Everything You Need to Know About Three Phase Transformer Chart Sourcing in 2025

Introduction: Navigating the Global Market for three phase transformer chart

In the ever-evolving landscape of global commerce, B2B buyers face the critical challenge of sourcing the right three phase transformers to meet their operational needs. Whether you are in Nigeria or Brazil, understanding the nuances of three phase transformer charts is essential for making informed purchasing decisions. This guide delves into the intricacies of these vital components, offering insights into various types, applications, and performance specifications, while also addressing key factors such as supplier vetting and cost considerations.

Navigating the complexities of transformer specifications can be daunting, particularly for international buyers who must consider regional differences in electrical standards and market dynamics. By providing a comprehensive overview of three phase transformers, this guide equips you with the knowledge needed to evaluate options effectively and make strategic choices that enhance your operational efficiency.

From detailed charts that break down full load amps to expert advice on selecting reliable suppliers, this resource is tailored to empower businesses across Africa, South America, the Middle East, and Europe. With actionable insights at your fingertips, you will be better positioned to optimize your procurement process, ensuring you secure high-quality transformers that meet your unique requirements and budget constraints.

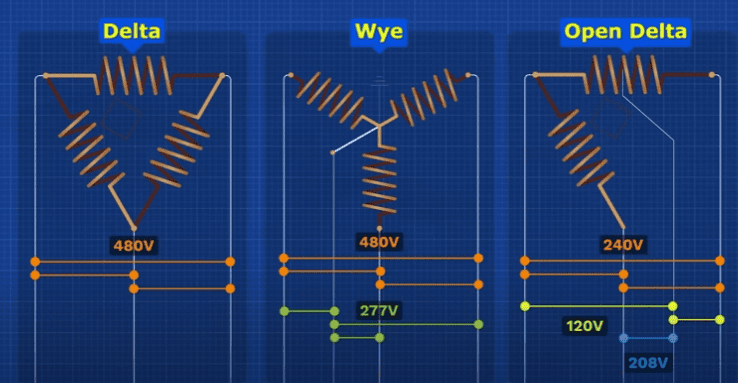

Understanding three phase transformer chart Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Delta-Wye Transformer | Features a delta primary and wye secondary configuration; provides phase shift. | Industrial power distribution, renewable energy systems. | Pros: Better voltage regulation, reduced harmonics. Cons: More complex installation and maintenance. |

| Wye-Wye Transformer | Both primary and secondary windings are connected in wye; suitable for high voltage applications. | Utility applications, high-rise buildings. | Pros: Balanced load distribution, lower phase voltage. Cons: Not suitable for unbalanced loads. |

| Delta-Delta Transformer | Both primary and secondary windings are connected in delta; provides high efficiency. | Heavy machinery, manufacturing plants. | Pros: High efficiency, can handle high current loads. Cons: Potential for higher harmonics. |

| Autotransformer | Single winding serves as both primary and secondary; compact and cost-effective. | Power transmission, voltage regulation. | Pros: Smaller size, lower cost. Cons: Less isolation between circuits. |

| Isolation Transformer | Provides electrical isolation between circuits; often used for safety. | Hospitals, data centers, sensitive equipment. | Pros: Enhanced safety, reduces noise. Cons: Generally larger and more expensive. |

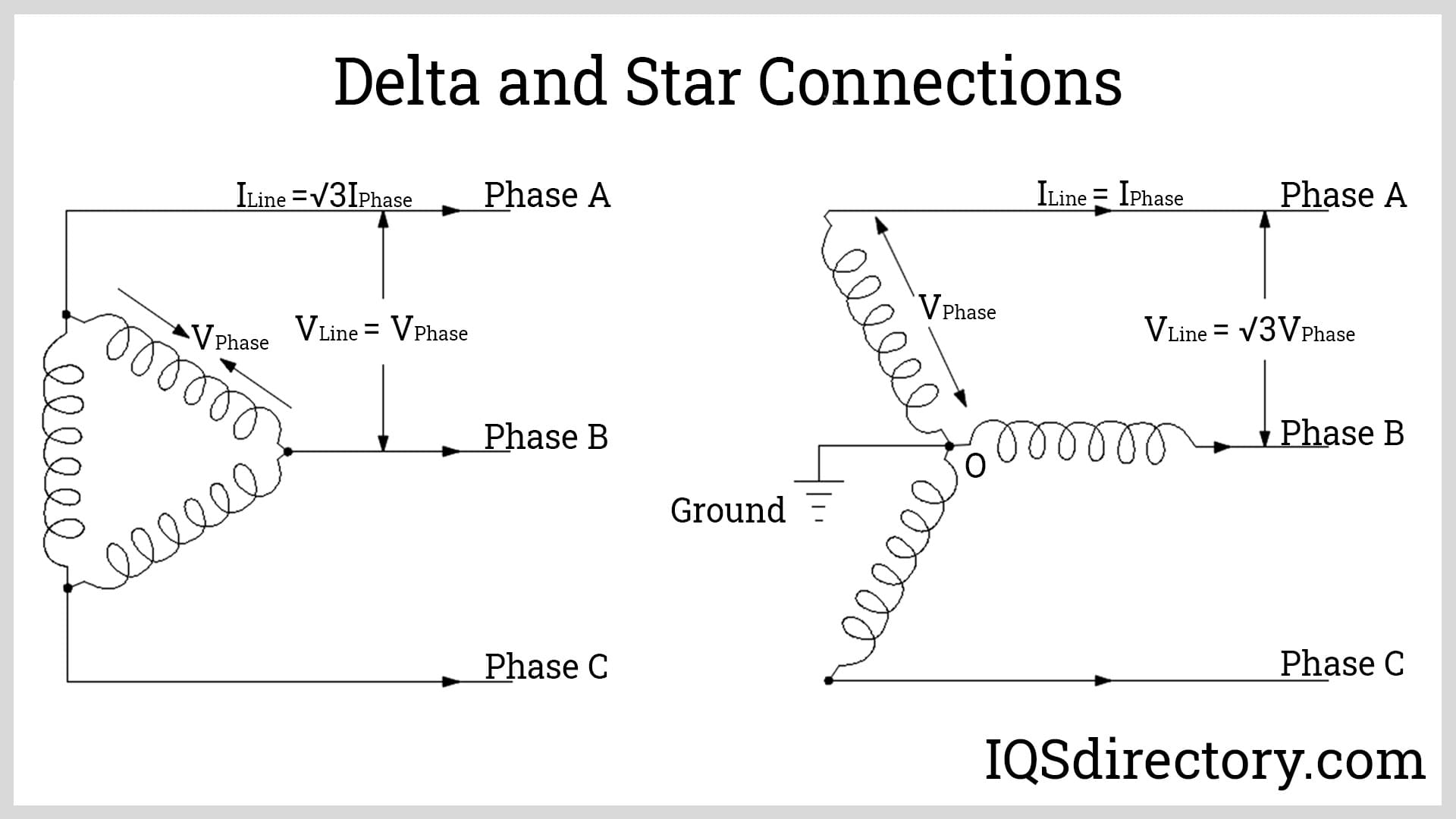

What are the Key Characteristics of Delta-Wye Transformers?

