Everything You Need to Know About Union Bolt Sourcing in 2025

Introduction: Navigating the Global Market for union bolt

In today’s competitive global market, sourcing union bolts presents a unique set of challenges for B2B buyers. These essential fasteners are crucial in various industries, including automotive, construction, and manufacturing, where reliability and performance are paramount. However, navigating the complexities of international procurement—such as supplier reliability, product specifications, and compliance with regional standards—can be daunting. This guide aims to demystify the process, providing comprehensive insights into the different types of union bolts, their applications across industries, and critical factors to consider when selecting suppliers.

Understanding the nuances of union bolt procurement is essential for decision-makers, particularly in regions such as Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. This guide will equip international B2B buyers with the knowledge to effectively vet suppliers, assess costs, and understand the implications of various materials and designs. By focusing on actionable insights and best practices, we empower businesses to make informed purchasing decisions that align with their operational needs and budget constraints.

With a thorough examination of market trends and the competitive landscape, this guide serves as a valuable resource for those looking to optimize their sourcing strategy for union bolts. Whether you are expanding your supply chain or seeking to enhance product quality, the information contained herein will enable you to navigate the global marketplace with confidence.

Understanding union bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Union Bolt | Commonly used, available in various sizes | General mechanical applications | Pros: Widely available, versatile; Cons: May lack specific customizations. |

| Filter Housing Union Bolt | Designed for specific engine types with sensor ports | Automotive applications, especially in racing | Pros: Tailored for performance; Cons: Limited to specific models. |

| Grease Union Bolt | Used in lubrication systems, often low-viscosity | Industrial machinery, automotive maintenance | Pros: Essential for proper lubrication; Cons: Requires compatible systems. |

| High-Pressure Union Bolt | Built to withstand extreme pressures | Oil and gas, hydraulic systems | Pros: Durable and reliable under pressure; Cons: Higher cost than standard options. |

| Stainless Steel Union Bolt | Corrosion-resistant, ideal for harsh environments | Marine applications, chemical processing | Pros: Long-lasting, resistant to rust; Cons: Typically more expensive. |

What Are the Characteristics of Standard Union Bolts?

Standard union bolts are the most common type found in various industries. They are versatile and manufactured in different sizes and thread types, making them suitable for a wide range of mechanical applications. B2B buyers appreciate their availability and adaptability, as they can be easily sourced for diverse projects. However, buyers should consider that while standard union bolts are widely available, they may not offer the specific features required for specialized applications.

How Do Filter Housing Union Bolts Serve Automotive Needs?

Filter housing union bolts are specifically designed for automotive applications, particularly in high-performance engines. These bolts often feature sensor ports, allowing for better integration with engine monitoring systems. B2B buyers in the automotive sector should consider these bolts when customizing or upgrading vehicle components. However, their specificity means they may only be suitable for certain vehicle models, which could limit their applicability.

What Role Do Grease Union Bolts Play in Industrial Machinery?

Grease union bolts are integral to lubrication systems, especially in machinery requiring low-viscosity grease. They facilitate the connection of lubrication lines to various components, ensuring optimal performance and maintenance. For B2B buyers in industrial sectors, these bolts are crucial for maintaining machinery efficiency. However, compatibility with existing lubrication systems must be verified to avoid operational issues.

Why Choose High-Pressure Union Bolts for Critical Applications?

High-pressure union bolts are engineered to endure extreme pressure conditions, making them essential in industries like oil and gas and hydraulic systems. Their robust design ensures reliability in critical applications where failure is not an option. B2B buyers should invest in these bolts for projects requiring high durability. Nonetheless, the higher cost compared to standard options may be a consideration for budget-conscious buyers.

What Advantages Do Stainless Steel Union Bolts Offer?

Stainless steel union bolts are known for their corrosion resistance, making them ideal for harsh environments such as marine applications or chemical processing. Their longevity and durability can lead to reduced maintenance costs over time, appealing to B2B buyers looking for sustainable solutions. However, the initial investment is often higher than that of other materials, which may impact purchasing decisions.

Key Industrial Applications of union bolt

| Industry/Sector | Specific Application of union bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Oil filter connection in engines | Ensures leak-proof seals, enhancing engine performance and longevity | Quality certifications (ISO, TS), compatibility with engine models |

| Industrial Machinery | Central lubrication systems | Reduces wear and tear on machinery, increasing operational efficiency | Material specifications, resistance to corrosion, and pressure ratings |

| Construction | Structural connections in frameworks | Provides robust support and stability for heavy structures | Load ratings, compliance with local building codes, and material strength |

| Agriculture | Equipment assembly in agricultural machinery | Enhances reliability and reduces downtime in critical farming equipment | Availability in bulk, resistance to environmental factors, and ease of installation |

| Oil & Gas | Pipeline connections and fittings | Ensures safe and efficient transport of fluids, minimizing leaks | Compliance with safety standards, pressure ratings, and material compatibility |

How Is Union Bolt Utilized in the Automotive Industry?

