Everything You Need to Know About Types Of Dust Collectors Sourcing in 2025

Introduction: Navigating the Global Market for types of dust collectors

In the complex landscape of industrial operations, sourcing the right types of dust collectors is critical for maintaining air quality and ensuring compliance with health and safety regulations. B2B buyers, especially those from Africa, South America, the Middle East, and Europe, face the challenge of navigating diverse market options while balancing cost, efficiency, and regulatory requirements. This guide serves as a comprehensive resource, detailing various dust collector types, including pulse jet, shaker, cartridge, and cyclone systems, along with their specific applications in different industrial settings.

As you delve into this guide, you will gain insights into how to effectively vet suppliers, assess the total cost of ownership, and understand the nuances of each dust collection system. We aim to empower decision-makers with actionable knowledge to facilitate informed purchasing decisions that align with their operational needs and regulatory obligations. By providing a thorough understanding of the types of dust collectors available, along with best practices for implementation and maintenance, this guide positions you to enhance workplace safety, improve air quality, and ultimately drive operational efficiency. Whether you’re operating in a manufacturing plant or a processing facility, the information presented here will be invaluable in selecting the right dust collection solution tailored to your unique requirements.

Understanding types of dust collectors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pulse Jet Dust Collectors | Utilizes compressed air for filter cleaning; high efficiency | Manufacturing, woodworking, food processing | Pros: Continuous operation, high filtration efficiency. Cons: Higher initial costs. |

| Shaker Dust Collectors | Mechanical shaking mechanism for filter cleaning; offline cleaning possible | Metalworking, construction, textile industries | Pros: Lower operational cost, easy maintenance. Cons: Requires manual intervention for cleaning. |

| Cartridge Collectors | Compact design with high filtration efficiency; quick filter replacement | Small workshops, laboratories, fine dust applications | Pros: Space-saving, minimal safety hazards. Cons: Limited to certain airflow rates. |

| Cyclone Dust Collectors | Uses centrifugal force for dust separation; often a pre-cleaning step | Bulk material handling, mining, recycling | Pros: Effective for larger particles, low maintenance. Cons: Less effective for fine dust. |

| Explosion-Proof Collectors | Designed to prevent ignition of flammable dust/gases; robust construction | Chemical, pharmaceutical, and food industries | Pros: Enhanced safety in hazardous environments. Cons: Higher costs due to specialized design. |

What Are the Key Characteristics of Pulse Jet Dust Collectors?

Pulse jet dust collectors are renowned for their efficiency in removing particulate matter from industrial air streams. They employ a sophisticated system where compressed air is released in short bursts to clean the filter bags, allowing for continuous operation without downtime. This makes them ideal for manufacturing environments where air quality is critical. When considering a purchase, buyers should evaluate the initial investment against long-term operational efficiency and compliance with environmental regulations.

How Do Shaker Dust Collectors Function in Industrial Settings?

Shaker dust collectors rely on a mechanical shaking mechanism to dislodge dust from filter bags. This can be done either manually or via a motorized system. They are particularly useful in industries where compressed air is not readily available. While they are easier to maintain and more cost-effective than some alternatives, they may require more manual intervention, which can be a consideration for companies looking to minimize labor costs.

What Advantages Do Cartridge Collectors Offer for Smaller Facilities?

Cartridge collectors are designed for environments with limited space, providing high filtration efficiency despite their compact size. They are particularly effective in applications requiring quick filter changes and minimal safety risks, making them suitable for small workshops and laboratories. Buyers should consider the specific airflow needs of their operations, as these systems are best suited for certain environments where space and efficiency are paramount.

Why Are Cyclone Dust Collectors Used as Pre-Cleaners?

Cyclone dust collectors utilize centrifugal force to separate larger particles from the air stream, making them an excellent choice for pre-cleaning before finer filtration systems. They are commonly employed in bulk material handling and mining applications. While they require low maintenance and are effective for larger particles, buyers should note that they are less effective for fine dust, which may necessitate additional filtration solutions.

What Makes Explosion-Proof Collectors Essential in Certain Industries?

Explosion-proof dust collectors are specifically engineered to handle environments where flammable dust or gases may be present, such as in chemical and pharmaceutical industries. Their robust design prevents ignition and ensures safety in hazardous conditions. While they provide critical safety benefits, the specialized design leads to higher costs, making it essential for buyers to assess their specific safety requirements and budget constraints before purchasing.

Key Industrial Applications of types of dust collectors

| Industry/Sector | Specific Application of types of dust collectors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Dust collection in metalworking and machining processes | Enhances air quality, reduces health risks, improves productivity | Ensure compliance with local regulations and safety standards |

| Food Processing | Collection of flour and particulate matter in milling | Prevents contamination, improves worker safety, and maintains product quality | Consider hygiene standards and ease of maintenance |

| Pharmaceuticals | Dust control in tablet manufacturing and powder handling | Ensures product purity, minimizes cross-contamination | Look for systems with HEPA filtration and compliance certifications |

| Construction | Dust extraction during concrete cutting and grinding | Reduces respiratory hazards, improves site safety | Evaluate mobility and ease of installation in varying environments |

| Woodworking | Collection of wood dust and particles | Enhances workshop safety, improves equipment lifespan | Assess filter efficiency and compatibility with existing systems |

How Are Dust Collectors Used in Manufacturing, and What Problems Do They Solve?

