Everything You Need to Know About Springlocks For Sale Sourcing in 2025

Introduction: Navigating the Global Market for springlocks for sale

In the ever-evolving global market, sourcing high-quality springlocks for sale poses a significant challenge for B2B buyers across various industries. With diverse applications ranging from automotive to construction, selecting the right springlock can directly impact operational efficiency and product safety. This comprehensive guide addresses key considerations in the procurement process, including an overview of different types of springlocks, their specific applications, and the importance of supplier vetting to ensure reliability and compliance with industry standards.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Brazil, will find actionable insights tailored to their unique needs. This guide delves into pricing strategies, allowing businesses to navigate cost fluctuations while maximizing value. Additionally, we explore the significance of understanding local regulations and standards, which can vary greatly across markets.

By equipping buyers with in-depth knowledge and practical tools, this guide empowers informed purchasing decisions that enhance operational success. Whether you are a seasoned procurement professional or new to the market, understanding the intricacies of sourcing springlocks will ultimately lead to better product quality, increased safety, and improved bottom lines. Prepare to navigate the complexities of the global springlock market with confidence and clarity.

Understanding springlocks for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Universal Long Spring Lock | Made of steel, versatile for various trailer types | Car trailers, towing equipment | Pros: Durable, cost-effective. Cons: Limited to specific trailer uses. |

| Spring-Lock Duct Reinforcement | Stronger than plastic, no crimping required | HVAC ductwork, construction | Pros: Quick installation, high strength. Cons: May require specific tools for installation. |

| Spring Lock for Archery | Compact design, used in bowstring applications | Archery equipment manufacturing | Pros: Lightweight, easy to use. Cons: Niche application limits market. |

| Heavy-Duty Spring Lock | Enhanced load-bearing capacity, suitable for rugged conditions | Industrial machinery, heavy equipment | Pros: High durability, supports heavy loads. Cons: Higher cost compared to standard locks. |

| Adjustable Spring Lock | Customizable tension settings, adaptable for various uses | Automotive, mechanical applications | Pros: Versatile, enhances user control. Cons: Complexity may lead to installation challenges. |

What are the Characteristics of Universal Long Spring Locks?

Universal Long Spring Locks are primarily constructed from steel, making them a robust choice for various trailer applications. Their design allows for easy installation and removal, catering to the needs of car trailers and towing equipment. Buyers should consider the weight capacity and compatibility with their specific trailer models, as these locks are tailored for certain uses. Their affordability often appeals to budget-conscious businesses looking for reliable solutions.

How Does Spring-Lock Duct Reinforcement Stand Out?

Spring-Lock Duct Reinforcement hardware offers a significant advantage over traditional plastic alternatives, boasting a strength that is 150% greater. This type of spring lock is particularly suitable for HVAC systems, where secure duct reinforcement is essential. B2B buyers should evaluate the installation process, as it requires no crimping or deburring, making it a time-efficient choice. However, understanding the specific requirements of duct construction regulations is crucial for compliance.

Why Choose Spring Locks for Archery Equipment?

Spring Locks designed for archery are compact and lightweight, making them ideal for bowstring applications. These locks are particularly relevant for manufacturers in the archery sector, where precision and reliability are paramount. While they offer ease of use and installation, buyers should be aware that their specialized nature limits broader applications, which could affect purchasing decisions.

What Makes Heavy-Duty Spring Locks Essential for Industrial Use?

Heavy-Duty Spring Locks are engineered to withstand rigorous conditions and support substantial loads, making them indispensable in industrial machinery and heavy equipment applications. Businesses in sectors such as construction and manufacturing should prioritize these locks for their durability and performance. However, the investment may be higher than standard options, so evaluating the cost against the expected load requirements is vital for cost-effective purchasing.

How Do Adjustable Spring Locks Enhance Versatility?

Adjustable Spring Locks provide customizable tension settings, making them suitable for a wide range of automotive and mechanical applications. This adaptability is particularly beneficial for businesses that require specific locking mechanisms for various projects. While they offer enhanced control and versatility, the complexity of installation may deter some buyers. Understanding the technical specifications and installation requirements is essential for effective usage in diverse applications.

Illustrative image related to springlocks for sale

Key Industrial Applications of springlocks for sale

| Industry/Sector | Specific Application of springlocks for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Securing components in car trailers | Enhanced safety and reliability during transport | Material quality, weight capacity, and compatibility |

| Construction | Duct reinforcement in HVAC systems | Improved structural integrity and compliance with standards | Compliance with local building codes and regulations |

| Manufacturing | Assembly line equipment fastening | Increased efficiency and reduced downtime | Bulk purchasing options and lead times |

| Marine | Fastening components on boats and marine vessels | Resistance to corrosion and durability in harsh conditions | Material specifications for marine environments |

| Sports Equipment | Holding components in archery and sports gear | Improved performance and safety for athletes | Weight considerations and material sourcing |

How Are Springlocks Used in the Automotive Industry?

In the automotive sector, springlocks are critical for securing components in car trailers. These locks provide robust fastening solutions that enhance safety and reliability during transport. Buyers should consider the weight capacity and material quality, as these factors directly influence the effectiveness of the locks. Sourcing high-quality steel springlocks is particularly important for international buyers, especially in regions like Nigeria and Brazil, where transportation conditions may vary.

What Role Do Springlocks Play in Construction?