In the automotive sector, union bolts are critical for securing oil filter connections in various engine models. These bolts ensure a leak-proof seal, which is essential for maintaining engine performance and longevity. Buyers in this industry must focus on sourcing bolts that meet stringent quality certifications, such as ISO or TS, and ensure compatibility with specific engine models to avoid costly repairs and downtime.

What Role Do Union Bolts Play in Industrial Machinery?

Union bolts are extensively used in central lubrication systems within industrial machinery. They play a vital role in connecting various components, ensuring that lubricants are delivered efficiently to reduce wear and tear. For international buyers, it is crucial to consider the material specifications, resistance to corrosion, and pressure ratings to ensure the bolts can withstand the harsh operating conditions often found in manufacturing environments.

How Are Union Bolts Applied in Construction?

In construction, union bolts are employed for structural connections in frameworks, providing robust support and stability for heavy structures. This application is vital for maintaining the safety and integrity of buildings and other constructions. Buyers should pay attention to load ratings and ensure compliance with local building codes, as well as the material strength, to mitigate risks associated with structural failures.

What Is the Importance of Union Bolts in Agriculture?

Union bolts are essential in the assembly of agricultural machinery, ensuring that components are securely fastened for optimal performance. This reliability is crucial in reducing downtime, especially during peak farming seasons. Buyers should look for availability in bulk, resistance to environmental factors such as moisture and dirt, and ease of installation to streamline their procurement processes.

How Do Union Bolts Contribute to the Oil & Gas Industry?

In the oil and gas sector, union bolts are used for connecting pipelines and fittings, playing a critical role in ensuring safe and efficient transport of fluids. The integrity of these connections is paramount to minimize leaks, which can lead to significant environmental and financial repercussions. Buyers must prioritize compliance with safety standards, pressure ratings, and material compatibility to ensure the reliability of their operations.

3 Common User Pain Points for ‘union bolt’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Union Bolt for Specific Applications

The Problem:

B2B buyers often face challenges when sourcing union bolts that meet specific requirements for their applications. For instance, companies in industries like automotive, manufacturing, or construction may need union bolts that are compatible with particular machinery or systems. This can lead to frustration when suppliers offer generic options that do not align with the technical specifications needed, resulting in delays in projects and increased costs. Furthermore, the lack of clarity regarding the appropriate materials or sizes can complicate the procurement process, especially when buyers are unfamiliar with technical jargon or standards.

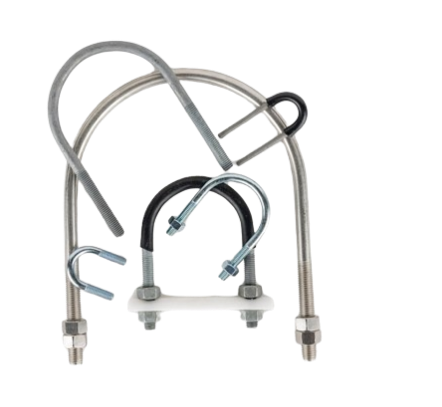

Illustrative image related to union bolt

The Solution:

To effectively source the right union bolt, buyers should start by clearly defining their requirements, including the size, material, thread type, and any specific standards that must be met (e.g., ASTM, ISO). Engaging with suppliers who specialize in union bolts for particular industries can provide valuable insights into the best options available. Buyers should also consider establishing a relationship with a reliable supplier who can offer tailored solutions based on their ongoing needs. Additionally, utilizing online tools and catalogs to compare specifications and read user reviews can help in making informed decisions. Regular communication with suppliers about upcoming projects can also facilitate better forecasting and ensure the timely availability of the right union bolts.

Scenario 2: Concerns Over Quality and Durability of Union Bolts

The Problem:

Quality and durability are critical considerations for B2B buyers, especially when purchasing union bolts for heavy-duty applications. Buyers often worry about the reliability of union bolts sourced from various suppliers, fearing that substandard products may lead to system failures, safety hazards, and costly downtime. In industries such as oil and gas, where equipment operates under high pressure and extreme conditions, the stakes are even higher. The challenge lies in identifying trustworthy suppliers who provide high-quality union bolts that can withstand the demands of their specific applications.

The Solution:

To mitigate concerns over quality, buyers should prioritize suppliers who provide certifications and quality assurance documentation for their products. Conducting thorough research on suppliers, including checking for industry accreditations and customer reviews, can help establish trust. It’s advisable to request samples of union bolts before committing to larger orders to assess their quality firsthand. Implementing a robust quality control process upon receipt can also safeguard against receiving defective items. Additionally, consider investing in union bolts made from high-grade materials, such as stainless steel or high-strength alloys, which offer enhanced durability and resistance to corrosion, thus ensuring long-term performance.

Scenario 3: Managing Lead Times and Supply Chain Disruptions

The Problem:

International B2B buyers often encounter lead time challenges and supply chain disruptions when ordering union bolts, particularly from overseas suppliers. These delays can significantly impact project timelines and operational efficiency, leading to increased costs and potential penalties for late deliveries. Buyers may struggle to obtain accurate delivery estimates, leaving them uncertain about when to expect their orders. This issue is exacerbated by global supply chain complexities, including shipping delays, customs clearance, and fluctuating demand.