In the manufacturing sector, dust collectors play a critical role in metalworking and machining processes, where fine metallic particles are generated. By capturing these particles, dust collectors enhance air quality, thereby reducing health risks associated with inhalation of harmful dust. For international buyers, it is crucial to ensure that the dust collection systems comply with local regulations, such as those set by OSHA or the EPA, to avoid costly fines and operational disruptions.

What Are the Applications of Dust Collectors in Food Processing?

In food processing, particularly in milling operations, dust collectors are essential for capturing flour and other particulate matter. This application not only prevents contamination of the final product but also significantly improves worker safety by minimizing slip hazards and respiratory issues. Buyers in this sector should prioritize systems that meet stringent hygiene standards and allow for easy maintenance to ensure compliance with food safety regulations.

Illustrative image related to types of dust collectors

How Do Dust Collectors Benefit the Pharmaceutical Industry?

Pharmaceutical manufacturing involves handling fine powders, where dust collectors are utilized to control dust emissions during tablet production. This is vital for ensuring product purity and minimizing cross-contamination between different substances. Buyers should look for dust collection systems equipped with HEPA filters, as they provide the highest level of filtration efficiency, ensuring compliance with industry standards and maintaining the integrity of sensitive pharmaceutical products.

What Is the Importance of Dust Extraction in Construction?

In the construction industry, dust collectors are indispensable during concrete cutting and grinding activities. They help reduce respiratory hazards and improve site safety by capturing harmful silica dust and other particulates. For buyers, evaluating the mobility and ease of installation of dust collection systems is crucial, especially in dynamic construction environments where flexibility and adaptability are required.

How Do Woodworking Operations Benefit from Dust Collectors?

In woodworking, dust collectors are used to extract wood dust and particles generated during cutting, sanding, and finishing processes. This not only enhances workshop safety by reducing fire hazards associated with dust accumulation but also prolongs the lifespan of machinery by preventing clogging. Buyers should assess filter efficiency and ensure compatibility with existing systems to optimize performance and maintain operational continuity.

3 Common User Pain Points for ‘types of dust collectors’ & Their Solutions

Scenario 1: Overcoming Inefficiencies in Dust Collection Systems

The Problem:

A manufacturing facility in South America experiences frequent operational disruptions due to dust buildup on equipment and work surfaces. The existing dust collection system struggles to maintain optimal airflow, leading to reduced efficiency and increased maintenance costs. Employees express concerns about health risks associated with inhaling airborne particulates, which creates a need for an effective solution to ensure compliance with workplace safety regulations.

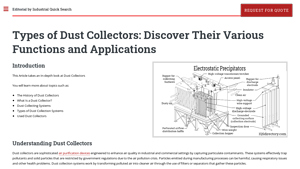

Illustrative image related to types of dust collectors

The Solution:

To address these inefficiencies, it’s crucial to evaluate the current dust collector type and its suitability for the facility’s specific operations. Consider upgrading to a pulse jet dust collector, which offers superior filtration efficiency. This system utilizes bursts of compressed air to clean the filter bags, maintaining consistent airflow and minimizing downtime. When sourcing a pulse jet system, assess the filter bag materials and their compatibility with the types of dust generated in the facility. Engage with suppliers that offer customization options tailored to the unique dust characteristics and regulatory requirements of your industry. Regular monitoring and maintenance schedules should also be established to ensure optimal performance and compliance with health standards.

Scenario 2: Managing Space Constraints in Dust Collector Installation

The Problem:

A European startup in the woodworking sector faces a significant challenge with limited floor space for their dust collection needs. The existing large baghouse system is cumbersome and inefficient for their smaller production area, leading to inadequate dust management and potential regulatory violations. This scenario not only affects productivity but also increases the risk of fines from local environmental authorities.

The Solution:

For businesses operating in tight spaces, a cartridge dust collector is an ideal solution. Cartridge collectors are designed to provide high filtration efficiency in a compact footprint, making them suitable for smaller workshops. When selecting a cartridge system, prioritize units that allow for external filter changes to minimize downtime and enhance safety. Additionally, consult with manufacturers to explore options that include HEPA filters for superior air quality. Implementing a centralized dust collection system can also optimize space utilization by connecting multiple workstations to a single collector, thereby improving overall dust management while adhering to safety regulations.

Scenario 3: Ensuring Safety in Explosive Environments

The Problem:

In the Middle East, a chemical processing plant operates in an environment where flammable dust is generated. The existing dust collector is not explosion-proof, raising serious safety concerns about potential ignition sources and compliance with industry regulations. The management team is under pressure to enhance safety measures to protect employees and avoid costly shutdowns.

