Everything You Need to Know About Thermocouple Photos Sourcing in 2025

Introduction: Navigating the Global Market for thermocouple photos

In an increasingly competitive global market, sourcing high-quality thermocouple photos can pose significant challenges for B2B buyers. These images are not just visual assets; they represent essential components in various industries, including manufacturing, food processing, and pharmaceuticals. Understanding the nuances of thermocouples, from their types to their applications, is crucial for making informed purchasing decisions. This guide provides a comprehensive overview, addressing the diverse types of thermocouples, their specific applications, and insights into supplier vetting processes, ensuring you choose the right partner for your needs.

Navigating the intricacies of the thermocouple market requires an awareness of regional considerations, particularly for buyers from Africa, South America, the Middle East, and Europe, including key markets like Brazil and Nigeria. By delving into cost factors, quality standards, and supplier reliability, this guide empowers international B2B buyers to make strategic decisions that enhance operational efficiency and compliance with industry regulations.

Moreover, the visual aspect of thermocouples plays a vital role in understanding their construction and functionality, aiding buyers in recognizing the right products for their applications. With this resource, you will gain the insights needed to confidently navigate the global thermocouple market, ensuring that your investments yield optimal results in your respective industry.

Understanding thermocouple photos Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| General Purpose Thermocouples | Standard design, versatile, available in various materials | Manufacturing, HVAC, laboratory settings | Pros: Cost-effective, widely available. Cons: Limited to standard temperature ranges. |

| High-Temperature Thermocouples | Designed for extreme temperatures, often with specialized sheaths | Aerospace, metal processing, furnace applications | Pros: Accurate at high temps, durable. Cons: Higher cost, may require specific installation conditions. |

| Explosion-Proof Thermocouples | Robust construction, designed to prevent ignition in hazardous environments | Oil & gas, chemical processing | Pros: Safety compliance, reliable in hazardous areas. Cons: Heavier, more expensive than standard types. |

| Surface Mount Thermocouples | Flat design for direct attachment to surfaces, quick response time | Food processing, HVAC, automotive testing | Pros: Fast readings, easy installation. Cons: Limited to surface temperatures, may require adhesive. |

| Multi-Point Thermocouples | Multiple sensing points in one unit, allowing for varied temperature readings | Pharmaceutical, chemical processing | Pros: Comprehensive data collection, space-saving. Cons: Complex installation, higher initial investment. |

What Are the Characteristics of General Purpose Thermocouples?

General purpose thermocouples are the most commonly used type of thermocouple, characterized by their standard design and versatility. They can be constructed from various materials, making them suitable for a wide range of applications in manufacturing, HVAC, and laboratory settings. When sourcing general-purpose thermocouples, B2B buyers should consider factors such as temperature range, accuracy, and compatibility with existing systems. Their affordability and availability make them an attractive option for many businesses, although their limitations in extreme conditions should also be noted.

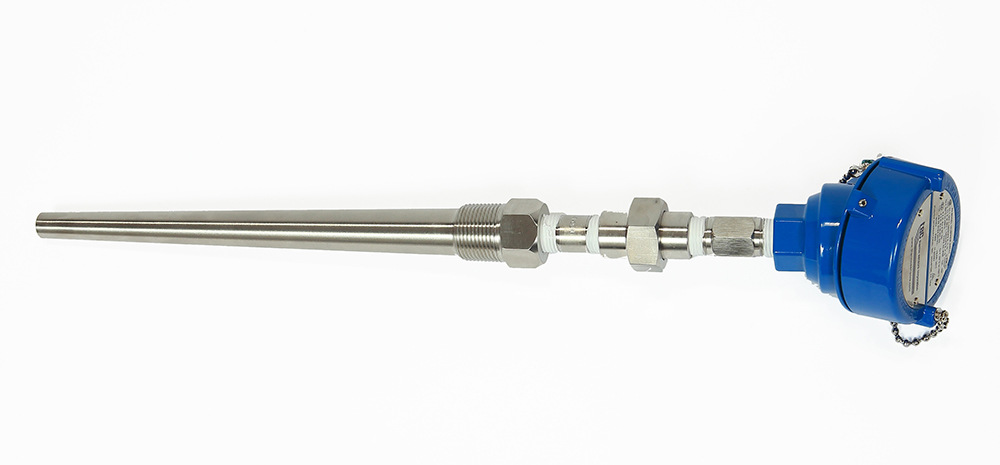

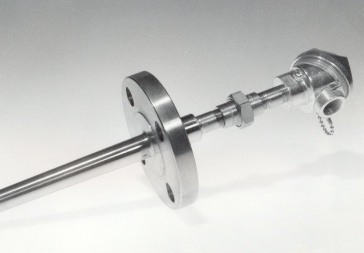

How Do High-Temperature Thermocouples Stand Out?

High-temperature thermocouples are specifically designed to operate in extreme heat environments, often featuring specialized sheaths to protect the sensing element. These thermocouples are commonly used in industries such as aerospace, metal processing, and furnace applications where precise temperature control is critical. B2B buyers should evaluate the specific temperature range and material compatibility when purchasing high-temperature thermocouples. While they offer durability and accuracy in demanding conditions, the higher cost and specific installation requirements may deter some buyers.

Illustrative image related to thermocouple photos

Why Choose Explosion-Proof Thermocouples?

Explosion-proof thermocouples are engineered with robust construction to prevent ignition in potentially hazardous environments, making them ideal for the oil and gas sector and chemical processing industries. Buyers should prioritize safety compliance and reliability when selecting these thermocouples. Although they provide essential safety features, their heavier weight and increased cost compared to standard thermocouples may be a consideration for procurement teams.