Delta-Wye transformers are characterized by their unique winding configuration, which combines delta on the primary side and wye on the secondary. This design allows for a phase shift of 30 degrees, making it particularly effective in applications requiring phase balancing and voltage regulation. They are widely used in industrial power distribution and renewable energy systems, where stable and efficient power delivery is critical. When purchasing, businesses should consider installation complexity and maintenance requirements, as well as the transformer’s ability to handle harmonics.

How do Wye-Wye Transformers Operate and Where are They Best Used?

Wye-Wye transformers feature both primary and secondary windings connected in a wye configuration, which is advantageous for high voltage applications. This setup provides balanced load distribution and is particularly suitable for utility applications and high-rise buildings where consistent voltage is essential. Buyers should be aware of the limitations concerning unbalanced loads, as this can affect performance. Additionally, the transformer’s ability to maintain lower phase voltages makes it a preferred choice for specific B2B applications.

What Benefits Do Delta-Delta Transformers Offer to Industries?

Delta-Delta transformers are known for their high efficiency and ability to manage high current loads effectively. With both primary and secondary windings connected in a delta configuration, these transformers can handle heavy machinery and manufacturing equipment demands. However, potential buyers should weigh the advantages of high efficiency against the risk of increased harmonics, which can affect power quality. Understanding the specific load requirements and harmonic performance is essential for businesses in the manufacturing sector.

Why Consider Autotransformers for Power Transmission?

Autotransformers utilize a single winding that acts as both the primary and secondary, making them compact and cost-effective solutions for power transmission and voltage regulation. Their design allows for significant savings in material costs and space, which is appealing to businesses looking for efficient solutions. However, the lack of electrical isolation may pose safety risks, making it crucial for buyers to assess their specific application needs and safety standards before purchasing.

How Do Isolation Transformers Enhance Safety in Sensitive Applications?

Isolation transformers are specifically designed to provide electrical isolation between circuits, making them invaluable in environments such as hospitals, data centers, and facilities housing sensitive equipment. By reducing electrical noise and enhancing safety, these transformers protect critical systems from power surges and faults. However, their size and cost may be higher than other transformer types, so businesses should evaluate their safety requirements and budget constraints when considering an isolation transformer for their operations.

Key Industrial Applications of three phase transformer chart

| Industry/Sector | Specific Application of three phase transformer chart | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power supply for heavy machinery | Ensures reliable operation of critical equipment | Voltage ratings, load capacity, and efficiency |

| Renewable Energy | Integration in solar and wind farms | Facilitates energy conversion and distribution | Environmental compliance, durability, and scalability |

| Mining and Minerals | Power distribution in remote locations | Supports continuous operations in challenging terrains | Robustness, maintenance support, and local regulations |

| Construction | Temporary power supply at construction sites | Enables uninterrupted work schedules | Portability, safety standards, and installation ease |

| Data Centers | Power management for IT infrastructure | Enhances system reliability and uptime | Cooling requirements, redundancy features, and capacity |

How is the ‘Three Phase Transformer Chart’ Utilized in Manufacturing?

In manufacturing, the three phase transformer chart serves as a crucial tool for determining the power supply needs for heavy machinery. By providing detailed specifications regarding voltage ratings and load capacities, it enables businesses to select the right transformers that ensure the reliable operation of critical equipment. This is particularly important in regions like Nigeria and Brazil, where power supply issues can lead to significant downtime. Buyers must consider efficiency ratings and the ability to handle fluctuating loads to optimize production processes.

What Role Does the ‘Three Phase Transformer Chart’ Play in Renewable Energy?

In renewable energy sectors, particularly solar and wind farms, the three phase transformer chart aids in the integration of these energy sources into the grid. It provides vital information about energy conversion and distribution requirements, which is essential for maximizing the efficiency of renewable installations. As international buyers increasingly focus on sustainable energy solutions, sourcing transformers that comply with environmental regulations and offer durability in harsh conditions becomes paramount. These considerations help ensure long-term viability and performance.

How is the ‘Three Phase Transformer Chart’ Essential for Mining Operations?

Mining and mineral extraction often occur in remote locations where reliable power distribution is critical. The three phase transformer chart assists in identifying transformers capable of supporting continuous operations under challenging terrains. For businesses in this sector, sourcing robust transformers that can withstand harsh environments and provide maintenance support is essential. Compliance with local regulations regarding safety and operational standards is also a key consideration for international buyers, particularly in regions with stringent mining laws.

Why is the ‘Three Phase Transformer Chart’ Important for Construction Sites?

Construction projects frequently require temporary power solutions to support various activities. The three phase transformer chart helps contractors determine the appropriate transformers needed for these temporary setups. Reliable power supply ensures uninterrupted work schedules, which is crucial for meeting project deadlines. Buyers should prioritize portability and adherence to safety standards when sourcing transformers for construction applications, especially in diverse environments across Africa and South America.

How Does the ‘Three Phase Transformer Chart’ Enhance Data Center Operations?

In data centers, the three phase transformer chart is vital for effective power management of IT infrastructure. It aids in selecting transformers that enhance system reliability and uptime, which are critical for maintaining service continuity. With increasing demands for data processing, international buyers must consider transformers with adequate cooling capabilities and redundancy features. These factors are essential to ensure that data centers can operate efficiently and withstand potential power fluctuations, particularly in regions with unstable power grids.

3 Common User Pain Points for ‘three phase transformer chart’ & Their Solutions

Scenario 1: Difficulty in Understanding Load Requirements

The Problem: B2B buyers often struggle to accurately interpret the load requirements for their specific applications when using a three phase transformer chart. This challenge can stem from a lack of familiarity with electrical specifications or the complexity of the chart itself. Misunderstanding these requirements can lead to selecting an undersized transformer, resulting in inefficiencies and potential damage to electrical equipment, or an oversized transformer, which can be an unnecessary financial burden.

The Solution: To effectively navigate a three phase transformer chart, buyers should start by consulting with an electrical engineer or a knowledgeable supplier who can provide insight into load calculations specific to their application. It’s vital to gather detailed information about the operational requirements, such as voltage levels, amperage, and power factor. Once these parameters are clearly defined, buyers can utilize the transformer chart to match their needs with the appropriate transformer specifications, ensuring a balance between performance and cost. Additionally, creating a checklist of required specifications before consulting the chart can streamline the decision-making process.

Scenario 2: Incompatibility with Existing Systems

The Problem: Another common issue faced by B2B buyers is the compatibility of new transformers with existing electrical systems. Organizations, especially those in regions with varying voltage standards, may find that the transformers they initially consider do not align with their current equipment or infrastructure. This can lead to additional costs associated with retrofitting or replacing existing systems, thereby delaying projects and increasing operational downtime.

The Solution: To avoid compatibility issues, buyers should conduct a thorough assessment of their existing electrical infrastructure prior to purchasing a three phase transformer. This includes reviewing voltage requirements, connection types, and load characteristics. Engaging a qualified electrical consultant can provide expert insights into potential compatibility issues. Furthermore, when reviewing the transformer chart, buyers should look for models that explicitly state compatibility with various voltage standards and connection types. Documenting existing system specifications and discussing them with suppliers can ensure a seamless integration of new transformers into the existing setup.