The Solution:

To manage lead times effectively, buyers should engage in proactive planning by establishing a clear timeline for when union bolts are needed and communicating this to suppliers. Building a diverse supplier network can also help mitigate risks associated with relying on a single source. Implementing just-in-time (JIT) inventory practices can reduce the need for large stockpiles while ensuring that materials arrive as needed. Furthermore, leveraging technology, such as supply chain management software, can provide real-time updates on order status and help forecast potential delays. Regularly reviewing supplier performance and maintaining open lines of communication can foster a collaborative relationship that enables quicker resolutions to any arising issues.

Strategic Material Selection Guide for union bolt

When selecting materials for union bolts, it is essential to consider the specific application requirements and environmental conditions. Below is an analysis of four common materials used in the manufacturing of union bolts, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Carbon Steel for Union Bolts?

Carbon steel is a widely used material for union bolts due to its strength and versatility. It typically offers good tensile strength and can withstand high pressure and temperature conditions, making it suitable for various applications. Carbon steel bolts can be treated with coatings to enhance their corrosion resistance, although they are inherently susceptible to rusting when exposed to moisture.

Pros: Carbon steel is relatively inexpensive and easy to manufacture. It is also widely available, making it a convenient choice for many industries.

Cons: The primary drawback is its susceptibility to corrosion unless adequately coated. Additionally, carbon steel may not perform well in extreme environments, such as those involving aggressive chemicals.

Illustrative image related to union bolt

Impact on Application: Carbon steel union bolts are suitable for general-purpose applications, including plumbing and automotive sectors, where exposure to moisture is limited.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards (such as ASTM or DIN) for corrosion resistance, particularly in humid climates.

How Does Stainless Steel Perform as a Material for Union Bolts?

Stainless steel is known for its excellent corrosion resistance, making it an ideal choice for union bolts used in harsh environments. The alloying elements in stainless steel, particularly chromium, provide a protective layer that prevents rust formation. Stainless steel also maintains its strength at elevated temperatures.

Pros: The durability and aesthetic appeal of stainless steel are significant advantages. It is suitable for applications involving exposure to chemicals and moisture, making it ideal for marine and food processing industries.

Cons: The primary disadvantage is the higher cost compared to carbon steel. Additionally, stainless steel can be more challenging to machine, which may increase manufacturing complexity.

Illustrative image related to union bolt

Impact on Application: Stainless steel union bolts are particularly effective in applications where hygiene and corrosion resistance are critical, such as in the food and beverage industry.

Considerations for International Buyers: Buyers in Europe, especially Germany, should be aware of specific standards for stainless steel grades (like AISI or EN standards) to ensure compatibility with local regulations.

What Are the Benefits of Brass as a Material for Union Bolts?

Brass is another material option for union bolts, particularly in plumbing applications due to its excellent corrosion resistance and machinability. Brass is an alloy of copper and zinc, which provides good strength and ductility.

Pros: Brass is resistant to corrosion and has a low friction coefficient, making it suitable for applications involving moving parts. It also has antimicrobial properties, which can be beneficial in certain environments.

Cons: Brass is generally more expensive than carbon steel and may not be suitable for high-pressure applications due to lower tensile strength.

Impact on Application: Union bolts made of brass are commonly used in plumbing and electrical applications where corrosion resistance is crucial.

Considerations for International Buyers: Buyers should ensure that brass components meet relevant international standards, particularly regarding lead content, as regulations may vary significantly by region.

Why Consider Plastic or Composite Materials for Union Bolts?

Plastic or composite materials are increasingly being used for union bolts in specific applications, particularly in environments where corrosion resistance and weight reduction are priorities. These materials can be engineered to withstand various chemicals and temperatures.

Pros: The lightweight nature of plastics and composites makes them easy to handle and install. They also offer excellent resistance to corrosion and chemical exposure.

Cons: The primary limitation is their lower mechanical strength compared to metals, which may restrict their use in high-pressure applications.

Impact on Application: Union bolts made from plastic or composite materials are ideal for applications in the chemical industry or other environments where metal corrosion is a concern.

Considerations for International Buyers: Buyers should verify that the selected plastic or composite materials meet relevant safety and performance standards, particularly in regions with stringent regulations.

Summary Table of Material Selection for Union Bolts

| Material | Typical Use Case for union bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General-purpose applications (plumbing, automotive) | Cost-effective and strong | Susceptible to corrosion | Low |

| Stainless Steel | Marine, food processing, and chemical industries | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Plumbing and electrical applications | Corrosion resistance and machinability | More expensive, lower tensile strength | Med |

| Plastic/Composite | Chemical industry and lightweight applications | Lightweight and corrosion-resistant | Lower mechanical strength | Med |

This guide aims to provide valuable insights for B2B buyers in selecting the appropriate material for union bolts, ensuring that their choices align with application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for union bolt

What Are the Key Stages in the Manufacturing Process of Union Bolts?

