Everything You Need to Know About Thermowell Types Sourcing in 2025

Introduction: Navigating the Global Market for thermowell types

In the ever-evolving landscape of industrial processes, sourcing the right thermowell types can pose significant challenges for B2B buyers. These protective tubes, essential for safeguarding temperature sensors against extreme conditions, vary greatly in design and functionality, making the selection process critical. This comprehensive guide delves into the diverse thermowell types, exploring their applications across various industries, from oil and gas to food processing, and providing insights into supplier vetting, cost considerations, and best practices for procurement.

As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (including markets such as Nigeria and Brazil) seek to enhance operational efficiency, understanding the nuances of thermowell design—such as straight, tapered, and stepped configurations—becomes paramount. This guide empowers decision-makers to navigate the complexities of thermowell sourcing with confidence, ensuring they select products that meet their specific process requirements while optimizing performance and reliability. By equipping buyers with actionable insights and expert recommendations, this resource aims to facilitate informed purchasing decisions, ultimately contributing to enhanced productivity and reduced downtime in their operations.

With a focus on practical applications and strategic sourcing, this guide is your essential companion in the global market for thermowell types.

Understanding thermowell types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight | Uniform diameter throughout; cost-effective | Moderate pressure and temperature systems | Pros: Simple installation, lower cost. Cons: Less effective under high-stress conditions. |

| Tapered | Gradually reduces diameter; enhances vibration resistance | High-pressure and high-velocity applications | Pros: Durable, minimizes vibrations. Cons: Higher manufacturing costs. |

| Stepped | Abrupt diameter changes; balances response time and stress distribution | Medium-pressure applications | Pros: Faster response time, cost-effective. Cons: Stress distribution not as even as tapered. |

| Threaded | External threads for easy screw-in installation | Low to medium-pressure environments | Pros: Simple installation, economical. Cons: Not suitable for high-pressure applications. |

| Welded | Permanently welded for robust connections | High-pressure and temperature processes | Pros: Leak-proof, strong connections. Cons: Difficult to remove, higher installation cost. |

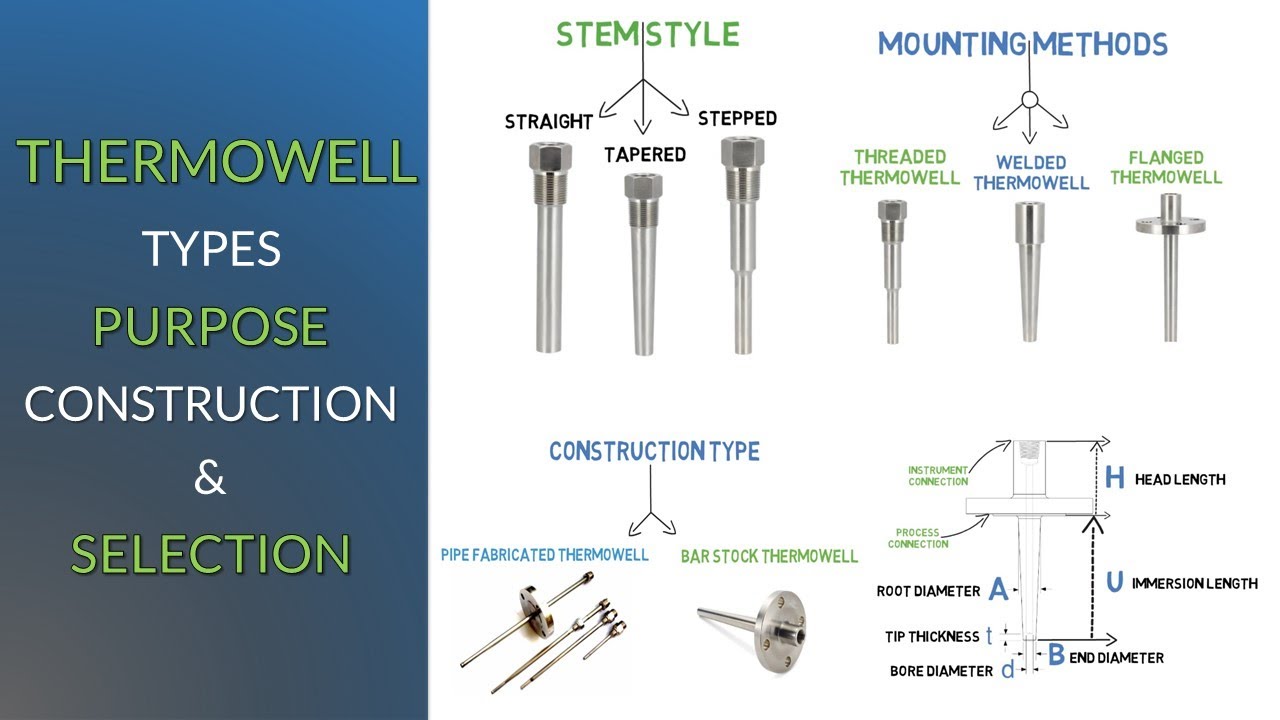

What Are the Characteristics of Straight Thermowells?

Straight thermowells feature a consistent diameter along their entire length, making them ideal for applications with moderate pressure and temperature conditions. Their straightforward design allows for cost-effective manufacturing and installation, making them a popular choice among B2B buyers looking for economical solutions. However, they may not perform as effectively in high-stress environments or turbulent fluid flows, which can lead to potential measurement inaccuracies.