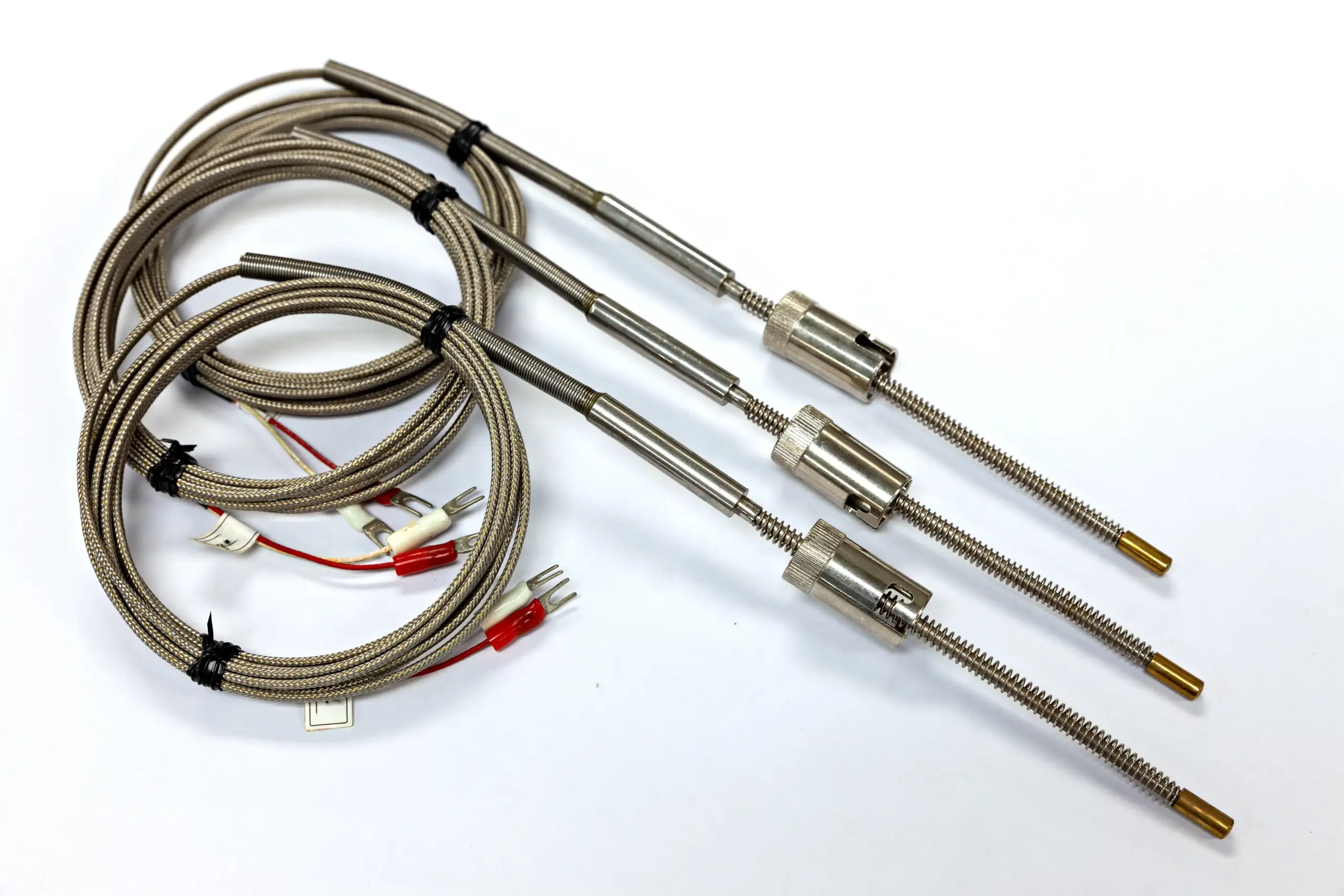

What Are the Benefits of Surface Mount Thermocouples?

Surface mount thermocouples feature a flat design that allows for direct attachment to surfaces, providing quick response times for temperature readings. They are particularly useful in food processing, HVAC, and automotive testing applications. B2B buyers should assess the ease of installation and the need for adhesives when considering surface mount options. While they offer rapid readings and simplified installation, their limitation to surface temperatures may restrict their application in some scenarios.

How Do Multi-Point Thermocouples Enhance Data Collection?

Multi-point thermocouples are designed to measure temperatures at multiple points within a single unit, allowing for comprehensive data collection in applications such as pharmaceuticals and chemical processing. When purchasing multi-point thermocouples, B2B buyers should consider installation complexity and the specific data requirements of their processes. While these thermocouples provide significant advantages in data collection and space efficiency, they may require a higher initial investment and more intricate installation compared to single-point options.

Key Industrial Applications of thermocouple photos

| Industry/Sector | Specific Application of thermocouple photos | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Energy & Power Generation | Monitoring turbine temperatures in power plants | Ensures optimal performance and safety in operations | Look for high-temperature resistance and durability |

| Food & Beverage Processing | Temperature control in food processing equipment | Maintains product quality and compliance with safety regulations | Seek suppliers with FDA-compliant sensors |

| Chemical Manufacturing | Temperature measurement in reactors and distillation columns | Enhances process efficiency and product consistency | Consider accuracy and reliability in harsh environments |

| Automotive Manufacturing | Testing engine and exhaust temperatures | Improves vehicle performance and emissions compliance | Focus on sensors that can withstand high vibrations |

| Aerospace | Monitoring temperatures in engine components and avionics | Critical for safety and performance in flight operations | Ensure compliance with industry standards and certifications |

How Are Thermocouple Photos Utilized in the Energy Sector?

In the energy and power generation sector, thermocouple photos are essential for visualizing the installation and configuration of temperature sensors in turbine monitoring systems. These images help engineers understand the precise placement and integration of sensors, ensuring optimal performance and safety. High-temperature resistance is critical in this application, as turbines operate under extreme conditions. International buyers must prioritize suppliers that provide durable and reliable thermocouples, which can withstand the rigors of power generation environments.

What Role Do Thermocouple Photos Play in Food and Beverage Processing?

In food and beverage processing, thermocouple photos are used to illustrate various temperature control systems within processing equipment. These images aid in identifying the right sensor type for specific applications, such as pasteurization or cooking. Maintaining product quality and compliance with safety regulations is paramount in this industry. B2B buyers, particularly in regions with strict food safety standards, should look for suppliers that offer FDA-compliant thermocouples to ensure they meet regulatory requirements.

How Are Thermocouple Photos Applied in Chemical Manufacturing?

