Everything You Need to Know About Springs Locks Sourcing in 2025

Introduction: Navigating the Global Market for springs locks

In an increasingly interconnected world, sourcing reliable spring locks presents a significant challenge for international B2B buyers. Whether you’re operating in the bustling markets of Nigeria or Brazil, the need for durable and secure locking mechanisms is paramount. This guide delves deep into the global market for spring locks, equipping you with the knowledge to make informed purchasing decisions. We explore various types of spring locks, their applications across different industries, and crucial factors for vetting suppliers.

Understanding the diverse functionalities of spring locks—from simple residential solutions to robust commercial applications—can significantly impact your operational efficiency and security standards. Additionally, we provide insights into cost considerations, helping you navigate pricing structures and negotiate effectively with suppliers.

By leveraging this comprehensive guide, B2B buyers from Africa, South America, the Middle East, and Europe will gain the confidence to select the right spring locks tailored to their specific needs. The information presented herein not only empowers you to enhance your procurement strategies but also ensures that you align your security needs with reliable and quality-driven suppliers in the global marketplace.

Understanding springs locks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spring-Loaded Latch | Utilizes a spring mechanism to retract the latch | Residential doors, cabinets | Pros: Easy to install, cost-effective. Cons: May not withstand heavy use. |

| Heavy-Duty Spring Lock | Made from robust materials, designed for high traffic | Commercial doors, industrial equipment | Pros: Durable, high security. Cons: Higher cost, requires professional installation. |

| Adjustable Spring Lock | Features adjustable tension for varying security needs | Gates, machinery, storage units | Pros: Versatile, customizable. Cons: Complexity can lead to installation challenges. |

| Cabinet Spring Lock | Compact design, often with a push-to-release feature | Furniture, office storage | Pros: Discreet, easy to use. Cons: Limited security for high-risk areas. |

| Tumbler Spring Lock | Combines spring mechanism with tumbler security | High-security areas, safes | Pros: Enhanced security, reliable. Cons: More expensive, requires specific keys. |

