, allowing for precise control of water flow. By using solenoid valves activated by these coils, farmers can ensure optimal water distribution, which is crucial for crop health. This application addresses challenges like water wastage and uneven irrigation, making it essential for buyers in regions with water scarcity, such as parts of Africa and South America. Buyers should prioritize compatibility with existing irrigation infrastructure and ensure the selected coils can handle the required voltage.

What role do valve coils play in Oil & Gas for Drilling Fluid Systems?

In the oil and gas industry, valve coils are vital for managing drilling fluid systems. These coils control solenoid valves that regulate the flow of drilling fluids, ensuring optimal pressure and preventing blowouts. This application enhances safety and operational efficiency, particularly in challenging environments like offshore drilling in the Middle East. Buyers must consider the durability of the coils, as they need to withstand extreme temperatures and corrosive substances, along with compliance with industry certification standards.

How are valve coils utilized in Manufacturing for Automation?

Manufacturing industries leverage valve coils in automated assembly lines to control pneumatic and hydraulic systems. These coils enable precise actuation of valves, leading to streamlined operations and increased production rates. The use of valve coils reduces labor costs and minimizes human error. For international buyers, especially in Europe, sourcing coils with customizable features and high reliability ratings is crucial to maintaining production efficiency and meeting quality standards.

In what ways do valve coils enhance HVAC Systems?

In HVAC systems, valve coils are essential for regulating temperature through solenoid valves that control refrigerant and air flow. This application leads to improved energy efficiency and enhanced comfort levels in residential and commercial spaces. Buyers in regions with extreme weather conditions, such as Europe and the Middle East, should focus on voltage specifications and environmental ratings to ensure optimal performance and compliance with local regulations.

How do valve coils contribute to Water Treatment processes?

Valve coils are employed in water treatment facilities to regulate flow in filtration and purification systems. By controlling solenoid valves, these coils enhance water quality and ensure compliance with environmental regulations. This application is particularly important for international buyers in regions facing water quality challenges, such as parts of Africa and South America. Buyers should prioritize sourcing materials that are compatible with various water treatment chemicals and ensure the coils offer reliable performance over time.

3 Common User Pain Points for ‘valve coil’ & Their Solutions

Scenario 1: Difficulty in Sourcing Compatible Valve Coils for Diverse Applications

The Problem: B2B buyers often face challenges when sourcing valve coils that are compatible with a variety of valve types and specifications. This issue is particularly pronounced in industries like hydraulics and automation, where different systems require specific voltage ratings and connection types. Buyers may experience frustration when the coils they purchase do not fit the existing valve infrastructure, leading to costly delays and operational disruptions. Additionally, inadequate technical documentation can make it difficult to ascertain whether the chosen coil will function correctly with a specific valve model.

The Solution: To mitigate these challenges, B2B buyers should conduct thorough research prior to purchasing valve coils. Start by compiling a list of the specific valve models in use, along with their voltage requirements and connection types (e.g., DIN, Deutsch). Engage with reliable suppliers who can provide detailed product specifications and compatibility charts. When considering a purchase, request samples or technical documentation to validate compatibility before placing larger orders. Investing time in this upfront research will ensure that the coils sourced will seamlessly integrate with existing systems, thus avoiding potential downtime.

Scenario 2: High Failure Rates of Valve Coils Leading to Increased Maintenance Costs

The Problem: Frequent failures of valve coils can result in significant maintenance costs and operational inefficiencies. Buyers may encounter coils that do not meet industry standards for durability, leading to premature failures, especially in high-demand environments such as manufacturing or chemical processing. This not only affects the bottom line but also creates a ripple effect of production delays and the need for emergency repairs, which can strain resources and disrupt workflows.

The Solution: To combat high failure rates, it is essential to prioritize quality over cost when sourcing valve coils. Look for manufacturers that offer coils designed for specific applications and that adhere to relevant quality standards (e.g., ISO certifications). Consider investing in coils that feature built-in protection mechanisms, such as Zener diodes, which can prevent damage from voltage spikes. Additionally, implementing a proactive maintenance schedule that includes regular inspections and replacements based on usage can help extend the lifespan of valve coils and reduce unexpected failures.