Scenario 3: Unclear Maintenance and Operational Guidelines

The Problem: Buyers may find that the maintenance and operational guidelines for three phase transformers are not clearly communicated, leading to confusion about how to maintain these critical components effectively. Without proper maintenance, transformers can experience reduced efficiency, shortened lifespan, and potential failure, all of which can incur significant costs for businesses.

The Solution: To mitigate this risk, buyers should seek out comprehensive documentation from manufacturers that outlines maintenance schedules and operational guidelines specific to the chosen transformer model. Additionally, investing in training sessions for the maintenance team can be invaluable. This could include workshops or online courses that focus on transformer maintenance best practices. When utilizing the three phase transformer chart, buyers should also pay attention to any notes or recommendations related to maintenance intervals, common issues, and troubleshooting techniques. Establishing a routine maintenance plan based on these guidelines can enhance the longevity and reliability of the transformers, ultimately supporting operational efficiency and cost management.

By addressing these common pain points with targeted strategies, B2B buyers can enhance their experience with three phase transformers, ensuring effective and efficient power management for their operations.

Strategic Material Selection Guide for three phase transformer chart

What Are the Key Materials Used in Three Phase Transformers?

When selecting materials for three phase transformers, understanding the properties, advantages, and limitations of common materials is crucial for optimizing performance and ensuring compliance with international standards. Below is an analysis of four prevalent materials used in three phase transformers.

1. Copper

Key Properties:

Copper is renowned for its excellent electrical conductivity, thermal conductivity, and corrosion resistance. It typically operates effectively at temperatures up to 200°C and can handle significant mechanical stress.

Pros & Cons:

Copper’s high conductivity results in lower energy losses, making it a preferred choice for windings. However, it is relatively expensive compared to alternatives like aluminum. Additionally, its weight can be a disadvantage in applications where weight reduction is critical.

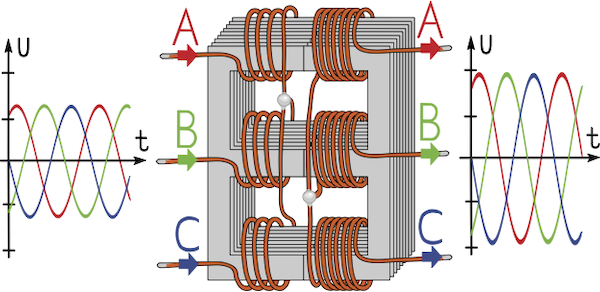

Illustrative image related to three phase transformer chart

Impact on Application:

Copper’s superior conductivity makes it ideal for high-efficiency transformers, especially in urban settings where energy costs are a concern. However, its susceptibility to corrosion in harsh environments may necessitate protective coatings.

Considerations for International Buyers:

B2B buyers in regions like Africa and South America should consider local copper prices and availability. Compliance with standards such as ASTM B170 for copper conductors is essential to ensure quality.

2. Aluminum

Key Properties:

Aluminum is lighter than copper and offers good conductivity, although not as high as copper. It has a typical operating temperature range of up to 150°C and is resistant to corrosion due to its natural oxide layer.

Illustrative image related to three phase transformer chart

Pros & Cons:

The primary advantage of aluminum is its cost-effectiveness and lower weight, making it suitable for large transformers where weight is a concern. However, its lower conductivity means larger wire sizes are required, potentially increasing manufacturing complexity.

Impact on Application:

Aluminum is often used in medium-voltage transformers where weight and cost are significant factors. Its corrosion resistance makes it suitable for outdoor installations, particularly in humid or coastal environments.

Considerations for International Buyers:

Buyers should ensure compliance with standards like IEC 60228 for conductor performance. In regions with high humidity, additional coatings may be necessary to enhance corrosion resistance.

3. Silicon Steel

Key Properties:

Silicon steel is used for transformer cores due to its magnetic properties and low hysteresis loss. It typically operates effectively at temperatures up to 150°C and has excellent electrical resistance.

Illustrative image related to three phase transformer chart

Pros & Cons:

The main advantage of silicon steel is its ability to reduce energy losses during operation, enhancing transformer efficiency. However, it is more brittle than other materials, which can complicate manufacturing and installation.

Impact on Application:

Silicon steel is critical in applications requiring high efficiency and minimal energy loss, such as in industrial and power distribution transformers. Its magnetic properties significantly impact the overall performance of the transformer.

Considerations for International Buyers:

B2B buyers should be aware of the importance of compliance with standards such as ASTM A677 for silicon steel. Different regions may have specific requirements regarding core design and efficiency ratings.

4. Insulating Materials (e.g., Polyester, Epoxy)

Key Properties:

Insulating materials are crucial for transformer safety and performance. They typically have high dielectric strength and can withstand temperatures ranging from -40°C to 150°C, depending on the specific type.

Pros & Cons:

The primary advantage of insulating materials is their ability to prevent electrical leakage and ensure safety. However, the cost can vary significantly based on the type and quality of insulation used.

Illustrative image related to three phase transformer chart

Impact on Application:

Insulating materials are essential in preventing short circuits and ensuring the longevity of transformers, especially in high-voltage applications. The choice of insulation can significantly impact thermal management and overall efficiency.

Considerations for International Buyers:

Buyers should verify compliance with international insulation standards such as IEC 60085. Additionally, local climatic conditions may dictate the choice of insulation type, particularly in regions with extreme temperatures.

Summary Table of Material Selection for Three Phase Transformers

| Material | Typical Use Case for three phase transformer chart | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-efficiency transformers | Superior conductivity | High cost and weight | High |

| Aluminum | Medium-voltage transformers | Cost-effective and lightweight | Lower conductivity | Medium |

| Silicon Steel | Industrial and power distribution transformers | Reduces energy losses | Brittle and complex to manufacture | Medium |

| Insulating Materials | High-voltage transformers | Prevents electrical leakage | Variable cost based on type | Medium to High |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions that align with both performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for three phase transformer chart