Springlocks are widely utilized in the construction industry for duct reinforcement in HVAC systems. By offering a quick and efficient method to secure ducts, these locks improve structural integrity and ensure compliance with industry standards. International buyers must focus on compliance with local building codes and regulations when sourcing springlocks. Additionally, understanding the specific requirements for installation can help mitigate potential issues on-site.

How Are Springlocks Beneficial in Manufacturing?

In manufacturing, springlocks are essential for fastening assembly line equipment, which can significantly increase operational efficiency. These locks reduce downtime by providing a reliable fastening solution that can withstand the rigors of industrial use. When sourcing springlocks, businesses should explore bulk purchasing options and lead times to ensure a steady supply chain. This is especially vital for manufacturers in regions with fluctuating demand.

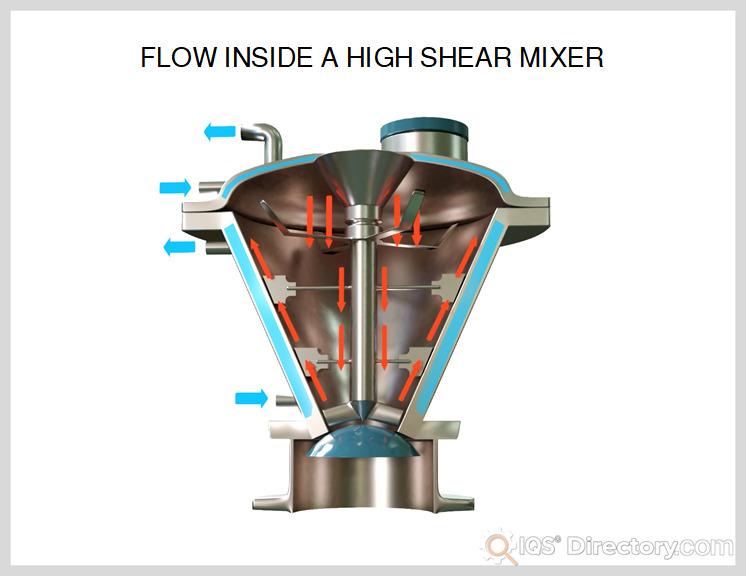

Illustrative image related to springlocks for sale

Why Are Springlocks Important for Marine Applications?

Marine industries rely on springlocks to fasten components on boats and other vessels. The locks are designed to resist corrosion, ensuring durability in harsh marine environments. For international buyers, particularly in the Middle East and Africa, it’s crucial to verify material specifications to ensure compliance with marine standards. Understanding the specific environmental challenges can also guide the selection of appropriate springlocks.

How Do Springlocks Enhance Sports Equipment?

In the sports equipment sector, springlocks are used to hold components securely in archery and other sports gear. Their reliable performance enhances safety and improves the overall experience for athletes. Buyers should consider weight and material sourcing when selecting springlocks, as these factors can influence the performance of the equipment. Ensuring that the locks meet specific performance standards is essential for maintaining safety and functionality.

3 Common User Pain Points for ‘springlocks for sale’ & Their Solutions

Scenario 1: Sourcing Quality Springlocks for Diverse Applications

The Problem: B2B buyers often struggle to find high-quality springlocks that meet specific application requirements, particularly when sourcing internationally. For businesses operating in regions like Africa or South America, where local suppliers may offer limited options, the challenge escalates. This can lead to concerns about product durability, performance, and compliance with local regulations. Additionally, buyers may worry about the inconsistency in product specifications and quality control when ordering from overseas manufacturers.

The Solution: To effectively source high-quality springlocks, buyers should begin by researching reputable suppliers with a proven track record in the industry. Engaging with manufacturers that offer certifications and compliance with international standards is crucial. Buyers should specify their unique requirements—such as material, size, and load-bearing capacity—before placing bulk orders. Utilizing platforms that allow for direct communication with suppliers can also help clarify product specifications and quality assurances. Establishing relationships with multiple suppliers can mitigate risks and ensure access to quality products tailored to specific needs.

Scenario 2: Understanding the Application and Installation Process for Springlocks

The Problem: Many B2B buyers are not fully aware of how to properly apply and install springlocks for their intended uses, leading to potential mishaps or inefficient operations. For example, in industries such as construction or automotive, improper installation can result in equipment failure or safety hazards. This lack of understanding can stem from inadequate product documentation or insufficient training on best practices.

The Solution: To overcome this knowledge gap, buyers should seek comprehensive product documentation and installation guides from suppliers. Requesting hands-on training sessions or webinars from manufacturers can also provide valuable insights into the correct usage of springlocks. Additionally, leveraging online resources and forums specific to the industry can facilitate knowledge sharing among professionals facing similar challenges. By investing in training and education on proper installation techniques, businesses can enhance operational efficiency and ensure safety in their applications.

Scenario 3: Managing Inventory and Cost-Effectiveness of Springlocks

The Problem: B2B buyers often face the challenge of managing inventory levels while ensuring cost-effectiveness in their procurement of springlocks. Fluctuating prices and the risk of overstocking can significantly impact cash flow, especially for businesses operating on tight budgets. Moreover, suppliers may have varying pricing structures, which complicates budgeting and forecasting.