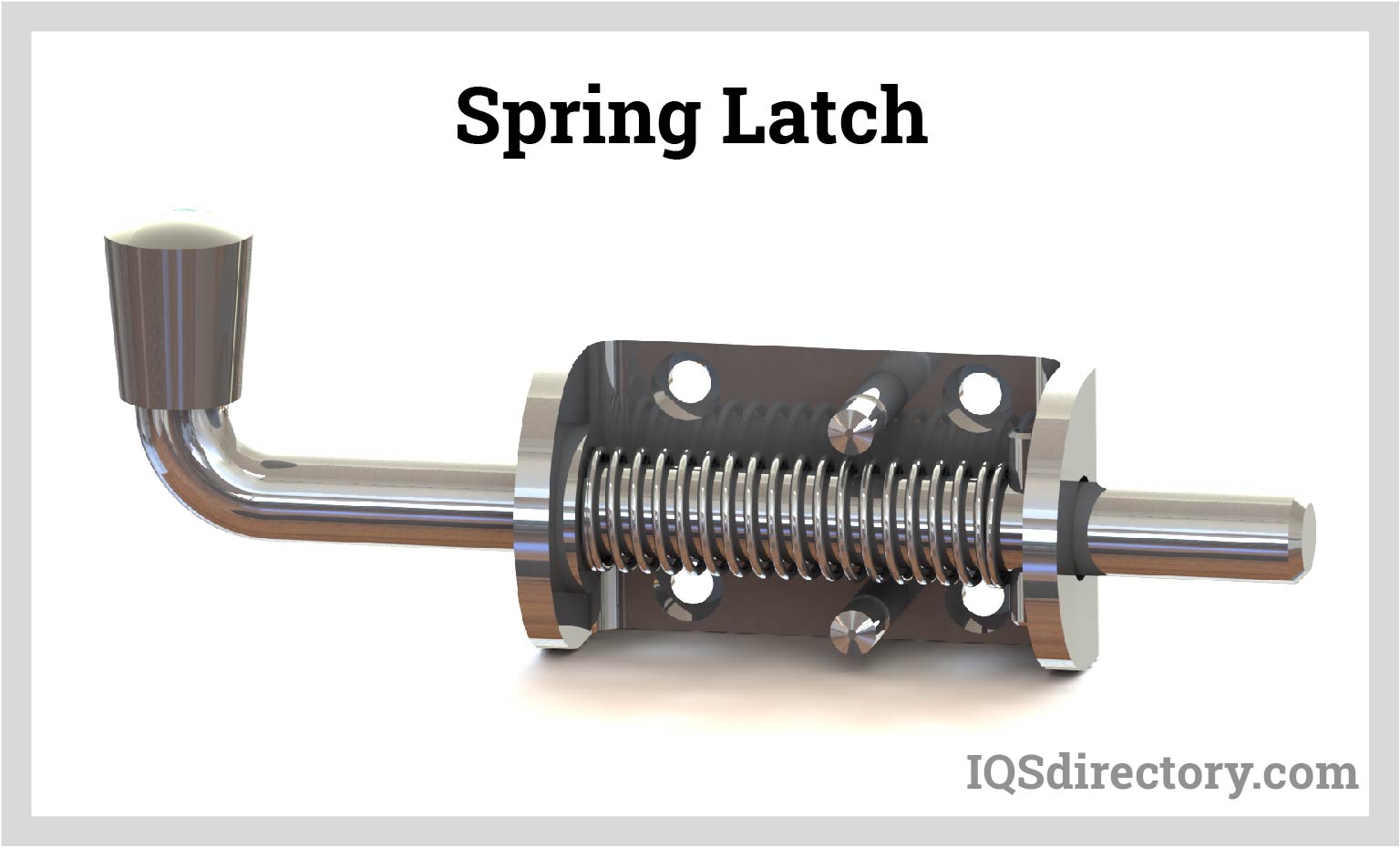

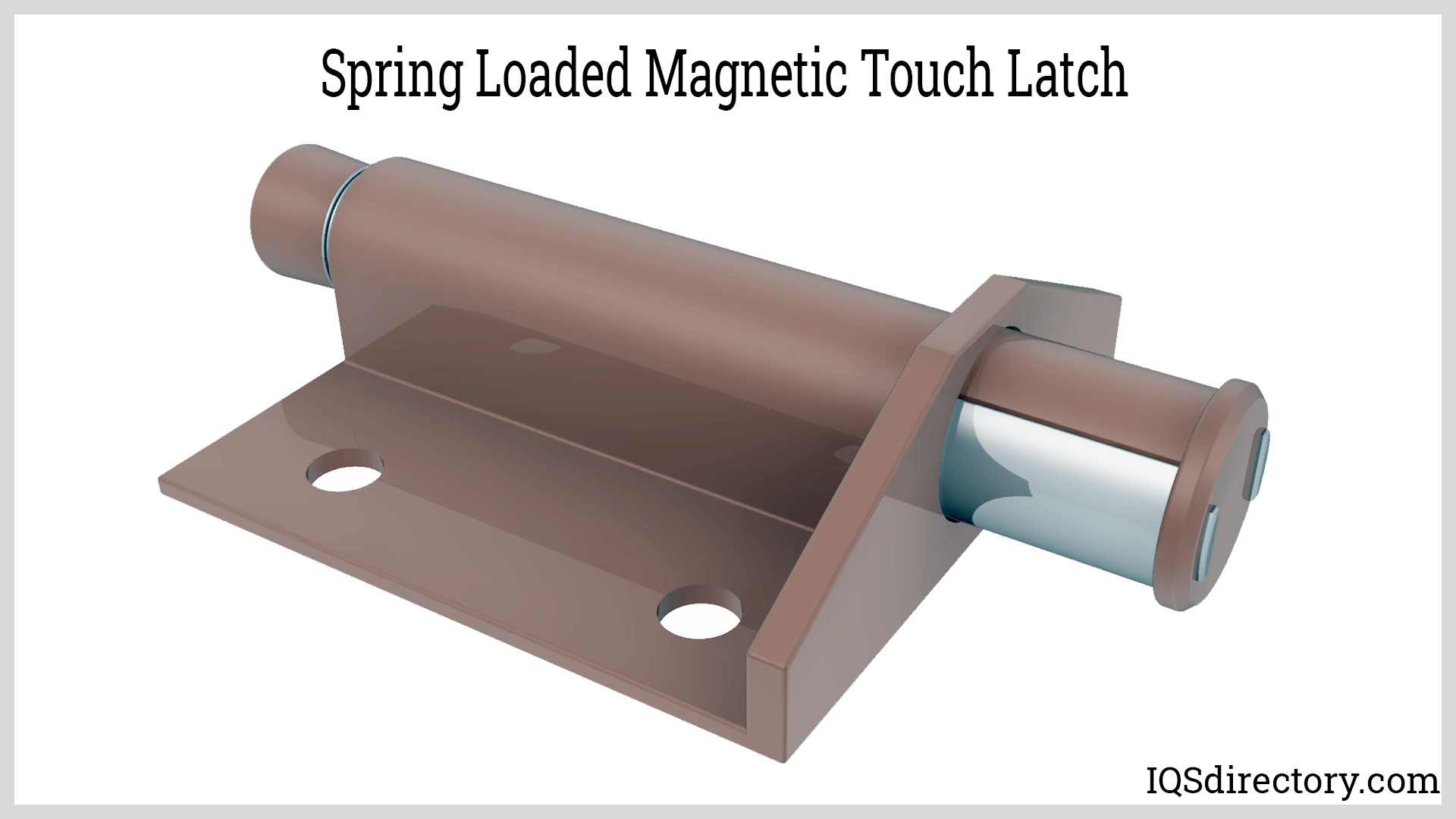

What Are the Key Characteristics of Spring-Loaded Latches?

Spring-loaded latches are characterized by their simple yet effective design, utilizing a spring to retract the latch when the door knob is turned. They are commonly used in residential applications such as doors and cabinets, making them an attractive option for B2B buyers seeking cost-effective solutions. When purchasing, consider the material and finish, as these factors affect durability and aesthetics. While easy to install, they may not be suitable for high-traffic areas due to potential wear over time.

How Do Heavy-Duty Spring Locks Stand Out in Commercial Settings?

Heavy-duty spring locks are built with robust materials to withstand frequent use, making them ideal for commercial applications such as office doors and industrial equipment. Their key distinguishing feature is their enhanced security, which often includes thicker bolts and reinforced mechanisms. B2B buyers should assess the lock’s specifications to ensure it meets industry standards for security and durability. Although they come at a higher price point, the investment can lead to long-term savings through reduced maintenance and replacement costs.

Why Choose Adjustable Spring Locks for Versatility?

Adjustable spring locks offer the flexibility to customize tension settings, making them suitable for various applications, including gates and machinery. Their ability to adapt to different security needs is a significant advantage for B2B buyers looking for versatile locking solutions. However, the complexity of installation may require professional assistance, which could increase initial costs. Buyers should weigh the benefits of customization against installation challenges when considering this type of lock.

What Makes Cabinet Spring Locks a Popular Choice for Furniture?

Cabinet spring locks are designed with a compact profile and often feature a push-to-release mechanism, making them ideal for office storage and furniture applications. Their discreet design allows for seamless integration into various environments. B2B buyers should consider the level of security required, as these locks may not be suitable for high-risk areas. While they are easy to use and install, their limited security features may necessitate additional measures in more vulnerable settings.

How Do Tumbler Spring Locks Enhance Security?

Tumbler spring locks combine traditional spring mechanisms with tumbler technology, providing enhanced security for high-risk areas such as safes and secure facilities. Their design requires a specific key to operate, adding an extra layer of protection. B2B buyers should evaluate the lock’s security ratings and key control measures when selecting this option. Although they tend to be more expensive than other types, the reliability and peace of mind they offer can justify the investment in security-focused environments.

Key Industrial Applications of springs locks

| Industry/Sector | Specific Application of Springs Locks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC and Ductwork | Duct Reinforcement in HVAC Systems | Enhanced durability and compliance with regulations | Quality of materials, ease of installation, and volume discounts |

| Automotive | Safety Locks for Transport Equipment | Improved safety and operational efficiency | Compliance with safety standards, reliability, and compatibility with existing systems |

| Construction and Infrastructure | Securing Temporary Structures | Cost-effective and quick installation | Material strength, weather resistance, and ease of use |

| Agricultural Equipment | Locking Mechanisms for Machinery and Storage Units | Increased security for valuable assets | Durability against environmental factors, ease of maintenance, and adaptability to various equipment |

| Furniture Manufacturing | Latches for Cabinets and Drawers | Enhanced user experience and product longevity | Aesthetic compatibility, ease of installation, and material quality |

How Are Springs Locks Used in HVAC and Ductwork Applications?