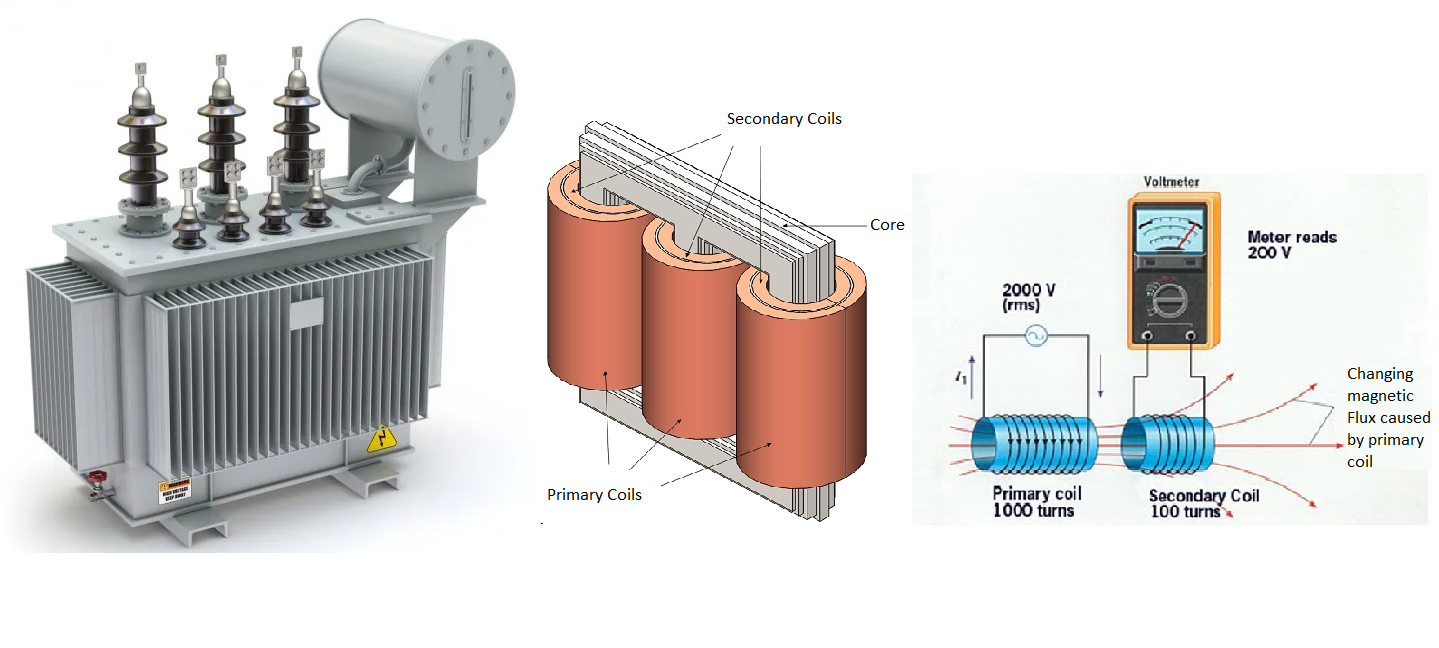

What Are the Main Stages in the Manufacturing Process of Three Phase Transformers?

The manufacturing process of three phase transformers involves several critical stages, each of which plays a vital role in ensuring the final product meets industry standards and customer requirements.

-

Material Preparation: This stage begins with sourcing high-quality raw materials such as copper for windings, silicon steel for the core, and insulating materials. Suppliers should be vetted for material quality, as the performance of the transformer heavily relies on these components. The materials are tested for electrical and mechanical properties to ensure they comply with the necessary specifications.

-

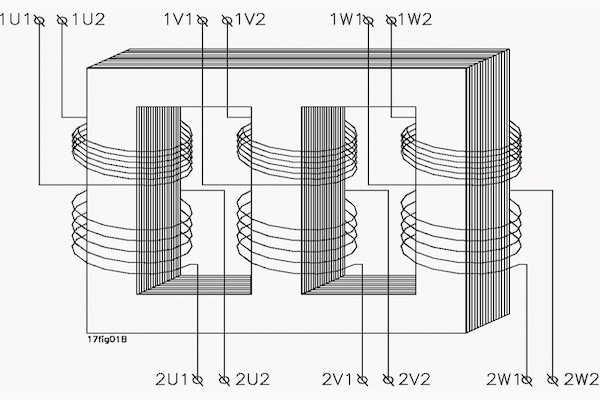

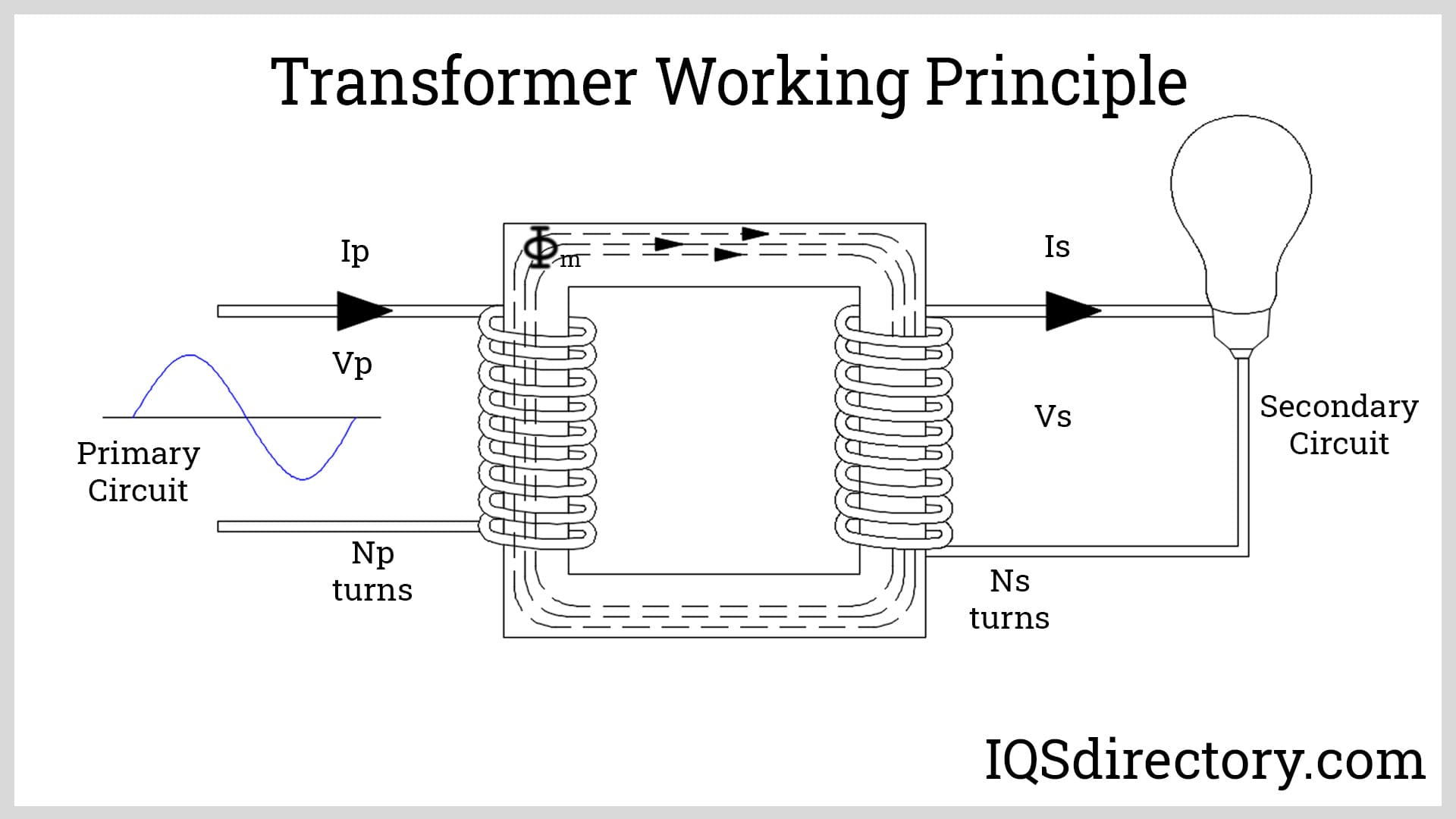

Forming: The next phase involves forming the core and windings. The core is typically manufactured using laminations of silicon steel to minimize energy losses. The windings are crafted using precision techniques to ensure optimal electrical performance. This stage may involve advanced technologies like CNC machining for precise cuts and shaping.