The Solution: Implementing an inventory management system that tracks usage rates and forecasts future needs can help buyers optimize their purchasing strategies. Establishing relationships with suppliers who offer volume discounts or loyalty programs can also reduce costs. Buyers should consider negotiating long-term contracts with preferred suppliers to lock in prices and ensure consistent supply. Additionally, conducting regular market research to compare prices and supplier offers will enable buyers to make informed decisions that align with their financial goals. By strategically managing inventory and leveraging supplier relationships, businesses can achieve a more cost-effective procurement process for springlocks.

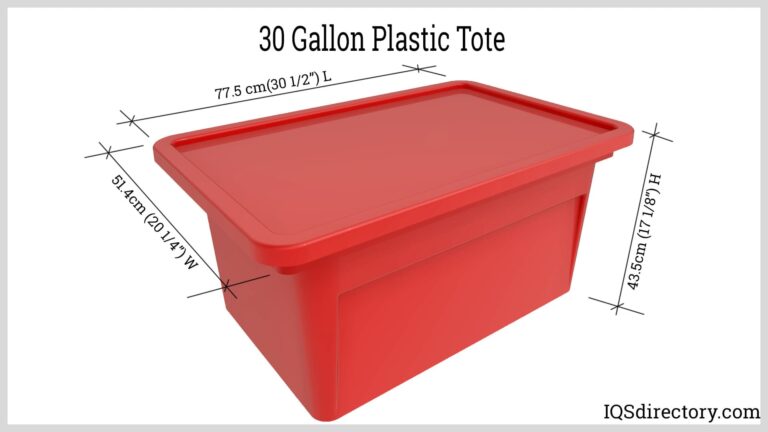

Illustrative image related to springlocks for sale

Strategic Material Selection Guide for springlocks for sale

What Are the Key Materials Used in Springlocks for Sale?

When selecting springlocks for various applications, the choice of material is critical. Different materials offer unique properties that can significantly affect performance, durability, and cost-effectiveness. Below, we analyze four common materials used in springlocks, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform as a Material for Springlocks?

Key Properties: Steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It typically exhibits good resistance to wear and can withstand high temperatures, although its performance may degrade in highly corrosive environments unless treated.

Pros & Cons: The primary advantage of steel is its strength, which allows it to handle significant loads without deforming. However, it can be prone to rusting if not properly coated or treated, which may necessitate additional maintenance. Manufacturing complexity can vary based on the specific steel grade used.

Impact on Application: Steel springlocks are ideal for applications involving heavy machinery or automotive uses, where high strength is essential. However, they may not be suitable for environments with high humidity or exposure to corrosive substances unless adequately protected.

Considerations for International Buyers: Buyers should be aware of compliance standards such as ASTM for the United States or EN standards in Europe. Additionally, countries in Africa and South America may have specific regulations concerning the use of steel products that must be adhered to.

Illustrative image related to springlocks for sale

What Role Does Stainless Steel Play in Springlock Applications?

Key Properties: Stainless steel offers excellent corrosion resistance due to the presence of chromium, which forms a protective oxide layer. It also maintains strength at elevated temperatures, making it a versatile choice for various conditions.

Pros & Cons: The primary advantage of stainless steel is its resistance to corrosion, which extends the lifespan of springlocks in harsh environments. However, it is generally more expensive than standard steel, which can impact budget considerations for large orders.

Impact on Application: Stainless steel springlocks are particularly suitable for marine applications or environments with high moisture levels. Their durability makes them a reliable choice for industries requiring long-lasting performance.

Illustrative image related to springlocks for sale

Considerations for International Buyers: Compliance with international standards, such as ISO or ASTM, is crucial. Buyers should also consider the availability of stainless steel in their region, as it may affect lead times and costs.

How Do Plastic Springlocks Compare in Terms of Performance?

Key Properties: Plastic springlocks are lightweight and resistant to corrosion, making them suitable for specific applications where metal may not be ideal. They can also be molded into complex shapes, allowing for versatile designs.

Pros & Cons: The main advantage of plastic springlocks is their resistance to corrosion and low weight, which can reduce shipping costs. However, they generally lack the strength of metal options and may not withstand high temperatures or heavy loads.

Impact on Application: These springlocks are often used in lightweight applications, such as in the automotive or consumer goods sectors, where weight savings are essential. However, they may not be suitable for high-stress environments.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with relevant safety and environmental regulations, particularly in regions with strict plastic use policies.

What Benefits Do Composite Materials Offer for Springlocks?

Key Properties: Composite materials combine different substances to create a product that can offer enhanced properties, such as improved strength-to-weight ratios and resistance to environmental degradation.

Pros & Cons: The primary advantage of composites is their ability to be tailored for specific applications, offering both strength and lightweight characteristics. However, they can be more expensive to manufacture and may require specialized knowledge for installation.

Impact on Application: Composite springlocks are ideal for applications in aerospace or high-performance automotive sectors, where both weight and strength are critical.

Considerations for International Buyers: Buyers should be aware of the specific certifications required for composite materials in their industry, which can vary significantly between regions.

Summary Table of Material Selection for Springlocks

| Material | Typical Use Case for springlocks for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive applications | High strength and durability | Prone to rust without treatment | Medium |

| Stainless Steel | Marine applications, high-moisture areas | Excellent corrosion resistance | Higher cost than standard steel | High |

| Plastic | Lightweight automotive, consumer goods | Lightweight and corrosion-resistant | Lower strength and temperature limits | Low |

| Composite | Aerospace, high-performance automotive | Tailored properties for specific needs | Higher manufacturing complexity | High |

This guide provides a comprehensive overview of the materials commonly used in springlocks, equipping international B2B buyers with the necessary insights to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for springlocks for sale

What Are the Key Stages in the Manufacturing Process of Springlocks?