The Solution:

To mitigate these risks, it is essential to invest in explosion-proof dust collectors specifically designed to handle flammable materials. When sourcing these systems, ensure they meet relevant safety standards such as NFPA and OSHA regulations. An effective solution is to implement a cyclone dust collector as a pre-cleaner, which can separate heavier particles before they reach the main filtration system. This setup reduces the load on the primary collector and minimizes the risk of dust accumulation. Collaborate with suppliers who have expertise in hazardous environments to ensure that the selected dust collector is equipped with features like spark detection and extinguishing systems, further enhancing workplace safety. Regular training sessions for employees on dust handling and safety protocols will also be vital in fostering a culture of safety within the organization.

Strategic Material Selection Guide for types of dust collectors

What Are the Key Materials Used in Dust Collectors?

Selecting the right materials for dust collectors is crucial for ensuring optimal performance, longevity, and compliance with industry standards. Below, we analyze four common materials used in various types of dust collectors, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Do Different Fabrics Affect Dust Collector Performance?

1. Polyester Fabric

Key Properties: Polyester fabric is known for its excellent tensile strength and resistance to abrasion. It typically operates effectively at temperatures up to 260°C (500°F) and has good chemical resistance against a range of acids and bases.

Pros & Cons: Polyester is durable and relatively inexpensive, making it a popular choice for many applications. However, its performance can degrade when exposed to high humidity or certain chemicals, which may limit its suitability in specific environments.

Impact on Application: Polyester is suitable for general dust collection applications, especially in industries like woodworking and metalworking. However, it may not be the best choice for environments with extreme temperatures or aggressive chemicals.

Considerations for International Buyers: Buyers should ensure that polyester fabrics meet local compliance standards, such as ASTM in the U.S. or DIN in Germany. In regions with high humidity, such as parts of Africa and South America, it is essential to evaluate the fabric’s performance in humid conditions.

2. Polypropylene Fabric

Key Properties: Polypropylene fabric is lightweight and has excellent chemical resistance, particularly against acids and bases. It typically operates effectively at temperatures up to 90°C (194°F).

Pros & Cons: The primary advantage of polypropylene is its cost-effectiveness and chemical resistance. However, it has lower tensile strength compared to polyester and can be less durable in high-temperature applications.

Illustrative image related to types of dust collectors

Impact on Application: This material is ideal for industries dealing with corrosive dust, such as chemical manufacturing. Its lightweight nature allows for easy handling and installation.

Considerations for International Buyers: Polypropylene’s lower temperature rating may limit its use in certain industrial applications. Buyers should also check for compliance with local regulations, especially in the Middle East, where chemical processing is prevalent.

3. Fiberglass Fabric

Key Properties: Fiberglass fabric can withstand high temperatures, often exceeding 300°C (572°F), and offers excellent dimensional stability. It is also resistant to many chemicals, making it suitable for harsh environments.

Pros & Cons: The durability and high-temperature resistance of fiberglass are significant advantages. However, it is more expensive than other materials and can be challenging to handle due to its rigidity.

Illustrative image related to types of dust collectors

Impact on Application: Fiberglass is often used in high-temperature applications, such as foundries and glass manufacturing. Its ability to handle extreme conditions makes it a preferred choice for specialized industries.

Considerations for International Buyers: Buyers in Europe and North America often have stringent regulations regarding emissions and material safety. Ensuring compliance with standards such as REACH in Europe is essential when selecting fiberglass for dust collectors.

4. Stainless Steel

Key Properties: Stainless steel offers exceptional corrosion resistance and can withstand high temperatures and pressures. It is durable and can last for many years with minimal maintenance.

Pros & Cons: The primary advantage of stainless steel is its longevity and resistance to corrosion, making it ideal for harsh environments. However, it is significantly more expensive than fabric options and can be heavier, which may complicate installation.

Impact on Application: Stainless steel is commonly used in food processing, pharmaceuticals, and chemical industries where hygiene and corrosion resistance are critical.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel required for their applications. Compliance with international standards, such as ISO and ASTM, is crucial, particularly in regions with strict food safety regulations.

Summary Table of Material Selection for Dust Collectors

| Material | Typical Use Case for types of dust collectors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester Fabric | General dust collection | Durable and cost-effective | Performance may degrade in humidity | Low |

| Polypropylene Fabric | Corrosive dust environments | Excellent chemical resistance | Lower tensile strength and durability | Low |

| Fiberglass Fabric | High-temperature applications | High-temperature resistance | More expensive and challenging to handle | High |

| Stainless Steel | Food processing and pharmaceuticals | Exceptional durability and corrosion resistance | High cost and heavier weight | High |

This strategic material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions tailored to their specific dust collection needs.

In-depth Look: Manufacturing Processes and Quality Assurance for types of dust collectors

What Are the Main Stages of Manufacturing Dust Collectors?

The manufacturing of dust collectors involves several critical stages that ensure the end product meets performance and safety standards. The typical manufacturing process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Dust Collector Production?