The manufacturing of union bolts involves several critical stages, each designed to ensure that the final product meets the required specifications for strength, durability, and functionality. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to union bolt

How Is Material Prepared for Union Bolt Production?

The process begins with the selection of raw materials, typically high-strength steel or other alloys that provide the necessary mechanical properties. The material is often subjected to quality checks upon receipt, ensuring it meets specific standards such as tensile strength and corrosion resistance. Following this, the material is cut to size, often using precision cutting techniques like saws or lasers, to prepare it for the forming process.

What Forming Techniques Are Commonly Used for Union Bolts?

Once the material is prepared, it undergoes forming processes that shape it into the desired bolt configuration. Common techniques include:

- Forging: This involves deforming the metal under high pressure, which enhances its structural integrity. Forged bolts are often stronger and more reliable than those produced through other methods.

- Machining: After forging, bolts may be machined to achieve precise dimensions and surface finishes. This includes processes like turning, milling, and threading, ensuring compatibility with various applications.

- Casting: In some cases, casting is used for complex shapes. This method allows for intricate designs but may require additional finishing to meet strength standards.

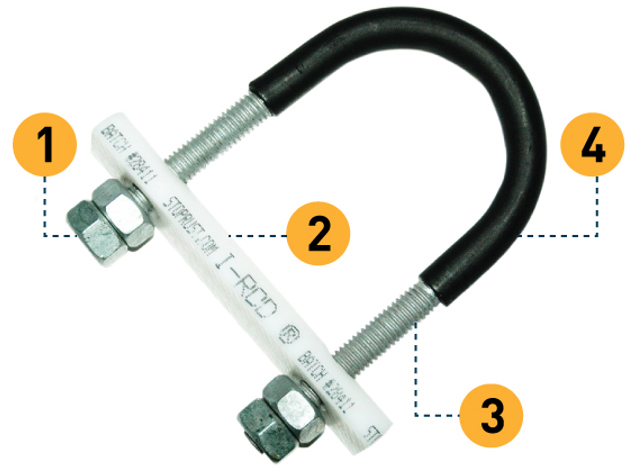

What Assembly Processes Are Involved in Union Bolt Production?

For union bolts that incorporate additional components, assembly is a critical stage. This can involve the integration of seals, washers, or other fittings that enhance performance. Each component must be carefully aligned and secured to ensure the final product functions correctly. Automated assembly lines may be employed to increase efficiency and reduce human error.

How Is the Finishing Process Conducted for Union Bolts?

The finishing stage is essential for improving the corrosion resistance and aesthetic appearance of union bolts. Common finishing techniques include:

- Plating: Zinc or nickel plating is frequently applied to enhance corrosion resistance.

- Coating: Powder coating or other protective coatings may be applied to further safeguard against environmental factors.

- Polishing: This provides a smooth surface finish, which can be critical for applications where friction is a concern.

What Are the Quality Assurance Measures for Union Bolts?

Quality assurance (QA) is paramount in the manufacturing of union bolts, as these components often operate under high-stress conditions. Adherence to international standards and industry-specific certifications is essential for B2B buyers, particularly those in regions with stringent regulations.

Illustrative image related to union bolt

Which International Standards Should B2B Buyers Consider?

International standards, such as ISO 9001, are crucial for ensuring consistent quality in manufacturing processes. ISO 9001 focuses on quality management systems and requires organizations to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Additionally, certifications like CE mark (for European markets) and API (for the oil and gas industry) may be relevant, depending on the application of the union bolts.

What Are the Key Quality Control Checkpoints in Union Bolt Manufacturing?

Quality control is typically conducted at various checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet predefined specifications before they enter the production process.

- In-Process Quality Control (IPQC): During production, ongoing inspections and tests are conducted to monitor the manufacturing process and identify any deviations from quality standards.

- Final Quality Control (FQC): Once the union bolts are completed, a final inspection is performed. This includes dimensional checks, mechanical property tests, and visual inspections to ensure that the product is free from defects.

What Testing Methods Are Commonly Used for Union Bolts?

Various testing methods are employed to verify the integrity and performance of union bolts:

- Tensile Testing: Measures the strength of the bolt under tension and helps ensure it can withstand operational loads.

- Hardness Testing: Determines the material’s hardness, which correlates with wear resistance.

- Corrosion Testing: Assesses how well the bolt can resist environmental factors, crucial for applications in corrosive environments.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in international markets, verifying supplier quality control is critical. Here are some actionable steps:

- Supplier Audits: Conducting regular audits of suppliers allows buyers to assess their quality management systems and adherence to industry standards. This can include evaluating documentation, processes, and equipment.

