Everything You Need to Know About Strike Latch Sourcing in 2025

Introduction: Navigating the Global Market for strike latch

In the dynamic landscape of global commerce, sourcing high-quality strike latches presents a unique challenge for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, the need for reliable door hardware is universal, yet the complexities involved in sourcing can be daunting. This guide aims to demystify the process of navigating the global market for strike latches by offering actionable insights into various types, applications, and best practices for supplier vetting.

From traditional mechanical strike latches to advanced electric strike systems, understanding the nuances of each type is essential for making informed purchasing decisions. This comprehensive resource will explore critical factors such as material quality, compatibility with existing hardware, and cost considerations, ensuring that you are equipped to select the best products for your specific needs.

Additionally, we will delve into strategies for identifying and evaluating trustworthy suppliers across different regions, helping you mitigate risks and establish long-term partnerships. By empowering B2B buyers with the knowledge and tools necessary to navigate the complexities of the strike latch market, this guide serves as a vital resource for achieving successful procurement outcomes in today’s competitive landscape.

Understanding strike latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Strike Latch | Basic design, usually made of steel or brass, fits most door frames. | Residential and commercial door installations. | Pros: Affordable, widely available. Cons: May lack advanced security features. |

| Electric Strike Latch | Operates electronically, allowing remote access control. | High-security facilities, access control systems. | Pros: Enhanced security, remote operation. Cons: Higher installation costs, requires power source. |

| Deadbolt Strike Latch | Reinforced design to accommodate deadbolts, providing superior locking. | Secure residential and commercial environments. | Pros: High security, durable. Cons: More expensive, may require specific door configurations. |

| Adjustable Strike Latch | Features movable components to fit various door alignments. | Custom installations, retrofitting existing doors. | Pros: Flexible installation, accommodates misalignments. Cons: Can be more complex to install. |

| Rim Strike Latch | Surface-mounted design, ideal for retrofitting. | Older buildings, non-standard door frames. | Pros: Easy installation, works with various door types. Cons: Less secure than other options, limited aesthetic appeal. |

What are the Key Characteristics of Standard Strike Latches?

Standard strike latches are the most common type found in residential and commercial settings. Typically constructed from steel or brass, they are designed to fit a wide variety of door frames. Their simplicity makes them a cost-effective solution for many applications, though they may not offer advanced security features. Buyers should consider the compatibility with existing door hardware and the overall durability of the material used.

How Do Electric Strike Latches Enhance Security?

Electric strike latches integrate electronic mechanisms that allow for remote access control, making them ideal for high-security environments such as government buildings and corporate offices. These latches can work in conjunction with access control systems, providing enhanced security. However, potential buyers must factor in installation costs and the need for a reliable power source, which can be a consideration for operations in remote areas.

Why Choose Deadbolt Strike Latches for Secure Environments?

Deadbolt strike latches are designed to work in tandem with deadbolts, offering superior security for both residential and commercial properties. Their reinforced construction ensures durability and resistance to forced entry. While they provide excellent protection, buyers should be aware of the higher costs and the specific door configurations required for proper installation.

What Advantages Do Adjustable Strike Latches Offer?

Adjustable strike latches are particularly beneficial for custom installations and retrofitting existing doors. Their design allows for movable components that can accommodate various door alignments, making them versatile for different environments. However, the complexity of installation may deter some buyers, especially those looking for straightforward solutions.

When to Use Rim Strike Latches?

Rim strike latches are surface-mounted and are ideal for retrofitting older buildings or non-standard door frames. Their ease of installation makes them a popular choice for quick upgrades. However, they may not provide the same level of security as other options, and their aesthetic appeal is often limited, which should be considered by buyers focusing on design as well as functionality.

Key Industrial Applications of strike latch

| Industry/Sector | Specific Application of strike latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Used in residential and commercial door installations | Enhances security and ease of access for occupants | Ensure compliance with local building codes and standards |

| Automotive | Securing compartments in vehicles | Provides reliability and durability under stress | Consider materials that withstand environmental factors |

| Industrial Manufacturing | Securing machinery access points | Increases safety by restricting access to hazards | Look for heavy-duty options that can handle frequent use |

| Hospitality | Door security in hotels and restaurants | Improves guest safety and operational efficiency | Focus on aesthetics and ease of installation for varied designs |

| Retail | Securing display cases and storage areas | Protects valuable inventory and enhances customer experience | Evaluate compatibility with existing locking systems |

How is a Strike Latch Used in the Construction Industry?

In the construction sector, strike latches are integral to both residential and commercial door installations. They provide a secure means of locking while allowing for easy access. This balance is crucial in buildings where safety and security are paramount. International buyers should ensure that the strike latches meet local building codes and standards, particularly in regions with stringent regulations. Additionally, selecting latches that are resistant to environmental wear can prolong their lifespan and reduce maintenance costs.

What Role Does a Strike Latch Play in the Automotive Sector?