The first stage, material preparation, involves sourcing high-quality raw materials that are essential for durability and functionality. Common materials include high-grade steel, aluminum, and specialized fabrics for filter media. Suppliers must ensure that materials meet industry specifications and standards, such as ASTM or ISO certifications. This phase often includes thorough inspections and testing of incoming materials, known as Incoming Quality Control (IQC), to confirm their integrity before they enter the production line.

What Techniques Are Used in the Forming Stage?

Once materials are prepared, the forming stage begins. This typically involves several techniques, including:

- Cutting and Shaping: Raw materials are cut to size using advanced laser cutting or plasma cutting technologies to ensure precision.

- Welding and Fabrication: Components are welded together using MIG or TIG welding methods, ensuring strong and durable joints. This stage may also include forming processes such as bending and stamping to create necessary shapes for dust collector bodies and frames.

- Filter Media Preparation: For fabric filtration systems, filter media, including bag filters or cartridges, are sewn or molded into required shapes. This step is crucial for ensuring optimal airflow and dust capture efficiency.

These processes must be executed under strict quality control measures to minimize defects.

How Is the Assembly Process Structured for Dust Collectors?

The assembly stage is where individual components come together to form a complete dust collector system. This process typically includes:

- Component Integration: Key components such as motors, fans, and control systems are integrated with the main body of the dust collector. This may involve both manual assembly and the use of automated systems for precision.

- Electrical Wiring: Proper wiring and connections are established for operational efficiency. This includes the integration of sensors for monitoring dust levels and system performance.

- System Calibration: Once assembled, the system undergoes calibration to ensure it operates within specified parameters. This step is crucial for ensuring that the dust collector meets performance requirements.

What Finishing Techniques Are Employed in Dust Collector Manufacturing?

The finishing stage focuses on enhancing the appearance and longevity of dust collectors. Key techniques include:

- Surface Treatment: Treatments such as powder coating or galvanization are applied to protect against corrosion and wear. This is particularly important for dust collectors used in harsh environments.

- Quality Inspection: A final inspection is conducted to check for any defects or inconsistencies. This is often referred to as Final Quality Control (FQC) and involves visual inspections, measurements, and functional tests.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is essential in the manufacturing of dust collectors to ensure compliance with international and industry-specific standards. Buyers should be familiar with several key certifications:

- ISO 9001: This international standard focuses on quality management systems and is crucial for manufacturers aiming to meet customer and regulatory requirements.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: Relevant for dust collectors used in oil and gas industries, API standards ensure that products meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints in Dust Collector Manufacturing?

Quality control checkpoints are vital throughout the manufacturing process to ensure that each dust collector meets the required standards. Key checkpoints include:

Illustrative image related to types of dust collectors

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival at the manufacturing facility.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to ensure that processes are adhering to quality standards.

- Final Quality Control (FQC): The final product is subjected to rigorous testing to verify that it meets all specifications before shipment.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are effective strategies:

- Conduct Audits: Regular audits of suppliers can provide insight into their quality management practices. This includes reviewing documentation and inspecting production facilities.

- Request Quality Reports: Suppliers should be able to provide detailed quality assurance reports that outline their compliance with international standards and internal processes.

- Engage Third-Party Inspectors: Employing independent third-party inspectors can offer an unbiased assessment of the supplier’s quality control measures and product reliability.

What Are the QC Nuances for International B2B Buyers?

International buyers must navigate various nuances in quality control that can impact their sourcing decisions. Key considerations include:

- Understanding Local Regulations: Different regions may have specific regulations regarding dust collector performance and safety. Familiarity with these can help buyers ensure compliance.

- Cultural Differences in Quality Standards: Buyers should be aware that quality expectations may vary by region. Engaging in clear communication with suppliers about quality requirements can mitigate misunderstandings.

- Logistical Challenges: Shipping and handling can affect product quality. Buyers should work with suppliers to ensure that products are packaged and transported in a manner that minimizes damage.

By understanding these manufacturing processes and quality assurance standards, B2B buyers can make informed decisions when sourcing dust collectors, ensuring they select reliable suppliers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘types of dust collectors’

In the pursuit of effective dust management solutions, this practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure different types of dust collectors. By following these steps, you can ensure that your investment aligns with your operational needs and industry standards.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your facility is critical. Consider factors such as the type of dust generated, airflow requirements, and the layout of your workspace. This will help in selecting a dust collector that meets your filtration efficiency needs while accommodating the available space.

- Dust Type: Identify whether you are dealing with fine dust, heavy particles, or hazardous materials.

- Airflow Requirements: Determine the cubic feet per minute (CFM) needed to maintain optimal air quality.

Step 2: Assess Compliance with Regulatory Standards

Ensure that your selected dust collectors comply with local and international regulations, such as OSHA and EPA standards. Non-compliance can lead to hefty fines and operational shutdowns.

- Documentation: Request compliance certificates and documentation from suppliers.