-

Assembly: During assembly, the core and windings are combined, and insulation materials are applied to prevent electrical faults. This stage requires skilled labor and quality tools to ensure proper alignment and secure connections. The assembly process also includes installing protective casings and terminals.

-

Finishing: The final stage involves painting or coating the transformer to protect against environmental factors and enhance durability. This may include the application of corrosion-resistant coatings and insulation treatments. Quality checks are performed to ensure that all components are securely fastened and that the finished product meets aesthetic and functional standards.

What Are the Key Techniques Used in Transformer Manufacturing?

The manufacturing of three phase transformers employs various advanced techniques to enhance efficiency and reliability.

- Winding Techniques: The use of automated winding machines allows for precise and uniform winding of coils, reducing the risk of short circuits and improving overall performance.

- Core Assembly: Advanced core assembly techniques, such as the use of interleaved laminations, help reduce eddy current losses and enhance magnetic efficiency.

- Vacuum Impregnation: This technique is often used in the insulation process, where the windings are immersed in resin under vacuum to eliminate air bubbles and enhance insulation properties.

How Is Quality Assurance Implemented in Three Phase Transformer Manufacturing?

Quality assurance (QA) is critical in the manufacturing of three phase transformers to ensure product reliability and compliance with international standards.

-

International Standards Compliance: Adhering to standards such as ISO 9001 ensures that manufacturers implement effective quality management systems. Other industry-specific certifications like CE mark and API standards may also be relevant, depending on the application and regional requirements.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, various checks are performed to identify any defects early on. This may include monitoring winding tension, core alignment, and insulation integrity.

– Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing, including electrical testing for insulation resistance, load testing, and thermal imaging to identify potential hot spots.

What Testing Methods Are Commonly Used for Three Phase Transformers?

Testing methods are essential for verifying the performance and safety of three phase transformers. Common techniques include:

- Dielectric Testing: This assesses the insulation strength of the transformer under high voltage conditions to prevent electrical breakdown.

- Transformer Turns Ratio (TTR) Testing: This method evaluates the turns ratio between the primary and secondary windings, ensuring they are within acceptable limits.

- Load Testing: Conducted to simulate operational conditions, load testing verifies that the transformer can handle its rated capacity without overheating or failing.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial for ensuring product reliability.

- Audits: Conducting on-site audits of manufacturing facilities allows buyers to assess the quality management systems in place. This includes reviewing documentation, observing processes, and evaluating equipment.

- Quality Reports: Requesting detailed quality reports, including test results and compliance certificates, can provide insight into the supplier’s adherence to international standards.

- Third-Party Inspections: Engaging third-party inspection agencies can further validate the supplier’s quality claims. These agencies can conduct independent evaluations of the manufacturing process and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of several nuances regarding quality control in the context of three phase transformers:

- Regulatory Differences: Different regions may have varying regulatory requirements. Understanding these can help buyers ensure compliance and avoid legal issues.

- Cultural Differences in Quality Standards: Quality expectations may differ across cultures. Buyers should communicate their requirements clearly and confirm that suppliers understand and can meet these standards.

- Post-Sale Support and Warranty: Buyers should also consider the supplier’s post-sale support and warranty policies, as these can significantly impact long-term satisfaction and performance.

In conclusion, the manufacturing processes and quality assurance measures for three phase transformers are multifaceted and require careful consideration by B2B buyers. By understanding these aspects, buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘three phase transformer chart’

In the realm of electrical engineering, sourcing a reliable three-phase transformer chart is critical for ensuring optimal power distribution and system efficiency. This guide provides a practical checklist to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Start by outlining the specific technical requirements for the three-phase transformer chart. Consider factors such as voltage ratings, power capacities, and load characteristics. Clearly defined specifications will help in identifying the right product that meets your operational needs.

- Voltage Ratings: Ensure compatibility with your existing electrical systems.

- Power Capacity: Assess the maximum load to avoid underperformance or overload situations.

- Load Characteristics: Identify whether your operations require balanced or unbalanced loads.

Step 2: Research Market Trends and Standards

Understanding current market trends and compliance standards is crucial. Familiarize yourself with industry benchmarks and certifications relevant to three-phase transformers. This will not only aid in making informed decisions but also ensure compliance with local regulations.

- Industry Standards: Look for standards set by organizations such as IEC or IEEE.

- Market Trends: Stay updated on innovations that might enhance performance or efficiency.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers who specialize in three-phase transformer charts. This initial selection should focus on suppliers known for their reliability and quality.

- Supplier Reputation: Research online reviews and case studies.

- Regional Considerations: Consider suppliers that understand local market dynamics, especially if you are sourcing from Africa, South America, or the Middle East.

Step 4: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and compliance with industry standards. This step is essential to ensure the quality and safety of the transformers.

- ISO Certification: Look for suppliers with ISO 9001 certification, which indicates a commitment to quality management.

- Product Certifications: Ensure the products meet relevant safety and performance standards.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, delivery timelines, and terms of service. This is critical for comparing options effectively.

- Breakdown of Costs: Ensure quotations provide a clear breakdown of costs, including shipping and handling.

- Lead Times: Understand the delivery timelines to align with your project schedules.

Step 6: Review Warranty and Support Services

Check the warranty terms and after-sales support offered by the suppliers. A robust warranty and good customer service can be crucial in the long run.

- Warranty Duration: A longer warranty period may indicate higher product reliability.

- Support Services: Ensure the supplier provides adequate technical support and assistance for installation and maintenance.

Step 7: Finalize Your Purchase Agreement

After thorough evaluation and comparison, finalize your purchase agreement with the chosen supplier. Ensure all terms are clearly outlined and agreed upon.

- Contractual Terms: Pay attention to payment terms, delivery schedules, and return policies.

- Legal Considerations: Review any legal requirements specific to your region or industry.

By following these steps, B2B buyers can make informed decisions when procuring three-phase transformer charts, ensuring they select products that meet their operational needs while adhering to industry standards.

Illustrative image related to three phase transformer chart

Comprehensive Cost and Pricing Analysis for three phase transformer chart Sourcing

What Are the Key Cost Components in Sourcing Three Phase Transformers?

When sourcing three-phase transformers, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts the transformer’s cost. High-grade copper and silicon steel are often used for windings and cores, respectively. The prices of these materials can fluctuate based on market demand and geopolitical factors, particularly affecting international buyers.

-

Labor: Labor costs vary by region and can influence the overall price. Skilled labor is essential for manufacturing high-quality transformers, and regions with higher labor costs may produce transformers that come at a premium.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Efficient production processes can help minimize these costs, affecting the final pricing.

-

Tooling: The cost of tooling depends on the complexity of the transformer design. Custom tooling for specialized transformers may require higher upfront investment, which can be amortized over larger production runs.

-

Quality Control: Ensuring that transformers meet international standards requires a robust QC process, which adds to the overall cost. Certifications such as ISO and IEC can further influence pricing, as compliance often necessitates additional testing and documentation.

-

Logistics: Shipping costs play a crucial role, especially for international buyers. Factors like distance, shipping method, and customs duties can all contribute to the total cost.

-

Margin: Suppliers typically mark up the cost of production to ensure profitability. This margin can vary based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect the Cost of Three Phase Transformers?