Scenario 3: Lack of Knowledge on Proper Installation and Maintenance Procedures

The Problem: Many B2B buyers and their teams may lack the necessary expertise to install and maintain valve coils effectively, which can lead to improper operation and further complications. This issue is particularly relevant for companies that may not have dedicated technical staff or those that are new to using solenoid valves in their operations. Inadequate installation can result in issues such as leaks, miscommunication between electrical systems, and even complete system failures.

The Solution: To ensure proper installation and maintenance of valve coils, B2B buyers should invest in training programs for their staff, focusing on the technical aspects of valve coil operation. Collaborate with suppliers who offer comprehensive installation guides, video tutorials, or on-site training sessions. Additionally, develop a checklist for installation that includes verifying voltage compatibility, securing connections, and testing functionality before putting the system into full operation. Regular refresher training sessions can also help reinforce best practices and ensure that all team members are up to date with the latest installation techniques and maintenance protocols. By fostering a knowledgeable team, companies can reduce the risk of operational issues stemming from improper valve coil management.

Strategic Material Selection Guide for valve coil

What Are the Key Materials Used in Valve Coils?

When selecting materials for valve coils, it is essential to consider various factors such as performance, durability, and cost. Here, we analyze four common materials used in valve coils: copper, aluminum, stainless steel, and plastic. Each material has unique properties that make it suitable for specific applications in diverse industrial environments.

How Does Copper Perform in Valve Coils?

Copper is a widely used material for valve coils due to its excellent electrical conductivity and thermal properties. It typically has a high melting point, making it suitable for applications that involve heat. Copper coils can withstand moderate pressure and are resistant to corrosion in non-acidic environments.

Pros: Copper is durable and has a long lifespan, which reduces the frequency of replacements. It is also relatively easy to manufacture, allowing for efficient production processes.

Cons: However, copper can be expensive compared to other materials, and its susceptibility to corrosion in acidic or saline environments may limit its applicability in certain regions.

Impact on Application: In regions like Brazil and Saudi Arabia, where humidity and saline conditions are prevalent, copper coils may require protective coatings to enhance their longevity.

What Are the Benefits of Aluminum in Valve Coils?

Aluminum is another popular choice for valve coils, known for its lightweight nature and good thermal conductivity. It is often used in applications where weight is a critical factor, such as in mobile machinery.

Pros: Aluminum is cost-effective and provides a good balance between performance and price. It is also resistant to corrosion, particularly when anodized, making it suitable for various environments.

Cons: The main limitation of aluminum is its lower tensile strength compared to copper or stainless steel, which may not be ideal for high-pressure applications.

Impact on Application: Buyers in the Middle East may prefer aluminum coils for their lightweight properties, especially in applications where mobility is essential. Compliance with local standards for corrosion resistance is also crucial.

Why Choose Stainless Steel for Valve Coils?

Stainless steel is renowned for its exceptional durability and corrosion resistance, making it ideal for harsh environments. It can withstand high temperatures and pressures, making it suitable for a wide range of industrial applications.

Pros: The longevity of stainless steel coils reduces maintenance costs over time. Its strength and resistance to corrosion make it a versatile choice for various media, including aggressive chemicals.

Cons: The primary drawback is the higher cost of stainless steel compared to copper and aluminum. Additionally, manufacturing stainless steel coils can be more complex, which may lead to longer lead times.

Impact on Application: For international buyers, particularly in Europe, compliance with standards such as ASTM and DIN is essential when selecting stainless steel coils to ensure they meet the required specifications for safety and performance.

What Role Do Plastics Play in Valve Coils?

Plastic materials, such as polyamide and polycarbonate, are increasingly used in valve coils, particularly in applications where weight and cost are significant factors. They offer good electrical insulation and can be manufactured in various shapes and sizes.

Pros: Plastics are lightweight and resistant to corrosion, making them suitable for a wide range of applications. They are also less expensive than metals, which can be advantageous for budget-conscious buyers.

Cons: However, plastics typically have lower temperature and pressure ratings compared to metals, which may limit their use in high-demand environments.

Impact on Application: Buyers in Africa may find plastic coils advantageous due to their lower cost and ease of handling. However, they must ensure that the selected plastic is compatible with the specific media used in their applications.