In chemical manufacturing, thermocouple photos are crucial for showcasing the integration of temperature measurement devices in reactors and distillation columns. These images assist engineers in selecting the appropriate sensors for monitoring critical chemical processes. Accurate temperature measurement enhances process efficiency and ensures product consistency. Buyers should consider sourcing thermocouples that are designed for harsh chemical environments, focusing on reliability and accuracy to minimize downtime and maintain production quality.

What Is the Importance of Thermocouple Photos in Automotive Manufacturing?

Thermocouple photos are vital in automotive manufacturing, particularly for visualizing temperature sensors used in engine and exhaust systems. These images help manufacturers understand the placement and specifications needed for effective temperature monitoring, which is essential for improving vehicle performance and emissions compliance. B2B buyers should prioritize sourcing thermocouples that can withstand high vibrations and extreme temperatures, ensuring they are suitable for demanding automotive applications.

How Do Thermocouple Photos Benefit the Aerospace Industry?

In the aerospace sector, thermocouple photos are instrumental in illustrating the deployment of temperature sensors in engine components and avionics systems. These images provide insights into proper installation practices, which are critical for ensuring safety and performance during flight operations. Buyers in this industry must ensure that the thermocouples sourced meet stringent industry standards and certifications, as reliability is paramount for mission-critical applications in aviation.

3 Common User Pain Points for ‘thermocouple photos’ & Their Solutions

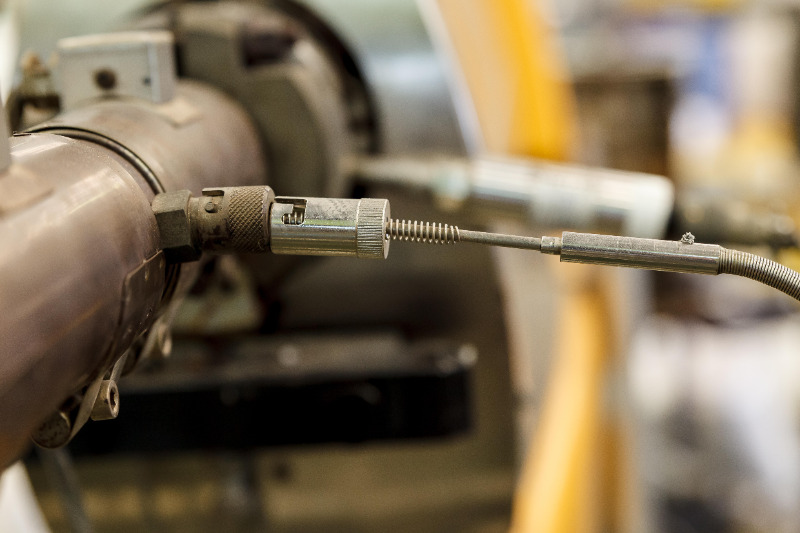

Scenario 1: Difficulty in Identifying the Right Thermocouple Type through Photos

The Problem: B2B buyers often struggle to identify the specific type of thermocouple that suits their application based on available images. With numerous designs—such as armored, bayonet mount, or surface mount—buyers can find it challenging to distinguish between them when browsing through stock photos. This can lead to confusion and potentially costly mistakes in purchasing the wrong type for their specific needs.

Illustrative image related to thermocouple photos

The Solution: To address this challenge, buyers should look for suppliers that provide comprehensive image galleries with detailed descriptions accompanying each thermocouple photo. The descriptions should include specifications such as temperature range, application suitability, and material composition. Additionally, sourcing images from manufacturers or suppliers that offer educational content alongside their galleries can enhance understanding. Buyers should also consider utilizing comparison tools or interactive features on supplier websites that allow them to visualize different thermocouple types in context, ensuring they make informed purchasing decisions.

Scenario 2: Poor Image Quality Leading to Misinterpretation of Product Features

The Problem: Low-resolution images or poorly lit photographs can lead to misinterpretations of critical features in thermocouples. Buyers may overlook essential aspects like connection types, size specifications, or even compatibility with their existing systems. This can result in purchasing items that do not meet quality standards or operational requirements, ultimately affecting production efficiency.

The Solution: Buyers should prioritize suppliers that provide high-resolution, professionally taken images that clearly display the thermocouples from multiple angles. Images should also include zoom-in features to highlight specific elements such as connectors or calibration markings. Additionally, requesting sample photos or videos demonstrating the product in use can provide greater clarity. If sourcing from stock photo websites, buyers should filter for high-quality images and consider options that allow for licensing the images for commercial use, ensuring they can present the products accurately in their own materials.

Scenario 3: Limited Access to Localized Thermocouple Solutions via Images

The Problem: In regions such as Africa or South America, B2B buyers may find it challenging to access thermocouple solutions that are tailored to local conditions or industry standards. Photos available online often come from suppliers that do not cater to the specific requirements of these markets, leading to potential mismatches between product capabilities and local needs.

The Solution: Buyers can overcome this issue by seeking out local distributors or manufacturers who can provide thermocouple images that reflect products designed for their regional applications. Engaging with these suppliers can yield customized solutions that are more aligned with local environmental factors or industry regulations. Additionally, buyers should leverage online platforms that connect them with manufacturers offering localized products, ensuring the images they view represent the specifications necessary for their operations. Participating in industry forums or trade shows can also help buyers discover suppliers who cater specifically to their region, enhancing their sourcing process.

Strategic Material Selection Guide for thermocouple photos

What Are the Common Materials Used in Thermocouples?

When selecting materials for thermocouples, it is essential to consider their properties, advantages, and limitations. The choice of material can significantly affect performance, durability, and application suitability. Here, we analyze four common materials used in thermocouples: Type K (Chromel-Alumel), Type J (Iron-Constantan), Type T (Copper-Constantan), and Inconel.

How Does Type K (Chromel-Alumel) Perform in Thermocouples?

Type K thermocouples are made from Chromel (nickel-chromium alloy) and Alumel (nickel-aluminum alloy). They are widely used due to their broad temperature range, typically from -200°C to 1260°C, and good oxidation resistance.

Illustrative image related to thermocouple photos

Pros: They offer excellent stability and accuracy, making them suitable for a variety of applications, including industrial processes and food processing. Their relatively low cost also makes them a popular choice.