Several factors can influence the pricing of three-phase transformers, making it essential for buyers to consider these variables during negotiations.

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Buyers should assess their needs to determine the optimal order size that balances inventory costs and cost savings.

-

Specifications and Customization: Custom specifications can lead to increased costs due to specialized materials and tooling. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications can raise the price. However, investing in quality can lead to lower maintenance costs and increased reliability, which is essential for long-term operations.

-

Supplier Factors: The supplier’s reputation, location, and production capacity can influence pricing. Established suppliers with a track record of reliability may charge higher prices, but this can be justified by the quality and support they offer.

-

Incoterms: Understanding shipping terms is vital for international purchases. Different Incoterms (e.g., FOB, CIF) can significantly affect the total landed cost of the transformers.

What Tips Can Buyers Implement to Negotiate Better Prices for Three Phase Transformers?

-

Negotiation Strategies: Leverage volume purchasing and long-term contracts to negotiate better pricing. Building a relationship with suppliers can also lead to better terms and conditions.

-

Focus on Cost Efficiency: Evaluate the total cost of ownership rather than just the initial purchase price. Consider factors like installation, maintenance, and energy efficiency to make a comprehensive assessment.

-

Pricing Nuances for International Buyers: Buyers in Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and import tariffs that can affect pricing. Establishing a clear understanding of these factors can aid in budgeting and financial planning.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide insights into market pricing and help identify the best value for the desired specifications.

-

Assess Supply Chain Reliability: Evaluate the supplier’s logistics capabilities to ensure timely delivery and minimize disruptions, which can lead to additional costs.

Disclaimer

Prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and specific project requirements. Always conduct thorough research and engage with suppliers to obtain accurate pricing for your specific needs.

Alternatives Analysis: Comparing three phase transformer chart With Other Solutions

Introduction: Understanding Alternative Solutions for Three Phase Transformers

In the realm of electrical engineering and power distribution, three-phase transformer charts serve as a vital resource for determining the operational parameters of transformers. However, buyers in international markets, particularly in regions like Africa, South America, the Middle East, and Europe, may consider various alternatives that fulfill similar roles. This section explores alternative solutions, comparing their performance, cost, ease of implementation, maintenance, and best use cases against traditional three-phase transformer charts.

Comparison Table

| Comparison Aspect | Three Phase Transformer Chart | Transformer Simulation Software | Smart Grid Technology |

|---|---|---|---|

| Performance | Accurate load calculations | High accuracy with scenario modeling | Real-time data analytics |

| Cost | Low initial investment | Moderate cost, requires software licenses | High setup and infrastructure costs |

| Ease of Implementation | Simple to use, no special training needed | Requires training and expertise | Complex setup, requires integration |

| Maintenance | Minimal upkeep | Regular software updates needed | Ongoing maintenance and updates |

| Best Use Case | Standard load calculations | Detailed system analysis and forecasting | Dynamic load management and efficiency optimization |

Detailed Breakdown of Alternatives

Transformer Simulation Software: Is It Worth the Investment?

Transformer simulation software offers advanced capabilities for analyzing transformer performance under various load conditions. This alternative provides high accuracy by allowing users to model different scenarios, which can be particularly beneficial for engineers designing complex systems. However, the cost of software licenses can be a barrier for small businesses or projects with limited budgets. Additionally, the need for specialized training can complicate the implementation process. Overall, this solution is best suited for projects that require in-depth analysis and forecasting.

Smart Grid Technology: The Future of Power Distribution?

Smart grid technology represents a significant advancement in the management of electrical distribution systems. By utilizing real-time data analytics, smart grids can optimize load management and enhance energy efficiency. This technology, however, comes with a high initial setup cost and demands substantial infrastructure investment. Furthermore, integrating smart grid systems requires ongoing maintenance and updates, which can be resource-intensive. This solution is ideal for organizations looking to modernize their electrical systems and improve operational efficiencies, particularly in urban areas.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers navigating the complexities of electrical systems, selecting the right solution hinges on specific operational needs and budget constraints. While the three-phase transformer chart remains a reliable tool for standard load calculations, alternatives like transformer simulation software and smart grid technology offer enhanced capabilities for specific applications. Buyers should evaluate their project requirements, considering factors such as performance needs, cost implications, and ease of implementation to make informed decisions that align with their long-term objectives.

Essential Technical Properties and Trade Terminology for three phase transformer chart

What Are the Key Technical Properties of a Three Phase Transformer?

Understanding the essential technical properties of three phase transformers is crucial for B2B buyers, especially when making investment decisions. Here are some critical specifications to consider:

-

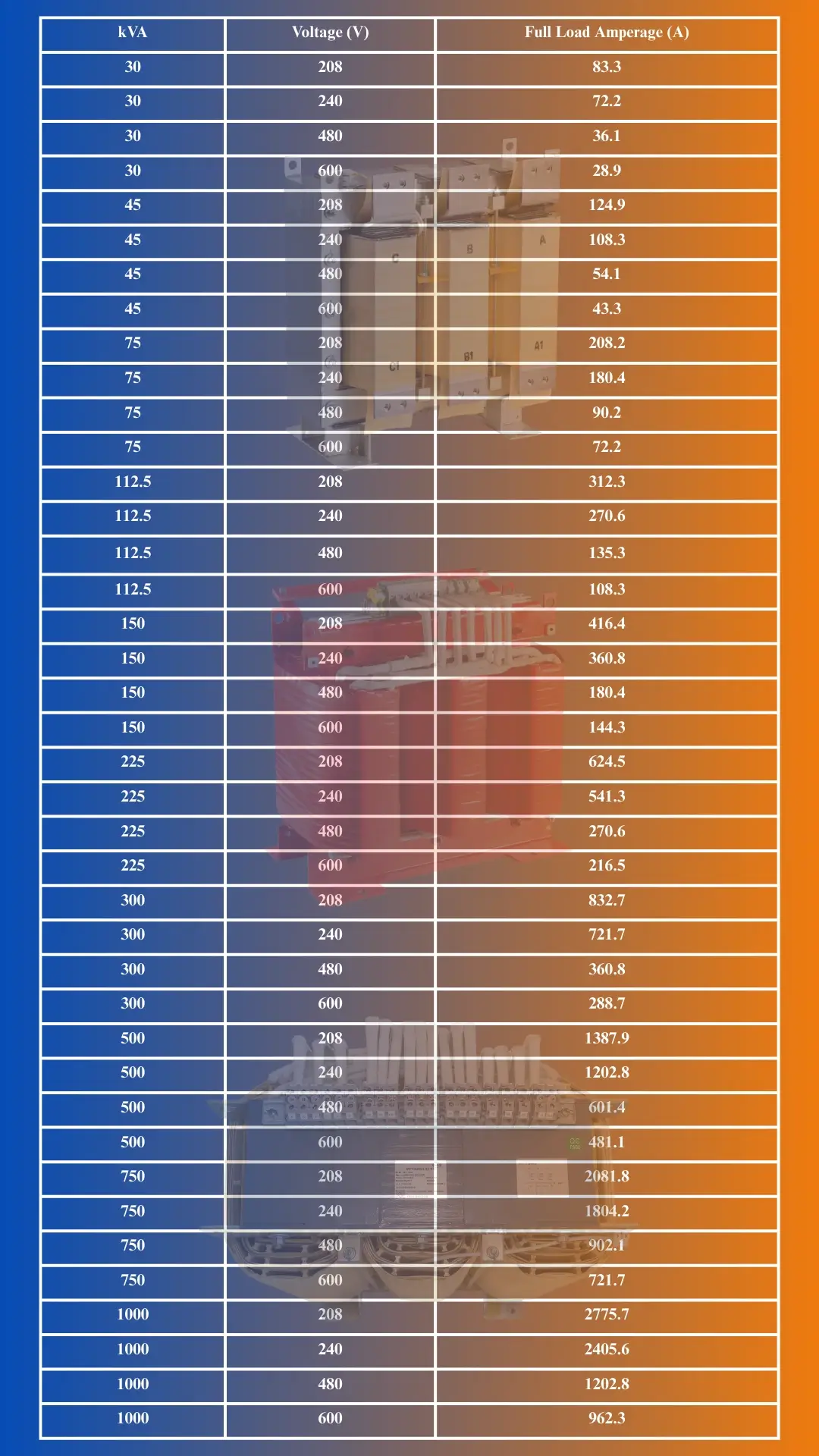

Power Rating (kVA)

The power rating indicates the maximum load a transformer can handle. It is measured in kilovolt-amperes (kVA) and directly correlates with the transformer’s efficiency and capacity to supply power. For businesses, selecting a transformer with the appropriate power rating is vital to ensure reliability and avoid operational downtime. -

Voltage Rating (Primary and Secondary)

Voltage ratings define the input (primary) and output (secondary) voltages of the transformer. They are essential for compatibility with existing electrical systems. Choosing a transformer with the correct voltage ratings ensures optimal performance and safety, preventing equipment damage or energy losses. -

Efficiency Rating

This specification reflects the transformer’s ability to convert input power into output power without significant losses. High-efficiency transformers save on energy costs and contribute to sustainability initiatives, making them attractive to businesses aiming to reduce their carbon footprint. -

Impedance (%)

Impedance is a critical parameter that impacts the transformer’s short-circuit current and voltage regulation. A lower impedance results in better voltage regulation under load. For B2B buyers, understanding impedance is essential for system design and ensuring the transformer meets the operational requirements of connected loads. -

Temperature Rise

This specification indicates how much the transformer’s temperature will increase under full load conditions. It is crucial for ensuring the longevity and reliability of the transformer. Selecting a transformer with an appropriate temperature rise rating helps prevent overheating and extends service life. -

Material Grade

The materials used in the construction of a transformer, such as core steel and winding conductors, directly affect performance and durability. High-grade materials enhance efficiency and reduce losses. B2B buyers should prioritize transformers made from quality materials to ensure long-term reliability.

What Are Common Trade Terms Related to Three Phase Transformers?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for reliable sources for their transformer needs, ensuring that they receive quality products that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers to understand the financial commitment required and to negotiate better purchasing terms. A low MOQ may be advantageous for smaller companies or those testing new products. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. This process allows businesses to compare pricing and terms from multiple suppliers, ensuring they get the best deal possible. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international shipping and freight. Understanding Incoterms is vital for B2B buyers to clarify responsibilities regarding shipping, insurance, and tariffs, reducing potential disputes. -

Lead Time

Lead time indicates the duration between placing an order and receiving the product. For businesses, knowing lead times is essential for project planning and inventory management, ensuring that operations run smoothly without delays. -

Certification Standards

These are industry-specific standards that ensure transformers meet safety and performance criteria. Familiarity with certification standards, such as ISO or IEC, is important for B2B buyers to ensure compliance and reliability in their electrical systems.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the three phase transformer chart Sector

What Are the Current Market Dynamics and Key Trends in the Three Phase Transformer Sector?

The global three phase transformer market is experiencing significant growth, driven by an increasing demand for reliable power distribution systems, particularly in emerging economies in Africa, South America, and the Middle East. Factors such as urbanization, industrialization, and the expansion of renewable energy sources are propelling this demand. The rise of smart grid technologies is also influencing market dynamics, as businesses seek more efficient and automated systems for energy distribution.

In terms of sourcing trends, international B2B buyers are gravitating towards suppliers who can offer advanced technology solutions, including transformers equipped with IoT capabilities. These technologies facilitate real-time monitoring and predictive maintenance, enhancing operational efficiency. Furthermore, the growing emphasis on cost-effective solutions has led buyers to explore regional suppliers, particularly those within their geographical vicinity, to reduce logistics costs and lead times.

Emerging markets like Nigeria and Brazil are seeing increased investments in infrastructure, which directly impacts the demand for three phase transformers. As these countries enhance their power generation capabilities, there is a corresponding need for transformers that can handle varying loads while ensuring stability and reliability in power supply.

How Does Sustainability and Ethical Sourcing Impact the Three Phase Transformer Sector?

Sustainability has become a critical factor in the sourcing decisions of international B2B buyers. The environmental impact of manufacturing processes in the three phase transformer sector is under scrutiny, pushing companies to adopt greener practices. This includes the use of recyclable materials and energy-efficient manufacturing processes that minimize carbon footprints.

Ethical sourcing has gained traction as buyers seek to ensure that their suppliers adhere to social responsibility standards. This includes fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for suppliers aiming to secure contracts with conscientious buyers.

Buyers are also increasingly interested in ‘green’ certifications for transformers, which indicate compliance with environmental regulations and standards. This trend not only enhances brand reputation but also aligns with the global push towards sustainable development, making it a key consideration in procurement strategies.

Illustrative image related to three phase transformer chart

What Is the Brief Evolution and Historical Context of the Three Phase Transformer Sector?

The evolution of the three phase transformer sector can be traced back to the late 19th century when the need for efficient power transmission became apparent. Initially, transformers were large, bulky devices with limited efficiency. However, advancements in materials, technology, and manufacturing processes have significantly improved their performance and reliability.

The introduction of silicon steel cores in the mid-20th century marked a pivotal moment, enhancing the efficiency and reducing the size of transformers. As electrical grids expanded, the demand for three phase transformers surged, particularly in industrial and commercial applications. Today, with the integration of digital technology, the sector is witnessing a transformation towards smart transformers, which offer enhanced monitoring and management capabilities.

In summary, understanding the current market dynamics, sustainability trends, and historical context is crucial for international B2B buyers in the three phase transformer sector, particularly as they navigate the complexities of global sourcing and procurement.

Frequently Asked Questions (FAQs) for B2B Buyers of three phase transformer chart

1. How do I determine the correct size of a three-phase transformer for my application?

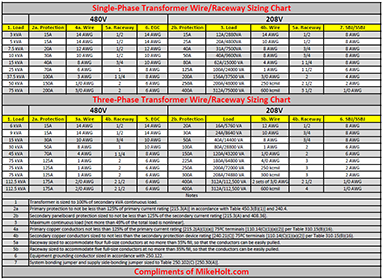

To determine the appropriate size of a three-phase transformer, start by calculating the total load in kilowatts (kW) that the transformer will support. Convert this load to kilovolt-amperes (kVA) using the formula: kVA = kW / power factor. Additionally, consider factors such as future expansion, inrush currents, and the type of load (resistive, inductive). It’s essential to consult the transformer chart to match your calculated kVA with available transformer ratings, ensuring optimal performance and efficiency.