The manufacturing process for springlocks typically involves several critical stages that ensure the final product meets performance and durability standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used and How Are They Processed?

The primary materials used for manufacturing springlocks are high-quality metals, often steel or alloys, which provide strength and resilience. The process begins with the careful selection of raw materials, followed by cutting and shaping them into manageable pieces. This stage may involve processes such as shearing or laser cutting to ensure precision.

Once the materials are cut to size, they undergo a cleaning process to remove any contaminants or oils that could affect the quality of the final product. This cleaning is crucial, especially for international buyers who may have strict standards regarding material purity and safety.

How Is the Forming Process Executed for Springlocks?

The forming stage is where the raw materials are transformed into the desired springlock shape. Techniques such as stamping, forging, or bending are commonly used, depending on the design specifications.

For instance, stamping involves using dies to create specific shapes and features in the metal, while forging applies pressure to mold the metal into the required form. Each method has its advantages, and the choice often depends on the volume of production and the complexity of the design.

What Does the Assembly Process Involve for Springlocks?

Following the forming stage, the components of the springlock are assembled. This may include fitting various parts together, such as springs, locking mechanisms, and housings.

Automated assembly lines are often utilized to enhance efficiency and consistency. However, manual assembly may also be used for more intricate designs. Quality checks are typically integrated into this stage to ensure that each assembly meets the specified tolerances.

What Types of Finishing Techniques Are Applied to Springlocks?

The finishing process is essential for enhancing the performance and aesthetic appeal of springlocks. Techniques such as coating, plating, and polishing are commonly employed.

Illustrative image related to springlocks for sale

Coatings, like powder coating or anodizing, can improve corrosion resistance, which is crucial for products used in outdoor or high-moisture environments. Plating with materials like zinc or nickel can also provide a protective layer, while polishing enhances the visual appeal.

How Is Quality Assurance Implemented in Springlock Manufacturing?

Quality assurance (QA) is a critical component of the manufacturing process for springlocks, ensuring that products meet both international and industry-specific standards.

Which International Standards Should B2B Buyers Be Aware Of?

International standards, such as ISO 9001, provide a framework for quality management systems. Compliance with these standards indicates that a manufacturer has established processes to consistently provide products that meet customer and regulatory requirements.

In addition to ISO certifications, springlocks may also need to comply with industry-specific standards such as CE marking for European markets or API standards for products used in the petroleum industry. B2B buyers should verify these certifications as part of their supplier evaluation process.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure quality is maintained at every stage. These checkpoints typically include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to verify they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor production processes and identify any deviations from quality standards.

-

Final Quality Control (FQC): After production, a final inspection is performed to ensure that the finished springlocks meet all specifications and quality standards before they are packaged and shipped.

What Common Testing Methods Are Used to Ensure Product Quality?

Several testing methods are employed to validate the quality of springlocks. These may include:

- Tensile Testing: Determines the strength and ductility of the material.

- Fatigue Testing: Assesses how the springlock performs under cyclic loading conditions.

- Corrosion Testing: Evaluates resistance to environmental factors that could lead to degradation.

These tests help ensure that the springlocks will perform reliably in their intended applications.

How Can B2B Buyers Verify the Quality Control Measures of Suppliers?

For B2B buyers, especially those sourcing from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are actionable steps buyers can take:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should look for ISO certifications and other relevant accreditations during these audits.

-

Request Quality Reports: Suppliers should be willing to provide detailed quality reports that outline their testing procedures, results, and compliance with international standards.

-

Engage Third-Party Inspectors: Utilizing independent inspection services can provide an unbiased assessment of the supplier’s production quality. This is especially important for international transactions where buyers may not be able to visit the manufacturing site.

-

Understand Regional Compliance Nuances: Buyers should familiarize themselves with the specific regulations and quality standards applicable in their region. This understanding helps in evaluating whether a supplier can meet both international and local compliance requirements.

Conclusion: Why Quality Assurance in Springlock Manufacturing Matters for B2B Buyers

In summary, the manufacturing processes and quality assurance measures for springlocks are critical to ensuring product reliability and performance. By understanding these processes and implementing thorough verification methods, B2B buyers can make informed decisions, minimize risks, and secure high-quality products that meet their operational needs. This approach not only enhances supply chain efficiency but also builds trust and long-term partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘springlocks for sale’

In the competitive landscape of B2B procurement, sourcing springlocks effectively is crucial for ensuring quality and reliability in your operations. This guide provides a structured checklist to assist international buyers in making informed decisions when purchasing springlocks, whether for trailers, duct reinforcement, or other applications.

Step 1: Define Your Technical Specifications

Before starting the sourcing process, clearly outline the technical specifications for the springlocks you need. Consider the material (e.g., steel or plastic), size, weight capacity, and any regulatory requirements specific to your industry. This clarity helps you communicate effectively with suppliers and ensures you receive products that meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in springlocks. Look for manufacturers with a strong reputation in the market and positive reviews from other B2B clients. Utilize platforms like industry forums, trade directories, and even social media to gather insights and recommendations.

- Tip: Consider suppliers who offer volume discounts or flexible payment terms, especially if you plan to make large orders.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers have the necessary certifications and compliance with international standards. This includes quality management certifications (like ISO 9001) and any industry-specific standards relevant to your region. Certifications assure you of the supplier’s commitment to quality and safety.