- Industry-Specific Standards: Check if your industry has additional requirements, such as NFPA compliance for combustible dust.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure reliability and quality. Investigate their reputation within the industry by requesting company profiles, case studies, and references from similar businesses.

- Experience: Look for suppliers with a proven track record in your industry.

- Technical Support: Assess the level of customer service and technical support they offer post-purchase.

Step 4: Consider Customization Options

Customization can significantly enhance the performance of dust collectors in specialized applications. Discuss with suppliers the possibility of tailoring systems to meet your unique operational challenges.

- Modular Designs: Inquire about modular systems that can be expanded as your needs grow.

- Specific Features: Ask about features like HEPA filters for enhanced air quality or explosion-proof designs for hazardous environments.

Step 5: Compare Total Cost of Ownership

Look beyond the initial purchase price to evaluate the total cost of ownership (TCO). This includes installation, maintenance, energy consumption, and potential downtime.

- Energy Efficiency: Investigate energy consumption ratings to identify cost-saving options.

- Maintenance Requirements: Assess the ease of maintenance and the availability of spare parts.

Step 6: Request Demonstrations and Samples

Whenever possible, request demonstrations or samples of the dust collectors you are considering. This will allow you to assess their performance firsthand and ensure they meet your expectations.

- Live Testing: If feasible, arrange for a trial period in your facility.

- Performance Metrics: Evaluate the effectiveness of the dust collector in real-time conditions.

Step 7: Finalize Your Purchase Agreement

Before finalizing your purchase, carefully review the terms and conditions of the agreement. Pay attention to warranties, return policies, and service agreements to safeguard your investment.

- Warranty Coverage: Ensure that the warranty covers critical components and offers adequate protection.

- Service Agreements: Consider long-term service agreements for maintenance and support to keep your system running smoothly.

By following this checklist, B2B buyers can navigate the complexities of sourcing dust collectors effectively, ensuring they choose the right solution for their operational needs.

Comprehensive Cost and Pricing Analysis for types of dust collectors Sourcing

What Are the Key Cost Components in Dust Collector Manufacturing?

When sourcing dust collectors, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the total cost. High-quality steel, filter media, and components like motors and sensors are common materials used in dust collectors. For instance, HEPA filters, known for their efficiency, can raise costs but are crucial for industries requiring stringent air quality standards.

-

Labor: Labor costs can vary based on the complexity of the dust collector’s design and the skills required for assembly. Skilled labor may command higher wages but is essential for ensuring quality and efficiency in production.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, equipment depreciation, and facility costs. Efficient manufacturing processes can help keep these costs down.

-

Tooling: Initial tooling costs can be substantial, especially for custom dust collectors. These costs are amortized over the production volume, so larger orders can reduce the per-unit tooling expense.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet industry standards and customer specifications. While this adds to the cost, it can prevent costly recalls and enhance customer satisfaction.

-

Logistics: Shipping and handling costs vary based on the destination and shipping methods. International buyers should consider the implications of customs duties and taxes, which can significantly affect overall costs.

-

Margin: Suppliers typically apply a margin to cover their operational costs and profit. Understanding the market and competitive pricing can help buyers negotiate better terms.

How Do Price Influencers Affect Dust Collector Sourcing?

Several factors can influence the pricing of dust collectors, making it essential for buyers to evaluate their specific needs and market conditions.

-

Volume/MOQ (Minimum Order Quantity): Ordering in larger quantities often leads to price discounts. Suppliers may have set MOQs, and understanding these can help buyers negotiate better pricing.

-

Specifications and Customization: Customized dust collectors tailored to specific applications may incur additional costs. Buyers should weigh the benefits of customization against standard models to determine the best value.

-

Materials: The choice of materials not only affects durability but also pricing. Premium materials can elevate costs but may result in longer-lasting equipment, providing better value over time.

-

Quality and Certifications: Dust collectors that meet international standards or possess certifications (e.g., ISO, CE) may come at a premium. Buyers should assess whether these certifications are necessary for their operations and markets.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may command higher prices due to their proven track record, while emerging suppliers might offer competitive rates to gain market share.

-

Incoterms: The terms of shipping can significantly impact the total cost. Buyers should clarify whether the price includes shipping, insurance, and duties, as this will affect budgeting and financial planning.

What Are the Best Practices for B2B Buyers in Dust Collector Sourcing?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several best practices when sourcing dust collectors.

-

Negotiation: Leverage your understanding of the cost components and market conditions to negotiate favorable terms. Don’t hesitate to seek quotes from multiple suppliers to compare offerings.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes not just purchase price but also maintenance, energy consumption, and operational efficiency over time. Sometimes, a higher upfront cost can lead to lower operational costs.

-

Pricing Nuances for International Buyers: Different regions may have varying price structures due to local manufacturing capabilities, import duties, and logistics costs. Understanding these nuances can lead to better sourcing decisions.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including their manufacturing capabilities, customer reviews, and delivery timelines. Establishing a solid relationship with reputable suppliers can lead to better pricing and service.

-

Consider Local Regulations: Ensure that the dust collectors comply with local environmental and safety regulations, which can affect installation and operational costs.