In the automotive industry, strike latches are utilized to secure various compartments within vehicles, including trunks, glove boxes, and engine hoods. Their reliability and durability are essential, especially in high-stress environments where vibration and movement are constant. Buyers in this sector should prioritize materials that can withstand harsh conditions, such as extreme temperatures and humidity. Sourcing from suppliers who understand automotive standards can ensure compliance and enhance product longevity.

How Do Strike Latches Enhance Safety in Industrial Manufacturing?

Strike latches are vital in industrial manufacturing settings, particularly for securing access points to machinery and hazardous areas. By restricting unauthorized access, these latches significantly improve workplace safety. Buyers should consider heavy-duty options that can endure frequent use and potential impacts. It’s also important to evaluate the latch’s compatibility with other safety systems, ensuring a comprehensive approach to workplace safety.

Why Are Strike Latches Important in the Hospitality Industry?

In the hospitality sector, strike latches are commonly used in hotels and restaurants to secure guest room doors and service areas. They enhance guest safety while providing operational efficiency for staff. International buyers should focus on latches that not only meet security standards but also complement the aesthetic of the establishment. Ease of installation and maintenance is also critical, as it affects the overall operational workflow in these environments.

How Do Strike Latches Secure Retail Environments?

In retail settings, strike latches are essential for securing display cases and storage areas, protecting valuable inventory from theft and damage. They contribute to a safer shopping environment, which can enhance customer experience and satisfaction. Buyers should evaluate the compatibility of strike latches with existing locking systems to ensure seamless integration. Additionally, considering the aesthetics of the latch can improve the overall appeal of the retail space, making it more inviting to customers.

3 Common User Pain Points for ‘strike latch’ & Their Solutions

Scenario 1: Inconsistent Door Alignment Causing Latch Failure

The Problem: Many B2B buyers face challenges with strike latches when doors do not align properly due to building settling or improper installation. This misalignment can lead to latches failing to engage securely, resulting in security vulnerabilities and potential operational disruptions. For example, a manufacturing facility may find that the doors to their shipping and receiving areas fail to latch consistently, creating a risk for unauthorized access and inventory loss.

The Solution: To address this issue, it is crucial to conduct a thorough assessment of door alignment before installation. When sourcing strike latches, opt for adjustable models that can accommodate slight variations in door alignment. Additionally, consider using a shim or adjustable strike plate to ensure a secure fit. Regular maintenance checks should also be scheduled to reassess the door alignment and make necessary adjustments. Providing training to facility staff on how to identify misalignment early can prevent long-term issues.

Scenario 2: Limited Product Knowledge Leading to Incorrect Specifications

The Problem: B2B buyers often struggle with selecting the right strike latch for specific applications due to a lack of product knowledge. For instance, a contractor might purchase standard strike latches for high-traffic commercial doors, only to find that they are not durable enough to withstand frequent use. This not only results in product failures but also increases costs due to the need for replacements and repairs.

The Solution: To mitigate this challenge, buyers should invest time in understanding the various types of strike latches available, including electric strikes, deadlatch strikes, and privacy latches. Collaborating with manufacturers or suppliers who offer educational resources can be beneficial. Create a specification checklist that includes factors such as door material, traffic volume, and security requirements. When making purchases, consult with technical representatives to ensure that the selected latch matches the intended use case. This proactive approach can lead to better purchasing decisions and long-term savings.

Scenario 3: Incompatibility with Existing Hardware

The Problem: Another significant pain point for B2B buyers is the incompatibility of new strike latches with existing door hardware. For example, a facility might upgrade to a more secure latch system but discover that the new strike plates do not fit with the existing doors and frames, resulting in unexpected delays and additional expenses for retrofitting. This situation is particularly prevalent in facilities with older infrastructure where standardization was not prioritized during installation.

The Solution: To avoid compatibility issues, a detailed inventory of existing door hardware should be taken before sourcing new strike latches. When selecting latches, focus on universal designs that can be adapted to various door types and frames. It is also advisable to work closely with suppliers who provide compatibility guides or installation support. If retrofitting is necessary, consider consulting with a locksmith or a door hardware specialist to ensure that modifications are executed correctly without compromising security or functionality. By taking these steps, businesses can streamline their upgrades and ensure seamless integration with their current systems.

Strategic Material Selection Guide for strike latch

What Are the Key Materials Used in Strike Latch Manufacturing?

When selecting materials for strike latches, it is crucial to consider the specific requirements of the application, including environmental conditions, mechanical stresses, and compliance with regional standards. Here, we analyze four common materials used in the manufacturing of strike latches: stainless steel, brass, zinc alloy, and plastic.

How Does Stainless Steel Perform as a Material for Strike Latches?

Stainless steel is known for its high corrosion resistance and strength, making it an ideal choice for environments exposed to moisture or harsh conditions. Its ability to withstand high temperatures also adds to its appeal in industrial applications. However, stainless steel can be more expensive than other materials, and its manufacturing process can be complex due to the need for specialized tooling.