- Sub-bullet: Ask for documentation to verify these certifications and check their validity.

Step 4: Request Samples

Before placing a bulk order, request samples of the springlocks to assess their quality and compatibility with your needs. Testing samples allows you to evaluate the product’s durability, ease of installation, and overall performance. This step is essential to avoid costly mistakes later on.

Illustrative image related to springlocks for sale

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare pricing, shipping costs, and payment terms. While price is important, consider the total cost of ownership, including shipping, duties, and potential warranty claims. Look for suppliers who offer competitive pricing without compromising on quality.

- Tip: Negotiate terms that align with your procurement strategy, such as longer payment periods for larger orders.

Step 6: Assess Customer Support and After-Sales Service

Evaluate the level of customer support and after-sales service offered by the suppliers. Reliable suppliers should provide assistance with installation, troubleshooting, and warranty claims. Good communication is key to resolving issues quickly and maintaining a smooth operational flow.

Step 7: Finalize Your Order and Monitor Delivery

Once you have selected a supplier, finalize your order while confirming delivery timelines and logistics. Keep track of your order to ensure timely delivery, and maintain open communication with the supplier throughout the process. This proactive approach helps mitigate any potential disruptions in your supply chain.

By following this checklist, you can confidently navigate the complexities of sourcing springlocks, ensuring that your procurement aligns with your operational goals and quality standards.

Comprehensive Cost and Pricing Analysis for springlocks for sale Sourcing

What Are the Key Cost Components for Springlocks in B2B Sourcing?

When sourcing springlocks, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to springlocks for sale

-

Materials: The choice of materials significantly impacts cost. Steel is commonly used for its durability, while alternatives like plastic may reduce costs but could compromise strength. Prices fluctuate based on market conditions, so it’s wise to keep an eye on commodity trends.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Areas with lower labor costs may offer competitive pricing, but ensure that quality standards are not sacrificed.

-

Manufacturing Overhead: This encompasses costs related to facility operation, utilities, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom or specialized springlocks. This cost is often spread over the volume of orders, impacting the unit price.

-

Quality Control (QC): Rigorous QC processes ensure product reliability, particularly for applications in safety-sensitive industries. Incorporating QC costs into the pricing structure is essential for maintaining high standards.

-

Logistics: Shipping and handling costs should not be overlooked. These costs can vary widely based on distance, mode of transport, and the weight of the shipment.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs and desired profitability. Understanding this can aid in negotiations.

How Do Price Influencers Impact Springlock Costs?

Several factors can influence the pricing of springlocks, including volume, specifications, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing significantly. Larger orders generally qualify for volume discounts, leading to lower per-unit costs. Conversely, smaller orders may incur higher prices.

-

Specifications and Customization: Custom specifications can drive up costs. Standardized products are often cheaper, so consider whether customization is necessary for your application.

-

Materials and Quality: Higher quality materials and certifications (e.g., ISO, CE marking) generally come with a premium. Evaluate the long-term benefits of investing in higher-quality options versus cheaper alternatives.

-

Supplier Factors: Established suppliers may command higher prices due to their reputation and reliability. However, they often provide better service and quality assurance, which can reduce the total cost of ownership (TCO).

-

Incoterms: The terms of trade can significantly impact costs. Understanding whether costs include shipping, insurance, and duties can help you calculate the total landed cost of your order.

What Buyer Tips Can Enhance Cost-Efficiency in Springlock Procurement?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, strategic approaches can enhance cost efficiency.

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Highlighting your potential for repeat business can lead to more favorable terms.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the entire lifecycle cost, including maintenance, replacement, and potential downtime. A higher upfront cost may be justified by lower long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and their impact on pricing. Additionally, understand import duties and taxes that can affect the overall cost.

-

Supplier Research: Conduct thorough due diligence on potential suppliers. Evaluating their financial stability, production capacity, and customer reviews can lead to more informed purchasing decisions.

Disclaimer on Indicative Prices

Pricing for springlocks can vary based on multiple factors, including market conditions, supplier pricing strategies, and specific order requirements. The prices mentioned in this analysis are indicative and should be confirmed with suppliers for accuracy. Always seek multiple quotes to ensure competitive pricing and terms.

Alternatives Analysis: Comparing springlocks for sale With Other Solutions

Understanding Alternatives to Springlocks for Sale

In the realm of securing and enhancing the functionality of equipment and structures, various solutions exist alongside springlocks. Buyers must evaluate these alternatives based on specific operational needs, performance requirements, and budget constraints. This analysis will compare springlocks with two viable alternatives: duct reinforcement hardware and traditional mechanical fasteners.

| Comparison Aspect | Springlocks For Sale | Duct Reinforcement Hardware | Traditional Mechanical Fasteners |

|---|---|---|---|

| Performance | Reliable for securing various applications, particularly in towing and trailers. | Offers enhanced strength, 150% stronger than plastic alternatives; ideal for ductwork. | Provides robust fastening, suitable for multiple applications. |

| Cost | Generally low-cost ($8.99 to $9.49 per unit). | Moderate cost ($560 to $580 for 1,000 sets). | Varies widely based on type; generally affordable but can add up in bulk. |

| Ease of Implementation | Simple installation process; requires minimal tools. | Quick installation, no crimping or deburring needed; user-friendly. | Requires tools and expertise for proper installation; may be time-consuming. |

| Maintenance | Low maintenance; durable materials. | Low maintenance; designed for longevity. | Varies; may require periodic checks and tightening. |

| Best Use Case | Ideal for car trailers and light-duty applications. | Best suited for HVAC and duct reinforcement in commercial settings. | Versatile; used in construction, automotive, and machinery applications. |

Analyzing Duct Reinforcement Hardware: What Are Its Benefits and Drawbacks?