Summary Table of Material Selection for Valve Coils

| Material | Typical Use Case for valve coil | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical applications in moderate heat | Excellent conductivity and durability | Susceptible to corrosion in acidic environments | High |

| Aluminum | Lightweight applications in mobile machinery | Cost-effective and corrosion-resistant | Lower tensile strength | Medium |

| Stainless Steel | Harsh environments with aggressive media | Exceptional durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Plastic | Cost-sensitive applications requiring insulation | Lightweight and corrosion-resistant | Lower temperature and pressure ratings | Low |

This guide provides a comprehensive overview of the strategic material selection for valve coils, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for valve coil

What Are the Main Stages of Manufacturing Valve Coils?

The manufacturing of valve coils involves several critical stages, each designed to ensure the final product meets the high standards required for industrial applications. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality raw materials, such as copper wire for the coil windings and high-grade plastics or metals for the housing. Suppliers often perform initial inspections to ensure materials meet specific standards, such as conductivity and durability.

-

Forming: This stage involves winding the copper wire around a bobbin to create the coil. Advanced techniques such as automated winding machines are commonly used to ensure uniformity and precision. The number of turns and the gauge of the wire are critical parameters that impact the coil’s performance and efficiency.

-

Assembly: After forming, the coils are assembled into their respective housings. This includes integrating components like connectors and diodes, which are essential for the coil’s operation. Automated assembly lines are often employed to enhance efficiency and reduce human error.

-

Finishing: The final stage involves applying surface treatments, such as coatings or insulation, to protect the coils from environmental factors. This step is vital for ensuring the longevity and reliability of the coils in demanding industrial environments.

How Is Quality Assurance Implemented in Valve Coil Manufacturing?

Quality assurance (QA) is a crucial aspect of valve coil manufacturing, ensuring that every product meets international standards and customer specifications. The QA process typically adheres to several international standards, including ISO 9001, which focuses on quality management systems, and industry-specific certifications such as CE marking and API standards for valves.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Suppliers should provide certificates of conformity to verify that materials meet specified standards. This step helps prevent defects caused by substandard materials.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to monitor production quality. This includes checking the precision of the winding process and the assembly of components. Statistical process control (SPC) techniques are often employed to analyze data and detect variations in real time.

-

Final Quality Control (FQC): Once the valve coils are fully assembled, they undergo rigorous testing to ensure functionality and reliability. Common testing methods include electrical testing for continuity and insulation resistance, as well as performance tests under simulated operational conditions.

What International Standards and Certifications Are Relevant for Valve Coils?

International standards play a significant role in the quality assurance of valve coils. Compliance with these standards not only ensures product reliability but also facilitates smoother international trade. Key standards include:

-

ISO 9001: This standard outlines the requirements for a quality management system, emphasizing continuous improvement and customer satisfaction. Manufacturers seeking ISO 9001 certification must demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: For products sold in the European Economic Area (EEA), CE marking signifies compliance with health, safety, and environmental protection standards. This marking is essential for valve coils used in various applications across Europe.

-

API Standards: The American Petroleum Institute (API) sets standards for products used in the oil and gas industry. Manufacturers of valve coils for this sector must adhere to specific API standards to ensure safety and efficiency.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive measures to verify the quality control processes of potential suppliers. Here are several strategies:

-

Supplier Audits: Conducting audits of suppliers’ manufacturing facilities can provide valuable insights into their quality management systems. Buyers can assess compliance with international standards and identify areas for improvement.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand their QC processes. These reports should include data from IQC, IPQC, and FQC stages, as well as results from any testing performed.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control. This is particularly important for international buyers who may not be able to conduct on-site audits.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Here are key considerations:

-

Regulatory Compliance: Understanding the regulatory landscape in the destination country is essential. Buyers must ensure that the products they import comply with local standards and certifications.

-

Logistical Challenges: The transportation of valve coils across borders can introduce risks, such as damage during transit. Buyers should consider suppliers who offer robust packaging and handling solutions to mitigate these risks.

-

Cultural Differences: Communication barriers and differences in business practices can affect quality assurance. Establishing clear expectations and maintaining open lines of communication with suppliers is crucial for successful collaboration.