In the HVAC industry, springs locks are crucial for duct reinforcement. They provide a secure fastening solution that meets SMACNA regulations without the need for crimping or de-burring, making installation straightforward. This is particularly valuable in regions where compliance with safety standards is critical. Buyers must prioritize the quality of materials to ensure long-lasting performance and consider sourcing options that offer volume discounts, especially for large-scale projects.

What Role Do Springs Locks Play in Automotive Safety?

In the automotive sector, springs locks are employed as safety locks for transport equipment, ensuring that cargo remains secure during transit. This application enhances operational efficiency by preventing accidental openings and potential damage. International buyers should focus on sourcing locks that comply with local safety regulations and standards, ensuring reliability and compatibility with existing transport systems.

Why Are Springs Locks Essential for Construction and Infrastructure?

In construction, springs locks are used to secure temporary structures, providing a cost-effective and efficient solution for site management. They allow for quick assembly and disassembly, essential in dynamic construction environments. Buyers in this sector should consider the material strength and weather resistance of the locks to withstand varying environmental conditions, ensuring safety and reliability throughout the project lifecycle.

Illustrative image related to springs locks

How Do Springs Locks Enhance Security in Agricultural Equipment?

Agricultural equipment often utilizes springs locks as locking mechanisms for machinery and storage units. This application is vital for protecting valuable assets from theft and damage. Buyers from agricultural sectors must prioritize durability against harsh environmental factors and ease of maintenance, ensuring that the locks remain functional over time while adapting to various equipment types.

What Benefits Do Springs Locks Provide in Furniture Manufacturing?

In the furniture manufacturing industry, springs locks serve as latches for cabinets and drawers, enhancing user experience by providing smooth operation and secure closure. This contributes to the overall longevity of the furniture. Buyers should consider the aesthetic compatibility of the locks with their product designs, as well as the ease of installation and quality of materials to ensure a premium finish.

3 Common User Pain Points for ‘springs locks’ & Their Solutions

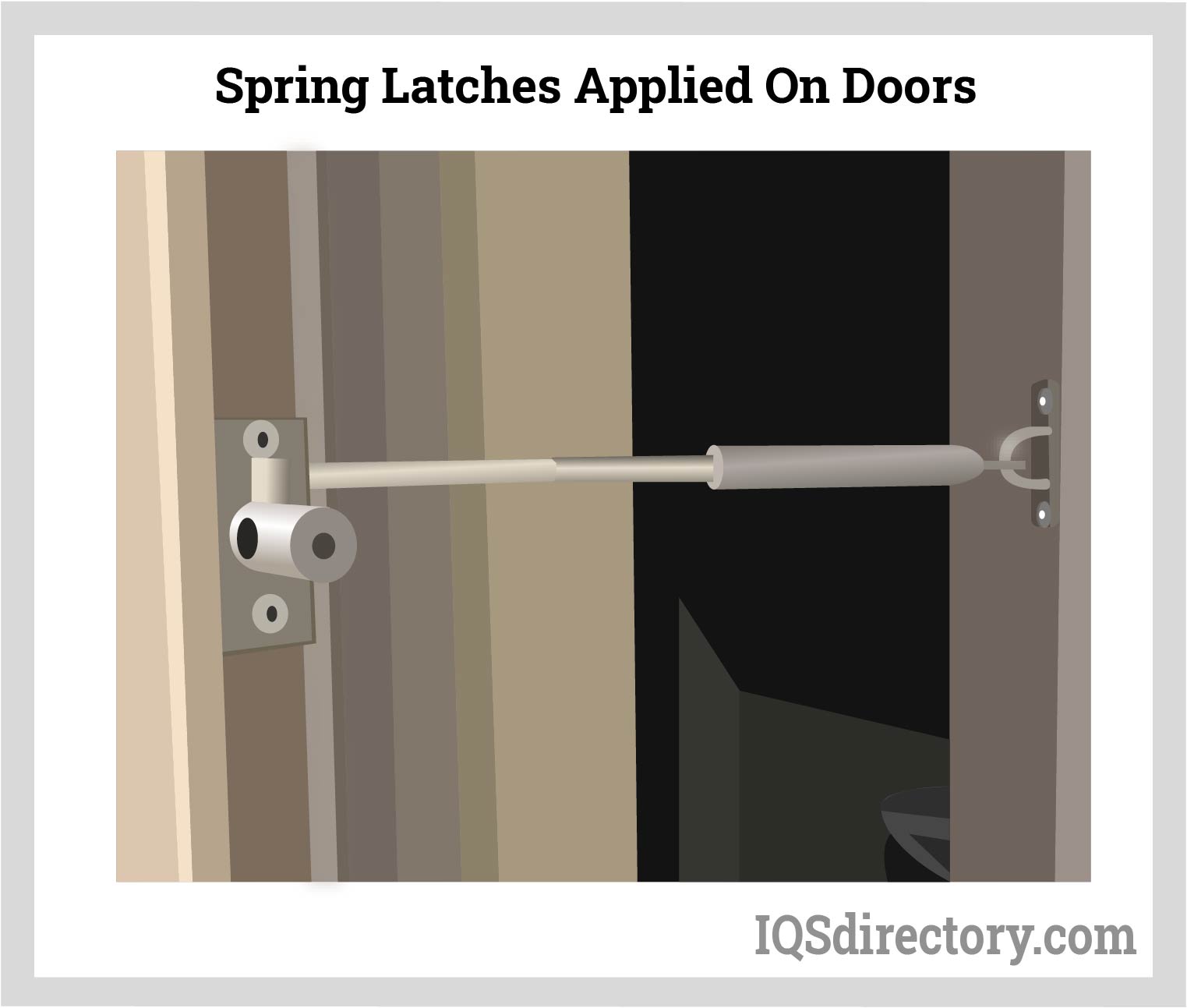

Scenario 1: Difficulty with Installation and Compliance

The Problem: B2B buyers often struggle with the installation of spring locks, particularly in compliance with industry regulations such as SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association) standards. The complexity of ensuring that the locks are installed correctly can lead to delays in project timelines, increased labor costs, and potential safety violations. Moreover, the lack of clear guidelines can result in improper installation, leading to malfunctioning locks that compromise security.