Duct reinforcement hardware provides a robust alternative, especially in HVAC applications. Its strength significantly surpasses that of plastic plugs, making it an ideal choice for projects requiring durability and compliance with industry standards. While the initial cost may be higher, the long-term benefits of reduced failure rates and the absence of maintenance make it a compelling option. However, its specialized nature limits its applicability to ductwork, which may not serve buyers looking for multipurpose solutions.

Exploring Traditional Mechanical Fasteners: Are They Right for Your Needs?

Traditional mechanical fasteners, such as bolts and screws, are widely recognized for their versatility across various industries. They can be adapted to different materials and applications, providing a secure hold in construction, automotive, and machinery contexts. However, the installation process can be labor-intensive, often requiring skilled labor and specialized tools. Additionally, over time, these fasteners may require maintenance to ensure continued effectiveness, especially in high-stress environments.

Making the Right Choice for Your Business Needs

When selecting between springlocks and alternative solutions, B2B buyers should consider their specific operational requirements and budget. For applications involving light-duty securing tasks, springlocks may offer the best balance of cost and performance. Conversely, for projects that demand higher strength and compliance, duct reinforcement hardware could be the superior choice. Meanwhile, traditional mechanical fasteners provide unmatched versatility, albeit with a potentially higher labor cost. Ultimately, understanding the unique demands of your application will guide you in making the most informed decision.

Essential Technical Properties and Trade Terminology for springlocks for sale

What Are the Essential Technical Properties of Springlocks?

When considering springlocks for sale, understanding the key technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that international B2B buyers should be aware of:

-

Material Grade

Springlocks are commonly made from various materials, including steel and aluminum. Steel springlocks offer high durability and strength, making them suitable for heavy-duty applications, such as car trailers. Aluminum, while lighter, is often used for applications where weight savings are paramount. Selecting the right material grade is essential for ensuring the longevity and reliability of the product in your specific application. -

Weight Capacity

Each springlock has a specified weight capacity, which indicates the maximum load it can safely support. This is particularly important in industries like transportation and construction, where failure could lead to significant safety hazards. Understanding the weight capacity ensures that you select a springlock that meets your operational requirements without risking structural integrity. -

Dimensions and Tolerances

The dimensions of springlocks, including length and diameter, are critical for compatibility with other components in your system. Tolerances refer to the allowable deviation from specified dimensions, which can affect fit and function. Accurate dimensions and tolerances ensure that the springlock will integrate seamlessly into your existing setups, preventing operational disruptions. -

Corrosion Resistance

Many springlocks are exposed to harsh environments, making corrosion resistance an important property. Springlocks made from galvanized steel or treated with protective coatings can withstand moisture and chemicals, extending their service life. For buyers in humid or chemically aggressive environments, investing in corrosion-resistant springlocks is a wise choice to minimize maintenance costs. -

Operating Temperature Range

Understanding the operating temperature range of a springlock is vital for applications that may experience extreme heat or cold. Materials may behave differently under varying temperatures, affecting performance and safety. Ensure that the selected springlock can operate effectively within the temperature conditions of your application. -

Compliance Standards

Compliance with industry standards (e.g., ISO, ASTM) can be a significant factor in selecting springlocks. These standards ensure that the products meet specific safety, quality, and performance criteria. When sourcing springlocks, check for compliance documentation to ensure you are purchasing a reliable product that meets regulatory requirements.

What Are Common Trade Terms Associated with Springlocks?

In the realm of purchasing springlocks, familiarity with industry jargon can facilitate smoother transactions and better communication with suppliers. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces components or products that are used in another company’s end products. In the context of springlocks, sourcing from an OEM ensures that you receive high-quality components designed specifically for your application. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management. Suppliers often set MOQs to ensure profitability, and being aware of these can help in negotiating better terms. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. When looking to purchase springlocks, issuing an RFQ can help you gather competitive bids, ensuring you make a cost-effective choice. -

Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms is crucial for understanding the logistics and costs associated with importing springlocks. -

Lead Time

Lead time is the duration between placing an order and receiving the goods. Knowing the lead time for springlocks can help you plan your inventory and project timelines more effectively, ensuring that you have the necessary components when needed. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of the product. Understanding the warranty terms for springlocks can protect your investment and provide peace of mind regarding product reliability.

By comprehending these technical properties and industry terms, B2B buyers can make well-informed decisions when sourcing springlocks for their operations, ensuring safety, compatibility, and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the springlocks for sale Sector

What Are the Current Market Trends for Springlocks in the B2B Sector?

The global market for springlocks is influenced by various factors, including rising demand in the automotive and construction industries. As international trade continues to expand, particularly in regions like Africa, South America, the Middle East, and Europe, B2B buyers must be aware of the key trends shaping the sector. A significant driver is the increasing emphasis on efficiency in supply chains, with businesses seeking to streamline their operations through technology. Automation and digital platforms are gaining traction, enabling buyers to source products like springlocks more effectively while reducing lead times and costs.