How Do Tapered Thermowells Enhance Performance?

Tapered thermowells are designed with a gradually reducing diameter from base to tip, which helps distribute stress evenly across the structure. This design is particularly beneficial in high-pressure and high-velocity applications, where vibration resistance is crucial. While they are more durable than their straight counterparts, the complexity of their manufacturing results in higher costs. B2B buyers should weigh the benefits of enhanced durability against the initial investment.

What Are the Advantages of Stepped Thermowells?

Stepped thermowells incorporate abrupt diameter changes along their length, providing a balance between response time and stress distribution. They are suitable for medium-pressure applications and offer a quicker response time compared to straight thermowells. While they are generally more affordable than tapered designs, buyers should consider that the stress distribution is not as uniform, which could affect performance in certain scenarios.

Why Choose Threaded Thermowells for Low-Pressure Applications?

Threaded thermowells are characterized by external threads that allow for easy screw-in installation, making them an attractive option for low to medium-pressure environments. Their simplicity and cost-effectiveness are significant advantages, especially for companies looking to minimize installation time and expenses. However, buyers should be cautious as these thermowells are not recommended for high-pressure applications due to potential leak risks.

What Makes Welded Thermowells Suitable for High-Pressure Applications?

Welded thermowells provide robust, leak-proof connections due to their permanent welding to the process system. This design is ideal for high-pressure and high-temperature applications where reliability is paramount. While they ensure strong connections, the trade-off is that they are more challenging to remove and typically come with a higher installation cost. B2B purchasers should assess the long-term benefits of durability against the complexities of installation and maintenance.

Key Industrial Applications of thermowell types

| Industry/Sector | Specific Application of thermowell types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Temperature monitoring in pipelines and refineries | Enhanced safety and efficiency in operations | Material compatibility with corrosive substances, pressure ratings |

| Food & Beverage | Monitoring temperatures in pasteurization processes | Ensures product quality and compliance with safety standards | Hygienic design requirements, easy maintenance |

| Chemical Manufacturing | Temperature control in reactors and distillation units | Improved process control and product consistency | Resistance to aggressive chemicals, suitable connection types |

| HVAC Systems | Monitoring temperatures in heating and cooling systems | Optimized energy consumption and system longevity | Adaptability to various installation methods and environments |

| Pharmaceutical Production | Temperature measurement in drug formulation processes | Guarantees product integrity and regulatory compliance | High precision and reliability in extreme conditions |

How Are Thermowell Types Used in the Oil & Gas Industry?

In the oil and gas sector, thermowells are essential for monitoring temperatures in pipelines and refineries. They protect temperature sensors from harsh conditions, ensuring accurate readings that enhance safety and operational efficiency. Buyers should consider materials like Inconel or stainless steel for corrosion resistance and high-pressure ratings, critical for maintaining system integrity in challenging environments typical of oil extraction and processing.

What Role Do Thermowell Types Play in the Food & Beverage Industry?

In food and beverage applications, thermowells are used to monitor temperatures during pasteurization and other critical processes. They ensure compliance with safety standards and help maintain product quality by providing accurate temperature readings. Buyers in this sector must prioritize hygienic designs and ease of maintenance to meet stringent health regulations while also considering the materials used to avoid contamination.

Why Are Thermowell Types Important in Chemical Manufacturing?

Chemical manufacturing relies on thermowells for effective temperature control in reactors and distillation units. These devices protect temperature sensors from aggressive chemicals while ensuring precise readings that lead to improved process control and product consistency. Buyers should focus on sourcing thermowells made from materials that can withstand harsh chemical environments and evaluate connection types to ensure compatibility with their systems.

How Do Thermowell Types Enhance HVAC Systems?

In HVAC systems, thermowells are crucial for monitoring temperatures in heating and cooling applications. By providing accurate temperature data, they help optimize energy consumption and prolong system lifespan. Buyers should look for thermowells that are adaptable to various installation methods and environments, ensuring they can integrate seamlessly into existing systems while maintaining reliability under varying operational conditions.

What Is the Significance of Thermowell Types in Pharmaceutical Production?

Thermowells are vital in pharmaceutical production for measuring temperatures during drug formulation processes. Accurate temperature monitoring is essential to guarantee product integrity and compliance with regulatory standards. Buyers must ensure that the thermowells they select offer high precision and reliability, particularly in extreme conditions, and consider the compatibility of materials to safeguard against contamination and degradation.

3 Common User Pain Points for ‘thermowell types’ & Their Solutions

Scenario 1: Challenges with High-Pressure Applications

The Problem: Buyers often struggle with thermowell failures in high-pressure environments, which can lead to costly downtime and safety hazards. A common issue arises when standard thermowells are unable to withstand the extreme conditions, resulting in leaks or even catastrophic failures. This scenario is particularly relevant in industries such as oil and gas, chemical processing, and power generation, where equipment must endure harsh operational demands.

The Solution: To address this challenge, it’s critical to choose thermowells specifically designed for high-pressure applications. Opt for welded thermowells that provide secure, leak-proof connections, ensuring they can withstand elevated pressures and temperatures. When sourcing, look for thermowells made from robust materials like Inconel or Hastelloy, which offer excellent strength and corrosion resistance. Additionally, consider the diameter and length of the thermowell to ensure it is compatible with the process conditions. Engage with suppliers who can provide detailed specifications and data sheets, allowing for informed decisions that enhance operational safety and efficiency.