From an application perspective, stainless steel strike latches are suitable for both indoor and outdoor use, particularly in coastal regions where saltwater corrosion is a concern. International buyers should ensure that the stainless steel grade complies with local standards, such as ASTM A240 for corrosion resistance, which is particularly relevant in regions like Europe and the Middle East.

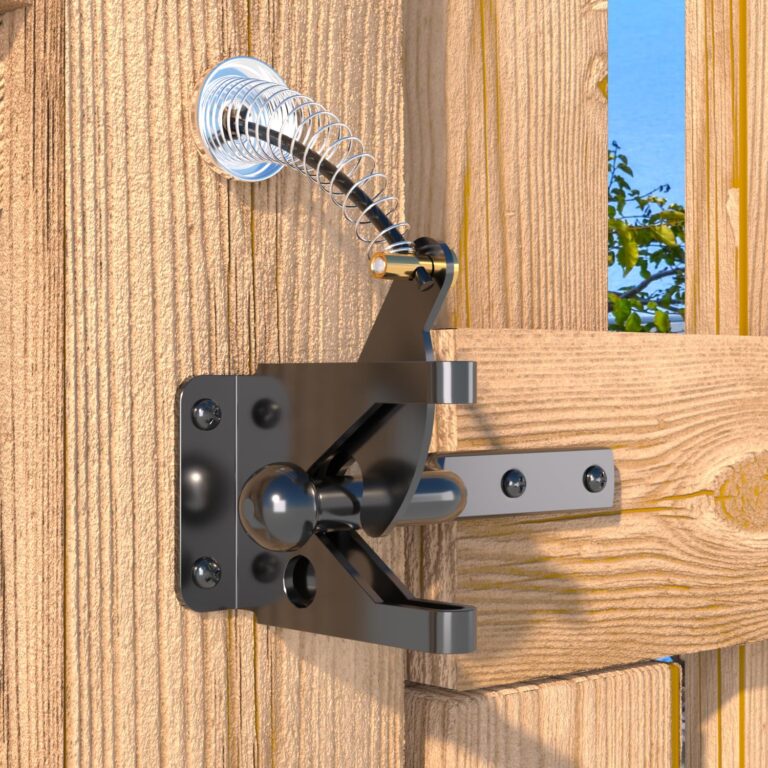

Illustrative image related to strike latch

What Advantages Does Brass Offer for Strike Latch Applications?

Brass is a popular material for strike latches due to its aesthetic appeal and inherent anti-corrosive properties. It is relatively easy to machine, allowing for intricate designs and customizations. However, brass can be softer than steel, which may affect its longevity under heavy use. Additionally, it can tarnish over time, necessitating regular maintenance.

Brass strike latches are commonly used in residential applications and decorative doors, making them a preferred choice in markets focused on aesthetics, such as Europe and South America. Buyers should consider compliance with relevant standards like ASTM B453 to ensure quality and performance.

Why Choose Zinc Alloy for Strike Latches?

Zinc alloy is often chosen for its cost-effectiveness and excellent casting properties, allowing for the production of complex shapes. It offers decent corrosion resistance, particularly when coated, and is relatively lightweight, which can be advantageous in certain applications. However, zinc alloy may not perform well under high-stress conditions, leading to potential failure over time.

Illustrative image related to strike latch

Zinc alloy strike latches are frequently used in commercial settings where cost is a key factor, such as in budget-friendly construction projects. International buyers should verify that the alloy meets local standards, such as JIS H 8601 in Japan or similar specifications in Africa and South America.

What Role Does Plastic Play in Strike Latch Manufacturing?

Plastic, particularly high-density polyethylene (HDPE) or polycarbonate, is often utilized for strike latches in environments where weight reduction is critical. It is resistant to corrosion and can be produced at a lower cost compared to metals. However, plastic may not withstand high temperatures or heavy loads as effectively as metal options.

Plastic strike latches are suitable for lightweight applications, such as interior doors or temporary structures. Buyers in regions with stringent environmental regulations should ensure that the plastic used complies with standards like REACH in Europe or similar regulations in Africa and the Middle East.

Summary Table of Material Selection for Strike Latches

| Material | Typical Use Case for strike latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor and industrial applications | High corrosion resistance and strength | Higher cost and complex manufacturing | High |

| Brass | Residential and decorative doors | Aesthetic appeal and good corrosion resistance | Softer material, may tarnish | Medium |

| Zinc Alloy | Budget-friendly commercial settings | Cost-effective and good casting properties | Not suitable for high-stress applications | Low |

| Plastic | Lightweight and temporary structures | Lightweight and corrosion-resistant | Limited load-bearing capacity and temperature resistance | Low |

This strategic material selection guide provides B2B buyers with essential insights into the characteristics, advantages, and limitations of various materials used in strike latch manufacturing. By understanding these factors, buyers can make informed decisions that align with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for strike latch

What Are the Main Stages in the Manufacturing Process of Strike Latches?