Cons: However, Type K thermocouples can suffer from corrosion in certain environments, particularly in reducing atmospheres. They are not recommended for use in vacuum conditions.

Impact on Application: Type K thermocouples are compatible with a wide range of media, including air and gases, but may not be suitable for corrosive environments.

Considerations for International Buyers: Compliance with international standards such as ASTM E230 is crucial. Buyers from regions like Africa and South America should consider local environmental conditions that may affect the thermocouple’s performance.

What Are the Characteristics of Type J (Iron-Constantan) Thermocouples?

Type J thermocouples consist of iron and constantan (copper-nickel alloy). They are effective in measuring temperatures from -40°C to 750°C.

Illustrative image related to thermocouple photos

Pros: One of their main advantages is their high sensitivity, making them ideal for low-temperature applications. They are also relatively inexpensive.

Cons: However, Type J thermocouples are prone to oxidation at high temperatures, which can lead to inaccuracies and reduced lifespan.

Impact on Application: They are suitable for applications involving air and non-corrosive gases but are not recommended for use in vacuum or high-humidity environments.

Considerations for International Buyers: Buyers should be aware of the specific temperature limits and the need for protective sheaths in corrosive environments. Compliance with local standards is also essential.

Why Choose Type T (Copper-Constantan) Thermocouples?

Type T thermocouples are composed of copper and constantan, suitable for measuring temperatures from -200°C to 350°C.

Pros: They are known for their excellent stability and resistance to corrosion, making them ideal for cryogenic applications and environments where moisture is present.

Cons: The main limitation is their lower maximum temperature range compared to other types, which may restrict their use in high-temperature applications.

Impact on Application: Type T thermocouples are particularly effective in measuring temperatures in food processing and pharmaceutical applications due to their accuracy and reliability.

Considerations for International Buyers: Buyers should ensure compliance with standards like JIS and DIN, especially in regions with stringent safety regulations.

What Advantages Does Inconel Provide in Thermocouples?

Inconel is a nickel-chromium alloy known for its exceptional resistance to oxidation and corrosion, making it suitable for high-temperature applications exceeding 1000°C.

Pros: Inconel thermocouples excel in harsh environments, including chemical processing and aerospace applications, due to their durability and long service life.

Cons: The primary disadvantage is the high cost of Inconel, which may not be feasible for all applications.

Impact on Application: They are ideal for extreme conditions, including high pressure and corrosive media, ensuring reliable temperature measurement.

Considerations for International Buyers: Buyers must consider the specific requirements of their applications and the associated costs. Compliance with international standards is also vital for ensuring safety and reliability.

Summary Table of Material Selection for Thermocouple Photos

| Material | Typical Use Case for thermocouple photos | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Type K | Industrial processes, food processing | Broad temperature range | Corrosion in reducing atmospheres | Medium |

| Type J | Low-temperature applications | High sensitivity | Prone to oxidation at high temps | Low |

| Type T | Food processing, pharmaceuticals | Excellent stability and corrosion resistance | Lower maximum temperature range | Medium |

| Inconel | Chemical processing, aerospace | Exceptional resistance to oxidation | High cost | High |

This comprehensive analysis of thermocouple materials provides valuable insights for B2B buyers, enabling informed decisions based on application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for thermocouple photos

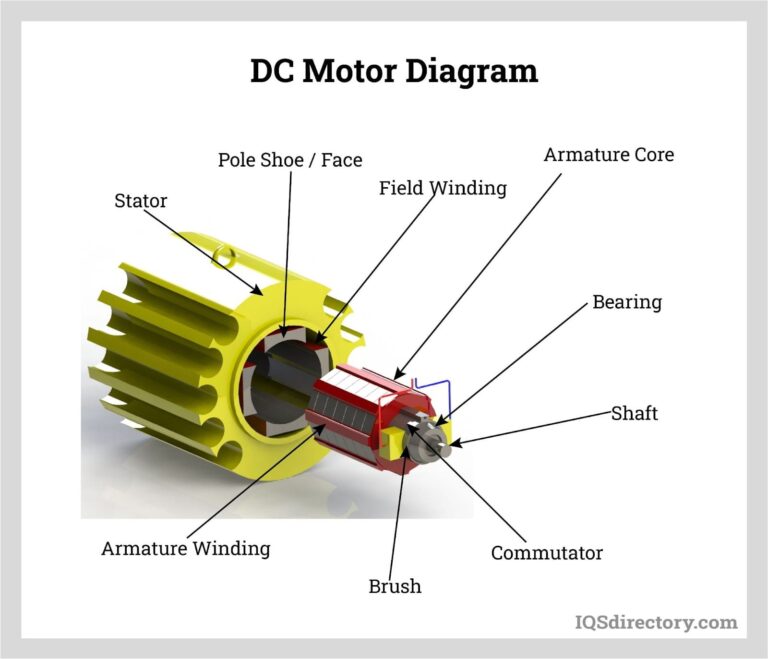

What Are the Main Stages of Manufacturing Thermocouple Photos?

Manufacturing thermocouple photos involves a series of well-defined stages, each critical to producing high-quality temperature sensors. Understanding these stages helps B2B buyers assess the reliability and performance of thermocouples they are considering for purchase.

Illustrative image related to thermocouple photos

Material Preparation

The first stage in the manufacturing process is material preparation. High-quality thermocouples are typically made from specific metal alloys known for their thermal properties. Common materials include copper, constantan, and various types of stainless steel, depending on the application. The selection of the right alloy is crucial as it directly influences the accuracy and reliability of temperature readings. Suppliers often conduct thorough material testing to ensure that the metals meet industry standards and specifications, which is a fundamental requirement for any thermocouple intended for critical applications.

Forming Techniques

Once the materials are prepared, the next step is forming. This can involve various techniques such as wire drawing, which produces thin wires from bulk metal. These wires are then shaped into thermocouples through processes like welding or soldering, ensuring the junctions are correctly formed for accurate temperature readings. Advanced techniques such as laser welding may also be employed for precision. The choice of forming technique can affect the thermal response time and durability of the thermocouple, making it essential for buyers to inquire about the methods used by their suppliers.