- Requesting Quality Reports: Buyers should request detailed quality reports and certifications from suppliers. These documents provide insights into testing results and compliance with relevant standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes. These agencies can conduct random inspections and testing to ensure compliance with specifications.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers, particularly those from diverse markets like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Different regions may have varying standards and regulations, which can affect the acceptance of products. Understanding local compliance requirements and ensuring that suppliers can meet these standards is crucial for successful procurement.

Furthermore, language barriers and cultural differences may affect communication regarding quality expectations. Establishing clear lines of communication and documentation can help mitigate misunderstandings and ensure that all parties are aligned on quality standards.

By understanding the manufacturing processes and quality assurance measures associated with union bolts, B2B buyers can make informed decisions and foster strong supplier relationships that ensure consistent quality and reliability in their supply chains.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘union bolt’

When sourcing union bolts, it’s essential to approach the procurement process methodically to ensure quality, compatibility, and cost-effectiveness. This guide serves as a practical checklist for B2B buyers looking to procure union bolts, particularly in international markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it’s crucial to clearly define your technical specifications for the union bolts. This includes dimensions, material types (e.g., stainless steel, carbon steel), and any relevant industry standards (like ISO or ASTM). Providing precise specifications helps avoid compatibility issues and ensures that the union bolts meet your operational requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in union bolts. Look for manufacturers and distributors with a strong reputation in your industry. Utilize online platforms, trade directories, and industry forums to gather a list of candidates. Pay attention to their experience and customer reviews, which can provide insights into their reliability and product quality.

Illustrative image related to union bolt

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is a critical step in ensuring product quality and compliance with industry standards. Check for certifications such as ISO 9001 for quality management systems or specific certifications relevant to your industry. This step not only assures the quality of the union bolts but also mitigates risks associated with non-compliance in your supply chain.

Step 4: Request Samples and Test Quality

Before placing a bulk order, request samples of the union bolts from shortlisted suppliers. Testing these samples for durability, corrosion resistance, and dimensional accuracy will provide tangible evidence of quality. Ensure the samples meet your specifications and are suitable for the intended application, as this can save significant costs in the long run by avoiding defective products.

Step 5: Assess Pricing and Payment Terms

Once you have verified quality, it’s time to assess pricing and payment terms. Compare quotes from different suppliers, ensuring that you understand the pricing structure, including bulk discounts or additional costs like shipping and customs duties. Look for favorable payment terms that suit your cash flow while maintaining a balance between cost and quality.

Step 6: Review Shipping and Delivery Options

Consider the logistics of shipping and delivery when sourcing union bolts. Discuss lead times with suppliers and ensure they can meet your timelines. Evaluate their shipping options, including international shipping capabilities and costs, as delays can impact your production schedules significantly.

Step 7: Establish a Long-term Relationship

Building a long-term relationship with a supplier can lead to better pricing, priority service, and access to new products. Communicate openly with your suppliers about your needs and future projects. Regular engagement can foster trust and reliability, ensuring that your sourcing process becomes more efficient over time.

Illustrative image related to union bolt

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing union bolts, ultimately ensuring that they acquire high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for union bolt Sourcing

What Are the Key Cost Components in Union Bolt Manufacturing?

When sourcing union bolts, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for union bolts include carbon steel, stainless steel, and alloy steel. Prices fluctuate based on market demand, availability, and quality specifications.

-

Labor: Labor costs can vary based on the region and the skill level required for manufacturing. Skilled labor is typically more expensive but essential for ensuring high-quality production.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory expenses. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: The initial investment in specialized tooling for production can be substantial. However, these costs can be amortized over larger production runs, making bulk orders more cost-effective.

-

Quality Control (QC): Implementing strict quality control processes ensures that the union bolts meet the necessary specifications and standards. While this adds to the upfront cost, it can prevent costly returns and damage to reputation in the long run.

-

Logistics: Transportation and shipping costs can vary significantly based on the destination. The choice of shipping method (air, sea, or land) and Incoterms will influence these costs.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding the industry standard margins can help buyers assess whether pricing is competitive.

How Do Price Influencers Affect Union Bolt Costs?

Several factors can influence the pricing of union bolts, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in larger quantities often leads to reduced per-unit pricing. Suppliers may have minimum order quantities (MOQs) that can impact pricing and inventory management.

-

Specifications/Customization: Custom-designed union bolts will generally incur additional costs due to the need for specialized tooling and processes. Buyers should weigh the benefits of customization against the increased costs.

-

Quality and Certifications: Higher quality materials and certifications (such as ISO) can raise costs but may be necessary for specific applications, particularly in regulated industries.

-

Supplier Factors: The reputation, reliability, and geographic location of suppliers can also affect pricing. Suppliers with strong logistics networks may offer better shipping rates, while those with a proven track record in quality may justify higher prices.

-

Incoterms: The chosen Incoterms will dictate who is responsible for shipping costs, insurance, and risk. Understanding these terms is crucial for budgeting accurately and avoiding unexpected expenses.