Scenario 2: Slow Response Time Issues

The Problem: Another prevalent issue faced by B2B buyers involves delayed temperature readings due to the insulating properties of thermowells. In industries where rapid temperature changes are critical—such as food processing or pharmaceuticals—slow response times can lead to suboptimal production conditions and affect product quality. Buyers often feel frustrated when they realize that their existing thermowells are not suited for quick measurement needs.

The Solution: To mitigate slow response times, consider switching to tapered or stepped thermowell designs. These designs are engineered to minimize thermal lag by allowing heat transfer to the sensor more efficiently. When specifying a new thermowell, ensure it has the right diameter and length to match the application requirements while also considering the flow characteristics of the process media. Furthermore, consult with manufacturers about response time data for different thermowell designs to select the most effective option. This proactive approach can significantly enhance measurement accuracy and process control.

Scenario 3: Vibration and Mechanical Stress Failures

The Problem: In dynamic environments where equipment experiences significant vibrations, such as in manufacturing or heavy machinery applications, thermowells can suffer from mechanical failures. Buyers often report issues such as fatigue or breakage, which can lead to sensor damage and increased maintenance costs. This situation is particularly acute in processes with high-velocity flows, where the stress on thermowells is exacerbated.

The Solution: To combat vibration-induced failures, it is advisable to invest in tapered thermowells, which are specifically designed to distribute stress more evenly and reduce the risk of fatigue. Additionally, implementing vibration dampening solutions, such as vibration isolators or supports, can further enhance the longevity of thermowells in these conditions. When sourcing, work closely with suppliers who can provide insights into the best practices for installation and maintenance, ensuring that the thermowell is securely mounted and capable of withstanding environmental challenges. Regularly reviewing the performance of thermowells and conducting maintenance checks will also help in identifying potential issues before they escalate, ultimately saving time and costs in the long run.

Strategic Material Selection Guide for thermowell types

When selecting thermowells for industrial applications, the choice of material is critical. Different materials offer unique properties that can significantly influence performance, durability, and cost. Here, we analyze four common materials used in thermowell construction: stainless steel, Inconel, Hastelloy, and brass. Each material has its advantages and disadvantages, which must be considered in the context of specific applications and regional standards.

What Are the Key Properties of Stainless Steel for Thermowells?

Stainless steel is one of the most widely used materials for thermowells due to its excellent combination of strength, corrosion resistance, and temperature tolerance. Typically, grades such as 304 and 316 are favored for their ability to withstand temperatures up to 800°F (427°C) and pressures exceeding 1500 psi. Stainless steel’s inherent resistance to oxidation and corrosion makes it suitable for a variety of media, including water, oil, and chemicals.

Pros: The durability of stainless steel thermowells is a major advantage, as they can last longer in harsh environments. They are relatively cost-effective compared to high-performance alloys and are easier to manufacture.

Cons: However, stainless steel may not be the best choice for highly corrosive environments, such as those involving chlorides, which can lead to pitting. Additionally, while they are generally easy to install, threaded connections may not be suitable for high-pressure applications.

How Does Inconel Perform in High-Temperature Applications?

Inconel is a nickel-chromium-based superalloy known for its exceptional performance in high-temperature and high-pressure environments. It can withstand temperatures up to 2200°F (1204°C) and is highly resistant to oxidation and corrosion, making it ideal for extreme conditions.

Pros: The primary advantage of Inconel thermowells is their ability to maintain structural integrity in extreme environments, thus extending sensor life and reliability. They are particularly suitable for applications involving aggressive media, such as acids and high-temperature gases.

Cons: On the downside, Inconel is significantly more expensive than stainless steel and is more complex to manufacture, which can increase lead times. Additionally, the weight of Inconel can be a consideration in certain applications.

What Are the Benefits of Using Hastelloy for Thermowells?

Hastelloy is another high-performance alloy, primarily used in applications that require exceptional corrosion resistance. It is particularly effective against reducing environments and can handle temperatures up to 2000°F (1093°C).

Pros: The key advantage of Hastelloy is its versatility and resistance to a wide range of corrosive chemicals, making it suitable for chemical processing industries. Its durability ensures long-term performance, reducing the frequency of replacements.

Cons: However, Hastelloy is one of the most expensive materials available for thermowells, which can be a limiting factor for budget-conscious buyers. Its manufacturing complexity can also lead to longer lead times.

Why is Brass Considered for Thermowell Applications?

Brass is often used in lower-cost applications where corrosion resistance is less critical. It typically handles temperatures up to 400°F (204°C) and is suitable for non-corrosive media such as water and air.

Pros: The primary advantage of brass thermowells is their low cost and ease of manufacturing, making them ideal for budget-sensitive projects. They also provide good thermal conductivity, which can enhance sensor response times.

Cons: However, brass is not suitable for high-temperature or corrosive environments, which limits its use. Additionally, it may not withstand high-pressure applications, making it less versatile compared to other materials.