Conclusion

The manufacturing processes and quality assurance protocols for valve coils are integral to ensuring product reliability and performance in diverse industrial applications. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful partnerships and high-quality outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘valve coil’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure valve coils. Sourcing the right valve coil is critical for ensuring the efficiency and reliability of your industrial applications. By following these steps, you can make informed decisions and select suppliers that meet your operational needs.

Step 1: Define Your Technical Specifications

Before you begin sourcing, clearly outline the technical specifications of the valve coils you require. This includes parameters such as voltage ratings (e.g., 12V DC, 24V DC), connection types (e.g., DIN connectors, Deutsch DT-06), and body types (e.g., aluminum finish). Understanding these specifications will help you communicate effectively with potential suppliers and ensure compatibility with your existing systems.

Step 2: Research Market Trends and Pricing

Investigate current market trends and pricing for valve coils. Knowing the average price range—such as $37.58 to $69.95 for various models—can help you identify competitive offers. Additionally, understanding trends in voltage and connection types can guide you toward the most relevant products for your industry.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product catalogs, and case studies, particularly focusing on their experience in your industry or region. Check for customer references and reviews to gauge their reliability and service quality. This step is crucial to avoid disruptions in your supply chain.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications that validate their quality standards and compliance with international regulations. Certifications such as ISO 9001 or industry-specific standards can indicate a commitment to quality and reliability. This verification process minimizes the risk of receiving subpar products.

Step 5: Request Samples or Prototypes

If possible, request samples or prototypes of the valve coils you are considering. Testing these samples in your operational environment allows you to assess their performance and compatibility with your systems. This step is essential to avoid costly mistakes and ensure that the products meet your requirements.

Step 6: Assess Lead Times and Delivery Options

Discuss lead times and delivery options with your suppliers. Understanding their production capabilities and shipping processes is vital for planning your inventory and project timelines. Consider suppliers who offer flexible shipping solutions, especially if you operate in regions with logistical challenges.

Step 7: Negotiate Terms and Finalize Purchase

Once you have chosen a supplier, engage in negotiations to finalize the terms of your purchase. Discuss pricing, payment terms, warranties, and return policies to ensure mutual agreement. Clear communication at this stage can prevent misunderstandings and foster a strong working relationship with your supplier.

By following this checklist, B2B buyers can streamline their sourcing process for valve coils, ensuring they choose the right products and suppliers for their industrial needs.

Comprehensive Cost and Pricing Analysis for valve coil Sourcing

What Are the Key Cost Components in Valve Coil Manufacturing?

When sourcing valve coils, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials for valve coils include copper wire, aluminum for the body, and insulation materials. High-quality materials may increase upfront costs but can enhance durability and performance.

-

Labor: Labor costs encompass the wages of skilled workers involved in assembly and quality control. Regions with higher labor costs may lead to increased prices, while countries with lower labor costs could offer competitive pricing.

-

Manufacturing Overhead: This includes costs associated with the factory, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead and impact pricing positively.

-

Tooling: Investment in specialized tools for production can affect costs. If a supplier has advanced tooling, they might offer better quality and efficiency, which can justify higher prices.

-

Quality Control (QC): Rigorous QC processes ensure that valve coils meet industry standards. Suppliers that invest in comprehensive QC may charge more, but this can reduce the risk of failures and returns.

-

Logistics: Shipping costs can vary significantly based on the distance, shipping method, and Incoterms. Understanding these logistics is crucial for total cost calculations.

-

Margin: Supplier profit margins can vary widely. A supplier with a strong reputation may have higher margins, reflecting their quality and reliability.

What Influences Pricing for Valve Coils in B2B Markets?

Several factors influence the pricing of valve coils, particularly for international B2B buyers:

-

Volume/MOQ: Minimum Order Quantities (MOQ) often dictate pricing structures. Larger orders typically benefit from volume discounts, making it crucial to assess your needs and negotiate effectively.

-

Specifications and Customization: Custom designs or specific voltage requirements can lead to higher costs. Buyers should clearly communicate specifications to avoid unexpected charges.