What Are Essential Buyer Tips for Cost-Efficient Union Bolt Sourcing?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to enhance cost efficiency:

-

Negotiate: Leverage your purchasing power by negotiating terms with suppliers. Bulk orders, long-term contracts, or consistent business can provide leverage for better pricing.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider factors such as shipping, handling, storage, and potential maintenance costs. A lower upfront cost may lead to higher TCO if quality is compromised.

-

Understand Pricing Nuances: Be aware of the market dynamics in both the supplier’s and buyer’s regions. Currency fluctuations, tariffs, and regional demand can affect pricing and should be factored into your sourcing strategy.

-

Research and Compare: Utilize multiple suppliers to compare pricing, quality, and service. A comprehensive market analysis will help identify the best options for your specific needs.

Disclaimer

The prices mentioned in this guide are indicative and may vary based on market conditions, supplier pricing strategies, and regional economic factors. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing union bolt With Other Solutions

Understanding Alternatives in Union Bolt Solutions

In the competitive landscape of industrial fasteners, evaluating alternatives to union bolts is crucial for B2B buyers seeking efficiency, cost-effectiveness, and reliability. Union bolts are commonly used in various applications, particularly in the automotive and lubrication sectors, but several alternatives may better suit specific operational needs. This analysis compares union bolts with two viable alternatives: Compression Fittings and Threaded Couplings.

Comparison Table

| Comparison Aspect | Union Bolt | Compression Fittings | Threaded Couplings |

|---|---|---|---|

| Performance | High pressure resistance | Excellent for fluid flow | Reliable for heavy loads |

| Cost | Moderate ($4.71 each) | Low to moderate | Moderate to high |

| Ease of Implementation | Simple installation | Requires precise alignment | Requires threading skills |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance |

| Best Use Case | Lubrication systems | Plumbing and HVAC | Heavy machinery assembly |

Detailed Breakdown of Alternatives

Compression Fittings

Compression fittings are widely used in plumbing and HVAC applications. They consist of a fitting that compresses a sleeve onto the pipe as it is tightened, creating a seal. The primary advantages of compression fittings include their ease of installation and compatibility with various pipe materials. They do not require threading, making them suitable for quick repairs. However, their performance under high-pressure conditions may not match that of union bolts, which could be a concern for applications involving high-stress environments.

Threaded Couplings

Threaded couplings are another alternative that provides a secure connection for pipes and hoses. These couplings are designed to screw onto threads, which allows for a tight seal that can handle significant pressure. Their main benefits include strong performance in heavy-load applications and versatility in various industrial contexts. However, the need for threading skills can complicate installation, and the potential for wear over time may necessitate more frequent maintenance compared to union bolts.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between union bolts and their alternatives, B2B buyers should carefully consider their specific application requirements, including performance demands, budget constraints, and installation capabilities. Union bolts offer a robust solution for lubrication systems, while compression fittings excel in plumbing scenarios due to their ease of use. On the other hand, threaded couplings are better suited for heavy machinery applications but may require more technical expertise for installation. Ultimately, the right choice will depend on the operational context and the specific needs of the business, ensuring optimal performance and cost efficiency in their operations.

Essential Technical Properties and Trade Terminology for union bolt

What Are the Key Technical Properties of Union Bolts?

Understanding the technical properties of union bolts is crucial for B2B buyers, especially in industries such as manufacturing, automotive, and construction. Here are essential specifications to consider:

Illustrative image related to union bolt

-

Material Grade

Union bolts are typically made from various materials, including stainless steel, carbon steel, and alloy steel. The material grade affects strength, corrosion resistance, and suitability for specific applications. For instance, stainless steel bolts are ideal for environments exposed to moisture, while carbon steel offers high tensile strength, making it suitable for heavy-duty applications. -

Thread Type and Size

The thread type (e.g., metric or imperial) and size (diameter and pitch) are critical for ensuring proper fit and compatibility with existing components. Standardization in thread specifications facilitates easier procurement and assembly, reducing the risk of mismatches that could lead to equipment failure. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in dimensions. Precise tolerance levels are vital for ensuring that union bolts fit seamlessly with other components in assemblies. Poor tolerance can result in loose fittings, leading to operational inefficiencies or safety hazards. -

Surface Treatment

Surface treatments, such as galvanization or coating, enhance corrosion resistance and reduce wear. This is particularly important in industries operating in harsh environments. Buyers should consider the specific environmental conditions where the bolts will be used to choose the appropriate treatment. -

Load Rating

The load rating indicates the maximum load a union bolt can handle before failure. Understanding load ratings helps in selecting the right bolts for applications requiring specific strength characteristics. Overloading can lead to catastrophic failures, making this a critical consideration in procurement. -

Compatibility with Lubrication Systems

In applications involving lubrication, such as central lubrication systems, the design and specifications of the union bolt should accommodate the type of grease or oil used. This ensures optimal performance and longevity of the equipment.

What Are Common Trade Terms Related to Union Bolts?