Assembly Process

Following the forming stage, assembly takes place. This involves integrating various components such as insulation materials, connection heads, and protective sheaths. The assembly process must ensure that the thermocouple is sealed properly to withstand harsh environments, particularly in industries like oil and gas, where exposure to extreme conditions is common. B2B buyers should look for suppliers who use automated assembly lines, which can enhance consistency and reduce the potential for human error in the production process.

Finishing Touches

The final stage in manufacturing thermocouple photos includes finishing processes such as calibration and testing. Calibration ensures that the thermocouple provides accurate readings across its operating range, which is vital for applications requiring precision. Additionally, finishing may involve applying protective coatings to enhance corrosion resistance, especially for thermocouples used in aggressive environments. Buyers should verify that their suppliers follow rigorous finishing protocols to ensure the longevity and reliability of the products.

Illustrative image related to thermocouple photos

How Is Quality Assurance Implemented in Thermocouple Manufacturing?

Quality assurance (QA) is a critical aspect of thermocouple manufacturing, ensuring that products meet both international and industry-specific standards. For B2B buyers, understanding these QA processes can significantly influence purchasing decisions.

What Are the Relevant International Standards?

One of the foremost standards in quality assurance is ISO 9001, which outlines requirements for a quality management system. Manufacturers adhering to ISO 9001 demonstrate their commitment to quality and customer satisfaction. Additionally, compliance with industry-specific standards such as CE marking (for products sold in Europe) and API specifications (for oil and gas applications) further assures buyers of the product’s reliability and safety.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Illustrative image related to thermocouple photos

- IQC involves inspecting raw materials and components upon receipt to ensure they meet specified standards before production begins.

- IPQC monitors the manufacturing process at various stages, checking for adherence to technical specifications and identifying defects early.

- FQC occurs at the end of the manufacturing process, where finished products undergo rigorous testing, including functional tests and thermal response evaluations.

B2B buyers should inquire about these QC checkpoints to ensure their suppliers maintain high standards throughout the manufacturing process.

What Testing Methods Are Commonly Used for Thermocouples?

Testing methods for thermocouples vary based on application and industry requirements. Common methods include:

- Thermal Testing: This involves subjecting thermocouples to known temperature points to verify accuracy.

- Durability Testing: Assessing how thermocouples perform under extreme conditions, including high temperatures and pressures, is essential, particularly for industrial applications.

- Calibration Testing: Regular calibration against standardized temperature sources is crucial for ensuring ongoing accuracy.

B2B buyers should look for suppliers that provide detailed testing reports and certifications to verify compliance with relevant industry standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for B2B buyers, particularly those sourcing thermocouples from diverse regions like Africa, South America, the Middle East, and Europe.

What Steps Can Buyers Take?

-

Supplier Audits: Conducting on-site audits can provide firsthand insight into a supplier’s manufacturing and quality control practices. Buyers should prioritize suppliers who welcome audits and demonstrate transparency.

-

Requesting Documentation: Buyers should ask for quality assurance documentation, including ISO certifications, testing reports, and compliance certificates. This information can help assess the supplier’s adherence to international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an additional layer of assurance. These independent entities can evaluate suppliers’ manufacturing processes and quality control measures, offering unbiased reports.

-

Understanding QC Nuances: Buyers should be aware of the specific quality control nuances that may vary by region. For example, suppliers in Europe may have stricter regulations compared to those in other regions. Familiarity with local standards can help buyers make informed decisions.

Conclusion

Understanding the manufacturing processes and quality assurance measures for thermocouples is crucial for B2B buyers seeking reliable temperature sensors. By focusing on material preparation, forming techniques, assembly, finishing, and robust quality control practices, buyers can make informed decisions that align with their operational needs. Engaging with suppliers who prioritize quality and compliance with international standards will ultimately lead to better purchasing outcomes and enhanced operational efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘thermocouple photos’

To assist B2B buyers in procuring high-quality thermocouple photos for their business needs, this guide provides a structured checklist that outlines essential steps. Each step focuses on specific actions that will ensure the selection of the most appropriate images while also considering the supplier’s reliability and the relevance of the images to your applications.

Step 1: Identify Your Image Requirements

Understanding your specific image needs is crucial. Determine the types of thermocouples you want to showcase, such as industrial, explosion-proof, or specialized sensors. This clarity will guide your search and help ensure that the images accurately represent the products you intend to market or use.

Step 2: Research Reputable Sources for Thermocouple Photos

Before selecting images, identify reliable sources that offer high-quality thermocouple photos. Explore stock photo websites, manufacturer galleries, and industry-specific image libraries. Look for platforms with extensive collections and positive reviews from other B2B buyers to ensure you access diverse and relevant options.

- Recommended Platforms:

- Stock photo sites like Shutterstock or Adobe Stock

- Manufacturer websites that provide product images

- Free image resources like Freepik for budget-friendly options

Step 3: Evaluate Image Quality and Resolution

Not all images are created equal; the quality and resolution can significantly impact their usability. Ensure that the photos you consider are high-resolution and suitable for both digital and print applications. Low-quality images can detract from your brand’s professionalism and credibility.

Step 4: Verify Licensing and Usage Rights

Understanding the licensing agreements associated with the images is essential to avoid legal issues. Check whether the photos are royalty-free or require a licensing fee, and ensure that the usage rights align with your intended applications. This diligence will protect your business from potential copyright infringements.

Step 5: Assess Supplier Credibility and Customer Support

Before finalizing your choice, research the suppliers of the images. Check their reputation in the industry by looking for testimonials and reviews from other businesses. A credible supplier should also provide good customer support, ready to assist with any questions or issues related to image usage or licensing.

Step 6: Request Sample Images for Evaluation

If possible, ask suppliers for sample images before making a purchase. This allows you to assess the quality and relevance of the images in real-world applications. It also provides an opportunity to gauge the supplier’s responsiveness and willingness to accommodate your needs.

Step 7: Make Your Purchase and Document Your Sources

Once you have identified the right images, proceed with the purchase. Keep thorough documentation of your sources, including licenses and invoices, for future reference. This practice ensures compliance with usage rights and provides a clear record for any potential audits or inquiries.