-

Material Quality and Certifications: Coils that meet specific industry certifications or standards will usually be priced higher. Investing in certified products can provide assurance of reliability and performance.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Established suppliers may charge a premium for their reliability, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international sourcing. They determine who is responsible for shipping, insurance, and tariffs, influencing the total landed cost.

How Can Buyers Negotiate for Better Pricing on Valve Coils?

To ensure cost-efficiency when sourcing valve coils, buyers should consider the following tips:

-

Conduct Market Research: Understanding the market landscape and average prices can empower buyers during negotiations. Comparing offers from multiple suppliers can also reveal competitive pricing.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs and negotiate better pricing based on larger volumes. This strategy can significantly reduce per-unit costs.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the long-term costs associated with maintenance, performance, and potential failures. Higher-quality coils may have a higher initial price but can result in lower TCO.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms over time. Regular communication and feedback can foster loyalty and preferential treatment.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, import duties, and local market conditions that can affect pricing. Understanding these nuances can help in making informed purchasing decisions.

Conclusion: Navigating the Cost Landscape for Valve Coils

While sourcing valve coils, understanding the underlying cost components and pricing influencers is crucial for making informed decisions. By leveraging negotiation strategies and being aware of total costs, international buyers can optimize their sourcing strategies and achieve significant savings. Always consult multiple suppliers and assess the total value offered to ensure the best return on investment.

Alternatives Analysis: Comparing valve coil With Other Solutions

Exploring Alternatives to Valve Coils: What Should B2B Buyers Consider?

In the industrial landscape, valve coils play a crucial role in controlling fluid flow. However, there are alternative solutions that can achieve similar objectives, each with its own set of advantages and limitations. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational needs and budget.

| Comparison Aspect | Valve Coil | Pneumatic Actuators | Electric Actuators |

|---|---|---|---|

| Performance | High precision and reliability in fluid control. | Quick response times; ideal for large flow volumes. | Variable speed and torque; flexible in control applications. |

| Cost | Moderate cost, typically ranging from $37 to $70. | Higher initial investment but cost-effective for large systems. | Varies widely; can be economical or expensive based on specifications. |

| Ease of Implementation | Generally straightforward installation; compatible with most systems. | Requires more extensive piping and setup; may need specialized training. | Installation can be complex depending on the system; may need electrical expertise. |

| Maintenance | Low maintenance; periodic checks recommended. | Moderate maintenance; requires regular checks for air leaks. | Low maintenance; mainly involves electrical checks. |

| Best Use Case | Ideal for precise control in hydraulic systems. | Best for heavy-duty applications requiring rapid actuation. | Suitable for applications needing variable control and automation. |

What Are Pneumatic Actuators and How Do They Compare?

Pneumatic actuators utilize compressed air to create motion, making them suitable for applications that require fast and powerful actuation. The primary advantage of pneumatic systems is their ability to handle large volumes of fluid quickly, which can be beneficial in high-demand environments. However, they can be more expensive to install due to the need for extensive piping and air supply systems. Maintenance can also be a concern, as regular checks for air leaks and system integrity are necessary.

How Do Electric Actuators Stack Up Against Valve Coils?

Electric actuators provide a different approach by using electric motors to control movement. They offer variable speed and torque, making them highly adaptable for various applications. The flexibility in control can lead to increased efficiency, especially in automated systems. However, the cost of electric actuators can vary significantly based on their specifications, and installation may require electrical expertise, making them less straightforward than valve coils. Maintenance is typically low but does involve electrical system checks.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting between valve coils and their alternatives, B2B buyers should consider their specific operational needs, budget constraints, and the technical requirements of each solution. Valve coils excel in precision and reliability for fluid control, while pneumatic actuators are ideal for high-speed applications, and electric actuators offer flexibility and automation. Assessing the unique demands of your industry and the compatibility of each option with your existing systems will guide you toward the most effective choice. Ultimately, the right solution will depend on balancing performance, cost, and ease of implementation to meet your operational goals.

Essential Technical Properties and Trade Terminology for valve coil

What Are the Key Technical Properties of Valve Coils?