2. What specifications should I look for in a three-phase transformer chart?

When reviewing a three-phase transformer chart, focus on specifications such as voltage ratings, kVA capacity, full load amps, and efficiency ratings. Additionally, consider the transformer’s impedance, temperature rise, and cooling method (oil or air). Ensure that the chart includes information about the physical dimensions and weight, as well as compliance with international standards. This information is crucial for ensuring compatibility with your existing infrastructure and meeting regulatory requirements in your region.

3. How can I ensure the quality of three-phase transformers from international suppliers?

To ensure quality when sourcing three-phase transformers from international suppliers, conduct thorough due diligence. Verify the supplier’s certifications, such as ISO 9001 for quality management. Request samples or visit their manufacturing facilities if possible. Additionally, review customer testimonials and third-party quality assessments. Establishing a clear quality assurance process and setting up regular communication can also help maintain standards throughout the production and delivery phases.

4. What are the common payment terms for purchasing three-phase transformers internationally?

Payment terms for international purchases of three-phase transformers typically vary by supplier but often include options like Letter of Credit (LC), advance payments, or open account terms. It’s crucial to negotiate terms that protect both parties, ensuring security and trust. Discussing partial payments based on milestones (e.g., down payment, upon shipping) can also be beneficial. Always clarify the currency and the method of payment to avoid misunderstandings and ensure compliance with local financial regulations.

5. What is the minimum order quantity (MOQ) for three-phase transformers?

Minimum order quantities (MOQs) for three-phase transformers can vary significantly between manufacturers and depend on the type and specifications of the transformers. Commonly, MOQs may range from 1 to 10 units for standard models, while custom transformers may have higher MOQs due to specialized production processes. When negotiating with suppliers, express your needs clearly, as some may offer flexibility on MOQs for long-term partnerships or larger orders.

6. How do I arrange logistics for importing three-phase transformers?

Arranging logistics for importing three-phase transformers involves several key steps. First, select a reliable freight forwarder experienced in handling heavy machinery and electrical equipment. Discuss shipping options, including air freight for speed or sea freight for cost-effectiveness. Ensure that all necessary customs documentation, such as commercial invoices and packing lists, is prepared. Additionally, consider insurance to protect against damage during transit and coordinate delivery timelines with your operational requirements.

7. What are the customization options available for three-phase transformers?

Customization options for three-phase transformers often include variations in voltage ratings, kVA capacity, and physical dimensions to fit specific applications. Suppliers may also offer features such as different cooling methods, tap changers for voltage adjustment, and protective enclosures for harsh environments. Discuss your specific requirements with the manufacturer early in the negotiation process to ensure they can meet your needs while adhering to industry standards and regulations.

8. How can I verify the compliance of a three-phase transformer with international standards?

To verify compliance with international standards for three-phase transformers, request documentation from the supplier, including certificates of conformity and testing reports. Common standards to look for include IEC (International Electrotechnical Commission) and ANSI (American National Standards Institute). Additionally, inquire about the testing procedures the transformers underwent, such as short-circuit tests and temperature rise tests. Engaging a third-party inspection service can also provide an additional layer of assurance regarding compliance before shipment.

Top 5 Three Phase Transformer Chart Manufacturers & Suppliers List

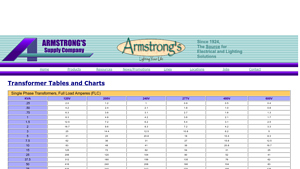

1. Armstrong’s Supply – Transformer Tables and Charts

Domain: armstrongssupply.com

Registered: 2002 (23 years)

Introduction: Armstrong’s Supply offers transformer tables and charts for single phase and three phase transformers. Key details include: 1. Single Phase Transformers: Full Load Amperes (FLC) for various KVA ratings (0.25 to 1000) at voltages of 120V, 208V, 240V, 277V, 480V, and 600V. 2. Three Phase Transformers: FLC for KVA ratings (3 to 1000) at voltages of 208V, 240V, 480V, and 600V. 3. Insulation Class and …

2. Meta Power Solutions – Pad Mount Transformers

Domain: metapowersolutions.com

Registered: 2021 (4 years)

Introduction: Single Phase Pad Mount Transformers: 25 kVA, 50 kVA, 75 kVA, 100 kVA, 125 kVA, Clam-Shell 150 kVA; Three Phase Pad Mount Transformers: 50 kVA, 80 kVA, 100 kVA, 160 kVA, 200 kVA, 250 kVA, 315 kVA, 500 kVA, 630 kVA, 800 kVA, 1000 kVA, 1500 kVA, 2000 kVA, 2500 kVA, 3000 kVA, 3750 kVA, 5000 kVA; Substation Transformers: 76 MVA, 1000 kVA, 1500 kVA, 2000 kVA, 2500 kVA, 3000 kVA, 3750 kVA, 5000 kVA, 1000…

3. Electronics Tutorials – Three-Phase Transformers

Domain: electronics-tutorials.ws

Introduction: Three-phase transformers are essential for electrical power distribution, utilizing Delta or Star connected windings. They are used for generating and transmitting electric power over long distances for industrial and office use. Three-phase transformers can be constructed by connecting three single-phase transformers or using a pre-assembled three-phase transformer with three pairs of windings on…

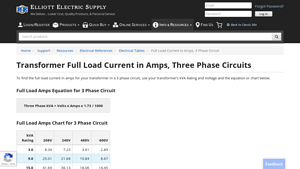

4. Elliott Electric – Transformer Full Load Current Guide

Domain: elliottelectric.com

Registered: 1997 (28 years)

Introduction: Transformer Full Load Current in Amps for Three Phase Circuits

5. ShinEnergy – Three-Phase Transformers

Domain: shinenergy.net

Registered: 2010 (15 years)

Introduction: Three-phase transformers are devices used in three-phase power systems, consisting of three windings corresponding to each phase. They step up or step down voltage to meet different power requirements and are widely used in power grids, factories, and commercial buildings for stable electricity supply. Compared to single-phase transformers, three-phase transformers offer higher efficiency and bala…

Strategic Sourcing Conclusion and Outlook for three phase transformer chart

In navigating the complexities of the three-phase transformer market, strategic sourcing emerges as a crucial component for B2B buyers. Understanding the full load amps, voltage ratings, and efficiency metrics of transformers allows for informed decision-making that aligns with operational needs and budgetary constraints. With the increasing demand for reliable energy solutions in regions such as Africa, South America, the Middle East, and Europe, leveraging a comprehensive three-phase transformer chart can significantly enhance procurement strategies.

International buyers should prioritize partnerships with manufacturers who demonstrate a commitment to quality, sustainability, and innovation. This not only ensures the acquisition of high-performance transformers but also fosters long-term relationships that can adapt to evolving market demands.

Illustrative image related to three phase transformer chart

As global energy landscapes continue to shift, now is the time to reassess your sourcing strategies. Embrace the insights gained from this guide to drive efficiency and resilience in your operations. Equip yourself with the knowledge to make strategic investments in three-phase transformers that will power your growth. Engage with suppliers who can offer tailored solutions that meet your unique requirements, and lead your organization towards a sustainable energy future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.