Summary Table of Thermowell Materials

| Material | Typical Use Case for thermowell types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Water, oil, and moderate chemicals | Durable and cost-effective | Limited in highly corrosive environments | Medium |

| Inconel | High-temperature and high-pressure applications | Exceptional corrosion resistance | High cost and complex manufacturing | High |

| Hastelloy | Chemical processing and aggressive media | Versatile and durable | Very high cost and longer lead times | High |

| Brass | Low-cost applications, non-corrosive media | Low cost and easy to manufacture | Unsuitable for high-temperature or corrosive environments | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, particularly those operating in diverse environments across Africa, South America, the Middle East, and Europe. Understanding the specific properties and limitations of each material will aid in making informed decisions that align with application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for thermowell types

What Are the Key Stages in the Manufacturing Process of Thermowells?

The manufacturing process of thermowells involves several critical stages designed to ensure precision and durability. Understanding these stages is essential for B2B buyers looking to procure high-quality thermowells that meet their specific application requirements.

Material Preparation: What Materials Are Commonly Used for Thermowells?

The first step in manufacturing thermowells is material preparation. Common materials include stainless steel, Inconel, and Hastelloy, chosen for their mechanical strength and resistance to corrosion and high temperatures. The selection of material depends on the application’s environmental conditions, including pressure and chemical exposure.

After selecting the appropriate material, it undergoes a series of treatments to enhance its properties. Processes such as annealing and hardening are often employed to improve the material’s strength and ductility. This stage is crucial as it directly impacts the thermowell’s performance in demanding industrial environments.

How Are Thermowells Formed?

The forming stage involves shaping the prepared material into the desired thermowell design. This can be achieved through various techniques, including:

-

Machining: Utilized to create precise dimensions and features, machining is often employed for straight thermowells. CNC machines are commonly used to ensure high accuracy and repeatability.

-

Hot and Cold Forging: These techniques are typically used for tapered and stepped thermowells. Hot forging allows for shaping the material at elevated temperatures, enhancing ductility, while cold forging is utilized for achieving tight tolerances.

-

Welding: For connection types such as flanged or welded thermowells, welding techniques are employed to join different sections securely. This requires skilled personnel to ensure that welds are robust and leak-proof.

What Happens During Assembly and Finishing?

Once the thermowell is formed, the assembly stage involves integrating components such as connections and seals. Each component must be precisely aligned and securely fastened to ensure that the thermowell can withstand operational stresses.

Finishing processes, including surface treatment and coating, are applied to enhance corrosion resistance and improve aesthetic appeal. Common finishing techniques include polishing, passivation, and applying protective coatings. These processes not only improve longevity but also ensure compliance with industry standards.

What Quality Assurance Measures Are in Place for Thermowells?

Quality assurance (QA) is paramount in thermowell manufacturing, ensuring that products meet both international and industry-specific standards. B2B buyers should be familiar with these measures to verify the quality of thermowells they are purchasing.

Which International Standards Apply to Thermowells?

Thermowell manufacturers often adhere to international quality management standards such as ISO 9001. This standard emphasizes a process-oriented approach to quality management, covering all aspects of production, from design to delivery.

In addition to ISO standards, industry-specific certifications like CE marking for the European market and API standards for the oil and gas industry may apply. These certifications ensure that thermowells meet rigorous safety and performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are crucial throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter production. Materials are inspected for compliance with specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections and measurements are taken to ensure that the thermowell is being produced according to specifications. This includes monitoring dimensions, material properties, and assembly integrity.

-

Final Quality Control (FQC): Once manufacturing is complete, final inspections are conducted to ensure that the thermowell meets all quality and performance standards. This may include pressure testing, dimensional checks, and functionality tests.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring product reliability. Here are some actionable strategies:

-

Request Certification Documents: Buyers should request copies of ISO, CE, or API certification documents from suppliers. This provides assurance that the manufacturer adheres to recognized quality standards.

-

Conduct Audits: Periodic audits of suppliers can help verify compliance with quality processes. Buyers can request to visit manufacturing facilities to assess production capabilities and quality assurance practices firsthand.

-

Seek Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased verification of product quality. These agencies can conduct tests and audits, ensuring that the thermowells meet the required standards before shipment.

-

Review Quality Reports: Suppliers should be able to provide comprehensive quality reports, detailing the results of various tests conducted during manufacturing. Analyzing these reports can help buyers understand the consistency and reliability of the thermowells.

What Nuances Should International B2B Buyers Be Aware Of?

B2B buyers operating internationally should be aware of specific nuances regarding quality control and certification. For instance, certain regions may have additional regulatory requirements that suppliers must meet. Buyers should conduct thorough research into the regulations applicable to their target markets.

Moreover, understanding the logistical challenges associated with international shipping and customs can affect the overall quality of thermowells upon arrival. Ensuring proper handling and storage during transit is crucial to maintain product integrity.

Illustrative image related to thermowell types

By being informed about manufacturing processes and quality assurance measures, B2B buyers can make more educated decisions when sourcing thermowells, ultimately leading to enhanced operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘thermowell types’

In the competitive landscape of industrial equipment procurement, sourcing the right thermowell type is critical for ensuring optimal temperature measurement and sensor protection. This practical checklist will guide B2B buyers through the essential steps to make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your application is the first step in selecting the appropriate thermowell. Consider factors such as the operating temperature, pressure levels, and the nature of the media being measured. These parameters will determine the material and design of the thermowell, ensuring it meets the demands of your industrial processes.

- Key Considerations:

- Maximum and minimum temperature ratings.

- Pressure ratings to avoid failure during operation.

- Compatibility with corrosive or abrasive media.