Emerging technologies, such as AI and machine learning, are transforming procurement processes, allowing for data-driven decision-making. This trend is particularly beneficial for international buyers who can leverage these tools to identify reliable suppliers and track market fluctuations. Furthermore, the shift toward e-commerce has made it easier for businesses to access a wider array of products, enhancing competition and driving down prices. Buyers in regions like Nigeria and Brazil are increasingly adopting online platforms for procurement, enabling them to compare products and prices from various manufacturers seamlessly.

How Is Sustainability Reshaping the Sourcing of Springlocks?

Sustainability and ethical sourcing are becoming paramount in the B2B landscape, with buyers increasingly prioritizing environmentally friendly products. The manufacturing of springlocks, traditionally reliant on steel and other metals, poses certain environmental challenges. Therefore, suppliers are now exploring ‘green’ certifications and sustainable materials, such as recycled steel, to appeal to environmentally conscious buyers.

Illustrative image related to springlocks for sale

Ethical supply chains are essential for building brand reputation and customer loyalty. B2B buyers are encouraged to inquire about suppliers’ sourcing practices, labor conditions, and environmental impact. Implementing a sustainability framework not only fulfills corporate social responsibility but also aligns with global trends toward reducing carbon footprints. Certifications such as ISO 14001 for environmental management and other industry-specific standards can help buyers identify trustworthy suppliers committed to sustainability.

What Is the Historical Context of Springlocks in the B2B Market?

The evolution of springlocks can be traced back to the early 20th century when they were primarily used in mechanical applications for securing components. Over the decades, their application has expanded, particularly in the automotive sector, where they are now essential for trailer safety and load management. The introduction of advanced materials and manufacturing techniques has significantly enhanced the strength and durability of springlocks, making them indispensable in various industries, including construction and logistics.

As markets have globalized, the demand for reliable and cost-effective springlocks has surged, prompting manufacturers to innovate continuously. This historical context highlights the importance of understanding market dynamics and sourcing trends, enabling B2B buyers to make informed decisions when procuring springlocks for their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of springlocks for sale

-

How do I choose the right springlock for my application?

Selecting the appropriate springlock involves understanding its intended use and the specifications required for your application. Consider factors such as the load capacity, material (e.g., steel or plastic), and compatibility with existing equipment. It’s also vital to evaluate the environmental conditions it will be exposed to, such as moisture or temperature fluctuations. Consulting with suppliers for technical data sheets and performance ratings can guide you in making an informed choice. -

What types of springlocks are available for purchase?

Springlocks come in various types, including universal, long, and short springlocks, tailored for different applications such as trailers, duct reinforcement, and more. Each type has specific attributes, such as weight capacity and material composition, affecting its suitability for various environments. When sourcing, ensure you specify your needs to suppliers to get options that best fit your operational requirements. -

What are the minimum order quantities (MOQs) for springlocks?

Minimum order quantities can vary widely among suppliers and are often influenced by factors such as product type, material, and pricing structures. Generally, MOQs may range from a few dozen to several hundred units. It’s advisable to discuss your requirements with potential suppliers to negotiate terms that align with your business needs, especially if you are looking to test a new product line. -

How can I vet suppliers of springlocks effectively?

To ensure you engage with reliable suppliers, conduct thorough due diligence. Start by checking their credentials, industry experience, and customer reviews. Request samples to evaluate product quality and compliance with international standards. Additionally, inquire about their production capabilities and supply chain logistics to ensure they can meet your volume and delivery requirements. -

What payment terms should I expect when purchasing springlocks internationally?

Payment terms can vary significantly based on the supplier’s policies and your negotiation skills. Common terms include advance payment, letters of credit, or net 30/60 days. For international transactions, consider using secure payment methods and discuss terms upfront to avoid misunderstandings. Additionally, ensure that the payment terms are compliant with your country’s trade regulations. -

What quality assurance measures should I look for in springlocks?

Quality assurance is crucial when sourcing springlocks. Look for suppliers that provide certifications such as ISO 9001, which indicates adherence to quality management standards. Ask about their testing procedures, including load tests and material inspections, to ensure product reliability. A transparent supplier should readily provide documentation regarding their quality control processes. -

How do I handle logistics and shipping for springlock orders?

Managing logistics for international shipments involves coordinating with your supplier and freight forwarders. Discuss shipping options, including air and sea freight, and their associated costs and delivery timelines. Make sure to clarify who will handle customs clearance and any duties or taxes applicable upon import. Having a clear logistics plan can help mitigate delays and additional costs. -

Can I customize springlocks to meet specific needs?

Many suppliers offer customization options for springlocks, allowing you to tailor products to your specifications, such as size, material, or branding. When discussing customization, provide clear details regarding your requirements and expected quantities. Be prepared to discuss lead times and potential cost implications, as custom orders often require additional production time and resources.