Illustrative image related to thermocouple photos

By following this structured checklist, B2B buyers can streamline their process of sourcing thermocouple photos, ensuring they acquire high-quality images that meet their specific business needs while mitigating risks associated with licensing and supplier reliability.

Comprehensive Cost and Pricing Analysis for thermocouple photos Sourcing

What Are the Key Cost Components for Sourcing Thermocouple Photos?

When sourcing thermocouple photos, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The materials involved in creating thermocouple images can vary significantly based on the quality and type of thermocouples being photographed. High-resolution images that highlight intricate details may require more sophisticated equipment and techniques, thereby increasing costs.

-

Labor: Skilled photographers and editors are essential for producing high-quality images. Labor costs will vary depending on the expertise of the professionals involved and the complexity of the shoot. A photographer with specialized knowledge in industrial applications may command higher fees.

-

Manufacturing Overhead: This includes the costs associated with the equipment used for photography, studio space, and utilities. Overhead can be substantial, especially if the supplier operates in a high-cost area or utilizes advanced technology for image capture.

-

Tooling: For customized thermocouple images, such as those showcasing specific features or applications, specialized tooling or setups may be required. This can add to the overall expense.

-

Quality Control (QC): Ensuring that the images meet specific standards is essential, particularly for B2B applications. QC processes may involve additional labor and resources, contributing to the overall cost.

-

Logistics: If sourcing images internationally, logistics costs such as shipping files, storage, and potential tariffs must be considered. These can vary significantly based on the location of the supplier and the buyer.

-

Margin: Finally, suppliers will include a margin on top of the production costs. This margin can vary based on market demand, supplier reputation, and the exclusivity of the images.

How Do Price Influencers Affect Thermocouple Photos?

Several factors influence the pricing of thermocouple photos, impacting the total cost for buyers:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs). Ordering in larger quantities can lead to discounts, making it more cost-effective for businesses needing multiple images.

-

Specifications and Customization: Custom images tailored to specific applications or showcasing particular features may incur higher costs due to additional labor and resources required. Standard images, in contrast, are generally cheaper.

-

Materials and Quality Certifications: High-quality images that require specialized photography techniques or equipment will be priced higher. Additionally, images that come with quality certifications can command a premium.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding the terms of trade (Incoterms) is vital for international buyers. Different Incoterms can affect shipping costs and responsibilities, influencing the overall pricing.

What Buyer Tips Can Enhance Cost Efficiency in Thermocouple Photos Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially for bulk orders. Suppliers may be willing to offer discounts or better terms to secure larger contracts.

-

Assess Total Cost of Ownership (TCO): Consider not just the upfront costs but also the long-term value of the images. High-quality images may lead to better marketing outcomes, justifying a higher initial investment.

-

Understand Pricing Nuances: Be aware of potential hidden costs, such as licensing fees for image usage, which can add to the overall expense. Clarifying these details upfront can prevent budget overruns.

-

Leverage Local Suppliers: Whenever possible, sourcing from local suppliers can reduce shipping costs and tariffs, leading to overall savings.

Disclaimer on Indicative Prices

It’s essential to note that prices for thermocouple photos can vary widely based on the aforementioned factors. Always obtain quotes from multiple suppliers and conduct thorough due diligence to ensure you are making an informed purchasing decision.

Alternatives Analysis: Comparing thermocouple photos With Other Solutions

Understanding the Alternatives to Thermocouple Photos

In the realm of industrial temperature measurement, thermocouples are a widely used solution due to their reliability and versatility. However, businesses often seek alternatives that might better fit their specific needs, whether it be due to cost, ease of implementation, or particular application requirements. This section compares thermocouple photos with two viable alternatives: infrared thermometers and resistance temperature detectors (RTDs).

Illustrative image related to thermocouple photos

Comparison Table

| Comparison Aspect | Thermocouple Photos | Infrared Thermometers | Resistance Temperature Detectors (RTDs) |

|---|---|---|---|

| Performance | High accuracy in extreme conditions | Good for non-contact measurements | Very high accuracy, stable over time |

| Cost | Moderate to high (depending on type) | Generally lower initial cost | Higher initial investment |

| Ease of Implementation | Requires calibration and installation | Simple to use, minimal setup | Requires careful installation |

| Maintenance | Low maintenance needs | Minimal maintenance required | Regular calibration recommended |

| Best Use Case | Industrial processes, food safety | Moving targets, hazardous areas | Lab environments, precision applications |

Detailed Breakdown of Alternatives

Infrared Thermometers

Infrared thermometers are non-contact temperature measurement devices that detect thermal radiation emitted from objects. Their primary advantage lies in their ease of use, allowing for quick measurements from a distance, making them ideal for applications where contact with the object is impractical or hazardous. They are often more affordable than thermocouples, which can be appealing for businesses on a budget. However, their accuracy can be affected by factors such as emissivity and environmental conditions, which may limit their effectiveness in certain scenarios.

Resistance Temperature Detectors (RTDs)

RTDs are known for their high accuracy and stability over time. They utilize the principle that the resistance of a metal changes with temperature, providing precise readings. This makes RTDs suitable for applications that require consistent and reliable temperature monitoring, such as in laboratory environments or critical industrial processes. While they offer superior performance, RTDs come with a higher initial cost and require careful installation, which might be a barrier for some businesses. Additionally, regular calibration is essential to maintain their accuracy, adding to long-term operational costs.

Conclusion: How to Choose the Right Temperature Measurement Solution

When selecting the right temperature measurement solution, B2B buyers must consider their specific application needs, budget constraints, and operational environments. Thermocouple photos provide a robust option for industries requiring precise temperature monitoring in challenging conditions. In contrast, infrared thermometers offer a cost-effective and user-friendly alternative for non-contact measurements, while RTDs excel in accuracy and stability for sensitive applications. By carefully evaluating the performance, cost, ease of implementation, and maintenance of each option, businesses can make informed decisions that align with their operational goals and enhance their overall efficiency.

Essential Technical Properties and Trade Terminology for thermocouple photos

What Are the Key Technical Properties of Thermocouples That Buyers Should Know?