Illustrative image related to springs locks

The Solution: To address installation challenges, it’s crucial for buyers to source spring locks that come with comprehensive installation guides and support. Suppliers should provide detailed documentation that outlines step-by-step procedures, including diagrams and troubleshooting tips. Additionally, training sessions or webinars offered by the manufacturer can help contractors understand best practices and compliance requirements. When purchasing, consider locks designed for quick installation, such as those that do not require crimping or de-burring, which can save time and reduce the likelihood of installation errors. Building a relationship with a supplier who offers ongoing support can also ensure that any issues are resolved swiftly, minimizing downtime on projects.

Scenario 2: Inconsistent Quality Across Suppliers

The Problem: B2B buyers often encounter a significant challenge in ensuring the consistent quality of spring locks from different suppliers. Variations in materials, manufacturing processes, and design can lead to discrepancies in performance and durability. This inconsistency can result in increased operational costs, as buyers may have to frequently replace locks that fail prematurely or do not meet security standards.

The Solution: To mitigate quality issues, buyers should conduct thorough due diligence when selecting suppliers. Look for manufacturers with established reputations, verified quality control processes, and certifications such as ISO 9001. Request samples before making bulk purchases to assess the lock’s material and construction firsthand. Additionally, consider establishing long-term partnerships with a select few suppliers who consistently meet quality expectations. Implementing a regular review process for supplier performance, including quality audits and feedback loops, can also help maintain high standards and ensure that the locks meet the specific needs of your operations.

Scenario 3: Inefficiencies in Inventory Management

The Problem: Managing inventory levels of spring locks can be a pain point for B2B buyers, especially those with large-scale operations. Over-ordering can lead to excess stock that ties up capital, while under-ordering can result in project delays due to insufficient supplies. This balancing act is further complicated by fluctuating demand and varying lead times from suppliers.

The Solution: To improve inventory management, buyers should adopt a just-in-time (JIT) inventory strategy, which aligns orders with production schedules and reduces carrying costs. Leveraging technology, such as inventory management software, can provide real-time insights into stock levels and usage patterns, helping to forecast demand more accurately. Engage with suppliers who offer flexible ordering options, such as smaller minimum order quantities or the ability to quickly replenish stock. Establishing a regular communication channel with suppliers regarding anticipated project timelines can also help ensure that necessary materials are available when needed without over-committing resources. By taking a proactive approach to inventory management, businesses can enhance operational efficiency and reduce costs associated with excess inventory.

Strategic Material Selection Guide for springs locks

What Are the Key Properties of Common Materials Used in Springs Locks?

When selecting materials for springs locks, it’s essential to consider their properties, as they directly influence performance, durability, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of springs locks: stainless steel, carbon steel, brass, and plastic composites.

How Does Stainless Steel Perform in Springs Locks?

Stainless steel is widely recognized for its excellent corrosion resistance and strength. It can withstand a range of temperatures, making it suitable for various environments. This material is often used in outdoor applications or in settings where moisture is prevalent.

Pros: Stainless steel offers high durability and longevity, reducing the need for frequent replacements. Its aesthetic appeal also makes it a preferred choice for visible installations.

Cons: The primary drawback is its higher cost compared to other materials. Manufacturing processes for stainless steel can also be more complex, requiring specialized equipment.

Impact on Application: Stainless steel is compatible with a variety of media, including water and chemicals, making it ideal for industrial applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers in Africa and South America should ensure that the stainless steel grades meet local regulations for corrosion resistance.

What Are the Advantages of Using Carbon Steel in Springs Locks?

Carbon steel is known for its high tensile strength and affordability. It is often used in applications where cost is a significant factor, and the environment is less corrosive.

Pros: Carbon steel is relatively low-cost and easy to manufacture, making it an attractive option for high-volume production.

Cons: Its susceptibility to rust and corrosion limits its use in outdoor or humid environments unless properly treated with coatings.

Illustrative image related to springs locks

Impact on Application: Carbon steel is suitable for applications where the locking mechanism is not exposed to harsh conditions, such as indoor machinery or equipment.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to enhance longevity, especially in humid regions like the Middle East. Compliance with relevant standards is also essential.

Why Choose Brass for Springs Locks?

Brass is often favored for its excellent machinability and corrosion resistance, particularly in environments where aesthetics matter.

Pros: Brass has a unique appearance and is resistant to corrosion, making it ideal for decorative applications. It also has good anti-bacterial properties, which can be beneficial in healthcare settings.

Cons: The main limitation is its relatively lower strength compared to stainless and carbon steel, making it unsuitable for heavy-duty applications.

Impact on Application: Brass is commonly used in residential locks and fixtures where appearance and moderate security are priorities.

Considerations for International Buyers: Buyers in Europe and Africa should consider the cost implications, as brass can be more expensive than carbon steel. Compliance with local standards for safety and durability is also necessary.

How Do Plastic Composites Fit into Springs Lock Applications?

Plastic composites are increasingly being used in springs locks due to their lightweight and corrosion-resistant properties.

Pros: They are cost-effective and can be manufactured in various colors and designs, making them suitable for consumer products.

Cons: Plastic locks may not offer the same level of security or durability as metal options, which can limit their application in high-security environments.

Illustrative image related to springs locks

Impact on Application: Plastic composites are often used in lightweight applications, such as in consumer goods or non-critical locking mechanisms.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with relevant safety and environmental regulations, particularly in regions with stringent standards like Europe.

Summary Table of Material Selection for Springs Locks

| Material | Typical Use Case for springs locks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor applications | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Indoor machinery | Low cost and high tensile strength | Susceptible to rust without coatings | Low |

| Brass | Residential locks | Aesthetic appeal and corrosion resistance | Lower strength compared to steel | Medium |

| Plastic Composites | Consumer goods | Lightweight and cost-effective | Limited security and durability | Low |

This guide provides actionable insights for B2B buyers to make informed decisions about material selection for springs locks, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for springs locks

What Are the Main Stages of Manufacturing Springs Locks?

The manufacturing process for spring locks involves several key stages, each crucial for ensuring the final product meets quality and performance standards. Here’s a breakdown of the main stages:

Material Preparation: What Materials Are Used in Spring Locks?

The process begins with the selection of high-quality materials. Most spring locks are made from steel due to its superior strength and durability. Stainless steel is also a popular choice for applications requiring corrosion resistance. The raw materials are carefully sourced and undergo initial inspections to ensure they meet specified standards. After selection, the materials are cut to the required sizes for further processing.

Illustrative image related to springs locks

How Are Spring Locks Formed?

The forming stage typically involves several techniques, including:

- Stamping: This technique uses a die to shape metal sheets into specific forms, creating components such as the lock body and latch.

- Machining: For precision parts, machining processes like turning and milling are employed to achieve tight tolerances on components.