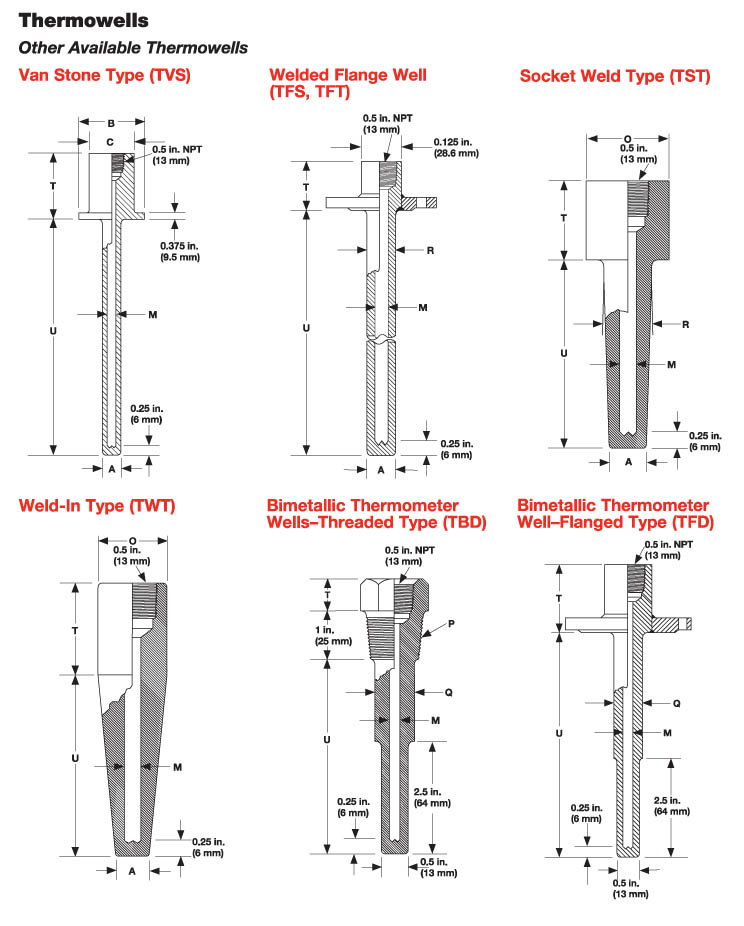

Step 2: Choose the Right Thermowell Design

Select a thermowell design that aligns with your process conditions. The main types include straight, tapered, and stepped thermowells, each with distinct advantages. For example, tapered thermowells offer better vibration resistance, making them suitable for high-velocity applications.

- Design Implications:

- Straight thermowells are cost-effective but less durable under stress.

- Tapered designs provide enhanced durability but may come at a higher cost.

- Stepped designs offer a balance between response time and stress distribution.

Step 3: Evaluate Material Options

The material of the thermowell is crucial for ensuring longevity and performance. Common materials include stainless steel, Inconel, and Hastelloy, each offering varying degrees of resistance to corrosion and temperature extremes.

- Material Factors to Assess:

- Chemical compatibility with the process media.

- Temperature tolerance and mechanical strength.

- Cost-effectiveness based on material properties.

Step 4: Select Connection Type

The connection type between the thermowell and the process system is vital for operational integrity. Common connection types include threaded, welded, flanged, and socket-welded. Each type has its own advantages and limitations regarding installation ease, pressure handling, and potential leak risks.

- Connection Insights:

- Threaded connections are easier to install but may leak under high pressure.

- Welded connections provide leak-proof security but complicate maintenance.

- Flanged connections allow for easy replacement but can be leak paths.

Step 5: Verify Supplier Certifications

Before finalizing a supplier, ensure they hold relevant certifications and adhere to industry standards. Certifications such as ISO 9001 or ASME can indicate a commitment to quality and reliability.

- Verification Steps:

- Request documentation of certifications.

- Inquire about the supplier’s quality control processes.

- Check for compliance with international standards relevant to your industry.

Step 6: Assess Supplier Experience and Reputation

Evaluate the supplier’s experience in the thermowell market and their reputation within the industry. A supplier with a solid track record can provide valuable insights and support throughout the procurement process.

- Reputation Check:

- Look for case studies or testimonials from previous clients.

- Research their history of delivering products on time and within specifications.

- Engage with industry peers to gather feedback on potential suppliers.

Step 7: Negotiate Terms and Pricing

Once you have narrowed down your options, engage in discussions to negotiate terms and pricing. Consider not only the initial costs but also the total cost of ownership, including maintenance, warranty, and replacement costs.

- Negotiation Tips:

- Compare quotes from multiple suppliers.

- Discuss potential bulk discounts or long-term contracts.

- Clarify warranty terms and after-sales support to ensure value.

By following this checklist, B2B buyers can navigate the complexities of sourcing thermowell types effectively, ensuring the selection aligns with their operational needs and enhances overall process efficiency.

Illustrative image related to thermowell types

Comprehensive Cost and Pricing Analysis for thermowell types Sourcing

When sourcing thermowell types, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This analysis breaks down the key cost components and price influencers, alongside actionable tips for effective negotiation.

What Are the Key Cost Components in Thermowell Sourcing?

-

Materials: The choice of material significantly impacts the cost of thermowells. Common materials include stainless steel, Inconel, and Hastelloy, each with varying price points based on their corrosion resistance, temperature tolerance, and mechanical strength. For instance, Inconel is typically more expensive than stainless steel due to its superior performance in high-temperature environments.