Familiarity with industry terminology can help B2B buyers navigate procurement processes more effectively. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications ensures that buyers acquire parts that meet the quality and compatibility standards required for their applications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Recognizing MOQ is essential for budgeting and inventory management, as purchasing below this threshold may lead to higher costs per unit. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. Including detailed specifications for union bolts in an RFQ can lead to more accurate quotations, helping buyers make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, insurance, and risk management associated with purchasing union bolts from overseas suppliers. -

Tensile Strength

This term refers to the maximum amount of tensile (pulling) stress a material can withstand before failure. Knowing the tensile strength of union bolts is crucial for ensuring they can handle the forces they will encounter in service. -

Lead Time

Lead time is the time taken from placing an order to receiving the product. Understanding lead times helps buyers plan their projects more effectively, ensuring that they have the necessary components on hand when needed.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies and ensure they select the right union bolts for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the union bolt Sector

What Are the Key Trends and Drivers in the Global Union Bolt Market?

The global union bolt market is experiencing significant transformation driven by technological advancements, increasing demand for specialized applications, and a heightened focus on efficiency and cost-effectiveness. One of the most prominent trends is the integration of smart technologies in manufacturing processes, allowing for enhanced precision in production and inventory management. Digitalization, including the use of AI and IoT, is becoming more prevalent, enabling real-time monitoring of inventory levels and automated replenishment systems. This trend is particularly relevant for international B2B buyers who seek reliability and efficiency in their supply chains.

Moreover, the market dynamics are also shaped by regional demands. For buyers in Africa and South America, there is a growing interest in durable and versatile union bolts suitable for infrastructure projects and automotive applications. Conversely, in Europe and the Middle East, the focus leans towards high-performance materials that meet stringent quality standards, especially in sectors like automotive and aerospace. The competitive landscape is also evolving, with suppliers increasingly offering customizable solutions to meet specific client needs, further driving differentiation in the market.

How Is Sustainability Influencing Sourcing Decisions for Union Bolts?

The importance of sustainability in the union bolt sector cannot be overstated. As environmental regulations tighten globally, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable practices. The environmental impact of production processes, particularly in terms of energy consumption and waste generation, is under scrutiny. Buyers are encouraged to seek union bolts manufactured from recyclable materials or those produced through energy-efficient methods.

Illustrative image related to union bolt

Furthermore, the trend toward sustainable sourcing is also reflected in the growing availability of ‘green’ certifications. Buyers should look for suppliers who hold certifications that validate their commitment to environmental stewardship, such as ISO 14001 or similar standards. These certifications not only enhance a company’s reputation but also align with the corporate social responsibility goals of many organizations. By prioritizing sustainable and ethically sourced union bolts, businesses can mitigate risks associated with supply chain disruptions and enhance their overall brand value in the eyes of eco-conscious consumers.

What Is the Historical Context of Union Bolts in B2B Markets?

The evolution of union bolts has been closely linked to advancements in industrial technologies and the increasing complexity of engineering applications. Initially, union bolts were designed primarily for basic mechanical applications, focusing on strength and durability. Over the decades, as industries evolved, so did the specifications for union bolts. The rise of specialized sectors such as automotive, aerospace, and renewable energy has led to the development of high-performance bolts engineered to meet rigorous standards.

Historically, the production of union bolts has transitioned from manual processes to highly automated systems, improving consistency and reducing lead times. This evolution has enabled suppliers to cater to a global market, providing customized solutions that meet specific industry requirements. As international trade continues to expand, understanding the historical context of union bolts will empower buyers to make informed decisions that align with their strategic objectives in today’s competitive B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of union bolt

-

How do I choose the right union bolt for my application?

Choosing the right union bolt depends on various factors, including the material compatibility, size, and intended application. Consider the environment where the bolt will be used—whether it will be exposed to high temperatures, chemicals, or moisture. Additionally, check the specifications such as thread type and size, as well as any industry standards relevant to your sector. Collaborating with suppliers who offer technical support can also help you make an informed choice. -

What is the best material for union bolts in harsh environments?

For harsh environments, stainless steel or high-grade alloys are often the best choices for union bolts. Stainless steel offers excellent corrosion resistance, making it ideal for applications exposed to moisture or chemicals. In contrast, high-strength alloys can provide enhanced durability and performance under extreme conditions. Always confirm the material specifications with your supplier to ensure compatibility with your specific environmental needs. -

What are the minimum order quantities (MOQ) for union bolts?

Minimum order quantities (MOQ) for union bolts can vary significantly between suppliers and regions. Typically, MOQs range from a few dozen to several hundred units, depending on the supplier’s policies and the specific product. When sourcing internationally, it’s advisable to discuss MOQs upfront to avoid unexpected costs. Some suppliers may offer flexibility for bulk orders or long-term contracts, which can be beneficial for large projects. -

What payment terms should I expect when sourcing union bolts internationally?

Payment terms for international orders of union bolts can vary widely. Common practices include advance payment, letters of credit, or payment upon delivery. Many suppliers also offer net payment terms, allowing a set period after delivery for payment. It’s crucial to negotiate these terms clearly before finalizing your order, as well as to confirm the currency of payment and any potential additional fees related to international transactions. -

How can I ensure the quality of union bolts from international suppliers?