When sourcing thermocouples, understanding their technical specifications is critical for ensuring that the selected product meets application requirements. Here are some essential properties to consider:

Illustrative image related to thermocouple photos

-

Material Grade

Thermocouples can be made from various materials, including nickel, copper, and precious metals like platinum. The choice of material affects the thermocouple’s durability, temperature range, and resistance to corrosion. For instance, Type K thermocouples, made from chromel and alumel, are suitable for general-purpose applications, while Type R or S thermocouples, made of platinum, are ideal for high-temperature settings. -

Temperature Range

Different thermocouples operate effectively within specific temperature ranges. For example, Type K thermocouples can measure temperatures from -200°C to 1260°C, making them versatile for many industrial processes. Understanding the temperature requirements of your application will guide you in selecting the appropriate thermocouple type. -

Tolerance

Tolerance indicates the accuracy of the temperature measurement and is often defined by the ANSI/ASTM E230 standard. For example, a Class 1 thermocouple has a tolerance of ±1.5°C or ±0.004 times the temperature reading (whichever is greater). Higher tolerances are crucial in applications where precise temperature control is essential, such as in pharmaceuticals or food processing. -

Response Time

The speed at which a thermocouple can respond to temperature changes is vital for dynamic applications. Response time can be influenced by the thermocouple’s design, such as its diameter and insulation type. A fast response time is particularly important in environments where temperature fluctuations are rapid. -

Sheath Material and Construction

The sheath protects the thermocouple’s junction from environmental factors. Common sheath materials include stainless steel, Inconel, and ceramics. The choice of sheath material affects the thermocouple’s resistance to corrosion, pressure, and temperature extremes, ensuring long-term reliability in harsh conditions. -

Connector Types

Thermocouples can come with various connector types (e.g., mini, standard, or custom connectors). The choice of connector affects the ease of installation and compatibility with existing equipment. Understanding the connector type is essential for ensuring seamless integration into your temperature measurement systems.

What Are Common Trade Terms Related to Thermocouple Purchases?

Navigating the procurement process involves understanding key industry terminology. Here are some common terms that will enhance your purchasing experience:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that may be marketed by another company. In the context of thermocouples, working with an OEM ensures that you receive high-quality components tailored to specific applications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for businesses that may not need large quantities at once. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products or services. Submitting an RFQ for thermocouples allows buyers to compare costs and terms from different suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms helps in understanding shipping costs, risks, and liabilities, which is particularly important for international purchases. -

Calibration

Calibration refers to the process of adjusting the thermocouple to ensure accurate temperature readings. Regular calibration is essential for maintaining measurement integrity and compliance with industry standards. -

Thermocouple Type

Thermocouples are categorized into types (e.g., Type K, J, T) based on their materials and temperature ranges. Knowing the type of thermocouple required for a specific application is vital for optimal performance and reliability.

Understanding these technical properties and trade terminology will empower B2B buyers to make informed decisions when sourcing thermocouples, ensuring that they meet their specific industrial needs effectively.

Navigating Market Dynamics and Sourcing Trends in the thermocouple photos Sector

What Are the Key Market Dynamics and Trends Influencing Thermocouple Photos?

The global thermocouple market is driven by the increasing demand for precise temperature measurement across various industries, including energy, automotive, pharmaceuticals, and food processing. As manufacturing processes become more automated and data-driven, the need for high-precision thermocouples is paramount. In regions like Africa and South America, there is a growing emphasis on industrialization and modernization, which further propels the demand for reliable temperature sensors.

Illustrative image related to thermocouple photos

Emerging technologies such as IoT and Industry 4.0 are also reshaping sourcing trends, as companies seek advanced thermocouple solutions that integrate seamlessly with digital platforms for real-time monitoring and analytics. Furthermore, the rise of e-commerce has made it easier for B2B buyers to access a broader range of suppliers and compare offerings, thereby increasing competition and pushing manufacturers to innovate continuously. Buyers from Europe and the Middle East are particularly interested in high-quality thermocouples that comply with strict safety and environmental regulations, making sourcing decisions increasingly complex.

How Is Sustainability and Ethical Sourcing Shaping the Thermocouple Photos Market?

Sustainability is becoming a critical factor in sourcing decisions for thermocouple photos. As environmental concerns rise globally, B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their environmental impact. This includes adopting sustainable manufacturing processes, using eco-friendly materials, and ensuring ethical labor practices throughout the supply chain.

Buyers should look for suppliers that hold certifications such as ISO 14001, which indicates an effective environmental management system. Additionally, the use of recyclable materials in the production of thermocouples can enhance a supplier’s appeal to environmentally conscious buyers. By investing in suppliers who prioritize sustainability, companies not only comply with regulatory demands but also enhance their brand reputation and appeal to a growing base of eco-aware consumers.

What Is the Evolution of Thermocouples and Their Impact on B2B Sourcing?

The history of thermocouples dates back to the early 19th century when Thomas Johann Seebeck discovered the thermoelectric effect. Over the decades, advancements in materials and technology have transformed thermocouples into essential tools for temperature measurement in various industrial applications. Initially, thermocouples were rudimentary devices; however, today’s models are highly specialized, offering features such as rapid response times and the ability to withstand extreme conditions.

This evolution has significant implications for B2B sourcing, as buyers now have access to a diverse range of thermocouples tailored for specific applications. The ability to choose from various types—such as MGO, explosion-proof, or high-temperature thermocouples—allows businesses to optimize their processes and ensure compliance with safety standards. As the technology continues to advance, B2B buyers must stay informed about the latest innovations and trends to make educated sourcing decisions that align with their operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of thermocouple photos

-

How do I source high-quality thermocouple photos for my business?

To source high-quality thermocouple photos, start by exploring reputable stock photo platforms that specialize in industrial imagery. Look for images that showcase various thermocouple types and applications relevant to your industry. Verify the licensing agreements to ensure that the photos can be used for commercial purposes. Additionally, consider reaching out directly to thermocouple manufacturers or suppliers who may have their own image galleries, as they often provide authentic images that highlight their products in real-world settings. -

What types of thermocouple photos should I consider for my marketing materials?