The manufacturing of strike latches involves several critical stages, each designed to ensure precision and durability. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality materials, typically stainless steel, brass, or zinc alloy, chosen for their strength, corrosion resistance, and aesthetic appeal. The raw materials are inspected and prepared through cutting, grinding, and cleaning processes to eliminate impurities and ensure uniformity.

-

Forming: In this stage, the prepared materials are shaped into components using techniques such as stamping, machining, and forging. Stamping is common for producing flat plates, while machining may be used for more intricate parts requiring precision. Forging can enhance strength and durability by aligning the material’s grain structure.

-

Assembly: After forming, the various components of the strike latch are assembled. This process often involves automated machinery for efficiency, but skilled labor is also essential for quality assurance. Components are aligned and fixed together using screws, rivets, or welding, depending on the design specifications.

-

Finishing: The final stage includes surface treatments such as plating, powder coating, or anodizing to enhance aesthetics and protect against wear and corrosion. Quality checks during this stage ensure that the finish meets the required standards for durability and appearance.

Which Quality Assurance Standards Are Relevant for Strike Latch Manufacturing?

Quality assurance is a critical component of strike latch production, ensuring that products meet international and industry-specific standards. For B2B buyers, understanding these standards is essential when selecting suppliers.

-

International Standards: ISO 9001 is a widely recognized quality management standard that outlines requirements for an effective quality management system. Compliance with ISO 9001 indicates that a manufacturer consistently meets customer and regulatory requirements, enhancing product reliability.

-

Industry-Specific Certifications: Depending on the application, additional certifications may apply. For instance, CE marking is necessary for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards. Similarly, API (American Petroleum Institute) standards may be relevant for latches used in oil and gas applications.

What Are the Key Quality Control Checkpoints in Strike Latch Production?

Quality control (QC) checkpoints are integral to the manufacturing process, ensuring that each stage adheres to established standards. Common checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and compliance with specifications before they enter the production process. This step is crucial to prevent defects from the outset.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the manufacturing process. This includes checking dimensions, tolerances, and assembly integrity at various stages. Any deviations are addressed immediately to avoid compounding issues.

-

Final Quality Control (FQC): Once production is complete, the finished strike latches undergo thorough testing. This may include functional tests, stress tests, and inspections of surface finishes. Only products that pass these tests are packaged and shipped.

What Common Testing Methods Are Used in Strike Latch Quality Assurance?

Several testing methods are employed to ensure that strike latches meet quality standards:

-

Mechanical Testing: This includes tensile strength tests to evaluate the material’s ability to withstand pulling forces, as well as fatigue tests to assess durability over repeated use.

-

Corrosion Resistance Testing: Strike latches, particularly those used in outdoor applications, undergo salt spray tests to determine their resistance to corrosion. This is crucial for maintaining functionality and appearance over time.

-

Functional Testing: This involves testing the latch mechanism to ensure it operates smoothly and securely. Functional tests simulate real-world conditions to verify performance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are key strategies:

Illustrative image related to strike latch

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing process, quality control checkpoints, and compliance with relevant standards. This firsthand observation can provide valuable insights into a supplier’s capabilities.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the testing methods used, results obtained, and any corrective actions taken. These reports should cover IQC, IPQC, and FQC outcomes.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of a supplier’s quality control processes. These agencies can conduct tests and audits, ensuring that the supplier meets international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control:

-

Regulatory Compliance: Understanding the specific regulations and standards applicable in different regions is crucial. For example, products exported to Europe must comply with CE marking, while those sold in the U.S. may need to meet ANSI (American National Standards Institute) standards.

-

Cultural Differences: Communication and cultural differences can impact quality control processes. Establishing clear expectations and maintaining open lines of communication with suppliers can help mitigate misunderstandings.

-

Supply Chain Considerations: Buyers should consider the entire supply chain, including logistics, transportation, and local regulations, which can affect product quality and compliance. Building relationships with reliable logistics partners can enhance the overall quality assurance process.

Conclusion

For B2B buyers in the international market, understanding the manufacturing processes and quality assurance protocols for strike latches is critical. By focusing on each stage of production, adhering to relevant standards, and implementing robust quality control measures, manufacturers can ensure that their products meet the high expectations of global buyers. Through diligent supplier verification and an awareness of regional nuances, buyers can confidently source high-quality strike latches that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘strike latch’

Introduction

This guide provides a comprehensive checklist for B2B buyers looking to procure strike latches. Strike latches are critical components in door hardware, impacting security, functionality, and compatibility. A systematic approach to sourcing will ensure you select the best products that meet your specific needs and compliance requirements.

Illustrative image related to strike latch

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for the strike latch. Consider factors such as the type of door (wood, metal, glass), the latch mechanism (manual or electric), and the load-bearing capacity required. This clarity will help you filter suppliers and products effectively.

- Compatibility: Ensure the latch is compatible with existing door hardware.

- Standards Compliance: Identify any industry standards or certifications that the latch must meet, such as ANSI or ISO.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reliable suppliers specializing in strike latches. Look for suppliers with a strong reputation in the industry and a proven track record of quality and service.