In conclusion, buyers must navigate a complex landscape of costs and pricing factors when sourcing dust collectors. By understanding these elements and adopting strategic sourcing practices, businesses can achieve optimal value and compliance with international standards.

Alternatives Analysis: Comparing types of dust collectors With Other Solutions

Understanding Alternatives to Dust Collectors

In industrial environments, the need for effective air quality management is paramount. While dust collectors are widely used for capturing particulate matter, there are alternative solutions that can also fulfill similar roles. This analysis compares various types of dust collectors against other viable methods, providing insights for B2B buyers looking to optimize their operations.

| Comparison Aspect | Types Of Dust Collectors | Alternative 1 Name: Central Vacuum Systems | Alternative 2 Name: Industrial Blowers |

|---|---|---|---|

| Performance | High efficiency in capturing fine dust and particulate matter. | Effective for continuous cleaning of large areas but may not capture fine particles as effectively. | Primarily enhances airflow; not specifically designed for dust collection. |

| Cost | Initial investment can be high, but long-term operational savings can be realized. | Moderate initial investment, with lower operational costs. | Generally lower initial costs, but can incur higher energy costs over time. |

| Ease of Implementation | Requires significant installation effort and space. | Easier to implement with minimal structural changes needed. | Simple installation, often portable, but may require additional ductwork. |

| Maintenance | Regular maintenance needed to ensure optimal performance; can be complex. | Requires routine checks but generally easier to maintain. | Low maintenance, but may need frequent cleaning of filters or fans. |

| Best Use Case | Ideal for manufacturing environments with high dust generation and strict air quality standards. | Best for facilities needing continuous cleaning and flexibility in operations. | Suitable for environments where airflow needs to be increased without strict dust capture requirements. |

What Are the Pros and Cons of Central Vacuum Systems?

Central vacuum systems are designed to remove dirt and dust from a facility using a network of pipes that connect to a central unit. Pros include ease of implementation and lower operational costs, making them attractive for facilities looking for a less invasive solution. However, they may not capture fine particulates as effectively as dust collectors, limiting their effectiveness in environments with stringent air quality requirements.

Illustrative image related to types of dust collectors

How Do Industrial Blowers Compare?

Industrial blowers enhance airflow in a workspace, making them useful for improving ventilation. Their pros include lower initial costs and ease of installation, which can be beneficial for businesses with tight budgets. However, they do not specifically target dust collection, which can lead to ongoing air quality issues. For facilities where dust is a secondary concern, industrial blowers may suffice, but they are not a substitute for dedicated dust collection systems in high-dust environments.

Choosing the Right Solution for Your Needs

Selecting the right dust management solution requires a comprehensive understanding of your facility’s specific needs and constraints. B2B buyers should assess the volume and type of dust generated, regulatory compliance requirements, and budgetary constraints. For industries with stringent air quality standards, investing in a robust dust collector may be necessary. Conversely, for operations where dust is less of an issue, alternatives like central vacuum systems or industrial blowers might provide a more cost-effective solution. Ultimately, the decision should align with both operational goals and the overall health and safety of the workplace.

Essential Technical Properties and Trade Terminology for types of dust collectors

What are the Key Technical Properties of Dust Collectors?

When selecting a dust collector for industrial applications, understanding specific technical properties is crucial for ensuring optimal performance and compliance with safety standards. Here are several critical specifications to consider:

-

Filtration Efficiency

– This refers to the dust collector’s ability to remove particulate matter from the air. Efficiency ratings, often expressed as a percentage, indicate how effectively the system captures dust particles. High filtration efficiency is essential for maintaining air quality and meeting environmental regulations, particularly in industries with stringent air quality standards. -

Airflow Capacity

– Measured in cubic feet per minute (CFM), airflow capacity is the volume of air that can be processed by the dust collector. It is vital to match the airflow capacity to the specific needs of your facility, as insufficient airflow can lead to dust accumulation and potential health hazards. B2B buyers should evaluate their operational requirements to ensure that the selected dust collector can handle peak dust loads. -

Material Grade

– The materials used in the construction of dust collectors, such as the housing and filter media, significantly impact durability and performance. Common materials include carbon steel, stainless steel, and specialized polymers. Selecting the appropriate material grade is crucial for ensuring longevity, especially in corrosive environments or where high temperatures are present. -

Cleaning Mechanism

– Dust collectors utilize various cleaning mechanisms, including pulse jet, shaker, and automatic systems. Understanding the cleaning mechanism is essential for maintaining efficiency and minimizing downtime. For example, pulse jet systems allow for continuous operation while cleaning, which is advantageous for high-volume applications. -

Noise Level

– Noise levels, measured in decibels (dB), can affect workplace safety and employee comfort. Many regions have regulations governing permissible noise levels in industrial settings. Buyers should consider dust collectors designed to operate quietly to enhance the working environment and comply with local regulations. -

Size and Configuration

– The physical dimensions and configuration of the dust collector can affect its installation and operation. Buyers should assess available space and determine whether a modular, compact, or traditional design best meets their needs. Proper sizing ensures effective operation without wasting energy or space.