When selecting valve coils for industrial applications, understanding the critical technical properties is essential for ensuring compatibility and efficiency. Here are some key specifications to consider:

-

Material Grade

The material used in valve coils, often aluminum or plastic, impacts durability and thermal conductivity. Aluminum coils are lightweight and resistant to corrosion, making them suitable for harsh environments. Understanding material specifications helps buyers ensure that the coils can withstand operational demands and environmental conditions. -

Voltage Rating

Valve coils operate on specific voltage ratings, typically ranging from 12V to 220V, depending on the application. Selecting the appropriate voltage is crucial for the functionality of the solenoid valve system. Misalignment can lead to coil failure, operational inefficiency, or even safety hazards. -

Wattage

The wattage rating, usually specified in watts (W), indicates the power consumption of the coil. It is essential to match the wattage with the system’s power supply to avoid overheating or underperformance. This specification also informs energy efficiency considerations, which can be a deciding factor for cost-sensitive buyers. -

Connection Type

The connection type, such as 3-Prong DIN or Deutsch DT-06, determines how the coil interfaces with other components. Proper connectivity ensures reliable operation and simplifies installation. Buyers should assess their existing setups to select coils with compatible connection types. -

Operating Temperature Range

This specification indicates the range of temperatures within which the coil can operate effectively. For industries with extreme temperature variations, selecting a coil with an appropriate operating temperature range is critical to avoid performance issues or failure. -

Tolerance Levels

Tolerance refers to the permissible limits of variation in a physical property, such as coil dimensions or electrical resistance. Understanding tolerance levels is vital for ensuring that coils fit correctly within their designated systems and perform reliably over time.

What Common Trade Terms Should You Know When Buying Valve Coils?

Navigating the procurement of valve coils involves familiarizing yourself with industry terminology. Here are some essential terms that can aid in the purchasing process:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing valve coils, working with OEM suppliers ensures you receive components that meet specific performance and quality standards, which is vital for maintaining system integrity. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is crucial for budget planning and inventory management, especially for businesses looking to minimize costs while ensuring sufficient supply. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. Submitting an RFQ for valve coils allows buyers to compare prices, lead times, and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Understanding these terms is essential for determining who bears the cost and risk during shipping, which can significantly affect the overall pricing and delivery timelines of valve coils. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. Knowing the lead time for valve coils is important for planning production schedules and managing customer expectations. -

Certification Standards

Certification standards, such as ISO or CE marking, indicate that the products meet specific safety and quality regulations. Buyers should look for these certifications to ensure compliance with industry standards, which can enhance the credibility of their own operations.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions, ensuring that they procure the right valve coils for their applications while optimizing costs and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the valve coil Sector

What Are the Key Market Dynamics and Trends in the Valve Coil Sector?

The valve coil market is experiencing significant growth driven by the increasing demand for automation across various industrial sectors. Key drivers include the rise of smart manufacturing and Industry 4.0, which necessitate precise control systems for efficient operations. As industries such as oil and gas, manufacturing, and agriculture modernize, the need for reliable and efficient valve coils becomes paramount. Additionally, the expansion of infrastructure projects in emerging markets, particularly in Africa and South America, is fueling demand for hydraulic and pneumatic systems that rely on high-quality valve coils.

Emerging B2B tech trends are reshaping the sourcing landscape for valve coils. Digital platforms and e-commerce solutions are streamlining the procurement process, allowing international buyers to access a wider array of suppliers and products. This trend is especially beneficial for buyers in regions like Brazil and Saudi Arabia, where traditional sourcing methods may be less efficient. Moreover, the integration of IoT technology in valve coils is enhancing their functionality and performance, making them more attractive to B2B buyers looking to invest in advanced industrial solutions.

How Is Sustainability and Ethical Sourcing Impacting the Valve Coil Sector?

As the global focus on sustainability intensifies, ethical sourcing and environmental considerations are becoming critical factors for B2B buyers in the valve coil market. The production of valve coils can have a substantial environmental impact, particularly in terms of energy consumption and material waste. Consequently, manufacturers are increasingly adopting sustainable practices, such as utilizing recyclable materials and reducing energy usage during production.

Buyers are now prioritizing suppliers with green certifications, such as ISO 14001, which signifies a commitment to environmental management. Additionally, the demand for valve coils made from eco-friendly materials is on the rise, aligning with the global trend toward greener industrial practices. For B2B buyers, aligning procurement strategies with sustainability goals not only enhances their corporate responsibility but also positions them favorably in a market that increasingly values ethical sourcing.