- Market Presence: Consider suppliers with a substantial market presence in your region (Africa, South America, Middle East, or Europe).

- Product Range: Evaluate their product range to ensure they offer various strike latches suited to your specifications.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that your selected suppliers hold relevant certifications and quality assurance standards. This step is vital for ensuring product reliability and safety.

- ISO Certification: Check for ISO 9001 certification, indicating a commitment to quality management.

- Local Compliance: Ensure they comply with local regulations and standards applicable in your region.

Step 4: Request Samples for Testing

Request samples of the strike latches you are considering. Testing samples will allow you to evaluate their quality, functionality, and compatibility with your existing systems before making a bulk purchase.

- Functionality Testing: Assess the ease of installation and operation under real-world conditions.

- Durability Assessment: Test for durability and resistance to wear and tear, particularly in high-traffic environments.

Step 5: Compare Pricing and Terms

Gather pricing information and compare the total costs associated with each supplier. Look beyond the unit price to consider shipping, import duties, and any potential bulk discounts.

- Cost-Benefit Analysis: Analyze the overall value by considering quality against cost.

- Payment Terms: Review payment terms and conditions, including any financing options available.

Step 6: Check Customer Reviews and References

Investigate customer reviews and request references from past clients to gauge supplier reliability and service quality. This feedback can provide insight into the supplier’s responsiveness and support.

- Online Reviews: Look for reviews on trusted platforms or forums relevant to your industry.

- Direct References: Contact references to ask specific questions about their experience with the supplier.

Step 7: Finalize Your Order and Monitor Delivery

Once you have selected your supplier, finalize your order while ensuring all terms are agreed upon. Monitor the delivery process to ensure timely arrival and compliance with your specifications.

- Order Confirmation: Confirm the order details in writing, including quantities, specifications, and delivery timelines.

- Delivery Tracking: Stay in contact with the supplier for updates on shipment and delivery status.

By following this checklist, B2B buyers can streamline the sourcing process for strike latches, ensuring they select the right products and suppliers to meet their operational needs.

Comprehensive Cost and Pricing Analysis for strike latch Sourcing

What Are the Key Cost Components in Strike Latch Sourcing?

When sourcing strike latches, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the cost of strike latches. Common materials include stainless steel, brass, and plastic. Higher-quality materials tend to yield better durability and security, thus justifying higher prices.

-

Labor: Labor costs vary by region and can affect the total price of manufacturing. In countries with higher wage standards, such as those in Europe, labor can constitute a significant portion of the overall cost.

-

Manufacturing Overhead: This includes costs related to factory operation, utilities, and equipment maintenance. Efficient production processes can help minimize these overheads, impacting pricing.

-

Tooling: Custom tooling for specific designs or functionalities can increase initial costs but may lead to long-term savings if they enhance production efficiency.

-

Quality Control: Investing in quality control measures ensures that products meet industry standards and customer expectations. However, this also adds to the overall cost, which should be factored into the pricing.

-

Logistics: Shipping and handling costs vary based on the distance, mode of transport, and Incoterms. International buyers should consider these logistics costs when calculating the total expenditure.

-

Margin: Suppliers typically add a profit margin to the cost of production. This margin can vary widely based on the supplier’s market position, brand reputation, and competition.

What Influences Pricing for Strike Latches?

Several factors can influence the pricing of strike latches.

-

Volume/MOQ: Bulk orders often come with significant discounts. Understanding the Minimum Order Quantity (MOQ) can help buyers negotiate better rates.

-

Specifications and Customization: Custom-designed strike latches tailored to specific applications may incur additional costs. Buyers should balance the need for customization with budget constraints.

-

Material Quality and Certifications: Certifications such as ISO or ANSI can enhance the perceived value of a product. However, these certifications may also come with higher costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge more due to their perceived quality assurance.

-

Incoterms: The chosen Incoterms dictate who bears the costs and risks during shipping. Understanding these terms is crucial for calculating the total landed cost.

What Are the Best Tips for Buyers to Ensure Cost-Efficiency?

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Leverage your purchasing power to negotiate better terms, including discounts and payment terms.

-

Total Cost of Ownership: Look beyond the initial purchase price. Consider maintenance, replacement, and operational costs over the product’s lifecycle to get a clearer picture of the total cost.

-

Pricing Nuances for International Buyers: Be aware of local market conditions and currency fluctuations, which can affect pricing. For instance, import duties and taxes can significantly impact costs for buyers in Africa, South America, and the Middle East.

-

Supplier Diversification: Consider sourcing from multiple suppliers to create competition and potentially lower prices. This approach can also mitigate risks associated with relying on a single supplier.

-

Quality vs. Cost: While it may be tempting to choose the lowest-priced option, ensure that quality meets your requirements. A poor-quality latch may lead to higher costs due to replacements or repairs.