To ensure the quality of union bolts, conduct thorough supplier vetting, including checking certifications and reviews from other clients. Request product samples to assess the quality before placing a larger order. It’s also beneficial to inquire about the supplier’s quality assurance processes and any third-party testing they may employ. Establishing clear quality standards in your purchase agreement can help mitigate risks associated with international sourcing. -

What logistics considerations should I keep in mind when importing union bolts?

When importing union bolts, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. Air freight is faster but generally more expensive than sea freight, which may be more suitable for bulk orders. Ensure you are aware of any tariffs or duties applicable to your imports. Collaborating with a logistics partner familiar with international shipping can streamline this process and help avoid delays. -

Can union bolts be customized for specific applications?

Yes, many suppliers offer customization options for union bolts to meet specific application requirements. Customization may include alterations in size, threading, or material specifications. Discuss your needs with the supplier, providing detailed specifications, to determine the feasibility and any additional costs involved. Custom solutions can enhance the performance and longevity of the bolts in your unique operational environment. -

What certifications should I look for when sourcing union bolts?

When sourcing union bolts, look for certifications that reflect industry standards, such as ISO 9001 for quality management or ASTM specifications for materials. Depending on your application, certifications related to safety and environmental standards may also be relevant. These certifications assure you of the supplier’s commitment to quality and compliance with international standards, which is particularly important in highly regulated industries.

Top 5 Union Bolt Manufacturers & Suppliers List

1. Toyota – Union Bolt #9040112097

Domain: autoparts.toyota.com

Registered: 1994 (31 years)

Introduction: Union Bolt #9040112097, Genuine Toyota part, used in Body/Fuel Tank & Tube, Engine-Fuel/Injection Nozzle, and Engine-Fuel/Fuel Injection System. Designed to seal connections, prevent leaks, and ensure smooth fuel transmission. Part number: 90401-12097. Previous versions: 90410-12097; 90401-12019. Warranty coverage for defects in material or workmanship. In-store pickup only; cannot be shipped. Rec…

2. Toyota – Union Bolt #9040112039

Domain: autoparts.toyotaofelcajon.com

Registered: 2000 (25 years)

Introduction: Union Bolt #9040112039 is a crucial auto part in the Drive-Chassis/Transaxle Assembly of hybrid, battery, or fuel cell electric vehicles. It ensures proper connection and fit of various parts within the system, securing and fastening components to maintain system integrity during operation. Genuine Toyota Union Bolt offers compatibility with Toyota vehicles and is covered by Toyota’s genuine parts…

3. Arctic Cat – Union Bolt

Domain: shop.arcticcat.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Union Bolt”, “part_number”: “3004-346”, “price”: “$4.71”, “inventory_status”: “In stock”, “purchase_increment”: “2”}

4. Würth – Union Bolt for Central Lubrication Units

Domain: eshop.wuerth-industrie.com

Registered: 1999 (26 years)

Introduction: Union bolt for low-viscosity grease central lubrication units. Application area: For the connection of a line to connection pieces. Usage notice: To be used in conjunction with a tapered ring. Available in 1 version. Prices for customers after login. Exclusively for trade customers. RAL-colour code selection required for order. Note: On-screen visualisation of the colour differs from real colour s…

5. ATE – Union Bolt

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“item_name”:”ATE Union Bolt”,”item_number”:”154188763383″,”manufacturer_part_number”:”03.3516-2300.1″,”interchange_part_number”:”390317 A0578″,”condition”:”New”,”quantity_available”:2,”price”:”$6.34″,”shipping_cost”:”$16.87″,”estimated_delivery”:”Wed, Oct 29 – Thu, Nov 27″,”seller_name”:”Cars245 Online-Store Americas”,”seller_feedback”:”99.1% positive feedback”,”returns_accepted”:”No”,”shipping_o…

Strategic Sourcing Conclusion and Outlook for union bolt

In today’s competitive landscape, strategic sourcing of union bolts plays a pivotal role in ensuring operational efficiency and cost-effectiveness for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe continue to evolve, understanding the diverse applications and specifications of union bolts becomes essential. Sourcing from reliable suppliers not only guarantees product quality but also fosters long-term partnerships that can lead to better pricing and supply chain stability.

Key considerations in strategic sourcing include evaluating the reliability of suppliers, understanding regional market dynamics, and recognizing the importance of compliance with local regulations. By leveraging these insights, businesses can optimize their procurement processes, reduce lead times, and enhance product availability.

Illustrative image related to union bolt

Looking ahead, the demand for high-quality union bolts is expected to grow, driven by advancements in technology and increasing industrial activities. International buyers are encouraged to engage with suppliers who demonstrate a commitment to innovation and sustainability. By prioritizing strategic sourcing, companies can position themselves to capitalize on emerging opportunities in the global marketplace. Embrace this approach to elevate your procurement strategy and secure a competitive edge in your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to union bolt