What Is the Historical Context of the Valve Coil Industry?

The valve coil industry has evolved significantly over the past few decades, transitioning from traditional mechanical systems to advanced electronic solutions. Initially, valve coils were simple electromechanical devices used primarily in basic applications. However, as industrial processes became more complex and automation technologies advanced, the design and functionality of valve coils improved dramatically.

In recent years, the integration of digital technologies and smart materials has revolutionized valve coil applications, allowing for greater precision and reliability. This evolution has been driven by the need for enhanced operational efficiency and the growing importance of automated systems in various industries. For international B2B buyers, understanding this historical context is essential for making informed decisions and anticipating future trends in the valve coil market.

Frequently Asked Questions (FAQs) for B2B Buyers of valve coil

-

How do I solve compatibility issues with valve coils?

To address compatibility issues with valve coils, first, verify the specifications of your existing system, including voltage requirements, connection types, and physical dimensions. Consult the manufacturer’s datasheet for both the valve and the coil to ensure they match. If you are uncertain, reach out to suppliers for guidance or opt for customizable coils that can be tailored to your specific needs. Additionally, consider working with a knowledgeable distributor who can provide insights on compatible products from various manufacturers. -

What is the best valve coil for industrial applications?

The best valve coil for industrial applications typically depends on your specific operational requirements, such as voltage, load capacity, and environmental conditions. Look for coils designed for durability and efficiency, such as those with aluminum bodies and integrated protection features like Zener diodes. Brands like HydraForce and Aeromist offer high-performance coils suitable for diverse industrial settings. Always assess product reviews and technical specifications to ensure optimal performance for your application. -

What factors should I consider when vetting suppliers for valve coils?

When vetting suppliers for valve coils, consider their industry experience, product range, and customer service. Look for suppliers with a proven track record of reliability and quality assurance processes. Request samples to evaluate the coils’ performance and durability. Additionally, inquire about their certifications, warranty policies, and after-sales support. Establishing a strong communication channel will also help in addressing any concerns or specific needs you may have as a buyer. -

What is the typical minimum order quantity (MOQ) for valve coils?

Minimum order quantities (MOQ) for valve coils can vary significantly among suppliers, often ranging from 10 to 100 units. Some manufacturers may offer flexible MOQs for first-time buyers or smaller businesses. It’s essential to discuss your requirements with the supplier to negotiate suitable terms. Understanding the MOQ will help you plan your budget and inventory effectively, especially if you are sourcing for international markets where shipping costs can impact overall expenses. -

What are the common payment terms for international valve coil purchases?

Common payment terms for international valve coil purchases typically include options like advance payment, letters of credit, or payment upon delivery. Depending on your relationship with the supplier, you may also negotiate partial payments at different stages of the order process. It’s crucial to clarify payment terms upfront to avoid misunderstandings. Always ensure that the payment methods are secure and offer buyer protection, especially when dealing with new or overseas suppliers. -

How can I ensure quality assurance for valve coils?

To ensure quality assurance for valve coils, request detailed quality control measures from your supplier. This may include inspection reports, certifications, and compliance with international standards such as ISO 9001. Consider engaging third-party quality inspectors to evaluate the coils before shipment. Additionally, maintaining open communication with the supplier throughout the manufacturing process can help identify and resolve potential quality issues early. -

What logistics considerations should I keep in mind when sourcing valve coils internationally?

When sourcing valve coils internationally, consider shipping methods, transit times, and customs regulations specific to your region. Choose a reliable logistics partner experienced in handling industrial goods to ensure timely delivery. Be aware of potential tariffs and taxes that may apply during importation. Additionally, ensure that the packaging is robust to protect the coils during transit, reducing the risk of damage. -

Can valve coils be customized for specific applications?

Yes, many suppliers offer customization options for valve coils to meet specific application needs. Customizations can include modifications to voltage, size, connection types, and additional features such as built-in protection circuits. Discuss your requirements with the supplier to explore available options. Custom coils may incur additional costs and longer lead times, so plan accordingly to align with your project timelines.