Conclusion

Navigating the complexities of strike latch sourcing requires a thorough understanding of cost components, pricing influencers, and effective negotiation strategies. By applying these insights, international B2B buyers can optimize their procurement processes, ensuring both cost-effectiveness and quality in their purchasing decisions. Remember, the prices listed in supplier catalogs are indicative and may vary based on specific agreements and market conditions.

Alternatives Analysis: Comparing strike latch With Other Solutions

When evaluating solutions for securing doors, it is essential to explore various alternatives to the traditional strike latch. Each option has its unique advantages and drawbacks that can significantly influence operational efficiency, security, and cost-effectiveness. This analysis will provide insights into how a strike latch compares to electric strikes and traditional deadbolts, helping B2B buyers make informed decisions.

| Comparison Aspect | Strike Latch | Electric Strike | Traditional Deadbolt |

|---|---|---|---|

| Performance | Reliable for standard doors; good security | Allows for remote access; effective for high-security needs | High resistance to forced entry; reliable in various conditions |

| Cost | Low to moderate cost | Moderate to high cost | Low to moderate cost |

| Ease of Implementation | Simple installation; requires minimal tools | Requires electrical wiring; may need professional installation | Straightforward installation; no wiring needed |

| Maintenance | Low maintenance | Moderate maintenance; requires checks on electrical components | Low maintenance; mechanical parts may need lubrication |

| Best Use Case | Residential and light commercial use | High-security facilities, access-controlled environments | Residential, commercial, or industrial applications needing robust security |

What are the Benefits and Drawbacks of Electric Strikes Compared to Strike Latches?

Electric strikes are advanced locking mechanisms that offer enhanced access control capabilities. They replace the traditional strike plate and can be integrated with various security systems. The primary advantage of electric strikes is their ability to facilitate remote unlocking, making them ideal for high-security environments such as government buildings or corporate offices. However, they generally come at a higher cost and require professional installation due to the need for electrical wiring, which can complicate the implementation process.

How Do Traditional Deadbolts Compare to Strike Latches in Terms of Security?

Traditional deadbolts offer a robust locking mechanism, providing excellent resistance against forced entry. They are typically less expensive than electric strikes and have a straightforward installation process. However, they lack the convenience of remote access and may require manual operation. While they are effective for residential and commercial applications, they may not suit environments where quick access is necessary, such as in high-traffic areas or facilities requiring frequent entry and exit.

Conclusion: How Can B2B Buyers Select the Right Door Locking Solution?

Choosing the right locking solution depends on various factors, including the specific security needs of the facility, budget constraints, and installation capabilities. For businesses prioritizing ease of access and integration with security systems, electric strikes may be the best choice despite their higher cost. In contrast, traditional deadbolts are ideal for buyers seeking a balance of security and affordability for residential or less critical applications. Strike latches are suitable for standard use in both residential and light commercial settings. Ultimately, understanding the unique requirements of the environment will guide buyers toward the most effective locking solution.

Illustrative image related to strike latch

Essential Technical Properties and Trade Terminology for strike latch

What Are the Key Technical Properties of Strike Latches?

When sourcing strike latches for various applications, understanding their technical specifications is essential for ensuring optimal performance and compatibility. Here are several critical properties to consider:

-

Material Grade

The material from which a strike latch is made significantly affects its durability and functionality. Common materials include stainless steel, brass, and zinc die-cast. Stainless steel offers superior corrosion resistance and strength, making it ideal for outdoor or high-moisture environments. Brass provides aesthetic appeal but may not be as robust against wear. Choosing the right material can impact the latch’s lifespan and maintenance needs. -

Load Capacity

Load capacity refers to the maximum weight a strike latch can securely hold without failure. This is crucial in applications such as commercial doors, where heavy traffic or high-security requirements are present. Understanding load capacity helps buyers ensure that the latch will perform under expected conditions, thereby reducing the risk of malfunction or damage. -

Finish Type

The finish on a strike latch not only contributes to its appearance but also affects its corrosion resistance and wear properties. Common finishes include chrome, nickel, and powder-coated options. Selecting the appropriate finish is important for aligning with the aesthetic of the installation site and for enhancing the product’s durability against environmental factors. -

Tolerance Levels

Tolerance levels determine the permissible variation in dimensions during the manufacturing process. High tolerance levels ensure that strike latches fit correctly with their corresponding components, leading to smoother operation and improved security. For B2B buyers, understanding tolerance is essential for ensuring compatibility with existing hardware and for minimizing installation issues. -

Fire Rating

Fire ratings indicate the ability of a strike latch to withstand high temperatures and prevent the spread of fire. This is particularly important in commercial buildings or areas with strict fire safety regulations. Selecting a strike latch with the appropriate fire rating not only enhances safety but also ensures compliance with local building codes.

What Are Common Trade Terms Related to Strike Latches?