- Spring Coiling: The spring mechanism, a core element of spring locks, is produced by coiling wire into a spiral shape. This process requires precise tension control to ensure the spring can effectively secure the lock.

Each forming method contributes to the overall functionality and reliability of the lock.

What Does the Assembly Process Entail?

Once individual components are formed, they move to the assembly stage. This is where parts such as the latch, bolt, and spring are brought together. Automated assembly lines may be used for higher volume production, while manual assembly might be employed for more specialized or complex locks.

Quality checks during assembly include ensuring proper fit and function of the components, as any misalignment can compromise the lock’s effectiveness.

How Are Finishing Techniques Applied?

The final stage in manufacturing involves surface finishing, which is essential for both aesthetic appeal and functional longevity. Techniques like:

- Electroplating: This process applies a thin layer of metal to enhance corrosion resistance.

- Powder Coating: A finish that provides a durable surface and allows for various color options.

- Heat Treatment: This process strengthens the metal, enhancing durability and resistance to wear.

Finishing not only improves the product’s appearance but also contributes to its overall durability and performance.

Illustrative image related to springs locks

What International Standards Govern Quality Assurance for Spring Locks?

Quality assurance in the production of spring locks is critical to ensure safety and reliability. Various international standards, such as ISO 9001, set the framework for quality management systems (QMS). Compliance with ISO 9001 indicates that a manufacturer consistently meets customer requirements and regulatory obligations.

Which Industry-Specific Certifications Should B2B Buyers Consider?

In addition to ISO standards, industry-specific certifications can enhance buyer confidence. For example:

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Certification: Relevant for locks used in the oil and gas industry, ensuring they meet specific performance criteria.

These certifications signify adherence to rigorous safety and quality standards, making them essential considerations for B2B buyers.

How Do Quality Control Checkpoints Ensure Product Integrity?

Quality control (QC) is integral to the manufacturing process of spring locks. Several checkpoints are established to ensure product integrity:

Illustrative image related to springs locks

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before production. It ensures that only high-quality materials are used.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken to verify that processes are being followed correctly. This includes checking dimensions, material properties, and assembly accuracy.

-

Final Quality Control (FQC): Before packaging and shipping, final inspections are conducted. This includes functional testing of locks to ensure they operate as intended.

What Common Testing Methods Are Used for Spring Locks?

Testing is crucial in validating the performance and reliability of spring locks. Common methods include:

-

Tensile Testing: This assesses the strength of materials used in the lock, ensuring they can withstand applied forces.

-

Cycle Testing: Locks are subjected to repeated locking and unlocking to simulate long-term use and assess durability.

-

Corrosion Testing: Especially important for outdoor applications, this tests the lock’s resistance to rust and degradation over time.

These testing methods help ensure that the locks will perform reliably under various conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are effective strategies:

-

Supplier Audits: Conducting audits can provide insights into a manufacturer’s processes, standards, and compliance with international regulations. This may involve on-site visits or reviewing internal quality management documentation.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality assurance processes, including results from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality practices, ensuring that products meet specified standards before shipment.

What Nuances Should International Buyers Be Aware of Regarding Quality Certification?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding quality certification:

-

Regional Regulations: Different regions may have varying requirements for product certification. For instance, CE marking is essential for products entering the European market but may not be necessary in other regions.

-

Customs and Import Regulations: Certain countries may require specific documentation or certifications for imported goods. Understanding these requirements can streamline the import process and avoid delays.

-

Cultural Considerations: Building relationships with suppliers can often enhance communication regarding quality expectations and regulatory compliance.

In conclusion, understanding the manufacturing processes and quality assurance protocols for spring locks can empower B2B buyers to make informed purchasing decisions. By focusing on material quality, manufacturing techniques, and robust QC measures, buyers can ensure they procure reliable and high-performance locking solutions tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘springs locks’

In today’s competitive market, sourcing high-quality spring locks is essential for ensuring security and functionality in various applications. This checklist will guide international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, through the critical steps of procuring spring locks effectively.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, outline the specific requirements for the spring locks you need. Consider factors such as material (e.g., steel or brass), size, load capacity, and application (residential vs. commercial). Clear specifications will help you communicate effectively with suppliers and ensure that the products meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of spring locks. Look for manufacturers with a proven track record in your industry, and consider their geographical location for logistics and shipping efficiency. Utilize online platforms, industry forums, and trade shows to gather a list of potential suppliers.

Step 3: Evaluate Supplier Certifications

It’s critical to verify that your chosen suppliers hold the necessary certifications and standards, such as ISO or ANSI. These certifications indicate that the supplier adheres to quality management systems and industry standards, which can reduce risks associated with product defects and ensure compliance with local regulations.

Step 4: Request Samples for Testing

Once you’ve narrowed down your options, request samples of the spring locks to evaluate their quality and performance. Testing samples allows you to assess their functionality, durability, and ease of installation. Ensure the samples reflect the specifications you require, particularly if they are intended for specific applications.

Step 5: Compare Pricing and Terms

Gather pricing quotes from multiple suppliers and compare them against your budget and quality requirements. Pay attention not only to the unit price but also to bulk order discounts, shipping costs, and payment terms. Understanding the total cost of ownership will help you make a more informed decision.

Step 6: Review Supplier Reputation and References

Before finalizing your order, conduct a background check on the suppliers. Look for reviews and testimonials from other B2B buyers, particularly those in your industry or region. Ask for references and reach out to previous clients to understand their experiences with the supplier’s products and customer service.

Step 7: Establish Clear Communication Channels

Once you’ve selected a supplier, establish clear lines of communication to facilitate efficient order processing and address any potential issues. Set expectations regarding timelines, delivery schedules, and after-sales support. Regular communication will help ensure a smooth procurement process and build a strong supplier relationship.

By following this practical checklist, B2B buyers can streamline their sourcing process for spring locks, ensuring they select the right products that meet their specifications and operational requirements.

Comprehensive Cost and Pricing Analysis for springs locks Sourcing

What Are the Key Cost Components in Sourcing Springs Locks?

When sourcing springs locks, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. High-quality steel is commonly used for durability, while alternative materials like brass or plastic can reduce costs. However, opting for lower-quality materials may compromise lock performance and longevity.

-

Labor: Labor costs vary by region and manufacturing process. Automated production may lower labor costs, but specialized locks requiring skilled craftsmanship can increase expenses. It’s important to assess the labor conditions in the supplier’s region, as this can influence overall pricing.