-

Labor: Labor costs can vary based on the complexity of the manufacturing process. Custom designs or specialized features may require skilled labor, thus increasing costs. Regions with lower labor costs may offer competitive pricing, but this should be balanced against quality and delivery timelines.

-

Manufacturing Overhead: This encompasses costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, but these savings may not always be passed on to the buyer.

-

Tooling: The initial investment in tooling can be substantial, especially for custom designs. Buyers should inquire about tooling costs and whether they are amortized over production runs, as this can affect pricing structures significantly.

-

Quality Control (QC): Ensuring that thermowells meet industry standards involves rigorous QC processes. High-quality certifications may add to the overall cost but are essential for ensuring reliability and compliance in demanding applications.

-

Logistics: Shipping and handling costs can fluctuate based on the origin and destination of the products. International buyers must consider tariffs, duties, and freight charges, which can substantially influence the total cost.

-

Margin: Suppliers typically include a margin to cover business risks and profit. Understanding the average margins in your specific market can help in evaluating supplier pricing.

What Influences Pricing in Thermowell Sourcing?

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Custom designs or specific material requirements will lead to higher costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Quality and Certifications: Thermowells that meet stringent international standards will command higher prices. Buyers should weigh the importance of certifications against their application requirements.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their proven quality and service, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers in terms of shipping, insurance, and tariffs, affecting the final price.

What Are Effective Buyer Tips for Thermowell Sourcing?

-

Negotiate Wisely: Utilize your understanding of the cost components and pricing influencers to negotiate better terms. Don’t hesitate to ask for discounts on larger orders or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price to evaluate TCO, which includes maintenance, operational efficiency, and potential downtime costs due to failures.

-

Be Aware of Pricing Nuances: Different regions have varying pricing structures based on local market conditions, currency fluctuations, and supply chain dynamics. Understanding these nuances can provide leverage in negotiations.

-

Seek Multiple Quotes: Obtaining quotes from multiple suppliers can help in benchmarking prices and identifying the best value for your requirements.

-

Evaluate Supplier Relationships: Building strong relationships with reliable suppliers can lead to better pricing, priority service, and insights into market trends.

Disclaimer

Prices mentioned here are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and updated pricing information.

Alternatives Analysis: Comparing thermowell types With Other Solutions

Understanding Alternatives to Thermowell Types

In the industrial landscape, selecting the right temperature measurement solution is crucial for optimizing process efficiency and ensuring safety. While thermowells are widely recognized for their protective capabilities and versatility, it is essential to explore alternative solutions that may offer distinct advantages depending on specific application requirements. This section compares thermowell types with two viable alternatives: direct temperature sensors and immersion heaters.

Comparison Table

| Comparison Aspect | Thermowell Types | Direct Temperature Sensors | Immersion Heaters |

|---|---|---|---|

| Performance | Effective protection under varying conditions; response time affected by design | Quick response time; direct contact with media | Fast heating of liquids; effective in various applications |

| Cost | Moderate to high due to materials and design complexity | Generally lower upfront cost; fewer materials | Variable costs; often lower than thermowells |

| Ease of Implementation | Requires skilled installation, especially for welded types | Simple installation; minimal setup needed | Easy to install; typically plug-and-play |

| Maintenance | Moderate; threaded and flanged types allow for easy maintenance | Low; sensors can be easily replaced | Moderate; requires periodic checks but less frequent |

| Best Use Case | High-pressure, corrosive environments where sensor protection is critical | Applications requiring rapid temperature changes | Heating liquids in tanks, vats, or other containers |

Detailed Breakdown of Alternatives

Direct Temperature Sensors

Direct temperature sensors, such as thermocouples and RTDs, are popular for their ability to provide immediate temperature readings. These sensors function by measuring the temperature of the media directly, which allows for a rapid response time. However, their lack of protective casing means they are more susceptible to damage in harsh environments, which can lead to shorter lifespans and higher replacement costs. They are best suited for applications where quick temperature changes are common, and the media is not overly corrosive or under extreme pressure.

Immersion Heaters

Immersion heaters offer a different approach by directly heating the liquid or material they are placed into. They are ideal for applications that require consistent heating, such as in water tanks or chemical processing. The primary advantage of immersion heaters is their efficiency in transferring heat to the media, resulting in quicker heating times. However, they do not provide temperature measurement capabilities on their own and may require additional sensors to monitor temperature, leading to a more complex system. Additionally, immersion heaters can be costly to operate in terms of energy consumption, depending on the application.

Illustrative image related to thermowell types

Conclusion: Making the Right Choice for Your Needs

When evaluating temperature measurement solutions, B2B buyers must consider the specific requirements of their applications. Thermowells provide a robust option for high-pressure and corrosive environments, ensuring sensor longevity and reliability. However, for scenarios where rapid temperature changes are critical, direct temperature sensors may be more effective. On the other hand, immersion heaters are ideal for applications focused on heating rather than measurement. By assessing performance, cost, ease of implementation, maintenance, and best use cases, buyers can make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for thermowell types

What Are the Key Technical Properties of Thermowell Types?

Understanding the technical specifications of thermowells is essential for B2B buyers who seek to make informed decisions. Here are some critical specifications:

-

Material Grade: Thermowells are commonly constructed from materials such as stainless steel, Inconel, and Hastelloy. The material choice significantly impacts durability, corrosion resistance, and thermal conductivity. For instance, stainless steel is suitable for most applications, while Inconel is ideal for high-temperature and corrosive environments. Selecting the appropriate material can lead to longer operational life and reduced maintenance costs.