Which Trade Terms are Essential in the Dust Collector Industry?

Familiarity with industry-specific jargon is vital for effective communication and negotiation in the dust collector market. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that manufactures components or products that are sold under another company’s brand. Understanding OEM relationships can help buyers identify reliable manufacturers and assess product quality. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers who need to manage inventory levels and ensure cost-effectiveness in procurement. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a detailed price quote for specific products or services. It is a critical step in the purchasing process, allowing buyers to compare prices, terms, and conditions from multiple suppliers. -

Incoterms (International Commercial Terms)

– Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight), is essential for avoiding misunderstandings regarding shipping, insurance, and delivery obligations. -

EPA Compliance

– Compliance with Environmental Protection Agency (EPA) regulations is crucial for dust collectors operating in the United States. Understanding these regulations helps ensure that selected dust collection systems meet necessary environmental standards, preventing legal issues and promoting sustainability. -

HEPA (High-Efficiency Particulate Air) Filters

– HEPA filters are specialized filters designed to trap 99.97% of particles that are 0.3 microns or larger. They are critical for applications requiring high air quality, such as pharmaceuticals and electronics manufacturing. Knowledge of HEPA filters can guide buyers in selecting appropriate filtration options for specific industry needs.

By understanding these essential technical properties and trade terminology, B2B buyers can make informed decisions when sourcing dust collectors, ultimately ensuring compliance, efficiency, and safety in their operations.

Navigating Market Dynamics and Sourcing Trends in the types of dust collectors Sector

What Are the Current Market Dynamics and Key Trends in the Dust Collector Sector?

The global dust collector market is witnessing robust growth driven by increasing industrialization, stringent environmental regulations, and heightened awareness of occupational health and safety. As manufacturers from regions such as Africa, South America, the Middle East, and Europe ramp up production capabilities, the demand for efficient dust collection systems is surging. A significant trend is the adoption of advanced technologies, such as IoT-enabled dust collectors, which allow for real-time monitoring and predictive maintenance. This tech-savvy approach not only enhances operational efficiency but also minimizes downtime, appealing to B2B buyers looking for cost-effective solutions.

Moreover, the shift towards automation in manufacturing processes is influencing sourcing trends. Automated dust collection systems are becoming increasingly popular, as they reduce human intervention and improve safety. Another emerging trend is the customization of dust collection systems to meet specific industry needs. This bespoke approach is particularly relevant for buyers in specialized sectors, such as pharmaceuticals and food processing, where compliance with stringent regulations is paramount.

The impact of geopolitical factors cannot be overlooked, especially in regions like Europe, where regulatory compliance is becoming more stringent. B2B buyers are now more inclined to source dust collectors that not only meet local compliance standards but also offer flexibility to adapt to future regulations. In summary, international buyers are navigating a dynamic market characterized by technological advancements, customization, and compliance-driven sourcing strategies.

How Are Sustainability and Ethical Sourcing Influencing the Dust Collector Market?

Sustainability is increasingly becoming a priority in the dust collector sector as companies recognize the environmental impact of their operations. B2B buyers are now seeking dust collectors that minimize energy consumption and reduce emissions. Manufacturers are responding by developing energy-efficient models that utilize advanced filtration technologies and materials that are easier to recycle or dispose of responsibly.

Ethical sourcing practices are also gaining traction, with companies emphasizing the importance of supply chain transparency. Buyers are more likely to engage with suppliers who demonstrate a commitment to ethical manufacturing processes and materials. Certifications such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) for green building practices are becoming essential for manufacturers aiming to enhance their marketability.

In addition, the use of ‘green’ materials in dust collector production is becoming a common expectation among B2B buyers. For instance, utilizing biodegradable filter media or recyclable components can significantly improve a company’s sustainability profile. As the market evolves, companies that prioritize sustainability and ethical sourcing will likely gain a competitive edge, appealing to environmentally conscious buyers across various international markets.

How Has the Dust Collector Industry Evolved Over Time?

The evolution of dust collectors dates back to the early industrial revolution when rudimentary systems were employed to manage airborne particulates. Initially, these systems were simplistic, often involving manual cleaning methods that were inefficient and labor-intensive. However, as industrial processes became more complex, the need for advanced dust collection solutions emerged.

The introduction of fabric filtration systems, such as baghouses, marked a significant milestone in the industry. These systems offered improved efficiency and reliability, enabling manufacturers to comply with emerging environmental regulations. Over the decades, technological advancements have led to the development of more sophisticated systems, such as pulse jet and cartridge collectors, which provide higher filtration efficiencies and lower maintenance costs.

Today, the dust collector market is characterized by a focus on automation, energy efficiency, and sustainability. The integration of IoT technology into dust collection systems has further transformed the landscape, allowing for smarter, more responsive solutions that meet the needs of modern manufacturing environments. As the industry continues to evolve, B2B buyers are presented with a wealth of options that can enhance operational efficiency while also addressing environmental concerns.