Top 6 Valve Coil Manufacturers & Suppliers List

1. HydraForce – 12V & 24V Solenoid Coils

Domain: summit-hydraulics.com

Registered: 2016 (9 years)

Introduction: Brand: HydraForce, Valve Replacement Series/Size: 10 (5/8″), Voltage Options: 12V DC, 24V DC, Connection Type: 3 Prong DIN Deutsch DT-06, Body Type: E Coil (Aluminum Finish), Zener Diode: 12V DC, 24V DC, Product Range: 12v DC Solenoid Coil for Summit Hydraulic Multiplier ($49.95), 24v DC Solenoid Coil for Summit Hydraulic Multiplier ($44.95), MFZ10-37YC Solenoid Coil for DV50 Diverter Valves & D60…

2. Aeromist – Solenoid Valve Coil

Domain: aeromist.com

Registered: 2001 (24 years)

Introduction: {“Product Name”:”Solenoid Valve Coil”,”Starting Price”:”$37.58″,”Voltage Options”:[“120 VAC”,”220 VAC”],”Description”:”Enhance the performance of your solenoid valve with our premium Solenoid Coil. Engineered for efficiency and reliability, this coil is an essential component for precise control and effective operation of your solenoid valve systems. Ideal for a variety of industrial applications,…

3. Valveman – Solenoid Coils

Domain: valveman.com

Registered: 2009 (16 years)

Introduction: Solenoid coils designed for safe and efficient operation in solenoid valve actuating systems. Manufactured for both electric and pneumatic actuators. Uniform performance specifications across various industries. Available in multiple voltages, configurations, and materials for a range of applications. Assistance available for sourcing the appropriate solenoid coil.

4. Connexion Developments – Solenoid Valve Coils

Domain: connexion-developments.com

Registered: 2013 (12 years)

Introduction: Solenoid Valve Coils convert electrical energy into lateral motion. They consist of copper wire wound around a hollow bobine, generating a magnetic field when electric current flows. Used to control direct acting solenoid valves, Assisted Lift Solenoid Valves, or Servo/Pressure Assisted solenoid valves. Available in various sizes, voltages, IP protection levels, temperature ratings, and power leve…

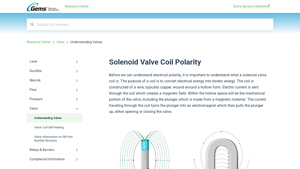

5. Gems Sensors – Solenoid Valve Coil

Domain: article.gemssensors.com

Registered: 1995 (30 years)

Introduction: Solenoid Valve Coil: Converts electrical energy into kinetic energy; constructed of copper wire wound around a hollow form; creates a magnetic field when electric current is sent through; operates a plunger made from magnetic material to open or close the valve. Electrical Polarity: Typically does not matter for solenoid valve coils; lead wires are usually the same color. Exceptions: Polarity matt…

6. HYDAC – Solenoid Coils

Domain: hydac.com

Registered: 1996 (29 years)

Introduction: This company, HYDAC – Solenoid Coils, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for valve coil

What Are the Key Takeaways for Sourcing Valve Coils?

In the competitive landscape of industrial operations, strategic sourcing of valve coils plays a pivotal role in ensuring efficiency and reliability. Key considerations for B2B buyers include understanding the diverse voltage requirements, compatibility with existing systems, and the importance of selecting high-quality materials to enhance durability. Investing in well-engineered solenoid coils can lead to improved system performance, reduced downtime, and long-term cost savings.

How Can Strategic Sourcing Drive Value for Your Business?

By prioritizing strategic sourcing, businesses can foster strong supplier relationships, enabling better pricing, timely delivery, and access to innovative technologies. This approach not only optimizes procurement processes but also aligns purchasing decisions with overall operational goals, ensuring that your valve coil systems are equipped to meet the demands of various applications across sectors.

What’s Next for International Buyers in Emerging Markets?

As we look ahead, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe must leverage the advantages of strategic sourcing to enhance their supply chains. By engaging with reputable suppliers, conducting thorough market research, and adopting best practices, organizations can position themselves for growth in a dynamic marketplace. Explore partnerships that can drive efficiency and elevate your operations—take the next step in optimizing your valve coil procurement today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.