-

Manufacturing Overhead: This encompasses costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can mitigate these costs, but fluctuations in energy prices may affect overhead.

-

Tooling: Tooling costs are crucial, especially for custom designs. Investment in specialized tooling can lead to higher initial costs but may reduce production costs in the long run if the tooling is used for high-volume runs.

-

Quality Control (QC): Ensuring that springs locks meet industry standards requires investment in quality assurance measures. This can include testing protocols and certifications, which add to the overall cost but are vital for ensuring product reliability.

-

Logistics: Transportation and warehousing expenses must be factored into the total cost. International shipping can significantly increase costs, especially for bulky items like springs locks. Understanding the logistics landscape in your region can help optimize these expenses.

-

Margin: Suppliers typically mark up prices to cover their costs and ensure profitability. Understanding the supplier’s pricing strategy can provide leverage in negotiations.

What Influences the Price of Springs Locks?

Several factors can influence the pricing of springs locks, especially for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often result in lower per-unit costs. Suppliers may offer discounts for larger orders, so negotiating MOQ can be beneficial.

-

Specifications and Customization: Customized locks with specific features or dimensions typically incur additional costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Locks that meet international quality standards or possess specific certifications (such as ISO or CE) may command higher prices. Buyers should weigh the benefits of certified products against their budgets.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium, but their proven track record can justify the cost.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They dictate responsibilities related to shipping, insurance, and tariffs, impacting the overall cost of procurement.

What Are Effective Buyer Tips for Sourcing Springs Locks?

B2B buyers should adopt strategic approaches to optimize their sourcing experience:

-

Negotiation: Building strong relationships with suppliers can facilitate negotiations for better pricing. Regular communication can also lead to favorable terms and conditions.

-

Focus on Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors like durability, maintenance, and potential replacement costs to make informed decisions.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local market conditions that may affect pricing.

-

Research and Compare Suppliers: Conduct thorough research to compare offerings from various suppliers. This not only helps in understanding market rates but also in identifying suppliers that provide the best value for money.

-

Request Samples: Before committing to a large order, requesting samples can help assess the quality and functionality of the springs locks, ensuring they meet your specifications.

Disclaimer

The prices and insights provided are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate pricing and terms.

Alternatives Analysis: Comparing springs locks With Other Solutions

Introduction to Alternative Locking Solutions

In the realm of security solutions, businesses often seek alternatives to traditional locking mechanisms, such as spring locks. Understanding the various options available is crucial for B2B buyers, particularly in diverse markets across Africa, South America, the Middle East, and Europe. This analysis will compare spring locks with two viable alternatives: electronic locks and padlocks, allowing businesses to make informed decisions based on their unique security needs.

Comparison Table

| Comparison Aspect | Springs Locks | Electronic Locks | Padlocks |

|---|---|---|---|

| Performance | Reliable, quick locking mechanism | Advanced security features | Versatile, easy to use |

| Cost | Moderate ($560 – $580 per box) | Higher initial investment | Low to moderate |

| Ease of Implementation | Simple installation | Requires electrical setup | Easy to install |

| Maintenance | Low maintenance | Regular battery changes needed | Minimal maintenance |

| Best Use Case | Duct reinforcement in HVAC | High-security areas, access control | General-purpose security |

Detailed Breakdown of Alternatives

1. Electronic Locks

Electronic locks offer a modern approach to security with features such as keypads, biometric readers, or RFID technology. They provide enhanced security through customizable access controls and audit trails, making them ideal for high-security areas in commercial environments. However, their higher initial investment and dependency on electricity can be drawbacks. Additionally, regular battery changes or technical malfunctions may pose challenges in areas with unreliable power sources.

Pros:

– High-security features.

– Customizable access control.

– Audit trails for monitoring access.

Cons:

– Higher upfront costs.

– Requires electrical installation and maintenance.

– Potential technical issues.

2. Padlocks

Padlocks are a versatile solution suitable for various applications, from securing gates to lockers. They are easy to use and install, making them a popular choice for many businesses. While they offer flexibility and portability, their security level can vary significantly based on the quality and design. Lower-end models may be susceptible to picking or cutting, which could compromise security in more demanding environments.

Pros:

– Easy to install and use.

– Portable and versatile.

– Generally lower cost.

Cons:

– Security can vary widely by quality.

– Not suitable for high-security needs.

– Limited features compared to electronic locks.

Illustrative image related to springs locks

Conclusion: Choosing the Right Locking Solution

When selecting a locking mechanism, B2B buyers must consider their specific security requirements, budget constraints, and operational environments. Spring locks are ideal for applications where simplicity and reliability are paramount, particularly in duct reinforcement scenarios. In contrast, businesses looking for advanced security features may find electronic locks more suitable, despite their higher costs. Padlocks serve well in versatile applications but may not meet the needs of high-security environments. Ultimately, understanding the unique strengths and limitations of each option will guide businesses in making the best choice for their security needs.

Essential Technical Properties and Trade Terminology for springs locks

What Are the Key Technical Properties of Spring Locks for B2B Buyers?

When evaluating spring locks for industrial applications, understanding their technical specifications is crucial for ensuring optimal performance and security. Below are essential properties that buyers should consider:

1. Material Grade

The material used in manufacturing spring locks significantly impacts their durability and performance. Common materials include stainless steel, brass, and carbon steel. Stainless steel is preferred for its corrosion resistance, making it ideal for outdoor applications. Brass offers aesthetic appeal and good resistance to wear, while carbon steel provides strength and cost-effectiveness. Selecting the right material ensures longevity and reduces maintenance costs.

2. Tensile Strength

Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can withstand before failure. For spring locks, higher tensile strength means increased durability under stress, particularly in high-use environments such as commercial or industrial settings. This property is essential for maintaining security and functionality over time, making it a critical specification for B2B buyers.

3. Tolerance Levels

Tolerance levels indicate the permissible limits of variation in the dimensions of the spring lock components. Precision in manufacturing is crucial for the proper functioning of the locking mechanism. Poor tolerances can lead to operational failures, such as jamming or improper locking. Buyers should ensure that suppliers adhere to stringent tolerance standards to guarantee product reliability and performance.

Illustrative image related to springs locks

4. Spring Load Rating

The spring load rating measures the amount of force a spring can exert when compressed or extended. This rating is vital for applications requiring specific locking forces to secure doors or gates effectively. Understanding load ratings helps buyers select the right spring locks for their specific applications, ensuring that they meet safety and operational requirements.