Illustrative image related to types of dust collectors

Frequently Asked Questions (FAQs) for B2B Buyers of types of dust collectors

-

1. How do I solve dust contamination issues in my facility?

To effectively solve dust contamination, first assess the specific types of dust generated in your facility. Implementing the right dust collector type is crucial; options include pulse jet, shaker, and cyclone dust collectors. Each type offers unique benefits based on your operation’s size, dust characteristics, and airflow requirements. Regular maintenance and filter replacement schedules will also help ensure optimal performance. Consulting with a dust collection specialist can provide tailored solutions that meet your facility’s specific needs. -

2. What is the best type of dust collector for my manufacturing process?

The best type of dust collector for your manufacturing process depends on several factors, including the type of dust produced, the volume of air to be filtered, and space constraints. Pulse jet dust collectors are excellent for high dust loads and continuous operation, while cartridge collectors are suited for smaller spaces with lower dust volumes. Cyclone collectors can serve as pre-cleaners to enhance the efficiency of other systems. Analyzing your operational needs will guide you in selecting the most efficient system. -

3. How do I ensure compliance with international dust collection regulations?

To ensure compliance with international dust collection regulations, familiarize yourself with local and global standards, such as those set by OSHA and the EPA. Collaborate with suppliers who offer equipment designed to meet these standards and can provide documentation of compliance. Regular audits and maintenance checks should be conducted to ensure ongoing adherence to safety and environmental regulations. Additionally, consider investing in customized solutions that align with the specific requirements of your industry and region. -

4. What are the customization options for dust collectors?

Customization options for dust collectors can include varying filter types, sizes, and configurations to suit specific operational needs. You may also consider features like automation capabilities, explosion-proof designs, and enhanced filtration technologies such as HEPA filters. Suppliers often provide tailored solutions that can incorporate specific demands, such as reduced noise levels or compact designs for limited spaces. Engaging in discussions with potential suppliers about your unique requirements will help you identify the best options. -

5. What are the minimum order quantities (MOQs) when purchasing dust collectors?

Minimum order quantities (MOQs) for dust collectors can vary significantly between manufacturers and regions. Some suppliers may have low MOQs for standard models, while custom solutions may require higher quantities to justify production costs. It is advisable to inquire directly with suppliers about their MOQs and negotiate terms based on your project needs. This can help optimize your budget and ensure you have the right equipment available when required. -

6. What payment terms should I expect when sourcing dust collectors internationally?

Payment terms for international purchases of dust collectors typically range from upfront payment to net 30 or net 60 days after delivery. Some suppliers may also offer financing options or payment in installments based on project milestones. It is crucial to clarify these terms before finalizing contracts, as they can impact your cash flow. Working with reputable suppliers who have transparent policies will help mitigate risks and ensure a smooth transaction process. -

7. How can I vet suppliers of dust collectors in international markets?

To vet suppliers of dust collectors, start by researching their industry reputation, experience, and customer reviews. Request references from previous clients and check their compliance with international quality standards. Engage in direct conversations to assess their customer service and responsiveness. Additionally, consider visiting their manufacturing facilities if possible or seeking third-party verification services. This thorough vetting process will help ensure you partner with reliable suppliers. -

8. What logistics considerations should I keep in mind when importing dust collectors?

When importing dust collectors, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Ensure that the supplier provides all necessary documentation, including invoices, packing lists, and compliance certificates. Calculate total landed costs, including tariffs and taxes, to avoid budget overruns. Partnering with a logistics provider experienced in handling industrial equipment can streamline the process and mitigate potential delays or complications during transit.

Top 1 Types Of Dust Collectors Manufacturers & Suppliers List

1. IQS Directory – Dust Collectors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Dust collectors are sophisticated air purification devices designed to enhance air quality in industrial and commercial settings by capturing particulate contaminants. They transform polluted air into cleaner air using filters or separators. Compliance with OSHA and EPA regulations is essential for manufacturing companies, which rely on dust collection systems to meet air quality standards. Key co…

Strategic Sourcing Conclusion and Outlook for types of dust collectors

In today’s competitive industrial landscape, the strategic sourcing of dust collectors is paramount for businesses aiming to enhance operational efficiency and ensure compliance with environmental regulations. Understanding the various types of dust collectors—such as pulse jet, shaker, cartridge, and cyclone systems—allows companies to select the most suitable technology tailored to their unique needs. This not only aids in maintaining air quality but also contributes to the overall safety and productivity of the workplace.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe navigate this decision-making process, they must prioritize suppliers that offer customization options and robust support services. The right dust collector can significantly reduce downtime and operational costs while improving air quality management.

Looking ahead, the demand for advanced dust collection solutions will continue to grow, driven by stricter regulations and an increasing focus on sustainability. Buyers are encouraged to engage with suppliers who can provide innovative, tailored solutions that align with their operational goals. By investing in the right dust collection technology, businesses not only protect their workforce but also enhance their reputation as responsible industry players.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.