-

Pressure Rating: This specification indicates the maximum pressure a thermowell can withstand without failure. It is crucial for ensuring safety and functionality in high-pressure systems. Buyers must match the thermowell’s pressure rating with the operational conditions of their processes to prevent catastrophic failures.

-

Temperature Rating: Similar to pressure ratings, temperature ratings specify the maximum temperature that a thermowell can endure. This property is vital in applications involving extreme heat, ensuring that the thermowell maintains its integrity and performance over time. Selecting a thermowell with an inadequate temperature rating can lead to sensor failure and costly downtime.

-

Tolerance: This refers to the allowable deviation in the thermowell’s dimensions and performance characteristics. In precision applications, tighter tolerances ensure better performance and reliability. Buyers should assess their application requirements to determine the necessary tolerance levels for optimal results.

-

Connection Type: The type of connection—threaded, welded, flanged, or socket welded—affects installation and maintenance. Understanding these options helps buyers choose the most suitable thermowell for their specific process conditions and allows for easier integration into existing systems.

Which Trade Terms Should B2B Buyers of Thermowells Know?

Familiarity with industry jargon can facilitate smoother transactions and better communication. Here are several key terms:

Illustrative image related to thermowell types

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the thermowell context, understanding OEM capabilities can help buyers assess the quality and compatibility of thermowells with their existing systems.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for businesses looking to minimize excess stock.

-

RFQ (Request for Quotation): An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. Submitting an RFQ is a crucial step in the procurement process, allowing buyers to compare offers and negotiate better terms.

-

Incoterms (International Commercial Terms): These are a set of predefined trade terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping costs, risks, and delivery responsibilities, ensuring a smoother supply chain process.

-

Lead Time: This term refers to the amount of time between placing an order and receiving the goods. Knowing the lead time is critical for planning and inventory management, especially in industries where timely delivery is essential.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions, streamline procurement processes, and enhance operational efficiency in their industries.

Navigating Market Dynamics and Sourcing Trends in the thermowell types Sector

What Are the Key Market Drivers Impacting Thermowell Types?

The thermowell market is witnessing robust growth driven by various global factors. Increasing industrial automation and the rising demand for temperature monitoring in sectors like oil and gas, chemical processing, and food and beverage are primary catalysts. In regions such as Africa, South America, and the Middle East, infrastructure development and the expansion of manufacturing capabilities are pushing the need for reliable temperature measurement solutions. Moreover, European regulations mandating stringent safety and environmental standards are prompting businesses to invest in high-quality thermowells.

Current trends indicate a shift towards smart thermowell solutions, integrating IoT and advanced data analytics to enhance operational efficiency. These innovations enable real-time monitoring, predictive maintenance, and improved decision-making, making them attractive for international B2B buyers looking to optimize processes. Additionally, there is a growing preference for customized thermowell solutions tailored to specific application requirements, which allows buyers to achieve better performance in their unique operational environments.

How Are Sustainability and Ethical Sourcing Influencing Thermowell Procurement?

Sustainability and ethical sourcing are becoming integral to the procurement strategies of international B2B buyers in the thermowell sector. The environmental impact of manufacturing processes, particularly in terms of carbon emissions and resource consumption, is under scrutiny. Companies are increasingly looking for suppliers who prioritize sustainable practices, such as using recycled materials and minimizing waste in production.

Illustrative image related to thermowell types

The importance of ethical supply chains cannot be overstated. Buyers are more likely to engage with manufacturers who demonstrate transparency in their sourcing practices and labor conditions. Certifications such as ISO 14001 for environmental management and other ‘green’ labels are becoming essential for suppliers aiming to establish credibility in the market. Additionally, the use of environmentally friendly materials, such as stainless steel with lower carbon footprints, is gaining traction as businesses seek to align with global sustainability goals.

How Has the Thermowell Market Evolved Over Time?

The evolution of the thermowell market can be traced back to the industrial revolution when the need for reliable temperature measurement became paramount in various manufacturing processes. Initially, thermowells were simple metal tubes, but advancements in materials science and engineering have led to the development of sophisticated designs that offer enhanced durability and performance.

Over the decades, the integration of technology into thermowell design has transformed the sector. The introduction of smart sensors and IoT capabilities has enabled real-time data transmission, significantly improving monitoring accuracy and response times. As industries face increasing demands for efficiency and safety, the thermowell market continues to innovate, adapting to the needs of modern applications while maintaining a strong focus on sustainability and ethical practices.

Illustrative image related to thermowell types

In summary, the thermowell sector is poised for growth, with key market drivers stemming from technological advancements, sustainability imperatives, and evolving buyer expectations. International B2B buyers should focus on leveraging these trends to enhance their procurement strategies and ensure they are sourcing from responsible and innovative suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of thermowell types

-

How do I select the right thermowell for my application?

Selecting the right thermowell involves evaluating several factors, including process conditions (temperature and pressure), material compatibility, and design type. For high-stress environments, tapered or stepped thermowells are preferable due to their better stress distribution. Additionally, consider the connection type (threaded, welded, flanged, or socket welded) based on the installation requirements and the ability to facilitate maintenance. Always consult with suppliers to ensure compliance with industry standards and to address specific application needs. -

What materials are commonly used for thermowells, and why are they important?