5. Corrosion Resistance

Corrosion resistance is a critical property for locks used in harsh environments. Buyers should look for locks that are treated or made from materials designed to withstand moisture, chemicals, and other corrosive elements. This property not only extends the lifespan of the lock but also ensures consistent performance in demanding conditions.

What Are Common Trade Terms Used in the Spring Locks Industry?

Familiarizing oneself with industry jargon can facilitate smoother transactions and better understanding among B2B buyers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end products. In the context of spring locks, OEM suppliers provide locks that are integrated into larger systems or machinery. Understanding OEM relationships can help buyers ensure they are sourcing quality components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, being aware of MOQs is crucial for budgeting and inventory management. It can also affect the cost per unit; larger orders often reduce the overall price.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers to request pricing for specific products or services. In the spring locks industry, an RFQ can help buyers gather competitive pricing, assess suppliers’ capabilities, and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is essential for B2B transactions, as they clarify who bears the costs and risks at various stages of the shipping process.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. In the spring locks industry, understanding lead times is vital for project planning and inventory management. It enables buyers to align their procurement processes with operational needs.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when sourcing spring locks, ultimately leading to better procurement outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the springs locks Sector

What Are the Key Trends Influencing the Springs Locks Market?

The springs locks market is witnessing dynamic shifts driven by several global factors. Firstly, the increasing demand for security solutions, particularly in emerging markets across Africa, South America, the Middle East, and Europe, is propelling the growth of this sector. Regions like Nigeria and Brazil are experiencing urbanization and industrial growth, leading to heightened security needs in residential and commercial spaces.

Moreover, technological advancements are reshaping sourcing trends. The integration of smart technology into traditional spring locks is gaining traction, with manufacturers focusing on innovations that enhance security while maintaining user-friendliness. For instance, spring locks that can be integrated with smart home systems are becoming more popular, appealing to tech-savvy consumers and businesses alike.

Sourcing trends are also evolving, with international buyers increasingly favoring suppliers that offer volume discounts and custom solutions. This shift reflects a move towards more strategic partnerships where quality, reliability, and adaptability are prioritized. Additionally, the ongoing emphasis on cost-effectiveness is prompting buyers to seek materials that balance durability with affordability, ensuring long-term value.

How Is Sustainability Shaping the Springs Locks Sector?

Sustainability and ethical sourcing are becoming essential considerations for B2B buyers in the springs locks sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt greener practices. This includes using recycled materials and minimizing waste during production. Buyers are increasingly interested in suppliers who prioritize eco-friendly processes, as this aligns with global sustainability goals.

Ethical supply chains are also gaining importance, particularly in regions with stringent regulations regarding labor practices and environmental standards. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming critical for manufacturers to demonstrate compliance and commitment to ethical sourcing.

Furthermore, the use of sustainable materials, such as those derived from renewable resources, is a growing trend. Manufacturers that can provide ‘green’ certifications or materials will likely find favor with conscientious buyers who wish to enhance their own sustainability credentials.

What Is the Evolution of Springs Locks and Its Relevance for B2B Buyers?

The evolution of springs locks is a fascinating journey that reflects advancements in both security technology and material science. Initially, springs locks were rudimentary devices made from basic materials, primarily designed for simple locking mechanisms. Over the decades, however, these locks have evolved into sophisticated systems that utilize high-quality steel and innovative designs to enhance security and reliability.

Key developments include the introduction of tumbler mechanisms, which significantly increased security levels, and the use of stronger materials that have improved durability and performance. This historical progression is relevant for B2B buyers, as it underscores the importance of investing in high-quality locks that offer enhanced security features. Understanding this evolution allows buyers to appreciate the value of modern springs locks, which not only fulfill basic security needs but also incorporate advanced safety features essential for contemporary applications.

In summary, as the springs locks market continues to grow and evolve, B2B buyers must stay informed about market dynamics, sustainability practices, and the historical context that informs current innovations in the sector. By aligning their sourcing strategies with these trends, international buyers can secure reliable and effective locking solutions that meet their diverse needs.

Frequently Asked Questions (FAQs) for B2B Buyers of springs locks

-

How do I select the right spring lock for my application?

Choosing the appropriate spring lock involves evaluating your specific requirements, including the environment, frequency of use, and security needs. For industrial applications, opt for heavy-duty spring locks that can withstand rigorous use. In contrast, lighter locks may suffice for residential purposes. Additionally, consider the material and design; stainless steel options offer corrosion resistance, while specialized designs, like weatherproof locks, cater to outdoor settings. Consulting with suppliers for technical specifications and performance data can also guide your decision. -

What are the key differences between residential and commercial spring locks?

Residential spring locks typically prioritize convenience and basic security, often featuring simple latch mechanisms. In contrast, commercial spring locks are designed for higher security and durability, incorporating robust materials and advanced features like access control compatibility. When selecting locks for commercial use, focus on their ability to handle high traffic and their compliance with industry standards. Understanding the specific needs of your environment is crucial for making an informed choice. -

What customization options are available for spring locks?

Many manufacturers offer customization options for spring locks to meet specific needs. You can request variations in size, material, color, and even locking mechanisms. Some suppliers may also provide branding options, allowing you to add your logo or markings. When discussing customization with suppliers, ensure you communicate your requirements clearly, including quantity and lead times, as these factors can influence production capabilities and costs. -

What are the minimum order quantities (MOQ) for spring locks?

Minimum order quantities for spring locks vary by supplier and product type. Typically, MOQs can range from 100 to several thousand units, especially for customized products. It is advisable to inquire about MOQs when contacting suppliers, as some may offer flexibility for bulk orders or repeat customers. Understanding MOQ is essential for budgeting and planning your inventory needs effectively. -

What payment terms should I expect when sourcing spring locks internationally?

Payment terms for international purchases of spring locks often include options such as wire transfers, letters of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for custom orders. It’s essential to discuss payment terms during negotiations to ensure they align with your financial processes. Additionally, be aware of potential currency exchange rates and fees that may impact your overall cost. -

How can I ensure the quality of spring locks from international suppliers?

To guarantee quality when sourcing spring locks internationally, conduct thorough supplier vetting. Request samples to assess the locks’ performance and durability firsthand. Additionally, check for certifications, such as ISO or relevant industry standards, which indicate adherence to quality control processes. Establishing clear communication regarding your quality expectations and implementing a quality assurance process, including inspections upon arrival, can further mitigate risks. -

What logistics considerations should I keep in mind when importing spring locks?