Top 7 Springlocks For Sale Manufacturers & Suppliers List

1. Mytee Products – Universal Long Spring Lock, Steel

Domain: myteeproducts.com

Registered: 2003 (22 years)

Introduction: {“name”: “Universal Long Spring Lock, Steel”, “SKU”: “SpringLock-Long”, “material”: “Steel”, “weight”: “1.1 lbs”, “price”: “$9.49”, “availability”: “In stock”, “for_use_with”: “Car Trailers”, “bulk_pricing”: {“4_units_price”: “$9.29”, “20_units_price”: “$8.99”}, “warning”: “California Proposition 65 Warning: This product can expose you to chemical which is known to the State of California to cause…

2. Craft Inc – Springlock Top Slot Method

Domain: craft-inc.com

Registered: 1996 (29 years)

Introduction: Springlock Top Slot Method is a product designed for use in various applications. It features a unique springlock mechanism that ensures secure fastening and easy installation. The product is suitable for both indoor and outdoor use, providing durability and reliability. It is compatible with a range of materials and can be used in different settings, making it a versatile choice for professionals…

3. Penn Elcom – Durable Spring Locks

Domain: penn-elcom.com

Registered: 2003 (22 years)

Introduction: Spring locks provide secure closure and easy access for crate construction projects. They are suitable for the shipping industry, woodworking, and crate organization. The reusable spring locks are available in small, medium, and large sizes, made from high-quality materials for durability and longevity. They offer effortless operation and reliable performance, enhancing security during transportat…

4. SpringLOCK – 50 Bridges & Locks Set

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 4647 SpringLOCK 50 Bridges 50 Locks 100 Screws; Condition: New; Price: $34.99 or Best Offer; Shipping: $11.70; Estimated delivery: Fri, Sep 12 – Tue, Sep 16; Seller: Sunshine*Road (99.9% positive feedback); Quantity available: 6; Returns accepted.

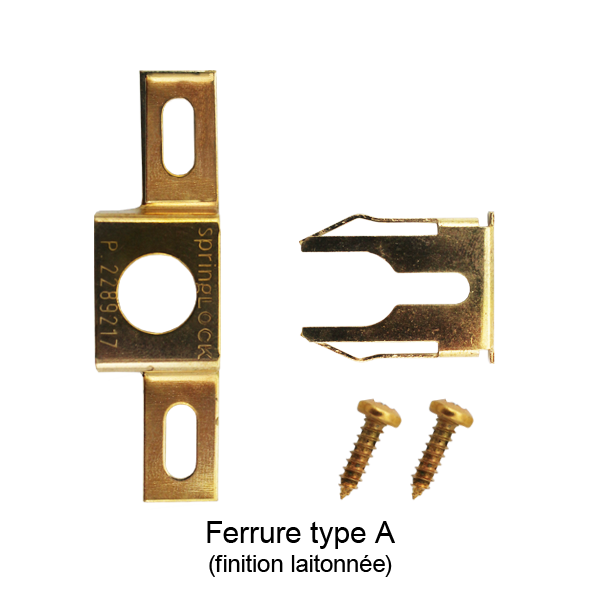

5. ChassiTech – SpringLock™ Secure Wall Hanging System

Domain: chassitech.com

Registered: 2000 (25 years)

Introduction: SpringLock™ is a secure wall hanging system designed for frames and valuable objects, recognized for its anti-theft properties. It is suitable for public spaces such as waiting rooms and hotel rooms. The system consists of two fittings: Fitting A with a round hole and removable lock insert, and Fitting B with a T-shaped hole. Made from zinc-plated steel, it accommodates up to 25 works of art with …

6. Tackle Warehouse – Essential Fishing Accessories

Domain: tacklewarehouse.com

Registered: 1998 (27 years)

Introduction: [{‘name’: ‘Banjo Minnow Hardware Kit’, ‘price’: ‘$7.99’}, {‘name’: ‘Eagle Claw Lazer Sharp Springs for Soft Plastics 8p’, ‘price’: ‘$4.49’}, {‘name’: ‘Flatlands Tackle Pro Hitch Hiker Bait Keepers Large 5pk’, ‘price’: ‘$2.59’}, {‘name’: ‘Gamakatsu Double Down Spring Lock’, ‘price’: ‘$4.79’, ‘original_price’: ‘$5.39’}, {‘name’: ‘Gamakatsu Spring Lock 5pk’, ‘price’: ‘$1.49’, ‘original_price’: ‘$1.79…

7. Etsy – Spring Lock Carabiner Clasps

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Spring Lock products available on Etsy include various types of carabiner clasps and connectors, with details as follows: 1. 18K Gold Filled Oval Carabiner Clasp – Sale Price: $11.45 (Original Price: $12.72, 10% off) from seller JazzyJcharms. 2. 14K REAL Solid Gold Oval Paperclip & Barrel Shaped Charm – Sale Price: $157.56 (Original Price: $196.95, 20% off) from seller Anygolds, with free shipping…

Strategic Sourcing Conclusion and Outlook for springlocks for sale

In today’s competitive landscape, strategic sourcing of springlocks is vital for businesses looking to enhance operational efficiency and reduce costs. As demonstrated, high-quality springlocks—whether for automotive applications or duct reinforcement—offer durability and reliability that can significantly impact the overall performance of your operations. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should prioritize suppliers who provide not only competitive pricing but also robust support and product variety.

Moreover, leveraging bulk purchasing options and understanding the benefits of material choices—such as steel versus plastic—can lead to substantial long-term savings. Establishing relationships with reputable manufacturers ensures access to innovative products that meet evolving industry standards.

Illustrative image related to springlocks for sale

Looking ahead, the demand for high-quality springlocks is expected to rise, driven by increased infrastructure development and automotive growth in emerging markets. We encourage B2B buyers to explore diverse sourcing opportunities, engage with suppliers who offer customization, and remain proactive in their procurement strategies. By doing so, businesses can position themselves for sustainable success in an increasingly interconnected marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.