When selecting thermocouple photos for marketing materials, focus on images that illustrate different types of thermocouples, such as industrial, explosion-proof, and high-temperature models. Including images that show thermocouples in operational contexts, like food processing or aerospace applications, can enhance relevance. Additionally, consider using diagrams or images that depict the installation process, as these can aid in educating your audience about product functionality and benefits. -

What are the typical licensing terms for thermocouple photos?

Licensing terms for thermocouple photos can vary widely depending on the source. Stock photo platforms usually offer several options, including royalty-free licenses that allow for unlimited use after an initial fee, or rights-managed licenses that restrict usage based on specific criteria. Always review the licensing agreement carefully to understand any limitations regarding distribution, modification, or duration of use. For custom images, negotiate terms directly with the photographer or agency to ensure they meet your business needs. -

How can I verify the quality and authenticity of thermocouple photos?

To verify the quality and authenticity of thermocouple photos, consider the source of the images. Reputable stock photo agencies typically provide high-resolution images taken by professional photographers. Look for detailed descriptions accompanying the photos that explain the context and features of the thermocouples depicted. Additionally, check for reviews or testimonials regarding the image provider to ensure they have a history of delivering quality content that aligns with industry standards. -

What customization options are available for thermocouple images?

Customization options for thermocouple images may include editing services to adapt images for specific branding requirements, such as adding logos or adjusting color schemes. Some suppliers or photographers might offer bespoke photoshoots where you can specify the types of thermocouples and settings you want featured. This approach ensures that the images resonate with your target audience and reflect your unique value proposition. Always discuss customization possibilities upfront to gauge feasibility and associated costs. -

What is the minimum order quantity (MOQ) for purchasing thermocouple photos?

The minimum order quantity (MOQ) for thermocouple photos largely depends on the platform or supplier you are working with. Stock photo websites often allow the purchase of single images, while custom photography services might impose an MOQ based on the complexity of the shoot. When dealing with suppliers, clarify any MOQ requirements during the initial discussions to avoid misunderstandings later. If sourcing multiple images, inquire about bulk purchase discounts that can enhance cost-effectiveness. -

What payment terms should I expect when purchasing thermocouple photos?

Payment terms for purchasing thermocouple photos can vary depending on the provider. Stock photo platforms typically require upfront payment, while custom photography services may offer flexible payment options, such as deposits followed by final payments upon delivery. Always confirm the payment methods accepted, whether credit cards, bank transfers, or digital wallets. Additionally, inquire about any applicable taxes or fees that may impact the overall cost and ensure you have a clear understanding of the payment timeline. -

How do I handle logistics when sourcing thermocouple photos internationally?

Handling logistics for sourcing thermocouple photos internationally involves understanding the delivery methods, timelines, and potential customs issues. Most stock photo platforms provide immediate digital downloads, simplifying logistics. For custom images, discuss delivery options with the photographer, including whether they can provide high-resolution files electronically or if physical prints are needed. Be aware of any import duties or taxes that may apply if you are obtaining physical copies, and ensure that all transactions comply with international trade regulations to avoid delays.

Top 7 Thermocouple Photos Manufacturers & Suppliers List

1. Thermocouple Assemblies – Essential Temperature Sensors

Domain: thermocouple-assemblies.com

Registered: 2001 (24 years)

Introduction: Thermocouples are essential temperature sensors used in various industrial and commercial applications, providing accurate temperature measurements for monitoring and process control in harsh environments. Types of thermocouples include industrial thermocouples, MGO thermocouples, and explosion-proof thermocouples, serving applications in manufacturing, food processing, and aerospace industries. L…

2. Adobe Stock – Thermocouple Images

Domain: stock.adobe.com

Registered: 1986 (39 years)

Introduction: Thermocouple Images – Browse 26 Stock Photos, Vectors, and Video | Adobe Stock. Includes options for images, videos, audio, templates, and 3D assets. Offers a free trial for 10 images or 1 video, and additional options for 3 videos or 25 images. License terms and support available. Region selection may change language and promotional content.

3. Thermometrics Corp – Thermocouples

Domain: thermometricscorp.com

Registered: 1999 (26 years)

Introduction: Thermocouples: General Purpose Thermocouples, Bayonet Mount Thermocouple, Thermocouple With Plug, Thermocouple With Connection Head, Armored Thermocouple, Handheld Thermocouple, High-Temperature Thermocouple, Surface Mount Thermocouple, Transition Joint Thermocouple, Bare Lead Thermocouple, Overbraided Thermocouple, Multi-Point Thermocouple, Autoclave Thermocouple, Magnet Mount Thermocouple, Repla…

4. iStock – Thermocouple Stock Images

Domain: istockphoto.com

Registered: 2000 (25 years)

Introduction: 125,400+ Thermocouple Stock Photos, Pictures & Royalty-Free Images

5. Shutterstock – Thermocouple Images

Domain: shutterstock.com

Registered: 2003 (22 years)

Introduction: This company, Shutterstock – Thermocouple Images, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Freepik – Thermocouple Graphics

Domain: freepik.com

Registered: 2010 (15 years)

Introduction: This company, Freepik – Thermocouple Graphics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Getty Images – Thermocouple Photos

Domain: gettyimages.com

Registered: 1999 (26 years)

Introduction: This company, Getty Images – Thermocouple Photos, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for thermocouple photos

In conclusion, effective strategic sourcing of thermocouple photos is integral for international B2B buyers aiming to enhance their procurement processes. By selecting reputable suppliers that showcase high-quality images, buyers can make informed decisions about the types and specifications of thermocouples that best meet their industry needs. The emphasis on accurate temperature measurement and reliable performance in demanding environments underscores the necessity of choosing the right products.

Furthermore, leveraging visual resources not only aids in understanding product applications but also fosters stronger supplier relationships through transparent communication. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for precision in temperature sensing solutions will only increase.

Illustrative image related to thermocouple photos

Looking ahead, we encourage buyers to explore diverse suppliers and utilize available resources to stay ahead of industry trends. By embracing strategic sourcing practices, businesses can ensure they are equipped with the best thermocouple solutions, ultimately driving operational efficiency and competitiveness in their respective markets. Engage proactively with suppliers, review their offerings, and make choices that will propel your organization towards future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.