When importing spring locks, consider shipping methods, costs, and lead times. Depending on your location and the supplier’s base, you may choose air freight for faster delivery or sea freight for cost savings. Be sure to factor in customs duties, taxes, and potential delays in transit. Working with a logistics partner experienced in international shipping can streamline the process and help you navigate any regulatory requirements effectively. -

What safety features should I look for in spring locks?

When evaluating spring locks, safety features are paramount to ensure reliable security. Look for locks that incorporate tamper-resistant designs, such as reinforced strike plates and longer latch bolts that provide deeper engagement. Additionally, some locks may have integrated security features like anti-drill plates or secondary locking mechanisms for added protection. Discuss these features with suppliers to ensure the locks meet your specific safety requirements.

Top 9 Springs Locks Manufacturers & Suppliers List

1. PROFAB – Spring-Lock Hardware

Domain: productionproducts.net

Registered: 2002 (23 years)

Introduction: {“Product Name”: “Spring-Lock Hardware”, “Manufacturer”: “Production Products, Inc.”, “Brand”: “PROFAB”, “SKU”: “SUDRH-0400”, “Price Range”: “$560.00 – $580.00 per box”, “Set Options”: [{“Size”: “½ inch”, “Price”: “$0.56 each”, “Quantity”: “1,000 sets/box”}, {“Size”: “¾ inch”, “Price”: “$0.58 each”, “Quantity”: “1,000 sets/box”}], “Components”: “1 Stud/Spring-Lock, 1 neoprene bonded washer, 1 flan…

2. B/A Products – Spring Lock w/Long Drive Pin

Domain: baprod.com

Registered: 1997 (28 years)

Introduction: B/A Products Spring Locks & Accessories include various types of spring locks and replacement parts designed for reliable anchoring points in auto transport. Key products include: 1. Spring Lock w/Long Drive Pin – SL-3P: Durable steel construction for long-lasting use. 2. Spring Lock w/Short Drive Pin – SL-2P: Engineered for dependability and longevity. 3. Long Spring For Spring Lock – BA-SL102L: …

3. Tackle Warehouse – Banjo Minnow Hardware Kit

Domain: tacklewarehouse.com

Registered: 1998 (27 years)

Introduction: [{‘name’: ‘Banjo Minnow Hardware Kit’, ‘price’: ‘$7.99’}, {‘name’: ‘Eagle Claw Lazer Sharp Springs for Soft Plastics 8p’, ‘price’: ‘$4.49’}, {‘name’: ‘Flatlands Tackle Pro Hitch Hiker Bait Keepers Large 5pk’, ‘price’: ‘$2.59’}, {‘name’: ‘Gamakatsu Double Down Spring Lock’, ‘price’: ‘$4.79’, ‘original_price’: ‘$5.39’}, {‘name’: ‘Gamakatsu Spring Lock 5pk’, ‘price’: ‘$1.49’, ‘original_price’: ‘$1.79…

4. Service Spring – Garage Door Locks & Parts

Domain: shop.servicespring.com

Registered: 2000 (25 years)

Introduction: This company, Service Spring – Garage Door Locks & Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Specialty Products Mfg. – D/Bolt Cap Pins

Domain: clksupplies.com

Registered: 2004 (21 years)

Introduction: [{‘name’: ‘D/Bolt Cap Pins For Schlage Locks’, ‘manufacturer’: ‘Specialty Products Mfg.’, ‘pack_size’: ‘Pack of 100’, ‘price’: ‘$4.05’}, {‘name’: ‘D/Bolt Cap Springs For Schlage Locks’, ‘manufacturer’: ‘Specialty Products Mfg.’, ‘pack_size’: ‘Pack of 100’, ‘price’: ‘$4.05’}, {‘name’: ‘Schlage F Series Compressible Spring For T-Pin’, ‘part_number’: ‘F506-453’, ‘material’: ‘Stainless Steel’, ‘pack_s…

6. McMaster – Lock Springs

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Lock Springs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Historicallocks – Essential Springs

Domain: historicallocks.com

Registered: 2007 (18 years)

Introduction: Springs are vital features of lock technology, made from iron or steel. They are essential for the function of locks, creating tension that the key must displace to turn the bolt. Historical examples of lock springs include: 1. Simple plate spring (200 AD – 17th century) 2. Ward springs (100 BC – 19th century) 3. V-shaped plate springs (15th – 17th century) 4. Tumbler with plate spring (15th centu…

8. Corrections Products Co – Detention Lock Springs

Domain: correctionsproductsco.com

Registered: 2004 (21 years)

Introduction: Detention Lock Springs: Compression springs, torsion springs, and hybrid springs available. Designed as direct replacements for original equipment manufacturers (OEM). Meets or exceeds OEM’s technical specifications regarding materials and dimensions. OEM’s name, part number, and trademarks used for identification purposes only.

9. PAC Racing – 500 Series Valve Locks

Domain: racingsprings.com

Registered: 2000 (25 years)

Introduction: PAC Racing 500 Series Valve Locks are made of ultra-high strength lightweight Ti-17 material optimized for thickness and strength. They undergo stringent material certifications and ultimate strength testing for consistent peak performance. Available styles include Standard 10 Degree, Standard 8 Degree, FMOD A 7 Degree, Mini 8 Degree, Standard 7 Degree, and LS-1 7 Degree. Valve lock groove quantit…

Strategic Sourcing Conclusion and Outlook for springs locks

How Can Strategic Sourcing Enhance Your Spring Lock Procurement?

In summary, strategic sourcing of spring locks can significantly enhance your procurement process by ensuring quality, efficiency, and cost-effectiveness. Understanding the diverse applications and types of spring locks is crucial for making informed purchasing decisions that align with your specific operational needs. By engaging with reputable suppliers who offer robust products, such as those with patented designs or advanced materials, businesses can achieve higher durability and reliability in their security solutions.

Moreover, leveraging volume discounts and establishing long-term relationships with manufacturers can lead to better pricing strategies and enhanced service support. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe explore their sourcing options, it is essential to consider not only the immediate costs but also the overall value that high-quality spring locks can provide.

Illustrative image related to springs locks

Looking ahead, the demand for innovative security solutions will continue to grow. By proactively evaluating your sourcing strategies and staying informed about advancements in lock technology, you can position your business to thrive in an increasingly competitive landscape. Engage with trusted suppliers today to ensure your organization is equipped with the best locking solutions for tomorrow’s challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to springs locks