Familiarity with industry-specific jargon is key for effective communication and negotiation in the B2B sector. Here are some common terms you might encounter:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of strike latches, sourcing from an OEM can provide assurance of quality and compatibility with existing systems, as they often adhere to specific standards. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it can affect inventory management and cash flow. Suppliers may set MOQs to ensure that production costs are covered, so it’s important to negotiate terms that align with business needs. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. This is an essential step in the procurement process for strike latches, allowing buyers to compare options and make informed decisions based on price and specifications. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. These terms clarify who is responsible for shipping, insurance, and tariffs, which is vital for B2B transactions involving strike latches sourced from different countries. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the products. This is a critical factor for B2B buyers, as longer lead times can impact project timelines and inventory management. Understanding lead times allows for better planning and scheduling.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing strike latches, ensuring they meet both functional and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the strike latch Sector

What Are the Current Market Dynamics and Key Trends in the Strike Latch Sector?

The global strike latch market is experiencing significant shifts driven by technological advancements, changing consumer preferences, and evolving security standards. The integration of smart technologies, such as electric strikes, is becoming increasingly popular, particularly in commercial applications. This trend is influenced by the growing demand for enhanced security solutions in urban environments across regions like Africa, South America, the Middle East, and Europe. As businesses prioritize security, strike latches equipped with electronic access control systems are gaining traction, leading to a diversification of product offerings.

Illustrative image related to strike latch

Moreover, international buyers are increasingly focused on sourcing high-quality, durable materials. Manufacturers are responding by developing strike latches from robust materials like stainless steel and brass, which offer both longevity and aesthetic appeal. The trend towards customization is also notable, as businesses seek products tailored to specific applications, such as commercial versus residential use.

In terms of sourcing trends, the rise of e-commerce platforms is revolutionizing how international B2B buyers procure strike latches. Buyers from regions like Vietnam and Nigeria are leveraging online marketplaces to access a broader range of products and suppliers, often leading to better pricing and faster delivery times. Additionally, the emphasis on local sourcing is growing, driven by the desire to reduce lead times and carbon footprints.

How Can Sustainability and Ethical Sourcing Impact the Strike Latch Industry?

Sustainability and ethical sourcing are becoming paramount in the strike latch sector as businesses recognize their environmental responsibilities. The production of strike latches can have a notable impact on the environment, particularly in terms of resource consumption and waste generation. Therefore, manufacturers are increasingly adopting sustainable practices, such as utilizing recycled materials and implementing energy-efficient manufacturing processes.

For B2B buyers, the importance of ethical supply chains cannot be overstated. Sourcing from suppliers who prioritize sustainability not only enhances brand reputation but also aligns with the growing consumer demand for environmentally friendly products. Certifications like LEED (Leadership in Energy and Environmental Design) and ISO 14001 (Environmental Management) are becoming essential indicators of a supplier’s commitment to sustainability.

Furthermore, the use of ‘green’ materials in the production of strike latches, such as eco-friendly finishes and coatings, is gaining popularity. Buyers are encouraged to seek out suppliers who can provide transparency in their sourcing practices and demonstrate a commitment to reducing the environmental impact of their products.

What Is the Brief Evolution and History of Strike Latches in the B2B Context?

The strike latch has evolved significantly since its inception, transitioning from basic mechanical devices to sophisticated locking mechanisms integral to modern security systems. Historically, strike latches were simple devices used primarily in residential applications. However, as urbanization increased and security concerns grew, the demand for more advanced locking solutions surged.

In the late 20th century, the introduction of electric strikes marked a pivotal moment in the evolution of strike latches. These devices allowed for remote access control, becoming essential in commercial settings where security was paramount. Today, with the rise of smart technologies, strike latches continue to evolve, incorporating features such as mobile access and integration with broader security systems.

As international B2B buyers navigate this dynamic market, understanding the evolution of strike latches is crucial for making informed sourcing decisions that align with current security needs and technological advancements.

Frequently Asked Questions (FAQs) for B2B Buyers of strike latch

-

How do I solve alignment issues with strike latches?

Alignment issues with strike latches can often be resolved by adjusting the position of the latch or the strike plate. Begin by checking the door frame for any warping or damage that could affect alignment. If the latch doesn’t line up with the strike plate, you may need to reposition the strike plate by loosening its screws and adjusting its placement. In some cases, using a shim can help achieve the correct alignment. Ensure that all adjustments are tested thoroughly for smooth operation before finalizing. -

What is the best strike latch for high-security applications?

For high-security applications, look for strike latches made from durable materials such as stainless steel, which offers enhanced resistance to tampering and corrosion. Electric strikes can also be an excellent choice as they provide additional access control features, allowing for remote locking and unlocking. Additionally, select strike latches that are tested to meet industry standards, such as UL 294 for access control systems, ensuring they can withstand forced entry attempts. -

What should I consider when sourcing strike latches from international suppliers?

When sourcing strike latches internationally, consider factors such as the supplier’s reputation, certifications, and compliance with local regulations. Evaluate their manufacturing capabilities, lead times, and shipping options to ensure timely delivery. It’s also vital to request product samples and review quality assurance processes. Finally, ensure that the supplier can provide documentation for any certifications needed for your region, as this can streamline customs processes and prevent delays. -

What are typical minimum order quantities (MOQs) for strike latches?