Common materials for thermowells include stainless steel, Inconel, and Hastelloy. The choice of material is critical as it impacts the thermowell’s resistance to corrosion, temperature extremes, and mechanical stress. Stainless steel is typically used for its balance of cost and durability, while Inconel and Hastelloy are chosen for harsh chemical environments. Assess your application’s chemical compatibility and thermal requirements before finalizing your material choice. -

What are the advantages and disadvantages of different thermowell designs?

Thermowell designs include straight, tapered, and stepped configurations. Straight thermowells are cost-effective but less suitable for high-stress applications. Tapered thermowells offer better vibration resistance and stress distribution, making them ideal for high-pressure environments, though they tend to be more expensive. Stepped thermowells provide a compromise, enhancing response time while maintaining reasonable costs. Weigh these factors based on your specific operational needs. -

What minimum order quantities (MOQs) should I expect when sourcing thermowells?

Minimum order quantities for thermowells can vary significantly based on the supplier and the specific type of thermowell required. Generally, MOQs can range from a few units for standard models to larger quantities for customized designs. It’s advisable to communicate directly with suppliers to negotiate MOQs that align with your purchasing capabilities while ensuring the best pricing and lead times. -

How can I ensure the quality of thermowells from international suppliers?

To ensure quality, verify that suppliers adhere to industry standards, such as ISO certifications. Request product samples and review their quality assurance protocols, including testing methods for pressure and temperature resistance. Conducting factory audits, if possible, can provide additional insights into manufacturing practices. Building relationships with reputable suppliers and asking for references from other clients can also help mitigate risks. -

What payment terms are commonly offered for thermowell purchases?

Payment terms can vary by supplier but typically include options like net 30, net 60, or upfront payments. Some suppliers may offer discounts for early payments or flexible financing options for larger orders. Ensure to discuss and agree on terms before placing an order, and consider using secure payment methods to protect your investment, especially in international transactions. -

What logistics considerations should I keep in mind when importing thermowells?

When importing thermowells, consider shipping costs, customs duties, and lead times for delivery. It’s essential to work with suppliers who have experience in international shipping and can provide documentation for customs clearance. Evaluate the reliability of logistics partners and consider insurance options for high-value shipments to mitigate risks associated with transportation. -

Can thermowells be customized for specific applications?

Yes, many suppliers offer customization options for thermowells, allowing you to tailor specifications such as length, diameter, and connection type to meet your unique requirements. Customization may also extend to material selection and design features. Engage with suppliers early in the process to discuss your needs and explore available options, as this can enhance performance and longevity in your specific application.

Top 4 Thermowell Types Manufacturers & Suppliers List

1. Tameson – Thermowells

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: A thermowell is a protective tube for temperature sensors, used in industrial processes to shield against extreme conditions. Key details include: 1. **Design Types**: – Straight: Consistent diameter, cost-effective, suitable for moderate processes. – Tapered: Gradually reducing diameter, vibration resistant, suitable for high-pressure applications. – Stepped: Abrupt diameter changes, enhanced res…

2. Ashcroft – Thermowell Solutions

Domain: blog.ashcroft.com

Registered: 1995 (30 years)

Introduction: A thermowell is a protective device for temperature monitoring instruments in industrial applications, safeguarding them from corrosive media, high pressure, and high-velocity flow. It is made from solid metal bar stock and allows for the insertion of temperature instruments like bi-metal thermometers, gas-actuated thermometers, RTDs, or thermocouples. Key considerations for selecting a thermowell…

3. Sino-Inst – Thermowells

Domain: sino-inst.com

Registered: 2019 (6 years)

Introduction: Thermowells are essential for temperature measurement applications, compatible with thermocouples, thermal resistors, and bimetal thermometers. They protect temperature sensors from corrosive, high-temperature, high-pressure, and large-flow media, allowing for sensor replacement during operation. Available styles include welded, threaded, and flange types. Material options include: 1Cr18Ni9Ti (-20…

4. Conax Technologies – Thermowells

Domain: conaxtechnologies.com

Registered: 2006 (19 years)

Introduction: Thermowells are pressure-tight receptacles designed to extend the life of temperature sensors in environments where the sensor is not chemically compatible with the process media or lacks the mechanical strength to withstand process flow or pressure. They allow for easy removal, replacement, or checking of sensors without draining the process system. Key design factors include:

– Material of Const…

Strategic Sourcing Conclusion and Outlook for thermowell types

In conclusion, the strategic sourcing of thermowells is essential for optimizing temperature measurement systems across various industries. Understanding the different types of thermowells—straight, tapered, and stepped—along with their respective advantages and disadvantages allows B2B buyers to make informed decisions tailored to their specific process conditions. The choice of material, design, and connection type plays a crucial role in ensuring the durability and effectiveness of the temperature sensors they protect.

For international buyers in regions such as Africa, South America, the Middle East, and Europe, selecting the right thermowell can significantly enhance operational efficiency and reduce maintenance costs. As industrial processes continue to evolve, so too does the need for reliable temperature measurement solutions.

Now is the time to engage with suppliers who can provide customized thermowell solutions that meet your unique requirements. By prioritizing strategic sourcing, you can ensure that your operations are equipped with the best technology, paving the way for increased productivity and long-term success. Embrace the future of temperature measurement by investing in high-quality thermowells today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to thermowell types