Minimum order quantities for strike latches can vary significantly based on the supplier and the specific product. Generally, MOQs can range from as low as 50 units to over 500 units for custom or specialized latches. It’s essential to discuss your needs with potential suppliers to negotiate terms that suit your business requirements. Keep in mind that larger orders may offer better pricing per unit, so consider your inventory turnover rate when making purchasing decisions. -

How can I customize strike latches for my specific applications?

Customization options for strike latches often include variations in size, material, and finish. Many manufacturers offer bespoke solutions where you can specify dimensions, colors, and additional features, such as enhanced security mechanisms. To initiate customization, provide detailed specifications to your supplier and discuss any necessary adjustments for compatibility with existing door hardware. Ensure to request prototypes to verify that the custom latches meet your performance and aesthetic requirements before bulk ordering. -

What payment terms should I expect when buying strike latches?

Payment terms for purchasing strike latches can vary depending on the supplier’s policies and the scale of your order. Common terms include a deposit upfront (usually 30-50%) with the remainder due upon delivery or net 30/60 days after receipt of goods. It’s advisable to clarify payment terms before finalizing orders, especially for international transactions, as some suppliers may offer discounts for early payment or impose penalties for late payments. -

How can I ensure quality assurance for strike latches?

To ensure quality assurance for strike latches, request certifications from suppliers that demonstrate compliance with industry standards, such as ISO 9001. Additionally, inquire about their quality control processes, including inspection protocols and testing methods used during manufacturing. Conducting factory audits or utilizing third-party inspection services can also help verify product quality before shipment. Maintaining open communication with the supplier throughout the production process will further help in addressing any quality concerns proactively. -

What logistics considerations should I keep in mind when importing strike latches?

When importing strike latches, logistics considerations include shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with international shipping, as they can help navigate complex customs procedures and ensure compliance with import regulations. It’s also important to factor in shipping costs and potential delays that may arise due to customs clearance. Having a clear understanding of the delivery timeline will help in planning your inventory and minimizing disruptions in your supply chain.

Top 3 Strike Latch Manufacturers & Suppliers List

1. Maglocks – Electric Strikes

Domain: maglocks.com

Registered: 2000 (25 years)

Introduction: Electric strikes are access control devices used for doors, replacing the fixed strike faceplate often used with a latchbar. They feature a ramped surface that pivots out of the way upon command when the door lock is in the locked position, allowing the door to be opened. The product offerings include various models from manufacturers like SDC, HES, Adams Rite, and Folger Adam, with features such …

2. TM Hardware – Door Latches & Accessories

Domain: tmhardware.com

Registered: 2011 (14 years)

Introduction: Door Latches and Door Strikes, Door Pulls and Push Bars, Door Closers, Panic Bars, Exit Devices, Gate Locks, Door Glass, Lite Kits, Door Louvers, Door Accessories including Door Stoppers and Kick Plates. Various types of Door Hardware including Door Knobs, Handles, Smart Locks, Deadbolts, Mortised Locks, and different series of Emtek Door Hardware. Includes a wide range of materials and styles for…

3. Primeline – Latch Strike Plate

Domain: primelineparts.com

Registered: 2025 (0 years)

Introduction: [{‘name’: ‘Latch Strike Plate’, ‘finish’: ‘Stainless Steel’, ‘packaging’: ‘2 Pack’, ‘SKU’: ‘E 2301’, ‘price’: ‘$8.66’}, {‘name’: ‘Box Armored Security Strike’, ‘dimensions’: ‘4-7/8 inch Height x 1-1/4 inch Width’, ‘packaging’: ‘Single Pack’, ‘finish’: ‘Bronze’, ‘SKU’: ‘U 95397’, ‘price’: ‘$7.34’}, {‘name’: ‘Adjustable Strike’, ‘dimensions’: ‘2-3/4 in. x 2-1/8 in.’, ‘type’: ‘Three Piece’, ‘finish’:…

Strategic Sourcing Conclusion and Outlook for strike latch

In today’s competitive landscape, effective strategic sourcing for strike latches is crucial for businesses aiming to enhance security and operational efficiency. Buyers must prioritize quality, compatibility, and supplier reliability while considering regional preferences and compliance with local standards. The diverse applications of strike latches—from residential to commercial environments—highlight the importance of tailoring sourcing strategies to meet specific market demands.

Investing in high-quality strike latches not only ensures superior performance but also reduces long-term costs associated with maintenance and replacements. By leveraging supplier relationships and exploring bulk purchasing options, businesses can achieve significant savings while ensuring the integrity of their locking mechanisms.

Looking ahead, international B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to remain proactive in their sourcing efforts. By embracing innovative solutions and staying informed about market trends, companies can enhance their competitive edge. Now is the time to evaluate your sourcing strategies for strike latches—seize the opportunity to partner with trusted suppliers who can provide both quality products and exceptional service.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.